An edge curling machine is a metalworking machine, specialized in curling the edges of round sheet metal parts. Curling is a metal forming process carried out by a sheet metal curling tool. The round part is put on the turning mold. The mold is rotated from the downside rotating shaft. There is also an upper mold that is idle. The part between the downside and upside molds is rotated while the edge curling tool moves into the part direction.

The aim of the curling process in the sheet metal industry is to create a hollow circle at the end of the edges to have a better and a more safe finishing. The machine that carries out the curling operation in sheet metal is called “Edge curling machine” or “Edge wrapping and curling machine”

An edge curling machine is a metalworking tool used to curl the edges of sheet metal components, typically into a cylindrical or conical shape. It is commonly employed in various industries to produce reinforced edges that enhance the strength, rigidity, and aesthetics of sheet metal components.

Operation of an Edge Curling Machine

The operation of an edge curling machine typically involves the following steps:

- Workpiece Preparation: The sheet metal workpiece is cleaned and prepared for curling by removing any surface imperfections or debris.

- Workpiece Positioning: The workpiece is securely positioned on the machine’s worktable or chuck, ensuring it is properly aligned with the curling tool.

- Curling Tool Selection: The appropriate curling tool is selected based on the desired curl radius and the material of the workpiece.

- Curling Process: The curling tool is rotated against the edge of the workpiece, gradually curling the material into the desired shape.

- Pressure Adjustment: The pressure applied by the curling tool is adjusted to achieve the desired curl depth and prevent excessive deformation of the workpiece.

- Curling Progression: The curling process continues along the edge of the workpiece until the desired curl is achieved throughout the entire length.

Applications of Edge Curling Machines

Edge curling machines are used in various industries for a wide range of applications, including:

- Cylindrical Component Manufacturing: Edge curling machines are used to curl the edges of cylindrical components, such as cans, drums, and barrels, to provide reinforcement and a smooth finish.

- Conical Component Manufacturing: Edge curling machines are employed to curl the edges of conical components, such as buckets, funnels, and hoppers, to enhance their structural integrity and prevent material spillage.

- Sheet Metal Edge Reinforcement: Edge curling machines are used to curl the edges of sheet metal components, such as panels, brackets, and enclosures, to improve their strength and rigidity.

- Edge Finishing and Aesthetics: Edge curling machines are used to create a smooth, finished edge on sheet metal components, enhancing their aesthetic appeal and reducing sharp edges.

- Protective Edge Forming: Edge curling machines are employed to form protective edges on sheet metal components, preventing damage or injury from sharp edges.

Benefits of Edge Curling Machines

Edge curling machines offer several advantages over other methods of curling or forming sheet metal edges, including:

- Precise Control: Edge curling machines provide precise control over the curl radius, ensuring consistent and uniform results.

- Efficient Operation: Edge curling machines can curl long edges quickly and efficiently, improving production speed and reducing labor costs.

- Versatility: Edge curling machines can handle a wide range of sheet metal materials and thicknesses, making them adaptable to various applications.

- Durability: Edge curling machines are constructed from durable materials and designed for long-term operation in industrial environments.

Safety Precautions

When operating edge curling machines, it is crucial to follow safety precautions to prevent injuries and ensure proper operation:

- Wear Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and a hearing protection device to protect yourself from flying debris, sparks, and noise.

- Securely Clamp the Workpiece: Ensure the workpiece is firmly clamped to the machine’s worktable or chuck to prevent it from slipping or moving during curling.

- Use the Correct Curling Tool: Choose the appropriate curling tool for the specific application and material being curled. Using the wrong tools can damage the workpiece or cause injury.

- Maintain Proper Machine Speed: Maintain a moderate speed to prevent overheating the workpiece or damaging the curling tool.

- Avoid Overheating the Workpiece: Avoid applying excessive pressure or operating the machine for extended periods to prevent overheating the workpiece and potential damage.

- Regularly Clean and Maintain the Machine: Keep the machine clean and inspect it regularly for worn or loose components.

- Operate the Machine in a Well-ventilated Area: Use the machine in a well-ventilated area to minimize dust accumulation and protect yourself from harmful fumes.

- Never Touch the Moving Curling Tool: Never touch the moving curling tool while the machine is in operation.

- Turn Off the Machine Before Making Adjustments: Always turn off the machine before making any adjustments or changing the curling tool.

- Store the Machine Properly: Store the machine in a safe, secure location when not in use, keeping it out of reach of children and unauthorized users.

By adhering to these safety guidelines and operating the machine responsibly, you can effectively utilize edge curling machines to create precise, high-quality curled edges on various sheet metal components.

The edge curling tool is moved into the rotating sheet metal part direction by a servo motor. The operator can adjust the working stroke of this edge curling tool from the touch screen. The edge curling operation has to be done after the edge cutting process which removes the unwanted rims of the sheet metal parts caused by the deep drawing process.

Edge Curling Machine Operation

Operating an edge curling machine involves several steps to ensure safe and efficient operation. Here’s a step-by-step guide:

- Preparation:

- Safety Precautions: Always wear appropriate safety gear, including safety glasses, gloves, and hearing protection, to prevent injuries from flying debris, sparks, or noise.

- Workpiece Preparation:

- Cleaning: Clean the sheet metal workpiece to remove any dirt, debris, or surface imperfections that could affect the curling process.

- Positioning: Securely clamp the workpiece to the machine’s worktable or chuck using appropriate clamps or fixtures to prevent movement during curling.

- Curling Tool Selection:

- Material Compatibility: Choose the appropriate curling tool based on the material of the workpiece. Different materials may require different curling tools to achieve optimal results.

- Curl Radius: Select a curling tool with the desired curl radius, which is the curvature of the curled edge. The curl radius should match the design specifications.

- Curling Process:

- Alignment: Ensure the workpiece is properly aligned with the curling tool to achieve a consistent and uniform curl along the edge.

- Pressure Adjustment: Adjust the pressure applied by the curling tool to match the material and thickness of the workpiece. Excessive pressure can damage the workpiece, while insufficient pressure may not produce the desired curl.

- Curling Speed: Maintain a moderate curling speed to prevent overheating of the workpiece or damage to the curling tool. Slow curling may not provide sufficient force, while excessively fast curling may result in irregularities.

- Curling Progression:

- Continuous Curl: Engage the curling tool and rotate it against the edge of the workpiece, gradually curling the material into the desired shape.

- Consistent Pressure: Maintain consistent pressure throughout the curling process to ensure a uniform curl along the entire edge.

- Visual Inspection: Regularly inspect the curled edge to ensure it meets the desired specifications and adjust the pressure or curling speed as needed.

- Completion and Safety:

- Curling Completion: Once the desired curl is achieved along the entire edge, disengage the curling tool and carefully remove the workpiece from the machine.

- Machine Shutdown: Turn off the machine and secure any moving parts before leaving the workstation.

Additional Safety Considerations:

- Regular Maintenance: Regularly inspect the edge curling machine for worn or damaged components and ensure proper maintenance to maintain its safety and effectiveness.

- Work Area Ventilation: Operate the machine in a well-ventilated area to minimize dust accumulation and protect yourself from harmful fumes.

- Proper Tool Handling: Always handle curling tools carefully and avoid touching them while they are in motion.

- Unauthorized Access Restriction: Keep the machine out of reach of unauthorized individuals, especially children, to prevent accidental operation or injury.

The machine is switched on from the main switch. This gives energy both to the power and control parts of the machine. The operator puts the round sheet metal part onto the down mold. The part needs to sit tight on the mold to have a good finishing. The mold is manufactured according to the sample part provided by the customer

The second step is to push the 2 start buttons together. For safety measures, we put 2 start buttons, which are away from each other. With that, we aim for the operator to use both hands while starting the machine.

The third step is the movement of the edge curling tool. The edge curling tool is moved forward by the servo motor at the back and forces the tool to touch the edges of the round sheet metal part. Meanwhile, the part is rotated by another motor in the machine body. By that the tool gives a curling effect to the part rim for a few seconds.

The fourth step is the end step. The operator removes the part and puts the next part on the mold for the next curling operation.

Edge Curling Process in Sheet Metal

Curling is a special metal forming process where there comes out no metal chips. It is another finishing process to have better quality and safety in the end.

Curling is a metal forming process used to create a rolled edge on a sheet metal component. The curled edge can be used for aesthetic purposes, to increase the strength and rigidity of the component, or to provide a protective barrier against sharp edges.

Curling Process Steps

The curling process typically involves the following steps:

- Workpiece Preparation: The sheet metal workpiece is cleaned and prepared for curling by removing any surface imperfections or debris.

- Workpiece Positioning: The workpiece is securely positioned on the curling machine’s worktable or chuck, ensuring it is properly aligned with the curling tool.

- Curling Tool Selection: The appropriate curling tool is selected based on the desired curl radius and the material of the workpiece. Curling tools are typically made of hardened steel or other durable materials and have a specific shape that determines the curl radius.

- Curling Operation: The curling tool is rotated against the edge of the workpiece, gradually curling the material into the desired shape. The curling tool applies pressure to the workpiece, forcing it to bend and form the curled edge.

- Pressure Adjustment: The pressure applied by the curling tool is adjusted to achieve the desired curl depth and prevent excessive deformation of the workpiece. If too much pressure is applied, the workpiece may crack or deform excessively. If too little pressure is applied, the curled edge may not be deep enough or may not have the desired shape.

- Curling Progression: The curling process continues along the edge of the workpiece until the desired curl is achieved throughout the entire length. The curling tool is moved along the edge of the workpiece, applying consistent pressure and ensuring that the curl is uniform throughout.

Applications of Curling

Curling is used in a variety of applications, including:

- Reinforcing sheet metal edges: Curling can be used to reinforce the edges of sheet metal components, making them stronger and more resistant to damage. This is often used in applications where the edges of the component may be exposed to wear or impact.

- Improving aesthetics: Curling can also be used to improve the aesthetics of sheet metal components by creating a smooth, finished edge. This is often used in applications where the appearance of the component is important.

- Protecting against sharp edges: Curling can be used to protect against sharp edges on sheet metal components. This is often used in applications where the component may be handled or where there is a risk of injury from sharp edges.

- Creating a flange: Curling can be used to create a flange on a sheet metal component. This is often used in applications where the flange is needed to provide a mounting surface for another component or to seal a joint.

Types of Curling Machines

There are several different types of curling machines available, each with its own advantages and disadvantages. Some of the most common types of curling machines include:

- Hand curling machines: These machines are operated manually and are typically used for small or low-volume applications.

- Pneumatic curling machines: These machines are powered by compressed air and are typically used for medium-volume applications.

- Hydraulic curling machines: These machines are powered by hydraulic fluid and are typically used for high-volume applications.

- CNC curling machines: These machines are controlled by computer and are typically used for complex or high-precision applications.

Safety Precautions

When operating a curling machine, it is important to follow safety precautions to prevent injuries and ensure proper operation. Some of the most important safety precautions include:

- Wearing personal protective equipment (PPE): Always wear safety glasses, gloves, and a hearing protection device when operating a curling machine.

- Securing the workpiece: Ensure the workpiece is securely clamped to the machine’s worktable or chuck to prevent it from moving during curling.

- Using the correct curling tool: Choose the appropriate curling tool for the specific application and material being curled. Using the wrong tool can damage the workpiece or cause injury.

- Maintaining proper machine speed: Maintain a moderate speed to prevent overheating the workpiece or damaging the curling tool.

- Avoiding overheating the workpiece: Avoid applying excessive pressure or operating the machine for extended periods to prevent overheating the workpiece and potential damage.

- Regularly cleaning and maintaining the machine: Keep the machine clean and inspect it regularly for worn or loose components.

- Operating the machine in a well-ventilated area: Use the machine in a well-ventilated area to minimize dust accumulation and protect yourself from harmful fumes.

- Never touching moving parts: Never touch the moving curling tool or other moving parts of the machine while it is in operation.

- Turning off the machine before making adjustments: Always turn off the machine before making any adjustments or changing the curling tool.

It is widely used in cookware kitchenware bakeware industries. Also, water heater, boiler, and reservoir manufacturing companies use edge curling for the taps of their products.

Edge curling can be applied in most metals such as stainless steel, mild steel, aluminum, copper, tin, and titanium.

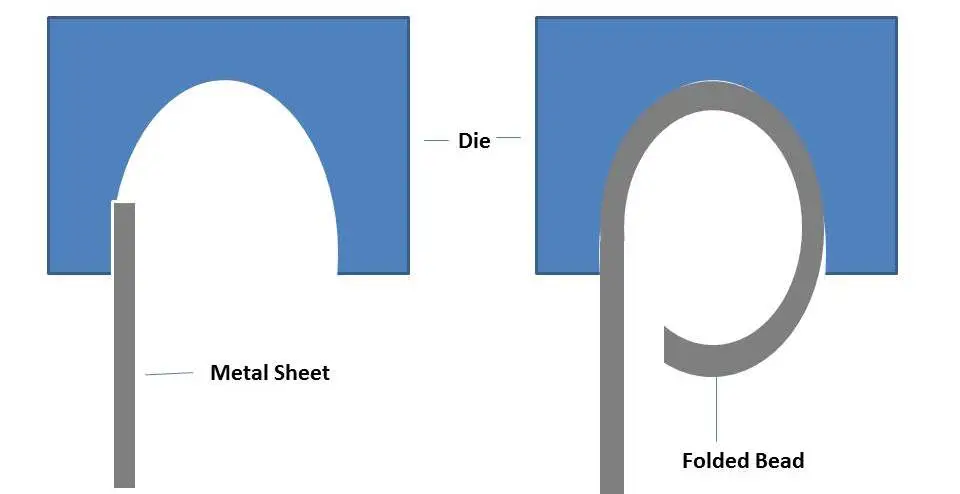

At the end of the sheet metal edge curling, we get a clean end effect with a hollow circle, also called as a folded bead.

Automatic Edge Flanging Machine

These edge trimming and curling machines are sometimes called as edge flanging machines. The Edge flanging machine can create a flange around the rim of the round sheet metal part. The sheet metal company usually buys this machine to form a round flange around their sheet metal products.

The operations carried out on the machine are: Trimming, flanging, radius forming, folding, etc.

An automatic edge flanging machine is a specialized tool used in metalworking to create a flange or edge bend along the perimeter of a sheet metal workpiece. It operates automatically, eliminating the need for manual operation, and ensures consistent, high-quality results.

Operation of an Automatic Edge Flanging Machine

The operation of an automatic edge flanging machine typically involves the following steps:

- Workpiece Loading: The sheet metal workpiece is placed on the machine’s feed table or conveyor belt, and it is automatically positioned and aligned for flanging.

- Flanging Tool Selection: The appropriate flanging tool or die set is selected based on the desired flange angle and the material of the workpiece.

- Flanging Process: The workpiece is fed into the flanging machine, and the flanging tool engages the edge of the workpiece, gradually bending it upwards or downwards to form the flange.

- Pressure and Speed Adjustment: The pressure applied by the flanging tool and the speed at which the workpiece is fed are controlled to ensure consistent and accurate flange formation.

- Flange Formation Progression: The flanging process continues along the entire perimeter of the workpiece, creating a uniform flange along the edge.

- Workpiece Unloading: Once the flanging is complete, the finished workpiece is automatically ejected from the machine.

Advantages of Automatic Edge Flanging Machines

Automatic edge flanging machines offer several advantages over manual flanging methods, including:

- Increased Productivity: Automatic operation significantly increases production speed compared to manual flanging, allowing for higher output and reduced labor costs.

- Consistent Quality: Automated control ensures consistent flange angles, dimensions, and surface finishes across all workpieces.

- Reduced Human Error: Automation eliminates human error, minimizing defects and improving overall product quality.

- Improved Safety: Automatic machines eliminate the need for operators to work near moving parts, reducing the risk of workplace injuries.

- Versatility: Automatic edge flanging machines can handle a wide range of sheet metal materials, thicknesses, and flange angles.

Applications of Automatic Edge Flanging Machines

Automatic edge flanging machines are widely used in various industries for a variety of applications, including:

- Sheet Metal Fabrication: Automatic edge flanging machines are used in sheet metal fabrication to create flanges for ducts, enclosures, panels, and other components.

- Appliance Manufacturing: Automatic edge flanging machines are employed in appliance manufacturing to form flanges on appliance bodies, doors, and panels.

- Automotive Industry: Automatic edge flanging machines are used in the automotive industry to create flanges on car body panels, bumpers, and other components.

- Electronics Manufacturing: Automatic edge flanging machines are employed in electronics manufacturing to form flanges on metal casings, enclosures, and brackets.

- HVAC and Ventilation Systems: Automatic edge flanging machines are used to create flanges for ductwork, ventilation systems, and other HVAC components.

- Metal Furniture Manufacturing: Automatic edge flanging machines are employed in metal furniture manufacturing to form flanges on tabletops, cabinet frames, and other furniture components.

Automatic edge flanging machines have become an essential tool in various industries due to their ability to produce high-quality flanges efficiently and consistently, enhancing the strength, rigidity, and aesthetics of sheet metal components.

Tea Kettle Curling

The tea kettle is one of the many kitchenware products that need curling on their edges. This makes the stainless steel edges of the kettle safer and easier to transport. On our edge curling machine, you can easily curl the edges of the tea kettles. The kettle curls are also good for decorative purposes.

Tea kettle curling is a precision metalworking process used to create a curled edge on the spout of a tea kettle. This curled edge serves several purposes, including:

- Reinforcing the spout: The curled edge distributes stress more evenly, making the spout more resistant to damage from repeated use.

- Improving the spout’s ability to pour: The curled edge creates a smooth, continuous surface that helps to prevent spills.

- Enhancing the aesthetics of the tea kettle: The curled edge adds a touch of elegance and sophistication to the tea kettle’s design.

Steps in Tea Kettle Curling

The process of tea kettle curling typically involves the following steps:

1. Workpiece Preparation:

- The tea kettle spout is carefully cleaned and inspected for any damage or imperfections.

- The spout is then securely clamped to the curling machine’s worktable or chuck.

2. Curling Tool Selection:

- The appropriate curling tool is selected based on the desired curl radius and the material of the tea kettle spout. The curling tool is typically made of hardened steel or other durable materials and has a specific shape that determines the curl radius.

3. Curling Operation:

- The curling tool is engaged with the spout’s edge and rotated gradually, applying pressure to bend the metal into the desired shape.

- The pressure applied by the curling tool is adjusted to achieve the desired curl depth and prevent excessive deformation of the spout.

4. Curl Progression:

- The curling process continues along the entire spout, ensuring a uniform curl throughout the entire length.

- The curling tool is moved along the spout edge, applying consistent pressure to maintain a smooth, continuous curl.

5. Curl Completion:

- Once the desired curl is achieved along the entire spout, the curling tool is disengaged and the tea kettle spout is removed from the machine.

Safety Precautions:

- Wear appropriate safety gear, including safety glasses, gloves, and a hearing protection device.

- Secure the workpiece firmly to prevent movement during the curling process.

- Choose the correct curling tool for the specific application and material.

- Maintain a moderate curling speed to prevent overheating the spout or damaging the curling tool.

- Avoid applying excessive pressure, which can damage the spout or cause it to crack.

- Regularly inspect the edging machine for worn or damaged components.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching