A hydraulic horizontal press brake is a machine that uses hydraulic pressure to bend metal sheets and plates into desired shapes. Unlike traditional press brakes, which bend plates vertically, horizontal press brakes bend plates horizontally, allowing for more complex bends and shapes.

The versatility of the Horizontal Press Brake allows us to bend, fold, bend, cut, form, enlarge and reduce flaring, swagging, assembling… all kinds of metal materials such as iron, steel, stainless, copper, brass, aluminium..

Pipe bending at fixed radius up to 150º could be considered one of the good features of these presses

Cutting, piercing and punching flat bars or metal sheets turn this horizontal bending press into a punching shears machine

Stretching and reducing pipes on the ends in order to make parts that fit or weld later.

It is also a solution to bend different profiles at different radius and keeping the ends straight, like when manufacturing handles and flanges.

Cold forge uses horizontal presses to make and form different shapes of balusters. Tube notching to assemble at 90 degrees.

Folding operations with wrought iron machines permit to completely bend the parts or pieces unlike conventional flat bar section bending machines

Its robustness, versatility, easy handling and 4.0 Technology are just four of the best features our hydraulic horizontal bending machine has. Folding operation with no risk of damaging the punches and dies with thick materials unlike conventional press brakes. Folding flat bars and sheets into completely close shapes. Conception of this horizontal bending press brake allows to make folding operations impossible to be carried out on a conventional press brake.

Fast tool change, punches and dies: This change does not take more than 30 seconds most of the times. A set of punch and folding die is supplied along with the machine. Performance by a safety double activation hold pedal. Low noise level, improving the quality of work of the operator. The machine is shipped completely assembled and ready to work. Palletized lower bench to easily transport the machine up to its working or storage site. Dies support shelf included. Lateral stop to place it right or left.

Hydraulic System

Monoblock hydraulic power unit with positioning and pressure regulation valves The hydraulic system can be regulated by means of pressure adjustment valves that affect the piston force. Pressure regulator with pressure gauge that allows to control the force carried out at any time.

Guided hydraulic cylinder: The hydraulic cylinder placed on the work bench allows us to transfer all the force directly on the tools. Fully guided hydraulic piston to prevent any bending during the folding operation.

Cylindrical fastening bolts: Cylindrical fastening bolts easy to install, to guarantee maximum firmness to the tools during machining operations. Plugs to prevent the residues of the folding from entering inside the machine.

Work table without frame: The work bench is frameless, this is great for the movement of the parts to be machined for there isn’t any element that obstructs its movement. The table is manufactured in a 60mm monoblock of welded steel, stabilized and machined. The operator’s working position must be at the side of the machine for accomplishing a better vision and control, as well as greater safety for the user since he will be outside the radius of action of the tools.

Our horizontal press brake machine series start as low as 20 tonnes. This bending machine is used to bend small items made of sheet metal.

Technical Characteristics of the Horizontal Hydraulic Hydraulic Press Brake Machine

- Working strength: 20.000 Kg (100 KN)

- Working speed: 10 mm/s.

- Return speed: 35 mm/s.

- Maximum displacement: 250 mm.

- Repetitivity: 0,05 mm.

- Bench size: 600×1170 mm.

- Working height: 950 mm.

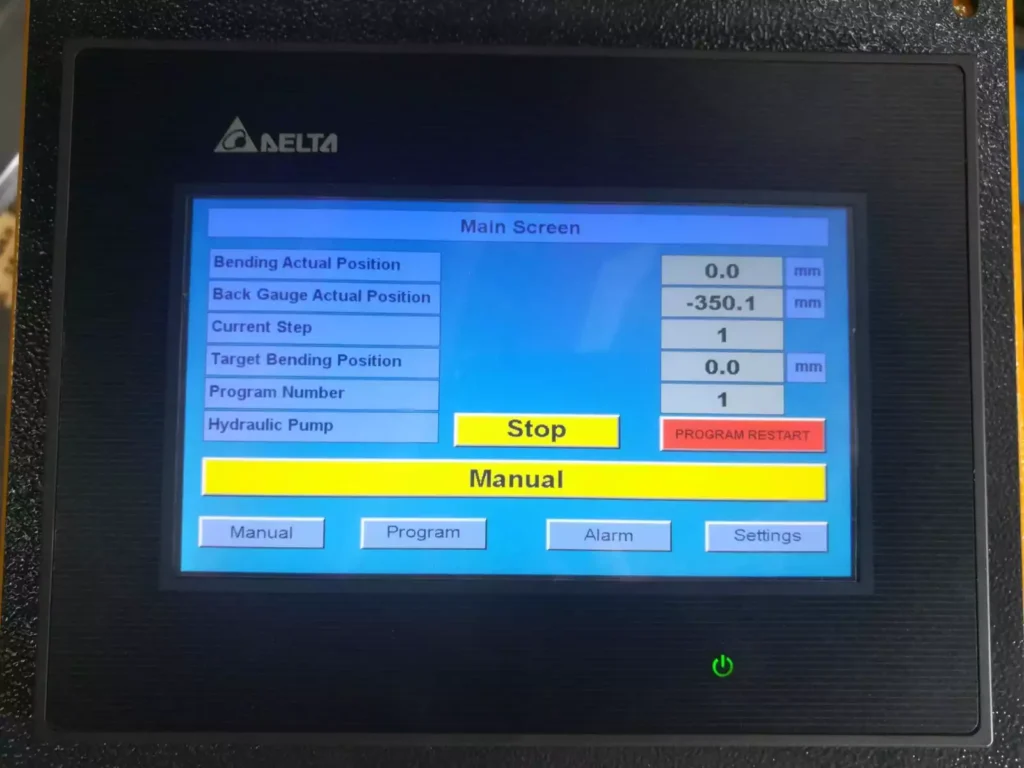

- Programming mode: Manual or Automatic.

- Safety Double acting hold pedal.

- Mechanically Guided Piston.

- Piece counter.

- Pressure regulator.

- Electric Tension: 230/400 V three-phased.

- Hydraulic pressure: 50 a 215 Kg/cm2.

- Hydraulic pump: 7,5 litres/minute.

- Tank Capacity: 40 liters.

- Dies support shelf included.

- Palletized lower bench to easily transport the machine up to its working or storage site.

- The machine is sent wholly assembled.

- Packing included:

- Wooden pallet NIMF15 and three-layer cardboard apt for suitable for sea freight.

A hydraulic press brake machine is manufactured with a machine die for bending sheet metal. The sheet metal bending machine is operated by a foot pedal and an NC control. The foot pedal is used in 2 ways: forward and backward. A brake machine can be a very good alternative to a big press brake machine when you don’t have long parts to bend.

For a brake press for sale, kindly send us your inquiry by mail. The metal press machine we manufacture are horizontal press machine, pipe bending machine and profile bending machine,. All the sheet metal machinery that we manufacture, are produced in our own facility in Istanbul Turkey

The hydraulic oil capacity of the EMS HP20 is 40 Liters. Motor power is 2,2 kw.

Key Features of Hydraulic Horizontal Press Brakes

- Horizontal Bending Capability: These machines bend plates horizontally, enabling the creation of complex bends and shapes not possible with vertical press brakes.

- Versatility: Horizontal press brakes can handle a wide range of plate thicknesses and materials, making them versatile tools for various applications.

- Precise Control: Hydraulic systems provide precise control over the bending force and speed, ensuring accurate and consistent bends.

- Ease of Operation: Horizontal press brakes typically feature user-friendly controls and intuitive programming interfaces.

- Safety Features: These machines incorporate safety features such as light guards, emergency stops, and interlocking mechanisms to protect operators.

Applications of Hydraulic Horizontal Press Brakes

- Sheet Metal Bending: Bending sheet metal for enclosures, ducts, housings, and other structural components.

- Plate Forming: Shaping plates for machinery frames, vehicle components, and industrial equipment.

- Bending Profiles: Creating bends and curves in metal profiles for architectural and structural applications.

- Complex Bends: Producing intricate bends and shapes that require precise control and flexibility.

- Specialty Applications: Custom bending for specific applications, such as automotive parts, aerospace components, and appliance manufacturing.

Selection and Operation of Hydraulic Horizontal Press Brakes

Choosing the appropriate hydraulic horizontal press brake depends on several factors, including:

- Plate Thickness: The machine should be capable of handling the plate thickness required for the application.

- Bending Force: The machine should provide sufficient bending force to achieve the desired bends in the material being used.

- Bending Length: The machine’s bending length should accommodate the maximum plate length to be bent.

- Accuracy Requirements: The machine should provide the desired level of accuracy and precision for the application.

- Production Volume: The machine should have sufficient capacity to meet the production demands.

When operating a hydraulic horizontal press brake, proper safety precautions should be followed to prevent accidents and injuries:

- Wear Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, safety glasses, and proper footwear, when operating a press brake.

- Securely Position the Plate: Ensure the plate is securely placed on the machine’s bed and properly aligned with the bending tools.

- Verify Bending Parameters: Double-check the bending parameters, including bend angle, bend radius, and bending speed, before initiating the bending process.

- Monitor the Bending Process: Closely monitor the bending process to detect any potential issues or irregularities.

- Follow Manufacturer Instructions: Strictly follow the manufacturer’s instructions and safety guidelines for the specific horizontal press brake in use.

Hydraulic horizontal press brakes are valuable tools for shaping and forming metal sheets and plates into desired shapes. Their ability to handle complex bends, provide precise control, and accommodate various materials makes them versatile and essential machines in various industries. By selecting the right machine, adhering to safety protocols, and following proper operating procedures, these machines contribute to efficient, safe, and productive manufacturing processes.

The versatility of the best Hydraulic Horizontal Press Brake Machine EMS HP20 makes it possible for us to make a great deal of forging parts and all kinds of operations in all kinds of materials: pipe, flat bar, several profiles, rods.

Hydraulic Press Machines

Hydraulic press machines are versatile and powerful tools that utilize hydraulic pressure to exert force and perform various tasks, including:

Metalworking: Hydraulic press machines are commonly used in metalworking applications such as:

- Bending: Pressing metal sheets and plates into desired shapes, such as angles, channels, and boxes.

- Punching: Pressing holes in metal sheets and plates using punches and dies.

- Blanking: Cutting out shapes from metal sheets using dies.

- Forming: Shaping metal parts into specific configurations using dies.

- Extruding: Forcing metal through a die to create various shapes, such as pipes or tubes.

Manufacturing: Hydraulic press machines are employed in various manufacturing processes, including:

- Assembly: Pressing components together to form assemblies.

- Embossing: Creating raised patterns or designs on metal surfaces.

- Coining: Pressing metal into dies to produce coins, medals, or other shaped parts.

- Laminating: Joining layers of different materials together using pressure.

- Testing: Compressing materials to assess their strength and properties.

Other Applications: Hydraulic press machines also find use in various industries beyond metalworking and manufacturing, such as:

- Agricultural: Pressing oilseeds to extract oil.

- Pharmaceutical: Compressing powders into tablets.

- Recycling: Compressing materials like cardboard or plastics for efficient waste disposal.

- Construction: Pressing concrete or other materials into desired shapes.

- Food Processing: Pressing juice from fruits or vegetables.

Key Components of Hydraulic Press Machines

The main components of a hydraulic press machine include:

- Frame: The frame provides the structural support for the machine and houses the other components.

- Hydraulic Cylinder: The hydraulic cylinder generates the force required for pressing operations. It contains a piston that is driven by hydraulic fluid.

- Hydraulic Pump: The hydraulic pump supplies hydraulic fluid to the hydraulic cylinder. It is typically powered by an electric motor.

- Press Ram: The press ram is the part that applies force to the workpiece. It is connected to the hydraulic cylinder and moves up and down to perform pressing operations.

- Bed: The bed is the surface where the workpiece is placed during pressing. It is typically adjustable to accommodate different workpiece sizes.

- Control Panel: The control panel allows the operator to control the machine’s functions, such as pressure, speed, and ram position.

- Tooling: Various tooling, such as dies, punches, and platens, are used to shape or form the workpiece during pressing.

Advantages of Hydraulic Press Machines

Hydraulic press machines offer several advantages over other types of presses:

- High Force Capability: They can generate high forces, making them suitable for pressing a wide range of materials.

- Precise Control: They provide precise control over the pressing force and speed, ensuring consistent and accurate results.

- Versatility: They can be adapted to a wide range of applications with different tooling options.

- Reliability: They are generally durable and reliable, requiring minimal maintenance.

- Safety: They incorporate safety features to protect operators from potential hazards.

Considerations When Choosing a Hydraulic Press Machine

Choosing the appropriate hydraulic press machine depends on several factors, including:

- Application Requirements: The machine should be capable of handling the specific task at hand, such as bending, punching, or forming.

- Workpiece Material: The machine should be compatible with the material being pressed.

- Workpiece Size: The machine should have sufficient capacity to accommodate the size of the workpiece.

- Force Requirements: The machine should provide sufficient force to achieve the desired pressing results.

- Production Volume: The machine should have sufficient capacity to meet the production demands.

- Budget and Cost-Effectiveness: The machine should fit within the project budget and offer cost-effective operation.

Hydraulic press machines are valuable tools in various industries, providing a combination of power, precision, and versatility. By selecting the right machine, adhering to safety protocols, and following proper operating procedures, these machines contribute to efficient, safe, and productive manufacturing processes.

Folding operations with a wrought iron press machine permit to completely bend the parts or pieces, unlike conventional flat bar section bending machines. Bending with a brake press at a fixed radius up to 150º could be considered one of the other good features of these presses. The stretching and reducing pipes on the ends in order to make parts that fit or weld later. Cutting, piercing, and punching flat bars or metal sheets turn this horizontal bending press into a punching shears machine. Many workshops use these presses to stretch and form different kinds of profiles. It is also a solution to bend different profiles at the different radii and keep the ends straight, like when manufacturing handles and flanges.

Bending with Horizontal Press

Bending with a horizontal press is a versatile and efficient method for shaping and curving metal sheets and plates into desired angles or shapes. This technique involves applying pressure from a horizontally positioned ram or plunger to gradually deform the workpiece into the desired curvature. Horizontal presses offer several advantages over other bending methods, making them a preferred choice in various industries.

Folding die at 161 mm · V 16, 22, 35, 50 mm

Folding or bending die up to 161mm with 4 openings (16, 22, 35, 50mm) and a punch of 80º. This multi-V die allows 1mm up to 8mm sheet to be folded. The 70mm outer diameter punch allows to make completely closed shapes to a minimum of 75mm inner wing.

Folding die reference: 125-16-01-00006

Folding punch reference: 131-16-01-00041

V 16: Sheet from 1 to 3mm

V 22: Sheet from 2 to 4mm

V 35: Sheet from 3 to 6mm

V 50: Sheet from 4 to 8mm

Max. Folding length: 161mm

Max. Folding thickness: 8mm

- Baluster forming die

- Ring forming

- Bending tool for big radius

- Twisted bars forming die

- Flat bar cutting tooling 100x10mm

- Tool to shape pipe ends

- Diameter reduction tools

- Diameter expansion tools

- Die to straighten out profiles

- Punching die

- Promecam punch holder

- Clamp forming die

- Bar clamps forming die

- Special punches

- Round, square, oval and rectangular punches and dies

- Pipe notching tool

- Rounding corner tool

- Metal tabs forming tool

Key Characteristics of Horizontal Press Bending

- Large Bending Capacity: Horizontal presses can handle large-format metal sheets and plates, typically up to 12 feet (3.6 meters) in width and 0.5 inches (12.7 millimeters) in thickness.

- Long Bend Capability: Horizontal presses can produce long, continuous bends without abrupt transitions, ensuring smooth and aesthetically pleasing curves.

- Reduced Springback: Horizontal presses minimize springback, the tendency of the metal to partially straighten after bending, resulting in more accurate and consistent bend angles.

- Uniform Bending: Horizontal presses produce uniform bending along the entire length of the workpiece, ensuring a consistent bend shape and eliminating uneven or distorted bends.

- Versatility: Horizontal presses can handle a wide range of metal types, including steel, aluminum, stainless steel, and copper, making them adaptable to various applications.

Applications of Horizontal Press Bending

Horizontal press bending finds extensive use in various industries due to its efficiency and effectiveness. Here are some common applications:

- Sheet Metal Forming: Horizontal presses are employed to bend sheet metal for architectural components, enclosures, ducts, and housings.

- Plate Bending: Horizontal presses are used to shape plates for machinery frames, automotive components, and industrial equipment.

- Curved Shapes: Horizontal presses can produce curved shapes for structural supports, decorative elements, and specialized components.

- Complex Bends: Horizontal presses can handle complex bends and angles that are difficult to achieve with other methods.

- High-Volume Production: Horizontal presses are well-suited for high-volume production runs, ensuring consistent quality and efficiency.

Overall, horizontal press bending is a valuable technique that offers a combination of precision, versatility, and effectiveness in shaping metal sheets and plates into desired forms. Its ability to handle large dimensions, produce long bends, and minimize springback makes it a preferred choice in various manufacturing and fabrication processes.

Punching with Horizontal Press

Punching with a horizontal press is a versatile and efficient method for creating holes and perforations in metal sheets and plates. This technique involves applying force from a horizontally positioned ram or plunger to drive a punch tool through the workpiece, removing a defined section of material and leaving a clean, precise hole. Horizontal presses offer several advantages over other punching methods, making them a preferred choice in various industries.

Key Characteristics of Horizontal Press Punching

- High Punching Force: Horizontal presses can generate high punching forces, enabling them to penetrate a wide range of materials, including thick and hard metals.

- Precise Hole Production: Horizontal presses provide precise control over the punching force and speed, resulting in clean, accurate holes with consistent dimensions.

- Variety of Hole Shapes: Horizontal presses can accommodate a variety of punch shapes, including round, square, rectangular, and oval, catering to diverse application requirements.

- Automated Operation: Horizontal presses can be automated using programmable controllers, enabling efficient and consistent punching operations for high-volume production.

- Safety Features: Horizontal presses incorporate safety features such as light guards, emergency stops, and interlocking mechanisms to protect operators from potential hazards.

Applications of Horizontal Press Punching

Horizontal press punching finds extensive use in various industries due to its efficiency and precision. Here are some common applications:

- Sheet Metal Fabrication: Horizontal presses are employed to punch holes in sheet metal for various components, such as electrical panels, enclosures, and ducting systems.

- Plate Perforation: Horizontal presses are used to perforate plates for sieves, filters, and gratings, ensuring consistent hole patterns and precise dimensions.

- Component Manufacture: Horizontal presses can punch holes in various industrial components, such as automotive parts, appliance housings, and machinery frames.

- Prototyping and Design: Horizontal presses are used to create prototypes and make design modifications in sheet metal and plate components.

- Decorative Elements: Horizontal presses can punch decorative holes and patterns in metal panels for architectural applications and signage.

Overall, horizontal press punching is a valuable technique that offers a combination of precision, versatility, and effectiveness in creating holes and perforations in metal sheets and plates. Its ability to handle a wide range of materials, produce accurate holes, and accommodate various hole shapes makes it a preferred choice in various manufacturing and fabrication processes.

Safety Guidelines for Horizontal Press Punching

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and proper footwear, when operating a horizontal press.

- Secure Workpiece Positioning: Ensure the workpiece is securely clamped in place on the press bed to prevent movement during punching.

- Clearance from Punch and Die: Maintain adequate clearance between the punch and die to avoid hand injuries or damage to the tooling.

- Emergency Stop Awareness: Familiarize yourself with the emergency stop location and be prepared to activate it in case of any unsafe conditions.

- Proper Tooling Selection: Use the appropriate punch and die combination for the desired hole size, shape, and material.

- Regular Maintenance: Follow proper maintenance procedures to ensure the press is in good working condition and free from potential hazards.

Blanking with Horizontal Press

Blanking with a horizontal press is a versatile and efficient method for cutting out shapes from metal sheets and plates. This technique involves applying force from a horizontally positioned ram or plunger to drive a blanking tool through the workpiece, removing a defined section of material and leaving a clean, precise edge. Horizontal presses offer several advantages over other blanking methods, making them a preferred choice in various industries.

Key Characteristics of Horizontal Press Blanking

- High Blanking Force: Horizontal presses can generate high blanking forces, enabling them to cut through a wide range of materials, including thick and hard metals.

- Precise Cut Quality: Horizontal presses provide precise control over the blanking force and speed, resulting in clean, accurate cuts with consistent dimensions.

- Complex Shape Blanking: Horizontal presses can handle complex shapes, including intricate contours and sharp angles, making them suitable for a variety of cutting applications.

- Automated Operation: Horizontal presses can be automated using programmable controllers, enabling efficient and consistent blanking operations for high-volume production.

- Safety Features: Horizontal presses incorporate safety features such as light guards, emergency stops, and interlocking mechanisms to protect operators from potential hazards.

Applications of Horizontal Press Blanking

Horizontal press blanking finds extensive use in various industries due to its efficiency and precision. Here are some common applications:

- Sheet Metal Components: Horizontal presses are employed to blank out sheet metal components for various products, such as appliances, automotive parts, and electronic enclosures.

- Gasket and Washer Blanking: Horizontal presses are used to blank out gaskets and washers for various industrial applications, ensuring consistent dimensions and precise shapes.

- Profiling and Part Formation: Horizontal presses can blank out complex profiles and shapes for various components, such as machine parts, decorative elements, and architectural features.

- Prototype and Design: Horizontal presses are used to blank out prototypes and make design modifications in sheet metal components.

- Precision Blanking: Horizontal presses can perform precision blanking operations, producing clean, burr-free edges and minimizing material waste.

Overall, horizontal press blanking is a valuable technique that offers a combination of precision, versatility, and effectiveness in cutting out shapes from metal sheets and plates. Its ability to handle a wide range of materials, produce accurate cuts, and accommodate complex shapes makes it a preferred choice in various manufacturing and fabrication processes.

Safety Guidelines for Horizontal Press Blanking

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and proper footwear, when operating a horizontal press.

- Secure Workpiece Positioning: Ensure the workpiece is securely clamped in place on the press bed to prevent movement during blanking.

- Clearance from Blanking Tool: Maintain adequate clearance from the blanking tool to avoid hand injuries or damage to the tooling.

- Emergency Stop Awareness: Familiarize yourself with the emergency stop location and be prepared to activate it in case of any unsafe conditions.

- Proper Tooling Selection: Use the appropriate blanking tool for the desired shape, material, and thickness of the workpiece.

- Regular Maintenance: Follow proper maintenance procedures to ensure the press is in good working condition and free from potential hazards.

Forming with Horizontal Press

Forming with a horizontal press is a versatile and efficient method for shaping and deforming metal sheets and plates into desired three-dimensional shapes. This technique involves applying force from a horizontally positioned ram or plunger to gradually deform the workpiece using specialized dies, resulting in complex shapes and contours. Horizontal presses offer several advantages over other forming methods, making them a preferred choice in various industries.

Key Characteristics of Horizontal Press Forming

- Controlled Deformation: Horizontal presses provide precise control over the forming force and speed, enabling the creation of complex shapes with consistent dimensions and smooth transitions.

- Deep Draw Forming: Horizontal presses can perform deep draw forming, producing deep pockets, cups, and recesses in sheet metal components.

- Variety of Formed Shapes: Horizontal presses can form a wide range of shapes, including cones, cylinders, domes, and irregular shapes, catering to diverse application requirements.

- High Production Volume: Horizontal presses are well-suited for high-volume production runs, ensuring consistent quality and efficiency.

- Automated Operation: Horizontal presses can be automated using programmable controllers, enabling efficient and consistent forming operations for high-volume production.

Applications of Horizontal Press Forming

Horizontal press forming finds extensive use in various industries due to its versatility and effectiveness in shaping metal components. Here are some common applications:

- Automotive Parts: Horizontal presses are employed to form automotive parts, such as door panels, hoods, trunk lids, and structural components.

- Appliance Components: Horizontal presses are used to form appliance components, such as refrigerator panels, washing machine tubs, and oven housings.

- Electronic Enclosures: Horizontal presses can form electronic enclosures for various devices, ensuring precise dimensions and smooth contours.

- Aerospace Components: Horizontal presses are used to form aerospace components, such as aircraft skins, engine covers, and structural supports.

- Decorative Elements: Horizontal presses can form decorative elements for architectural applications, furniture components, and signage.

Overall, horizontal press forming is a valuable technique that offers a combination of precision, versatility, and effectiveness in shaping and deforming metal sheets and plates into complex three-dimensional shapes. Its ability to handle a wide range of materials, produce consistent shapes, and accommodate automated operation makes it a preferred choice in various manufacturing and fabrication processes.

Safety Guidelines for Horizontal Press Forming

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and proper footwear, when operating a horizontal press.

- Secure Workpiece Positioning: Ensure the workpiece is securely clamped in place on the press bed to prevent movement during forming.

- Clearance from Forming Tools: Maintain adequate clearance from the forming tools to avoid hand injuries or damage to the tooling.

- Emergency Stop Awareness: Familiarize yourself with the emergency stop location and be prepared to activate it in case of any unsafe conditions.

- Proper Lubrication: Ensure the forming dies and workpiece are properly lubricated to reduce friction and prevent wear.

- Regular Maintenance: Follow proper maintenance procedures to ensure the press is in good working condition and free from potential hazards.

Extruding with Horizontal Press

Extruding with a horizontal press, also known as horizontal extrusion, is a versatile and efficient method for producing continuous lengths of metal shapes, tubes, or rods. This technique involves forcing heated metal through a die opening using a horizontally positioned ram or plunger, resulting in a continuous profile with the desired cross-sectional shape. Horizontal presses offer several advantages over other extrusion methods, making them a preferred choice in various industries.

Key Characteristics of Horizontal Press Extrusion

- High Extrusion Force: Horizontal presses can generate high extrusion forces, enabling them to extrude a wide range of materials, including hard and viscous metals.

- Continuous Extrusion: Horizontal presses produce continuous lengths of extruded material, eliminating the need for welding or joining separate pieces.

- Variety of Extruded Shapes: Horizontal presses can extrude a wide range of shapes, including round, square, rectangular, and complex profiles, catering to diverse application requirements.

- Precise Dimensional Control: Horizontal presses provide precise control over the extrusion process, resulting in consistent dimensions and smooth surface finishes.

- Automated Operation: Horizontal presses can be automated using programmable controllers, enabling efficient and consistent extrusion operations for high-volume production.

Applications of Horizontal Press Extrusion

Horizontal press extrusion finds extensive use in various industries due to its versatility and ability to produce continuous lengths of shaped metal products. Here are some common applications:

- Tubing and Pipe Manufacturing: Horizontal presses are employed to extrude seamless tubes and pipes for various applications, such as structural components, fluid conveyance systems, and electrical conduits.

- Rod and Bar Production: Horizontal presses are used to extrude rods and bars for various industrial applications, such as machine parts, structural components, and fasteners.

- Wire and Cable Extrusion: Horizontal presses can extrude wire and cable sheathing, providing protection and insulation for electrical conductors.

- Aluminum Extrusions: Horizontal presses are widely used to extrude aluminum shapes for various applications, including architectural components, window frames, and automotive parts.

- Specialty Extrusions: Horizontal presses can extrude complex shapes and profiles for specialized applications, such as medical implants, aerospace components, and decorative elements.

Overall, horizontal press extrusion is a valuable technique that offers a combination of precision, versatility, and efficiency in producing continuous lengths of shaped metal products. Its ability to handle a wide range of materials, produce consistent dimensions, and accommodate automated operation makes it a preferred choice in various manufacturing and fabrication processes.

Safety Guidelines for Horizontal Press Extrusion

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and proper footwear, when operating a horizontal press.

- Secure Die Installation: Ensure the extrusion die is securely installed and aligned with the extrusion chamber to prevent material jams or accidents.

- Proper Heating and Lubrication: Maintain the appropriate temperature and lubrication for the extruded material to ensure smooth flow and prevent material defects.

- Safety Interlocks and Guards: Familiarize yourself with the safety interlocks and guards on the press and ensure they are functioning properly to prevent accidental operation or injuries.

- Emergency Stop Awareness: Familiarize yourself with the emergency stop location and be prepared to activate it in case of any unsafe conditions.

- Regular Maintenance: Follow proper maintenance procedures to ensure the press is in good working condition and free from potential hazards.

Pipe notching with Horizontal Press

Pipe notching with a horizontal press brake is a versatile and efficient method for creating notches or cutouts in metal pipes. This technique involves using a specialized notching tool or die mounted on the ram of the horizontal press brake to apply pressure and deform the pipe material, resulting in a precise notch or cutout of the desired shape and size.

Key Characteristics of Pipe Notching with Horizontal Press Brake

- Precision Notching: Horizontal press brakes provide precise control over the notching force and speed, ensuring clean, accurate notches with consistent dimensions.

- Variety of Notch Shapes: Horizontal press brakes can accommodate a variety of notch shapes, including rectangular, trapezoidal, and V-shaped notches, catering to diverse application requirements.

- Efficient Production: Horizontal press brakes enable efficient notching operations, especially for high-volume production runs.

- Versatility: Horizontal press brakes can handle a wide range of pipe diameters and materials, making them versatile for various applications.

- Safety Features: Horizontal press brakes incorporate safety features such as light guards, emergency stops, and interlocking mechanisms to protect operators from potential hazards.

Applications of Pipe Notching with Horizontal Press Brake

Pipe notching with a horizontal press brake finds extensive use in various industries, particularly in piping systems and structural applications. Here are some common applications:

- Pipe Fitting Connections: Pipe notching is employed to create notches in pipes for connecting various fittings, such as elbows, tees, and flanges.

- Structural Reinforcements: Pipe notching can create notches in pipes for structural reinforcements, such as attaching brackets or supports.

- Pipe End Preparations: Pipe notching is used to prepare pipe ends for welding or joining, ensuring proper alignment and fit.

- Custom Notches: Horizontal press brakes can create custom notches for specialized applications, such as clearance notches for pipe routing or notches for specific component integration.

- Prototyping and Design: Pipe notching with a horizontal press brake can be used for prototyping and design iterations in piping systems and structural components.

Overall, pipe notching with a horizontal press brake is a valuable technique that offers a combination of precision, versatility, and efficiency in creating notches or cutouts in metal pipes. Its ability to handle a wide range of pipe diameters, produce accurate notches, and accommodate various notch shapes makes it a preferred choice in various industries, particularly in piping systems and structural applications.

Safety Guidelines for Pipe Notching with Horizontal Press Brake

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and proper footwear, when operating a horizontal press brake.

- Secure Pipe Positioning: Ensure the pipe is securely clamped in place on the press bed to prevent movement during notching.

- Proper Tool Selection: Use the appropriate notching tool or die for the desired notch shape, pipe diameter, and material.

- Clearance from Notching Tool: Maintain adequate clearance from the notching tool to avoid hand injuries or damage to the tooling.

- Emergency Stop Awareness: Familiarize yourself with the emergency stop location and be prepared to activate it in case of any unsafe conditions.

- Regular Maintenance: Follow proper maintenance procedures to ensure the press is in good working condition and free from potential hazards.

Sheet Metal Bending Tool

Sheet metal bending tools are devices used to bend sheet metal into various shapes and forms. They are commonly used in metalworking industries to create components for various applications, such as automotive parts, appliances, and architectural elements.

Types of Sheet Metal Bending Tools

Several types of sheet metal bending tools are available, each with its own capabilities and applications. Some of the most common types include:

- Bending brakes: These machines use a ram or plunger to apply force to a workpiece, causing it to bend along a predefined line. They are suitable for bending large sheets of metal into simple shapes, such as angles and channels.

- Press brakes: These machines use a hydraulic or pneumatic press to apply force to a workpiece, allowing for more precise bending and the creation of complex shapes. They are often used in high-volume production environments.

- Roll benders: These machines use a series of rollers to gradually bend sheet metal into a curved shape. They are suitable for long, continuous bends and are often used for forming pipes and tubes.

- Hand benders: These are portable tools that are used for bending sheet metal by hand. They are commonly used for smaller jobs and for making quick adjustments.

Factors to Consider When Choosing a Sheet Metal Bending Tool

When choosing a sheet metal bending tool, several factors should be considered:

- Type of bends: The type of bends required will determine the type of machine you need. For simple bends, a bending brake may be sufficient. For more complex bends, a press brake or roll bender may be necessary.

- Material thickness: The thickness of the material you will be working with will also influence your choice of machine. Thicker materials will require a machine with more power.

- Production volume: If you are producing high volumes of parts, an automated machine may be more efficient. However, for small-scale production or prototyping, a hand bender may be sufficient.

- Accuracy requirements: The accuracy required for your bends will also affect your choice of machine. Press brakes and roll benders can typically achieve higher levels of accuracy than bending brakes.

- Budget: The cost of sheet metal bending tools can vary significantly. It is important to consider your budget when making your decision.

Safety Precautions When Using Sheet Metal Bending Tools

When using sheet metal bending tools, it is important to follow safety precautions to prevent injuries:

- Wear personal protective equipment (PPE): This includes safety glasses, gloves, and a sturdy pair of shoes.

- Securely clamp the workpiece: The workpiece should be securely clamped in place before bending to prevent it from moving or slipping.

- Keep hands away from the bending area: Never place your hands near the bending area while the machine is in operation.

- Use the proper tools: Use the appropriate tools for the type of bend and material you are working with.

- Follow the manufacturer’s instructions: Always follow the manufacturer’s instructions for the specific machine you are using.

Horizontal press brake bending machine EMS HP20 includes the complete folding die. (See bottom of the page in standard accessories).

Technical Characteristics of the Horizontal Hydraulic Press Machine

- Working strength: 20.000 Kg (200 KN)

- Working speed: 10 mm/s.

- Return speed: 35 mm/s.

- Maximum displacement: 250 mm.

- Repetitivity: 0,05 mm.

- Bench size: 600×1170 mm.

- Working height: 950 mm.

- Programming mode: Manual or Automatic.

- Safety Double acting hold pedal.

- Mechanically Guided Piston.

- Piece counter.

- Pressure regulator.

- Engine power: 2.2 KW/3 HP a 1400 r.p.m.

- Electric Tension: 230/400 V three-phased.

- Intensity: 9/5 A.

- Hydraulic pressure: 50 a 215 Kg/cm2.

- Hydraulic pump: 7,5 litres/minute.

- Tank Capacity: 27 liters.

- Dies support shelf included.

- Palletized lower bench to easily transport the machine up to its working or storage site.

- The machine is sent wholly assembled.

- Packing included:

- Wooden pallet NIMF15 and three-layer cardboard apt for suitable for sea freight.

All our products are manufactured in our facilities in Turkey. Hydraulic and electrical components are all standard from the best leading European trademarks with technical support all over the world

Industrial Machinery for Bending

Industrial machinery for bending is used to shape and form metal sheets, plates, and tubes into various shapes and contours. These machines are essential tools in various industries, including metalworking, manufacturing, construction, and automotive production.

Types of Industrial Bending Machinery

Several types of industrial bending machinery are available, each with its own capabilities and applications. Some of the most common types include:

- Press Brakes: Press brakes are versatile machines that use a hydraulic or pneumatic press to apply force to a workpiece, causing it to bend along a predefined line. They can produce a wide range of bends, including angles, channels, and boxes.

- Roll Benders: Roll benders use a series of rollers to gradually bend metal into a curved shape. They are particularly well-suited for producing long, continuous bends and are often used for forming pipes and tubes.

- Horizontal Press Brakes: Horizontal press brakes are similar to press brakes but operate horizontally, allowing for the creation of complex bends and shapes that are difficult to achieve with vertical press brakes.

- Three-Roll Benders: Three-roll benders use three rollers to bend metal into a cylindrical or conical shape. They are commonly used for forming pipes, tanks, and other curved components.

- Rotary Benders: Rotary benders use a rotating mandrel to bend metal around a fixed axis. They are suitable for bending long, thin-walled tubes and pipes.

Applications of Industrial Bending Machinery

Industrial bending machinery is used in a wide variety of applications across various industries. Some common applications include:

- Sheet Metal Forming: Bending machines are used to form sheet metal into various shapes for components in appliances, automotive parts, architectural elements, and electrical enclosures.

- Pipe and Tube Bending: Bending machines are used to bend pipes and tubes for piping systems, structural supports, and fluid conveyance systems.

- Profile Bending: Bending machines can handle complex profiles, such as C-channels, I-beams, and angle irons, for structural components and industrial applications.

- Specialty Bending: Specialized bending machines can produce intricate bends, curves, and shapes for specialized applications, such as aerospace components, medical implants, and decorative elements.

Selection and Operation of Industrial Bending Machinery

Choosing the appropriate industrial bending machine depends on several factors, including:

- Workpiece Material: The machine should be compatible with the material being bent, such as steel, aluminum, or stainless steel.

- Workpiece Thickness: The machine should have sufficient capacity to handle the thickness of the workpiece being bent.

- Bending Requirements: The machine should be able to produce the desired bend angles, shapes, and precision.

- Production Volume: For high-volume production, an automated machine may be more efficient. For smaller-scale production or prototyping, a manual machine may suffice.

- Safety Features: Ensure the machine incorporates safety features such as light guards, emergency stops, and interlocking mechanisms.

When operating industrial bending machinery, proper safety precautions should be followed to prevent accidents and injuries:

- Wear PPE: Always wear appropriate PPE, including safety glasses, gloves, and proper footwear, when operating bending machinery.

- Secure Workpiece Positioning: Ensure the workpiece is securely clamped in place on the machine bed to prevent movement during bending.

- Proper Tooling Selection: Use the appropriate bending tools for the desired bend shape, workpiece material, and thickness.

- Clearance from Bending Tools: Maintain adequate clearance from the bending tools to avoid hand injuries or damage to the tooling.

- Emergency Stop Awareness: Familiarize yourself with the emergency stop location and be prepared to activate it in case of any unsafe conditions.

- Follow Manufacturer Instructions: Strictly follow the manufacturer’s instructions and safety guidelines for the specific bending machine in use.

Industrial bending machinery plays a crucial role in shaping and forming metal components across various industries. By selecting the right machine, adhering to safety protocols, and following proper operating procedures, these machines contribute to efficient, safe, and productive manufacturing processes.

Parts bent by a sheet metal press brake

Sheet metal horizontal presses are versatile machines that can be used to bend a wide variety of parts, including:

Automotive Parts:

- Door panels

- Hoods and trunk lids

- Fender panels

- Structural bracing

- Brackets and mounts

Appliance Components:

- Refrigerator panels

- Washing machine tubs

- Oven housings

- Dishwasher racks

- Control panels

Electronic Enclosures:

- Computer cases

- Server cabinets

- Audio/video equipment casings

- Electrical control panels

- Instrument housings

Architectural Elements:

- Roofing panels

- Siding panels

- Ductwork

- Gutters and downspouts

- Decorative accents

Industrial Components:

- Machinery guards

- Safety covers

- Tooling and fixtures

- Storage containers

- Material handling equipment

The specific parts that can be bent by a sheet metal horizontal press will depend on the size and capacity of the machine, as well as the tooling that is available. However, in general, horizontal presses are well-suited for bending large, flat pieces of sheet metal into a variety of shapes.

Here are some additional examples of parts that can be bent by a sheet metal horizontal press:

- Angles and channels

- Boxes and enclosures

- U-shapes and Z-shapes

- Louvers and vents

- Curvilinear shapes (with the appropriate tooling)

With its versatility and precision, the sheet metal horizontal press is a valuable tool for a wide range of metalworking applications.

As a steel plate bender, our EMS HP series metal press brake is the best in performance/price ratio.

A manual steel bending machine is a lightweight metalworking machine with which you can also make punching. A Punching machine is used to punch sheet metals to drill them. This is one of the most used types of plant machinery. The iron punching machine is a power press cutting machine which is a hydraulic sheet cutting machine.

All the machines and machinery parts are manufactured in our own production facility in Turkey. A hydraulic punch press or sheet metal press brake is a vital production machine used to punch sheet metal as a manual punch press.

Warranty

EMS Metalworking machines have 3 years warranty. This one encloses any manufacturing default all along these 3 years for components. Any misuse is excluded from this condition. Labor, back and forth shipping and any eventual repair, are not included in this warranty

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching