We will explain How to make cooking pots in different forms. These machines are used in metalworking industries for cookware manufacturing operations

How to Make Cooking Pots

In this essay, we will explore how to make cooking pots and gain insight into the fascinating process of crafting these indispensable culinary instruments.

If you’ve ever wondered how to make cooking pots, you are in the right place. In this section, we will explore the step-by-step process of creating these essential kitchen tools. By understanding the craftsmanship and techniques involved, you’ll gain a deeper appreciation for the artistry behind every cooking pot.

To begin, the first step of how to make cooking pots is understanding the materials used in making cooking pots. Traditionally, they are crafted from metals such as stainless steel or cast iron due to their durability and heat conductivity. These materials ensure even heat distribution and long-lasting performance. Next comes an important stage – joining different parts of the pot together. This is typically done through welding or soldering techniques. How to make cooking pots ensures a strong bond between various components like handles and lids. The quality of these joints plays a crucial role in determining the overall durability of the cooking pot.

Making cooking pots involves a series of intricate steps that transform raw materials into durable, functional, and visually appealing cookware. Each stage plays a crucial role in ensuring the quality, safety, and performance of these essential kitchen tools.

Stage 1: Material Preparation

1. Raw Material Selection: The process begins with the selection of high-quality aluminum or stainless steel. These materials are carefully inspected and tested to ensure they meet the required specifications for strength, durability, and safety.

2. Blanking: The prepared raw material is blanked into flat sheets of the desired thickness, typically using a blanking press or shearer. Precision is crucial to ensure uniform dimensions and minimize material waste.

Stage 2: Forming and Shaping

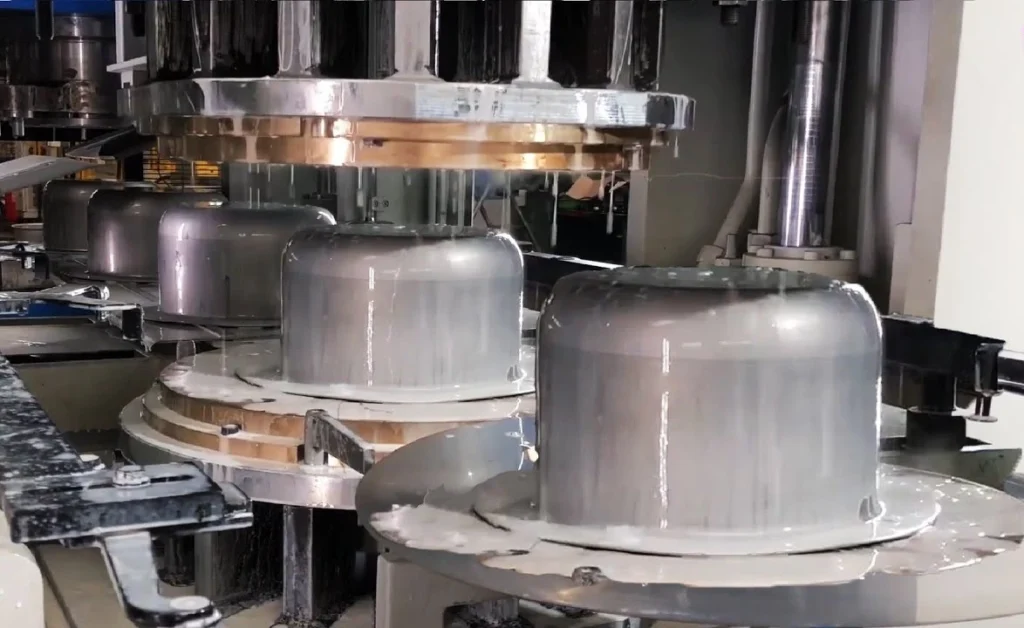

1. Deep Drawing: The blanked sheets undergo deep drawing, a process that transforms them into the desired shape of the pot body. This involves forcing the metal sheets into a die cavity using a hydraulic press, creating the deep contours of the pot.

2. Trimming: After deep drawing, excess material around the edges of the pot body is trimmed using trimming dies. This ensures precise dimensions and a clean, finished edge.

3. Bottom Forming: The bottom of the pot is formed using a spinning or stamping process, depending on the desired shape and thickness. This stage creates a durable and stable base for the pot.

Stage 3: Handle Attachment

1. Handle Preparation: The handles, typically made from stainless steel or heat-resistant plastic, are prepared for attachment. This may involve drilling or shaping the handles to fit the pot body.

2. Attachment Methods: The handles are securely attached to the pot body using welding or riveting techniques. Welding provides a strong and permanent bond, while riveting offers a detachable option for specific pot designs.

Stage 4: Surface Finishing

1. Surface Preparation: The pot undergoes a series of surface preparation processes to achieve a smooth, shiny, and attractive surface. These processes may involve polishing, buffing, sandblasting, or applying protective coatings, depending on the material and desired finish.

2. Quality Control: Throughout the production line, rigorous quality control measures are implemented to ensure that the pots meet the required standards for safety, functionality, and aesthetics. This includes visual inspections, dimensional checks, and material testing.

Stage 5: Packaging and Shipping

1. Protective Packaging: The finished pots are carefully packaged to protect them during transportation and ensure they reach customers in pristine condition. Packaging materials are selected based on their protective properties, environmental considerations, and aesthetic appeal.

2. Shipping Logistics: Efficient shipping logistics are established to ensure timely delivery of the pots to customers. This may involve coordinating with transportation providers, tracking shipments, and managing inventory levels.

Conclusion

The production of cooking pots is a complex and multifaceted endeavor that demands precision, craftsmanship, and a commitment to quality. Each stage plays a vital role in ensuring that these essential cookware pieces meet the highest standards of performance, safety, and durability. As technology advances and consumer preferences evolve, the production process continues to adapt, incorporating innovative techniques and materials to create ever-more functional and durable pots.

How to Make Cooking Pots

Once all parts are securely joined together, it’s time for surface finishing. This involves smoothing out any rough edges or imperfections on both the interior and exterior surfaces of the pot. Polishing techniques may be employed to enhance its appearance while maintaining its functionality. Lastly, a protective coating may be applied to prevent corrosion or rusting over time. This coating not only enhances longevity but also makes cleaning easier for users. By following these steps on how to make cooking pots, skilled craftsmen create high-quality cooking pots. These pots withstand rigorous use in kitchens around the world.

How Are Cooking Pots Made?

The main question is this: How are cooking pots made? Cooking pots are typically made from various materials. Each has its own unique manufacturing process. The most common materials used in the production of how to cooking pots include stainless steel, aluminum, copper, cast iron, and clay. Here’s how to make cooking pots from some of these materials:

Stainless steel cooking pots are the first choice. They are famous for their durability, resistance to corrosion, and aesthetic appeal. How are stainless steel pots made? To create stainless steel cooking pots, manufacturers start by cutting stainless steel sheets into the desired pot shape. These cut pieces are then formed into the pot’s shape. The name of this process is deep drawing. After forming, the pot is polished to achieve its characteristic shiny finish. Adding handles and lids, the pot is given a final inspection before being packaged for sale.

The other option is aluminum cooking pots. They are known for their excellent heat conductivity. To make these pots, aluminum sheets are cut into the required shape, just like with stainless steel pots. However, aluminum pots often go through an additional process called anodizing. Anodization involves subjecting the pot to an electrolytic solution to create an oxide layer on the surface. This enhances its durability and prevents corrosion.

The Steps of How to Make Cooking Pots

The first step of how to make cooking pots is the design and measurement. Deciding on the size and shape of your cooking pot begins with measuring and marking the dimensions on the aluminum sheet. You can use a pre-made template or create your own design. Secondly, the aluminum is cut. Using the saw, you can cut out the aluminum according to your measurements. This will form the body of your pot. The next step is shaping the pot. After shaping the aluminum piece into a pot, it becomes like form using a combination of hammering and molding. If desired, you can create a mold using molding sand for more precise shaping.

The following step of how to make cooking pots is sealing the seams. You must ensure that there are no gaps or openings in the pot. If needed, you can use a torch or kiln to heat the aluminum and seal any seams. The process continues with sanding and polishing. Use sandpaper or an abrasive material to smooth the pot’s surface and achieve the desired finish. The next step is adding handles. If you want, you can attach handles to your pot. These can be made from aluminum or other materials and securely attached using appropriate fasteners.

The last finishing touch of how to make cooking pots is to clean the pot thoroughly. Removing any metal shavings or residue can also consider coating it with a food-safe material for added protection. In conclusion, understanding how cooking pots are made allows us to appreciate not only their functional value but also their artistic craftsmanship. From shaping metals to joining components with precision, each step contributes to creating a reliable kitchen essential that brings joy to home cooks everywhere.

Deciding on How to Make Cooking Pots

How are cooking pots made? The answer is the process can be a fulfilling and creative endeavor. This allows you to craft a kitchen essential to your exact specifications. The process of how to make cooking pots may vary based on the chosen material and level of craftsmanship. Understanding the fundamental steps involved in creating cooking pots. These pots provide valuable insight into how these indispensable kitchen tools are made.

Copper pot making machines have revolutionized the way copper pans are made. These machines can quickly and accurately form pans from sheets of copper. As a result, this saves time and money in the production process. With the advent of modern copper utensils-making machines, the process has become faster and more efficient. Besides, still maintains the high-quality craftsmanship that is synonymous with copper pots.

In conclusion, how to make cooking pots is a skilled craft that requires precision and expertise. Therefore, we can guarantee that our customers will receive consistent, reliable performance from our company’s products. With our copper pot machines and the experience we have gained in this field, we can meet all needs and provide variable solutions for an invaluable tool for any workshop or production line.