We manufacture laboratory press types for sample production, sample testing, and small size particle manufacturing. Price for Sale directly from the manufacturer.

A laboratory press, also known as a hydraulic laboratory press or a laboratory hydraulic press, is a specialized piece of equipment used in scientific research and material testing laboratories. It is designed to apply controlled pressure to various samples or materials for research, analysis, and experimentation. Here are key details about laboratory presses:

1. Pressure Application:

- The primary function of a laboratory press is to apply pressure to samples or materials. This pressure can range from a few tons to several tons, depending on the specific model and application.

2. Hydraulic System:

- Laboratory presses are typically hydraulic, meaning they use hydraulic fluid to generate and control the pressure. Hydraulic systems allow for precise and uniform pressure application.

3. Pressure Control:

- Laboratory presses feature pressure control mechanisms, such as pressure gauges and controls, to adjust and monitor the applied pressure accurately.

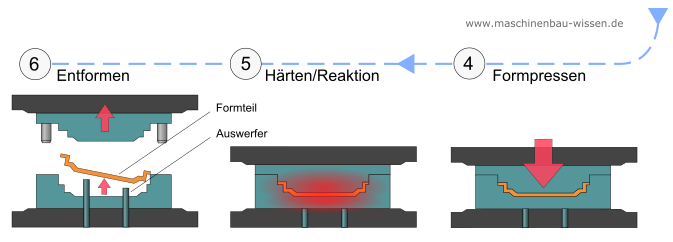

4. Heating Capability:

- Some laboratory presses are equipped with heating elements to apply both pressure and heat simultaneously. This is especially useful for applications such as sample molding and polymer research.

5. Sample Containers:

- Laboratory presses often include containers or molds in which the samples or materials are placed. These containers can be customized to suit various research needs.

6. Sample Preparation:

- Researchers prepare their samples or materials according to the experimental requirements and place them in the press for testing or analysis.

7. Material Testing:

- Laboratory presses are commonly used for material testing, including compression tests, tensile tests, and other mechanical property evaluations. They can assess the strength, deformation, and behavior of materials under controlled pressure conditions.

8. Research Applications:

- Laboratory presses find applications in a wide range of scientific fields, including materials science, chemistry, geology, and engineering. They are used for research, development, and quality control purposes.

9. Sample Consolidation:

- In geology and soil science, laboratory presses are used to consolidate soil or rock samples into specified sizes and shapes for testing and analysis.

10. Sample Preparation for Spectroscopy: – Laboratory presses are used to prepare thin pellet samples for spectroscopic analysis, such as X-ray diffraction (XRD) and Fourier-transform infrared (FTIR) spectroscopy.

11. Powder Compaction: – They are used for compacting powdered materials into tablets or pellets for pharmaceutical, chemical, and materials research.

12. Particle Size Analysis: – In particle size analysis, laboratory presses can be used to prepare solid samples for sieving or laser diffraction measurements.

13. Quality Control: – Laboratory presses are used for quality control in various industries to ensure that materials and products meet specified standards and requirements.

14. Safety Features: – Safety features, such as emergency stop buttons and safety guards, are typically incorporated into laboratory presses to protect operators during experiments.

15. Customization: – Some laboratory presses are highly customizable, allowing researchers to adapt them for specific research needs and applications.

Laboratory presses are valuable tools for scientists and researchers who need to apply controlled pressure to samples or materials as part of their investigations. They play a critical role in advancing research, quality control, and materials characterization in a wide range of scientific disciplines.

Laboratory Press

Laboratory presses play a crucial role in the development and testing of materials in scientific and industrial fields. These machines are designed to generate controlled pressure, typically ranging from a few pounds per square inch (PSI) to several tons, depending on the specific model and application. Laboratory presses are used for a variety of processes, such as molding, compression, laminating, or pelletizing materials for testing purposes.

The primary goal of laboratory presses is to reproduce consistent, repeatable results that are essential for material testing, research, and development. They are vital in laboratories where precision and accuracy are of utmost importance, such as those found in research institutions, universities, and commercial industries.

Some of the most common laboratory presses include those used in the plastics, polymer, pharmaceutical, and electronics industries. These machines can range from small benchtop models suitable for light-duty tasks to more robust, floor-standing versions that handle high-pressure applications. They typically come with features such as precise temperature control, programmable settings, and various safety features to ensure accurate, efficient operation.

Laboratory presses are often customized to meet the specific needs of the user, with manufacturers offering various options for pressure capacities, heating elements, platens, and control systems. The advancements in laboratory press technology have made it easier for operators to achieve exact results, while automation has reduced the need for manual labor in many cases.

In short, laboratory presses are indispensable in many research and development environments. Their flexibility, ease of use, and precision make them ideal tools for a wide range of applications.

Types of Laboratory Presses

Understanding the different types of laboratory presses is essential for selecting the right machine for specific applications. Here, we will explore the four primary types: manual, hydraulic, pneumatic, and electric presses.

2.1. Manual Presses

Manual presses are typically operated by hand, using a lever or screw mechanism to generate pressure. These presses are suitable for smaller applications where the required force is relatively low. While not as powerful as hydraulic or pneumatic presses, manual presses offer precision and are ideal for tasks that do not require high levels of force. They are also affordable, easy to maintain, and do not require external power sources, making them ideal for small-scale operations or educational environments.

Key features:

- Simple, robust design

- Ideal for low-force applications

- No need for external power

- Cost-effective and portable

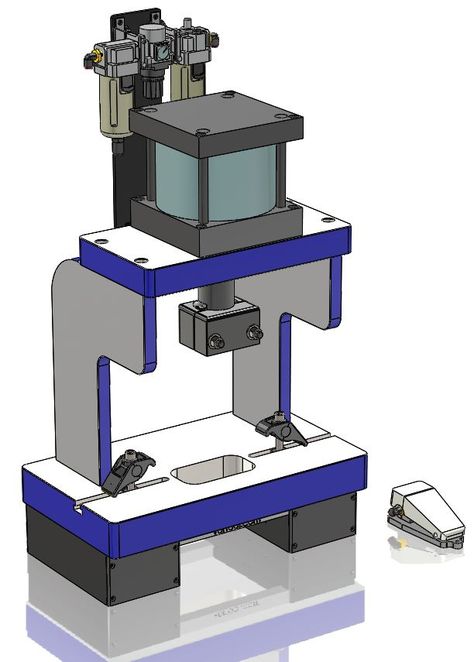

2.2. Hydraulic Presses

Hydraulic laboratory presses use hydraulic cylinders to generate force. These presses are known for their ability to produce high levels of pressure, making them suitable for applications that require more significant force, such as molding polymers or testing materials. Hydraulic presses offer precise control over the applied pressure and can be automated or manually operated, depending on the model. The hydraulic system enables the press to exert force evenly and consistently, making it ideal for industries like plastics, rubber, and pharmaceuticals.

Key features:

- Capable of producing high pressure

- Suitable for a variety of materials

- Consistent and even force distribution

- Available in both manual and automated versions

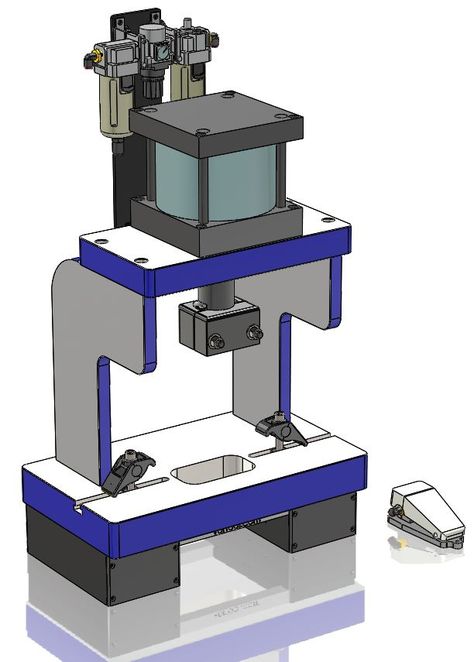

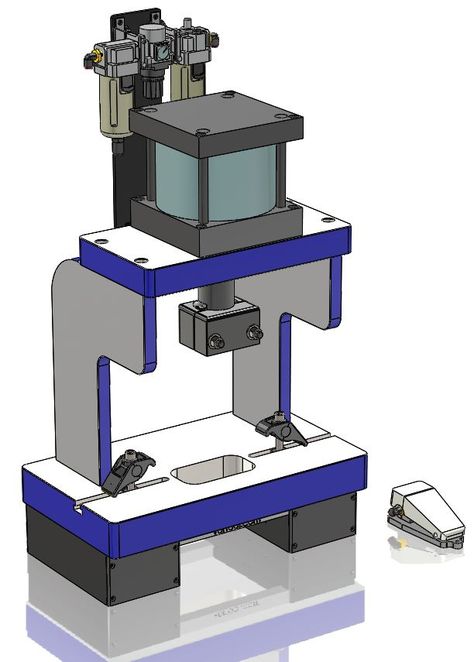

2.3. Pneumatic Presses

Pneumatic laboratory presses use compressed air to generate force, offering a more efficient solution for applications that require lower pressure. These presses are typically faster than hydraulic presses, making them ideal for operations where speed and efficiency are critical. However, they are limited in the amount of force they can produce, which is why they are best suited for light-duty tasks, such as laminating or small-scale compression.

Key features:

- Fast and efficient operation

- Best for lower-pressure applications

- Clean, requiring minimal maintenance

- Ideal for high-cycle processes

2.4. Electric Presses

Electric laboratory presses are powered by electric motors, offering a highly efficient and clean alternative to hydraulic and pneumatic presses. Electric presses are known for their precision and ease of use, as they allow operators to control the pressure and speed with high accuracy. They are also quieter and require less maintenance than other types of presses, making them an attractive option for laboratories that prioritize a clean, quiet working environment.

Key features:

- High precision and control

- Quiet operation

- Low maintenance

- Ideal for precision testing and small-scale manufacturing

2.5. Comparison of Different Types

When comparing the various types of laboratory presses, it is important to consider the specific needs of the application. Manual presses are ideal for simple, low-force tasks, while hydraulic presses offer higher pressure capabilities and are suitable for more demanding applications. Pneumatic presses provide speed and efficiency, while electric presses offer precision and cleanliness.

- Cost: Manual presses tend to be the most affordable, while hydraulic and electric presses can be more expensive.

- Pressure Capacity: Hydraulic presses offer the highest pressure capacity, followed by pneumatic and electric presses.

- Maintenance: Electric presses require the least maintenance, while hydraulic systems may require more upkeep due to fluid handling.

- Precision: Electric presses offer the highest level of control and precision, while manual presses may be less exact.

Components and Technical Features

Laboratory presses consist of several key components that determine their performance and functionality. These components vary slightly depending on the type of press but share common features that enhance their operation.

3.1. Frame Design

The frame of a laboratory press provides structural support and helps distribute force evenly during operation. Most laboratory presses have a steel or cast-iron frame designed to withstand high levels of pressure without bending or warping. The frame design can also determine the footprint of the machine, with benchtop presses having smaller, more compact frames for use in confined spaces.

3.2. Pressure Systems

The pressure system of a laboratory press is its core component. In hydraulic presses, the system consists of a hydraulic cylinder filled with fluid that generates force when pressure is applied. Pneumatic presses use compressed air to create pressure, while manual presses rely on mechanical force applied by a hand-operated lever or screw.

3.3. Heating Elements and Temperature Control

Many laboratory presses include integrated heating elements, which allow materials to be processed under controlled temperatures. Heating platens are essential for applications like laminating or molding polymers, where heat is necessary to activate the material. Temperature control systems ensure that the press operates within the desired temperature range, providing precise control over heating parameters.

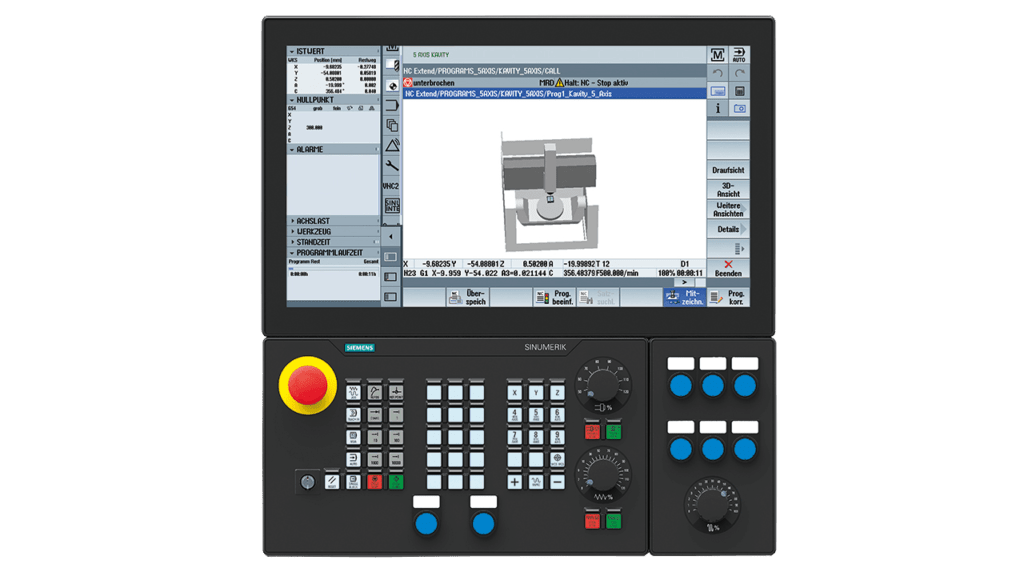

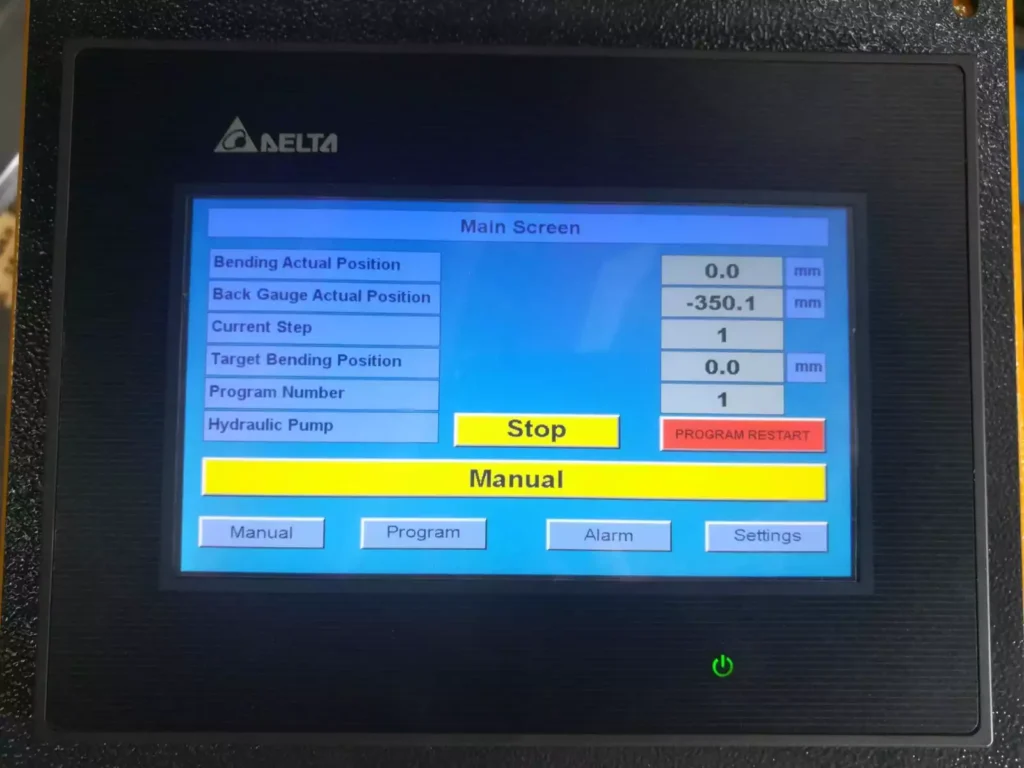

3.4. Control Panels and Monitoring Systems

Modern laboratory presses come equipped with digital control panels that allow operators to set pressure, temperature, and cycle time parameters with high precision. These control systems often include monitoring features that provide real-time feedback on the press’s performance, ensuring accurate and consistent results.

3.5. Customizable Features

Many laboratory presses offer customizable features to meet the specific needs of the user. These features can include interchangeable platens, programmable cycles, and additional safety mechanisms to enhance the machine’s versatility.

Applications of Laboratory Presses

Laboratory presses are used across various industries and research fields due to their ability to apply precise pressure and temperature. Below are some of the key applications:

4.1. Scientific Research

In academic and research laboratories, presses are used for material testing and sample preparation. They help in the development of new materials, ensuring uniformity and consistency in the samples produced for further analysis. Polymers, ceramics, and composite materials are frequently tested in these settings.

4.2. Material Testing

In material science and engineering, laboratory presses are indispensable tools for testing the properties of materials under controlled conditions such as high pressure and temperature. Laboratory presses are used to prepare specimens for tensile, compression, and bending tests, ensuring the materials meet industry standards. Some common materials tested include plastics, rubber, metals, and composites.

Laboratory presses are particularly essential in the development of new materials where precise control over pressure and temperature is required to study how these variables affect the mechanical properties of a material. This information is crucial for industries such as aerospace, automotive, and construction, where the materials used must meet rigorous performance standards.

4.3. Pharmaceutical Applications

The pharmaceutical industry makes extensive use of laboratory presses, particularly in the production of tablets. Tablet presses are used to compress powders into uniform tablets with precise dosage control. These presses allow for the accurate control of both the force applied and the shape of the tablets, ensuring consistency in drug formulation.

Additionally, laboratory presses are used in drug research and development to study the effects of compression on different formulations and to create sample batches for clinical trials. This is a critical step in pharmaceutical R&D as it helps to ensure that the final product will be effective and safe for patients.

4.4. Polymer and Plastics Industry

In the polymer and plastics industry, laboratory presses are employed for compression molding, a process that involves shaping materials by applying heat and pressure in a mold. This technique is widely used to produce high-strength plastic components and composite materials.

Presses are also used in testing polymer samples for properties like tensile strength, elasticity, and thermal stability. By simulating real-world conditions, these tests help manufacturers assess the performance of their materials and adjust their formulations to achieve the desired properties.

4.5. Electronics and Semiconductor Manufacturing

In the electronics and semiconductor industries, laboratory presses are utilized in several critical applications. These include the lamination of circuit boards, encapsulation of electronic components, and wafer bonding. The high precision and control offered by laboratory presses are essential for ensuring that the delicate electronic components are not damaged during the manufacturing process.

The pressure and temperature parameters can be finely tuned to match the specific needs of the application, making laboratory presses a key tool in the production of high-performance electronic devices.

4.6. Other Specialized Applications

Laboratory presses find uses in other specialized fields such as:

- Forensic Science: Used for the analysis of evidence, like creating casts of impressions found at crime scenes.

- Environmental Science: Presses are used in the preparation of samples for environmental testing, such as creating thin films for spectroscopic analysis.

- Food Science: Used to compress food samples for texture analysis, and in packaging tests to determine the strength of different materials.

Each of these applications requires the precision and versatility that laboratory presses provide, further underscoring their value across multiple industries.

Advantages of Laboratory Presses

Laboratory presses are indispensable due to their precision, versatility, and efficiency. Here are some of the most significant advantages they offer:

5.1. Precision and Control

One of the main advantages of laboratory presses is the high degree of precision they offer. Whether testing materials or manufacturing small parts, laboratory presses allow for precise control over parameters such as pressure, temperature, and duration. This ensures consistent and reliable results, which is critical in research and development environments.

Modern presses are equipped with advanced digital control systems that allow users to fine-tune the settings, monitor the process in real-time, and make adjustments as needed. This level of control is crucial in industries such as pharmaceuticals and electronics, where even the slightest variations can have significant consequences.

5.2. Versatility Across Multiple Industries

Laboratory presses are versatile machines used in various industries, from pharmaceuticals to electronics to polymers. Their ability to handle different materials and processes makes them valuable in both research laboratories and industrial production lines.

The adaptability of laboratory presses is enhanced by the availability of different models—manual, hydraulic, pneumatic, and electric—and the ability to customize the machine for specific applications. Whether creating a small batch of products or conducting large-scale material testing, laboratory presses can meet a wide range of needs.

5.3. Ease of Use and Safety Features

Most modern laboratory presses are designed with user-friendly interfaces that make them easy to operate. This is particularly important in environments where operators may not be highly specialized. Many presses are equipped with touch-screen control panels, pre-programmable cycles, and safety features such as overload protection, emergency stop buttons, and automatic shut-offs.

Safety is paramount when working with high-pressure and high-temperature equipment. Therefore, laboratory presses are typically designed to meet stringent safety standards, ensuring the well-being of the operators. Features such as transparent safety shields, automatic locking mechanisms, and temperature sensors help prevent accidents.

5.4. Compact Design for Laboratory Use

Most laboratory presses are designed with compactness in mind, making them suitable for use in laboratories with limited space. Benchtop models are especially popular in academic and research settings where the machine’s footprint needs to be small, yet capable of delivering reliable results. Even larger, floor-standing models are typically designed to fit within standard laboratory layouts without requiring major adjustments to the space.

This makes laboratory presses a practical choice for environments where space is at a premium, while still offering the full range of capabilities needed for precise material testing or small-scale production.

Buying Considerations and Specifications

Choosing the right laboratory press for your needs involves careful consideration of several factors. The machine must meet the specific requirements of your application, both in terms of performance and operational costs. Below are some key considerations to keep in mind:

6.1. Factors to Consider When Choosing a Laboratory Press

Several key factors should be considered when purchasing a laboratory press:

- Pressure Capacity: Determine the maximum pressure required for your application. This will influence whether you need a manual, hydraulic, pneumatic, or electric press.

- Heating Elements: Some applications require heat in addition to pressure. Be sure to check whether the press offers the necessary heating capabilities and if the temperature control is precise enough for your needs.

- Size and Footprint: Ensure the press fits within your laboratory’s available space. Benchtop presses are suitable for smaller spaces, while floor-standing models are better for more demanding applications.

- Automation: Depending on your needs, an automated press might save time and improve consistency by reducing the need for manual operation.

- Durability and Build Quality: Laboratory presses are an investment, so it’s essential to select a machine made from high-quality materials that can withstand constant use.

6.2. Standard Industry Specifications

Laboratory presses typically come with standard industry specifications that help ensure reliability and performance. These include:

- Pressure Ratings: Measured in tons or PSI, this indicates the maximum force the press can generate.

- Platen Size: Refers to the size of the heated or non-heated plates used for compression. Larger platens allow for bigger samples or multiple tests to be conducted simultaneously.

- Cycle Time: The time it takes for the press to complete a single cycle, including pressure application and, where applicable, heating and cooling.

- Safety Standards: Most presses adhere to international safety standards such as CE marking or ISO certifications, which ensure the equipment is safe for operation.

6.3. Cost, Maintenance, and Warranty Options

The cost of a laboratory press will vary depending on the type, size, and features. Manual presses tend to be the most affordable, while hydraulic and electric presses are more expensive due to their advanced systems. However, the initial cost should be weighed against the machine’s long-term benefits, such as precision, durability, and ease of use.

Maintenance is another factor to consider. Some types of presses, particularly hydraulic ones, may require regular maintenance to ensure optimal performance, such as fluid replacement or system calibration. Be sure to ask about maintenance schedules and support services when purchasing a press.

Lastly, consider the warranty options available. A good warranty will cover repairs and replacement parts for a specified period, ensuring peace of mind and protecting your investment.

6.4. Importance of Manufacturer Reputation

When buying a laboratory press, it’s crucial to purchase from a reputable manufacturer. Well-established manufacturers not only produce high-quality equipment but also offer reliable customer service and technical support. This ensures that your press will perform as expected and that any issues will be addressed promptly.

Look for manufacturers with a proven track record in your industry and those who offer comprehensive warranties and service packages. Reading customer reviews and requesting references from the manufacturer can also help you make an informed decision.

Introduction to EMS Metalworking Machinery

7.1. Company Overview and History

EMS Metalworking Machinery is a leading manufacturer of high-quality laboratory presses. Founded several decades ago, the company has grown into a global supplier of cutting-edge metalworking and laboratory equipment. Known for its innovative engineering and commitment to quality, EMS serves a wide range of industries including pharmaceuticals, polymers, electronics, and research institutions.

EMS’s reputation is built on its dedication to producing reliable, durable, and precise machinery. Their presses are designed to meet the specific needs of their clients, from small research laboratories to large-scale industrial manufacturers.

7.2. Specialization in Laboratory Press Manufacturing

Over the years, EMS has become a specialist in manufacturing laboratory presses. Their product lineup includes hydraulic, pneumatic, and electric models, all of which are customizable to meet specific customer requirements. EMS presses are known for their accuracy, ease of use, and robust construction, making them a top choice for organizations that require high-performance equipment.

The company invests heavily in research and development to stay ahead of the latest technological trends. This enables them to offer laboratory presses with state-of-the-art features such as digital control systems, automated processes, and advanced safety mechanisms.

7.3. Product Range and Customization Options

EMS offers a comprehensive range of laboratory presses, from benchtop models suitable for small laboratories to large, industrial-scale presses. Each press is built with high-grade materials and precision engineering to ensure consistent performance.

One of EMS’s key strengths is its ability to customize presses to meet the specific needs of its customers. Whether you need a press with additional heating elements, higher pressure capacity, or specialized safety features, EMS can design a solution tailored to your application.

7.4. Quality Control and Certifications

EMS Metalworking Machinery takes pride in its rigorous quality control process. Each machine is thoroughly tested to ensure it meets the highest industry standards before being shipped to the customer. The company is ISO 9001 certified, which demonstrates its commitment to quality management systems and continuous improvement.

Additionally, EMS laboratory presses are CE-marked, ensuring compliance with European safety standards. This gives customers confidence that they are purchasing equipment that is not only high-performing but also safe and reliable.

7.5. Global Market Presence and Clientele

EMS has a strong global market presence, with customers in over 50 countries. The company’s laboratory presses are used by top research institutions, pharmaceutical companies, and manufacturers around the world. EMS’s commitment to customer satisfaction has helped it build long-lasting relationships with its clients, many of whom return to EMS for additional equipment as their needs evolve.

The company’s international sales team works closely with clients to ensure they receive the right press for their application, providing technical support and advice throughout the purchasing process. EMS’s after-sales service is also highly regarded, offering ongoing support for maintenance, repairs, and upgrades.

Conclusion

In conclusion, laboratory presses are essential tools for a wide range of applications across industries such as pharmaceuticals, materials testing, electronics, and polymer manufacturing. Their precision, versatility, and ease of use make them invaluable in both research and industrial settings.

When selecting a laboratory press, it is important to consider factors such as pressure capacity, heating requirements, size, automation options, and manufacturer reputation. Investing in a high-quality press from a trusted manufacturer ensures reliable performance, durability, and peace of mind.

EMS Metalworking Machinery stands out as a leading manufacturer of laboratory presses, offering a comprehensive range of customizable models to meet the specific needs of its customers. With a focus on innovation, quality, and customer service, EMS has established itself as a global leader in the metalworking and laboratory press market. Their commitment to producing reliable, high-performance machinery makes them the ideal choice for any organization seeking top-quality laboratory presses.

Introduction to Laboratory Presses

Laboratory presses are specialized machines designed to apply controlled pressure and sometimes heat to various materials in a laboratory setting. These presses are essential tools for a range of industries, including pharmaceuticals, materials science, electronics, and polymers. By applying pressure, laboratory presses enable researchers and technicians to create samples, conduct material tests, or form products in a consistent and precise manner.

Laboratory presses come in a variety of types, each suited for specific applications. From manual to hydraulic, pneumatic, and electric, the selection of a press depends on the intended use, pressure requirements, temperature control, and budget constraints. The technology behind these machines has evolved considerably over the years, with modern presses offering advanced digital controls, safety features, and enhanced customization options.

The importance of laboratory presses extends to material testing, where accurate and repeatable pressure application is critical for determining the physical properties of materials. Moreover, in production settings, laboratory presses are used for small-batch manufacturing, making them indispensable tools for quality control and R&D.

Manual Laboratory Presses

2.1. Definition and Basic Operation

Manual laboratory presses are the most basic type of press, operated by hand using either a lever, screw, or toggle mechanism to generate pressure. These presses are widely used in educational settings, small laboratories, and for low-pressure applications. Due to their simplicity, manual presses require no external power source and can be used in remote or resource-limited environments.

2.2. Key Components

Manual presses generally consist of:

- Frame: The structure that holds the components together and bears the load during pressing.

- Pressure Mechanism: A lever or screw that converts manual force into pressure.

- Platen: The surface on which materials are placed during pressing, often removable or interchangeable.

- Pressure Gauge: A dial that measures the force being applied (for certain models).

2.3. Applications of Manual Presses

Manual presses are typically used for smaller tasks such as:

- Sample Preparation: Creating specimens for material testing.

- Tablet Pressing: In pharmaceutical labs to create small batches of tablets.

- Material Testing: Limited force applications for polymers or light materials.

2.4. Advantages and Disadvantages

Manual presses have several advantages:

- Low Cost: One of the most affordable types of presses.

- Simplicity: Easy to use with minimal training.

- Portability: Due to their size and lack of dependence on external power.

However, they also have limitations:

- Limited Pressure: Unsuitable for high-pressure applications.

- Operator Fatigue: Prolonged use can lead to physical strain.

2.5. Manual Press Variants

There are several subtypes of manual presses, each suited to specific applications:

- Hand-Operated Presses: The simplest version, where pressure is applied using a hand-operated lever.

- Screw Presses: A screw mechanism provides more control over pressure application.

- Toggle Presses: Utilize a toggle mechanism to apply pressure, offering a balance between ease of use and force generation.

Hydraulic Laboratory Presses

3.1. Definition and How They Work

Hydraulic laboratory presses use a hydraulic cylinder filled with oil to generate force. By compressing the oil in a confined space, hydraulic presses can produce very high levels of pressure, making them ideal for heavy-duty applications such as compression molding, material testing, and forming parts.

3.2. Components of a Hydraulic Press

- Hydraulic Cylinder: The main component that creates pressure through fluid compression.

- Pump: Responsible for moving the hydraulic fluid into the cylinder.

- Pressure Gauge: Displays the pressure being exerted by the press.

- Control Valve: Regulates the flow of hydraulic fluid, allowing the operator to control the pressure and release.

3.3. Types of Hydraulic Presses

There are several types of hydraulic presses used in laboratory settings:

- Single-Action Hydraulic Presses: These presses apply pressure in one direction and are commonly used in forming or compression applications.

- Double-Action Hydraulic Presses: These presses apply pressure in both upward and downward directions, increasing efficiency and versatility.

- Four-Post Hydraulic Presses: A robust design where four posts guide the platen, allowing for even pressure distribution across large surfaces.

3.4. Applications in Material Testing, Molding, and R&D

Hydraulic presses are versatile and used in a variety of fields, including:

- Compression Molding: Forming composite materials and polymers by applying heat and pressure.

- Material Testing: Testing materials for strength, durability, and other properties under high pressure.

- R&D: Developing new materials and testing their behavior under different conditions.

3.5. Advantages and Disadvantages of Hydraulic Presses

Advantages:

- High Pressure: Capable of generating extremely high force.

- Precision: Offers precise control over the pressure applied.

- Durability: Hydraulic systems are robust and long-lasting.

Disadvantages:

- Cost: More expensive than manual presses.

- Maintenance: Hydraulic systems require regular maintenance, including oil changes and seal replacements.

Pneumatic Laboratory Presses

4.1. Understanding Pneumatic Presses and Mechanisms

Pneumatic laboratory presses operate using compressed air to generate force. These presses are faster than hydraulic models and are suited for light to medium-duty applications. Pneumatic systems are highly efficient in terms of speed and can handle high-cycle processes with ease.

4.2. Key Components of Pneumatic Presses

- Air Cylinder: Uses compressed air to generate force.

- Compressor: Supplies the press with compressed air.

- Regulator: Controls the pressure within the system.

- Control System: Allows the operator to adjust the air pressure and force applied.

4.3. Applications in Industrial Labs

Pneumatic presses are ideal for tasks such as:

- Laminating: Used in the electronics industry to laminate circuit boards and other components.

- Pelletizing: Compressing powders into pellets for pharmaceutical or industrial use.

- Light Molding: Suitable for molding small parts or materials that don’t require high-pressure applications.

4.4. Advantages of Pneumatic Presses

- Speed: Faster than hydraulic presses, making them suitable for high-cycle processes.

- Efficiency: Low energy consumption and minimal waste.

- Easy to Operate: Pneumatic systems require less maintenance than hydraulic systems and are easier to control.

4.5. Disadvantages (Force Limitations, Maintenance)

- Limited Force: Cannot generate as much pressure as hydraulic presses.

- Air Supply Dependency: Requires a consistent supply of compressed air, adding operational costs.

Electric Laboratory Presses

5.1. Electric vs. Other Press Types

Electric laboratory presses use electric motors to generate force, providing a cleaner and quieter alternative to hydraulic and pneumatic systems. Electric presses offer precise control over pressure and are ideal for environments where accuracy and repeatability are crucial.

5.2. How Electric Presses Operate

Electric presses work by converting electrical energy into mechanical force. Motors drive the press, which can be finely controlled using digital systems. This allows for high precision in pressure application, making electric presses a preferred choice for sensitive applications.

5.3. Features and Advantages of Electric Presses (Precision, Quietness)

- Precision: Electric presses allow for very fine adjustments in pressure and cycle time, offering a high level of control.

- Quiet Operation: Since they do not rely on compressed air or fluid, electric presses operate with minimal noise.

- Low Maintenance: Electric presses have fewer moving parts than hydraulic or pneumatic models, reducing the need for regular maintenance.

5.4. Common Applications (Semiconductors, Electronics)

Electric presses are commonly used in industries such as:

- Semiconductors: Bonding and packaging semiconductor materials.

- Electronics: Laminating, encapsulating, and forming parts for electronic devices.

- Medical Devices: Used in the manufacturing of precision medical components.

5.5. Advantages and Disadvantages

Advantages:

- Energy Efficient: Consumes less energy compared to hydraulic systems.

- Clean and Environmentally Friendly: No fluids or compressed air required.

- Long Lifespan: Due to fewer moving parts, electric presses tend to last longer.

Disadvantages:

- Limited Force: Not suitable for heavy-duty applications that require very high pressure.

- Cost: Higher initial cost compared to manual or pneumatic presses.

Specialized Laboratory Presses

6.1. Hot Presses

Hot presses are designed to apply both pressure and heat to a material, making them ideal for processes like bonding, molding, and laminating. These presses are used in industries that work with thermoplastics, composites, and adhesives.

Key components of hot presses include:

- Heated Platens: Used to apply heat uniformly across the material.

- Temperature Control Systems: Allows the operator to set precise temperature ranges.

6.2. Cold Presses

Cold presses, on the other hand, are used when temperature is not a critical factor in the pressing process. They are commonly used in applications such as material testing or bonding processes where heat could potentially damage the material.

6.3. Vacuum Presses

Vacuum presses remove air from the press chamber before pressure is applied, making them ideal for applications where air bubbles or contamination would affect the quality of the material. These presses are often used in composite material manufacturing and laminating.

6.4. Hybrid Presses (Hydraulic-Electric, Pneumatic-Electric)

Hybrid presses combine elements of different types of presses to offer the best of both worlds. For example, a hydraulic-electric press may use hydraulic power for high pressure but an electric control system for precision.

6.5. Applications of Specialized Presses (R&D, Composite Materials)

Specialized presses are often used in research and development, where precise control over multiple parameters (pressure, temperature, vacuum) is needed to create new materials or study specific properties.

Comparative Analysis of Press Types

7.1. Pressure Capacity

- Manual Presses: Low pressure, typically up to a few tons.

- Hydraulic Presses: High pressure, suitable for heavy-duty applications.

- Pneumatic Presses: Moderate pressure, but limited compared to hydraulic presses.

- Electric Presses: Moderate pressure, ideal for precision applications.

7.2. Speed and Efficiency

- Pneumatic Presses: Fastest, best for high-cycle applications.

- Hydraulic Presses: Slower but more powerful.

- Electric Presses: Offer a balance of speed and precision.

7.3. Temperature Control Capabilities

- Hot Presses: Equipped with heating elements for applications requiring heat.

- Cold Presses: Suitable for processes where temperature control is not needed.

7.4. Size and Space Requirements

- Manual Presses: Typically the most compact.

- Hydraulic Presses: Larger and more space-consuming.

- Electric and Pneumatic Presses: Mid-range in terms of size.

7.5. Precision and Customization Options

- Electric Presses: Offer the highest level of precision.

- Hydraulic and Pneumatic Presses: Can be customized for various applications but may offer less precision than electric models.

7.6. Maintenance and Costs

- Hydraulic Presses: Require more maintenance due to fluid systems.

- Electric Presses: Low maintenance, but higher upfront costs.

- Manual Presses: Low cost and minimal maintenance.

Emerging Trends in Laboratory Press Technology

8.1. Automation and Digital Control

Automation is becoming increasingly common in laboratory presses, with systems that allow for the automatic control of pressure, temperature, and cycle times. This reduces operator error and improves consistency in production.

8.2. Advanced Materials Pressing

With the development of new materials such as composites and nanomaterials, laboratory presses are evolving to meet the demands of these new materials. Presses with enhanced temperature control, vacuum capabilities, and ultra-precision settings are becoming more prevalent.

8.3. Sustainability and Energy Efficiency

There is growing demand for laboratory presses that are energy efficient and environmentally friendly. Electric presses, in particular, are favored for their lower energy consumption and cleaner operation.

8.4. Impact of Industry 4.0 on Laboratory Presses

The integration of digital technologies, IoT (Internet of Things), and smart controls is transforming the way laboratory presses operate. Advanced data collection, remote monitoring, and predictive maintenance are some of the trends shaping the future of laboratory presses.

Conclusion

Laboratory presses come in many forms, each designed to meet specific industrial and research needs. From manual and hydraulic presses to pneumatic, electric, and specialized models, the range of available presses offers something for every type of laboratory. Understanding the differences in pressure capacity, speed, precision, and cost is key to selecting the right press for the job.

The future of laboratory presses is moving towards greater automation, precision, and energy efficiency, with manufacturers developing presses that are increasingly capable of handling complex and advanced materials. These innovations are pushing the boundaries of what can be achieved in both research and industrial settings.

As technology continues to evolve, laboratory presses will remain an indispensable tool for material testing, manufacturing, and scientific research, contributing to advancements across multiple industries.

Introduction to Laboratory Press Components

Laboratory presses are sophisticated machines designed to apply controlled pressure (and sometimes heat) to materials for various purposes such as molding, forming, and testing. While different types of laboratory presses serve a wide range of applications, from pharmaceuticals to material science, they all share several core components that work together to ensure the desired results.

The efficiency and functionality of a laboratory press depend significantly on its components. The components form the foundation of the press’s operation, whether it’s a manual press used for low-pressure applications or a hydraulic press designed for heavy-duty tasks. Understanding these components and their roles is critical for selecting and maintaining a laboratory press that will meet the specific demands of a laboratory or industrial environment.

Broadly, laboratory presses consist of structural parts like frames and platens, pressure generation systems (hydraulic, pneumatic, or mechanical), control mechanisms (manual or electronic), heating and cooling elements, safety features, and customizable parts such as interchangeable dies or platens.

In this comprehensive overview, we will explore each of these essential components, their construction, variations, and functions. By the end of this section, you will have a clear understanding of how these components work together to ensure precision, reliability, and safety in laboratory presses.

Frame and Structural Components

2.1. Types of Frames

The frame is the backbone of any laboratory press. It holds the press together, bears the brunt of the force applied during operation, and ensures that pressure is evenly distributed across the working area. There are several types of frames commonly used in laboratory presses, each with specific strengths and weaknesses:

- C-Frame: The C-frame design features a single open side, which allows for easy access to the working area. These presses are compact and space-efficient but may have limited capacity for high-pressure applications because of the uneven force distribution.

- H-Frame: H-frames are sturdier and more stable than C-frames, with a symmetrical structure that distributes force more evenly. They are better suited for heavy-duty applications but take up more space.

- Four-Post Frame: A four-post design provides the ultimate stability and uniform pressure application. The posts guide the platen, ensuring minimal deflection and even force distribution. These are often used in high-precision or high-pressure applications.

2.2. Material Considerations for Frames

The material from which the frame is constructed significantly affects its durability, weight, and performance. Common materials used for frames include:

- Steel: Steel frames are durable and strong, making them ideal for high-pressure applications. Steel frames can be treated with rust-resistant coatings to improve longevity.

- Cast Iron: Cast iron frames are often used in smaller, lighter presses. Cast iron provides excellent compressive strength but can be brittle under extreme pressure.

- Aluminum: In some cases, lightweight presses use aluminum frames, though these are generally limited to low-pressure or mobile units due to aluminum’s lower strength.

2.3. Frame Stability and Stress Distribution

The frame’s design directly impacts the stability and ability to distribute stress during pressing operations. H-frames and four-post frames excel in maintaining stability and distributing pressure evenly across the material, reducing the risk of deformation or damage to the sample.

2.4. Role of the Bed and Base Plates

The bed or base plate is where the lower platen and the material being pressed rest. Base plates must be rigid and durable to ensure they can withstand the forces applied without warping. Base plates may also include slots or grooves for the installation of dies or fixtures used in specific pressing applications.

Press Platens

3.1. Definition and Importance of Platens

Platens are the flat, usually metallic surfaces between which materials are compressed in a laboratory press. They are crucial for delivering consistent pressure across the material, ensuring uniformity in the pressed material’s thickness and structure.

3.2. Types of Platens

Different applications require different platen designs. Common types of platens include:

- Heated Platens: Often used in presses designed for compression molding, laminating, or material testing, heated platens allow materials to be worked under controlled temperature conditions. This is critical for thermoplastics, polymers, and certain composites.

- Cold Platens: These are standard platens with no built-in heating elements. They are ideal for applications where temperature control is unnecessary or where materials may be sensitive to heat.

- Customizable Platens: In specialized applications, platens can be customized to accommodate specific shapes, sizes, or surface textures to better grip or compress unique materials.

3.3. Material Composition of Platens

The material used for constructing platens plays a critical role in their performance:

- Steel Platens: Durable and capable of withstanding high temperatures and pressures, steel is often used for heavy-duty and high-temperature applications.

- Aluminum Platens: These are lighter and provide adequate strength for lower-pressure applications but may deform or degrade at higher temperatures or pressures.

- Ceramic-Coated Platens: Some presses use platens with a ceramic coating to provide excellent temperature stability and resistance to chemical corrosion.

3.4. Uniform Pressure Distribution and Surface Flatness

Ensuring uniform pressure distribution is critical for achieving consistent results in pressing applications. Platens must have extremely flat surfaces, as even small imperfections can result in uneven pressure distribution, which can affect the quality of the pressed material. High-quality platens are machined to be flat within micrometer tolerances.

3.5. Removable and Interchangeable Platens

Many presses allow for the platens to be removed and replaced with different designs, depending on the specific material or application. Interchangeable platens are particularly valuable in research and development settings, where flexibility and customization are key.

Pressure Generation Systems

4.1. Mechanical Pressure Systems (Levers, Screws)

Mechanical pressure systems rely on manual force, often applied via levers, screws, or toggle mechanisms, to generate pressure. While these systems are limited in the amount of force they can generate, they offer simplicity, portability, and ease of use, making them ideal for small-scale, low-pressure applications.

- Lever Mechanisms: In a simple manual press, a lever system multiplies the operator’s force to apply pressure to the material.

- Screw Mechanisms: Screw presses use a rotating screw to generate downward force on the material, offering more precise control than a lever system.

These systems are best suited for tasks such as sample preparation, small-scale compression, or educational purposes, where high pressure is not required.

4.2. Hydraulic Systems (Pumps, Cylinders, Fluid Circuits)

Hydraulic pressure systems use fluid (typically oil) to generate high levels of force. Hydraulic systems are widely used in laboratory presses for heavy-duty applications such as molding, material testing, and high-pressure forming.

- Hydraulic Pump: The pump is responsible for pressurizing the hydraulic fluid and delivering it to the cylinder.

- Hydraulic Cylinder: The cylinder converts the fluid pressure into mechanical force. The cylinder size and fluid pressure determine the total force the press can exert.

- Fluid Circuit: Hydraulic presses use a closed fluid circuit, consisting of hoses, valves, and reservoirs, to manage the flow and pressure of the hydraulic fluid.

Hydraulic systems provide excellent force multiplication and precision, making them ideal for high-pressure tasks. However, they require regular maintenance (such as fluid changes) and are generally more expensive than pneumatic or mechanical systems.

4.3. Pneumatic Systems (Air Cylinders, Compressors, Regulators)

Pneumatic systems use compressed air to generate pressure. They are well-suited for moderate-pressure applications and high-cycle processes, such as laminating, pelletizing, or light-duty molding.

- Compressor: The compressor supplies the press with the compressed air needed to generate force.

- Air Cylinder: Similar to a hydraulic cylinder, the air cylinder converts compressed air into mechanical force.

- Regulator: The regulator controls the air pressure supplied to the press, allowing for precise adjustments to the applied force.

Pneumatic systems are fast, efficient, and require less maintenance than hydraulic systems. However, they are limited in the amount of force they can generate compared to hydraulic presses.

4.4. Electric Pressure Systems (Electric Motors, Servo Systems)

Electric pressure systems use electric motors and sometimes servo systems to generate force. These systems are typically found in high-precision applications where the force and speed need to be finely controlled.

- Electric Motor: The motor drives the press’s mechanical components, providing precise control over the force and speed of the pressing operation.

- Servo Systems: Servo systems provide even greater control by allowing for exact positioning and feedback, making electric presses highly precise.

Electric systems are clean, quiet, and require minimal maintenance. They are ideal for applications such as electronics manufacturing, medical device assembly, and research and development.

4.5. Pressure Control Mechanisms (Manual, Digital)

Each pressure system (mechanical, hydraulic, pneumatic, electric) requires a means of controlling and regulating the force applied. In manual systems, this control is often achieved through mechanical adjustments such as handwheels or dials. In more advanced systems, digital controllers allow operators to set exact pressure values, which can be maintained automatically throughout the pressing cycle.

Control Systems

5.1. Manual Controls (Levers, Dials, Hand-Wheels)

In basic laboratory presses, control systems are entirely manual. Operators adjust force, speed, and cycle time by manipulating levers, dials, or hand-wheels. While these systems offer simplicity, they lack the precision and repeatability of more advanced electronic controls. Manual controls are typically found in mechanical or manual presses, where high precision is not a priority.

5.2. Electronic Control Panels (Touchscreens, Keypads)

Electronic control panels are more sophisticated than manual controls, offering digital interfaces such as touchscreens or keypads. These panels allow operators to input precise parameters for pressure, temperature, and cycle time. Additionally, electronic control panels often include preset programs for commonly used applications, reducing the risk of operator error.

- Touchscreen Controls: A modern feature in many high-end presses, touchscreens offer a user-friendly interface that makes it easy to set and monitor press parameters.

- Keypad Controls: Older or more basic electronic presses may use keypads for input. These are often paired with digital displays that show the current settings.

5.3. Programmable Logic Controllers (PLCs) and Automation

In automated laboratory presses, Programmable Logic Controllers (PLCs) are used to control the entire pressing process. PLCs allow for a high level of automation, including the ability to set and monitor multiple parameters simultaneously.

- Automated Press Cycles: PLCs enable presses to perform fully automated cycles, reducing the need for operator intervention and ensuring consistent results.

- Remote Monitoring: In some systems, PLCs can be connected to remote monitoring systems, allowing operators to control and monitor the press from a distance, enhancing safety and convenience.

5.4. Feedback Systems (Sensors, Gauges)

Feedback systems are critical for ensuring that the press is operating within the desired parameters. Common feedback devices include:

- Pressure Sensors: These measure the force being applied in real time, allowing for adjustments to be made if the pressure deviates from the set value.

- Temperature Sensors: In presses with heating elements, temperature sensors ensure that the platens remain at the desired temperature.

- Load Cells: These devices measure the actual force being applied to the material, providing real-time data that can be used to adjust the pressure.

5.5. Safety Mechanisms Integrated into Control Systems

Many presses include safety mechanisms within their control systems to prevent accidents or equipment damage. Common features include:

- Overload Protection: Automatically shuts off the press if the pressure exceeds a preset limit.

- Emergency Stop Buttons: Allow operators to halt the press immediately in the event of an emergency.

These systems ensure that presses are safe to operate, even in high-pressure environments.

Heating Elements and Temperature Control

6.1. Importance of Heat in Pressing Operations

For certain materials, especially plastics, polymers, and composites, heat is necessary to soften or activate the material during pressing. Laboratory presses that are used for these applications often include integrated heating elements in their platens.

6.2. Types of Heating Elements (Electric, Infrared, Induction)

The heating elements in laboratory presses come in various forms, depending on the specific application:

- Electric Heaters: The most common type of heating element, electric heaters use resistance wires to generate heat.

- Infrared Heaters: These heaters provide more localized heat, ideal for applications that require rapid heating of specific areas.

- Induction Heaters: Used for high-precision applications, induction heating elements provide fast, even heat without direct contact with the material.

6.3. Temperature Sensors and Thermocouples

To ensure precise temperature control, most laboratory presses include sensors such as thermocouples, which monitor the temperature of the platens in real time. These sensors are often linked to the control system, allowing for automatic adjustments if the temperature deviates from the set value.

6.4. Programmable Heating and Cooling Cycles

Advanced presses allow operators to program specific heating and cooling cycles, making it easy to create consistent, repeatable processes. These cycles may include:

- Ramp-Up Times: Gradually increasing the temperature over time to avoid thermal shock.

- Hold Times: Maintaining a specific temperature for a set period to ensure that the material is evenly heated.

- Cooling Cycles: Some presses include cooling elements to bring the material back to room temperature after pressing.

6.5. Heat Dissipation and Insulation Strategies

Managing heat dissipation is critical in presses that operate at high temperatures. To prevent heat loss and ensure safety, many presses are equipped with insulation around the platens and heating elements. Additionally, heat shields or guards may be used to protect operators from accidental burns.

Pressure Gauges and Monitoring Devices

7.1. Types of Pressure Gauges (Analog, Digital)

Pressure gauges are essential for monitoring the force being applied during pressing. These gauges come in two primary forms:

- Analog Gauges: Traditional pressure gauges that use a mechanical dial to display the force being applied. These are simple and reliable but may not offer the precision required for certain applications.

- Digital Gauges: More modern presses use digital pressure gauges, which offer greater precision and are often easier to read. Digital gauges are typically integrated into the press’s control system, allowing for real-time feedback.

7.2. Load Cells and Pressure Transducers

For high-precision applications, load cells and pressure transducers are used to measure the actual force applied to the material. These devices provide more accurate readings than traditional pressure gauges and can be used to control the press automatically.

7.3. Real-Time Monitoring and Data Logging

Many modern laboratory presses are equipped with systems that allow for real-time monitoring of pressure, temperature, and other parameters. This data can be logged for later analysis, which is particularly useful in research and development settings where documenting the process is critical.

7.4. Alarms and Safety Cutoffs

To prevent equipment damage or operator injury, many presses include alarms that sound if the pressure or temperature exceeds a safe limit. In some cases, the press will automatically shut off if these limits are reached, ensuring safe operation.

7.5. Calibration and Maintenance of Monitoring Devices

To ensure accuracy, pressure gauges and monitoring devices must be regularly calibrated. Calibration typically involves comparing the gauge readings to a known standard and adjusting the device if necessary. Regular maintenance of these devices is essential for ensuring that the press continues to operate within safe and accurate parameters.

Safety Components

8.1. Safety Shields and Guards

Safety is a critical consideration in any laboratory press. Many presses include safety shields or guards that prevent operators from coming into contact with moving parts or hot surfaces during operation. These shields may be made of transparent materials, such as tempered glass or polycarbonate, to allow operators to view the pressing process while remaining protected.

8.2. Emergency Stop Systems

In the event of an emergency, presses are equipped with emergency stop systems that allow the operator to halt the machine immediately. These stop systems are typically large, easily accessible buttons or levers located near the control panel.

8.3. Overload Protection Devices

Overloading a press can cause serious damage to the machine and endanger the operator. To prevent this, many presses include overload protection devices that automatically stop the press if the applied force exceeds the machine’s rated capacity. These devices are critical in preventing damage to both the press and the material being worked.

8.4. Pressure Relief Valves

Hydraulic presses are often equipped with pressure relief valves to release excess fluid pressure in the system. These valves prevent dangerous over-pressurization, which could result in system failure or rupture.

8.5. Operator Safety Standards and Certifications

Laboratory presses must adhere to strict safety standards to ensure they are safe to operate. These standards are often set by regulatory bodies such as CE (Conformité Européenne) marking in Europe or ISO certifications internationally. Manufacturers must meet these standards and provide documentation to prove compliance, ensuring their presses are built to the highest safety standards.

Customizable and Auxiliary Components

9.1. Interchangeable Platens and Dies

Many presses offer interchangeable platens and dies to accommodate different applications. For example, a press may include flat platens for general pressing tasks but can be equipped with custom-shaped dies for forming specific materials. Interchangeable components allow for greater flexibility and make it easier to adapt a press for various uses.

9.2. Vacuum Chambers

Some laboratory presses are equipped with vacuum chambers, which remove air from the pressing area before pressure is applied. This is particularly useful in applications such as composite material manufacturing, where air bubbles can compromise the integrity of the final product.

9.3. Automatic Ejection Systems

In some presses, automatic ejection systems are used to remove the material from the press after the cycle is complete. This is especially useful in high-cycle environments where manual removal would be too time-consuming or labor-intensive.

9.4. Sensors and Automation for Precision Pressing

For high-precision applications, presses may be equipped with additional sensors that monitor parameters such as pressure, temperature, and displacement. These sensors can feed data to an automated control system, ensuring that the press operates within tight tolerances and producing consistent results.

9.5. Cooling Systems and Water Circulation Units

Certain materials, particularly thermoplastics and composites, require controlled cooling after pressing. Some presses are equipped with cooling systems, such as water circulation units, to bring the material back to room temperature quickly and evenly.

Conclusion and Summary of Key Components

In conclusion, the components of a laboratory press are the foundation upon which its performance, efficiency, and safety are built. From the frame and pressure systems to the control mechanisms, platens, and safety features, each component plays a critical role in ensuring that the press operates reliably and consistently.

Choosing the right components for a laboratory press depends on the intended application, as different types of presses and components are better suited for specific tasks. For instance, hydraulic systems are ideal for high-pressure applications, while electric presses offer precision for delicate materials. Likewise, heated platens are essential for thermoplastic molding, while cold platens are sufficient for simpler tasks.

In the future, we can expect laboratory press components to become even more advanced, with greater emphasis on automation, real-time monitoring, and energy efficiency. As technology continues to evolve, laboratory presses will remain an indispensable tool in research, development, and production across numerous industries.

Introduction to Laboratory Presses and Their Applications

Laboratory presses are vital tools used to apply controlled pressure (and sometimes heat) to materials, enabling research, testing, and manufacturing in a variety of fields. These versatile machines can be found in laboratories across numerous industries, ranging from pharmaceuticals and polymers to aerospace and electronics. Laboratory presses are engineered to replicate real-world conditions, allowing researchers and engineers to understand how materials behave under pressure and to develop new products and materials based on precise data.

Laboratory presses are available in various types, including manual, hydraulic, pneumatic, and electric presses, each designed for specific applications. The controlled pressure that these presses apply allows users to manipulate materials in a way that ensures repeatability and accuracy—critical for scientific research and product development. Many modern laboratory presses also feature additional functionalities, such as heating elements for temperature control, programmable cycles, and real-time monitoring of force and other parameters, further enhancing their usefulness across applications.

Laboratory presses are used in a range of testing processes, including mechanical, thermal, and durability tests. They support industries such as pharmaceuticals for drug development, electronics for the manufacturing of circuit boards, and aerospace for the creation of lightweight composites. As technology evolves, so too do the applications of laboratory presses, especially with the growing demand for automation, sustainability, and advanced materials testing.

In this section, we will explore the various applications of laboratory presses in detail, focusing on how they support research, development, manufacturing, and quality control across different industries.

Scientific Research Applications

Laboratory presses play a significant role in scientific research, particularly in fields like material science, chemistry, and earth sciences. In research laboratories, these presses are used to prepare samples for analysis, simulate real-world conditions, and explore the mechanical and thermal properties of materials under controlled pressure and temperature conditions.

2.1. Material Science Research

In material science, laboratory presses are crucial for creating and testing new materials. Researchers use presses to explore the behavior of materials under stress, including how they deform, fracture, or compress under various pressure levels. Laboratory presses are also used to mold materials into specific shapes for further testing or application in real-world scenarios. The ability to control pressure precisely is essential when testing composite materials, ceramics, metals, or nanomaterials, all of which have diverse applications in industries ranging from construction to electronics.

2.2. Polymers and Plastics Development

Polymers and plastics are often tested using laboratory presses to evaluate their behavior under different conditions. Researchers use presses to perform compression molding, which involves applying heat and pressure to polymer samples to form a specific shape. This process helps researchers understand how new polymers will behave in real-world applications, such as in automotive parts, medical devices, or consumer goods.

Laboratory presses are also used to produce films, laminates, and plastic sheets for testing their mechanical and thermal properties. In R&D laboratories, scientists can experiment with polymer blends and composites, creating innovative materials with specific properties like flexibility, strength, or heat resistance.

2.3. Composite Materials Research

Composite materials, made by combining two or more different materials to create a superior product, are widely studied in academic and industrial research settings. Laboratory presses are used to create and test these composites by applying high pressure and heat to bond the materials together. Researchers often focus on creating composites with specific mechanical properties, such as strength-to-weight ratio or heat resistance, which are valuable in industries like aerospace, automotive, and construction.

In research laboratories, the ability to precisely control both the pressure and temperature is critical for ensuring that composite materials exhibit consistent properties. Presses allow researchers to replicate real-world conditions in a controlled environment, ensuring that the materials can withstand the stress and conditions of their intended application.

2.4. Geoscience and Earth Materials

In geosciences, laboratory presses are used to simulate the high-pressure and high-temperature conditions found deep within the Earth. These conditions are important for understanding processes like mineral formation, rock deformation, and tectonic activity. Geoscientists use laboratory presses to study the properties of rocks, minerals, and other earth materials by replicating the conditions of deep-earth environments.

For example, high-pressure presses can be used to replicate the forces experienced by materials in the Earth’s crust or mantle, helping researchers better understand the processes that lead to the formation of mountains, earthquakes, and volcanic activity. These presses are also valuable in paleontology for studying fossilized materials under controlled pressure conditions.

Material Testing Applications

Material testing is one of the most critical applications of laboratory presses across various industries. Laboratory presses are used to apply controlled pressure to test a material’s strength, durability, hardness, and thermal properties. These tests help ensure that materials meet the necessary quality and safety standards before they are used in production or consumer products.

3.1. Mechanical Testing (Compression, Tensile, Shear, etc.)

Laboratory presses are commonly used to perform mechanical tests on materials, including compression, tensile, and shear tests. In compression testing, materials are subjected to a controlled compressive force to determine their behavior under load. Compression tests are widely used to evaluate the strength and stiffness of materials like metals, plastics, and composites.

- Tensile Testing: Tensile testing involves stretching a material until it fractures. Laboratory presses are used to apply a steady force to the material, measuring how much stress it can withstand before breaking. This is particularly important for materials used in construction, automotive, and aerospace applications, where strength and durability are crucial.

- Shear Testing: Shear tests involve applying force parallel to a material’s surface to evaluate its shear strength. This type of testing is essential for materials used in joints, rivets, or any application where the material will experience forces in different directions.

Laboratory presses provide the controlled environment necessary for these mechanical tests, ensuring that the results are repeatable and accurate.

3.2. Thermal Testing (DSC, TGA)

Thermal testing helps determine how materials respond to changes in temperature. Laboratory presses, equipped with heating elements, are used to apply controlled heat while compressing materials, simulating real-world conditions in which materials are exposed to both heat and mechanical stress. Two common types of thermal testing are:

- Differential Scanning Calorimetry (DSC): DSC measures the heat flow into or out of a material as it is heated or cooled. Laboratory presses can be equipped with thermal control systems to compress materials while recording changes in thermal properties.

- Thermogravimetric Analysis (TGA): TGA measures the weight change of a material as it is subjected to heat. Laboratory presses with integrated heating elements are used to compress materials and assess their thermal stability or decomposition rates.

Thermal testing is especially important in industries where materials will be exposed to high temperatures, such as in aerospace, automotive, or electronics applications.

3.3. Hardness and Durability Tests

Hardness testing involves applying force to a material to determine how resistant it is to indentation, scratching, or abrasion. Laboratory presses are used in hardness tests like Rockwell, Brinell, or Vickers hardness tests, where controlled pressure is applied using a specific indenter shape and force.

Durability testing evaluates a material’s ability to withstand repeated loading or stress over time. Laboratory presses are used to simulate real-world conditions by applying repeated compressive or tensile forces to materials, helping determine their long-term performance in applications such as construction materials, automotive parts, and consumer goods.

3.4. Wear and Tear Tests

Wear and tear tests help manufacturers understand how materials will behave over time when subjected to friction, impact, or environmental stressors. Laboratory presses are used to apply controlled pressure and friction to materials to simulate real-world wear conditions. These tests are especially valuable for industries like automotive and aerospace, where materials are expected to endure extreme conditions over long periods.

Laboratory presses used in wear testing may be equipped with specialized platens that simulate abrasive surfaces, and the results of these tests can be used to improve the durability of products like tires, brakes, and engine components.

3.5. Fatigue Testing

Fatigue testing involves applying repeated or cyclical loads to a material to evaluate how it performs under long-term stress. Laboratory presses can simulate the repeated application of force over time, providing insights into how materials will perform in real-world applications. Fatigue testing is crucial for industries like construction, transportation, and aerospace, where materials must withstand constant loading and unloading cycles.

By subjecting materials to controlled cycles of compression or tension, laboratory presses help engineers and scientists understand when and how materials will fail due to fatigue. This information is critical for improving the design and safety of products that experience repeated stress, such as bridges, buildings, and aircraft components.

Pharmaceutical Applications

In the pharmaceutical industry, laboratory presses are essential tools for drug development, formulation, and quality control. From tablet pressing to the creation of drug delivery systems, laboratory presses ensure that pharmaceutical products meet stringent quality and safety standards.

4.1. Tablet Compression and Formulation

One of the most critical applications of laboratory presses in the pharmaceutical industry is tablet compression. Tablets are created by compressing powders into a solid form using a tablet press. Laboratory-scale tablet presses are used during the development phase to create sample batches for testing, enabling researchers to fine-tune formulations and ensure the correct dosage of active ingredients.

Laboratory presses allow pharmaceutical companies to simulate the conditions of large-scale tablet production, helping to identify potential issues with powder flow, compression, and tablet hardness before scaling up production. Additionally, presses are used to test different excipient formulations, ensuring that tablets have the necessary properties, such as disintegration time and dissolution rate, to be effective in delivering the drug.

4.2. Granulation and Pelletizing

In addition to tablet pressing, laboratory presses are used in the granulation and pelletizing processes. Granulation involves forming small particles (granules) from powders to improve flowability and compressibility. This process is essential in ensuring consistent tablet production. Pelletizing involves compressing powders into small, uniform spheres or pellets that can be used in various drug delivery systems, such as capsules or modified-release formulations.

Laboratory presses provide the controlled environment necessary for developing and optimizing granulation and pelletizing processes. Researchers use these presses to test different formulations and processing conditions, ensuring that the final product meets the desired specifications.

4.3. Drug Development and R&D Testing

Laboratory presses play an important role in the early stages of drug development and research. Researchers use presses to compress active pharmaceutical ingredients (APIs) and excipients into tablets for initial testing. This allows them to evaluate how the drug will perform in vivo, including its dissolution rate, bioavailability, and stability.

Presses are also used to create samples for clinical trials, ensuring that the drug meets all regulatory requirements before moving into large-scale production. This is especially important in the development of new drug formulations, where laboratory presses provide the precision and control needed to create consistent, high-quality samples.

4.4. Medical Device Manufacturing

In addition to pharmaceuticals, laboratory presses are used in the manufacturing of medical devices. Many medical devices, such as implants, catheters, and drug delivery systems, are made from polymers that require controlled pressure and heat during the manufacturing process.

Laboratory presses are used to form and bond these materials, ensuring that the devices meet strict quality and safety standards. For example, polymeric materials used in medical implants must be strong, biocompatible, and able to withstand the mechanical stresses of the human body. Laboratory presses are used to test and refine these materials during the development process.

Polymers and Plastics Industry Applications

The polymers and plastics industry relies heavily on laboratory presses for both product development and quality control. Laboratory presses are used to mold, shape, and test plastic materials, helping manufacturers create high-performance products for a variety of applications.

5.1. Compression Molding of Thermoplastics

Compression molding is a common process used to create plastic parts by applying heat and pressure to a polymer material in a mold. Laboratory presses are used for small-scale compression molding, allowing researchers and manufacturers to develop and test new thermoplastic materials before moving into full-scale production.