During pot production, the basic element is the disk, which has predefined characteristics in terms of quality (purity of the metal) and dimensions (diameter and thickness). In the case of rectangular disks, one begins with the outline, and after pressing, shearing of the surplus flange is required.

The production of pots is a complex and multifaceted process that involves a series of intricate steps to transform raw materials into durable, functional, and visually appealing cookware. Each stage plays a crucial role in ensuring the quality, safety, and performance of these essential kitchen tools.

Stage 1: Material Preparation

- Raw Material Selection: The process begins with the selection of high-quality aluminum or stainless steel. These materials are carefully inspected and tested to ensure they meet the required specifications for strength, durability, and safety.

- Blanking: The prepared raw material is blanked into flat sheets of the desired thickness, typically using a blanking press or shearer. Precision is crucial to ensure uniform dimensions and minimize material waste.

Stage 2: Forming and Shaping

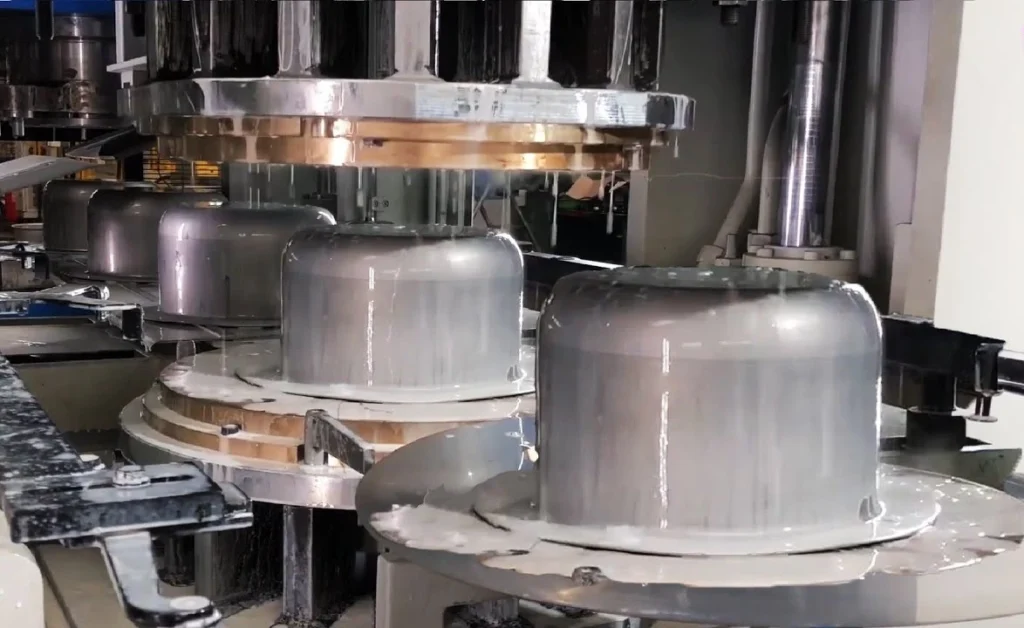

- Deep Drawing: The blanked sheets undergo deep drawing, a process that transforms them into the desired shape of the pot body. This involves forcing the metal sheets into a die cavity using a hydraulic press, creating the deep contours of the pot.

- Trimming: After deep drawing, excess material around the edges of the pot body is trimmed using trimming dies. This ensures precise dimensions and a clean, finished edge.

- Bottom Forming: The bottom of the pot is formed using a spinning or stamping process, depending on the desired shape and thickness. This stage creates a durable and stable base for the pot.

Stage 3: Handle Attachment

- Handle Preparation: The handles, typically made from stainless steel or heat-resistant plastic, are prepared for attachment. This may involve drilling or shaping the handles to fit the pot body.

- Attachment Methods: The handles are securely attached to the pot body using welding or riveting techniques. Welding provides a strong and permanent bond, while riveting offers a detachable option for specific pot designs.

Stage 4: Surface Finishing

- Surface Preparation: The pot undergoes a series of surface preparation processes to achieve a smooth, shiny, and attractive surface. These processes may involve polishing, buffing, sandblasting, or applying protective coatings, depending on the material and desired finish.

- Quality Control: Throughout the production line, rigorous quality control measures are implemented to ensure that the pots meet the required standards for safety, functionality, and aesthetics. This includes visual inspections, dimensional checks, and material testing.

Stage 5: Packaging and Shipping

- Protective Packaging: The finished pots are carefully packaged to protect them during transportation and ensure they reach customers in pristine condition. Packaging materials are selected based on their protective properties, environmental considerations, and aesthetic appeal.

- Shipping Logistics: Efficient shipping logistics are established to ensure timely delivery of the pots to customers. This may involve coordinating with transportation providers, tracking shipments, and managing inventory levels.

Conclusion

The production of pots is a complex and multifaceted endeavor that demands precision, craftsmanship, and a commitment to quality. Each stage plays a vital role in ensuring that these essential cookware pieces meet the highest standards of performance, safety, and durability. As technology advances and consumer preferences evolve, the production process continues to adapt, incorporating innovative techniques and materials to create ever-more functional and durable pots.

Pot Production Stages

The production of pots involves a series of intricate steps that transform raw materials into durable, functional, and visually appealing cookware. Each stage plays a crucial role in ensuring the quality, safety, and performance of these essential kitchen tools.

Stage 1: Material Preparation

- Raw Material Selection: The process begins with the selection of high-quality aluminum or stainless steel. These materials are carefully inspected and tested to ensure they meet the required specifications for strength, durability, and safety.

- Blanking: The prepared raw material is blanked into flat sheets of the desired thickness, typically using a blanking press or shearer. Precision is crucial to ensure uniform dimensions and minimize material waste.

Stage 2: Forming and Shaping

- Deep Drawing: The blanked sheets undergo deep drawing, a process that transforms them into the desired shape of the pot body. This involves forcing the metal sheets into a die cavity using a hydraulic press, creating the deep contours of the pot.

- Trimming: After deep drawing, excess material around the edges of the pot body is trimmed using trimming dies. This ensures precise dimensions and a clean, finished edge.

- Bottom Forming: The bottom of the pot is formed using a spinning or stamping process, depending on the desired shape and thickness. This stage creates a durable and stable base for the pot.

Stage 3: Handle Attachment

- Handle Preparation: The handles, typically made from stainless steel or heat-resistant plastic, are prepared for attachment. This may involve drilling or shaping the handles to fit the pot body.

- Attachment Methods: The handles are securely attached to the pot body using welding or riveting techniques. Welding provides a strong and permanent bond, while riveting offers a detachable option for specific pot designs.

Stage 4: Surface Finishing

- Surface Preparation: The pot undergoes a series of surface preparation processes to achieve a smooth, shiny, and attractive surface. These processes may involve polishing, buffing, sandblasting, or applying protective coatings, depending on the material and desired finish.

- Quality Control: Throughout the production line, rigorous quality control measures are implemented to ensure that the pots meet the required standards for safety, functionality, and aesthetics. This includes visual inspections, dimensional checks, and material testing.

Stage 5: Packaging and Shipping

- Protective Packaging: The finished pots are carefully packaged to protect them during transportation and ensure they reach customers in pristine condition. Packaging materials are selected based on their protective properties, environmental considerations, and aesthetic appeal.

- Shipping Logistics: Efficient shipping logistics are established to ensure timely delivery of the pots to customers. This may involve coordinating with transportation providers, tracking shipments, and managing inventory levels.

Conclusion

The production of pots is a complex and multifaceted endeavor that demands precision, craftsmanship, and a commitment to quality. Each stage plays a vital role in ensuring that these essential cookware pieces meet the highest standards of performance, safety, and durability. As technology advances and consumer preferences evolve, the production process continues to adapt, incorporating innovative techniques and materials to create ever-more functional and durable pots.

Pressing / Turning

1. Pressing

Description:

- Pressing, or stamping, is a metal forming process that involves the use of a press machine to shape flat sheets of metal into the desired pot shape.

Process:

- Material Preparation: Sheets of metal (often aluminum or stainless steel) are prepared for the pressing process.

- Die Design: A die, which is a specialized tool, is designed to create the shape of the pot. The die consists of male and female components that fit together.

- Pressing Operation: The metal sheet is placed between the male and female components of the die, and a press machine exerts force to shape the metal into the desired pot form.

- Trimming and Finishing: After pressing, the excess metal (flash) is trimmed off, and additional processes such as welding handles, attaching bases, or applying coatings may be performed.

Advantages:

- Rapid and cost-effective for mass production.

- High precision and repeatability.

Considerations:

- Initial tooling costs can be high.

- Limited to simpler shapes.

2. Turning (or Spinning)

Description:

- Turning, also known as spinning, is a metalworking process used to form pots, bowls, and other cylindrical shapes from a metal disc or tube.

Process:

- Material Preparation: A metal disc or tube is mounted on a lathe.

- Forming Tool: A forming tool, often shaped like the interior of the pot, is brought into contact with the rotating metal, causing it to take the desired shape.

- Pressure Application: Pressure is applied to the metal by the forming tool, and the metal gradually takes the shape of the tool.

- Trimming and Finishing: Excess metal is trimmed, and additional processes are performed, such as adding handles, finishing surfaces, and applying coatings.

Advantages:

- Well-suited for complex shapes and larger pots.

- Good material thickness control.

Considerations:

- Limited to rotational symmetry.

- Skilled operators are often required.

Additional Considerations

- Material Choice:

- The choice of material (aluminum, stainless steel, copper, etc.) impacts both the pressing and turning processes.

- Surface Finishing:

- After the initial forming, additional processes may include polishing, coating, or finishing to achieve the desired appearance.

- Handles and Attachments:

- Processes such as welding or attaching handles and bases may follow the forming stages.

Both pressing and turning are integral processes in the mass production of pots and cookware. The choice between these methods often depends on the complexity of the pot’s shape, production volume, and the desired characteristics of the final product.

The press forges the disk, which roughly assumes the desired shape. Subsequently, it is touched up to eliminate imperfections and is cleaned, giving the final appearance. For steel pots, a final working step known as polishing is needed, which gives the sheen typical of this metal.

Compared to pressing, it allows easy and quick preparation of the machine, aiding therefore the passage from one size to another in shorter times. It is carried out via the pressure of a lever on the cold sheet, which is modeled

by turning it on the underlying mold (a very similar concept to the manual working of clay).

With the help of computers, modern automatic lathes allow the generation of pieces that are identical to one another, whereas manual lathes still depend on experience and the hand of the operator. For aluminum, the next stage is its passage through the pickling tunnel, which guarantees cleanliness in order to have a container suitable for contact with food

Handles in Pot Production

Handles must meet certain important requirements to allow professional, safe and efficient use. First of all, they must be made of a material that does not conduct heat, to prevent the user from being burnt: for example tubular handles in inox steel are often used. Plastics are largely used only in domestic products, seeing as though in the professional environment high temperatures, long exposure times and the dimensions of the burner can compromise the handles.

One should not be fooled by the design, and instead, more functional aspects should be evaluated such as the safety of the handle and the stability of the joint: therefore the welded joints or the number of rivets with which the handles are applied to the body of the pot are also evaluated. Finally, the ease with which it can be cleaned should also be taken into account.

The application of handles onto copper and aluminum pots is carried out by nailing them onto the body of the pot with particularly resistant alloy rivets (AG5) or with rivets made from the same metal as the container. For steel on the other hand, which is a very hard material, the handles are soldered directly onto the body of the pot. In both cases it is necessary to check that the number of points of attachment is proportional to the dimensions of the recipient.

To guarantee robustness and resistance, the dimensions of the rivets should be assessed. Handles are mostly made from steel, in order to lower the risk of being burnt. Only in the case of copper, is the use of brass handles preferred, and this is due to aesthetic reasons.

Handles are crucial components in pot production, providing a means for users to grip and manipulate the cookware. The design, material, and attachment method of handles play significant roles in the functionality, safety, and aesthetic appeal of the finished pots. Here are key considerations regarding handles in pot production:

1. Material

- Stainless Steel Handles:

- Advantages: Durable, corrosion-resistant, matches well with stainless steel cookware.

- Considerations: Can get hot during cooking, may require additional insulation or design features for heat resistance.

- Plastic Handles:

- Advantages: Lightweight, affordable, available in various colors.

- Considerations: May not be as durable as metal, can melt under high heat.

- Bakelite or Phenolic Resin Handles:

- Advantages: Heat-resistant, stays cool during cooking.

- Considerations: Can become brittle over time.

- Wooden Handles:

- Advantages: Natural and aesthetically pleasing, stays relatively cool.

- Considerations: Requires more care to prevent damage from moisture, may not be as heat-resistant.

- Silicone or Rubber Handles:

- Advantages: Heat-resistant, provides a comfortable grip.

- Considerations: May not be as durable as metal, can wear out over time.

- Combination Handles:

- Advantages: Handles made from a combination of materials, such as stainless steel with a silicone grip for heat resistance.

- Considerations: Offers a balance of durability and comfort.

2. Design

- Ergonomic Designs:

- Advantages: Designed with user comfort in mind, featuring curves and contours.

- Considerations: Material may vary; common in high-end cookware.

- Cool-Touch Handles:

- Advantages: Designed to stay cool during cooking, reducing the risk of burns.

- Considerations: Material varies, often made of heat-resistant materials.

- Detachable Handles:

- Advantages: Handles that can be removed for compact storage.

- Considerations: Materials vary; may be plastic, metal, or a combination.

- Helper Handles:

- Advantages: Additional handles on larger pots for easier lifting and maneuvering.

- Considerations: Enhances stability and control, especially with heavier cookware.

3. Attachment Method

- Riveted Handles:

- Advantages: Rivets provide a strong and secure attachment.

- Considerations: Requires proper sealing to prevent water ingress.

- Welded Handles:

- Advantages: A seamless and modern look.

- Considerations: Quality welding is crucial for durability.

- Screwed or Bolted Handles:

- Advantages: Allows for easy replacement if needed.

- Considerations: Screws or bolts should be durable and resistant to corrosion.

4. Functionality

- Oven-Safe Handles:

- Advantages: Handles designed to withstand oven temperatures.

- Considerations: Materials and design should be suitable for oven use.

- Stay-Cool Handles:

- Advantages: Handles designed to remain cool to the touch during cooking.

- Considerations: Material and design choices are crucial for effective heat resistance.

- Easy-Grip Handles:

- Advantages: Textured or contoured handles for a comfortable and secure grip.

- Considerations: Design should prevent slipping and enhance control.

In pot production, the combination of material, design, and attachment method for handles contributes to the overall quality and user experience of the cookware. Manufacturers often consider factors such as heat resistance, durability, aesthetics, and comfort when selecting and designing handles for their pots.

Thermodiffusion Base and Induction in Pot Production

The use of a thermodiffusion base and induction technology in pot production has revolutionized the way cookware is designed and manufactured, offering enhanced heat distribution, energy efficiency, and versatility. Here’s an in-depth look at these two innovative features:

Thermodiffusion Base

A thermodiffusion base is a multi-layered construction that significantly improves the heat distribution in cookware, particularly those made from aluminum. It typically consists of an aluminum core sandwiched between layers of stainless steel or copper. This combination of materials leverages their unique properties to achieve optimal heat conduction and retention.

Benefits of Thermodiffusion Base

- Enhanced Heat Distribution: The aluminum core, known for its high thermal conductivity, efficiently spreads heat throughout the pot, preventing hot spots and ensuring even cooking.

- Heat Retention: The stainless steel or copper layers provide excellent heat retention, allowing food to cook evenly and thoroughly, even when heat is reduced.

- Versatility: Thermodiffusion bases make cookware suitable for various cooking methods, including stovetop cooking, oven roasting, and slow simmering.

Induction Technology

Induction cooking is a rapidly growing technology that offers precise temperature control, energy efficiency, and safety benefits. It utilizes an electromagnetic field to directly heat the cookware, rather than heating the surrounding surface. This results in faster cooking times and reduced energy consumption.

Benefits of Induction Technology

- Precise Temperature Control: Induction technology provides precise temperature control, allowing cooks to adjust heat levels with greater accuracy and responsiveness.

- Energy Efficiency: Induction cooking is highly energy efficient, as heat is directly generated within the cookware, minimizing heat loss and maximizing energy transfer.

- Safety: Induction cooking offers enhanced safety as the surrounding surface remains relatively cool, reducing the risk of burns.

Integration of Thermodiffusion Base and Induction

The combination of a thermodiffusion base and induction technology is a powerful synergy that enhances the performance of induction cookware. The thermodiffusion base’s efficient heat distribution complements the precise temperature control of induction, resulting in even cooking and energy efficiency.

Conclusion

The thermodiffusion base and induction technology have revolutionized pot production, offering cookware that is not only functional and durable but also energy efficient and safe. As technology advances, the integration of these features will continue to enhance the cooking experience for both home cooks and professional chefs.

The steel pots are endowed with a so-called “thermodiffusion” base, which makes up for the scarce heat conduction characteristic of this metal.

The procedure consists of applying a thick aluminum disk (6-7mm.) on the base of the pot, making it adhere using braze welding. It is possible to apply a second disk over this disk, but this time a steel one, onto which heavy pressure is placed, at a high temperature, aiding adhesion; this is

where the name “sandwich bottom” comes from.

The ferrite composition of this supplementary disk makes the pot suitable also for induction cooking. With a different method, coining, it is also possible to mount a ferrite steel disk on the external base of an aluminum pot, making it also suitable for use on modern electromagnetic induction heat sources. Another way of making an aluminum cooking utensil

suited for induction heat sources is to apply a ferrite layer on the bottom

Tinning of copper

Tinning is a process that involves coating a metal, typically copper, with a thin layer of tin. This process is used for various reasons, including preventing corrosion, improving solderability, and enhancing the appearance of the metal. Tinning can be applied to copper cookware, electrical components, roofing materials, and other items. Here’s an overview of the tinning process for copper:

Tinning Process for Copper

- Surface Preparation:

- The copper surface must be thoroughly cleaned to remove any oxidation, grease, or contaminants. This is typically done through mechanical cleaning, chemical cleaning, or a combination of both.

- Flux Application:

- Flux is applied to the cleaned copper surface. Flux is a chemical agent that helps remove any remaining oxides and promotes the wetting of the metal by the tin. It also prevents the formation of new oxides during the tinning process.

- Tinning Bath:

- The copper object is immersed in a molten tin bath. The temperature of the tin bath is carefully controlled to ensure proper adhesion and coverage. The tin adheres to the copper surface, forming a thin layer.

- Wiping or Drying:

- After the copper object is removed from the tin bath, excess tin may be wiped off or the object may be allowed to cool and solidify. The wiping process helps achieve a uniform coating and removes any excess tin.

- Cleaning:

- The tinned copper object may undergo additional cleaning processes to remove any residual flux or contaminants from the tinning process.

Reasons for Tinning Copper

- Corrosion Resistance:

- Tin is corrosion-resistant, and tinning copper helps protect it from oxidizing and corroding. This is particularly important for copper cookware and other items exposed to moisture.

- Solderability:

- Tinning improves the solderability of copper surfaces. Solder adheres more easily to a tinned surface, facilitating the joining of copper components in electrical applications.

- Appearance:

- Tinning can enhance the appearance of copper, giving it a shiny and uniform surface. This is often desirable for decorative or aesthetic purposes.

- Hygiene:

- In the case of copper cookware, tinning the interior helps create a barrier between the copper and the food, preventing any potential reaction between the copper and acidic or alkaline substances.

Considerations

- Quality of Tin:

- The quality of the tin used in the tinning process is important for achieving a durable and effective coating.

- Adhesion:

- Proper surface preparation and the use of flux are critical for ensuring good adhesion of the tin to the copper.

- Uniformity:

- Achieving a uniform layer of tin is essential for both functional and aesthetic reasons.

- Post-Tinning Treatment:

- Depending on the application, tinned copper objects may undergo additional treatments, such as polishing or coating, to enhance their appearance or provide further protection.

Tinning is a common practice in various industries, and the specific details of the process can vary based on the intended application of the tinned copper.

Copper is normally coated with an inert material: tin, which is a good conductor of heat. The best method of tinning is still handcrafting, on the forge, using virgin tin. Processing requires that the surface is first of all brushed, to facilitate the adhesion of the tin to the heated copper.

The recipient is then placed on the forge until the tin reaches its melting temperature, then “pig tin” is passed over the internal surface, which melts like a piece of butter. Finally, the tin is evenly distributed over the

walls, removing the excess with a ball of cotton wool. The tinned vessel is then immersed in a bath of boiling water to clean it and to allow the coating to fix. Tinning can be done repeatedly over time and therefore the pot lasts an eternity.

Antistick coating

Some vessels can be coated internally with a film of plastic material (PTFE) which confers an anti-stick property; such that it allows less fat to be used in cooking and makes it easier to wash. Processing involves an initial phase of preparation of the metal onto which the coating is to be

applied: cleaning or removal of grease, and sanding. Subsequently, there is the application phase, normally of more than one layer, until a thickness is

reached which allows it to perform to its maximum in terms of resistance against friction but also in terms of duration over time. Today two distinct methods of application are used, which give very different results in

terms of quality:

ROLLED: This consists of applying the coating directly bypassing the disk through rollers before the pot has taken on its definitive shape. This allows savings on the cost of processing but lessens the quality and duration of the product. In addition, during pressing, it is possible that the coating can become weak at certain points and can fall off. This type of work is used solely for products destined for domestic use. It can be easily recognized by the horizontal streaks present on the surface.

SPRAYED: Is applied by spraying the material, using the relevant device, directly onto the inside of the body which has already been pressed into its definitive shape, thus preventing any further work from compromising the sticking Painting is done in three steps: firstly the primer with a thickness of 15 microns, followed by passivation, the second phase of painting at 25 microns and the third layer of 6 microns.

Painting with B-ceramic is done in two layers, consisting of a “base ceramic” + “activator” paint, which creates hardness between the layer of aluminum and the finish (paint plus catalyst plus PTFE, to guarantee anti-stick properties at an extremely low dosage). The removable properties in the ceramic painting are based on “Sol-gel” (modified silica) with ceramic particles, which is much less elastic than PTFE and harder, while at the same time more fragile to chipping. It does not guarantee non-stick properties but is just a release agent and its performance is not as good as traditional PTFE.

Ability to conduct heat

The material with which a cooking container is made is the first and most important requirement to take into consideration. The aim of a pot is to cook food, and materials respond to heat conduction in different ways. Thus, the ability to conduct heat is the essential requirement to identify the most suitable instrument for various preparations.

Thermal Conductivity

Thermal conductivity is a property of materials that expresses the heat flux that will flow through the material uniformly and quickly if a certain temperature gradient exists over the material. It is expressed by means of the formula W/m°K. Let’s think about a boiling cup of coffee for example. If we immerse a silver teaspoon, this will burn in an instant, but, on the contrary, one made of steel will remain colder for longer.

A vessel that has a good thermal conductivity allows:

- Effective regulation of temperature at the various stages of cooking

- Uniform distribution of heat over the entire surface, both on the bottom and on the walls.

Energy Saving

In the professional environment, the prolonged use of heat sources becomes a relevant cost when considering the budget of a business, be it big or small. It is therefore important to assess how certain materials can reduce this expense: in fact, the cooking containers with good thermal conductivity will take less time to reach the desired temperatures, consuming less energy.

Specific Weight

The weight of a pot can be a problem in the professional environment due to the necessity to be able to easily manage large utensils with considerable thicknesses. Each material has, from the physical point of view, its own specific weight to bear in mind. For example 1 ft3 of aluminum weighs 168,48lb while 1 ft3 of stainless steel weighs 486,72lb, which means that, on the basis of equal dimensions and thickness, a pot made of S/S weighs three times more than one made of aluminum

Materials for Pot Production

The choice of materials for pot production is crucial for ensuring the quality, performance, and durability of cookware. Different materials offer unique properties that suit specific cooking needs and preferences.

Common Materials for Pot Production

- Aluminum: Aluminum is a lightweight, highly conductive metal that is widely used for pot production due to its ability to heat evenly and quickly. It is also relatively inexpensive and easy to form into various shapes.

- Stainless Steel: Stainless steel is a durable, corrosion-resistant, and non-reactive material that is preferred for its versatility and ease of cleaning. It can withstand high temperatures and is compatible with various cooking methods.

- Cast Iron: Cast iron is a heavy, heat-retaining material that is known for its exceptional durability and even heat distribution. It is ideal for slow cooking, searing, and baking.

- Copper: Copper is an exceptionally conductive metal that provides superior heat distribution and temperature control. It is often used in combination with other materials, such as stainless steel or aluminum, to create cookware with both performance and durability.

- Enameled Steel: Enameled steel is a combination of a steel base coated with a layer of porcelain enamel. The enamel coating provides a non-stick surface that is easy to clean and resistant to staining.

Considerations for Material Selection

When selecting materials for pot production, consider the following factors:

- Cooking Needs: The type of cooking you intend to do will influence the choice of material. For instance, aluminum is ideal for stir-fries and sautéing, while cast iron is suitable for slow cooking and searing.

- Heat Distribution: Consider the material’s ability to distribute heat evenly and prevent hot spots. Aluminum and copper are excellent conductors, while stainless steel is less conductive but still provides even cooking.

- Durability: Choose a material that can withstand regular use and cleaning. Stainless steel and cast iron are known for their durability, while aluminum and enameled steel may require more delicate handling.

- Reactivity: Ensure the material is non-reactive with food, particularly acidic ingredients. Stainless steel and cast iron are generally non-reactive, while aluminum may react with acidic foods.

- Maintenance: Consider the ease of cleaning and maintenance for the chosen material. Stainless steel and enameled steel are generally easy to clean, while cast iron requires more attention to prevent rust.

Conclusion

The selection of materials for pot production is a critical decision that impacts the performance, durability, and overall quality of cookware. By understanding the properties and characteristics of different materials, manufacturers can create cookware that is tailored to specific cooking needs and preferences, ensuring a satisfying and versatile cooking experience for users.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching