A CNC metal spinning lathe is a marvel of automation in the world of metalworking. It takes the core principles of metal spinning – using a rotating form and a tool to shape sheet metal – and infuses them with computer-controlled precision. Here’s a breakdown of what makes a CNC metal spinning lathe unique:

Traditional vs. CNC:

- Manual Machines: Traditional metal spinning lathes rely on the skill of the operator to manipulate the spinning tool and achieve the desired shape. This requires a high level of experience and dexterity to control the pressure and path of the tool for accurate shaping.

- CNC Machines: CNC metal spinning lathes, on the other hand, are all about automation. They utilize a pre-programmed digital blueprint that precisely controls the movements of the spinning tool. This eliminates human error and ensures consistent, repeatable results on every part.

CNC Operated Metal Spinning Machines and CNC Metal Spinning Lathe

CNC-operated metal spinning machines are advanced tools used for forming metal sheets into symmetrical shapes such as cones, cylinders, and hemispheres. These machines use computer numerical control (CNC) to automate and precisely control the spinning process. Here are the key aspects and benefits of CNC-operated metal spinning machines:

Key Aspects

- Computer Numerical Control (CNC):

- CNC systems use pre-programmed software to control the movement of the spinning machine. This ensures high precision and repeatability.

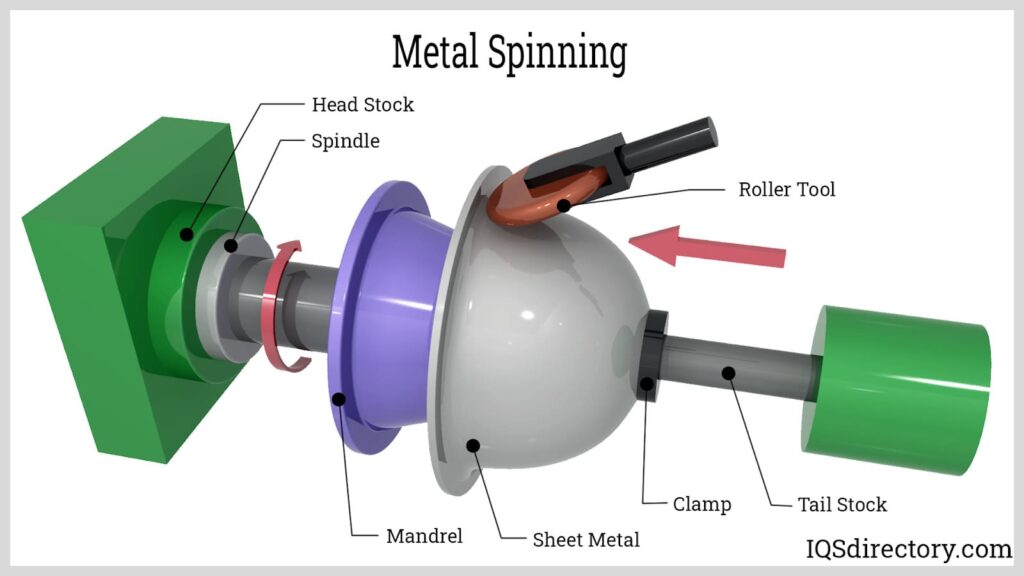

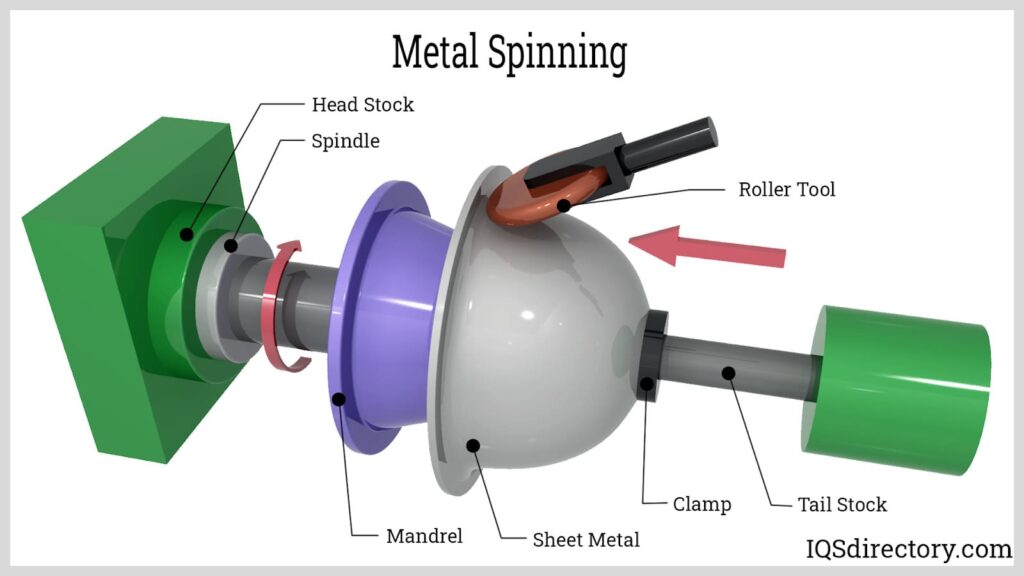

- Spindle and Mandrel:

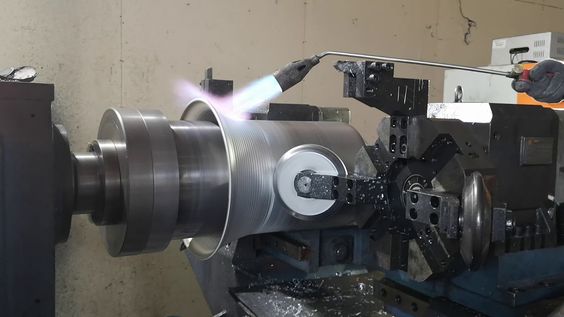

- The workpiece is mounted on a mandrel attached to the spindle, which rotates the workpiece at high speeds.

- Rollers/Tooling:

- Tools or rollers press against the rotating workpiece to shape it according to the desired profile. These tools can be adjusted and controlled by the CNC system.

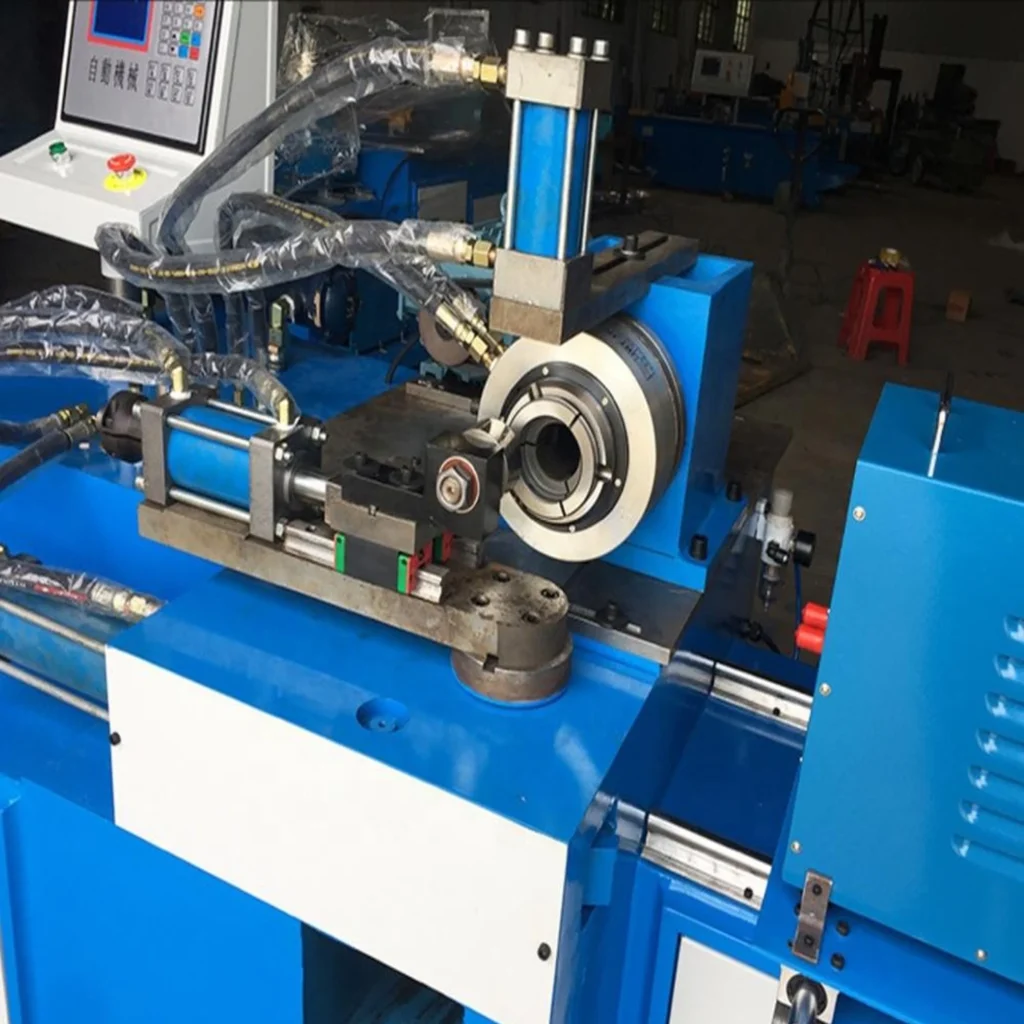

- Control Panel:

- An interface where the operator can input the desired parameters and monitor the machine’s performance. It includes a computer that interprets the CNC code.

- Tailstock:

- Provides support for the workpiece, especially for longer or more complex shapes. It can be moved to accommodate different workpiece lengths.

- Bed:

- The base of the machine that provides stability and support for all other components.

- Coolant System:

- A system that delivers coolant to the working area to reduce heat and friction, thereby extending the life of the tooling and improving workpiece quality.

How does Computer Numerical Control (CNC) control the Metal Spinning Machines?

Computer Numerical Control (CNC) systems control metal spinning machines through a combination of software and hardware that automates and precisely manages the movements and operations of the machine. Here’s a detailed explanation of how CNC controls metal spinning machines:

1. Programming

- CAD/CAM Software: The process begins with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. The desired shape or part is designed using CAD software, and then CAM software generates the CNC code (G-code or M-code) that instructs the machine on how to create the part.

- G-code/M-code: G-code provides the specific instructions for machine movements, tool paths, and operational parameters. M-code controls miscellaneous functions such as coolant on/off and spindle start/stop.

2. Controller

- CNC Controller: The CNC controller is the brain of the machine. It reads the G-code and translates it into electrical signals that control the machine’s movements and operations.

- User Interface: The controller typically includes a user interface (control panel) where the operator can input commands, start and stop programs, and monitor machine status.

3. Machine Movements

- Servomotors/Stepper Motors: The CNC system uses servomotors or stepper motors to control the movements of the machine. These motors are responsible for the precise positioning of the spindle, tailstock, and tooling.

- Axis Control: CNC metal spinning machines typically operate on multiple axes (e.g., X-axis for cross-slide movement, Z-axis for carriage movement). The controller coordinates the movements along these axes to shape the workpiece accurately.

4. Spinning Process

- Spindle Rotation: The CNC system controls the spindle speed, ensuring that the workpiece rotates at the desired rate for optimal forming.

- Tooling Control: The CNC controller manages the position and pressure of the spinning tools or rollers. It ensures that the tools follow the programmed path to shape the metal as specified in the CAD design.

- Feed Rate: The controller adjusts the feed rate, which is the speed at which the tool advances along the workpiece, to ensure a smooth and precise forming process.

5. Feedback Systems

- Sensors and Encoders: CNC machines are equipped with sensors and encoders that provide real-time feedback to the controller. This feedback helps the system make adjustments to maintain accuracy and precision.

- Closed-Loop Control: The feedback from sensors and encoders enables closed-loop control, where the system continuously monitors and adjusts the machine’s operations to correct any deviations from the programmed path.

6. Additional Features

- Coolant Control: The CNC system can control the coolant flow to manage heat and reduce friction during the spinning process.

- Safety Systems: CNC machines often include safety features such as interlocks, emergency stop buttons, and protective enclosures, all controlled by the CNC system to ensure operator safety.

7. Execution

- Automated Operation: Once the program is loaded and started, the CNC system takes over the entire operation, executing the instructions to form the metal workpiece with high precision and repeatability.

- Monitoring and Adjustments: The CNC system continuously monitors the process and makes necessary adjustments to ensure the final product meets the desired specifications.

By automating and precisely controlling the metal spinning process, CNC systems significantly enhance productivity, accuracy, and consistency in manufacturing complex metal parts.

Benefits

- Precision and Accuracy:

- CNC control ensures precise and consistent shaping of metal parts, reducing errors and material waste.

- Repeatability:

- Once a program is set, the machine can produce identical parts repeatedly, ensuring uniformity in production.

- Efficiency:

- Automation speeds up the production process, allowing for higher throughput compared to manual metal spinning.

- Complex Shapes:

- Capable of producing complex and intricate shapes that would be difficult or impossible to achieve manually.

- Reduced Labor Costs:

- Automation reduces the need for skilled labor, lowering overall production costs.

- Versatility:

- Can work with various metals including aluminum, steel, copper, and more, making it suitable for a wide range of applications.

- Safety:

- Enhanced safety features reduce the risk of accidents compared to manual spinning processes.

Applications

CNC-operated metal spinning machines are used in numerous industries, including:

- Aerospace: Manufacturing nose cones, rocket casings, and satellite dishes.

- Automotive: Producing parts like wheels, hubcaps, and exhaust components.

- Lighting: Creating light fixtures and reflectors.

- Cookware: Fabricating pots, pans, and other kitchenware.

- HVAC: Making components for heating, ventilation, and air conditioning systems.

- Medical: Producing surgical instruments and medical device housings.

- Industrial Machinery: Creating machine parts like pulleys and hoppers.

- Consumer Goods: Manufacturing musical instruments, decorative objects, and more.

CNC-operated metal spinning machines offer significant advantages in terms of precision, efficiency, and versatility, making them essential tools in modern manufacturing.

The Power of Programming:

The magic behind a CNC lathe lies in its computer programming. Here’s how it works:

- 3D Modeling: The desired final shape of the metal piece is first created using 3D modeling software. This software generates a precise digital blueprint of the part’s geometry.

- CNC Code Generation: The 3D model is then converted into CNC code, a set of instructions that tells the CNC machine exactly how to move the spinning tool along multiple axes. This code dictates the tool path, pressure application, and speed throughout the shaping process.

- Automated Shaping: Once the program is loaded into the CNC machine, the operator simply needs to secure the sheet metal onto the mandrel and initiate the program. The CNC machine then takes over, precisely controlling the spinning tool to shape the metal sheet according to the pre-programmed instructions.

Benefits of CNC Metal Spinning Lathes:

- Accuracy and Repeatability: CNC machines guarantee consistent and precise shaping every time. This is crucial for high-volume production runs where identical parts are needed.

- Complex Shapes: CNC technology can handle intricate shapes with complex geometries that would be extremely challenging, or even impossible, to achieve with manual spinning.

- Reduced Labor Costs: Automation eliminates the need for highly skilled manual operators, potentially reducing labor costs in production environments.

- Faster Production: CNC lathes can often spin parts faster than manual machines, especially for complex shapes, leading to increased production efficiency.

Applications of CNC Metal Spinning Lathes:

CNC metal spinning lathes are used in various industries due to their ability to produce precise and complex shapes. Here are some examples:

- Automotive Parts: Wheel covers, air intake scoops, and some headlight housings can be spun using CNC lathes.

- Aerospace: Certain rocket nose cones and other aerodynamic components can be formed with CNC spinning.

- Lighting Components: Reflectors and lamp shades with intricate curves can be precisely shaped using CNC control.

- Telecommunication Equipment: Parabolic dish antennas and waveguides can be efficiently produced with CNC spinning lathes.

- Medical Equipment: Cladding for medical instruments and specific sterile containers can be spun using CNC machines.

In conclusion, CNC metal spinning lathes represent a technological leap forward in the metal spinning industry. They offer unmatched precision, repeatability, and the ability to tackle complex shapes, making them a valuable tool for high-volume production and creating intricate metal components across various industries.

CNC (Computer Numerical Control) Metal Spinning

CNC (Computer Numerical Control) metal spinning is a highly specialized form of manufacturing that involves shaping a flat sheet or tube of metal into an axially symmetrical part by rotating the material while applying force using tools or rollers. The use of CNC in metal spinning allows for precise, automated control of the process, yielding consistent, repeatable results. This process is widely used in industries where precision, durability, and strength are crucial, such as aerospace, automotive, and medical sectors.

Historically, metal spinning was a manual, labor-intensive process dating back to ancient times. The advent of CNC technology revolutionized the field by introducing a computerized approach that automates much of the work, allowing for higher production volumes and finer tolerances. By employing computer programs to control the machines, manufacturers can achieve complex shapes that would have been impossible or very time-consuming using traditional spinning techniques.

The relevance of CNC metal spinning in modern manufacturing cannot be overstated. With increasing demand for precision-engineered components, the ability to automate the metal shaping process while ensuring a high degree of accuracy has made CNC metal spinning an indispensable technique for many industries. This introduction will discuss the fundamentals of CNC metal spinning, explore its importance, and highlight the key factors that have driven its adoption across various sectors.

The CNC Metal Spinning Process

The CNC metal spinning process can be broken down into several stages, each essential for producing the final part. Understanding each step of the process gives insight into the complexity and precision involved in manufacturing with this technique.

- Design and Programming: The first step in CNC metal spinning involves designing the part using CAD (Computer-Aided Design) software. Engineers develop detailed models of the desired shape and dimensions, which are then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program dictates the tool paths and operations the CNC machine will follow.

- Material Preparation: Once the design is complete, the appropriate material is selected. Common materials used in CNC metal spinning include aluminum, steel, copper, and titanium. The metal is typically in the form of a flat disc or tube, which will be spun into the desired shape.

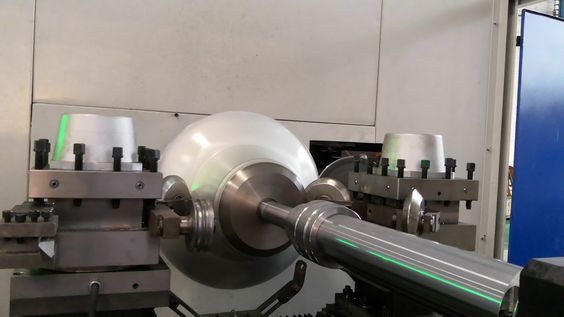

- Mounting the Workpiece: The prepared metal piece is mounted on a CNC lathe, where it is securely held in place. During the spinning process, the workpiece is rotated at high speeds while tools or rollers are applied to shape the material.

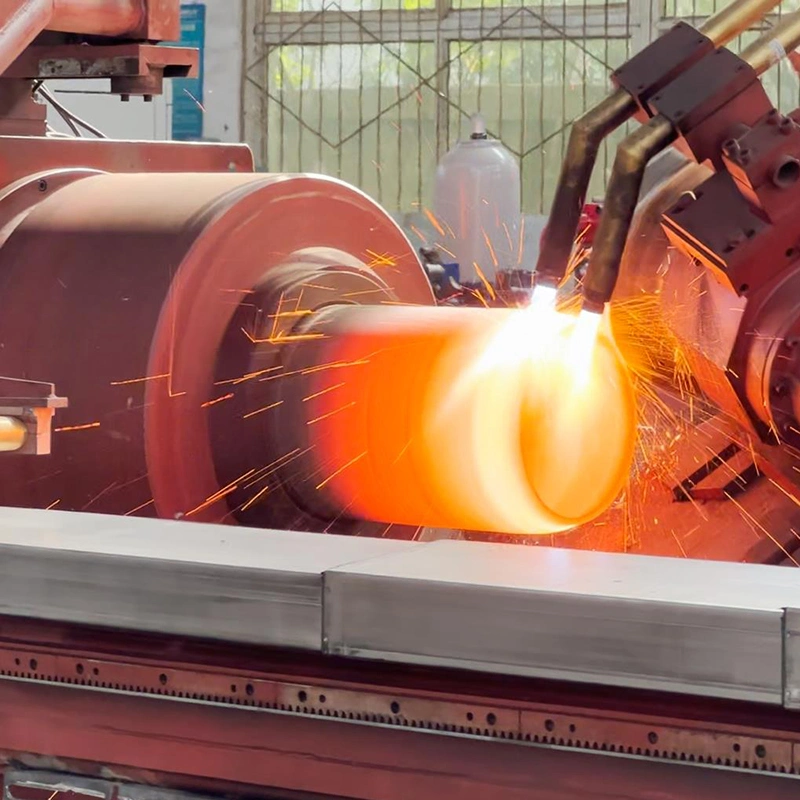

- Spinning and Forming: The CNC program controls the movement of the tools or rollers as they apply pressure to the spinning workpiece. The material is gradually formed into the desired shape, whether it be a cone, cylinder, or more complex geometry. The spinning process involves multiple passes, with the tool gradually applying more force to achieve the final shape.

- Finishing and Trimming: Once the part has been spun to the correct shape, it may require finishing operations to remove excess material or smooth out the surface. CNC machines can also be equipped with trimming tools that cut away any unnecessary material during the spinning process, ensuring the final part meets precise dimensional tolerances.

Advantages of CNC Metal Spinning

CNC metal spinning offers numerous advantages over traditional methods of metal forming and spinning, making it an attractive choice for manufacturers across various industries.

- Precision and Accuracy: One of the key advantages of CNC metal spinning is the precision it offers. CNC machines are capable of producing highly accurate parts with tight tolerances, ensuring consistency in production runs. This is particularly important for industries such as aerospace and medical, where even the smallest deviation can compromise the integrity of the final product.

- Efficiency and Scalability: CNC metal spinning is a highly efficient process, allowing for rapid production of parts with minimal waste. The automation of the process reduces the need for manual intervention, speeding up production times and lowering labor costs. Moreover, CNC systems can be easily scaled to accommodate both small and large production runs, making it a versatile option for manufacturers.

- Customization and Flexibility: The flexibility of CNC metal spinning allows for the production of custom parts in a wide range of shapes and sizes. Whether it’s a small prototype or a large batch of components, CNC systems can easily adapt to different requirements. This customization is particularly beneficial for industries that require unique, tailored parts.

Applications of CNC Metal Spinning in Various Industries

CNC metal spinning has applications across numerous industries, including aerospace, automotive, medical, and more.

- Aerospace Industry: In the aerospace sector, CNC metal spinning is used to produce components that are lightweight yet strong enough to withstand the harsh conditions of flight. Parts such as nose cones, engine components, and structural elements are often manufactured using CNC metal spinning due to its ability to create high-precision, durable parts.

- Automotive Industry: The automotive industry relies on CNC metal spinning for the production of various components, including wheels, exhaust systems, and suspension parts. The precision and consistency of CNC metal spinning ensure that these parts meet the high standards required for automotive applications.

- Medical Industry: In the medical field, CNC metal spinning is used to create custom medical devices and surgical instruments. The ability to produce precise, complex shapes with high levels of accuracy is crucial for ensuring the safety and effectiveness of these products.

Comparison with Traditional Metal Spinning

Traditional metal spinning and CNC metal spinning serve similar purposes in the manufacturing process, but there are distinct differences between the two methods. Understanding the differences between manual, traditional metal spinning and CNC-based systems helps to evaluate when each method might be more appropriate.

- Manual vs. Automated Control:

Traditional metal spinning is a hands-on process requiring skilled craftsmen to manipulate the material using a spinning lathe. This technique has been around for centuries, relying on the experience and expertise of the operator. In contrast, CNC metal spinning automates this process, using computer-controlled movements to guide the tools and shape the material. The CNC program provides a high level of precision that is difficult to achieve manually, and once programmed, the machine can produce identical parts with minimal deviation, even in large batches. - Complexity of Design:

CNC metal spinning is particularly advantageous when producing complex or intricate shapes. While traditional spinning is limited by the skill of the operator and the tools available, CNC systems can follow precise, intricate tool paths programmed into the software. This capability allows for more advanced designs and a higher degree of customization, making CNC spinning ideal for industries requiring complex geometries, such as aerospace and medical device manufacturing. - Production Volume and Speed:

Traditional metal spinning is best suited for low-volume production runs or prototypes, where the flexibility of manual control allows for rapid adjustments. However, this method is labor-intensive and less efficient for large-scale production. In contrast, CNC metal spinning excels in high-volume production due to its automated nature. Once the CNC machine is set up, it can operate continuously with little supervision, making it more efficient for mass production. - Cost Considerations:

One of the drawbacks of CNC metal spinning is the initial cost. The setup of CNC machines requires investment in programming, machinery, and software. However, the long-term savings in labor, material waste, and production efficiency often outweigh the initial costs, especially in large-scale manufacturing. Traditional metal spinning, on the other hand, has a lower upfront cost since it requires simpler machinery and less reliance on expensive technology. It is often a preferred method for smaller projects or where the added precision of CNC isn’t essential. - Skill and Training Requirements:

Traditional metal spinning demands a high level of manual dexterity and years of experience to master. Skilled spinners are required to monitor and adjust the process in real-time, making it a labor-intensive craft. On the other hand, CNC metal spinning places more emphasis on programming and machine operation skills. While this reduces the need for manual labor, it increases the need for training in CNC programming and machine maintenance. - When to Choose Traditional Spinning:

Despite the advantages of CNC metal spinning, traditional spinning has its place, particularly in situations where short-run production or rapid prototyping is needed. Traditional methods also offer more flexibility in terms of quick adjustments during the process. When working with small-scale projects or custom one-off pieces, the manual approach may be more cost-effective and suitable.

Equipment Used in CNC Metal Spinning

The effectiveness of CNC metal spinning relies on the precision and sophistication of the equipment used. The key equipment includes CNC lathes, spinning tools, software for design and programming, as well as ancillary machines that contribute to a safe and efficient manufacturing environment.

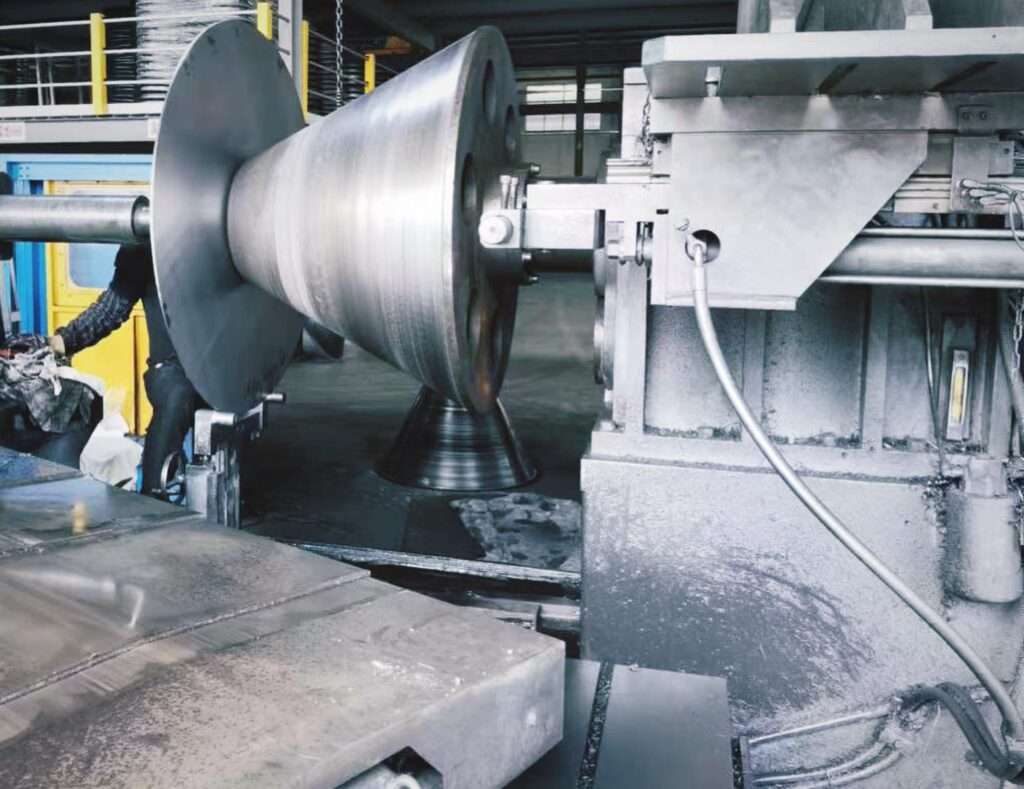

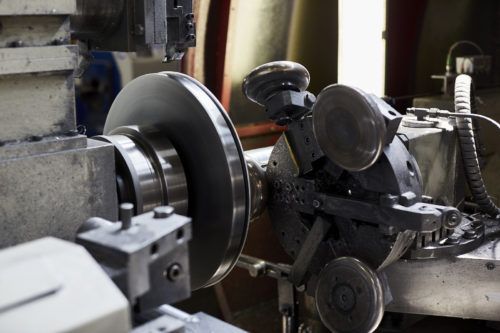

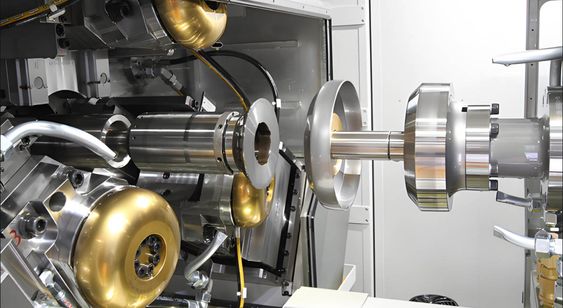

- CNC Lathes:

At the heart of CNC metal spinning is the CNC lathe. These machines rotate the workpiece at high speeds while applying force through various tools to shape the metal. CNC lathes can vary in size and capacity, depending on the specific application. Industrial-grade CNC lathes are capable of handling large, heavy pieces of metal and can run continuously for high-volume production. The high-speed rotation, combined with precision tool control, allows for the production of complex, symmetrical shapes. - Spinning Tools:

The tools used in CNC metal spinning are crucial for shaping the metal. These can include forming rollers, tools for trimming, and specialized cutters, each designed for different parts of the spinning process. Rollers come in different shapes and sizes, depending on the type of component being manufactured. Tool durability is essential, as the friction and pressure exerted during the spinning process can cause wear over time. High-quality tools, made from hardened steel or carbide, are commonly used to ensure longevity and reduce downtime for tool replacement. - Software Systems:

CNC metal spinning depends heavily on the software that controls the machinery. CAD (Computer-Aided Design) software is used to create the design of the component, while CAM (Computer-Aided Manufacturing) software translates this design into specific machine instructions. These instructions guide the CNC lathe, dictating the speed, pressure, and movement of the tools. Many CNC systems also incorporate simulation software that allows manufacturers to test the process virtually before running it on the actual machine. This reduces errors and material wastage, ensuring the process is as efficient as possible. - Safety Equipment:

Due to the high speeds and forces involved in CNC metal spinning, safety is a critical concern. Machines are typically equipped with protective shields to prevent debris from being ejected during the process. Operators must also wear protective gear, including gloves, eye protection, and sometimes even full-body protective suits, depending on the type of metal being spun. Modern CNC machines are often equipped with sensors and automated safety shut-off mechanisms to detect any issues during the spinning process and prevent accidents. - Machine Maintenance:

Regular maintenance of CNC metal spinning machines is essential for ensuring consistent production quality and minimizing downtime. Maintenance typically involves checking for wear on the spinning tools, cleaning and lubricating the machine’s moving parts, and ensuring that the CNC system is properly calibrated. CNC machines also need periodic software updates to maintain their precision and efficiency. - Automation Systems:

To further enhance productivity, many CNC metal spinning setups integrate automation systems such as robotic arms for loading and unloading materials. This minimizes the need for human intervention and reduces production time, especially in high-volume manufacturing environments. Automated systems also improve safety by reducing the risk of human error.

Challenges in CNC Metal Spinning

Despite its advantages, CNC metal spinning presents several challenges that manufacturers must address to optimize production.

- Tool Wear and Durability:

The spinning tools used in CNC processes endure high levels of stress and friction, which can lead to rapid wear, especially when working with hard metals like steel and titanium. Tool wear affects the precision of the final product and requires regular monitoring. High-quality materials such as carbide can reduce wear, but they are also more expensive. Developing strategies for extending tool life, such as better lubrication or improved tool design, is an ongoing challenge. - Material Limitations:

While CNC metal spinning is versatile, not all materials are suitable for the process. Some metals are too brittle to be spun without cracking, while others may have too low a melting point and deform under the heat generated by the spinning process. Manufacturers must carefully select materials that can withstand the forces applied during spinning. Additionally, thicker materials can be challenging to spin, requiring more powerful machines and specialized tools. - Tolerances and Consistency:

Maintaining tight tolerances over large production runs can be difficult. Although CNC systems are designed for precision, factors such as tool wear, machine calibration, and variations in material quality can affect the consistency of the final product. Manufacturers must regularly inspect parts and adjust the process as needed to ensure that tolerances remain within acceptable limits. - Programming and Setup Costs:

One of the main drawbacks of CNC metal spinning is the time and cost associated with programming the CNC machine. Creating a CNC program involves designing the part, simulating the process, and troubleshooting potential issues before actual production begins. This setup time can be costly, particularly for small production runs. While the costs are offset in large-scale manufacturing, they remain a consideration for smaller companies or custom projects. - Skilled Labor Requirements:

Although CNC machines reduce the need for manual labor, they still require skilled operators and programmers. CNC machinists must have a deep understanding of both the software and the machinery to set up, troubleshoot, and maintain the system. Training workers to operate CNC machines can be time-consuming, and the demand for CNC operators often exceeds supply, leading to labor shortages in some industries.

Sustainability and Environmental Impact

Sustainability has become an increasingly important consideration in the manufacturing industry, and CNC metal spinning offers several eco-friendly advantages compared to traditional manufacturing methods.

- Material Efficiency:

CNC metal spinning is a highly efficient process in terms of material usage. Unlike traditional machining processes, which often involve cutting away large amounts of material, spinning reshapes the metal without removing significant portions. This results in less waste and reduces the need for raw materials, contributing to a more sustainable manufacturing cycle. - Energy Efficiency:

The energy consumption of CNC metal spinning is relatively low compared to other metal-forming processes like stamping or forging, which require more force and heat. The combination of precision and reduced material waste also means fewer resources are needed to produce the same number of components. - Recycling and Waste Reduction:

Any scrap material generated during CNC metal spinning is typically recyclable. Manufacturers often work with recyclable metals such as aluminum, steel, and copper, contributing to a circular economy where materials can be reused. Additionally, the precision of CNC machines minimizes the production of scrap, further reducing waste.

Future Trends in CNC Metal Spinning

CNC metal spinning continues to evolve with advancements in technology. Several trends are shaping the future of this manufacturing method, including the incorporation of new technologies and a growing focus on sustainability.

- Incorporation of AI and Machine Learning:

The integration of artificial intelligence (AI) and machine learning into CNC systems is one of the most exciting trends. These technologies enable machines to learn from previous operations and optimize processes for greater efficiency and precision. AI can help reduce tool wear, improve material usage, and enhance overall machine performance by predicting and correcting errors in real-time. - Increased Automation:

The use of robotics in CNC metal spinning is expected to grow, particularly in high-volume production environments. Robotic arms can handle tasks such as loading and unloading materials, increasing efficiency and reducing the risk of human error. As automation technologies become more affordable, even smaller manufacturers are likely to adopt these systems. - Sustainable Manufacturing Practices:

As environmental regulations tighten and companies aim to reduce their carbon footprints, CNC metal spinning is likely to play a role in more sustainable manufacturing processes. The emphasis will be on using recyclable materials, minimizing energy consumption, and reducing waste.

Conclusion: The Importance of CNC Metal Spinning in Modern Manufacturing

CNC metal spinning is a critical technology in modern manufacturing, offering a combination of precision, efficiency, and flexibility that is unmatched by traditional methods. Its applications span across industries such as aerospace, automotive, medical, and many others, where high-quality, reliable components are essential. CNC metal spinning enables manufacturers to produce complex, symmetrical parts with minimal waste, making it a sustainable choice in today’s environmentally conscious market.

The future of CNC metal spinning looks promising, with advancements in AI, automation, and sustainable practices poised to enhance the process even further. For industries requiring high precision and efficiency, CNC metal spinning will remain a cornerstone of modern manufacturing techniques.

Spinning of Sheet Metal

Spinning sheet metal is a metalworking process that transforms flat sheets of metal into hollow, rotationally symmetrical shapes. It’s a versatile and cost-effective technique used for a wide range of products, from simple kitchenware to complex rocket nose cones. Here’s a breakdown of the key aspects:

The Core Concept:

- Imagine shaping clay on a potter’s wheel. Metal spinning works similarly. A flat sheet of metal is clamped onto a rotating mold (mandrel) that replicates the desired final shape.

- A spinning tool, typically a roller with various profiles, presses against the rotating sheet metal. The controlled pressure causes plastic deformation in the metal, essentially stretching the outer areas and compressing the inner regions to conform to the shape of the mandrel.

Process Steps:

- Preparation:

- Material selection (aluminum, steel, copper, brass) based on desired properties and final thickness.

- Choosing a mandrel with the final shape.

- Cutting a flat sheet of metal larger than the final product to account for shaping and trimming.

- Machine Setup and Shaping:

- Securing the metal sheet onto the mandrel on a metal spinning lathe.

- Selecting the appropriate spinning tool (roller, forming roller, etc.) based on the desired shape.

- Spinning the mandrel and metal sheet together at high speed.

- The operator skillfully guides the spinning tool along the mandrel, applying controlled pressure to progressively shape the sheet metal.

- Often a multi-pass approach is used, with each pass refining the shape and controlling material thickness.

- Finishing:

- Trimming away excess metal around the edge of the formed piece.

- Additional processes like polishing, sanding, or painting depending on the desired outcome.

Advantages:

- Cost-Effective: Relatively inexpensive for short to medium production runs compared to other methods.

- Complex Shapes: Excels at creating intricate, rotationally symmetrical shapes.

- Material Versatility: Works with a variety of sheet metals, offering flexibility in material selection.

- Fast Production: Can be a relatively quick way to form parts, especially for simpler shapes.

Types of Spinning Lathes:

- Manual: Relies on the operator’s skill to manipulate the spinning tool and achieve the desired shape.

- CNC (Computer Numerical Control): Utilizes a pre-programmed digital blueprint for precise and repeatable shaping, ideal for complex shapes and high-volume production.

Applications:

- Kitchenware (pots, bowls)

- Automotive parts (wheel covers, air intake scoops)

- Lighting components (reflectors, lamp shades)

- Telecommunication equipment (parabolic dish antennas)

- Medical equipment (cladding for instruments)

- Aerospace components (rocket nose cones)

Overall, spinning sheet metal is a valuable technique for creating a wide range of shapes for various applications. It offers a balance between cost-effectiveness, versatility, and the ability to produce complex geometries.

How does a CNC Metal Spinning Machine Operate?

A CNC metal spinning machine operates using a combination of computer-controlled precision and the core principles of traditional metal spinning. Here’s a breakdown of its working mechanism:

Traditional Metal Spinning vs. CNC:

- Traditional: A skilled operator manually guides a spinning tool against a rotating mandrel to shape the sheet metal. Their experience and dexterity are crucial for achieving the desired form.

- CNC: The process becomes automated. A pre-programmed digital blueprint controls the movements of the spinning tool via CNC (Computer Numerical Control) technology. This eliminates human error and ensures consistent results.

The Power of Programming:

- 3D Modeling: The first step involves creating a 3D model of the desired final metal shape using 3D modeling software. This software generates a precise digital blueprint with all the geometrical details of the part.

- CNC Code Generation: The 3D model is then converted into CNC code. This code essentially translates the digital blueprint into a set of instructions for the CNC machine. It dictates the exact path the spinning tool needs to follow along multiple axes, the pressure to be applied at different points, and the speed of the spinning process.

- Automated Shaping: Once the program is loaded into the CNC machine, the operator secures the sheet metal onto the mandrel. Initiating the program then triggers the automated shaping process. The CNC machine precisely controls the spinning tool based on the pre-programmed instructions, shaping the metal sheet into the desired form.

Benefits of CNC Metal Spinning:

- Accuracy and Repeatability: CNC machines guarantee consistent and precise shaping every single time. This is crucial for high-volume production runs where identical parts are needed.

- Complex Shapes: CNC technology can handle intricate shapes with complex geometries that would be extremely challenging, or even impossible, to achieve with manual spinning. The programmed tool path can follow precise contours for intricate details.

- Reduced Labor Costs: Automation eliminates the need for highly skilled manual operators, potentially reducing labor costs in production environments.

- Faster Production: CNC lathes can often spin parts faster than manual machines, especially for complex shapes, leading to increased production efficiency.

Applications of CNC Metal Spinning:

CNC metal spinning lathes are used in various industries due to their ability to produce precise and complex shapes. Here are some examples:

- Automotive Parts: Wheel covers, air intake scoops, and some headlight housings can be efficiently spun using CNC lathes.

- Aerospace: Certain rocket nose cones and other aerodynamic components can be formed with CNC spinning due to the ability to handle complex curves.

- Lighting Components: Reflectors and lamp shades with intricate curves can be precisely shaped using CNC control.

- Telecommunication Equipment: Parabolic dish antennas and waveguides can be efficiently produced with CNC spinning lathes.

- Medical Equipment: Cladding for medical instruments and specific sterile containers can be spun using CNC machines for precise shaping and consistent results.

In essence, CNC metal spinning machines combine the core principles of metal spinning with the precision and repeatability of computer control. This makes them a valuable tool for high-volume production of complex metal parts across various industries.

CNC Metal Spinning Lathe Application Areas

CNC metal spinning lathes are used in various industries due to their precision and versatility. Here are some common application areas:

- Aerospace Industry:

- Manufacturing of components such as nose cones, rocket motor cases, and other aerostructures.

- Production of satellite dishes and other communication equipment.

- Automotive Industry:

- Creation of vehicle parts like wheels, hubcaps, and reflectors.

- Manufacturing of exhaust components and other cylindrical parts.

- Lighting Industry:

- Production of light fixtures, reflectors, and other components used in lighting systems.

- Kitchenware and Cookware:

- Fabrication of pots, pans, and other cooking vessels.

- Creation of kitchen accessories like strainers and lids.

- HVAC Industry:

- Production of components for heating, ventilation, and air conditioning systems, such as ducts and cones.

- Medical Equipment:

- Manufacturing of medical device components, including surgical instruments and housings for medical devices.

- Industrial Machinery:

- Creation of parts for various types of machinery, including pulleys, hoppers, and tanks.

- Architectural Components:

- Fabrication of decorative elements like spires, domes, and other architectural details.

- Consumer Goods:

- Production of items like musical instruments, lamp bases, and various decorative objects.

CNC metal spinning lathes provide high precision and repeatability, making them suitable for producing complex shapes and components with tight tolerances in these industries.

CNC Metal Spinning Lathe Application Areas

A CNC metal spinning lathe is a sophisticated machine designed for precision metalworking. It consists of several key components, each serving a specific function. Here are the main parts of a CNC metal spinning lathe:

- Bed:

- The base of the lathe, providing stability and support for the entire machine.

- Headstock:

- Located at one end of the bed, it houses the main spindle and motor. The spindle holds the workpiece and rotates it during the machining process.

- Tailstock:

- Positioned on the opposite end of the headstock, it supports the other end of the workpiece, especially for longer pieces. It can be moved along the bed to accommodate different workpiece lengths.

- Spindle:

- The rotating axis that holds and spins the workpiece. It is driven by the motor and is crucial for the spinning process.

- Tool Post/Tool Turret:

- A structure that holds the cutting tools. In CNC lathes, this can be an automated turret that changes tools as needed during the machining process.

- Carriage:

- Moves along the bed and supports the cutting tools. It includes the cross slide and compound slide for precise control of tool movement.

- Cross Slide:

- Mounted on the carriage, it moves the cutting tool in and out, perpendicular to the workpiece axis.

- Compound Slide:

- Mounted on the cross slide, it allows angular adjustment of the cutting tool for precise machining operations.

- Control Panel/Controller:

- The interface where the operator programs and controls the CNC machine. It includes a computer system that interprets the CNC code and controls the lathe’s movements.

- Chuck:

- A clamping device that holds the workpiece securely on the spindle. It can be adjusted to fit different sizes and shapes of workpieces.

- Tailstock Quill:

- A part of the tailstock that can be moved in and out to accommodate the workpiece and provide additional support.

- Lead Screw:

- A long threaded rod that moves the carriage and cross slide along the bed. It is driven by the motor and ensures precise positioning of the cutting tool.

- Coolant System:

- A system that delivers coolant to the cutting area to reduce heat and friction, enhancing tool life and workpiece quality.

- Chip Pan:

- A tray or pan located at the base of the lathe to collect metal shavings (chips) produced during the machining process.

- Guarding/Safety Features:

- Protective covers and safety features to ensure the operator’s safety during operation.

These components work together to perform precise metal spinning operations, allowing the CNC metal spinning lathe to create complex shapes and parts with high accuracy and repeatability.

Article on Metal Spinning, Flow Forming, Shear Forming, and Wheel Forming Machines

Metal forming processes are integral to modern manufacturing, enabling the production of complex and precise components across various industries. Among these processes, metal spinning, flow forming, shear forming, and wheel forming stand out due to their unique methodologies and wide-ranging applications. Each process offers distinct advantages, making them suitable for different industrial requirements.

The importance of these metal forming techniques cannot be overstated, as they play a crucial role in the automotive, aerospace, military, and industrial sectors. From producing lightweight components for aircraft to manufacturing robust parts for automobiles, these processes contribute significantly to technological advancement and economic growth.

In this article, we will delve into the intricacies of metal spinning, flow forming, shear forming, and wheel forming machines. We will explore their principles, processes, machines, applications, advantages, and challenges. By understanding these processes, manufacturers and engineers can make informed decisions about the best techniques to employ for specific projects.

2. Metal Spinning

Principles and Process

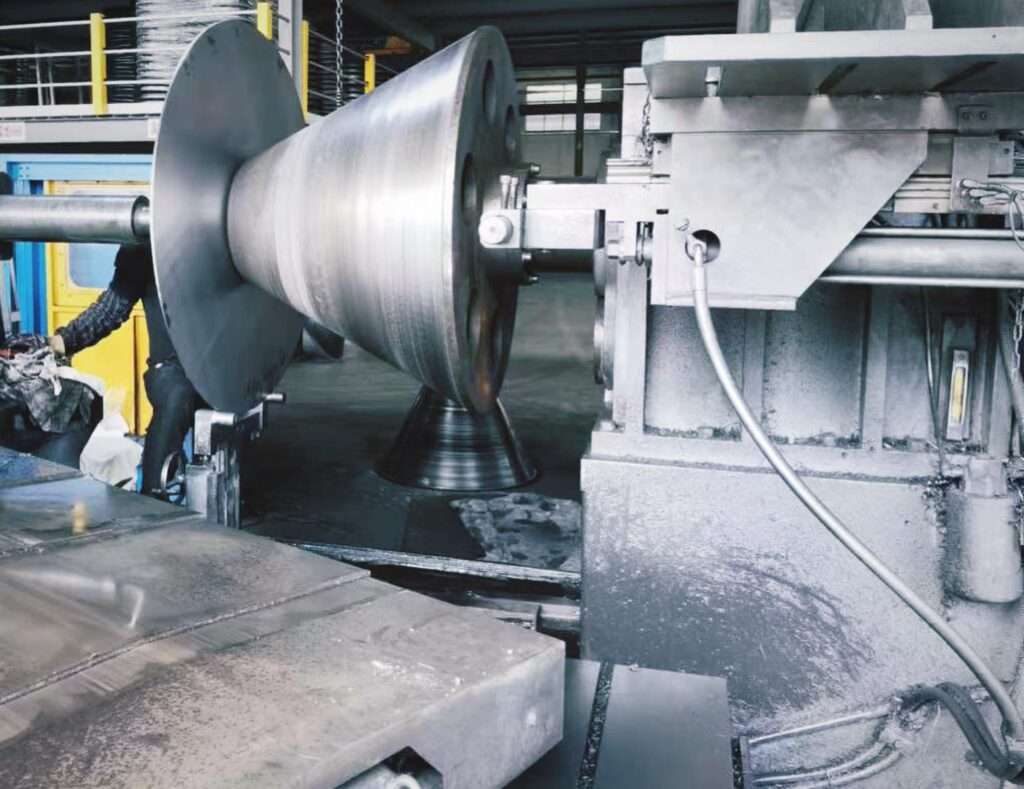

Metal spinning, also known as spin forming or spinning, is a metalworking process that forms a sheet or tube of metal into an axially symmetric part. This process involves rotating a metal disc or tube at high speed while applying pressure with a tool to shape the metal around a mandrel. The metal is stretched and compressed, resulting in a seamless, symmetrical shape.

Historically, metal spinning dates back to ancient Egypt, where artisans used simple tools to spin and shape metals. Today, it has evolved into a sophisticated process that utilizes advanced machinery and technology. Metal spinning is versatile and can be performed manually or using Computer Numerical Control (CNC) machines.

There are several types of metal spinning, including:

- Conventional spinning: Involves manually manipulating the metal using a lathe.

- CNC spinning: Utilizes computerized machines to automate the spinning process, allowing for greater precision and repeatability.

- Shear spinning: Similar to conventional spinning but involves thinning the metal as it is spun.

The basic steps in the metal spinning process are as follows:

- Preparation: The metal blank is cut to the desired size and shape.

- Mounting: The blank is mounted onto a spinning lathe or CNC machine.

- Rotation: The blank is spun at high speed.

- Forming: A tool is applied to the spinning blank, shaping it around the mandrel.

- Finishing: The final product is trimmed and polished to achieve the desired finish.

Machines and Equipment

Metal spinning machines vary in complexity, from simple manual lathes to advanced CNC machines. These machines are designed to provide precise control over the spinning process, ensuring consistent and high-quality results.

Key components of metal spinning machines include:

- Spindle: Rotates the metal blank at high speed.

- Mandrel: Provides a form around which the metal is shaped.

- Tooling system: Includes various tools for applying pressure and shaping the metal.

- Control system: Manages the speed, pressure, and movement of the tools.

Recent advancements in metal spinning machinery have focused on improving efficiency, precision, and automation. CNC machines have revolutionized the metal spinning industry by allowing for complex shapes and designs that were previously impossible to achieve manually. These machines offer enhanced control over the spinning process, reducing material waste and increasing productivity.

Applications

Metal spinning is used across a wide range of industries due to its versatility and ability to produce high-quality, seamless components. Some common applications include:

- Aerospace: Manufacturing lightweight components such as cones, nozzles, and housings for aircraft engines.

- Automotive: Producing parts like wheel rims, exhaust components, and decorative trims.

- HVAC: Creating ductwork, vent hoods, and other components for heating, ventilation, and air conditioning systems.

- Lighting: Fabricating reflectors, lamp bases, and other lighting fixtures.

- Kitchenware: Producing pots, pans, and other cookware.

The ability to create complex shapes with minimal material waste makes metal spinning an attractive option for manufacturers seeking to optimize production and reduce costs.

Advantages and Challenges

Advantages of metal spinning include:

- Cost-efficiency: Metal spinning requires minimal tooling compared to other forming processes, reducing production costs.

- Flexibility: The process can be used with various materials, including aluminum, steel, and copper.

- Seamless components: Metal spinning produces parts without seams or joints, enhancing their structural integrity.

- Customization: The ability to create complex shapes and designs allows for greater customization and innovation.

Despite its advantages, metal spinning also presents certain challenges:

- Limited to symmetrical shapes: Metal spinning is best suited for axially symmetric components, limiting its application for non-symmetrical parts.

- Material limitations: Certain materials may be difficult to spin, requiring specialized equipment and expertise.

- Skill requirement: Manual metal spinning requires skilled operators, although CNC machines have mitigated this challenge.

3. Flow Forming

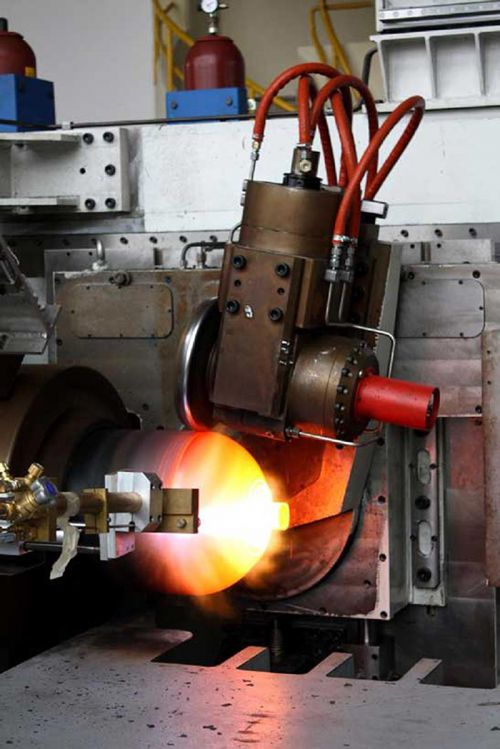

Flow forming, also known as rotary forming or flow turning, is an advanced metal forming process that transforms tubular blanks into precise, high-strength components. This process involves the controlled deformation of the metal blank, reducing its wall thickness and elongating its length.

Flow forming is distinct from other forming processes due to its ability to create thin-walled, seamless components with exceptional dimensional accuracy. The process is highly precise and allows for the creation of complex geometries and intricate designs.

The flow forming process consists of the following steps:

- Preparation: A tubular blank is cut to the desired length and pre-formed if necessary.

- Mounting: The blank is mounted onto a mandrel in a flow-forming machine.

- Rotation: The blank is rotated at high speed.

- Forming: Rollers apply pressure to the rotating blank, reducing its wall thickness and elongating its length.

- Finishing: The formed component is trimmed and finished to meet the desired specifications.

Flow forming can be performed using various methods, including:

- Forward flow forming: The rollers move in the same direction as the rotation of the blank, reducing the wall thickness and elongating the length.

- Reverse flow forming: The rollers move in the opposite direction of the blank’s rotation, allowing for greater control over the final shape.

- Tube spinning: Involves spinning the blank without altering its diameter, focusing on wall thickness reduction.

Machines and Equipment

Flow forming machines are highly specialized and designed to provide precise control over the forming process. These machines are equipped with advanced technology and automation capabilities to ensure consistent and high-quality results.

Key components of flow forming machines include:

- Spindle: Rotates the tubular blank at high speed.

- Mandrel: Provides support and shape for the forming process.

- Rollers: Apply controlled pressure to the blank, shaping it into the desired form.

- Control system: Manages the speed, pressure, and movement of the rollers, ensuring precision and accuracy.

Technological advancements in flow forming machinery have focused on improving automation, reducing material waste, and enhancing process control. Modern flow-forming machines utilize CNC technology to achieve precise and repeatable results, reducing the need for manual intervention and increasing productivity.

Applications

Flow forming is widely used in industries that require high-precision, thin-walled components. Some specific applications include:

- Aerospace: Manufacturing aircraft engine components, such as compressor cases and fan housings.

- Automotive: Producing lightweight, high-strength parts like drive shafts and wheel rims.

- Military: Creating artillery shells, missile casings, and other defense-related components.

- Industrial: Fabricating components for machinery and equipment, such as pump housings and pressure vessels.

The ability to produce components with tight tolerances and exceptional strength makes flow forming an ideal choice for industries that demand high-performance parts.

Advantages and Challenges

Advantages of flow forming include:

- Dimensional accuracy: Flow forming achieves tight tolerances and precise dimensions, ensuring high-quality components.

- Material efficiency: The process reduces material waste by minimizing the need for additional machining or finishing.

- Strength and durability: Flow-formed components exhibit enhanced mechanical properties, including increased strength and fatigue resistance.

- Design flexibility: The ability to create complex shapes and intricate designs allows for greater innovation and customization.

Despite its advantages, flow forming also presents certain challenges:

- Initial setup cost: Flow forming machines are specialized and can be expensive to purchase and maintain.

- Material limitations: Certain materials may be difficult to flow form, requiring specialized equipment and expertise.

- Process complexity: The process requires careful control and monitoring to achieve the desired results, necessitating skilled operators and advanced technology.

4. Shear Forming

Shear forming, also known as shear spinning, is a metal forming process that produces axisymmetric components by reducing the wall thickness of a blank while maintaining its diameter. This process is similar to conventional spinning but involves a shearing action that allows for greater control over the final shape and thickness of the component.

Shear forming is distinct from flow forming in that it focuses on altering the thickness of the blank while maintaining its diameter. This process is highly versatile and can be used to create a wide range of components with varying shapes and sizes.

The shear forming process consists of the following steps:

- Preparation: A blank is cut to the desired size and shape.

- Mounting: The blank is mounted onto a mandrel in a shear-forming machine.

- Rotation: The blank is rotated at high speed.

- Forming: A tool applies pressure to the rotating blank, reducing its wall thickness and shaping it into the desired form.

- Finishing: The formed component is trimmed and finished to meet the desired specifications.

Machines and Equipment

Shear forming machines are designed to provide precise control over the forming process, ensuring consistent and high-quality results. These machines are equipped with advanced technology and automation capabilities to optimize the shear-forming process.

Key components of shear forming machines include:

- Spindle: Rotates the blank at high speed.

- Mandrel: Provides support and shape for the forming process.

- Tooling system: Includes various tools for applying pressure and shaping the metal.

- Control system: Manages the speed, pressure, and movement of the tools, ensuring precision and accuracy.

Innovations in shear-forming technology have focused on improving process control, reducing material waste, and enhancing automation. Modern shear-forming machines utilize CNC technology to achieve precise and repeatable results, reducing the need for manual intervention and increasing productivity.

Applications

Shear forming is used in a wide range of industries due to its versatility and ability to produce high-quality, axisymmetric components. Some specific applications include:

- Aerospace: Manufacturing components such as turbine disks, flanges, and structural parts.

- Automotive: Producing parts like pulleys, hubs, and other rotational components.

- Industrial: Fabricating components for machinery and equipment, such as pump housings and pressure vessels.

- Medical: Creating components for medical devices and equipment, such as surgical instruments and implants.

The ability to create components with varying thicknesses and complex shapes makes shear forming an attractive option for manufacturers seeking to optimize production and reduce costs.

Advantages and Challenges

Advantages of shear forming include:

- Material efficiency: The process reduces material waste by minimizing the need for additional machining or finishing.

- Design flexibility: The ability to create complex shapes and varying thicknesses allows for greater innovation and customization.

- Strength and durability: Shear-formed components exhibit enhanced mechanical properties, including increased strength and fatigue resistance.

- Cost-effectiveness: Shear forming requires minimal tooling compared to other forming processes, reducing production costs.

Despite its advantages, shear forming also presents certain challenges:

- Limited to axisymmetric shapes: Shear forming is best suited for components with rotational symmetry, limiting its application for non-symmetrical parts.

- Material limitations: Certain materials may be difficult to shear form, requiring specialized equipment and expertise.

- Process complexity: The process requires careful control and monitoring to achieve the desired results, necessitating skilled operators and advanced technology.

5. Wheel Forming

Wheel forming is a specialized metal forming process used to produce wheels for various applications, particularly in the automotive and aerospace industries. This process involves shaping a metal blank into a wheel by applying pressure and force through a series of rollers or dies.

Wheel forming is distinct from other metal forming processes due to its focus on creating wheels and other rotational components. The process is highly efficient and allows for the production of lightweight, high-strength wheels with complex geometries.

The wheel-forming process consists of the following steps:

- Preparation: A metal blank is cut to the desired size and shape.

- Mounting: The blank is mounted onto a wheel-forming machine.

- Rotation: The blank is rotated at high speed.

- Forming: Rollers or dies apply pressure to the rotating blank, shaping it into the desired wheel form.

- Finishing: The formed wheel is trimmed and finished to meet the desired specifications.

Machines and Equipment

Wheel forming machines are highly specialized and designed to provide precise control over the forming process. These machines are equipped with advanced technology and automation capabilities to ensure consistent and high-quality results.

Key components of wheel forming machines include:

- Spindle: Rotates the blank at high speed.

- Mandrel: Provides support and shape for the forming process.

- Rollers or dies: Apply controlled pressure to the blank, shaping it into the desired wheel form.

- Control system: Manages the speed, pressure, and movement of the rollers or dies, ensuring precision and accuracy.

Recent advancements in wheel-forming technology have focused on improving automation, reducing material waste, and enhancing process control. Modern wheel-forming machines utilize CNC technology to achieve precise and repeatable results, reducing the need for manual intervention and increasing productivity.

Applications

Wheel forming is widely used in industries that require high-quality, lightweight wheels and rotational components. Some specific applications include:

- Automotive: Manufacturing wheels for cars, trucks, and motorcycles.

- Aerospace: Producing wheels for aircraft landing gear and other rotational components.

- Industrial: Fabricating wheels for machinery and equipment, such as conveyor systems and transport vehicles.

- Consumer goods: Creating wheels for bicycles, skateboards, and other consumer products.

The ability to produce wheels with tight tolerances and exceptional strength makes wheel forming an ideal choice for industries that demand high-performance rotational components.

Advantages and Challenges

Advantages of wheel forming include:

- Lightweight and high strength: Wheel-forming produces lightweight wheels with exceptional strength and durability.

- Dimensional accuracy: The process achieves tight tolerances and precise dimensions, ensuring high-quality wheels.

- Material efficiency: Wheel forming reduces material waste by minimizing the need for additional machining or finishing.

- Design flexibility: The ability to create complex geometries and intricate designs allows for greater innovation and customization.

Despite its advantages, wheel forming also presents certain challenges:

- Initial setup cost: Wheel forming machines are specialized and can be expensive to purchase and maintain.

- Material limitations: Certain materials may be difficult to wheel form, requiring specialized equipment and expertise.

- Process complexity: The process requires careful control and monitoring to achieve the desired results, necessitating skilled operators and advanced technology.

6. Comparative Analysis

In this section, we will compare metal spinning, flow forming, shear forming, and wheel forming processes to understand their differences, advantages, and suitability for various applications.

Comparison of Processes:

- Metal Spinning vs. Flow Forming: Metal spinning focuses on forming axially symmetric parts by rotating a blank around a mandrel, while flow forming involves reducing the wall thickness of a tubular blank through controlled deformation. Flow forming is more suitable for thin-walled, high-precision components, while metal spinning is ideal for larger, symmetrical parts.

- Shear Forming vs. Flow Forming: Shear forming and flow forming both involve reducing the wall thickness of a blank, but shear forming maintains the blank’s diameter, whereas flow forming can elongate the blank. Shear forming is preferred for components with varying thicknesses, while flow forming is used for high-precision, thin-walled parts.

- Wheel Forming vs. Other Processes: Wheel forming is specifically designed for creating wheels and rotational components, making it unique among the other processes. It offers advantages in producing lightweight, high-strength wheels with complex geometries, but is limited to wheel and rotational component applications.

Suitability for Different Applications:

- Aerospace: Flow forming and shear forming are highly suitable for aerospace applications due to their ability to produce high-precision, lightweight components with enhanced mechanical properties.

- Automotive: Metal spinning and wheel forming are commonly used in the automotive industry for manufacturing wheels, exhaust components, and decorative trims.

- Industrial: All four processes are utilized in various industrial applications, depending on the specific requirements of the components being produced.

- Consumer Goods: Metal spinning and wheel forming are popular choices for producing consumer goods, such as cookware, lighting fixtures, and wheels for bicycles and skateboards.

Technical and Economic Considerations:

- Material Costs: Metal spinning and shear forming require minimal tooling and have lower material costs, making them cost-effective options for certain applications.

- Process Complexity: Flow forming and wheel forming involve more complex processes and require advanced technology, resulting in higher initial setup costs but offering greater precision and quality.

- Production Volume: Metal spinning and wheel forming are suitable for both low and high-volume production, while flow forming and shear forming are more efficient for high-volume production due to their precision and automation capabilities.

7. Future Trends and Developments

The metal forming industry is constantly evolving, with new technologies and innovations shaping the future of metal spinning, flow forming, shear forming, and wheel forming processes. Some emerging trends and developments include:

- Additive Manufacturing Integration: Combining traditional metal forming processes with additive manufacturing techniques to create complex components with enhanced properties and reduced material waste.

- Automation and Industry 4.0: Increasing automation and the adoption of Industry 4.0 technologies, such as IoT and AI, to improve process control, efficiency, and productivity in metal forming operations.

- Advanced Materials: The development of new materials and alloys that are more suitable for metal forming processes, allowing for greater innovation and customization.

- Sustainability and Environmental Impact: Focus on reducing the environmental impact of metal forming processes through energy-efficient machinery and sustainable material sourcing.

As these trends continue to evolve, metal spinning, flow forming, shear forming, and wheel forming processes will play an increasingly important role in manufacturing, driving innovation and efficiency across various industries.

8. Conclusion

Metal spinning, flow forming, shear forming, and wheel forming are essential metal forming processes that offer unique advantages and capabilities for producing high-quality, precise components across various industries. Each process has its strengths and challenges, making them suitable for different applications and requirements.

By understanding the principles, machines, applications, and advantages of these processes, manufacturers and engineers can make informed decisions about the best techniques to employ for specific projects. As the metal forming industry continues to evolve, these processes will play a crucial role in driving innovation, efficiency, and sustainability in manufacturing.

Choosing the right materials for metal forming processes such as metal spinning, flow forming, shear forming, and wheel forming is crucial for achieving desired product characteristics, performance, and quality. Each process has specific material requirements based on the mechanical properties, formability, and intended application. Here’s an overview of recommended materials for each process:

Metal Spinning

Metal spinning is a versatile process that can work with a variety of metals. Key material properties to consider include ductility, malleability, and tensile strength. Here are some commonly used materials in metal spinning:

- Aluminum and Aluminum Alloys

- Properties: Lightweight, corrosion-resistant, good thermal and electrical conductivity.

- Applications: Aerospace components, automotive parts, cookware, and decorative items.

- Stainless Steel

- Properties: High corrosion resistance, strength, and durability.

- Applications: Food processing equipment, medical devices, and architectural components.

- Copper and Copper Alloys

- Properties: Excellent thermal and electrical conductivity, corrosion resistance, and antimicrobial properties.

- Applications: Lighting fixtures, electrical components, and decorative items.

- Brass and Bronze

- Properties: Corrosion resistance, electrical conductivity, and aesthetic appeal.

- Applications: Musical instruments, plumbing components, and decorative items.

- Carbon and Low-Alloy Steels

- Properties: High strength and durability.

- Applications: Automotive components, industrial machinery, and construction parts.

- Titanium and Titanium Alloys

- Properties: High strength-to-weight ratio, corrosion resistance, and biocompatibility.

- Applications: Aerospace components, medical implants, and sports equipment.

Flow Forming

Flow forming is ideal for materials that require high strength, precision, and reduced weight. Materials should exhibit good ductility and work hardening properties. Recommended materials for flow forming include:

- Aluminum Alloys

- Properties: Lightweight, corrosion-resistant, and high formability.

- Applications: Aerospace components, automotive parts, and military applications.

- High-Strength Low-Alloy (HSLA) Steels

- Properties: Enhanced mechanical properties and good formability.

- Applications: Automotive components, structural parts, and pressure vessels.

- Stainless Steel

- Properties: Corrosion resistance, strength, and durability.

- Applications: Aerospace and defense components, medical devices, and industrial equipment.

- Nickel and Nickel Alloys

- Properties: High-temperature resistance, corrosion resistance, and strength.

- Applications: Aerospace components, gas turbine engines, and chemical processing equipment.

- Titanium Alloys

- Properties: High strength-to-weight ratio, corrosion resistance, and biocompatibility.

- Applications: Aerospace components, medical implants, and military applications.

Shear Forming

Shear forming is suitable for materials with good ductility and shear formability. This process is often used for producing components with varying thicknesses. Recommended materials include:

- Aluminum and Aluminum Alloys

- Properties: Lightweight, corrosion-resistant, and good formability.

- Applications: Aerospace components, automotive parts, and consumer goods.

- Stainless Steel

- Properties: Corrosion resistance, strength, and durability.

- Applications: Industrial equipment, medical devices, and structural components.

- Carbon and Low-Alloy Steels

- Properties: High strength and wear resistance.

- Applications: Automotive components, machinery parts, and construction materials.

- Copper and Copper Alloys

- Properties: Good thermal and electrical conductivity, corrosion resistance.

- Applications: Electrical components, plumbing fixtures, and decorative items.

- Titanium and Titanium Alloys

- Properties: High strength-to-weight ratio and corrosion resistance.

- Applications: Aerospace components, medical devices, and sports equipment.

Wheel Forming

Wheel forming is used to create wheels and other rotational components, requiring materials with high strength and fatigue resistance. Recommended materials for wheel forming include:

- Aluminum Alloys

- Properties: Lightweight, corrosion-resistant, and high strength.

- Applications: Automotive wheels, aerospace components, and bicycle wheels.

- Magnesium Alloys

- Properties: Lightweight, good damping properties, and machinability.

- Applications: Automotive wheels, aerospace components, and electronics casings.

- Stainless Steel

- Properties: Corrosion resistance, strength, and durability.

- Applications: Heavy-duty industrial wheels, transportation equipment, and marine applications.

- Carbon and Low-Alloy Steels

- Properties: High strength, wear resistance, and durability.

- Applications: Heavy-duty automotive wheels, industrial machinery, and construction equipment.

- Titanium Alloys

- Properties: High strength-to-weight ratio, corrosion resistance, and fatigue resistance.

- Applications: Aerospace wheels, high-performance automotive wheels, and sports equipment.

Factors to Consider When Selecting Materials

When choosing materials for metal forming processes, several factors should be considered:

- Mechanical Properties: Ensure the material has the required strength, ductility, and toughness for the specific application.

- Formability: Consider the material’s ability to be formed without cracking or defects, as well as its work hardening characteristics.

- Corrosion Resistance: Select materials that can withstand the operating environment, especially for applications exposed to harsh conditions.

- Cost and Availability: Evaluate the cost-effectiveness and availability of the material, considering both short-term and long-term production needs.

- Application Requirements: Consider the specific requirements of the application, such as weight, thermal conductivity, electrical conductivity, and aesthetic appeal.

- Sustainability: Evaluate the environmental impact of the material and consider options that align with sustainability goals.

By carefully selecting the appropriate materials, manufacturers can optimize the metal forming process, reduce costs, and ensure high-quality, reliable components. If you need more detailed information or have specific applications in mind, feel free to ask!

Metal Spinning Machine Components

The components of machines used in metal forming processes such as metal spinning, flow forming, shear forming, and wheel forming are designed to deliver precise control and high-quality production. Each machine type is equipped with specialized parts that cater to the unique demands of the specific forming process. Below is an overview of the key components for each machine type, explaining their functions and significance.

Metal spinning machines range from manual lathes to advanced CNC-controlled systems. The fundamental components of a metal spinning machine include:

- Spindle:

- Function: The spindle is the rotating axis of the machine that holds and spins the metal blank at high speeds. It is crucial for maintaining balance and precision during the spinning process.

- Significance: Ensures consistent rotation speed and stability, allowing for uniform metal forming.

- Chuck or Mandrel:

- Function: Holds the metal blank in place and serves as the shaping mold for the final product. The mandrel determines the shape of the spun piece.

- Significance: Provides support and defines the final geometry of the component.

- Tailstock:

- Function: Supports the other end of the workpiece opposite the spindle, preventing wobble and maintaining alignment during spinning.

- Significance: Ensures stability and precision by supporting the blank throughout the process.

- Tool Rest and Tools:

- Function: The tool rest supports various forming tools, which are used to apply pressure and shape the metal as it spins.

- Types of Tools: Rollers, spoons, and other custom tools can be used depending on the desired shape and complexity of the component.

- Significance: Allows the operator or CNC program to apply pressure precisely and control the forming process.

- Bed:

- Function: The foundation that supports the entire machine structure, providing a stable platform for all operations.

- Significance: Ensures the rigidity and stability necessary for high-precision metal spinning.

- Control System:

- Function: Manages machine operations, including spindle speed, tool position, and pressure. In CNC machines, this includes programming capabilities for automated and complex spinning tasks.

- Significance: Provides precise control over the spinning process, enabling complex shapes and repeatable operations.

- Drive System:

- Function: Powers the spindle and other moving parts of the machine. This can include motors, belts, and gears.

- Significance: Ensures consistent power delivery and control over the machine’s movements.

Flow Forming Machine Components

Flow forming machines are highly specialized and designed to produce thin-walled components with precision. Key components include:

- Spindle and Chuck:

- Function: Similar to metal spinning, the spindle rotates the blank at high speed while the chuck securely holds it in place.

- Significance: Provides stability and precision necessary for reducing wall thickness accurately.

- Mandrel:

- Function: Serves as the internal form around which the blank is shaped. It supports the workpiece during the forming process.

- Significance: Defines the internal dimensions and helps achieve the desired wall thickness.

- Rollers:

- Function: The primary forming tools that apply pressure to the rotating blank, reducing its wall thickness and elongating it.

- Types of Rollers: Can be single or multiple rollers depending on the process and desired outcomes.

- Significance: Enables controlled deformation of the material, achieving precise dimensions and properties.

- Tool Post:

- Function: Holds the rollers and positions them for precise contact with the workpiece. Can adjust roller position and pressure.

- Significance: Allows fine control of the forming process, ensuring consistency and accuracy.

- Tailstock:

- Function: Supports the opposite end of the workpiece, ensuring it remains aligned and stable during forming.

- Significance: Provides additional support, especially for longer components.

- Control System:

- Function: Oversees the machine’s operations, controlling spindle speed, roller position, and pressure. In CNC machines, it handles complex forming paths and sequences.

- Significance: Provides automation and precision control, essential for high-quality production.

- Drive System:

- Function: Powers the spindle and rollers, using motors and gearing systems to deliver the necessary force and speed.

- Significance: Ensures consistent operation and control over the forming process.

- Cooling System:

- Function: Manages heat generated during the forming process, often using cooling fluids to prevent overheating.

- Significance: Maintains material properties and prevents machine wear by dissipating heat.

Shear Forming Machine Components

Shear forming machines share similarities with both metal spinning and flow forming machines but have specific components tailored to the shearing action:

- Spindle:

- Function: Rotates the blank at high speed, providing the necessary force for shearing.

- Significance: Ensures consistent rotation for uniform wall thickness reduction.

- Mandrel:

- Function: Supports the workpiece and defines its internal shape. It may also help control wall thickness.

- Significance: Critical for achieving the desired internal dimensions and structural integrity.

- Shear Tools:

- Function: Specialized tools that apply localized pressure, shearing the metal and reducing wall thickness while maintaining diameter.

- Significance: Enables the unique thinning characteristic of shear forming, allowing for complex component profiles.

- Tool Post:

- Function: Positions and supports shear tools, allowing precise adjustments for pressure and angle.

- Significance: Provides control over the shearing process, enabling accurate and consistent results.

- Tailstock:

- Function: Provides support for the workpiece opposite the spindle, ensuring stability and alignment.

- Significance: Ensures component stability and precision throughout the forming process.

- Control System:

- Function: Manages machine operations, controlling tool position, spindle speed, and shearing pressure. CNC systems allow for complex and automated operations.

- Significance: Enables precision and repeatability, crucial for producing high-quality components.

- Drive System:

- Function: Powers the spindle and shear tools, using motors, belts, and gears to control speed and force.

- Significance: Delivers consistent power for effective shearing and forming.

- Cooling and Lubrication System:

- Function: Manages heat and friction during forming, using fluids to cool and lubricate the workpiece and tools.

- Significance: Reduces wear, maintains material properties, and improves tool life.

Wheel Forming Machine Components

Wheel forming machines are specifically designed to produce wheels and other rotational components. Key components include:

- Spindle and Chuck:

- Function: Rotates the wheel blank at high speed, securing it in place for forming.

- Significance: Provides stability and precision, ensuring uniform wheel formation.

- Rollers or Dies:

- Function: Form the wheel by applying pressure to the rotating blank, shaping it into the desired wheel profile.

- Types of Dies: May include pre-forming and finishing dies for different stages of the process.

- Significance: Enables precise shaping of the wheel, achieving complex geometries and high strength.

- Mandrel:

- Function: Supports the blank and defines the internal geometry of the wheel.

- Significance: Ensures accurate internal dimensions and structural integrity.

- Tool Post:

- Function: Holds and positions rollers or dies, allowing for precise adjustments during the forming process.

- Significance: Provides control over the forming process, ensuring consistency and accuracy.

- Control System:

- Function: Manages machine operations, controlling spindle speed, die position, and pressure. CNC systems provide automation and precision.

- Significance: Ensures high-quality production with repeatable results.

- Drive System:

- Function: Powers the spindle and rollers/dies, delivering the necessary force and speed for forming.