We manufacture transfer lines and destacker units for automatic manufacturing systems with hydraulic and mechanical presses. Free Consultation.

Transfer lines, also known as transfer systems or transfer lines in manufacturing, are complex and highly automated production systems used in industries that require high-volume manufacturing of precision components. These systems consist of various machine tools, workstations, and conveyor systems that are interconnected to produce, process, and assemble parts efficiently. Here are key details about transfer lines:

1. High-Volume Production:

- Transfer lines are designed for mass production of components. They are ideal for industries where large quantities of identical or closely related parts need to be manufactured quickly and consistently.

2. Modular Design:

- Transfer lines are modular, allowing manufacturers to customize them to suit specific production requirements. Different machine tools and workstations can be integrated into the line to perform various operations.

3. Sequential Processing:

- Workpieces move sequentially through the line, with each station performing a specific operation, such as drilling, milling, turning, grinding, or assembly. These operations are carefully orchestrated for efficient processing.

4. Conveyor Systems:

- Transfer lines typically incorporate conveyor systems that move workpieces between stations. These conveyors can be linear or circular, depending on the layout and requirements of the manufacturing process.

5. Precision and Accuracy:

- Precision is a key feature of transfer lines. They are designed to provide consistent and accurate machining or assembly processes to meet tight tolerances.

6. Automation:

- Automation is a fundamental aspect of transfer lines. Robots, pick-and-place systems, and other automation technologies are often integrated to load and unload workpieces, perform inspections, and handle other tasks.

7. Reduced Labor Costs:

- By automating many manufacturing tasks, transfer lines help reduce labor costs and the risk of human error. Operators are typically responsible for monitoring and maintaining the system rather than performing manual tasks.

8. Process Monitoring:

- Transfer lines often include sensors and monitoring systems that continuously check the quality of workpieces during processing. This allows for real-time adjustments and ensures consistent quality.

9. Tooling and Fixture Changes:

- Tooling and fixtures can be changed quickly in a transfer line to accommodate different part designs or production runs. This flexibility enhances the system’s versatility.

10. Production Rate: – Transfer lines are capable of high production rates, making them suitable for industries such as automotive, aerospace, and consumer electronics, where demand for parts is extensive.

11. Quality Control: – Quality control measures are integrated into transfer lines to detect defects early in the production process. This helps prevent the production of faulty parts and reduces waste.

12. Maintenance: – Regular maintenance is essential to keep transfer lines running smoothly and efficiently. Maintenance schedules are carefully planned to minimize downtime.

13. Energy Efficiency: – Modern transfer lines are designed with energy efficiency in mind, using advanced technologies to reduce energy consumption and environmental impact.

14. Lean Manufacturing: – Transfer lines are often associated with lean manufacturing principles, which aim to eliminate waste, improve efficiency, and optimize resources in the production process.

15. Scalability: – Transfer lines can be scaled up or down to match changing production demands. Additional stations or machines can be added to increase capacity.

Transfer lines are particularly valuable in industries that require high precision, consistency, and efficiency in their manufacturing processes. They are a testament to the advanced automation and engineering capabilities employed in modern manufacturing.

Transfer Lines

Transfer lines for press automation refer to systems used in manufacturing processes, especially in metal forming, where a series of interconnected machines and devices work together to automate the production of stamped or formed parts. These transfer lines are commonly employed in automotive manufacturing, appliances, and other industries where mass production of metal parts is required. Here are key components and features of transfer lines for press automation:

- Press Machines: At the core of a transfer line is the press machine or a series of press machines. These machines are used to stamp or form the metal parts from coil or sheet metal.

- Transfer Systems: Transfer systems are responsible for moving the workpieces (metal blanks or parts) from one station to another within the transfer line. They can be mechanical, hydraulic, or servo-driven systems.

- Tooling and Dies: Tooling and dies are crucial components that shape and form the metal parts. The transfer line may include various dies for different operations, such as blanking, piercing, bending, and forming.

- Conveyors: Conveyors are used to transport materials, parts, or tooling within the transfer line. They facilitate the movement of components between different stations efficiently.

- Robotic Systems: Robots are often integrated into transfer lines to perform tasks such as loading and unloading parts, tool changing, quality inspection, and other handling operations.

- Automation Controls: Automation controls, often using programmable logic controllers (PLCs) and human-machine interface (HMI) systems, manage and coordinate the operation of various components within the transfer line.

- Safety Systems: Safety features such as sensors, guards, and interlocks are incorporated to ensure the safety of operators and prevent accidents in the automated manufacturing environment.

- Lubrication Systems: To ensure smooth operation and longevity of the machines, lubrication systems are integrated to provide the necessary lubrication to moving parts.

- Quality Control Systems: Vision systems and sensors may be employed for quality control, inspecting parts to ensure they meet specified standards and identifying defects or variations.

- Flexible Configurations: Transfer lines are often designed to be flexible, allowing for quick changeovers and adaptation to different part geometries or production requirements.

- Data Collection and Analysis: Modern transfer lines may include systems for collecting data on production metrics, machine performance, and quality parameters. This data can be analyzed for process improvement and optimization.

- Cooling Systems: In metal forming processes, especially for hot stamping or forging, cooling systems may be integrated to control the temperature of the tools and workpieces.

Transfer lines for press automation are designed to optimize efficiency, reduce manual labor, and ensure consistent and high-speed production of metal parts. They are a key element in the pursuit of lean manufacturing and mass production in various industries.

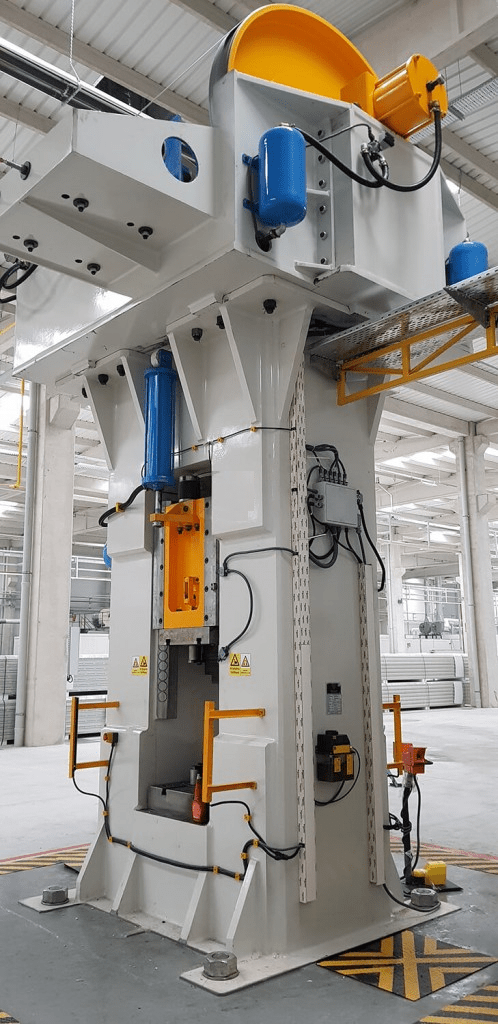

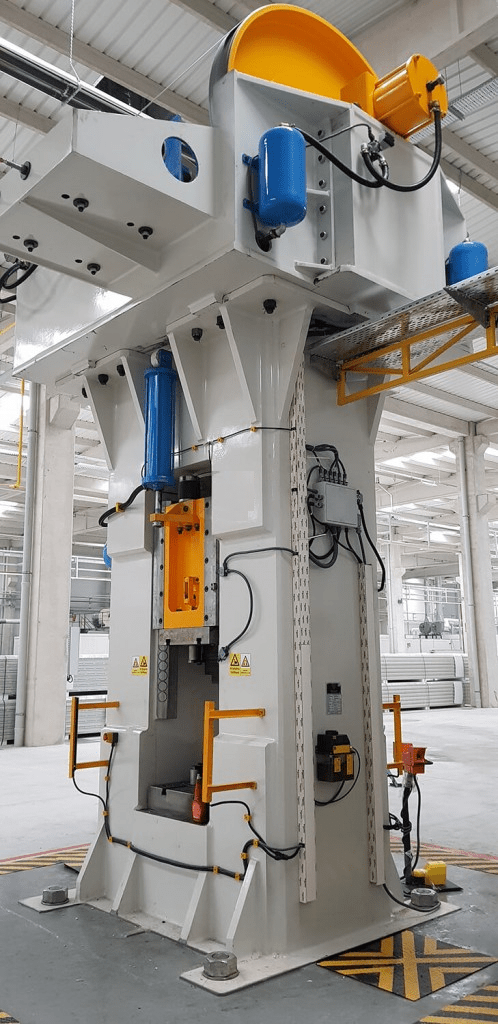

Press Machines

Press machines are mechanical devices used in manufacturing processes to shape or form materials into desired shapes through the application of force. These machines are widely used in various industries for tasks such as cutting, bending, punching, and stamping. There are different types of press machines, each designed for specific applications. Here are some common types of press machines:

- Mechanical Press: Mechanical presses use a flywheel and a mechanical clutch to deliver force to a tool or die. They are known for their straightforward design and are suitable for various applications, including blanking, piercing, and forming.

- Hydraulic Press: Hydraulic presses use hydraulic cylinders to generate force. These presses are versatile and can provide a consistent force throughout the stroke. They are often used for tasks such as deep drawing, compression molding, and metal forming.

- Pneumatic Press: Pneumatic presses use compressed air to generate force. They are often used for lighter-duty applications, such as assembly operations and small-scale stamping.

- Servo Press: Servo presses use an electric motor and a servo drive to precisely control the force and speed of the press. These presses offer high precision and are suitable for applications requiring fine control, such as forming delicate materials.

- Mechanical Press Brake: Press brakes are used for bending and shaping sheet metal. They use a punch and die setup to create bends in the material. Mechanical press brakes use a mechanical linkage to generate force.

- Hydraulic Press Brake: Hydraulic press brakes use hydraulic cylinders to apply force for bending operations. They provide accurate and consistent bending and are suitable for various materials and thicknesses.

- Stamping Press: Stamping presses are specifically designed for high-speed stamping operations, such as creating metal parts from sheet metal. They can be mechanical or hydraulic and are commonly used in automotive and appliance manufacturing.

- Coining Press: Coining presses are used for precision stamping to produce finely detailed and precise features on metal parts. They are often employed in the production of coins, medals, and small metal components.

- Forging Press: Forging presses are designed for hot or cold forging processes, where metal is shaped through the application of force. These presses are essential in the production of forged components for industries like aerospace and automotive.

- Extrusion Press: Extrusion presses are used to extrude materials, typically metals, through a die to create long, uniform shapes. They are commonly used in the production of aluminum profiles and other extruded products.

Press machines play a critical role in metalworking and manufacturing processes, contributing to the production of a wide range of products across various industries. The choice of a specific type of press machine depends on the intended application, material, and required precision.

Mechanical Press

A mechanical press is a machine tool that uses mechanical force to shape or cut materials. It is a type of press machine that operates based on mechanical principles, utilizing a motor-driven flywheel to generate and deliver force to a tool or die. Mechanical presses are widely used in various industries for processes such as metal forming, blanking, stamping, and coining. Here are key features and components of a mechanical press:

Key Features

- Flywheel Mechanism:

- Function: The flywheel is a heavy rotating wheel connected to the main drive motor. It stores and releases energy to provide a powerful and controlled force during the pressing operation.

- Clutch and Brake System:

- Function: The clutch engages and disengages the flywheel, controlling the transfer of energy. The brake system stops the motion of the flywheel when needed.

- Ram or Slide:

- Function: The ram, also known as the slide, is the moving component that carries the tool or die. It delivers the force to the workpiece during the pressing operation.

- Tool and Die Setup:

- Function: The tool and die are crucial components that shape or cut the material. The die is fixed, and the tool is attached to the ram, creating a matched set for specific forming or cutting operations.

- Bed or Bolster:

- Function: The bed, also called the bolster, is the stationary part of the press that provides support for the workpiece and the die.

- Mechanical Linkages:

- Function: Mechanical presses often use linkages, such as toggle mechanisms, to convert the rotary motion of the flywheel into linear motion of the ram with increased force.

- Adjustable Stroke Length:

- Function: Some mechanical presses allow for adjustment of the stroke length, providing flexibility for different forming operations and workpiece sizes.

- Adjustable Speed:

- Function: The speed of the ram’s movement can often be adjusted, allowing for control over the forming process and accommodating different materials and tooling requirements.

- Counterbalance Mechanism:

- Function: In some presses, a counterbalance mechanism is used to offset the weight of the ram and upper components, ensuring smooth and balanced operation.

- Safety Features:

- Function: Mechanical presses are equipped with safety features such as guards, emergency stop buttons, and interlocks to ensure the safety of operators and prevent accidents.

Operation

- Engagement:

- The operator engages the clutch, connecting the flywheel to the mechanical components of the press.

- Energy Storage:

- The motor drives the flywheel, storing energy in its rotational motion.

- Forming Operation:

- The clutch is engaged, releasing the stored energy in the flywheel. The energy is transferred to the ram, which moves downward to perform the forming or cutting operation.

- Return Stroke:

- After the forming operation, the ram returns to its original position, and the energy is dissipated.

- Disengagement:

- The clutch is disengaged, disconnecting the flywheel from the mechanical components, and the brake may be applied to stop the motion.

Mechanical presses are known for their robustness, simplicity, and cost-effectiveness. They are suitable for a variety of metal forming applications, ranging from small-scale operations to large-scale production environments. However, their stroke rates may be limited compared to other types of presses, and they may require more maintenance due to wear on mechanical components.

Hydraulic Press

A hydraulic press is a machine tool that uses a hydraulic cylinder to generate a compressive force. It is widely used in various industrial applications for tasks such as forming, molding, stamping, and metal shaping. Hydraulic presses are known for their ability to apply a consistent force across a wide range of operations. Here are key features and components of a hydraulic press:

Key Features

- Hydraulic Cylinder:

- Function: The hydraulic cylinder is a key component that generates the force required for the pressing operation. It consists of a piston inside a cylinder filled with hydraulic fluid.

- Hydraulic Pump:

- Function: The hydraulic pump is responsible for pressurizing the hydraulic fluid, creating the force necessary to move the piston within the hydraulic cylinder.

- Hydraulic Fluid:

- Function: Hydraulic fluid is used to transmit the pressure generated by the hydraulic pump to the hydraulic cylinder. It is an incompressible fluid that allows for the transfer of force.

- Ram or Platen:

- Function: The ram, also known as the platen, is the moving component of the press that applies force to the workpiece. It is attached to the piston inside the hydraulic cylinder.

- Frame or Housing:

- Function: The frame provides structural support for the press and houses the hydraulic components. It is designed to withstand the forces generated during the pressing operation.

- Bed or Bolster:

- Function: The bed, also called the bolster, is the stationary part of the press that provides support for the workpiece during the pressing operation.

- Control System:

- Function: The control system manages the operation of the hydraulic press. It includes valves, sensors, and other components to regulate the flow of hydraulic fluid and control the force and speed of the ram.

- Pressure Relief Valve:

- Function: The pressure relief valve is a safety feature that limits the maximum pressure in the hydraulic system, preventing overloading and damage to the press.

- Pressure Gauge:

- Function: The pressure gauge provides a visual indication of the hydraulic pressure in the system. It helps operators monitor and control the force applied during the pressing operation.

- Hydraulic Hoses and Pipes:

- Function: Hydraulic hoses and pipes transport hydraulic fluid between the pump, cylinder, and other components of the hydraulic system.

Operation

- Hydraulic Pump Activation:

- The hydraulic pump is activated, pressurizing the hydraulic fluid.

- Hydraulic Fluid Transmission:

- Pressurized hydraulic fluid is transmitted through hoses or pipes to the hydraulic cylinder.

- Piston Movement:

- The pressurized hydraulic fluid moves the piston inside the hydraulic cylinder, causing the ram to move downward and apply force to the workpiece.

- Forming or Shaping:

- The force applied by the ram is used to form, shape, or mold the workpiece according to the specifications of the operation.

- Pressure Release:

- The hydraulic pump can be deactivated, and the pressure relieved to allow the ram to return to its original position.

Hydraulic presses are valued for their ability to exert a high force consistently and evenly across the entire surface of the workpiece. They are commonly used in metal forming and fabrication, plastic molding, rubber processing, and other applications where precision and high force are required. The versatility of hydraulic presses makes them suitable for a wide range of manufacturing processes.

Servo Press

A servo press is a type of press machine that incorporates a servo motor and drive system for precise control over the speed, position, and force applied during the pressing operation. Unlike traditional mechanical or hydraulic presses, servo presses offer a high level of flexibility, accuracy, and energy efficiency. These presses are widely used in industries where precise and programmable force and motion control are critical. Here are key features and components of a servo press:

Key Features

- Servo Motor:

- Function: The servo motor is an electric motor that provides precise control over the movement of the press. It is capable of dynamic and highly accurate motion control.

- Drive System:

- Function: The drive system, often a combination of a servo drive and controller, controls the power supplied to the servo motor, allowing for precise control of speed, force, and position.

- Recirculating Ball Screw or Direct Drive System:

- Function: The press may use a recirculating ball screw or a direct drive system to convert the rotary motion of the servo motor into linear motion of the ram or slide.

- Ram or Slide:

- Function: The ram or slide is the moving component that applies force to the workpiece. It is attached to the mechanism driven by the servo motor.

- Control System:

- Function: The control system, often incorporating a programmable logic controller (PLC) or computerized numerical control (CNC), allows for precise programming of the press parameters, including force, speed, and dwell times.

- Load Cell or Force Sensor:

- Function: A load cell or force sensor is often integrated to measure the force applied during the pressing operation, providing feedback to the control system for closed-loop control.

- Encoder:

- Function: An encoder is used to provide feedback on the position of the ram or slide, enabling accurate control over the press’s stroke and position.

- Touchscreen Interface:

- Function: Many servo presses feature a touchscreen interface that allows operators to program and monitor the press parameters easily.

- Safety Features:

- Function: Safety features such as emergency stop buttons, interlocks, and overload protection are incorporated to ensure the safety of operators and protect the press from damage.

Advantages of Servo Presses

- Precision and Accuracy:

- Servo presses offer high precision and accuracy in controlling force, speed, and position, making them suitable for applications requiring tight tolerances.

- Flexibility:

- The programmability of servo presses allows for quick and easy adjustments to accommodate different workpieces, tooling, and forming operations.

- Energy Efficiency:

- Servo presses are energy-efficient because they only consume power based on the actual demand of the operation. The servo motor can be dynamically adjusted to match the required force and speed.

- Reduced Setup Time:

- Setup times are minimized due to the ease of programming and adjusting parameters. This is especially beneficial in environments with frequent changeovers.

- Versatility:

- Servo presses can be used for a wide range of applications, including stamping, forming, drawing, and other precision operations.

- Quiet Operation:

- Compared to traditional hydraulic presses, servo presses operate more quietly as there is no constant running of a hydraulic pump.

Servo presses find applications in industries such as automotive manufacturing, electronics, aerospace, and precision metal forming, where the demand for high precision and flexibility is critical. They are particularly well-suited for operations that involve complex forming processes and the need for optimal energy efficiency.

Transfer Systems

Transfer systems in the context of transfer presses refer to the automated systems used to move workpieces, often in the form of stamped or formed parts, between different stations within a transfer press. A transfer press is a specialized type of stamping or forming press that integrates a transfer system to efficiently move workpieces through various stages of the manufacturing process. Transfer systems are designed to optimize production by automating the transfer of workpieces between different dies or workstations. Here are key aspects of transfer systems in transfer presses:

Components of Transfer Systems in Transfer Presses

- Transfer Bars or Rails:

- Description: Transfer bars or rails are linear guides along which the transfer mechanisms move. Workpieces are typically attached to carriers that travel along these bars.

- Transfer Mechanisms:

- Description: Transfer mechanisms are the components responsible for moving the workpiece carriers along the transfer bars. They can include pneumatic or hydraulic cylinders, electric servos, or other automated systems.

- Workpiece Carriers:

- Description: Workpiece carriers are devices that hold and transport the workpieces through the various stages of the press. They are attached to the transfer mechanisms and move along the transfer bars.

- Die Sets or Stations:

- Description: Die sets or stations are specific locations within the transfer press where various forming, stamping, or assembly operations take place. Workpieces are transferred between different die sets as they progress through the manufacturing process.

- Clamps or Grippers:

- Description: Clamps or grippers are used to securely hold and release the workpieces at each die set or station. They ensure proper positioning and stability during the forming or stamping operation.

- Feeding Systems:

- Description: Feeding systems supply raw materials or workpieces to the transfer press. These systems can include coil feeders, strip feeders, or other mechanisms to ensure a continuous supply of material.

- Automation Controls:

- Description: Automation controls, such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs), are used to coordinate and control the movement of transfer mechanisms, clamps, and other components. They enable precise synchronization between different stages of the process.

- Safety Systems:

- Description: Safety features, such as sensors, emergency stop buttons, and safety interlocks, are integrated to ensure the protection of operators and prevent accidents during the operation of the transfer press.

Operation of Transfer Systems in Transfer Presses

- Loading and Feeding:

- Workpieces are loaded onto the workpiece carriers, either manually or through automated feeding systems.

- Transfer Between Die Sets:

- The transfer mechanisms move the workpiece carriers along the transfer bars, transferring the workpieces between different die sets or stations.

- Forming or Stamping:

- At each die set, forming or stamping operations take place. The workpieces are securely clamped in position, and the necessary operations are performed.

- Release and Transfer to Next Die Set:

- After completing the operations at one die set, the clamps or grippers release the workpieces, and the transfer mechanisms move them to the next die set for further processing.

- Repeat Process:

- The cycle repeats, with the workpieces sequentially moving through multiple die sets until the entire manufacturing process is completed.

Advantages of Transfer Systems in Transfer Presses

- High Productivity:

- Transfer systems enable high-speed and continuous production, reducing cycle times and increasing overall productivity.

- Versatility:

- Transfer presses with flexible transfer systems can accommodate a variety of workpiece sizes and geometries, making them versatile for different production requirements.

- Consistency and Precision:

- Automated transfer ensures consistent and precise positioning of workpieces at each die set, resulting in high-quality and uniform products.

- Efficient Material Handling:

- Transfer systems optimize material handling by automating the movement of workpieces between different stages, minimizing manual intervention and reducing the risk of errors.

- Reduced Setup Times:

- Quick and automated changeovers between different die sets or production setups contribute to reduced setup times and increased operational efficiency.

Transfer systems in transfer presses play a crucial role in modern manufacturing, particularly in industries where high-volume production and precision are essential. They are integral to the automation of complex forming and stamping processes.

Tooling and Dies

Tooling and dies are critical components in manufacturing processes, particularly in metalworking and forming operations. They are used to shape, cut, or form materials into specific shapes and dimensions. The design and precision of tooling and dies have a direct impact on the quality and accuracy of the final product. Here are key aspects related to tooling and dies:

- Definition:

- Tooling: Tooling refers to the general category of tools used in manufacturing, including various types of cutting tools, fixtures, jigs, and molds.

- Dies: Dies are specialized tools used to shape or form materials. They are often associated with metalworking and are crucial in processes like stamping, forging, and extrusion.

- Types of Tooling and Dies:

- Cutting Dies: Used for shearing or cutting materials into specific shapes, commonly seen in processes like blanking or die cutting.

- Forming Dies: Used for shaping materials without removing any material, such as in bending, drawing, or forming operations.

- Piercing Dies: Employed to create holes or openings in materials, often used in conjunction with other dies in stamping operations.

- Progressive Dies: Consist of a series of interconnected dies that perform multiple operations on a workpiece as it moves through the die.

- Extrusion Dies: Used in extrusion processes to shape materials into continuous profiles.

- Components of Dies:

- Die Block: The main supporting structure of the die, typically made from tool steel.

- Punch: The component that contacts and shapes the workpiece. It is often a protruding part of the die.

- Die Cavity: The void or open space in the die block that determines the final shape of the workpiece.

- Strippers: Used to eject the finished workpiece from the die after shaping.

- Guide Pins and Bushings: Ensure proper alignment of the die components.

- Materials Used:

- Tool Steel: Commonly used for dies due to its hardness, toughness, and resistance to wear.

- Carbide: Used for cutting edges and where high wear resistance is required.

- High-Speed Steel: Suitable for applications involving high temperatures, such as cutting tools.

- Design Considerations:

- Tolerances: Precision is crucial in die design to achieve the desired tolerances in the final product.

- Material Characteristics: The properties of the material being worked, such as its hardness and ductility, influence die design.

- Die Maintenance: Considerations for ease of maintenance and replacement of components to ensure the longevity of the die.

- Manufacturing Processes:

- Machining: Dies are often machined using processes like milling, turning, and grinding.

- Heat Treatment: To achieve the necessary hardness and toughness.

- Surface Coating: Coatings like nitriding or carbide coatings may be applied to enhance wear resistance.

- Applications:

- Stamping Dies: Used in sheet metal stamping processes to produce components for various industries.

- Forging Dies: Employed in hot or cold forging processes to shape metal.

- Extrusion Dies: Used in extrusion processes to create continuous profiles.

- Tool and Die Maintenance:

- Regular maintenance is essential to ensure the continued accuracy and performance of tooling and dies.

- Wear patterns, damage, and other issues should be regularly inspected and addressed.

Tooling and dies are fundamental to the efficiency and precision of many manufacturing processes. Their design, materials, and maintenance are critical factors in achieving high-quality and consistent production.

Conveyors

Conveyors are mechanical systems used to transport goods, materials, or items from one location to another within a facility or between different stages of a manufacturing or distribution process. Conveyors play a crucial role in various industries, providing an efficient and automated means of handling and transporting materials. There are several types of conveyors, each designed for specific applications. Here are some common types and features of conveyors:

- Belt Conveyors:

- Description: Belt conveyors consist of a continuous loop of material (the conveyor belt) that rotates around two or more pulleys. They are widely used for horizontal and inclined transport of bulk materials.

- Applications: Used in industries such as manufacturing, mining, food processing, and logistics for handling various types of products.

- Roller Conveyors:

- Description: Roller conveyors use rollers to facilitate the movement of items along a path. The rollers can be powered or non-powered, depending on the application.

- Applications: Commonly used for pallet handling, carton handling, and material accumulation in warehouses and distribution centers.

- Chain Conveyors:

- Description: Chain conveyors use chains to move materials along a path. They are durable and can handle heavy loads.

- Applications: Suitable for heavy-duty applications such as automotive assembly lines, steel production, and bulk material handling.

- Slat Conveyors:

- Description: Slat conveyors use slats or plates attached to a chain to move items. They are suitable for transporting heavy or irregularly shaped items.

- Applications: Used in industries such as automotive manufacturing, assembly lines, and material handling.

- Screw Conveyors:

- Description: Screw conveyors use a helical screw blade to move materials along a path. They are particularly effective for transporting bulk materials.

- Applications: Widely used in industries such as agriculture, food processing, and wastewater treatment.

- Bucket Elevators:

- Description: Bucket elevators use buckets attached to a rotating belt or chain to lift materials vertically. They are suitable for handling bulk materials.

- Applications: Used in industries such as agriculture, mining, and food processing for vertical material transport.

- Vibrating Conveyors:

- Description: Vibrating conveyors use vibrations to move materials. They are often used for applications where gentle handling is required.

- Applications: Commonly used in food processing, pharmaceuticals, and chemical industries.

- Overhead Conveyors:

- Description: Overhead conveyors are suspended from the ceiling, allowing materials to be transported in a vertical or horizontal manner.

- Applications: Used in industries such as automotive assembly, garment handling, and painting lines.

- Pneumatic Conveyors:

- Description: Pneumatic conveyors use air pressure to move materials through a system of pipes. They are suitable for transporting powdered or granular materials.

- Applications: Commonly used in industries such as food processing, pharmaceuticals, and chemical manufacturing.

- Flexible Conveyors:

- Description: Flexible conveyors can be extended or contracted as needed. They are versatile and can be easily adapted to different layouts.

- Applications: Suitable for distribution centers, shipping areas, and areas with variable space requirements.

- Modular Conveyors:

- Description: Modular conveyors consist of standardized segments that can be easily connected or disconnected to create different configurations.

- Applications: Used in industries where flexibility and adaptability are important, such as packaging and assembly lines.

Conveyors are integral to modern manufacturing and logistics, providing a reliable and efficient means of transporting materials and products throughout various stages of production and distribution. The choice of conveyor type depends on factors such as the nature of the materials being handled, the required throughput, and the layout of the facility.

Robotic Systems

Robotic systems, often referred to as robots, are versatile and programmable machines designed to perform various tasks autonomously or under the control of an operator. These systems can be found in a wide range of industries and applications, contributing to increased efficiency, precision, and automation. Here are key features and applications of robotic systems:

Key Features of Robotic Systems

- Programmability: Robots can be programmed to perform specific tasks or sequences of tasks. This flexibility allows them to adapt to different processes and applications.

- Sensors and Perception: Many robotic systems are equipped with sensors such as cameras, proximity sensors, and force sensors, enabling them to perceive and interact with their environment.

- End-of-Arm Tooling (EOAT): The end-of-arm tooling refers to the specialized tool or attachment mounted at the end of a robot’s arm. Different types of EOAT can be used for tasks such as gripping, welding, cutting, and more.

- Precision and Accuracy: Robotic systems are capable of highly precise and accurate movements, making them suitable for applications where precision is critical.

- Automation and Autonomy: Robots can operate autonomously in certain scenarios, reducing the need for constant human intervention. They excel in repetitive and hazardous tasks.

- Mobility: Some robots are designed with mobility, allowing them to navigate and move within a defined space. This is common in applications such as autonomous mobile robots (AMRs) in warehouses.

- Collaborative Features: Collaborative robots, or cobots, are designed to work safely alongside humans. They often have built-in safety features such as force-limiting and speed control.

- Communication: Robotic systems can communicate with other machines and systems, contributing to the integration of robotic automation into larger manufacturing or operational processes.

Automation Controls

Automation controls in transfer lines play a crucial role in managing and coordinating the movement and operation of various components within the system. These controls ensure that the transfer line functions smoothly, efficiently, and in accordance with the specified manufacturing or production requirements. Here are key aspects of the automation controls in transfer lines:

- Programmable Logic Controllers (PLCs):

- Description: PLCs are industrial computers designed to control and automate electromechanical processes. They are the backbone of automation controls in transfer lines.

- Functionality: PLCs are programmed to execute specific tasks, such as controlling the movement of conveyor systems, activating/deactivating workstations, and managing the overall sequence of operations.

- Human-Machine Interface (HMI):

- Description: HMIs provide a graphical interface for operators to monitor and interact with the transfer line. They often include touchscreens or display panels.

- Functionality: Operators can use HMIs to start or stop the transfer line, monitor the status of various components, and receive alerts or alarms.

- Sensors and Feedback Systems:

- Description: Sensors, including proximity sensors, photoelectric sensors, and encoders, are integrated into the transfer line to provide real-time feedback on the position, speed, and status of components.

- Functionality: The information from sensors allows the control system to make decisions, adjust the speed of conveyors, and ensure proper synchronization between different stations.

- Motion Control Systems:

- Description: Motion control systems regulate the movement of motors and actuators in the transfer line.

- Functionality: They ensure precise control of the speed, acceleration, and deceleration of moving components, such as conveyor belts, robotic arms, and transfer mechanisms.

- Safety Systems:

- Description: Safety controls are implemented to ensure the well-being of operators and prevent accidents. This includes emergency stop buttons, safety interlocks, and safety sensors.

- Functionality: In case of a safety breach or emergency, the control system can halt the operation of the transfer line to prevent harm to personnel or damage to equipment.

- Communication Protocols:

- Description: Communication protocols, such as Modbus, Profibus, or Ethernet/IP, enable devices within the transfer line to communicate with each other and with higher-level control systems.

- Functionality: Seamless communication is essential for the exchange of data, coordination between different components, and integration with other systems in the manufacturing environment.

- Variable Frequency Drives (VFDs):

- Description: VFDs are used to control the speed of motors, allowing for energy-efficient operation and the ability to adjust the speed based on production requirements.

- Functionality: VFDs can ramp up or down the speed of motors smoothly, reducing wear and tear on equipment and optimizing energy consumption.

- Control Algorithms and Logic:

- Description: Control algorithms and logic are programmed into the PLC to make decisions based on inputs from sensors and user commands.

- Functionality: These algorithms determine the sequence of operations, the coordination of movements, and responses to various conditions, ensuring that the transfer line operates as intended.

- Data Logging and Analysis:

- Description: Data logging systems record information about the performance of the transfer line, including cycle times, error rates, and other relevant metrics.

- Functionality: Analyzing this data allows for continuous improvement, troubleshooting, and optimization of the transfer line’s efficiency.

- Remote Monitoring and Control:

- Description: Some systems allow for remote monitoring and control, enabling operators to access the transfer line’s status and make adjustments from a central location.

- Functionality: Remote capabilities enhance flexibility and responsiveness in managing the transfer line, especially in large manufacturing facilities.

Automation controls in transfer lines are designed to provide a high level of precision, coordination, and reliability, contributing to the overall efficiency of manufacturing processes. The specific implementation of these controls can vary based on the complexity and requirements of the transfer line and the manufacturing application.

Applications of Robotic Systems

- Industrial Automation:

- Material Handling: Robots are used for tasks such as picking and placing items on assembly lines, packing, and palletizing.

- Welding and Fabrication: Robotic welding systems are employed for high-precision welding in industries like automotive and aerospace.

- Manufacturing:

- Assembly: Robots can perform intricate assembly tasks in industries ranging from electronics to automotive manufacturing.

- Painting and Coating: Automated robotic systems are used for precise and consistent painting and coating applications.

- Logistics and Warehousing:

- Order Picking: Autonomous mobile robots are utilized for order picking and transporting goods in warehouses.

- Palletizing and Depalletizing: Robots handle the stacking and destacking of pallets in logistics operations.

- Healthcare:

- Surgery: Surgical robots assist surgeons in performing minimally invasive surgeries with increased precision.

- Rehabilitation: Robotic devices are used in physical therapy for rehabilitation and assistance.

- Agriculture:

- Harvesting: Agricultural robots are designed for tasks such as fruit picking and harvesting in fields and orchards.

- Weeding: Robots equipped with sensors and cameras can identify and remove weeds in crop fields.

- Space Exploration:

- Exploration Rovers: Robots like Mars rovers are used for planetary exploration, collecting data and performing experiments in harsh environments.

- Consumer Electronics:

- Electronic Assembly: Robots are involved in the assembly of electronic components in the manufacturing of consumer electronics.

- Education and Research:

- Research Robots: Used in laboratories and research institutions for various experiments and studies.

- Educational Robots: Introduce students to robotics and programming concepts.

Robotic systems continue to advance, and their applications are expanding into new domains as technology evolves. The integration of robotics into various industries is driven by the pursuit of increased efficiency, improved safety, and the ability to handle complex tasks with precision.

Application Areas

Transfer lines, with their high-volume production capabilities and precision, find applications in various industries that require efficient and consistent manufacturing processes. Here are some common application areas for transfer lines:

- Automotive Industry:

- Transfer lines are extensively used in automotive manufacturing for producing engine components, transmission parts, chassis components, and brake systems. They enable cost-effective mass production of automotive parts with tight tolerances.

- Aerospace Industry:

- In aerospace, transfer lines are employed to manufacture critical components such as landing gear parts, engine components, and airframe structures. The precision and quality control offered by transfer lines are essential in this industry.

- Consumer Electronics:

- For electronics manufacturers, transfer lines are used to produce components like printed circuit boards (PCBs), connectors, and casings. They enable rapid and high-quality production of electronic devices.

- Metalworking and Machining:

- Transfer lines are applied in metalworking and machining industries for producing precision parts like gears, shafts, bearings, and fasteners. These parts are used in various machinery and equipment.

- Medical Device Manufacturing:

- Transfer lines play a crucial role in manufacturing medical devices, including surgical instruments, implants, and diagnostic equipment. The precision and consistency they offer are vital in medical applications.

- Industrial Equipment:

- Manufacturers of industrial equipment, such as pumps, compressors, and valves, use transfer lines to produce components with precise dimensions and high reliability.

- Hydraulic and Pneumatic Components:

- Transfer lines are employed to produce hydraulic and pneumatic components used in machinery, construction equipment, and industrial automation systems.

- Bearing Manufacturing:

- Transfer lines are integral in bearing manufacturing, where precision and consistency are paramount for reliable performance in various applications.

- Power Generation:

- Components for power generation equipment, such as turbines, generators, and transformers, are often produced using transfer lines to ensure high-quality and efficient energy production.

- Plastics and Injection Molding:

- In the plastics industry, transfer lines are used for producing injection-molded parts, ensuring consistent quality in products like automotive interior components, consumer goods, and packaging.

- Furniture and Woodworking:

- Transfer lines are applied in the production of furniture components and woodworking tasks, such as panel processing and furniture frame manufacturing.

- Defense and Military:

- The defense industry utilizes transfer lines to manufacture various components, including munitions, firearms, and military vehicles, ensuring precision and reliability.

- Renewable Energy:

- Transfer lines are involved in manufacturing components for renewable energy systems, such as wind turbines and solar panels, to meet growing demands for sustainable energy sources.

- Custom Machinery Manufacturing:

- Companies specializing in custom machinery and equipment rely on transfer lines to produce precise components for specialized industrial machines.

- General Metal Fabrication:

- Transfer lines can be adapted for general metal fabrication tasks, such as cutting, welding, and forming, in a variety of applications and industries.

Transfer lines continue to evolve with advanced automation and robotics technologies, making them valuable assets for industries that require high-quality, high-volume production with efficient and consistent processes.

Transfer Press

A transfer press, also known as a transfer stamping press, is a specialized machine used in metalworking and manufacturing industries to perform precision stamping, forming, and cutting operations on sheet metal or other materials. Transfer presses are designed for high-volume production and are known for their versatility and accuracy. Here are key details about transfer presses:

1. Mechanical or Hydraulic Operation:

- Transfer presses can operate using either mechanical or hydraulic systems. Mechanical presses use flywheels, eccentric shafts, and mechanical linkages to generate force, while hydraulic presses use fluid pressure to perform the work.

2. Multiple Stations:

- One of the defining features of transfer presses is their multiple stations. These stations, often called “dies,” are where various operations like stamping, forming, cutting, or piercing are performed. Transfer presses can have several die stations, each dedicated to a specific operation.

3. Die Setups:

- In a transfer press, a die setup is created at each station to perform the desired operation on the workpiece. These setups can be customized for different part geometries and production requirements.

4. Part Transfer:

- The term “transfer” in the name of the press refers to the movement of the workpiece between stations. A transfer mechanism, which can be mechanical or servo-driven, moves the workpiece from one die station to another, ensuring that each operation is completed sequentially.

5. High Production Rates:

- Transfer presses are designed for high-speed production, making them suitable for manufacturing large quantities of parts quickly and consistently. They are commonly used in industries with high-volume production requirements.

6. Precision and Accuracy:

- Transfer presses are known for their precision and accuracy. The dies and tooling are precisely engineered to produce parts with tight tolerances, ensuring consistent quality.

7. Tooling and Dies:

- Tooling and dies are critical components of transfer presses. Customized dies are used to shape, cut, or form the material. Die changes are a crucial part of the setup process when switching to different part designs.

8. Material Compatibility:

- Transfer presses can work with a variety of materials, including sheet metal, stainless steel, aluminum, plastics, and more. They are used in various industries, including automotive, aerospace, appliance manufacturing, and electronics.

9. Automation and Robotics:

- Many modern transfer presses incorporate automation and robotics for tasks like loading and unloading materials, part inspection, and quality control.

10. Quick Die Change Systems: – To minimize downtime during die changes, some transfer presses are equipped with quick die change systems, allowing for faster setup and production changeovers.

11. Safety Features: – Safety is a priority when working with transfer presses. They include safety mechanisms, guards, and interlocks to protect operators from hazards associated with high-speed stamping operations.

12. Maintenance: – Regular maintenance is essential to keep transfer presses running smoothly and to extend their operational lifespan.

Transfer presses are essential in industries that require high-volume production of stamped or formed parts with precise dimensions and shapes. Their ability to efficiently perform multiple operations in a sequential manner makes them valuable assets for manufacturers seeking cost-effective and consistent production processes.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as hydraulic transfer press, glass mosaic press, hydraulic deep drawing press, casting press, hydraulic cold forming press, hydroforming press, composite press, silicone rubber moulding press, brake pad press, melamine press, SMC & BMC Press, Labrotaroy press, edge cutting trimming machine, edge curling machine, trimming beading machine, trimming joggling machine, cookware production line, pipe bending machine, profile bending machine, bandsaw for metal, cylindrical welding machine, horizontal pres and cookware, kitchenware, hotelware, bakeware and cuttlery production machinery as a complete line as well as an individual machine such as edge cutting trimming beading machines, polishing and grinding machines for pot and pans, hydraulic drawing presses, circle blanking machines, riveting machine, hole punching machines and press feeding machine,

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching