A centerless grinding and polishing machine is a specialized tool used in manufacturing processes to grind and polish cylindrical workpieces without the need for a center point. This type of machine is particularly useful for achieving precise finishes on long, slender parts such as shafts, rods, and tubes.

Here’s how it typically works:

- Loading: The workpiece is loaded onto a support blade and a regulating wheel. The support blade and regulating wheel are set at a slight angle relative to each other, which causes the workpiece to rotate as it passes through the grinding area.

- Grinding: As the workpiece rotates, it encounters the grinding wheel, which is positioned above it. The grinding wheel applies force against the workpiece, removing material to achieve the desired diameter and surface finish. The regulating wheel, positioned opposite the grinding wheel, controls the rotational speed of the workpiece and ensures a consistent feed rate.

- Polishing: After the grinding process, if a polished finish is desired, additional polishing steps may be performed. This can involve using abrasive belts, wheels, or compounds to refine the surface finish further.

- Measuring and Quality Control: Throughout the process, measurements are taken to ensure that the workpiece meets the required specifications for diameter, roundness, and surface finish. This may involve using precision instruments such as micrometers and profilometers.

Centerless grinding and polishing machines offer several advantages over traditional grinding methods:

- High Precision: They can achieve extremely tight tolerances and consistent surface finishes.

- High Production Rates: They can process large volumes of workpieces quickly and efficiently.

- Versatility: They can handle a wide range of materials and part geometries.

- Reduced Setup Time: Because they don’t require centering or alignment of the workpiece, setup time is minimized.

- Cost Efficiency: They can reduce labor costs and material waste compared to traditional grinding methods.

These machines are commonly used in industries such as automotive, aerospace, medical device manufacturing, and precision engineering, where tight tolerances and high-quality surface finishes are essential.

Centerless Grinding and Polishing

Centerless grinding and polishing represent cutting-edge processes in the realm of precision machining, offering unparalleled accuracy and surface finish for cylindrical workpieces. Leveraging advanced machinery and meticulous techniques, these methods have revolutionized manufacturing across various industries, from automotive to aerospace, by delivering components with impeccable quality and dimensional precision.

At the heart of centerless grinding and polishing lies the principle of eliminating the need for a central axis or center point to secure the workpiece, thereby allowing for the processing of long, slender shafts, rods, and tubes with unmatched efficiency and consistency. This methodology hinges on three fundamental components: the grinding wheel, the regulating wheel, and the workrest blade.

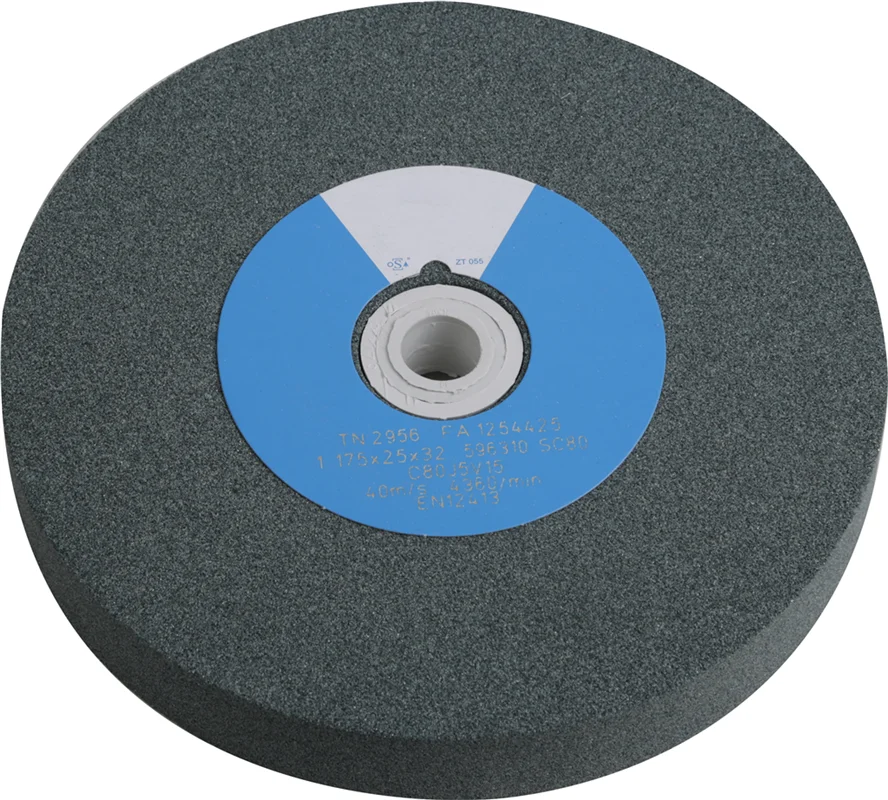

The grinding wheel, typically composed of abrasive grains bonded together, serves as the primary tool for material removal. Positioned above the workpiece, it imparts controlled force to precisely grind away excess material, shaping the cylindrical surface to the desired dimensions. The selection of abrasive grains and bonding materials is tailored to the specific requirements of each application, ensuring optimal cutting performance and surface finish.

Complementing the grinding wheel is the regulating wheel, situated opposite the grinding wheel and inclined at a slight angle. This wheel governs the rotational speed of the workpiece, dictating its linear feed rate through the grinding zone. By synchronizing the rotational velocities of the grinding and regulating wheels, manufacturers can maintain consistent stock removal rates and prevent irregularities in the finished product.

Crucial to the stability and support of the workpiece during processing is the workrest blade, which acts as a foundation upon which the cylindrical object rests. Positioned between the grinding and regulating wheels, this blade facilitates the smooth passage of the workpiece through the grinding zone, minimizing vibrations and deflections that could compromise dimensional accuracy and surface finish. Furthermore, the workrest blade aids in controlling the lateral position and alignment of the workpiece, ensuring uniformity across multiple machining passes.

The centerless grinding and polishing process unfolds in a meticulously orchestrated sequence of steps, beginning with the loading of the workpiece onto the support blade and regulating wheel. As the workpiece rotates, it encounters the abrasive action of the grinding wheel, gradually reducing its diameter and refining its surface texture to meet the specified tolerances. Simultaneously, the regulating wheel exerts precise control over the workpiece’s rotational speed, ensuring a consistent feed rate and uniform material removal.

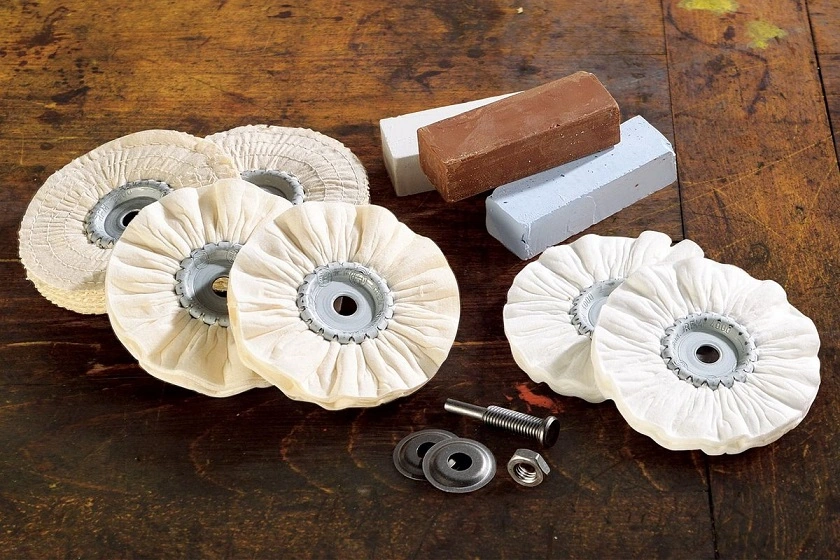

Upon completion of the grinding phase, additional polishing steps may be employed to further enhance the surface finish and aesthetic appearance of the workpiece. This may involve the use of specialized abrasive belts, wheels, or compounds, tailored to achieve the desired level of gloss and smoothness. Through meticulous attention to detail and rigorous quality control measures, manufacturers can achieve superior surface finishes that meet the most demanding standards of excellence.

In conclusion, centerless grinding and polishing represent the pinnacle of precision machining, offering unparalleled accuracy, efficiency, and surface finish for cylindrical workpieces. By harnessing the synergy between advanced machinery, meticulous techniques, and rigorous quality control, manufacturers can produce components of exceptional quality and dimensional precision, driving innovation and excellence across a myriad of industries.

Grinding

Grinding, an essential process in manufacturing and metalworking industries, encompasses a vast array of techniques and methodologies aimed at shaping, finishing, and refining workpieces to exacting specifications. From coarse stock removal to micron-level precision, grinding techniques have evolved to meet the diverse needs of modern industry, enabling the production of components with unparalleled accuracy and surface quality.

At its core, grinding involves the removal of material from a workpiece using abrasive grains bonded together in various configurations. These abrasive grains, typically made of aluminum oxide, silicon carbide, or diamond, are available in a multitude of shapes, sizes, and hardness levels, allowing for precise customization based on the application requirements.

The grinding process is executed through the interaction between the abrasive grains and the workpiece surface under controlled conditions of pressure, speed, and coolant application. Whether performed manually or with the aid of computer-controlled machinery, grinding operations can be broadly categorized into several key techniques:

- Surface Grinding: Widely employed for producing flat surfaces on workpieces, surface grinding utilizes a horizontal grinding wheel to remove material in a reciprocating or rotary fashion. This method is ideal for achieving tight dimensional tolerances and smooth surface finishes on large or irregularly shaped components.

- Cylindrical Grinding: Primarily used for machining cylindrical workpieces, cylindrical grinding involves the rotation of a cylindrical grinding wheel against the outer surface of the workpiece. This technique is renowned for its ability to produce precise cylindrical shapes, concentricity, and surface finishes, making it indispensable in the production of shafts, rods, and bearings.

- Centerless Grinding: Distinctive for its elimination of the need for a centering mechanism, centerless grinding excels at processing long, slender workpieces with minimal setup requirements. By positioning the workpiece between a grinding wheel and a regulating wheel, this method enables high-precision grinding of cylindrical components while maintaining consistent dimensional accuracy and surface finish.

- Internal Grinding: Tailored for machining internal surfaces, bores, and cavities within workpieces, internal grinding employs specialized grinding wheels or mounted points to access confined spaces. This technique is indispensable for producing precise internal features with tight tolerances and surface finish requirements, such as those found in automotive engine components and hydraulic cylinders.

- Thread Grinding: Dedicated to producing precision threads on cylindrical workpieces, thread grinding utilizes specialized grinding wheels with profiled surfaces to generate accurate thread forms. This method offers superior control over thread pitch, lead, and flank geometry, ensuring optimal functionality and compatibility in threaded assemblies.

In addition to these primary grinding techniques, various specialized methods, including creep feed grinding, form grinding, and gear grinding, cater to specific applications with unique geometric or surface finish requirements.

Throughout the grinding process, effective coolant application plays a critical role in dissipating heat, lubricating the grinding interface, and flushing away swarf and debris to prevent thermal damage and maintain grinding performance. Moreover, meticulous attention to machine setup, workpiece fixturing, and grinding parameters is essential to achieving consistent results and minimizing dimensional variations.

In conclusion, grinding stands as a cornerstone of modern manufacturing, offering a versatile suite of techniques for shaping, finishing, and refining workpieces to exacting standards. By leveraging advanced abrasive materials, precision machinery, and meticulous process control, manufacturers can realize the full potential of grinding in producing components with exceptional accuracy, surface quality, and performance across a myriad of industries.

Polishing

Polishing, a pivotal step in surface finishing and refinement, represents a sophisticated suite of techniques aimed at enhancing the appearance, texture, and performance of workpieces across diverse industries. From achieving mirror-like gloss on metallic components to smoothing rough surfaces on optical lenses, polishing methodologies have evolved to meet the exacting demands of modern manufacturing and craftsmanship.

At its essence, polishing involves the systematic removal of surface imperfections, scratches, and irregularities through the application of abrasive materials and specialized polishing compounds. Unlike grinding, which primarily focuses on material removal, polishing aims to create a smooth, defect-free surface with a high degree of luster and clarity.

The polishing process encompasses several key techniques, each tailored to specific materials, surface characteristics, and finishing requirements:

- Mechanical Polishing: The most traditional form of polishing, mechanical polishing relies on the mechanical action of abrasive particles suspended in polishing compounds or slurries to abrade the workpiece surface. This method is commonly used for achieving high-gloss finishes on metals, plastics, and composites, leveraging rotating buffing wheels, abrasive belts, or hand-held tools to impart a smooth, reflective surface.

- Chemical Polishing: Chemical polishing, also known as electrochemical polishing or chemical-mechanical polishing (CMP), involves the use of chemical solutions to selectively dissolve surface irregularities and promote material removal. This technique is particularly effective for polishing intricate geometries, delicate components, and semiconductor wafers, where mechanical polishing may be impractical or detrimental to the workpiece.

- Electrochemical Polishing: In electrochemical polishing, an electrolytic cell is utilized to facilitate the controlled dissolution of surface imperfections through electrochemical reactions. By applying an electrical current between the workpiece and an electrode immersed in an electrolyte solution, metal ions are selectively removed from the surface, resulting in improved surface smoothness and microstructure refinement.

- Abrasive Polishing: Abrasive polishing involves the use of abrasive materials, such as diamond paste, alumina, or silica, to achieve precise surface finishes through controlled material removal. This method is commonly employed in conjunction with mechanical or chemical polishing techniques to enhance surface flatness, remove subsurface damage, and achieve submicron-level roughness.

- Laser Polishing: Leveraging the intense energy of laser beams, laser polishing offers a non-contact, highly localized method for surface refinement. By precisely controlling the laser parameters, such as power, pulse duration, and spot size, manufacturers can selectively melt and resolidify surface layers, reducing roughness and eliminating defects with minimal material removal.

Throughout the polishing process, meticulous attention to surface preparation, polishing media selection, and process parameters is paramount to achieving consistent results and meeting stringent quality standards. Moreover, the integration of advanced metrology techniques, such as profilometry and interferometry, enables precise measurement and characterization of surface finish, ensuring compliance with exacting specifications.

In conclusion, polishing stands as a cornerstone of surface finishing and refinement, offering a diverse array of techniques for enhancing the appearance, texture, and functionality of workpieces across numerous industries. By harnessing the synergy between advanced abrasive materials, precision machinery, and sophisticated process control, manufacturers can realize the full potential of polishing in delivering components with superior aesthetics, performance, and durability.

Surface Grinding

Surface grinding is a fundamental machining process used to produce flat surfaces on workpieces with high precision and surface quality. It involves the removal of material from the surface of a workpiece using a rotating abrasive wheel, known as a grinding wheel. This process is widely employed in various industries, including automotive, aerospace, tool and die making, and general manufacturing, where flatness and surface finish are critical requirements.

The surface grinding process typically involves the following steps:

- Workpiece Preparation: Before surface grinding, the workpiece must be securely mounted on the grinding machine’s worktable or magnetic chuck. The workpiece should be cleaned of any contaminants and accurately positioned for machining.

- Grinding Wheel Selection: Choosing the appropriate grinding wheel is crucial to achieving the desired surface finish and dimensional accuracy. Factors such as abrasive type, grit size, bond type, and wheel hardness are carefully considered based on the material being ground, surface finish requirements, and machining conditions.

- Machine Setup: The grinding machine is set up to ensure proper alignment of the grinding wheel and workpiece. This includes adjusting the wheel’s position, speed, and feed rate, as well as ensuring adequate coolant flow to prevent overheating and maintain grinding performance.

- Grinding Operation: Once the machine is set up, the grinding operation begins. The grinding wheel is brought into contact with the workpiece surface, and material is removed through the combined action of abrasive particles and cutting forces. The grinding wheel traverses back and forth across the workpiece surface, gradually removing material to achieve the desired flatness and surface finish.

- Feed Control: During the grinding process, the feed rate of the grinding wheel across the workpiece surface is carefully controlled to maintain consistent material removal and prevent surface irregularities. This is typically achieved through precise adjustment of the machine’s feed mechanism or CNC programming for automated grinding operations.

- Coolant Application: Coolant is often applied during surface grinding to lubricate the grinding wheel-workpiece interface, dissipate heat, and flush away swarf and debris. Proper coolant selection and application help minimize thermal distortion, improve surface finish, and extend the life of the grinding wheel.

- Finishing Passes: Depending on the desired surface finish and dimensional accuracy, multiple grinding passes may be required to achieve the final result. Finer grit grinding wheels or special finishing techniques, such as spark-out grinding, may be used in the final passes to refine surface roughness and remove any remaining surface imperfections.

- Quality Inspection: After grinding, the workpiece undergoes thorough inspection to verify dimensional accuracy, surface finish, and other critical parameters. This may involve using precision measuring instruments, such as micrometers, surface profilometers, or optical comparators, to ensure that the finished part meets the specified tolerances and quality standards.

In summary, surface grinding is a versatile and precise machining process used to produce flat surfaces with high accuracy and surface finish. By carefully controlling machine setup, grinding parameters, and coolant application, manufacturers can achieve exceptional results in terms of dimensional integrity, surface quality, and productivity.

Cylindrical Grinding

Cylindrical grinding is a machining process utilized to create cylindrical shapes and achieve precise dimensions and surface finishes on cylindrical workpieces. This versatile and widely-used grinding method is employed across various industries, including aerospace, automotive, medical devices, and general manufacturing, where cylindrical components play a crucial role in machinery and equipment.

The cylindrical grinding process typically involves the following steps:

- Workpiece Mounting: The cylindrical workpiece is securely mounted between centers or on a chuck attached to the grinding machine. This ensures proper alignment and stability during the grinding operation.

- Grinding Wheel Selection: Choosing the appropriate grinding wheel is critical to achieving the desired surface finish and dimensional accuracy. Factors such as abrasive type, grit size, bond type, and wheel hardness are carefully considered based on the material being ground, surface finish requirements, and machining conditions.

- Machine Setup: The grinding machine is set up to ensure proper alignment of the grinding wheel and workpiece. This includes adjusting the wheel’s position, speed, and feed rate, as well as ensuring adequate coolant flow to prevent overheating and maintain grinding performance.

- Grinding Operation: Once the machine is set up, the grinding operation begins. The grinding wheel is brought into contact with the cylindrical surface of the workpiece, and material is removed through the combined action of abrasive particles and cutting forces. The grinding wheel traverses along the length of the workpiece, gradually removing material to achieve the desired cylindrical shape and surface finish.

- Feed Control: During the grinding process, the feed rate of the grinding wheel along the length of the workpiece is carefully controlled to maintain consistent material removal and prevent surface irregularities. This is typically achieved through precise adjustment of the machine’s feed mechanism or CNC programming for automated grinding operations.

- Coolant Application: Coolant is often applied during cylindrical grinding to lubricate the grinding wheel-workpiece interface, dissipate heat, and flush away swarf and debris. Proper coolant selection and application help minimize thermal distortion, improve surface finish, and extend the life of the grinding wheel.

- Finishing Passes: Depending on the desired surface finish and dimensional accuracy, multiple grinding passes may be required to achieve the final result. Finer grit grinding wheels or special finishing techniques, such as spark-out grinding, may be used in the final passes to refine surface roughness and remove any remaining surface imperfections.

- Quality Inspection: After grinding, the cylindrical workpiece undergoes thorough inspection to verify dimensional accuracy, surface finish, and other critical parameters. This may involve using precision measuring instruments, such as micrometers, bore gauges, or surface profilometers, to ensure that the finished part meets the specified tolerances and quality standards.

In summary, cylindrical grinding is a precise and versatile machining process used to produce cylindrical shapes with high accuracy and surface finish. By carefully controlling machine setup, grinding parameters, and coolant application, manufacturers can achieve exceptional results in terms of dimensional integrity, surface quality, and productivity.

Centerless Grinding

Centerless grinding is a machining process that efficiently grinds cylindrical workpieces without the need for a center point or chucking mechanism. This technique is widely utilized in various industries for producing precision components with tight tolerances and excellent surface finishes. The process is particularly well-suited for long, thin workpieces that require high levels of concentricity and dimensional accuracy.

The centerless grinding process typically involves the following steps:

- Workpiece Feeding: The workpiece, often in the form of a long rod or tube, is fed into the grinding machine between the grinding wheel and a regulating wheel. Unlike traditional grinding methods that require precise centering and chucking, centerless grinding allows for rapid loading and unloading of workpieces without the need for a fixed axis.

- Grinding Wheel and Regulating Wheel Setup: The grinding wheel, which rotates at high speed, is positioned above the workpiece. Simultaneously, the regulating wheel, located opposite the grinding wheel, rotates at a slightly slower speed and applies pressure to control the workpiece’s rotational speed and feed rate. This setup ensures consistent grinding pressure and precise material removal.

- Material Removal: As the workpiece passes through the grinding zone between the grinding wheel and regulating wheel, material is gradually removed from the outer diameter of the workpiece. The grinding wheel removes the excess material while the regulating wheel controls the workpiece’s rotational speed, ensuring uniform grinding across its entire length.

- In-feed or Through-feed Grinding: Centerless grinding can be performed using two primary methods: in-feed grinding and through-feed grinding. In in-feed grinding, the grinding wheel is adjusted to plunge into the workpiece to remove material from one end to the other. In through-feed grinding, the workpiece is continuously fed through the grinding zone between the wheels, allowing for continuous material removal along the entire length of the workpiece.

- Coolant Application: Coolant is often applied during centerless grinding to lubricate the grinding wheel-workpiece interface, dissipate heat, and flush away swarf and debris. Proper coolant selection and application help minimize thermal distortion, improve surface finish, and extend the life of the grinding wheel.

- Workpiece Exit and Final Inspection: After passing through the grinding zone, the workpiece exits the machine, typically on a conveyor or roller system. The finished workpieces undergo final inspection to verify dimensional accuracy, surface finish, and other critical parameters, ensuring they meet the specified tolerances and quality standards.

In summary, centerless grinding is a highly efficient machining process for producing cylindrical workpieces with exceptional precision and surface finish. By eliminating the need for a center point or chucking mechanism, centerless grinding offers numerous advantages, including increased productivity, reduced setup time, and enhanced dimensional accuracy, making it a preferred choice for a wide range of applications across various industries.

Internal Grinding

Internal grinding is a specialized machining process used to create precise internal diameters, bores, and other internal features within workpieces. This technique is employed in industries such as automotive, aerospace, and medical devices, where components with intricate internal geometries and tight tolerances are required.

The internal grinding process typically involves the following steps:

- Workpiece Mounting: The workpiece, often in the form of a cylindrical part or component, is securely mounted on a chuck or between centers on the internal grinding machine. Proper alignment and fixturing are essential to ensure concentricity and stability during the grinding operation.

- Grinding Wheel Selection: Choosing the appropriate grinding wheel is crucial to achieving the desired internal diameter and surface finish. Factors such as abrasive type, grit size, bond type, and wheel hardness are carefully considered based on the material being ground, surface finish requirements, and machining conditions.

- Machine Setup: The internal grinding machine is set up to ensure proper alignment of the grinding wheel and workpiece. This includes adjusting the wheel’s position, speed, and feed rate, as well as ensuring adequate coolant flow to prevent overheating and maintain grinding performance.

- Grinding Operation: Once the machine is set up, the grinding operation begins. The grinding wheel, mounted on a spindle, is brought into contact with the internal surface of the workpiece. Material is removed through the combined action of abrasive particles and cutting forces, gradually enlarging the internal diameter or shaping the internal feature to the desired dimensions.

- Feed Control: During the grinding process, the feed rate of the grinding wheel along the internal surface of the workpiece is carefully controlled to maintain consistent material removal and prevent surface irregularities. This is typically achieved through precise adjustment of the machine’s feed mechanism or CNC programming for automated grinding operations.

- Coolant Application: Coolant is often applied during internal grinding to lubricate the grinding wheel-workpiece interface, dissipate heat, and flush away swarf and debris. Proper coolant selection and application help minimize thermal distortion, improve surface finish, and extend the life of the grinding wheel.

- Finishing Passes: Depending on the desired internal diameter and surface finish, multiple grinding passes may be required to achieve the final result. Finer grit grinding wheels or special finishing techniques, such as honing or lapping, may be used in the final passes to refine surface roughness and remove any remaining surface imperfections.

- Quality Inspection: After grinding, the workpiece undergoes thorough inspection to verify dimensional accuracy, internal diameter, surface finish, and other critical parameters. This may involve using precision measuring instruments, such as bore gauges, micrometers, or surface profilometers, to ensure that the finished part meets the specified tolerances and quality standards.

In summary, internal grinding is a precise and specialized machining process used to create internal features with tight tolerances and excellent surface finish. By carefully controlling machine setup, grinding parameters, and coolant application, manufacturers can achieve exceptional results in terms of dimensional integrity, internal diameter, and surface quality, making internal grinding an indispensable technique in modern manufacturing and engineering.

Mechanical Polishing

Mechanical polishing is a surface finishing process that utilizes mechanical abrasion to remove surface irregularities, scratches, and defects from workpieces, resulting in a smooth, reflective surface finish. This technique is widely used across various industries, including automotive, aerospace, electronics, and jewelry, to enhance the appearance, functionality, and performance of components and products.

The mechanical polishing process typically involves the following steps:

- Surface Preparation: Before polishing, the workpiece undergoes thorough cleaning and surface preparation to remove contaminants, oxidation, and surface imperfections. This may involve washing, degreasing, and pre-grinding to ensure a uniform starting surface.

- Selection of Polishing Tools and Abrasives: Choosing the appropriate polishing tools, abrasives, and polishing compounds is crucial to achieving the desired surface finish. Various types of abrasive materials, such as abrasive pads, wheels, belts, and abrasive compounds, are available, each suited to specific materials, surface finishes, and polishing requirements.

- Polishing Machine Setup: The workpiece is securely mounted on a polishing machine, such as a bench grinder, polishing lathe, or automated polishing system. The machine is set up to control parameters such as rotational speed, pressure, and contact angle to achieve consistent and uniform polishing across the entire surface.

- Initial Rough Polishing: The polishing process begins with the application of coarse abrasives or polishing compounds to remove surface irregularities and scratches. The workpiece is held against the rotating polishing tool with controlled pressure and motion, gradually smoothing out imperfections and leveling the surface.

- Intermediate and Fine Polishing: After the initial rough polishing stage, progressively finer abrasives or polishing compounds are used to refine the surface finish further. This involves multiple polishing passes with gradually decreasing abrasive particle sizes, resulting in a smoother, more reflective surface with reduced surface roughness and defects.

- Final Polishing and Buffing: In the final polishing stage, ultra-fine abrasives or polishing compounds are applied to achieve the desired surface gloss, shine, and clarity. Buffing wheels or polishing pads made of soft materials, such as felt or cloth, are used to apply the polishing compounds evenly and uniformly, imparting a mirror-like finish to the workpiece.

- Cleaning and Inspection: After polishing, the workpiece is thoroughly cleaned to remove any residual polishing compounds, debris, or contaminants. It undergoes visual inspection and quality control to ensure that the desired surface finish and specifications have been achieved.

- Surface Protection: Depending on the application and requirements, the polished surface may be coated or treated with protective coatings, such as clear coats, lacquers, or sealants, to enhance durability, corrosion resistance, and longevity.

In summary, mechanical polishing is a versatile and effective surface finishing process used to achieve smooth, reflective surfaces on a wide range of materials and workpieces. By employing the right combination of polishing tools, abrasives, and techniques, manufacturers can achieve exceptional surface finishes that meet the most demanding aesthetic and functional requirements.

Grinding and Polishing Wheel Selection

Selecting the appropriate grinding and polishing wheels is crucial for achieving desired surface finishes, dimensional accuracy, and overall machining efficiency. The choice of wheels depends on various factors, including the material being processed, surface finish requirements, machining conditions, and the specific characteristics of the grinding or polishing operation. Here’s a breakdown of factors to consider when selecting grinding and polishing wheels:

- Abrasive Material: Different abrasive materials offer varying cutting properties and performance characteristics. Common abrasive materials include:

- Aluminum Oxide: Suitable for general-purpose grinding and polishing of ferrous and non-ferrous metals.

- Silicon Carbide: Ideal for grinding and polishing hard and brittle materials such as ceramics, glass, and composites.

- Diamond: Known for its exceptional hardness and wear resistance, diamond abrasives are used for high-precision grinding and polishing of hard materials like carbides, ceramics, and stones.

- Grit Size: The grit size of the abrasive particles determines the surface finish and material removal rate. Coarser grits (lower numbers) are used for rapid material removal, while finer grits (higher numbers) produce smoother surface finishes. It’s essential to select the appropriate grit size based on the desired surface finish and material removal requirements.

- Wheel Shape and Size: Grinding and polishing wheels come in various shapes and sizes to accommodate different machining tasks and workpiece geometries. Common wheel shapes include flat, cylindrical, and cup wheels. The wheel diameter and thickness should be selected based on the size and shape of the workpiece, as well as the specific requirements of the grinding or polishing operation.

- Wheel Bond: The wheel bond refers to the material that holds the abrasive grains together. Different bond types offer varying levels of hardness, porosity, and resilience, impacting the cutting performance and wheel life. Common bond types include:

- Vitrified Bond: Known for its high strength and resistance to heat and wear, vitrified bonds are suitable for heavy-duty grinding operations.

- Resin Bond: Resin bonds offer excellent cutting performance and are often used for precision grinding and polishing applications.

- Metal Bond: Metal bonds provide superior abrasive retention and are commonly used for grinding hard and brittle materials.

- Wheel Structure: The wheel structure refers to the arrangement of abrasive grains within the wheel matrix. Wheel structures can vary from open to dense, impacting the wheel’s porosity, chip clearance, and material removal characteristics. Open structures are preferred for aggressive material removal, while dense structures provide finer surface finishes.

- Coolant Compatibility: Consider the compatibility of the wheel material and bond with coolant or lubricants used during grinding and polishing operations. Some abrasive materials and bonds may be more resistant to coolant-induced degradation or loading, ensuring prolonged wheel life and consistent performance.

- Special Features: Depending on specific application requirements, specialized grinding and polishing wheels with unique features may be necessary. For example, segmented grinding wheels are used for rapid stock removal, while diamond impregnated wheels are employed for precise polishing of hard materials.

By carefully considering these factors and matching the properties of grinding and polishing wheels to the requirements of the machining task, manufacturers can optimize performance, achieve superior surface finishes, and extend the life of abrasive tools. It’s essential to consult with wheel manufacturers or suppliers to ensure the selection of the most suitable wheels for each application.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching