An EMS Longitudinal Welding Machine optimizes the welding process, reduces shrinkage and distortion, reduces welding costs, and improves the quality of the weld. The linear welding speed and precision you depend on, both for today’s needs and for the future, enable high-volume cylinder production, joining thin-gauge metal, welding coiled sheets, and more.

A longitudinal welding machine, also known as a seam welding machine or a stake bed welder, is a specialized machine designed to weld flat sheets or cylindrical components along a straight line. It is commonly used in the manufacturing and construction industries to join plates, pipes, tanks, and other structures.

Key Components of Longitudinal Welding Machines:

- Welding Head: The welding head consists of the welding torch, filler metal feed mechanism, and shielding gas nozzle. It is precisely positioned and aligned with the weld joint to ensure proper weld penetration and fusion.

- Workpiece Clamping System: The workpiece clamping system securely holds the workpiece in place during the welding process. This clamping system prevents movement of the workpiece, ensuring consistent weld quality along the entire weld joint.

- Travel Carriage: The travel carriage moves the welding head along the weld joint at a controlled speed. This consistent travel speed ensures proper heat distribution and weld penetration along the entire weld length.

- Control System: The control system regulates the welding parameters, such as welding current, voltage, travel speed, and shielding gas flow. It ensures consistent and repeatable welding conditions for achieving high-quality welds.

Advantages of Longitudinal Welding Machines:

- Efficient Welding: Longitudinal welding machines offer efficient welding of long, straight seams, significantly reducing welding time compared to manual welding methods.

- Consistent Weld Quality: The precise positioning of the welding head and the controlled travel speed ensure consistent weld quality along the entire weld length.

- Automation Integration: These machines can be integrated with robotic arms or automated systems, enabling high-volume production and reducing labor costs.

- Versatility: Longitudinal welding machines can handle a variety of workpiece materials, thicknesses, and welding processes. They can weld flat sheets, pipes, tanks, and other structures with varying geometries.

- Safety Features: Longitudinal welding machines incorporate safety features, such as interlocks, guards, and emergency stop buttons, to protect operators from hazards.

Applications of Longitudinal Welding Machines:

- Manufacturing: Joining sheets for the production of tanks, containers, and structural components.

- Construction: Welding pipes, tanks, and other cylindrical structures in construction projects.

- Automotive Industry: Joining sheet metal components for vehicle bodies and frames.

- Shipbuilding: Welding ship hulls, decks, and piping systems.

- Aerospace Industry: Welding components for aircraft structures, such as fuselages, wings, and landing gear.

- Food and Beverage Industry: Joining stainless steel and aluminum components in food processing equipment.

- Chemical Industry: Welding pipes, tanks, and other components in chemical processing equipment.

- Oil and Gas Industry: Welding pipelines, pressure vessels, and storage tanks.

Future Trends in Longitudinal Welding Machines:

- Advanced Automation: Integration of sophisticated robotics, sensors, and control systems for greater automation and precision.

- Real-Time Monitoring: Implementation of monitoring systems to track welding parameters, weld quality, and potential defects in real-time.

- Adaptive Welding Control: Development of adaptive welding control systems to adjust welding parameters based on workpiece material, geometry, and environmental factors.

- Remote Operation: Incorporation of remote operation capabilities to allow for control and monitoring of welding processes from a distance.

- Data-Driven Optimization: Utilization of welding data and analytics to optimize welding parameters, improve weld quality, and predict potential issues.

Longitudinal welding machines play a vital role in various industries, providing efficient, precise, and reliable methods for joining long, straight seams in a variety of materials and applications. Their versatility, advanced automation capabilities, and safety features make them indispensable tools for manufacturing and construction processes. As technology advances, longitudinal welding machines are expected to become even more sophisticated, enabling further automation, enhanced control, and improved weld quality across diverse industries.

A longitudinal welding machine is a type of welding equipment used to join two metal plates or sheets along their length or longitudinal axis. This type of welding is often used in the fabrication of large cylindrical structures such as pipelines, pressure vessels, and tanks.

The longitudinal welding process involves moving the workpiece through the welding machine while a welding torch produces a continuous weld along the length of the seam. The torch typically uses a wire electrode that is fed into the weld pool to create a strong and durable bond between the two metal sheets or plates.

Longitudinal welding machines can be operated manually or automated, depending on the complexity and size of the workpiece. Automated machines can offer greater precision and consistency, as well as faster production times, while manual machines may be more suitable for smaller or simpler workpieces.

Overall, the use of a longitudinal welding machine can result in a high-quality and efficient welding process that is essential for the production of many large metal structures used in various industries such as oil and gas, chemical, and construction.

Longitudinal Welding Machine

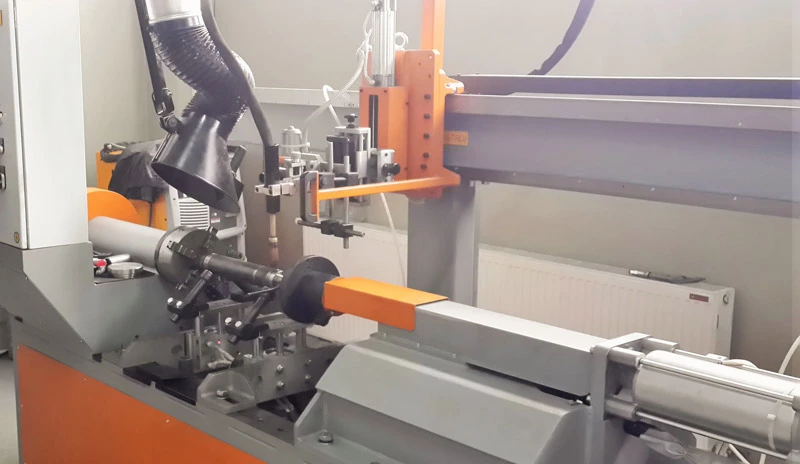

The EMS Metalworking range of Seam Welding machines has been designed for welding longitudinal seams of cylindrical, conical, and rectangular workpieces and, in addition, flat sheets or plates.

The robust construction of the machine and patented design of the clamping finger operation ensure the correct alignment for the welding on-gauge material in stainless steel, mild steel, titanium, copper, or aluminum. The variable speed traveling carriage which traverses an accurately machined beam ensures the torch follows precisely the welding seam.

The Bode EMS Metalworking range will produce uniformly strong welds and reduce welding costs using TIG (Argon Arc), MIG (Metal Inert Gas using Arcon, CO2 or Gas mixtures), or Submerged Arc processes.

Welding Head

A welding head is a critical component of welding equipment that holds the welding torch, filler metal feed mechanism, and shielding gas nozzle. It is responsible for precisely positioning and directing these elements to create a strong and durable weld.

Key Components of a Welding Head:

- Welding Torch: The welding torch is the heart of the welding head, containing the electrode and nozzle that deliver the welding current and shielding gas. The type of welding torch used depends on the specific welding process, such as gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), or submerged arc welding (SAW).

- Filler Metal Feed Mechanism: The filler metal feed mechanism automatically delivers the welding wire or rod to the weld puddle, ensuring consistent metal deposition and preventing gaps or porosity in the weld.

- Shielding Gas Nozzle: The shielding gas nozzle directs a protective gas stream around the weld area to prevent oxidation and contamination of the weld pool. The type of shielding gas used depends on the welding process and the workpiece material.

Functions of a Welding Head:

- Precise Positioning: The welding head ensures that the welding torch and filler metal are accurately positioned in relation to the workpiece to achieve proper weld penetration and fusion.

- Consistent Heat Input: The welding head controls the heat input provided by the welding torch, ensuring that the weld is not excessively hot or cold, preventing defects such as burn-through or lack of fusion.

- Weld Parameter Control: The welding head allows for precise control of welding parameters, such as current, voltage, and travel speed, to optimize the welding process and achieve the desired weld properties.

- Shielding Gas Delivery: The welding head effectively directs the shielding gas around the weld area to protect the weld puddle from oxidation and contamination, ensuring a clean and high-quality weld.

Applications of Welding Heads:

- Welding of various materials: Welding heads can be used with a wide range of materials, including steel, aluminum, stainless steel, and copper, making them versatile for various applications.

- Automated and robotic welding: Welding heads are commonly used in automated and robotic welding systems, enabling efficient and repeatable welding processes for high-volume production.

- Different welding processes: Welding heads can accommodate various welding processes, including GMAW, GTAW, SAW, and flux-cored arc welding (FCAW), providing flexibility for different applications.

- Precision welding of complex geometries: Welding heads can precisely position the torch and filler metal for welding complex geometries, such as joints in pipes, tanks, and vessels.

- Maintenance and repair of metal structures: Welding heads are essential for maintaining and repairing metal structures in various industries, such as manufacturing, construction, and infrastructure.

Welding heads play a crucial role in achieving high-quality welds and enabling efficient welding processes across various industries. Their precision, versatility, and ability to handle different welding processes make them indispensable tools for modern manufacturing and construction.

Welding Torch

A welding torch is a critical component of welding equipment that delivers the arc energy and shielding gas to the weld joint. It is the interface between the welding power supply and the workpiece.

Key Components of a Welding Torch:

- Electrode: The electrode is the conductor that provides the arc current to the weld joint. It is typically a non-consumable tungsten electrode for gas tungsten arc welding (GTAW), or a consumable wire for gas metal arc welding (GMAW) and flux-cored arc welding (FCAW).

- Nozzle: The nozzle directs the shielding gas from the shielding gas supply to the weld joint. It also protects the electrode from oxidation and contamination.

- Shielding Gas Supply: The shielding gas supply provides a stream of inert gas, such as argon or helium, to the weld joint. This shielding gas prevents the weld metal from oxidizing or contaminating, ensuring a clean and high-quality weld.

Functions of a Welding Torch:

- Arc Generation: The welding torch generates an electric arc between the electrode and the workpiece, providing the heat necessary for melting the base metal and filler metal.

- Shielding Gas Delivery: The shielding gas supply directs a stream of shielding gas to the weld joint, preventing oxidation and contamination of the molten metal and shielding the arc from atmospheric gases.

- Filler Metal Delivery: For consumable electrode welding processes, the welding torch delivers the filler metal into the weld pool. This filler metal contributes to the buildup of the weld deposit.

- Welding Parameter Control: The welding torch may incorporate sensors and controls to regulate welding parameters, such as arc current, voltage, and travel speed, to optimize the welding process and achieve the desired weld properties.

Types of Welding Torches:

- Gas Tungsten Arc Welding (GTAW) Torch: This torch uses a non-consumable tungsten electrode and requires a separate filler metal feed mechanism.

- Gas Metal Arc Welding (GMAW) Torch: This torch uses a consumable wire electrode and incorporates a built-in wire feeder mechanism.

- Flux-Cored Arc Welding (FCAW) Torch: This torch uses a consumable flux-cored wire electrode that provides both the filler metal and shielding gas.

- Submerged Arc Welding (SAW) Torch: This torch utilizes a consumable wire electrode and submerges the weld area in flux to protect the arc and provide a protective atmosphere.

Selection Considerations for Welding Torches:

- Welding Process: The welding torch should be compatible with the specific welding process being used to ensure proper arc generation and shielding gas delivery.

- Workpiece Material: The welding torch should be compatible with the workpiece material to prevent contamination and ensure a strong and durable weld.

- Application Requirements: The welding torch should meet the specific requirements of the welding application, such as joint geometry, workpiece size, and required welding speed.

- Safety Features: The welding torch should incorporate safety features to protect operators from potential hazards, such as interlocks, guards, and emergency stop buttons.

- Ease of Use and Maintenance: The welding torch should be easy to use and maintain for optimal performance and operator experience.

Welding torches are essential components of modern welding equipment, enabling efficient, precise, and repeatable welding processes. They play a crucial role in achieving high-quality welds in various industries, from manufacturing to construction.

Filler Metal Feed Mechanism

A filler metal feed mechanism is an essential component of welding equipment that automatically delivers the filler metal into the weld puddle during the welding process. It ensures a continuous supply of filler metal, maintaining a consistent arc length and preventing weld defects caused by insufficient filler metal.

Purposes of a Filler Metal Feed Mechanism:

- Consistent Filler Metal Deposition: The filler metal feed mechanism provides a consistent and controlled flow of filler metal into the weld pool, ensuring proper weld penetration and fusion. This consistency prevents gaps or porosity in the weld.

- Arc Stability: The filler metal feed mechanism maintains a consistent arc length by adjusting the filler metal delivery rate. This stability minimizes arc fluctuations and prevents arc outages.

- Weld Quality Enhancement: The filler metal feed mechanism contributes to improved weld quality by ensuring proper weld reinforcement and preventing weld defects such as undercut, overlap, and porosity.

- Increased Productivity: The filler metal feed mechanism automates the filler metal feeding process, reducing the workload for the welder and increasing welding speed. This automation improves productivity, especially in high-volume production environments.

- Reduced Labor Costs: The filler metal feed mechanism eliminates the need for manual filler metal feeding, reducing labor costs and improving overall production efficiency.

Types of Filler Metal Feed Mechanisms:

- Push-Pull Systems: These systems utilize a combination of push rollers and pull rollers to precisely control the movement of the filler metal. They are commonly used in gas metal arc welding (GMAW) and flux-cored arc welding (FCAW) processes.

- Push-Type Systems: These systems use a set of drive rollers to push the filler metal into the weld puddle. They are typically used for welding processes that require high filler metal deposition rates, such as submerged arc welding (SAW).

- Spool-Type Systems: These systems employ a spool of filler metal wire that is fed into the weld puddle through a guidance tube. They are commonly used for GMAW and FCAW processes.

- Drum-Type Systems: These systems utilize a drum of filler metal wire that is fed into the weld puddle through a guidance tube. They are typically used for SAW processes.

Selection Considerations for Filler Metal Feed Mechanisms:

- Welding Process: The filler metal feed mechanism should be compatible with the specific welding process being used to ensure proper filler metal delivery and compatibility with the welding equipment.

- Workpiece Material: The filler metal feed mechanism should accommodate the type of filler metal required for the workpiece material to ensure proper weld properties and compatibility.

- Filler Metal Diameter: The filler metal feed mechanism should be compatible with the diameter of the filler metal being used to ensure proper feeding and control.

- Welding Speed: The filler metal feed mechanism should be capable of providing the required filler metal deposition rate at the specified welding speed to maintain a stable arc and prevent weld defects.

- Ease of Use and Maintenance: The filler metal feed mechanism should be easy to set up, operate, and maintain for optimal performance and operator experience.

Filler metal feed mechanisms play a crucial role in achieving high-quality welds in various industries. Their ability to precisely deliver filler metal into the weld puddle ensures consistent weld quality, increased productivity, and reduced labor costs.

Shielding Gas Nozzle

A shielding gas nozzle is an essential component of welding equipment that directs a stream of shielding gas to the weld joint, preventing oxidation and contamination of the weld metal. It protects the weld from impurities in the air and atmosphere, ensuring a clean and high-quality weld.

Purposes of a Shielding Gas Nozzle:

- Oxidation Prevention: The shielding gas nozzle prevents the weld metal from oxidizing or contaminating by shielding it from the surrounding air and atmosphere.

- Contamination Prevention: The shielding gas nozzle also protects the weld from contamination by dust, dirt, and other airborne particles.

- Arc Stability: The shielding gas nozzle maintains a stable arc by shielding it from external interference.

- Reduced Weld Defects: The shielding gas nozzle helps to reduce weld defects such as porosity, spatter, and undercut by creating a clean and stable welding environment.

- Improved Weld Quality: The shielding gas nozzle contributes to improved weld quality by ensuring proper weld penetration and fusion.

Types of Shielding Gas Nozzles:

- Straight Nozzles: These nozzles are the most common type and are used for a variety of welding applications.

- Conical Nozzles: These nozzles have a tapered shape that helps to focus the shielding gas and improve weld penetration.

- Vented Nozzles: These nozzles have holes or slots that allow excess shielding gas to escape, preventing turbulence and improving arc stability.

- Gas Lenses: These nozzles are more complex than traditional nozzles and incorporate multiple orifices and channels to direct the shielding gas more precisely.

Selection Considerations for Shielding Gas Nozzles:

- Welding Process: The shielding gas nozzle should be compatible with the specific welding process being used to ensure proper gas flow and compatibility with the welding equipment.

- Workpiece Material: The shielding gas nozzle should be compatible with the workpiece material to prevent contamination and ensure a strong and durable weld.

- Welding Current: The shielding gas nozzle should be capable of handling the required welding current to prevent overheating and nozzle damage.

- Weld Joint Geometry: The shielding gas nozzle should be sized appropriately for the weld joint geometry to ensure proper gas coverage of the weld puddle.

Safety Precautions:

- Proper Gas Selection: Use the correct type and flow rate of shielding gas for the specific welding process and workpiece material.

- Nozzle Condition: Regularly inspect and replace nozzles as needed to ensure proper gas flow and prevent contamination.

- Avoid Overheating: Do not overheat the nozzle, as this can damage it and prevent proper gas flow.

- Proper Ventilation: Ensure adequate ventilation to remove welding fumes and gases from the work area.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and a welding helmet, to protect yourself from welding hazards.

Shielding gas nozzles play a crucial role in achieving high-quality welds in various industries. Their ability to protect the weld from impurities and maintain a stable arc contributes to consistent weld quality and reduced weld defects.

Workpiece Clamping System

A workpiece clamping system is an essential component of welding equipment that securely holds the workpiece in place during the welding process. It ensures that the workpiece remains stationary and properly aligned with the welding torch, preventing movement or distortion that could compromise the quality of the weld.

Purposes of a Workpiece Clamping System:

- Secure Holding: The clamping system firmly grips the workpiece, preventing it from moving or shifting during welding. This stability is crucial for achieving a consistent and high-quality weld.

- Precise Alignment: The clamping system ensures that the workpiece is properly aligned with the welding torch, allowing for accurate positioning of the weld joint and consistent weld penetration.

- Workpiece Stability: The clamping system prevents warping, distortion, or movement of the workpiece due to the heat generated during welding. This stability maintains the integrity of the workpiece and prevents defects caused by movement.

- Safety Enhancement: The clamping system secures the workpiece, minimizing the risk of accidental movement or displacement during welding. This safety feature protects operators from potential hazards.

Types of Workpiece Clamping Systems:

- Mechanical Clamps: These clamps use mechanical force to grip the workpiece, providing a secure hold for various workpiece shapes and sizes.

- Pneumatic Clamps: These clamps utilize pressurized air to apply clamping force, offering precision control and adaptability to different workpiece geometries.

- Hydraulic Clamps: These clamps employ hydraulic pressure to generate high clamping forces, suitable for heavy-duty applications and large workpieces.

- Magnetic Clamps: These clamps utilize magnetic force to adhere to ferrous workpieces, providing a non-contact clamping method suitable for delicate or thin materials.

- Vacuum Clamps: These clamps use a vacuum to hold onto non-porous workpieces, offering a clean and versatile clamping solution for various materials.

Considerations for Selecting a Workpiece Clamping System:

- Workpiece Material: The clamping system should be compatible with the workpiece material to ensure secure holding and prevent damage to the workpiece.

- Workpiece Shape and Size: The clamping system should accommodate the shape and size of the workpiece, ensuring effective clamping and alignment.

- Welding Process: The clamping system should be compatible with the specific welding process being used to ensure proper workpiece positioning and prevent interference with the welding equipment.

- Safety Requirements: The clamping system should comply with safety regulations and incorporate safety features to protect operators from potential hazards.

- Cost and Efficiency: The clamping system should balance cost with the required level of performance and efficiency for the intended application.

Workpiece clamping systems are crucial for achieving high-quality welds and ensuring the safety of welding operations. Their ability to securely hold workpieces, maintain precise alignment, and adapt to various materials and welding processes make them indispensable tools for modern welding applications.

Travel Carriage

A travel carriage is a critical component of welding equipment that moves the welding head along the weld joint at a controlled speed. It ensures consistent weld quality and reduces the risk of weld defects caused by uneven heat distribution.

Purposes of a Travel Carriage:

- Uniform Heat Distribution: The travel carriage moves the welding head at a consistent speed along the weld joint, ensuring uniform heat distribution throughout the weld. This uniformity prevents localized overheating or cold spots that could lead to defects such as burn-through or lack of fusion.

- Repetitive Welding: The travel carriage facilitates repetitive welding by automating the movement of the welding head along the weld joint. This automation ensures consistent weld quality and reduces the risk of operator errors.

- Efficient Welding: The travel carriage enables efficient welding by eliminating the need for manual movement of the welding head. This efficiency is particularly beneficial for large-scale production and repetitive welding tasks.

- Precision Welding: The travel carriage allows for precise welding by controlling the speed and positioning of the welding head. This precision is crucial for achieving high-quality welds with consistent weld dimensions.

- Versatility: Travel carriages can be adapted to various welding processes, such as gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), and submerged arc welding (SAW). This versatility expands their applicability across different welding applications.

Types of Travel Carriages:

- Linear Track Carriage: This type of carriage moves along a linear track to position the welding head along the weld joint. It is commonly used in automated welding systems.

- Gimbal Carriage: This type of carriage rotates and translates along a curved path, allowing for welding complex geometries, such as pipes, tanks, and vessels. It is often used in robotic welding systems.

- Multi-axis Carriage: This type of carriage offers more degrees of freedom than linear or gimbal carriages, allowing for precise positioning and movement of the welding head in three-dimensional space. It is used in highly specialized welding applications.

Selection Considerations for Travel Carriages:

- Welding Process: The travel carriage should be compatible with the specific welding process being used to ensure compatibility with the welding head and torch.

- Workpiece Material: The travel carriage should accommodate the weight and size of the workpiece to ensure stability and prevent movement during welding.

- Application Requirements: The travel carriage should meet the specific requirements of the welding application, such as weld joint length, weld geometry, and required welding speed.

- Safety Features: The travel carriage should incorporate safety features to protect operators from potential hazards, such as interlocks, guards, and emergency stop buttons.

- Cost-effectiveness: The travel carriage should balance cost with the required level of performance and functionality for the intended application.

Travel carriages are essential components of advanced welding systems, enabling efficient, precise, and repeatable welding processes. Their ability to precisely position and move the welding head along the weld joint is crucial for achieving high-quality welds in various industries.

General Specifications of the Longitudinal Welding Machine

General specifications of a longitudinal welding machine can vary depending on the specific model and manufacturer, but some common specifications include:

Workpiece Specifications

- Maximum weldable thickness: The maximum thickness of the workpiece that the machine can weld. This is typically measured in millimeters (mm) or inches (in).

- Minimum weldable thickness: The minimum thickness of the workpiece that the machine can weld. This is important for ensuring that the weld is strong enough to support the load of the workpiece.

- Maximum weldable width: The maximum width of the workpiece that the machine can weld. This is typically measured in millimeters (mm) or inches (in).

- Workpiece material: The types of materials that the machine can weld. This typically includes steel, stainless steel, aluminum, and other metals.

Welding Specifications

- Welding process: The type of welding process that the machine can use. This is typically gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), or submerged arc welding (SAW).

- Welding current: The maximum welding current that the machine can supply. This is typically measured in amperes (A).

- Welding voltage: The maximum welding voltage that the machine can supply. This is typically measured in volts (V).

- Welding speed: The maximum welding speed that the machine can achieve. This is typically measured in meters per minute (m/min) or inches per minute (in/min).

Power Specifications

- Power input: The electrical power required to operate the machine. This is typically measured in kilowatts (kW).

- Power supply: The type of power supply that the machine requires. This is typically single-phase or three-phase.

Other Specifications

- Dimensions: The overall dimensions of the machine. This is typically measured in millimeters (mm) or inches (in).

- Weight: The weight of the machine. This is typically measured in kilograms (kg) or pounds (lb).

- Safety features: The safety features that the machine incorporates. This may include interlocks, guards, and emergency stop buttons.

Additional Considerations

- Automation level: The level of automation that the machine offers. This may range from manual to fully automated.

- Ease of use: The ease of use of the machine. This is important for ensuring that operators can quickly and easily learn how to use the machine.

- Maintenance requirements: The maintenance requirements of the machine. This is important for ensuring that the machine can be kept in good working condition.

- Cost: The cost of the machine. This will vary depending on the specific features and capabilities of the machine.

Operation of Longitudinal Welding Machine

Operating a longitudinal welding machine involves a series of steps to ensure safe, efficient, and high-quality welding. Here’s a general outline of the operation process:

- Preparation and Setup:a. Workplace Preparation: Ensure the workpiece is clean, free of debris, and properly positioned on the welding machine’s support bed.b. Machine Inspection: Inspect the welding machine for any visible damage or malfunctions. Check the power supply connections and ensure all safety features are operational.c. Shielding Gas Setup: Connect the shielding gas supply and adjust the gas flow rate according to the welding process and workpiece material.

- Welding Parameter Setting:a. Welding Process Selection: Choose the appropriate welding process based on the workpiece material and desired weld properties.b. Welding Current Adjustment: Set the welding current based on the workpiece thickness and material type. Refer to welding procedure specifications for recommended current values.c. Welding Voltage Adjustment: Set the welding voltage based on the welding current and arc characteristics.d. Welding Speed Adjustment: Set the welding speed based on the workpiece thickness, material type, and desired weld penetration.

- Welding Torch Positioning:a. Travel Carriage Positioning: Position the travel carriage along the weld joint to align the welding torch with the starting point of the weld.b. Torch Angle Adjustment: Adjust the welding torch angle to achieve the desired weld bead shape and penetration.c. Shielding Gas Nozzle Positioning: Position the shielding gas nozzle to ensure adequate shielding of the weld puddle from atmospheric contaminants.

- Welding Initiation and Execution:a. Arc Initiation: Initiate the arc by bringing the welding electrode into contact with the workpiece and then withdrawing it slightly to establish a stable arc.b. Travel Carriage Movement: Activate the travel carriage to move the welding torch along the weld joint at the specified welding speed.c. Filler Metal Feeding: For consumable electrode welding processes, maintain a consistent filler metal feed rate to ensure proper weld reinforcement.

- Welding Monitoring and Adjustments:a. Visual Monitoring: Continuously monitor the welding process to observe the arc stability, weld bead formation, and shielding gas coverage.b. Weld Quality Assessment: Periodically check the weld quality by inspecting the weld appearance, penetration, and absence of defects.c. Parameter Adjustments: If necessary, make fine adjustments to welding parameters, such as current, voltage, or travel speed, to optimize weld quality.

- Welding Completion and Cleanup:a. Arc Termination: Once the weld joint is complete, terminate the arc by gradually withdrawing the welding torch from the workpiece.b. Weld Cooling: Allow the weld to cool naturally or employ cooling methods if necessary to prevent cracking or distortion.c. Slag Removal: Remove any slag or spatter from the weld using a chipping hammer or wire brush.d. Machine Shutdown: Turn off the welding machine and shielding gas supply, disconnect power cords, and perform routine maintenance as per manufacturer’s instructions.

Remember to always follow safety guidelines and wear appropriate personal protective equipment (PPE) when operating any welding machine. Refer to the specific user manual and welding procedure specifications for detailed instructions and safety precautions.

Longitudinal Welding Machine Features

Longitudinal welding machines are specialized machines designed for welding cylindrical or rectangular workpieces along their longitudinal axis. They offer a variety of features that enhance their functionality and effectiveness in various welding applications. Here are some key features of longitudinal welding machines:

- High Welding Speed and Efficiency: Longitudinal welding machines are designed for high-speed welding, enabling efficient production of long welds in a shorter time frame. They can achieve welding speeds up to several meters per minute, depending on the workpiece thickness and material type.

- Precise Weld Positioning and Alignment: Longitudinal welding machines incorporate precision guides and control systems to ensure accurate positioning and alignment of the welding torch along the weld joint. This precision contributes to consistent weld quality and minimizes the risk of defects.

- Variable Welding Parameters: Longitudinal welding machines allow for adjustment of welding parameters, such as welding current, voltage, and travel speed, to optimize the welding process for different workpiece materials and weld requirements.

- Shielding Gas Delivery and Control: Longitudinal welding machines provide a controlled supply of shielding gas to protect the weld puddle from atmospheric contaminants and ensure a clean and high-quality weld. The shielding gas flow rate can be adjusted according to the welding process and workpiece material.

- Filler Metal Feed Mechanism: For consumable electrode welding processes, longitudinal welding machines incorporate a filler metal feed mechanism that automatically delivers the filler wire into the weld puddle at a consistent rate. This consistency ensures proper weld reinforcement and prevents gaps or porosity.

- Welding Process Versatility: Longitudinal welding machines can accommodate various welding processes, including gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), submerged arc welding (SAW), and flux-cored arc welding (FCAW). This versatility makes them suitable for a wide range of welding applications.

- Safety Features and Interlocks: Longitudinal welding machines incorporate safety features, such as interlocks, guards, and emergency stop buttons, to protect operators from potential hazards. These safety features ensure safe operation and prevent accidental accidents.

- Automation and Control Options: Longitudinal welding machines can be equipped with various levels of automation, ranging from manual to fully automated systems. Automated systems offer increased productivity and consistency, while manual systems provide greater operator control.

- Ease of Use and Maintenance: Longitudinal welding machines are designed for ease of use and maintenance to minimize downtime and maximize productivity. User-friendly controls, intuitive interfaces, and accessible maintenance points simplify operation and upkeep.

- Durability and Reliability: Longitudinal welding machines are constructed from robust materials and components to withstand the demands of continuous welding operations. Their durability and reliability ensure long-term performance and cost-effectiveness.

These features make longitudinal welding machines valuable tools for various industries, including pipe manufacturing, pressure vessel fabrication, tank production, and structural steelwork. They enable efficient, high-quality welding of cylindrical and rectangular workpieces, contributing to improved production efficiency and product quality.

High Welding Speed and Efficiency

Longitudinal welding machines are designed for high-speed welding, enabling efficient production of long welds in a shorter time frame. This high welding speed is achieved through several factors, including:

- Automated Travel Carriage: Longitudinal welding machines typically utilize automated travel carriages to move the welding torch along the weld joint at a controlled, consistent speed. This automated movement eliminates the need for manual manipulation of the torch, allowing for faster welding cycles.

- Precision Guides and Controls: Longitudinal welding machines incorporate precision guides and control systems to precisely position and align the welding torch along the weld joint. This precision ensures that the torch maintains a consistent distance from the workpiece, minimizing deviations and maximizing weld speed.

- Optimized Welding Parameters: Longitudinal welding machines allow for adjustment of welding parameters, such as welding current, voltage, and travel speed, to optimize the welding process for different workpiece materials and weld requirements. These optimized parameters further contribute to faster welding speeds.

- Multiple Weldheads: Some longitudinal welding machines utilize multiple welding heads, allowing for simultaneous welding along multiple weld paths. This parallel processing significantly increases welding speed and productivity.

The combination of these factors enables longitudinal welding machines to achieve welding speeds of up to several meters per minute, depending on the workpiece thickness and material type. This high welding speed translates into increased production efficiency, reduced cycle times, and improved throughput.

In addition to high welding speed, longitudinal welding machines also contribute to overall welding efficiency by:

- Consistent Weld Quality: The automated and precise nature of longitudinal welding machines ensures consistent weld quality and minimizes the risk of defects.

- Reduced Labor Requirements: The automation of torch movement and filler metal feeding reduces the amount of labor required for welding, further enhancing overall efficiency.

- Reduced Heat Input: The high welding speed often results in reduced heat input, which can minimize distortion and reduce the risk of warping or cracking in the workpiece.

- Cost-Effectiveness: The combination of high welding speed, consistent weld quality, and reduced labor requirements makes longitudinal welding machines a cost-effective solution for various welding applications.

In summary, the high welding speed and efficiency of longitudinal welding machines make them valuable tools for various industries. They enable the efficient production of long welds with high quality and reduced labor requirements, contributing to improved productivity and cost-effectiveness.

Precise Weld Positioning and Alignment

Precise weld positioning and alignment are crucial aspects of longitudinal welding, ensuring consistent weld quality and minimizing the risk of defects. Longitudinal welding machines achieve this precision through a combination of mechanical and electronic systems.

Mechanical Accuracy:

- Guide Rails and Linear Bearings: Longitudinal welding machines incorporate guide rails and linear bearings to provide precise and stable movement of the welding torch along the weld joint. These components minimize lateral movement and ensure that the torch remains aligned with the weld path.

- Travel Carriage Design: The travel carriage, which houses the welding torch and filler metal feed mechanism, is designed with precision and rigidity to minimize vibration and ensure accurate torch positioning. This rigidity maintains consistent torch distance from the workpiece.

- Mechanical Adjustments: Longitudinal welding machines often have mechanical adjustments to fine-tune the torch angle and height relative to the workpiece. These adjustments allow for precise positioning of the weld bead and optimizes weld penetration.

Electronic Control Systems:

- Encoders and Sensors: Encoders and sensors provide feedback to the machine’s control system regarding the torch’s position and movement. This feedback enables real-time adjustments to maintain accurate positioning and alignment.

- Servomotors and Drives: Servomotors and drives are used to control the movement of the travel carriage and welding torch. These components receive commands from the control system and precisely execute the required movements.

- Programmable Logic Controllers (PLCs): Programmable logic controllers (PLCs) serve as the brain of the machine, coordinating the actions of various components and executing welding programs. They receive input from sensors and encoders, make calculations, and send commands to servomotors and other actuators.

The combination of mechanical accuracy and electronic control systems enables longitudinal welding machines to achieve precise weld positioning and alignment. This precision ensures consistent weld penetration, minimizes gaps or porosity, and contributes to overall weld quality.

Seam Welding Machine Options

Seam welding machines are specialized welding machines designed for producing continuous welds along overlapping or abutting seams. They offer various options to suit different welding applications and workpiece specifications. Here are some key seam welding machine options:

Welding Process Options:

- Gas Metal Arc Welding (GMAW): GMAW is a common process for seam welding, utilizing a consumable wire electrode and shielding gas to protect the weld puddle. It offers versatility and adaptability to various materials.

- Resistance Seam Welding (RSW): RSW utilizes electrical resistance to generate heat and fuse the workpieces together without filler metal. It is suitable for thin materials and offers high production rates.

- Laser Seam Welding (LSW): LSW uses a laser beam to melt and fuse the workpiece materials together. It is ideal for high-precision applications and produces narrow, clean welds.

- Friction Stir Welding (FSW): FSW creates a weld by rotating a non-consumable tool between the workpieces, generating heat and friction to join the materials. It is suitable for dissimilar metal welding and produces strong welds without filler metal.

Workpiece Material Options:

- Steel: Seam welding machines can weld a wide range of steel grades, including mild steel, stainless steel, and high-strength steels.

- Aluminum: Seam welding machines can be configured to weld aluminum alloys, offering high productivity and clean welds.

- Galvanized Steel: Seam welding machines can handle galvanized steel, preventing zinc burn-off and ensuring corrosion protection.

- Nickel Alloys: Seam welding machines can be adapted to weld nickel alloys, known for their high strength and corrosion resistance.

- Plastics: Seam welding machines can weld certain plastics, such as thermoplastics, using ultrasonic or IR welding techniques.

Welding Head Options:

- Fixed Welding Heads: Fixed welding heads are permanently mounted on the machine frame and are suitable for applications with consistent workpiece positioning.

- Traveling Welding Heads: Traveling welding heads can move along the seam, allowing for welding of curved or irregularly shaped workpieces.

- Robotic Welding Heads: Robotic welding heads offer flexibility and precision, enabling welding in complex geometries and hard-to-reach areas.

- Multi-Axis Welding Heads: Multi-axis welding heads provide even greater flexibility, allowing for complex weld patterns and movement in multiple directions.

Control System Options:

- Manual Control: Manual control systems allow operators to directly control welding parameters and torch positioning.

- Semi-Automatic Control: Semi-automatic control systems provide pre-programmed welding parameters and some automation, reducing operator workload.

- Fully Automated Control: Fully automated control systems integrate with production lines and execute welding programs without operator intervention.

- Adaptive Control Systems: Adaptive control systems monitor welding parameters and adjust them in real-time to maintain optimal weld quality.

Additional Options:

- Seam Tracking Systems: Seam tracking systems use sensors to follow the seam line and ensure accurate weld placement, especially for curved or irregular seams.

- Weld Quality Monitoring Systems: Weld quality monitoring systems use sensors or vision cameras to inspect the weld for defects, providing real-time feedback to the control system.

- Data Acquisition and Analysis Systems: Data acquisition and analysis systems collect and analyze welding data to optimize weld parameters, improve process consistency, and identify potential issues.

- Remote Monitoring and Control Systems: Remote monitoring and control systems allow operators to oversee and manage welding operations from a distance, improving efficiency and flexibility.

Seam welding machines offer a wide range of options to meet the specific requirements of various welding applications and workpiece materials. The choice of options depends on factors such as weld type, workpiece geometry, production volume, and desired level of automation.

Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding (GMAW), also known as MIG (Metal Inert Gas) welding, is a versatile welding process that uses a consumable wire electrode and shielding gas to join metals. It is widely used in various industries, including automotive, aerospace, shipbuilding, and construction.

Components of GMAW:

- Welding Power Source: The welding power source provides the electrical current necessary to create an arc between the welding electrode and the workpiece. It also controls the welding current, voltage, and wire feed speed.

- Welding Torch: The welding torch holds the consumable welding electrode and conveys shielding gas to the weld puddle. It also houses the wire feed mechanism, which delivers the electrode wire to the arc.

- Wire Feed Mechanism: The wire feed mechanism advances the electrode wire at a controlled rate to the arc. It ensures a continuous supply of filler metal for the weld.

- Shielding Gas: Shielding gas protects the weld puddle from atmospheric contaminants, such as oxygen and nitrogen, which can cause weld defects. Common shielding gases include argon, carbon dioxide, and mixtures of the two.

Process Principles:

- Arc Creation: The welding power source generates an electric arc between the welding electrode and the workpiece. The arc melts the electrode and a portion of the base metal, creating a weld pool.

- Filler Metal Delivery: The filler metal wire feeds into the arc, adding material to the weld pool and ensuring complete penetration and joint integrity.

- Shielding Gas Flow: The shielding gas surrounds the weld pool, preventing atmospheric contamination and promoting clean welds.

Advantages of GMAW:

- High Production Rate: GMAW is a high-speed welding process, enabling efficient production of welds.

- Versatility: GMAW can weld a wide range of materials, including steel, stainless steel, aluminum, and copper alloys.

- Accuracy: GMAW can produce precise and controlled welds, making it suitable for intricate applications.

- Automation: GMAW is readily adaptable to automated welding systems, further enhancing productivity and consistency.

Applications of GMAW:

- Automotive Industry: GMAW is extensively used in automotive manufacturing for welding various components, such as body panels, chassis, and engine parts.

- Aerospace Industry: GMAW plays a crucial role in aerospace manufacturing, ensuring strong and reliable welds for aircraft structures and components.

- Shipbuilding Industry: GMAW is employed in shipbuilding for joining steel plates and components in shipbuilding and marine structures.

- Construction Industry: GMAW is used in construction for welding structural steel, pipes, and other metal components.

Safety Considerations:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including welding helmet, gloves, safety glasses, and a welding jacket, to protect yourself from sparks, fumes, and arc rays.

- Working Environment: Ensure a well-ventilated working environment to minimize exposure to welding fumes and gases.

- Grounding and Electrical Safety: Properly ground the workpiece and yourself to prevent electrical shock.

- Post-Welding Cleaning: Properly clean the weld area after welding to remove slag and contaminants, preventing potential safety hazards.

Resistance Seam Welding (RSW)

Resistance Seam Welding (RSW) is a specialized welding process that utilizes electrical resistance to generate heat and fuse two or more overlapping metal pieces together. It is a common and efficient method for joining thin sheet metals, particularly in the automotive industry.

Principle of RSW:

- Electrical Resistance Heating: When an electric current passes through two overlapping metal pieces, electrical resistance in the contact area converts the electrical energy into heat.

- Localized Heating: The concentrated heat generated in the contact area causes the metal to melt and form a molten nugget.

- Plastic Deformation: The pressure applied to the overlapping pieces forces the molten metal to flow and fill the gaps between the sheets, creating a strong and continuous weld.

- Cooling and Solidification: Upon removing the electrical current and pressure, the molten metal cools and solidifies, forming a permanent joint.

Advantages of RSW:

- High Production Rate: RSW is a rapid welding process, enabling efficient production of continuous welds.

- Consistent Weld Quality: RSW produces consistent and high-quality welds with minimal operator involvement.

- No Filler Metal Required: RSW eliminates the need for filler metal, reducing material costs and simplifying the welding process.

- Suitable for Thin Materials: RSW is well-suited for welding thin sheet metals, typically less than 3mm thick.

- Minimal Heat Input: RSW generates localized heat, minimizing overall heat input and potential distortion of the workpiece.

Applications of RSW:

- Automotive Industry: RSW is extensively used in automotive manufacturing for welding various components, such as body panels, door frames, and fuel tanks.

- Appliance Industry: RSW is employed in appliance manufacturing for joining components in refrigerators, washing machines, and other household appliances.

- Electronics Industry: RSW is used in electronics manufacturing for welding components in circuit boards and enclosures.

- Aerospace Industry: RSW plays a role in aerospace manufacturing for joining thin-walled components in aircraft structures.

Safety Considerations:

- Electrical Safety: Ensure proper grounding and electrical safety practices to prevent electric shock hazards.

- Machine Guarding: Use safety guards to protect operators from moving parts and potential pinch points.

- Fume Extraction: Employ adequate fume extraction systems to remove welding fumes and gases from the work area.

- Eye Protection: Always wear appropriate eye protection, such as a welding helmet, to prevent eye damage from arc flashes and sparks.

- Proper Handling: Handle workpieces carefully to prevent injuries from sharp edges or hot surfaces.

Resistance Seam Welding offers a reliable, efficient, and cost-effective method for joining thin sheet metals in various industries. Its ability to produce consistent welds with minimal heat input and no filler metal makes it a valuable tool for manufacturing processes.

Laser Seam Welding (LSW)

Laser Seam Welding (LSW) is a specialized welding process that utilizes a highly focused laser beam to melt and fuse two or more overlapping metal pieces together. It is a precise and versatile welding method, particularly suitable for welding thin materials and creating intricate weld patterns.

Principle of LSW:

- Laser Beam Energy: The laser beam delivers a concentrated beam of high-energy photons to the weld joint, causing the metal to absorb the energy and rapidly heat up.

- Localized Melting: The intense heat generated by the laser beam melts the metal at the weld joint, creating a narrow and deep weld pool.

- Fusion and Solidification: The molten metal flows and fills the gaps between the overlapping pieces, creating a strong and continuous weld. Upon cooling and solidification, a permanent joint is formed.

Advantages of LSW:

- High Precision: LSW offers exceptional precision, enabling the production of narrow, clean welds with minimal heat-affected zones.

- Minimal Distortion: The localized heat input in LSW minimizes distortion and warping of the workpiece, making it suitable for welding delicate components.

- High Aspect Ratio: LSW produces welds with a high aspect ratio, meaning deep penetration into the workpiece without excessive surface width.

- Versatility: LSW can weld a variety of materials, including metals, plastics, and ceramics.

- Non-Contact Welding: LSW eliminates the need for physical contact between the laser and the workpiece, minimizing wear and tear on the welding equipment.

Applications of LSW:

- Electronics Industry: LSW is widely used in the electronics industry for welding components in smartphones, circuit boards, and microelectronic devices.

- Medical Device Manufacturing: LSW is employed in medical device manufacturing for joining components in pacemakers, surgical instruments, and implantable devices.

- Automotive Industry: LSW plays a role in the automotive industry for welding components in battery packs, fuel cells, and structural parts.

- Aerospace Industry: LSW is used in the aerospace industry for welding thin-walled components in aircraft structures and engine parts.

- Precision Engineering: LSW is utilized in precision engineering for welding delicate components in watches, sensors, and optical instruments.

Safety Considerations:

- Laser Safety: Ensure proper laser safety protocols are followed to prevent eye damage from direct or reflected laser beams.

- Fume Extraction: Employ adequate fume extraction systems to remove welding fumes and gases from the work area.

- Machine Guarding: Use safety guards to protect operators from moving parts and potential pinch points.

- Respiratory Protection: Wear appropriate respiratory protection, such as a respirator, if necessary, to prevent inhalation of welding fumes.

- Proper Handling: Handle workpieces carefully to prevent injuries from sharp edges or hot surfaces.

Laser Seam Welding is a valuable tool for manufacturing processes that require precise, high-quality welds with minimal heat input and distortion. Its ability to weld a variety of materials and create intricate weld patterns makes it a versatile solution for various industries.

Friction Stir Welding (FSW)

Friction Stir Welding (FSW) is a solid-state welding process that utilizes a rotating tool to generate frictional heat and plastic deformation in the weld joint, joining two or more metal pieces together without melting the base material. It is a versatile and advanced welding technology with several key advantages.

Principle of FSW:

- Rotating Tool: A non-consumable rotating tool, typically made of tungsten carbide, is plunged into the weld joint between the two workpieces.

- Frictional Heat Generation: The rotating tool generates frictional heat between the workpiece materials, causing the metal to heat up and soften.

- Plastic Deformation: The tool’s rotating motion and applied force induce plastic deformation in the softened metal, creating a stirred zone.

- Metal Flow and Consolidation: The plasticized metal flows and consolidates, eliminating the gap between the workpieces and forming a continuous weld.

- Solidification and Cooling: Upon withdrawing the tool, the weld metal solidifies and cools, creating a strong and metallurgically sound joint.

Advantages of FSW:

- Solid-State Welding: FSW joins metals without melting the base material, preventing the formation of undesirable microstructures.

- Minimal Heat Input: FSW generates localized heat, minimizing distortion and warping of the workpiece.

- High Strength Welds: FSW produces strong and durable welds with excellent mechanical properties.

- Suitable for Dissimilar Metals: FSW can weld dissimilar metals, such as aluminum and steel, without the need for filler metal.

- Versatility: FSW can weld a wide range of materials, including aluminum, steel, stainless steel, and nickel alloys.

Applications of FSW:

- Aerospace Industry: FSW is widely used in the aerospace industry for joining thin-walled components in aircraft structures and engine parts.

- Automotive Industry: FSW plays a role in the automotive industry for welding components in car bodies, chassis, and engine blocks.

- Shipbuilding Industry: FSW is used in the shipbuilding industry for joining structural components in ships and marine structures.

- Oil and Gas Industry: FSW is employed in the oil and gas industry for welding pipes and fittings in pipelines and offshore platforms.

- Medical Device Manufacturing: FSW is utilized in medical device manufacturing for joining components in implants, surgical instruments, and medical equipment.

Safety Considerations:

- Tool Rotation: Ensure proper handling and maintenance of the rotating tool to prevent injuries from unexpected tool breakage or misalignment.

- Machine Guarding: Use safety guards to protect operators from moving parts and potential pinch points.

- Workpiece Handling: Handle workpieces carefully to prevent injuries from sharp edges or hot surfaces.

- Proper Cleaning: Properly clean the weld area after welding to remove debris and contaminants, preventing potential safety hazards.

- Maintenance: Regularly maintain the FSW machine to ensure optimal performance and prevent potential safety issues.

Friction Stir Welding offers a unique combination of advantages, making it a valuable tool for various manufacturing applications. Its ability to join dissimilar metals, produce strong and defect-free welds, and minimize heat input makes it a preferred choice for several industries.

General Information about Longitudinal Welding Machine

A longitudinal welding machine is a specialized machine designed for welding cylindrical or rectangular workpieces along their longitudinal axis. It is commonly used in the manufacturing industry to produce long, continuous welds on various materials, including metals, plastics, and composites.

How does a longitudinal welding machine work?

The specific working principle of a longitudinal welding machine depends on the type of welding process being used. However, all longitudinal welding machines share the common goal of joining two or more workpieces together along their length. This is typically achieved by applying heat and pressure to the weld joint, causing the materials to fuse together.

What are the different types of longitudinal welding machines?

There are several different types of longitudinal welding machines available, each with its own unique advantages and limitations. Some of the most common types include:

- Resistance seam welding (RSW) machines: These machines use electrical resistance to generate heat and fuse overlapping metal pieces together. They are commonly used for welding thin sheet metals, particularly in the automotive industry.

- Laser seam welding (LSW) machines: These machines employ a highly focused laser beam to melt and fuse overlapping metal pieces. They are known for their precision and ability to produce clean, narrow welds.

- Submerged arc welding (SAW) machines: These machines utilize a consumable electrode and a layer of granular flux to weld along the longitudinal axis. They are suitable for welding thick workpieces and offer high deposition rates.

- Gas metal arc welding (GMAW) machines: These machines use a consumable wire electrode and shielding gas to weld along the longitudinal axis. They are versatile and can weld a wide range of materials.

- Friction stir welding (FSW) machines: These machines employ a rotating tool to generate frictional heat and plastic deformation in the weld joint, joining two or more metal pieces without melting the base material. They are particularly suitable for welding dissimilar metals.

What are the applications of longitudinal welding machines?

Longitudinal welding machines are used in a wide variety of applications in the manufacturing industry. Some of the most common applications include:

- Welding of pipes and tubes

- Welding of cylindrical tanks and vessels

- Welding of rectangular beams and frames

- Welding of sheet metal assemblies

- Welding of plastic and composite components

What are the benefits of using a longitudinal welding machine?

Longitudinal welding machines offer several benefits over other welding methods, including:

- High production rates: Longitudinal welding machines can achieve high welding speeds, allowing for efficient production of long welds.

- Consistent weld quality: Longitudinal welding machines produce consistent and high-quality welds with minimal defects.

- Versatility: Longitudinal welding machines can weld a wide range of materials and workpiece thicknesses.

- Automation: Longitudinal welding machines can be automated, reducing labor costs and improving process consistency.

Installation of the Seam Welding Machine

The installation of a seam welding machine is a complex process that should be carried out by trained and experienced personnel. Here’s a general overview of the steps involved:

1. Preparation of the Installation Site:

a. Clearance and Access: Ensure adequate clearance around the designated installation area to allow for safe movement of equipment and operators.

b. Leveling and Stability: Verify that the installation site is level and free from vibrations to ensure the machine’s stability and proper operation.

c. Electrical and Power Supply: Confirm that the electrical supply at the installation site meets the machine’s voltage and amperage requirements.

2. Unpacking and Inspection:

a. Careful Handling: Carefully unpack the machine and its components, following the instructions provided by the manufacturer.

b. Visual Inspection: Inspect the machine and its components for any damage or signs of mishandling during transportation.

c. Inventory Check: Verify that all components are present and in good condition, as per the machine’s packing list.

3. Positioning and Alignment:

a. Placement: Position the machine on a solid, stable surface, ensuring it is level and aligned with the intended welding path.

b. Alignment with Workpiece: Align the machine’s welding head or carriage with the workpiece, ensuring proper positioning and angle for the desired weld configuration.

c. Adjustment and Securing: Adjust the machine’s height, angle, and position as needed, and secure it firmly to the mounting surface using appropriate fasteners.

4. Connection and Integration:

a. Electrical Connections: Connect the machine’s electrical cables to the power supply, following the manufacturer’s instructions and safety guidelines.

b. Control System Integration: Connect the machine’s control system to any relevant automation or production management systems, if applicable.

c. Grounding and Shielding: Ensure proper grounding of the machine to prevent electrical hazards, and connect any necessary shielding or fume extraction systems.

5. Initial Checks and Testing:

a. Power-Up and Basic Functions: Power up the machine and verify that all components are functioning properly, including motors, controls, and safety interlocks.

b. Test Weld and Parameter Adjustment: Perform a test weld on a representative workpiece to assess weld quality and make adjustments to welding parameters as needed.

c. Calibration and Validation: Calibrate any sensors or measurement devices, and validate the machine’s performance against the manufacturer’s specifications and quality standards.

6. Training and Documentation:

a. Operator Training: Provide thorough training to operators on the machine’s operation, safety procedures, and maintenance protocols.

b. Documentation Review: Review and familiarize yourself with the machine’s user manual, safety guidelines, and maintenance schedules provided by the manufacturer.

c. Record Keeping: Maintain a record of all installation, maintenance, and repair activities for the machine.

Please note that the specific installation procedures may vary depending on the type of seam welding machine and manufacturer’s recommendations. Always consult the manufacturer’s instructions and safety guidelines for a detailed and accurate installation process.

Preparation for Welding

Connect the electrical power 115 volt 60 single phase line. Connect the shop air supply to the inlet at the filter. Connect the ground cable from the power supply to the ground lug. Refer to the appropriate manual supplied by the welding apparatus manufacturer for instructions on the hook-up of the electrode cable, inert gas, water supply, and water drain

Operation

Set the carriage speed for the welding parameters and the welding process you have chosen, as recommended by the manufacturer of the welding apparatus.

- Open the latch at the end of the mandrel.

- Slide the piece parts over the insert so that the edges to be welded are at the top.

- Close the latch.

- Telescope down the extension arms of the piece part centering devices and rotate the centering device blades down until they contact the center of the groove. Be sure that the backside of the blade is in alignment with the center of the groove.

- Align the left and edge (back side) of the piece part to be welded over the center of the insert groove placing the edge of the piece part against the rear surface of the blade and pushing the “left” button on the pendant control to close the rear bank of fingers. Rotate the centering device blades up and telescope up the extension arms of the centering devices.

- Align the right-hand edge (front side) of the piece part as close as possible to the piece part which is clamped in the seamer and push the “right” button on the pendant control. The fingers will close and remain clamped. In addition, the fingers on this side will move the piece- part in towards the previously clamped edge. This will effectively close the gap between the edges to be welded, provided they were accurately sheared.

- Set the welding parameter on the welding process you have selected. Refer to the appropriate manual supplied by the welding apparatus manufacturer.

- On completion of welding, push both buttons on the pendant control to raise the fingers; open the latch, and remove the part.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching