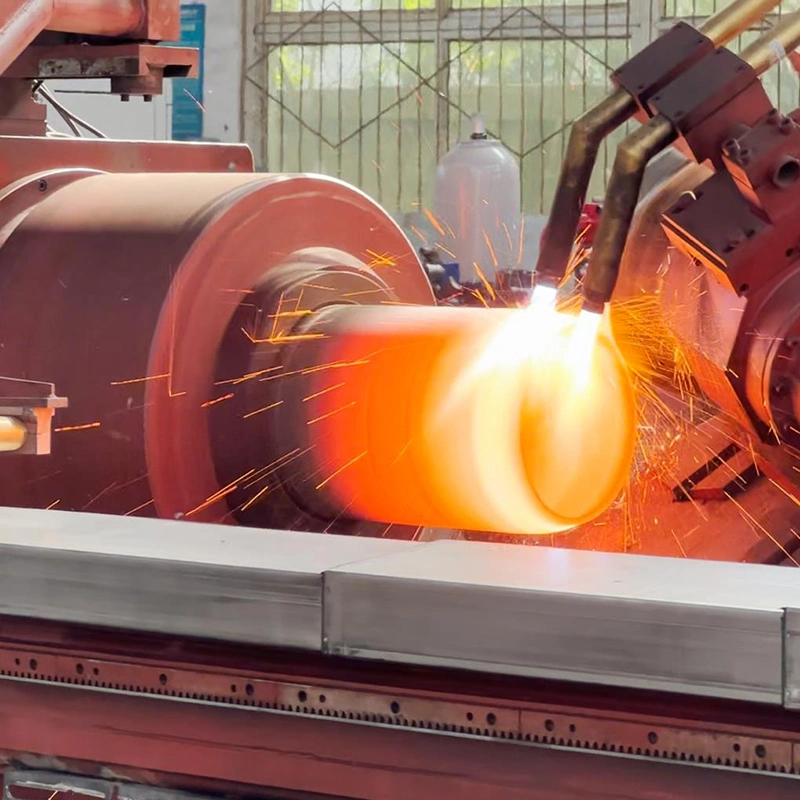

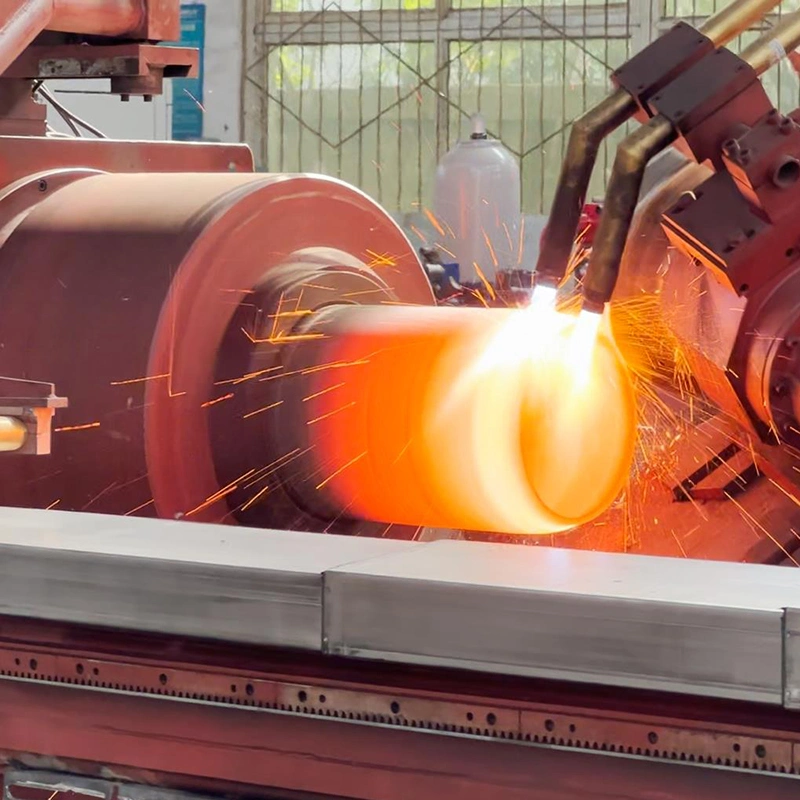

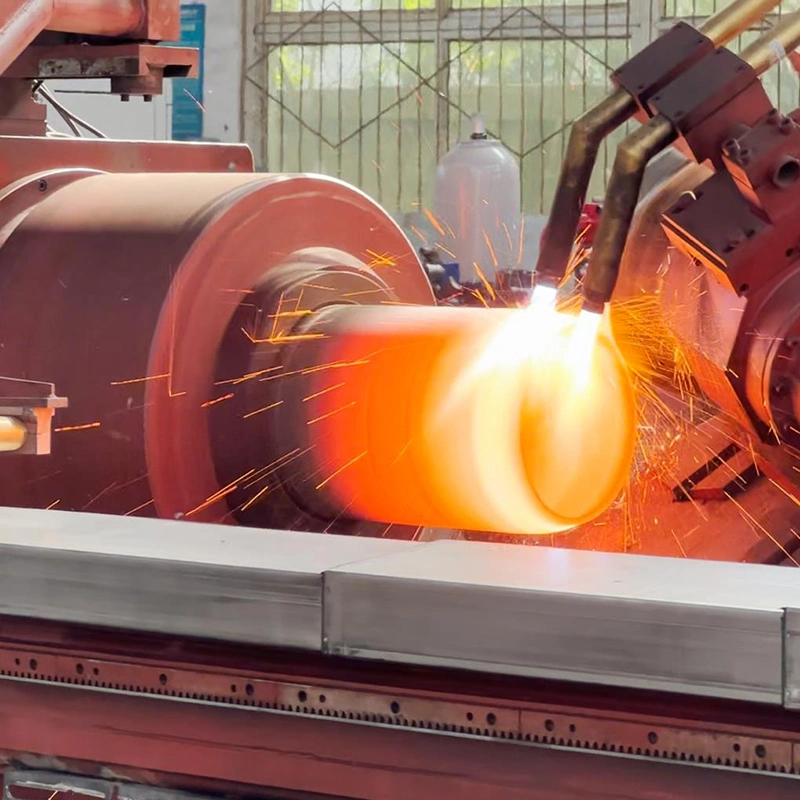

Hot Spinning Machine: A Metal Hot Spinning Machine is a specialized industrial machine used to shape metal parts—typically cylindrical or conical components—by a combination of rotational motion and localized high-temperature plastic deformation. It’s a subset of the broader metal spinning process but involves heating the metal (often with a torch or induction) to make it more malleable for forming complex or heavy-duty shapes.

Key Features:

- Rotating Mandrel: The pre-formed metal blank is mounted on a mandrel that spins at high speed.

- Rollers or Tools: Shaping tools press against the rotating heated metal, forming it over the mandrel.

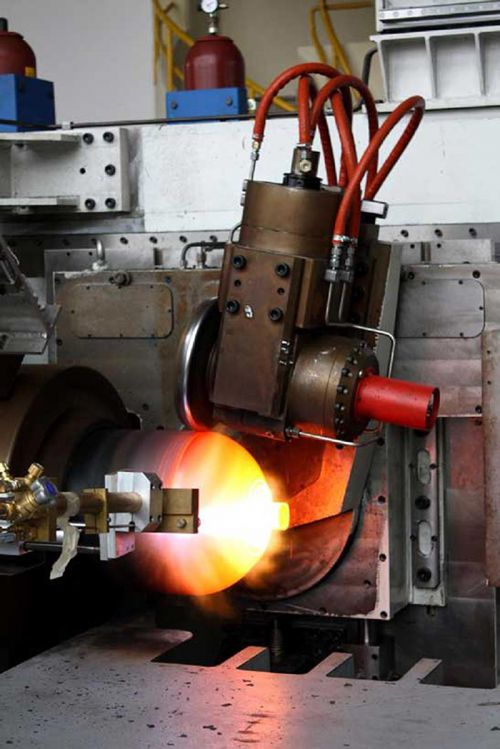

- Heat Source: Typically a gas torch or induction heater is used to heat the metal during spinning.

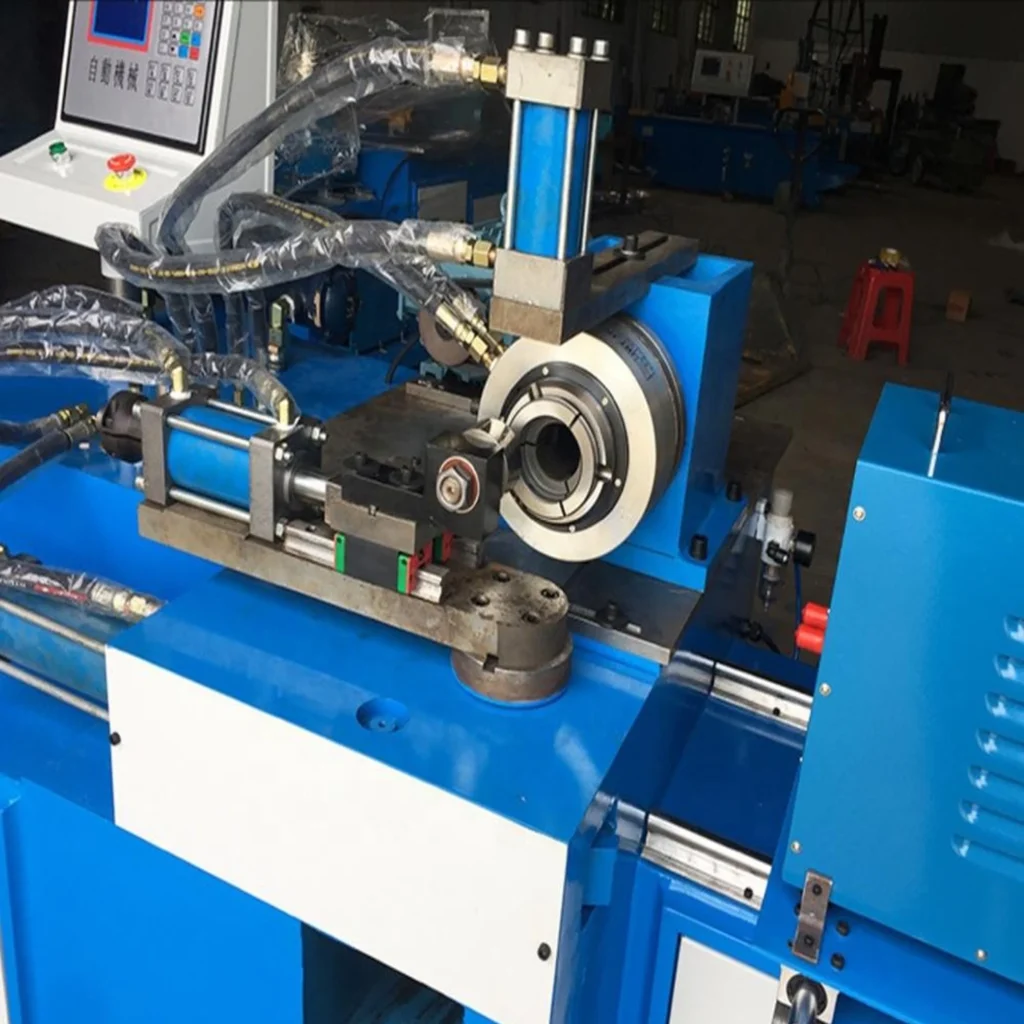

- CNC or Manual: Machines can be manually controlled or CNC-based for precision and repeatability.

Applications:

- Aerospace: Nose cones, rocket nozzles, and ducts.

- Automotive: Wheel rims, pressure vessels.

- Industrial: Large conical or dome-shaped components.

- Art & Architecture: Sculptural and decorative elements.

Materials Commonly Used:

- Aluminum

- Stainless steel

- Inconel

- Titanium

- Copper alloys

These materials are chosen based on their ability to withstand deformation at high temperatures and their intended use.

Advantages:

- Low material waste (near-net-shape process)

- High-strength end product due to work hardening

- Ability to create complex hollow shapes

- Good surface finish (with skilled operation or CNC)

Challenges:

- Requires skilled operators or precise CNC programming

- Tooling must withstand high temperatures

- Not ideal for very small batches unless automated

A metal hot spinning machine operates by forming metal sheets or blanks into axisymmetric shapes while they are heated to a high temperature, making them more malleable. The process starts by mounting a flat metal disc or preform onto a mandrel, which is rotated at high speed. A localized heat source, such as an oxy-acetylene torch or induction coil, is applied to the metal to bring it to a temperature suitable for plastic deformation, typically just below its melting point. Once heated, a roller or forming tool is pressed against the rotating blank, gradually shaping it over the mandrel. The operator or CNC controller applies force in a controlled path, ensuring that the metal flows smoothly into the desired contour without wrinkling, tearing, or thinning excessively.

The hot spinning process is particularly effective for forming high-strength alloys or thick-walled components that would be difficult to spin cold, such as titanium, Inconel, or hardened steels. It is widely used in aerospace, defense, and heavy industrial applications, especially for producing components like rocket nozzles, pressure vessels, domes, and turbine parts. Since the material is more ductile at elevated temperatures, hot spinning reduces forming force and enables the production of deeper or more complex geometries than cold spinning. The final product often exhibits improved mechanical properties due to the work-hardening and grain refinement that occur during deformation.

Machines used for hot spinning may be manual, semi-automatic, or fully CNC-controlled. CNC hot spinning machines allow precise control of tool paths, speeds, and heating cycles, enabling consistency across production runs. Tooling must be capable of withstanding high temperatures and pressures, and the process often involves water-cooled or specially coated rollers. Because the process is near-net-shape, material waste is low compared to subtractive methods. However, it requires careful setup and control, especially when forming exotic metals or maintaining tight tolerances.

In operation, the coordination between heat application and tool movement is critical. The metal must be hot enough to flow plastically but not so hot that it loses integrity or sticks to the mandrel or tools. Skilled operators or well-programmed CNC systems manage the timing and location of heat input to keep the deformation zone localized, which helps maintain control over the metal’s shape and thickness throughout the spinning process. Typically, only the area under active forming is heated, while the rest remains cooler, preserving structural stability.

As the tool presses the heated metal against the mandrel, it causes the material to stretch and compress in controlled patterns. This can be done in multiple passes, gradually shaping the metal without over-stressing it. Complex profiles, like stepped cones or parabolic curves, can be formed by carefully designing the tool path. Lubricants are sometimes used to reduce friction, though in hot spinning they are limited due to the high temperatures involved. In some systems, tooling and mandrels are also pre-heated to reduce thermal shock and maintain forming consistency.

The final part may require post-processing such as trimming, heat treatment, or machining for precise tolerances or surface finishes. Despite the thermal and mechanical demands, hot spinning offers cost and performance advantages, particularly when producing medium to large volumes of parts that would otherwise require welding or forging. It also allows the use of seamless construction, which improves strength and reduces failure points in pressure or high-stress applications. Overall, hot spinning machines combine thermal engineering and precision forming to enable the efficient creation of high-performance metal components in critical industries.

Advanced hot spinning systems often incorporate feedback mechanisms such as temperature sensors, force monitoring, and real-time shape measurement to ensure process control and repeatability. In CNC-based machines, these data inputs help adjust tool pressure, spinning speed, or heat application on the fly, which is crucial when working with materials that have narrow forming temperature windows or are prone to cracking under inconsistent conditions. These intelligent systems reduce dependency on manual skill and allow for tighter dimensional tolerances, making the process suitable for industries like aerospace, where part accuracy is critical.

The choice of mandrel material is another key factor. Mandrels are typically made from heat-resistant steel or alloy and must withstand the combined effects of high temperature and forming pressure. In some cases, expendable mandrels made from materials like graphite or ceramic are used for particularly complex or difficult-to-extract shapes. Some setups also allow for rotating or stationary mandrels, depending on the part geometry and machine design.

Compared to other forming processes like deep drawing or hydroforming, hot spinning offers greater flexibility in shape and wall thickness variations without needing extensive tooling changes. It also handles thicker materials better than cold spinning, which is limited by the material’s workability at room temperature. However, the higher energy requirements and setup complexity can make hot spinning less economical for short production runs unless specialized shapes or materials justify the cost.

Operators and engineers involved in hot spinning must understand both metallurgical behavior under heat and the mechanical dynamics of spinning. For example, metals like titanium require a precisely controlled atmosphere during heating to avoid oxidation or embrittlement, which is why inert gas shielding or vacuum environments are sometimes used. Safety is a major consideration too, given the high temperatures, spinning parts, and forming forces involved. Machines are typically enclosed and automated safety interlocks are standard to protect operators.

As technology progresses, hybrid techniques that combine hot spinning with laser-assisted forming, additive pre-forms, or automated inspection are being explored to expand the capabilities and applications of this forming method even further. These innovations point to a future where hot spinning is not just a niche process but an integral part of advanced manufacturing chains.

Preheating for Hot Spinning Machine

Preheating in hot spinning is a critical preparatory step that significantly affects the quality, accuracy, and safety of the spinning process. It involves heating the workpiece, tooling (especially the mandrel), or both to a specific temperature before and/or during the spinning operation to improve material formability and reduce forming forces.

Preheating serves multiple purposes. For the workpiece, it reduces the yield strength of the metal, making it more ductile and allowing it to deform more easily under pressure. This is especially important when spinning hard-to-form or high-strength alloys like titanium, Inconel, or certain stainless steels. Without proper preheating, these metals can crack, tear, or exhibit poor flow behavior. For thicker or larger components, preheating ensures uniform temperature distribution before forming begins, minimizing localized stress concentrations that might lead to defects.

Preheating the mandrel helps maintain consistent contact between the metal and the forming surface. A cold mandrel can act as a heat sink, rapidly cooling the metal during initial contact and interfering with the plastic flow, especially near the base or center of the part. Preheating the mandrel to a temperature closer to the forming temperature prevents this heat shock and reduces thermal gradients, which helps in achieving a better surface finish and more uniform wall thickness. However, care must be taken not to overheat the mandrel, especially if it is not made from high-temperature alloys.

The temperature range for preheating depends on the material being spun:

- For aluminum alloys, it’s typically around 300–400°C

- For stainless steel, 600–900°C

- For titanium and nickel alloys, 800–1100°C

The method of preheating can vary. Oxy-fuel torches, induction heaters, or electric resistance heaters are commonly used. Some systems also integrate multi-zone heating, allowing targeted preheating at specific points along the blank for more controlled deformation. In automated systems, infrared pyrometers or thermocouples may be used to monitor and regulate temperature in real time.

Improper preheating—or no preheating at all—can lead to several issues: increased forming force, tool wear, poor surface finish, inconsistent thickness, and part rejection due to cracks or wrinkles. Conversely, excessive preheating can lead to oxidation, grain growth, or loss of dimensional control. Hence, finding the right balance and applying heat uniformly and consistently are crucial.

In summary, preheating is not just a preparatory step but a core part of the hot spinning process. It directly influences formability, tool life, process efficiency, and final product quality.

The integration of preheating into the hot spinning workflow is often tailored to the specific part geometry, material type, and production rate. In many manual or semi-automatic setups, operators use handheld torches to preheat the blank and occasionally the mandrel before engaging the forming tool. This requires skill and experience to ensure that the heat is evenly distributed and reaches the correct temperature. In CNC-controlled or automated environments, induction heating is preferred due to its ability to deliver rapid, uniform, and localized heating. Induction coils can be precisely positioned around the spinning area to maintain the desired thermal profile throughout the forming process, which is particularly useful for high-performance alloys with narrow workable temperature ranges.

During forming, preheating transitions into active thermal management. As the roller begins to deform the heated metal, the forming zone is kept within a specific temperature band, often by moving the heat source in coordination with the tool or by pulsing the induction heater. If the temperature drops too much during spinning, the metal may harden prematurely and resist deformation, leading to higher tool loads and potential defects. If it overheats, the metal may soften excessively, risking wall thinning or distortion. In processes involving multiple forming passes or large diameters, intermittent re-heating may be required between passes to maintain formability.

Preheating also plays a role in stress control. Uniform heating of the blank minimizes thermal gradients that would otherwise induce residual stresses in the finished part. These stresses, if uncontrolled, can lead to warping, distortion, or cracking during cooling. To further manage thermal behavior, some setups include heated chucks, temperature-controlled mandrels, or environmental controls such as inert gas shrouding to prevent oxidation at high temperatures. This is particularly important when spinning reactive metals like titanium, which can oxidize or embrittle when exposed to air above certain temperatures.

Another consideration during preheating is part alignment and thermal expansion. As the blank heats up, it expands. The fixturing and mandrel must accommodate this expansion without introducing misalignment or slippage. Poor control during this stage can compromise part symmetry and concentricity. Additionally, if the heating process isn’t well timed with the start of spinning, the thermal advantage may be lost before forming begins, particularly in materials that cool rapidly once the heat source is removed.

Proper preheating strategies also contribute to tool life. By reducing the required forming force and minimizing the risk of hard spots or material rebound, they reduce tool wear and fatigue. In contrast, inconsistent or insufficient preheating increases mechanical loads on rollers, leading to accelerated wear, possible galling, and even tool failure in extreme cases. Given the cost of tooling, especially in CNC machines, consistent preheating practices help lower long-term operational costs.

In high-specification industries, preheating protocols are often standardized and documented as part of process qualification. Temperature thresholds, heating durations, ramp-up rates, and soak times are established through trial runs and validated through metallurgical testing. These parameters are then embedded into CNC programs or standard operating procedures to ensure repeatability and traceability across production batches. As component requirements grow more complex and material specifications more demanding, precision in preheating becomes not just helpful but essential for producing high-integrity parts.

As the hot spinning process continues, the influence of preheating extends into how the material behaves dynamically under stress. When the temperature is properly managed, the metal exhibits smooth, predictable plastic flow, which allows the forming tools to maintain consistent contact and force distribution. This contributes not only to dimensional accuracy but also to microstructural refinement in the final component. The continuous deformation at elevated temperature can lead to dynamic recrystallization, particularly in metals like stainless steel or nickel alloys, resulting in a finer grain structure that improves mechanical properties such as toughness, fatigue resistance, and uniformity.

During the final stages of forming, if the part has undergone multiple passes or varying deformation rates across its surface, localized reheating may still be necessary. This is common in parts with stepped contours, deep draws, or areas where material thickening is required. Targeted thermal input helps prevent cracking due to strain hardening and also supports smoother surface finish by reducing tool marks and surface tearing. This attention to thermal detail is especially important when forming parts that must meet high standards of internal pressure tolerance, fatigue life, or surface integrity, such as pressure vessels, aerospace engine components, or satellite hardware.

After forming is complete, cooling must be controlled as well. Sudden or uneven cooling can introduce unwanted residual stresses or dimensional distortion, especially if the part has complex geometry or varying wall thickness. Some operations use controlled air or inert gas cooling to manage this, while others rely on slow natural cooling in a protected environment. In cases where metallurgical properties are critical, post-forming heat treatments such as annealing, normalizing, or solution treating may be applied to relieve internal stresses and achieve the desired final hardness or ductility.

The effectiveness of the entire hot spinning process, from preheating to post-forming, often comes down to process discipline. When the heat input is consistent and precisely timed with tool engagement, and the material is within its optimal thermal and mechanical forming window, the process can produce components with exceptional structural integrity and minimal finishing requirements. On the other hand, any deviation—uneven preheat, thermal lag between blank and mandrel, or overheating—can lead to defects that compromise performance or require rework.

In modern manufacturing environments, preheating and spinning parameters are often integrated into a digital control system. This allows real-time monitoring and automated correction, ensuring that even complex parts with tight tolerances can be produced repeatedly and efficiently. Data from temperature sensors, force transducers, and displacement gauges can be logged and analyzed to optimize the process and predict tool wear or part failure trends. For critical industries like aerospace, nuclear, or medical, where regulatory compliance and traceability are mandatory, these digital records form part of the quality assurance documentation.

Ultimately, preheating in hot spinning is more than just warming the material—it is a precise, controlled application of thermal energy that directly influences every downstream aspect of the forming process. Whether shaping thick-walled titanium cones or lightweight aluminum domes, the quality, efficiency, and reliability of the operation are closely tied to how well the heat is managed before the first tool ever touches the spinning blank.

High-Temperature Process for Hot Spinning Machine

The high-temperature process in a hot spinning machine is the core element that differentiates it from cold spinning and enables the forming of tough, heat-resistant metals into complex geometries with minimal force and high precision. This process involves heating the metal workpiece to a temperature at which it becomes ductile enough to undergo significant plastic deformation without cracking. Depending on the material, this can range from 300°C for softer alloys like aluminum to over 1100°C for superalloys like Inconel or titanium. The elevated temperature reduces the yield strength and hardness of the material, allowing it to flow more easily under the pressure of the forming tool as it is spun over the mandrel.

At the heart of the high-temperature process is the synchronized application of heat and mechanical force. The metal blank is clamped against a mandrel, typically preheated to avoid acting as a heat sink. As the spindle rotates, a localized heat source—commonly an oxy-fuel torch or an induction heater—is applied to the region being formed. The forming roller, either manually operated or CNC-controlled, then presses against the heated zone, moving in a precise path to shape the metal over the mandrel. Only the area being deformed is kept at forming temperature, which helps maintain dimensional control and prevents softening of the entire workpiece. This localized heating approach allows for tight tolerances and consistent material flow even in thick or high-strength materials.

The forming speed, roller pressure, and heat intensity must be carefully balanced. Too much speed or pressure with insufficient heat can cause surface tearing or internal cracking. Too much heat with low tool force can lead to excessive thinning or loss of dimensional accuracy. Advanced machines use real-time monitoring tools, such as pyrometers or infrared sensors, to maintain the optimal temperature at the deformation zone. Some machines also integrate closed-loop control systems that adjust the heat input or tool path dynamically based on feedback from sensors, ensuring process consistency across every pass.

Materials processed in high-temperature hot spinning include titanium, nickel-based alloys, high-strength steels, and specialty aluminum grades. These metals, especially in thicker sections, are difficult or impossible to form cold without fracturing or requiring prohibitively high force. By heating them into a workable state, hot spinning allows for the formation of deep-drawn parts, long tapers, parabolic or hemispherical shells, and seamless conical sections with excellent structural integrity. The high-temperature process also facilitates work hardening and grain refinement through controlled deformation, often enhancing the mechanical properties of the finished part.

In some advanced applications, the entire forming process may take place in a controlled atmosphere or vacuum chamber to prevent oxidation, particularly with reactive metals like titanium or zirconium. This adds complexity and cost but is essential for components in aerospace, defense, and medical industries where surface purity and internal consistency are critical. Regardless of the environment, managing heat transfer, deformation rate, and tool wear is essential for maintaining repeatability and part quality. The high temperatures also demand specialized tooling, typically made from high-speed steel, tool steel alloys, or even ceramics in extreme cases, all designed to resist thermal fatigue and abrasion.

The high-temperature spinning process doesn’t end with forming. After the final shape is achieved, the component often undergoes controlled cooling to minimize residual stresses and avoid distortion. Depending on the application and material, post-forming heat treatments such as annealing or solution heat treating may follow. These steps help restore ductility or further enhance material properties altered during the high-temperature deformation.

In essence, the high-temperature process in hot spinning is a finely tuned balance of thermal and mechanical inputs that enables the efficient, precise, and defect-free formation of difficult-to-work metals into critical components. It expands the capabilities of conventional spinning far beyond thin-walled, ductile materials, opening up possibilities in high-performance and high-reliability sectors where precision and strength are paramount.

The success of the high-temperature process in hot spinning also depends on thermal stability during the entire operation. Once the spinning begins, any sudden drop or spike in temperature can instantly affect the material’s response to deformation. For example, a drop below the ductile range might cause localized hardening or cracking, while overheating could lead to excessive softening, oxidation, or even incipient melting in thin sections. The forming tool path must be synchronized with the thermal profile of the workpiece to ensure that the deformation happens within the controlled, plastic region. This is why induction heating is often favored in modern machines—it provides rapid, targeted heating with minimal thermal overshoot, making it easier to maintain the necessary temperature range as the tool moves across the surface.

Throughout the process, the interaction between the heated material and the tooling generates a mix of thermal and mechanical stresses. These stresses must be managed carefully to avoid tool failure or part distortion. The rollers are designed with heat-resistant coatings or are actively cooled to withstand the thermal load. In high-temperature spinning of alloys like Inconel or titanium, even small deviations in tool shape or position can lead to imperfections due to the narrow workability window of these materials. As the spinning progresses, each successive pass must account for the changes in material thickness, strain hardening, and heat distribution. The temperature of the material may need to be re-established before each pass to ensure uniformity, especially in deep-drawn or multi-stage operations.

Another important factor is the metallurgical transformation that occurs due to high-temperature deformation. In materials like stainless steels, titanium, or nickel-based alloys, dynamic recrystallization during spinning can refine the grain structure, improving mechanical properties such as fatigue life, ductility, and resistance to thermal cycling. However, if the temperature is too high or the strain rate too low, grain growth may occur instead, which can reduce strength and stability. This is why controlling not only the peak temperature but also the duration and cooling rate is essential. Some spinning operations are followed immediately by a controlled furnace cool or are placed into an inert atmosphere chamber to protect against oxidation and to stabilize the internal structure.

The final stages of the high-temperature process often involve trimming excess material, inspecting the surface and geometry, and, if needed, applying heat treatments like annealing to relieve internal stresses accumulated during spinning. Some parts may require finish machining, particularly at interfaces or mounting surfaces, but in many cases, the high-temperature spinning process delivers parts close to net shape with minimal post-processing. This contributes to material savings and reduces overall production time, especially when compared to forging or casting processes that involve complex tooling and longer cycle times.

As demands for stronger, lighter, and more thermally stable components continue to rise, particularly in aerospace, defense, and energy sectors, the high-temperature spinning process is being pushed further with new materials, more sophisticated heating systems, and more advanced CNC control. Developments like laser-assisted spinning, high-temperature ceramic tooling, and AI-based thermal feedback loops are being integrated into high-end systems to extend forming capabilities, reduce defects, and increase productivity. In these environments, the high-temperature process is not just a matter of reaching a certain heat level—it becomes a fully integrated thermal-mechanical forming strategy that must be controlled to a fine degree to deliver precision components with demanding performance criteria.

In the broader context of manufacturing efficiency and sustainability, the high-temperature spinning process also offers advantages in material utilization and production waste. Since the process shapes metal directly from blanks without cutting away large volumes of material, it results in minimal scrap compared to machining or multi-part assembly methods. Moreover, because hot spinning forms parts in a single, continuous operation, it eliminates the need for welds or joints in many applications, enhancing structural integrity and reducing inspection or maintenance requirements. This is particularly valuable in pressure-sensitive applications such as chemical storage vessels, aerospace engine housings, and rocket domes, where any discontinuity in the structure could become a point of failure under high stress or thermal cycling.

The repeatability of high-temperature spinning processes has also improved with the integration of advanced sensors and automation. Modern machines can record and respond to real-time data such as torque, forming load, spindle speed, tool position, and localized surface temperature. These systems help operators maintain a consistent forming environment even when external variables—like changes in blank material properties or ambient conditions—might otherwise cause fluctuations in performance. With CNC systems capable of storing complex multi-pass tool paths and corresponding heat cycles, once a part program is proven, it can be replicated across many units with minimal manual adjustment.

Another critical area of advancement involves thermal modeling and simulation. Before actual production begins, engineers can use finite element analysis (FEA) to simulate how the metal will respond to temperature gradients and forming forces. These simulations help in predicting the final shape, detecting potential thinning or wrinkling zones, and optimizing heating strategies to prevent hot spots or thermal fatigue. Such predictive modeling is especially useful when dealing with new alloys or when developing spinning processes for complex parts that will see high mechanical or thermal loads in service.

In highly regulated industries like aerospace or nuclear power, every step of the high-temperature spinning process must be documented and validated. This includes detailed records of preheat temperatures, forming temperatures, roller paths, spindle speeds, and cooling rates. Machines used for these purposes are often equipped with full digital traceability, where every component’s process history can be reviewed and verified. This level of control is not just about quality assurance—it is also about meeting strict certifications required for safety-critical applications.

As demand for more exotic materials continues to grow—such as refractory metals, intermetallics, and metal matrix composites—the high-temperature spinning process is evolving to accommodate them. These materials often require ultra-high forming temperatures, sometimes approaching 1500°C, and may involve multi-layer heating systems, protective atmospheres, or even vacuum environments to prevent oxidation and ensure material stability. Tooling design must also evolve, with materials selected for thermal resistance, low reactivity with the workpiece, and resistance to wear under high load and friction.

In summary, the high-temperature process in hot spinning is not a single phase but an ongoing, precisely controlled condition that influences the entire shaping operation from the first contact of the tool to the final cooling of the part. Its impact on material behavior, tool performance, and final product quality is both profound and interconnected. As technology continues to advance, this process is becoming even more refined, reliable, and adaptable, ensuring that hot spinning remains one of the most efficient and powerful methods for forming high-strength, high-performance components in modern industry.

Hot Work for Hot Spinning Machine

Hot work in the context of a hot spinning machine refers to the entire range of operations and conditions where the metal workpiece is plastically deformed at elevated temperatures. This term encompasses not only the spinning itself but also the preparation, heating, tooling interaction, and post-forming handling that collectively enable the shaping of metals that are otherwise too hard or brittle to form at room temperature.

During hot work, the metal undergoes significant changes in its physical and microstructural properties due to the combined effects of heat and mechanical deformation. Elevated temperature lowers the metal’s yield strength and increases ductility, allowing it to flow plastically under the pressure of the spinning rollers without cracking or excessive strain hardening. This enables the production of complex geometries with tight dimensional tolerances, particularly in materials like stainless steel, titanium alloys, nickel-based superalloys, and certain aluminum alloys.

The key characteristic of hot work in spinning is the controlled application of heat to maintain the workpiece within a specific temperature range optimized for its particular alloy. This temperature range is carefully chosen to balance ductility, strength, and microstructural stability. For example, hot work temperatures for steel might range from 900°C to 1250°C, while titanium alloys might require temperatures between 700°C and 1000°C. Operating within this range facilitates processes like dynamic recrystallization, which refines grain structure and improves mechanical properties such as toughness and fatigue resistance.

Hot work also involves considerations around tooling materials and design. Since the workpiece is at elevated temperature, tooling must withstand not only mechanical forces but also thermal stresses and possible chemical interaction with the metal. Tool steels, heat-resistant alloys, and ceramic coatings are commonly used to improve tool life. Additionally, lubrication during hot work is more challenging; many conventional lubricants break down at high temperatures, so specialized high-temperature lubricants or dry lubricants like graphite are often employed to reduce friction and tool wear.

The thermal cycle during hot work is critical. Heating, forming, and cooling rates must be managed to avoid issues such as thermal shock, distortion, or oxidation. Preheating the blank and mandrel, maintaining localized heat during forming, and controlled cooling afterward all contribute to the success of the process. Environmental controls, like inert gas atmospheres or vacuum chambers, are sometimes used to protect sensitive alloys from oxidation or contamination during hot work.

Because hot work induces internal stresses, residual stress management is an integral part of the process. Careful control of temperature gradients and deformation rates helps minimize these stresses, which otherwise could lead to warping, cracking, or reduced fatigue life in the finished part. Post-forming heat treatments are often applied to relieve residual stresses and stabilize the microstructure.

In summary, hot work in hot spinning is a complex interplay of thermal and mechanical factors that transforms the metal into a formable state and enables the precise shaping of high-performance components. It requires detailed understanding of material behavior at elevated temperatures, sophisticated thermal and mechanical control systems, and specialized tooling and process environments to produce parts that meet stringent industrial requirements.

Hot work in a hot spinning machine also demands careful coordination between the operator, tooling, and heating systems to maintain the delicate balance between temperature and deformation. As the metal is spun and formed, it continuously changes shape and thickness, which affects how heat is conducted and retained in the workpiece. Uneven heating or rapid cooling in some areas can cause localized hardening or softening, potentially leading to defects such as cracks, wrinkles, or excessive thinning. To avoid this, the process often includes intermittent reheating or carefully controlled continuous heating to maintain the optimal temperature window throughout the entire forming operation.

The design of the tooling itself is integral to successful hot work. The mandrel must not only withstand the thermal stresses of prolonged exposure to high temperatures but also maintain dimensional stability to ensure the final part geometry is accurate. Materials like heat-treated tool steels or high-temperature alloys are common choices, often combined with coatings or surface treatments to reduce friction and wear. Rollers are similarly designed to endure the combination of mechanical load and heat, sometimes incorporating internal cooling channels to prevent overheating and extend tool life.

Lubrication during hot work presents a unique challenge because typical oils or greases break down under elevated temperatures, leaving the metal-to-tool interface vulnerable to galling, sticking, or excessive friction. To address this, solid lubricants like graphite, molybdenum disulfide, or specialized ceramic coatings are used to provide a low-friction barrier that remains stable during the hot spinning process. These lubricants help protect both the tooling and the workpiece surface, improving the quality of the finished part and extending tool lifespan.

Environmental control is often necessary, especially when working with reactive metals such as titanium or certain high-strength alloys. Exposure to oxygen at elevated temperatures can cause surface oxidation or embrittlement, which degrade mechanical properties and surface finish. To mitigate this, hot spinning may take place under inert gas atmospheres like argon or in vacuum chambers. This not only preserves the surface integrity of the metal but also helps maintain consistent thermal conditions, further improving process stability and repeatability.

Monitoring and controlling the thermal profile during hot work is supported by advanced sensor technologies. Infrared cameras, thermocouples embedded in tooling, and pyrometers provide real-time data on temperatures at various points on the workpiece and tooling. This information feeds into control systems that adjust heating power, spinning speed, or roller pressure to keep the process within the desired parameters. This level of control is crucial for materials with narrow hot working windows, where even small temperature fluctuations can lead to defects or premature tool failure.

Post-forming operations following hot work often include stress-relief annealing or other heat treatments to reduce residual stresses induced during spinning. These residual stresses, if left unmanaged, can cause distortion or reduce fatigue life, especially in parts that will operate under cyclic loads or in high-temperature environments. In some cases, hot spinning and subsequent heat treatments can produce a microstructure superior to that achieved by other forming methods, enhancing performance characteristics like toughness, corrosion resistance, and thermal stability.

In industrial settings, the hot work process is standardized and documented as part of quality management systems to ensure repeatability and traceability. Parameters such as heating temperature, forming speed, roller force, and cooling rates are recorded and controlled, often with computer-aided process planning. This is particularly important in aerospace, nuclear, and medical device manufacturing, where components must meet strict regulatory standards.

Overall, hot work in hot spinning is a sophisticated process that blends metallurgy, thermal management, mechanical engineering, and automation to transform metals into complex, high-performance shapes. Its success depends on precise control of temperature and deformation conditions, specialized tooling and lubrication, and often controlled environments to protect material properties. This combination enables the efficient production of components that are lightweight, strong, and capable of withstanding demanding service conditions.

Another important aspect of hot work in hot spinning machines is the management of thermal expansion and distortion throughout the forming cycle. As the metal heats up, it expands, sometimes unevenly depending on its shape, thickness, and material properties. This expansion can alter the fit between the blank and the mandrel, potentially causing slippage, misalignment, or uneven contact with the rollers. To counteract this, mandrels and fixtures are often designed with thermal expansion compensation in mind, either by selecting materials with similar expansion coefficients or by incorporating adjustable or flexible components that accommodate dimensional changes during heating.

The dynamic nature of the hot work process also means that operators must be vigilant in adjusting process parameters in real time. Changes in the material condition, such as local work hardening or slight variations in temperature, can alter the metal’s response to deformation. Skilled operators or automated control systems can adjust roller pressure, spindle speed, or heating intensity to maintain consistent forming forces and surface finish. This adaptability is especially critical when working with advanced alloys that have tight processing windows and when manufacturing parts with complex geometries or varying wall thickness.

In addition to the technical challenges, hot work in hot spinning often requires stringent safety measures due to the elevated temperatures, heavy machinery, and potential for thermal radiation or burns. Proper shielding, ventilation, and operator training are essential to maintain a safe working environment. Automation and remote monitoring have also become more common to reduce human exposure to hazardous conditions, increase precision, and improve repeatability.

The integration of digital technologies is transforming hot work processes as well. Sensors embedded in tooling and the workpiece feed data into machine learning algorithms and process control software that can predict tool wear, detect anomalies, and optimize parameters on the fly. This smart manufacturing approach reduces downtime, improves product quality, and extends tool life, making hot spinning more efficient and cost-effective.

Furthermore, research continues into new materials and coatings for both tooling and workpieces to push the limits of hot work capabilities. High-entropy alloys, advanced ceramics, and nano-composite coatings are being explored to provide better resistance to heat, wear, and chemical interaction. On the workpiece side, metal matrix composites and functionally graded materials challenge traditional hot spinning methods, necessitating new heating and forming strategies tailored to their unique properties.

In conclusion, hot work in hot spinning machines is a complex, multidisciplinary process that requires precise thermal and mechanical control, advanced tooling, and often sophisticated automation. It enables the shaping of high-performance metals into intricate shapes that meet demanding structural and functional requirements. The ongoing evolution of this process, driven by technological innovation and material science advances, continues to expand its applications and improve its efficiency and reliability in modern manufacturing.

Heat Treatment for Hot Spinning Machine

Heat treatment in the context of hot spinning machines plays a crucial role both before and after the spinning process to optimize the material’s properties and ensure the quality and performance of the finished part. Since hot spinning involves deforming metals at elevated temperatures, heat treatment complements this by managing the microstructure and mechanical characteristics through controlled heating and cooling cycles.

Before spinning, heat treatment often serves as a preparation step to homogenize the microstructure, reduce residual stresses, and enhance ductility. For instance, annealing the metal blank prior to forming can relieve internal stresses from previous processing such as casting, forging, or machining. This makes the material more uniform and predictable during deformation, reducing the risk of cracking or uneven flow when subjected to the intense mechanical forces and high temperatures of spinning. In some cases, solution treating may be applied to dissolve precipitates and improve formability in alloys such as aluminum or titanium.

During hot spinning, the metal is heated locally and plastically deformed, which induces changes in grain structure and dislocation density. This often results in work hardening in regions where deformation is most intense. Heat treatment after spinning, commonly called post-forming heat treatment, aims to modify these microstructural changes to achieve desired mechanical properties. Typical treatments include stress-relief annealing, normalizing, or tempering, depending on the alloy and final application. These processes help reduce residual stresses, restore ductility, and sometimes enhance strength or toughness by refining grain size or precipitating beneficial phases.

Controlled cooling after spinning is also a vital aspect of heat treatment. Rapid cooling (quenching) may be employed to lock in certain microstructures, such as martensite in steels, while slower cooling rates allow for more stable phases like pearlite or ferrite to form. The choice of cooling method—air cooling, furnace cooling, oil quenching, or water quenching—depends on the alloy system and the targeted balance of hardness, strength, and ductility.

In alloys sensitive to oxidation or scaling at high temperatures, heat treatment environments are carefully controlled using inert atmospheres, vacuum furnaces, or protective coatings to prevent surface degradation. This ensures that the part retains not only mechanical integrity but also surface quality, which is critical in aerospace, medical, and other high-performance applications.

Advanced heat treatments may involve multiple cycles or specialized processes such as aging, precipitation hardening, or cryogenic treatments. These are designed to tailor the material’s performance characteristics precisely, often enhancing fatigue resistance, corrosion resistance, or thermal stability. In complex parts, selective heat treatment techniques, like localized induction heating or laser annealing, are sometimes used to optimize properties only in specific zones, reducing distortion and processing time.

Integration of heat treatment data with process control in hot spinning machines enables better prediction of final part properties and helps establish quality control standards. Modern manufacturing often includes in-line or near-line heat treatment processes, reducing handling time and ensuring that parts move quickly from forming to finishing with minimal thermal exposure variability.

Overall, heat treatment associated with hot spinning machines is a multifaceted process that ensures the metal is both ready to be formed and correctly stabilized after deformation. It directly impacts the mechanical properties, dimensional stability, and surface integrity of spun components, making it indispensable in producing reliable, high-performance parts.

Heat treatment after hot spinning also helps in relieving the residual stresses introduced by the plastic deformation at elevated temperatures. These stresses, if left untreated, can cause distortion, cracking, or premature failure during the part’s service life. Stress-relief annealing typically involves heating the part to a moderate temperature below the critical transformation range and holding it there long enough to allow atomic diffusion that reduces internal stresses. This process improves dimensional stability and enhances fatigue resistance, which is particularly important for components subjected to cyclic loads or thermal cycling.

In addition to stress relief, heat treatment can restore or improve ductility that may have been reduced during the spinning process due to work hardening. Tempering, for example, is commonly used on steels spun at high temperatures to balance hardness with toughness. For alloys like aluminum or titanium, aging treatments promote precipitation of strengthening phases, increasing yield strength and overall mechanical performance after forming. The precise heat treatment schedule—temperature, time, and cooling rate—is tailored to the specific alloy and final application requirements.

Surface quality is another consideration during heat treatment related to hot spinning. Oxidation or scaling can occur when metals are heated in air at high temperatures, degrading surface finish and sometimes requiring costly post-processing like grinding or polishing. To minimize this, heat treatments are often performed in controlled atmospheres such as argon, nitrogen, or vacuum environments. Protective coatings applied before heating can also reduce surface degradation. These measures ensure that critical surfaces, especially those that interface with other components or require tight sealing, retain their integrity.

Heat treatment can also influence the microstructural evolution initiated by the hot spinning deformation. Dynamic recrystallization that occurs during forming refines grain size, but the microstructure may remain in a non-equilibrium state. Post-spinning heat treatments allow further grain growth or phase transformations that stabilize the structure, improving mechanical properties such as toughness, creep resistance, and corrosion resistance. In high-performance alloys used in aerospace and medical fields, controlling these microstructural changes through heat treatment is essential for meeting stringent performance standards.

In some cases, the heat treatment cycle is integrated into a continuous production line with hot spinning, where parts are spun, heat treated, and cooled in sequence without removing them from the production environment. This integration reduces handling time, limits exposure to contaminants, and ensures consistent thermal histories, all of which improve overall product quality and manufacturing efficiency.

Advanced monitoring technologies are increasingly used during heat treatment to ensure process accuracy. Thermocouples, infrared sensors, and even ultrasonic stress measurements provide real-time data that operators or automated systems use to adjust temperature profiles, hold times, and cooling rates. This level of control is critical when working with alloys that have narrow process windows or when producing parts with tight mechanical specifications.

Finally, heat treatment cycles are carefully documented as part of quality assurance protocols. This documentation is often required to meet industry standards such as aerospace specifications, medical device regulations, or nuclear codes. Traceability of heat treatment parameters helps ensure that every component has undergone the proper process to achieve the necessary mechanical and structural properties, providing confidence in the reliability and safety of the final product.

In summary, heat treatment for hot spinning machines is a comprehensive and indispensable process that prepares metals for forming and then stabilizes their properties afterward. Through carefully controlled heating and cooling, it manages microstructure, relieves stresses, enhances mechanical performance, and preserves surface quality, all of which are essential to producing high-quality, durable spun components across a wide range of demanding applications.

Beyond the standard heat treatment cycles, innovations in heat treatment technology continue to enhance the performance and efficiency of hot spinning operations. Techniques such as induction heating are now frequently used for both preheating and post-spinning treatment due to their rapid, localized heating capabilities. Induction heating can quickly bring the workpiece or specific areas to the desired temperature without heating the entire part or surrounding tooling, reducing energy consumption and thermal distortion.

Laser-assisted heat treatments are also emerging, particularly for selective surface modification. This allows manufacturers to harden or anneal targeted regions of a spun part, optimizing wear resistance or mechanical properties exactly where needed, without affecting the entire component. Such precision reduces overall processing time and minimizes undesired changes in material properties.

Cryogenic treatments have found niche applications where extreme durability is required. By cooling the spun parts to very low temperatures after heat treatment, these processes can transform retained austenite into martensite in steels or relieve microstructural stresses, thereby improving wear resistance and dimensional stability. While not commonly integrated into every hot spinning operation, cryogenic treatments are valuable in high-performance applications like aerospace or tool manufacturing.

Automation and process integration further enhance heat treatment outcomes. Modern hot spinning facilities often feature computer-controlled furnaces and continuous monitoring systems linked to the spinning machine’s control software. This integration allows for seamless transitions between forming and heat treatment steps, reduces cycle times, and ensures that the thermal history of each part is precisely recorded and repeatable. This is particularly crucial for industries with strict regulatory requirements, where complete traceability is mandatory.

Material development also drives heat treatment evolution. New alloys designed for better hot workability or improved mechanical properties require customized heat treatment protocols. Additive manufacturing combined with hot spinning introduces another layer of complexity, as printed parts may have unique microstructures that respond differently to heat treatment. As such, the heat treatment process must be adapted to these materials to maximize their performance and lifespan.

Sustainability considerations are becoming increasingly important in heat treatment for hot spinning. Efforts to reduce energy use, minimize emissions, and recycle heat within the process are shaping equipment design and operational strategies. For example, recuperative burners and heat exchangers capture waste heat from furnaces and redirect it to preheat incoming blanks or the work environment. These advances lower operating costs and environmental impact without compromising part quality.

In conclusion, heat treatment within the hot spinning process is a dynamic field continuously enhanced by technological advances in heating methods, process control, materials science, and sustainability. It remains a critical factor in achieving the mechanical performance, dimensional precision, and surface integrity required for high-quality spun components across diverse industrial sectors. The ongoing integration of innovative heat treatment techniques ensures that hot spinning machines can meet increasingly demanding manufacturing challenges efficiently and reliably.

Thermal Expansion for Hot Spinning Machine

Thermal expansion is a critical factor in the operation and design of hot spinning machines because the metal workpiece and the machine components themselves undergo dimensional changes when exposed to elevated temperatures during the spinning process. As metals heat up, their atoms vibrate more vigorously, causing an increase in the material’s dimensions—this effect is quantified by the material’s coefficient of thermal expansion (CTE). Managing thermal expansion is essential to maintain precision, avoid tooling damage, and ensure the quality of the finished part.

During hot spinning, the metal blank is heated to high temperatures, often several hundred degrees Celsius above ambient. At these temperatures, the workpiece can expand significantly, sometimes by several tenths of a percent or more in linear dimensions. This expansion affects how the blank fits over the mandrel and interacts with the rollers. If the mandrel or tooling does not accommodate this change, it can lead to misalignment, slippage, or uneven forming pressures, which in turn may cause defects such as wrinkling, thinning, or distortion of the spun part.

The machine components—mandrels, rollers, fixtures, and frames—also experience thermal expansion due to the heat transferred from the workpiece and the heating systems. Because these components are often made from different materials than the workpiece, their expansion rates may vary. This mismatch can create gaps or unwanted contact, leading to inaccuracies in the forming process or excessive wear on tooling surfaces.

To address thermal expansion, engineers design mandrels and tooling with materials that have low or matched coefficients of thermal expansion relative to the workpiece material. In some cases, composite materials or specially alloyed steels are used for tooling to minimize differential expansion. Additionally, tooling can be engineered with adjustable features or flexible mounts that compensate for thermal growth, maintaining precise positioning during operation.

Thermal expansion is also considered when setting initial clearances and tolerances. For example, the mandrel diameter might be designed slightly smaller at room temperature to ensure that it fits perfectly once both mandrel and workpiece reach forming temperature. Similarly, roller positioning must account for thermal growth to maintain consistent forming pressure throughout the process.

During the heating and cooling cycles, uneven temperature distribution can cause differential thermal expansion within the workpiece itself, leading to internal stresses and potential warping. This is especially critical in parts with complex geometries or varying thicknesses, where some regions heat or cool faster than others. Controlled heating rates, uniform heating methods (such as induction coils or furnace atmospheres), and gradual cooling help mitigate these effects by promoting more uniform thermal expansion and contraction.

In addition to mechanical considerations, thermal expansion influences process control and monitoring. Sensors embedded in tooling or positioned near the workpiece track temperature changes, allowing control systems to predict and adjust for dimensional changes in real time. This integration helps maintain forming accuracy, protects tooling, and ensures consistent part quality.

Ignoring or poorly managing thermal expansion can lead to costly defects, increased wear, and downtime. Therefore, thorough analysis of thermal expansion behavior is part of the design and planning stages for hot spinning operations, supported by finite element modeling and thermal simulations. These tools predict how materials and tooling will behave under thermal loads, guiding decisions on material selection, machine design, and process parameters.

In summary, thermal expansion is a fundamental aspect of hot spinning machines that directly impacts machine design, process accuracy, tooling life, and part quality. Successful hot spinning depends on carefully understanding and controlling thermal dimensional changes throughout the heating, forming, and cooling phases to produce precise, defect-free components.

Thermal expansion also affects the dynamic behavior of the hot spinning process. As the temperature changes during the operation, the expanding and contracting components can alter the alignment and concentricity of the workpiece relative to the mandrel and rollers. Even small deviations can cause uneven material flow, surface defects, or increased mechanical stresses. To compensate, some advanced hot spinning machines incorporate real-time adjustment mechanisms, such as motorized actuators or servo-controlled tooling, which continuously fine-tune positions based on temperature feedback.

The choice of heating method plays a role in how thermal expansion is managed. For instance, induction heating tends to provide rapid and localized heating, which can create steep temperature gradients within the workpiece and tooling. These gradients exacerbate differential thermal expansion and increase the risk of distortion or thermal stress. In contrast, furnace heating or controlled atmosphere ovens offer more uniform heating but at slower rates. Balancing heating speed with thermal uniformity is a key design consideration to minimize problematic expansion effects.

Another factor is the thermal conductivity of the materials involved. Metals with high thermal conductivity, such as copper or aluminum, tend to distribute heat quickly and more evenly, reducing localized expansion. Conversely, alloys with lower conductivity may develop hot spots, increasing thermal gradients. Tooling materials with carefully selected thermal properties can help moderate heat flow and reduce uneven expansion.

Cooling after hot spinning introduces additional challenges. As the workpiece and tooling cool down, they contract at different rates, potentially leading to residual stresses or dimensional changes that affect final tolerances. Controlled cooling rates and sometimes post-process heat treatments are employed to minimize these effects and ensure dimensional stability.

The interplay between thermal expansion and mechanical deformation is complex. While expansion changes dimensions, the simultaneous plastic deformation of the metal workpiece modifies its microstructure and mechanical response. These combined effects influence not only the final shape but also properties like residual stress distribution, hardness, and fatigue resistance. Process simulation tools that integrate thermal and mechanical models are increasingly used to predict and optimize this behavior.

Maintenance routines for hot spinning machines often include checks for thermal distortion or wear caused by repetitive thermal cycling. Over time, components may warp or lose alignment, requiring recalibration or replacement. Designing machines with modular, adjustable parts and using materials resistant to thermal fatigue extends service life and reduces downtime.

In research and development, understanding thermal expansion in hot spinning supports innovation in new materials and complex part designs. For example, functionally graded materials or composites may have layers with different expansion coefficients, posing unique challenges in managing dimensional changes during heating. Solutions include tailored heating profiles, specialized tooling, or multi-stage forming processes to accommodate these variations.

Overall, thermal expansion is not just a physical phenomenon to accommodate but an active design and control parameter in hot spinning machines. By carefully accounting for and managing expansion through materials selection, tooling design, heating strategy, and process control, manufacturers achieve high precision, repeatability, and part quality in demanding applications.

Thermal expansion also plays a vital role in the calibration and setup of hot spinning machines. Before production runs, machines are typically warmed up to operating temperatures to allow components to expand and reach a steady-state dimension. This warm-up phase ensures that the initial alignment and clearances reflect actual working conditions rather than room temperature measurements, which would be misleading. Proper calibration at elevated temperatures reduces the risk of inaccuracies during actual forming and helps maintain consistent part geometry across batches.

In addition, the control systems for hot spinning machines increasingly incorporate predictive models of thermal expansion. By inputting temperature data, these systems can anticipate dimensional changes and adjust the positioning of mandrels, rollers, and spindles proactively rather than reactively. This predictive capability improves efficiency, reduces scrap rates, and enables tighter tolerances, which is especially critical in industries like aerospace or medical device manufacturing where precision is paramount.

Thermal expansion considerations also extend to the selection of fasteners, seals, and couplings in the machine’s construction. These components must accommodate dimensional changes without losing mechanical integrity or causing misalignment. Flexible couplings, spring-loaded fasteners, or materials with matched thermal expansion coefficients are often used to maintain the machine’s structural stability under thermal cycling.

Moreover, tooling designed for hot spinning may include built-in features to manage thermal stresses caused by expansion. These can be slots, relief cuts, or expansion joints that allow controlled movement of tooling parts without compromising strength or accuracy. Such design elements help prevent cracking, warping, or premature failure of expensive tooling.

On the material side, understanding how the workpiece expands during heating informs decisions about blank sizing and pre-forming operations. For example, the initial diameter or thickness of the metal blank might be adjusted to account for expected thermal growth so that the final spun part meets dimensional specifications after cooling and contraction.

Thermal expansion is also a key factor in multi-stage or incremental spinning processes where the workpiece is heated and formed multiple times. Each cycle introduces expansion and contraction, as well as mechanical deformation, requiring careful process planning to avoid cumulative dimensional errors or damage.

In some advanced applications, thermal expansion data is integrated with other process parameters such as strain, force, and temperature to create comprehensive digital twins of the hot spinning operation. These virtual models allow engineers to simulate and optimize the process before actual manufacturing, saving time and reducing costly trial-and-error iterations.

Finally, as hot spinning machines evolve with the integration of automation, robotics, and real-time sensing, the role of thermal expansion management becomes even more critical. Automated systems rely on precise dimensional feedback to adjust forming parameters on the fly, ensuring consistent quality despite thermal effects. The synergy between thermal management and automation leads to smarter, more efficient production capable of handling complex parts and advanced materials with minimal human intervention.

In essence, thermal expansion is woven throughout every aspect of hot spinning—from machine design and tooling to process control and quality assurance—making its management indispensable for successful hot spinning operations and high-performance finished products.

Induction Heating for Hot Spinning Machine

Induction heating is widely used in hot spinning machines as an efficient and precise method for rapidly heating metal workpieces before and during the spinning process. It involves generating an alternating electromagnetic field using a coil wrapped around or positioned near the workpiece, which induces eddy currents within the metal. These currents cause localized resistive heating, raising the temperature of the metal quickly and with high energy efficiency.

One of the key advantages of induction heating in hot spinning is its ability to deliver rapid, controlled, and localized heating without direct contact with the workpiece. This reduces heat loss, minimizes contamination, and allows selective heating of specific areas, such as the zone where deformation will occur, without unnecessarily heating the entire part. This precision improves thermal efficiency and shortens cycle times, increasing throughput in manufacturing.

Induction heating systems can be precisely controlled by adjusting parameters such as coil geometry, frequency, power input, and heating duration. Higher frequencies concentrate heating near the surface (skin effect), ideal for surface hardening or thin-walled components, while lower frequencies penetrate deeper, suitable for uniform heating of thicker sections. The flexibility in tuning these parameters allows manufacturers to tailor heating profiles to different materials, thicknesses, and part geometries, optimizing the hot spinning process for quality and efficiency.

Because induction heating is rapid, it reduces the time the workpiece spends at elevated temperatures, minimizing oxidation, scaling, and grain growth that could degrade material properties or surface finish. This is especially important when working with reactive metals like titanium or aluminum alloys, which are prone to oxidation. Often, induction heating is performed in protective atmospheres or with shielding gases to further reduce surface degradation.

Integration of induction heating with hot spinning machines enhances process automation. Sensors monitoring temperature feed data into control systems that adjust induction power in real time, maintaining the desired thermal profile throughout forming. This dynamic control ensures the workpiece remains within optimal temperature ranges, preventing overheating or underheating that could cause defects such as cracking or insufficient ductility.

Induction heating equipment for hot spinning machines typically includes water-cooled coils to manage coil temperature and prolong equipment life. The coil design must allow unobstructed access for spinning tooling while maintaining efficient coupling with the workpiece. In some machines, induction coils are mounted on movable arms or incorporated into the mandrel to provide uniform heating as the workpiece rotates.

While induction heating offers many benefits, it requires careful design and process integration. Coil design and positioning significantly impact heating uniformity and efficiency. Uneven heating can cause thermal stresses and distortion, compromising part quality. Therefore, extensive simulation and testing are used during setup to optimize coil configurations for specific parts and materials.

In summary, induction heating is a highly effective heating method for hot spinning machines that provides rapid, localized, and controllable heating. It improves energy efficiency, reduces cycle times, enhances surface quality, and supports advanced process automation, making it a preferred choice in modern hot spinning operations across industries like aerospace, automotive, and energy.

Induction heating also offers significant advantages in terms of safety and environmental impact compared to conventional heating methods such as gas or resistance furnaces. Because it is a clean, electrical process, induction heating produces no direct emissions and requires no combustion gases, which helps maintain a safer working environment and reduces the need for extensive ventilation or filtration systems. The precise control over heating zones also minimizes energy waste, making it a more sustainable choice for manufacturers focused on reducing their carbon footprint.

The ability to rapidly start and stop induction heating aligns well with flexible production schedules and small batch manufacturing. Unlike traditional furnaces that require long preheating and cooldown periods, induction heating can quickly bring a workpiece to the desired temperature and cool it down just as fast when power is cut. This on-demand heating capability reduces idle times and increases overall equipment utilization, which is especially valuable in high-mix, low-volume production environments.

In addition, induction heating systems can be designed to accommodate complex part geometries and varying sizes. Custom coil designs can be tailored to the shape of the workpiece, ensuring consistent heating even in areas that are difficult to reach with other heating methods. For parts with varying cross-sections, multi-zone induction coils or segmented coils can provide differential heating, allowing for precise temperature control across the component. This versatility makes induction heating suitable for a wide range of applications from simple disks to intricate aerospace components.

Maintenance and operational costs of induction heating systems are typically lower compared to other heating methods. Since there is no direct flame or combustion process, components like burners or refractory linings are unnecessary, reducing wear and replacement needs. Water-cooling systems for coils are the primary maintenance concern, but they are straightforward to monitor and service. The modular nature of induction heating units also allows for easier upgrades and scalability, adapting to changing production demands.

One limitation to consider is the initial investment cost for induction heating equipment, which can be higher than conventional heating systems. However, this is often offset by lower operating costs, improved process control, and increased throughput. The return on investment is typically favorable, particularly in industries where precision and repeatability are critical.

Integration of induction heating with other advanced manufacturing technologies is expanding its capabilities in hot spinning. For example, coupling induction heating with in-line temperature sensors, thermal imaging cameras, and closed-loop control systems enables real-time monitoring and adjustment of heating parameters. This integration supports adaptive manufacturing processes that respond dynamically to variations in material properties or environmental conditions, enhancing product consistency and reducing scrap rates.

Furthermore, induction heating complements the trend towards digital manufacturing and Industry 4.0. Data collected during induction heating cycles can feed into machine learning algorithms to optimize heating profiles over time, predict equipment maintenance needs, and ensure process reliability. This data-driven approach improves decision-making and helps manufacturers achieve higher efficiency and quality standards.

In conclusion, induction heating for hot spinning machines is a powerful technology that offers precise, efficient, and environmentally friendly heating solutions. Its rapid response, flexibility, and integration potential make it a cornerstone of modern hot spinning processes, enabling manufacturers to produce high-quality components with improved productivity and reduced operational costs.

Induction heating’s ability to selectively heat specific regions of a workpiece also enables innovative hot spinning techniques that would be difficult or impossible with conventional heating methods. For instance, partial or localized heating can soften targeted areas while leaving other sections relatively cooler and stronger. This selective softening allows complex shapes or features to be formed more easily, improving material flow and reducing forming forces. It also helps prevent distortion or damage in critical zones that must maintain dimensional stability.

In multi-material or layered components, induction heating can be precisely controlled to accommodate the differing thermal properties of each layer. This is especially valuable when spinning composite structures or metal-clad parts, where uneven heating could cause delamination or internal stresses. By adjusting heating parameters and coil positioning, manufacturers can maintain uniform temperature distributions tailored to these complex materials.

Another emerging application is combining induction heating with in-process quenching or rapid cooling methods. After forming, specific areas of a spun part can be quickly cooled to lock in desirable microstructures or mechanical properties, such as increased hardness or strength. This integration of heating and cooling steps within the hot spinning cycle improves efficiency and reduces the need for separate heat treatment operations.

The modularity of induction heating systems also supports customization and scalability in hot spinning lines. Manufacturers can configure induction coils and power supplies to handle a variety of part sizes and production volumes. This flexibility is critical for industries with diverse product ranges or evolving design requirements, allowing hot spinning equipment to adapt without major overhauls.

Training and skill requirements for operating induction-heated hot spinning machines have evolved as well. Operators and engineers must understand not only mechanical forming principles but also electromagnetic heating characteristics and process control technologies. This multidisciplinary expertise ensures optimal machine setup, heating parameter selection, and troubleshooting, maximizing the benefits of induction heating.

Looking ahead, research into novel coil materials, improved power electronics, and advanced control algorithms promises to further enhance induction heating performance. Innovations such as high-frequency solid-state power sources and adaptive coil geometries will increase heating precision, reduce energy consumption, and enable new process capabilities.

In summary, induction heating is not just a heating method but a versatile enabler of advanced hot spinning processes. Its precision, efficiency, and adaptability help manufacturers meet increasingly stringent demands for part quality, production speed, and cost-effectiveness. As technology continues to progress, induction heating will remain a key driver in the evolution of hot spinning machinery and manufacturing excellence.

Heating Unit of a Hot Spinning Machine

The heating unit of a hot spinning machine is a crucial subsystem designed to raise the temperature of the metal workpiece to the required level for plastic deformation during spinning. Its primary function is to deliver controlled, uniform heat efficiently and reliably, ensuring the workpiece achieves the optimal temperature to improve ductility, reduce forming forces, and avoid defects such as cracking or uneven thickness.

Typically, the heating unit consists of one or more of the following components:

- Heating Source: This may be an induction coil, resistance heating elements, gas burners, or furnace chambers depending on the machine design and application. Induction heating is increasingly common due to its rapid, localized heating and energy efficiency. Gas burners or electric furnaces are sometimes used for larger or more uniform heating requirements.

- Heating Chamber or Zone: The area where the workpiece is placed or positioned during heating. In some machines, the heating zone is integrated with the spinning mandrel or arranged around the workpiece in a furnace or induction coil. This chamber may have insulation to minimize heat loss and maintain temperature stability.

- Temperature Sensors: Thermocouples, infrared pyrometers, or thermal cameras monitor the temperature of the workpiece or heating zone. These sensors provide real-time feedback to control systems to regulate heating intensity, duration, and uniformity.

- Control System: The heating unit is managed by a dedicated control system that adjusts power input, timing, and heating profiles based on sensor data and process parameters. Advanced controls allow for programmable heating cycles, rapid response to temperature changes, and integration with the spinning machine’s overall operation.

- Cooling and Safety Features: Components such as water-cooled coils in induction systems, safety interlocks, and emergency shutoffs ensure safe operation and protect the equipment from overheating or damage.

The heating unit must be carefully designed to match the size, shape, and material of the workpieces, as well as the production rate. Uniform heating is essential to avoid thermal gradients that could induce residual stresses or distortion. In many setups, preheating stages gradually bring the workpiece to temperature to prevent thermal shock and ensure consistent material behavior during spinning.

In modern hot spinning machines, the heating unit is often seamlessly integrated into the machine structure, allowing simultaneous heating and forming. This integration enhances efficiency, reduces cycle times, and improves process control.