How to manufacture Sheet Metal Roasting Pan: Manufacturing sheet metal cookware involves several key steps that transform flat metal sheets into functional kitchen utensils like pots, pans, lids, trays, etc. The process includes cutting, forming, joining, surface treatment, and finishing. Here’s a detailed overview:

Material Selection

Common Metals Used:

- Stainless Steel (durable, corrosion-resistant)

- Aluminum (lightweight, good heat conductor)

- Carbon Steel (strong, good for woks/pans)

- Copper (excellent heat conductivity, usually lined)

Sheets typically range from 0.5 mm to 3 mm thick depending on the type of cookware.

Cutting the Sheet Metal

Processes:

- Shearing: Straight cuts using a mechanical or hydraulic shear.

- Laser Cutting: Precision cutting for complex shapes.

- Plasma Cutting: For thicker sheets.

- Punching: For holes, handles, or decorative designs.

Forming and Shaping

Forming Methods:

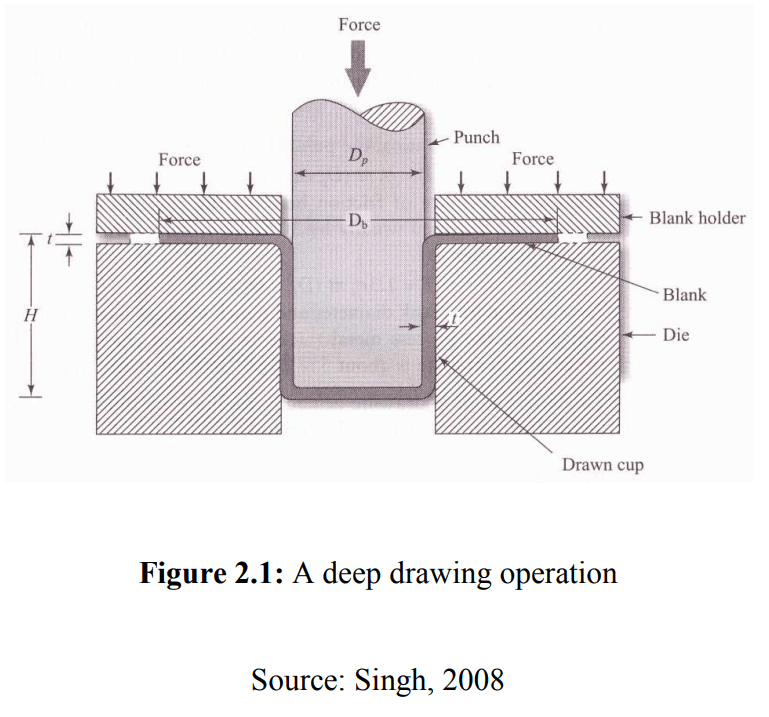

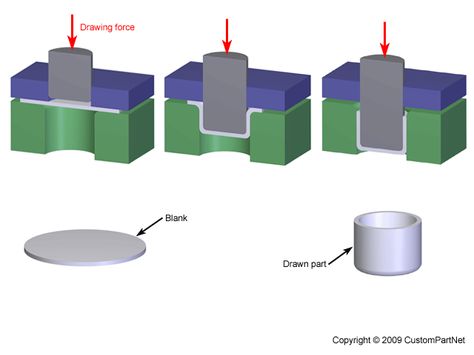

- Deep Drawing: Used to make pots, bowls, and pans. A punch pushes a blank sheet into a die.

- Spinning: Sheet is rotated at high speed and formed with a roller (used for round items like bowls or lids).

- Stamping/Pressing: Press tools form the metal into shape.

- Rolling/Bending: For handles or flatware.

Joining (if required)

Some cookware pieces need assembly or reinforcement.

- Spot Welding: For joining parts like handles.

- Riveting: Durable mechanical joining.

- Seam Welding: For airtight or watertight joints.

- Brazing/Soldering: For joining dissimilar metals (e.g., copper + stainless).

Surface Treatment

- Polishing: For a shiny finish or smooth surface.

- Passivation: (for stainless steel) to enhance corrosion resistance.

- Anodizing: (for aluminum) improves durability and aesthetics.

- Non-stick Coating: PTFE or ceramic coatings applied via spraying and baking.

- Sandblasting: For texture or matte finish.

Heat Treatment (Optional)

- To increase hardness or relieve stress after forming.

Cleaning & Quality Control

- Ultrasonic cleaning to remove residues.

- Visual and functional inspection for cracks, deformations, and coating defects.

Finishing and Packaging

- Final polishing or brushing.

- Labeling and packaging (sometimes with protective films or inserts).

Optional Enhancements:

- Encapsulated Bases (for better heat distribution): aluminum or copper core sandwiched in stainless steel.

- Induction-compatible bases: Ferritic stainless steel added.

Manufacturing sheet metal cookware starts with selecting the appropriate material, such as stainless steel, aluminum, carbon steel, or copper. Stainless steel is popular due to its corrosion resistance and durability, while aluminum is lightweight and a good heat conductor. Once the metal sheet (typically between 0.5 mm and 3 mm thick) is chosen, the first step is cutting it into the desired blank shape. This can be done using mechanical shearing for straight cuts or laser/plasma cutting for more intricate designs. If the product requires holes or slots—for example, to attach handles—those are punched out at this stage.

Next comes forming and shaping. This is usually done using deep drawing for pots, bowls, and other hollow shapes, where a punch presses the sheet into a die. For round or symmetrical shapes like lids, metal spinning is common: the sheet rotates at high speed while rollers shape it against a mold. Stamping and pressing are used for flatter items like trays, while rolling or bending is used for parts like handles or structural reinforcements.

If the cookware design requires multiple parts, joining techniques come into play. Handles might be attached by spot welding or riveting. Seam welding is used when a strong, leak-proof bond is needed, and in some cases, brazing or soldering is used, especially when different metals need to be joined, such as a copper base to a stainless body.

After forming and assembly, surface treatment is applied. Stainless steel may be passivated to enhance corrosion resistance, while aluminum can be anodized to increase surface hardness and color variety. Non-stick cookware receives a sprayed PTFE or ceramic coating, which is then baked at high temperature to cure it. Polishing and buffing improve appearance and remove minor surface imperfections. In some designs, the bottom of the cookware might be encapsulated with layers of aluminum or copper to improve heat distribution, often clad in stainless steel to work with induction cooktops.

The cookware then goes through cleaning—often with ultrasonic baths or chemical washes to remove oils and residues. A thorough inspection follows, checking for deformations, surface flaws, or coating defects. Once approved, the item is labeled, sometimes laser-etched, then packaged for distribution. Protective films, cardboard inserts, or bubble wrap may be added to protect the cookware during transport.

Alright, let’s take the example of a stainless steel frying pan and walk through how it’s manufactured from start to finish, step-by-step, in a real-world factory-style workflow.

It begins with coils of stainless steel sheet being unrolled and flattened. A blanking press then cuts out circular discs—the blanks—that will eventually become the body of the frying pan. These blanks are cleaned and sometimes annealed (softened by heating) to make the next step easier.

The blank is taken to a deep drawing press. This is where the flat disc is transformed into a shallow bowl shape using a punch and die. It’s done in multiple stages—progressive drawing and redrawing—because trying to do it all in one shot might tear the metal. Each step slightly deepens and reshapes the pan. The edge might be trimmed after drawing to maintain even height all around.

At this point, the pan has a rough shape but lacks a finished base. If it’s going to be a heavy-duty pan with good heat distribution, it’ll be fitted with a clad base—a thick disc made of aluminum or copper, sandwiched between stainless steel layers. This is fused to the bottom using high-pressure impact bonding or brazing. Some pans are made entirely of multi-layered (clad) material throughout the body, which is more advanced but costlier.

Now the sidewalls and rim are formed and cleaned up. The rim might be rolled or formed into a pouring lip. Any holes or rivet points for the handle are punched or drilled. The inside and outside surfaces are then polished, brushed, or buffed depending on the desired finish. If it’s a non-stick pan, the surface is roughened slightly—often by sandblasting—to help the coating adhere.

The non-stick coating is applied in a fine mist and built up in layers, typically two or three. Each layer is flash-heated to bond it to the metal. The final curing bake can go up to 400–450°C, creating a durable, heat-resistant surface.

Meanwhile, the handle—usually made from stainless steel, aluminum, or heat-resistant plastic—is manufactured separately. If it’s metal, it might be cast, stamped, or forged, then polished or brushed. It’s then attached using rivets (commonly for professional-grade cookware), spot welding, or sometimes screws. Riveting is especially strong and resistant to loosening over time.

After assembly, the pan is washed—either with solvents or ultrasonic cleaning baths—to remove oils, residues, and fingerprints. A final inspection ensures that the surface is smooth, the handle is secure, the base is flat (important for even heating), and the coating is flawless.

Once approved, the pan is dried, sometimes laser-etched with the brand and material specs, and then packaged. Packaging typically includes a cardboard sleeve or box, sometimes with protective paper or foam to prevent scratching. From there, it’s shipped to retailers or customers.

The whole process combines precision tooling with both automated and manual quality checks. For large-scale operations, many steps—especially drawing, trimming, polishing, and coating—are done by automated machines for consistency, while final inspection and assembly might still involve skilled hands.

It all starts with laminated sheet metal, also called clad metal. This material is made by bonding multiple layers—usually a core of aluminum or copper sandwiched between inner and outer layers of stainless steel. The stainless steel provides durability and corrosion resistance, while the inner core dramatically improves heat distribution. The bonding is done by roll bonding, where metal layers are cleaned, stacked, and pressed together under immense heat and pressure until they fuse into one composite sheet.

This sheet arrives at the cookware plant in coils or large sheets. It is cut into blanks, usually circular, using a blanking press. These blanks then go through deep drawing, just like with regular stainless steel cookware. However, because the material is thicker and harder due to the multiple layers, the forming process may need extra force and multiple drawing stages. Specialized lubricants are used during drawing to prevent galling (where metal sticks to the tooling).

Once the basic pot shape is drawn, it’s trimmed to achieve a clean and even edge. At this point, the cookware is already seamless and has its heat-conducting core built into the walls and base—no need for a bonded disc underneath like in cheaper models.

Next comes edge forming and flaring. The rim may be rolled inward for strength or outward for pouring. Some saucepans get an encapsulated lip to hide the layered structure for aesthetic reasons.

Then we move on to handle attachment. For clad cookware, stainless steel handles are most common. They may be hollow (to reduce heat transfer), and designed ergonomically with curves or rivets. The handle is either riveted through the body (common in premium cookware), spot-welded, or in rare cases cast as one piece with the body. Riveting is the most durable and allows easy repair or replacement.

At this stage, the pot gets a final shaping—slight flattening of the base ensures it sits evenly on all stove types, including glass and induction. If needed, magnetic stainless steel is used on the exterior layer to make the pot induction-compatible.

Then it goes into polishing. The interior is polished smooth or lightly brushed; some brands go for a mirror finish, while others prefer a matte or sanded texture. The exterior might get brushed lines or even patterned designs. This step is often automated but finished by hand for perfection.

If there’s any non-stick or ceramic coating, it would be applied here—though most clad saucepans are left uncoated for high-heat and metal-utensil compatibility.

Then comes laser marking or stamping, often on the bottom of the pan, where brand info, material composition, and sometimes measurement lines or country of origin are added.

After a final cleaning and inspection, each unit is packaged—often with a custom-fit cardboard wrap, instruction booklet, and sometimes a cloth bag for upscale lines. The lids—usually made from stainless steel or tempered glass—are often produced in parallel and matched with the pan during packaging.

This kind of cookware is built to last decades and is often passed down generations. It’s also a lot more expensive to make due to material costs, equipment, and precision tooling—but it performs beautifully.

If you’re interested, I can now walk you through how something even more specialized is made, like a pressure cooker, copper cookware, or a triply tiffin box. Let me know what you’d like to explore next.

How to manufacture Sheet Metal Paella Pan

Manufacturing a sheet metal paella pan is a specialized but relatively straightforward process compared to more complex cookware. Paella pans are wide, shallow, and typically made from materials like carbon steel, enameled steel, or stainless steel. The process focuses on achieving even heat distribution and structural integrity across a broad, flat surface. Here’s how it’s typically done:

Material Selection

The most common materials are:

- Carbon steel (traditional, affordable, excellent heat conduction)

- Enameled steel (carbon steel with a protective enamel coating)

- Stainless steel (rust-resistant, durable, lower maintenance)

Sheet thickness usually ranges from 1.0 mm to 2.5 mm depending on the desired quality and size.

Cutting the Blank

Large rolls or sheets of metal are fed into a blanking press or laser cutter to punch out large circular blanks. These blanks are slightly larger than the final diameter to account for shaping.

Shaping and Forming

The circular blank is taken to a hydraulic press or spinning lathe:

- The sheet is pressed or spun into the traditional shallow bowl shape with gently sloping sides.

- The pan must be wide and flat at the base, with a low profile for even cooking over open flame or burners.

For larger diameters (up to 50 cm or more), this may be done in multiple forming stages to prevent warping or thinning of the base.

Rim and Edge Finishing

The edges are often:

- Rolled or curled to eliminate sharpness and improve rigidity.

- Sometimes a reinforcing bead is formed near the rim to strengthen the shape and prevent warping from heat.

🖐️ 5. Handle Attachment

Traditional paella pans have two looped side handles. These are usually:

- Stamped or forged steel rings.

- Riveted or spot welded to the sidewalls of the pan, just below the rim. Welding is more common in industrial production, while riveting may be used in artisan pans.

Surface Treatment

Depending on the material, the treatment varies:

- Carbon steel pans are cleaned, lightly oiled, and sometimes pre-seasoned to prevent rust.

- Enameled pans are coated with a vitreous enamel (porcelain) and fired in a kiln to fuse the enamel to the metal.

- Stainless steel pans may be polished, brushed, or sandblasted for finish.

The inner surface may remain raw, polished, or coated depending on the brand and tradition.

Inspection and Flattening

The bottom is carefully checked to ensure it’s flat and stable—critical for good heat distribution. Minor adjustments may be made in a flattening press.

Cleaning, Labeling & Packaging

The finished pans are:

- Cleaned of residues or oils.

- Laser-marked or labeled with branding or size.

- Stacked and packaged in protective cardboard or shrink wrap, especially for export.

Optional Enhancements:

- Induction bases (for stainless pans): ferritic stainless or bonded disc on bottom.

- Non-stick coatings (less common): applied like in frying pans.

- Decorative rivets or artisan handles (in premium lines).

To manufacture a sheet metal paella pan, the process starts with selecting the right material. Traditional paella pans are often made from carbon steel because of its excellent heat conduction properties, while some are made from enameled steel or stainless steel for durability and ease of cleaning. The sheet metal is usually between 1.0 mm and 2.5 mm thick, depending on the size of the pan and the material.

The first step in production involves cutting the sheet metal into large circular blanks. This is done using a blanking press, or sometimes a laser cutter, which ensures precision in the size and shape of the pan. The blank is slightly larger than the final pan size to account for the shaping process.

Next, the circular metal blank is taken to a hydraulic press or spinning lathe to be formed into a shallow, bowl-like shape. The forming process is done gradually, often in stages, to avoid deforming the metal. The goal is to create the characteristic wide, shallow design with sloping sides, allowing the paella to be spread evenly across the surface. In some cases, multiple forming passes are needed to ensure the metal is evenly shaped without thinning out too much, especially in larger pans.

Once the basic pan shape is formed, attention turns to the rim and edge finishing. The edges are typically rolled or curled to prevent sharpness and to add some rigidity to the structure. Sometimes, a reinforcing bead is added around the rim to further strengthen the pan and prevent warping when subjected to heat. This is especially important for larger pans that will be used over open flames.

The next step is attaching the side handles, which are crucial for handling the pan, especially when it’s hot. Paella pans traditionally have two looped metal handles on opposite sides. These handles are either riveted or spot-welded to the sidewalls of the pan just below the rim. The handles are usually made from the same material as the pan, but they can also be reinforced or decorated in higher-end models.

After the pan is shaped and assembled, it undergoes surface treatment. For carbon steel pans, the inside of the pan is often seasoned with oil and heat-treated to prevent rust. Enameled pans are coated with a layer of vitreous enamel and then fired in a kiln to fuse the enamel to the metal, providing a smooth, durable surface. Stainless steel pans are typically polished or brushed for a clean, shiny appearance.

At this point, the pan is inspected to ensure the base is flat and the shape is consistent. The flatness of the pan is critical for cooking, as a warped bottom could cause uneven heating. Minor adjustments may be made using a flattening press to ensure the pan sits evenly on all heat sources.

Finally, the pans are cleaned to remove any residues from the production process. Depending on the brand, the pan may be laser-marked or stamped with the manufacturer’s logo, size, or material specifications. After inspection, the finished paella pans are packaged, usually in protective materials like cardboard boxes or shrink wrap, to prevent damage during shipping.

The process of making a paella pan combines precision and traditional techniques, with an emphasis on heat distribution, durability, and ease of handling. Whether for industrial use or artisanal craftsmanship, the focus is always on ensuring that the pan can withstand high heat and provide a perfect cooking surface for the signature wide and flat paella dish.

Once the paella pan is fully manufactured, there are a few final considerations to ensure the product meets the standards of both performance and aesthetic appeal.

After the pan is inspected for quality—checking for defects like uneven coating, cracks, or warping—the next step is to test the pans for functionality. For carbon steel pans, the pan may undergo a seasoning process where a thin layer of oil is applied to the interior and the pan is heated to form a natural non-stick layer. This is especially important for carbon steel pans, as they require this seasoning to build up a protective layer that improves cooking performance and prevents rusting. For enameled pans, the coating must be thoroughly checked to ensure even coverage and smoothness. Any chips or defects in the enamel coating could compromise the durability and function of the pan.

Once all pans pass quality control, the next stage involves branding and packaging. Typically, each paella pan is marked with the manufacturer’s logo, sometimes engraved on the bottom or stamped into the edge, to give it a unique identifier. Some brands also include measurement marks, temperature guidelines, or care instructions as part of the labeling.

Packaging varies based on market positioning. Higher-end paella pans often come in more elaborate packaging, sometimes with protective cardboard or soft liners to prevent scratches or dents. This can include branded boxes, instructions for care and seasoning, and even recipes for making traditional paella. More mass-produced versions may have simpler packaging, though it is still designed to prevent damage during transit.

For export or retail purposes, the pans are usually grouped in larger boxes, with each pan individually wrapped or placed in foam or protective plastic to prevent scratching during transportation. The packaging is designed to be both protective and aesthetic, as paella pans are often sold in sets or as part of culinary kits, sometimes marketed with specialty cooking utensils or recipes.

The entire process, from raw metal to finished product, involves a mix of precision engineering and craftsmanship, especially when you consider factors like the evenness of the metal’s heat distribution and the handling of the pan after cooking. These pans are not only functional but also carry a certain tradition of Mediterranean cooking, with each step of manufacturing contributing to the ultimate cooking experience.

If you’re planning to start your own production or exploring small-scale manufacturing, this would give you a good foundation of the necessary tools, machinery, and the key stages to focus on. Are you thinking of manufacturing a certain type of cookware, or perhaps setting up a small workshop? I can help with details on machines and costs if you’d like.

How to manufacture Sheet Metal Crepe Pan

Manufacturing a sheet metal crepe pan follows a process that shares many similarities with other types of cookware but with specific attention to the flat, wide surface and low sides characteristic of crepe pans. The goal is to achieve an even, smooth cooking surface that distributes heat uniformly across the pan to ensure the delicate cooking of crepes. Here’s a detailed process on how to manufacture a crepe pan:

Material Selection

The first step is choosing the right material. The most common materials for crepe pans are carbon steel, cast iron, and stainless steel, with carbon steel being the most traditional and effective for high-heat cooking. Aluminum pans are also used because they are lighter, but they might not provide as even heat distribution as carbon steel or cast iron. The metal sheets typically range from 1.0 mm to 2.5 mm thick, depending on the type of pan and the intended size.

Cutting the Sheet Metal

The process begins by taking large coils of the selected metal and feeding them into a blanking press or laser cutter, where circular blanks (flat, round pieces of metal) are cut from the sheet. These blanks will be the base of the pan, and they are usually slightly larger than the intended final size to account for shaping and trimming.

Shaping the Pan

The blank is then taken to a hydraulic press or spinning lathe to form the shallow, flat shape typical of a crepe pan. In spinning, the metal blank is rotated at high speed while a roller pushes the metal against a mold, gradually forming the desired shape. In hydraulic pressing, a die and punch are used to shape the metal, and it’s often done in multiple stages to ensure that the metal doesn’t warp or thin out in certain areas.

Since crepe pans need a wide, low-profile shape, the depth is kept shallow to facilitate easy flipping and spreading of crepe batter. The flat base is essential for even heat distribution, which is crucial when cooking crepes on high heat.

Rim and Edge Finishing

Once the pan’s base and sides are shaped, the edges are usually rolled or curled to remove sharp edges and add a touch of rigidity. The rolled edge also strengthens the pan’s structure, which helps prevent warping when subjected to high temperatures. A slight flaring of the rim may be done to make it easier to slide the crepes out of the pan.

Handle Attachment

Crepe pans typically have a single long handle, often made of stainless steel, cast iron, or heat-resistant plastic. The handle is attached by either riveting, spot welding, or casting (depending on the manufacturing process). The handle is important because it must remain cool to the touch during cooking, which is why some handles are designed with hollow air channels or covered with heat-resistant materials. For a more professional-grade pan, the handle is often riveted to ensure durability.

Surface Treatment

Once the pan is shaped and the handle attached, the next step is surface treatment. Carbon steel pans are often seasoned at this stage, which involves applying oil to the interior and heating the pan to form a non-stick surface. This seasoning process is critical for both rust prevention and ensuring even cooking over time. For enameled pans, the interior of the pan is coated with a layer of vitreous enamel, which is then fired in a kiln to fuse the enamel to the metal. This process creates a smooth, durable surface that is easy to clean and resistant to wear. Stainless steel pans may simply undergo polishing or brushing to achieve the desired appearance.

Inspection and Flattening

After the pan has undergone surface treatment, it is carefully inspected for defects like uneven surfaces, warping, or coating inconsistencies. The bottom of the pan must be flat to ensure it heats evenly and cooks the crepes without hot spots. If the pan is slightly warped, it can be adjusted using a flattening press to make sure it sits perfectly flat on cooking surfaces.

Final Cleaning and Marking

The pan is then cleaned to remove any oils, residues, or dust that may have accumulated during manufacturing. For enameled pans, additional cleaning ensures the coating is smooth and free from blemishes. After cleaning, the pan is often laser-marked or stamped with the brand logo, product name, or specifications. This step adds a personal touch and ensures traceability.

Packaging

Finally, the crepe pans are packaged for shipment. Typically, the pans are carefully wrapped in protective materials such as foam or cardboard to prevent any scratches or dents during transportation. Packaging may also include an informational booklet or care instructions, especially for pans that require seasoning (such as carbon steel) or have special cleaning needs.

Optional Features

Some higher-end crepe pans may come with specialized features such as:

- Non-stick coatings: A PTFE or ceramic coating is applied to the surface for easier cooking and cleaning.

- Induction compatibility: For stainless steel pans, an induction-compatible disc may be added to the base.

- Decorative features: Rivets or cast handles may be designed for both aesthetic appeal and function.

In essence, the manufacturing of a crepe pan focuses on shaping the metal into a smooth, wide surface with even heat distribution. Attention to detail in the forming process, handle attachment, and surface treatment ensures that the pan performs well for delicate cooking tasks like making crepes.

Once the crepe pan has been formed and the handle attached, the next step involves surface treatment. If the pan is made from carbon steel, the interior of the pan will be seasoned. This involves coating the pan with oil and heating it to a high temperature to create a non-stick layer. This process also helps to prevent rust, ensuring the pan remains durable over time. For enameled crepe pans, the interior is coated with vitreous enamel which is then baked in a kiln at high temperatures, forming a smooth and durable non-stick surface. Stainless steel pans might be polished or brushed for an aesthetically pleasing finish, though they typically don’t require seasoning.

After the pan undergoes its surface treatment, it moves on to a thorough inspection. The flatness of the base is particularly critical in crepe pans since even heat distribution is essential for perfect crepes. Any irregularities in the surface or the shape of the pan would lead to uneven cooking. The pan is checked for defects, ensuring there are no spots where the coating might have been missed or where the metal has warped during the shaping process. If any issues are found, the pan may undergo flattening to adjust the shape, ensuring that it sits flat on any cooking surface.

Once the pan passes inspection, it is then cleaned to remove any excess oil, dust, or residue left from the manufacturing process. This is especially important for pans that will be seasoned, as any leftover impurities can affect how the seasoning bonds to the surface. After cleaning, the pan is marked with the manufacturer’s logo, product details, and other specifications. This can be done through laser engraving or stamping.

Finally, the crepe pan is packaged for distribution. Protective materials such as foam, bubble wrap, or custom-fitted cardboard are used to ensure the pan is not scratched or damaged during shipping. If it’s a high-end product, it may also come with care instructions or recipe ideas, especially if it requires seasoning or special maintenance.

Throughout the entire process, attention to detail is key—especially in the shaping, surface treatment, and testing stages. The goal is to create a pan that cooks evenly, is durable, and provides a non-stick surface that makes crepe flipping easy. Whether the pan is being produced for mass market or as part of a specialized line, each step ensures that the final product will perform well in kitchens, helping to create the perfect crepes.

After the crepe pan is packaged and ready for distribution, there are additional aspects to consider in the long-term use and maintenance of the pans, especially for the carbon steel models. These pans need to be seasoned periodically to maintain their non-stick qualities and prevent rust. Seasoning creates a natural non-stick layer on the pan’s surface, which improves over time with use. For enameled or stainless steel crepe pans, the maintenance is simpler, often involving just regular cleaning and occasional polishing.

In terms of marketing and retail distribution, crepe pans are often sold both individually and in sets, with certain brands positioning their products as part of an authentic French cooking experience or a high-end cookware collection. The packaging design may play a large role in appealing to these markets, often highlighting the craftsmanship, material quality, and cooking performance of the pan.

For commercial or professional-grade pans, the focus shifts toward providing durability under frequent use, with some crepe pans featuring extra-reinforced handles, induction-compatible bases, and enhanced non-stick coatings that can withstand the high temperatures used in commercial kitchens. These pans often come in larger sizes to accommodate high-volume cooking in restaurants or street food setups.

As with many types of cookware, customer education is important—buyers are often advised to use the proper utensils (e.g., wooden or silicone spatulas) to avoid damaging non-stick surfaces. Special attention is given to the cooking surface, ensuring that it doesn’t become scratched, and for pans requiring seasoning, the correct method of oiling and heating is explained.

In conclusion, manufacturing a crepe pan involves multiple steps, from material selection to final packaging, with careful attention to shaping, surface treatments, and ensuring the pan meets the necessary standards for even heat distribution and cooking performance. Whether for casual home cooking or professional use, a well-made crepe pan will deliver excellent results, providing years of reliable service when cared for properly.

As we continue, it’s important to note that the evolution of crepe pan designs has led to the introduction of various modern features aimed at enhancing performance and user experience. For example, many commercial-grade crepe pans now include adjustable temperature control and electric heating elements for precise heat management. These innovations allow professional chefs or home cooks to maintain consistent heat, which is essential for achieving the perfect crepe.

Moreover, ergonomic handles are becoming more common, especially for stainless steel or carbon steel pans. These handles are designed not only for strength and durability but also to ensure ease of handling, especially when the pan is hot. Some handles are even designed to be heat-resistant or have removable components for easy storage or cleaning.

The spread of induction cooking technology has influenced cookware manufacturing across the board, including crepe pans. To be compatible with induction cooktops, the bottom of the pan may feature a magnetic base or a sandwiched aluminum layer. For pans made from carbon steel, this can be a particularly important feature since these pans traditionally don’t work well with induction unless specifically designed with a magnetic layer. Induction-compatible pans offer greater energy efficiency and faster heating times, which is particularly beneficial in fast-paced cooking environments.

Environmental considerations are also influencing how crepe pans are made today. With increasing demand for eco-friendly products, manufacturers are exploring sustainable production processes, using recycled metals where possible and minimizing waste in the production process. Some brands are now marketing non-toxic, PFOA-free non-stick coatings as part of their commitment to sustainability and safer cookware options. This trend is especially appealing to environmentally conscious consumers who are concerned about the materials and chemicals used in their kitchen products.

Research and Development in Cookware Manufacturing

Many cookware manufacturers invest in R&D to improve both the performance and aesthetic appeal of their products. For crepe pans, this often means developing new surface treatments or coatings that enhance non-stick properties, resist scratching, and maintain their heat retention. For example, some brands are experimenting with ceramic-based coatings, which are naturally non-stick and are considered a safer alternative to traditional PTFE coatings (which can break down at high temperatures).

Manufacturers are also developing pans that can handle multi-functional cooking—such as pans that can be used for both crepes and other dishes like pancakes, eggs, or even delicate seafood. These pans are designed to balance heat distribution and ensure that delicate foods don’t stick or burn, making them versatile for a variety of recipes.

Some high-end artisanal crepe pans are crafted with hand-forged edges and vintage-style handles, reflecting the growing appreciation for craftsmanship and premium materials in the cookware market. These pans are typically sold at a higher price point due to the labor-intensive techniques used in their creation, but they offer a unique, long-lasting product for chefs and home cooks alike.

The Global Market and Consumer Preferences

The global cookware market continues to grow, and crepe pans are gaining popularity, especially in countries with strong culinary traditions. In Europe, particularly France, where crepes are a staple dish, the demand for high-quality crepe pans remains steady. The trend has also expanded to other regions, with North America and Asia embracing French cuisine and the art of making crepes.

With growing interest in international cuisines, more consumers are seeking specialized cookware to recreate authentic dishes at home. This includes the use of crepe pans for making not only crepes but also similar dishes like pancakes, blinis, and other flat, thin pancakes. As more consumers become interested in specific tools to replicate restaurant-quality dishes, the demand for specialized, well-made cookware like crepe pans will continue to rise.

Finally, the future of cookware manufacturing will likely see further advancements in smart technology integrated into cookware. Smart pans with built-in sensors could eventually be designed to monitor temperature, cooking time, and even alert the user when their crepe is ready to flip, enhancing both convenience and cooking precision.

As the cookware market evolves, the crepe pan will likely continue to innovate, integrating modern materials, designs, and technologies to meet the growing expectations of both casual home cooks and professional chefs. Whether you’re crafting a traditional pan, experimenting with new surface coatings, or exploring the integration of smart technologies, there’s plenty of room for innovation in this specialized cookware sector.

How to manufacture Sheet Metal Dutch Oven

Manufacturing a sheet metal Dutch oven combines traditional techniques with modern technologies. The process requires attention to detail, as Dutch ovens need to retain heat well, be durable enough to withstand high temperatures, and provide a reliable cooking experience. The production process typically involves several stages, each requiring specific machinery and materials.

Material Selection

The first step in making a Dutch oven is selecting the appropriate material. Common materials include cast iron, enameled cast iron, carbon steel, and stainless steel. While cast iron is traditional for Dutch ovens because of its excellent heat retention, carbon steel and stainless steel offer lighter, more modern alternatives. For sheet metal Dutch ovens, carbon steel is often used because it is lightweight yet durable, and it can be seasoned to provide non-stick properties.

The sheet metal chosen for a Dutch oven will typically be between 2.0 mm and 3.0 mm thick, depending on the material used and the oven’s size.

Cutting the Sheet Metal

The manufacturing process begins with the cutting of sheet metal. The material is cut into circular or rectangular blanks using a laser cutter or blanking press. If making a round Dutch oven, the cut blanks will be round discs slightly larger than the desired size of the oven to allow for the shaping process. For enameled Dutch ovens, these blanks will later be coated with enamel to form the cooking surface.

Shaping the Dutch Oven

Next, the metal blanks are transferred to a hydraulic press or spinning lathe to form the body of the Dutch oven. Using spinning, the metal is gradually pressed into a shallow, cylindrical shape by a spinning tool and a mold, which shapes the body of the pot and the lid. This process may require several steps, gradually forming the walls and bottom of the oven to ensure uniform thickness and shape.

For stainless steel or carbon steel Dutch ovens, a spinning lathe will form the sidewalls and base, while the lid will be made separately, using a similar spinning process. For cast iron Dutch ovens, the material would be poured into molds in a casting process, but for sheet metal models, the pressing and spinning process will be more relevant.

Forming the Lid

The lid of a Dutch oven is just as important as the base in terms of functionality. The lid is typically shaped by using a pressing die or a spinning lathe to match the circumference of the body. It is often slightly convex to promote condensation and allow moisture to return to the food, which is a crucial feature for slow-cooking dishes. The edges of the lid may be rolled to ensure they fit snugly against the body and can maintain a good seal during cooking.

Once the lid and body have been shaped, the edges of the pan and lid may be rolled or curled to reinforce their structure and remove sharp edges. This also adds a nice finished look to the product.

Handle and Lid Knob Attachment

Once the body and lid are formed, the next step is adding the handles and lid knob. The handles of the Dutch oven are typically made from metal and can be either riveted, welded, or cast (in the case of cast iron). For a stainless steel or carbon steel Dutch oven, the handles are welded or riveted onto the sides. The handle design is crucial for both functionality (to easily lift the oven) and aesthetics.

The lid knob is attached to the center of the lid. The knob can be made from stainless steel, cast iron, or heat-resistant plastic, depending on the material of the Dutch oven. The knob needs to be sturdy enough to handle high temperatures without breaking or losing its integrity over time.

Surface Treatment and Coating

At this stage, the pan requires surface treatment. For enameled Dutch ovens, the cooking surface is coated with a layer of vitreous enamel that is fused to the metal by heating it in a kiln. This enamel coating provides a smooth, durable, non-stick surface that is easy to clean and prevents rusting. For carbon steel Dutch ovens, the interior of the pot is usually seasoned with oil and heated to create a non-stick surface, improving with continued use. Stainless steel Dutch ovens may undergo polishing or brushing to create a smooth, shiny finish.

For enameled Dutch ovens, the color and finish of the enamel can vary, providing options for aesthetic appeal. Popular colors include classic red, blue, and black, but some manufacturers offer other color choices for consumers.

Final Inspection and Flattening

After the Dutch oven has been formed and treated, it undergoes a final inspection to check for any defects in the surface, shape, or structure. The base must be completely flat to ensure even cooking, especially for stovetop or oven use. If necessary, the Dutch oven is passed through a flattening press to ensure its base sits evenly.

Cleaning and Branding

Once the Dutch oven passes inspection, it undergoes a thorough cleaning process to remove any dust, oils, or residues from the production process. After cleaning, the oven may be laser-marked or stamped with the brand logo, size, and any other necessary product information.

Packaging

The final Dutch oven is carefully packaged to ensure it arrives safely at the customer’s door. Packaging may include foam inserts, protective wraps, and custom-fit boxes to protect the product during shipping. In addition, some manufacturers include care instructions, especially for products that need seasoning (such as carbon steel) or for special cleaning instructions for enameled versions.

Optional Features

Some modern Dutch ovens may include induction-compatible bases for use on induction cooktops. Manufacturers might integrate a magnetic layer into the base of the pan, allowing it to work with induction cookers, which require a magnetic field to heat the cookware.

Additionally, high-end Dutch ovens may feature removable handles for easier storage or cleaning, oven-safe knobs, and additional aesthetic touches, like cast handles or decorative rivets.

Final Considerations

The key to manufacturing a successful sheet metal Dutch oven lies in maintaining a balance between functionality and aesthetics. The pot must be durable, heat-resistant, and able to evenly distribute heat. The process involves both modern technology (such as laser cutting and spinning lathes) and traditional methods (such as casting for some components and enameled finishes), which together create a high-quality product that performs well in the kitchen and looks great on the stovetop.

Each stage of the manufacturing process, from cutting to final inspection, must be done with precision to ensure that the Dutch oven provides the even cooking, durability, and functionality that users expect. As the cookware industry evolves, new materials, coatings, and designs will continue to shape the future of Dutch ovens, offering consumers even more choices in terms of performance and aesthetics.

The manufacturing process of a sheet metal Dutch oven involves a blend of advanced technology and traditional craftsmanship to create a high-performance cookware item. After selecting the material—typically carbon steel or stainless steel for lighter, more modern alternatives to traditional cast iron—the first step is cutting the material into blanks. These blanks, which are flat, circular pieces of metal, are made larger than the final size to account for the shaping process.

Next, the blanks are transferred to a hydraulic press or spinning lathe where they are shaped into the desired form. In this process, the metal is pressed or spun over a mold to create the body of the Dutch oven. The shaping needs to be precise, ensuring the oven has the correct depth and a consistent thickness throughout to ensure even cooking. This step also involves the formation of the lid, which is shaped separately and typically features a slightly convex design to allow for condensation and moisture retention while cooking.

Once the body and lid are formed, the edges of the pan are often rolled or curled to reinforce the structure and provide a clean, finished look. Afterward, the pan is equipped with handles and a lid knob. The handles are typically made from metal and are either riveted or welded to the pan’s sides, while the lid knob is attached to the center of the lid. Both parts need to be sturdy enough to withstand high temperatures and repeated use.

The next stage involves surface treatment. If the Dutch oven is made from carbon steel, the interior is usually seasoned by applying oil and heating the pan to create a protective, non-stick layer. For enameled Dutch ovens, the cooking surface is coated with a layer of vitreous enamel, which is baked in a kiln to fuse the enamel to the metal. This treatment gives the pan a smooth, durable, and easy-to-clean surface, preventing rust and ensuring longevity.

Once the surface treatment is complete, the Dutch oven undergoes a final inspection to ensure that the base is flat and the pan meets the required quality standards. The base must be perfectly even to ensure that the pot will sit properly on a stovetop or in the oven, providing uniform heat distribution. If any imperfections are found, the pan may go through additional steps to flatten it.

After passing inspection, the Dutch oven is cleaned to remove any residues left from the manufacturing process. This is especially important for enameled versions, as any leftover contaminants could interfere with the finish. The pan is then marked with the brand logo, size, and other product details, often through laser engraving or stamping.

The final step is packaging. The Dutch oven is carefully wrapped in protective materials such as foam or bubble wrap to prevent scratches or damage during transport. It is then placed in a box designed for secure shipping. Some brands include care instructions or additional materials like recipe cards, particularly for ovens that require seasoning or special maintenance.

Throughout the entire process, attention to detail is essential to ensure that the Dutch oven performs well and remains durable over time. Whether it’s the heat retention from carbon steel, the ease of cleaning from enameled coatings, or the overall aesthetics of the design, every step is crucial for creating a product that meets customer expectations. As the cookware industry evolves, manufacturers continue to innovate, incorporating new materials and technologies to improve performance, making Dutch ovens a versatile and enduring piece of cookware for both home cooks and professional kitchens.

Continuing from the previous steps, after the Dutch oven is packaged and prepared for shipment, the next critical phase is its market positioning and consumer education. Dutch ovens are versatile cooking tools, often marketed as the ideal cookware for slow cooking, baking, roasting, and stewing. Manufacturers highlight their excellent heat retention, which ensures even cooking, as well as their ability to be used on a variety of heat sources, such as gas and electric stovetops, ovens, and even campfires.

With increasing consumer interest in sustainable living, many manufacturers focus on eco-friendly practices. This includes using recycled metals in production or opting for PFOA-free non-stick coatings. The appeal of environmentally-conscious products is especially strong among consumers who are concerned about the chemicals used in traditional non-stick cookware. This trend extends to packaging as well, with manufacturers moving toward minimalistic, recyclable packaging that further appeals to eco-conscious buyers.

As part of the ongoing evolution of cookware, some high-end Dutch ovens now feature induction-compatible bases. Induction cooking has grown in popularity due to its energy efficiency and precise heat control, so many manufacturers are adapting their products to meet these needs. For non-magnetic metals, such as stainless steel, this typically involves incorporating a magnetic stainless steel layer at the base of the Dutch oven, enabling it to be used on induction cooktops.

Innovation continues to be a driving force in cookware manufacturing. For example, smart technology is beginning to make its way into the Dutch oven market. Future Dutch ovens might feature embedded sensors that can monitor internal temperatures or even communicate with your smartphone or smart oven to alert you when the contents are cooking at the right temperature, or when it’s time to add ingredients or turn the heat down. These features could help streamline cooking processes, especially for those who might be cooking more complex recipes.

Additionally, modern manufacturing methods allow for customization options. For example, customers might be able to choose from a variety of colors or even personalized engravings on their Dutch oven. Some brands might offer specialty lids with built-in features like self-basting lids—a design that helps circulate moisture back into the food, enhancing the flavor and tenderness of the dish.

Once Dutch ovens hit the market, consumer feedback and reviews play an essential role in shaping the product’s future development. Many manufacturers now gather data from customer experiences to improve the design of their products, address any functional concerns, and incorporate popular features in newer models. For instance, if customers consistently mention that a particular lid design doesn’t maintain moisture or that the handles overheat, those elements will likely be addressed in future iterations of the product.

Lastly, as with any cookware product, the durability and longevity of a Dutch oven are essential selling points. To further cement the Dutch oven’s place in the market, manufacturers might offer warranties or guarantees, giving customers peace of mind that their investment will last for many years. Given that Dutch ovens are considered an essential piece of cookware in many homes and professional kitchens, the ongoing development of better-performing, more versatile, and user-friendly models will continue to drive demand.

In conclusion, manufacturing a sheet metal Dutch oven is a complex process that requires careful attention to material selection, precise shaping, surface treatments, and rigorous quality control. By incorporating modern technologies and focusing on consumer preferences for sustainability, versatility, and ease of use, Dutch oven manufacturers are positioning their products for long-term success in a competitive market. The continued evolution of cookware—whether through new materials, innovations in smart tech, or more eco-friendly practices—ensures that the Dutch oven will remain a staple in kitchens worldwide for years to come.

As the market for Dutch ovens grows and diversifies, there are additional trends and factors that will continue shaping the manufacturing and consumer experience. One such trend is the rise of premium and artisanal Dutch ovens. These are often marketed as high-end, hand-crafted products with a focus on exceptional quality, unique designs, and premium materials. For example, some manufacturers now produce Dutch ovens with hand-forged edges, custom enamel finishes, and specialty handles that cater to consumers looking for a unique, luxurious cooking experience. These products often command a higher price point but are seen as heirloom-quality pieces that can last for generations.

Additionally, the use of advanced manufacturing techniques such as robotics and artificial intelligence in the production line could further improve the efficiency, precision, and consistency of Dutch oven manufacturing. These technologies can streamline processes such as shaping, welding, and coating, reducing production times while maintaining high standards of quality control. For instance, the incorporation of robotic arms for handle welding or automated painting systems for enamel coating can result in greater uniformity in the finished product.

Another growing area in cookware manufacturing is the rise of direct-to-consumer (DTC) sales. More cookware brands are opting for an online-only or hybrid sales model, cutting out traditional retail intermediaries. This allows them to offer products at more competitive prices and build closer relationships with customers through direct feedback, customization options, and personalized customer service. Dutch oven manufacturers embracing this model can engage more directly with their audience, offering cooking tips, recipes, and warranty support through online platforms.

With the increasing focus on health-conscious cooking, Dutch ovens are often marketed for their ability to cook food in a healthier manner. Because of their excellent heat retention and ability to cook food evenly at lower temperatures, Dutch ovens are ideal for slow-cooking methods that preserve nutrients and reduce the need for added fats or oils. This aspect is particularly appealing to health-conscious consumers who want to prepare wholesome, flavorful meals with minimal added ingredients.

Another consideration in Dutch oven manufacturing is the adoption of alternative energy sources. As consumers become more aware of the environmental impact of their cooking methods, there may be an increasing push for Dutch ovens to be designed for solar cooking, camping, or other energy-efficient cooking methods. Dutch ovens that can be used with portable solar stoves or campfire cooking might become more popular in markets where outdoor cooking is a common activity. Manufacturers may begin designing Dutch ovens with highly heat-retentive materials or multi-fuel compatibility to accommodate these needs.

Furthermore, customer loyalty programs and community-building efforts are becoming increasingly important for cookware manufacturers. For instance, companies might offer rewards for repeat customers or foster online communities where home cooks can share recipes, cooking tips, and their personal experiences with the Dutch oven. This builds a sense of belonging among customers, encouraging brand loyalty and providing valuable marketing feedback.

As the market becomes more competitive, manufacturers are also exploring collaborations with celebrity chefs, cooking influencers, and popular food bloggers. These partnerships help raise awareness and generate excitement for new product lines. For example, limited-edition Dutch ovens endorsed by famous chefs or designed for specific cooking techniques (such as Braise & Stew or Bread Baking) can create a sense of exclusivity and further enhance the appeal of these premium products.

In terms of global expansion, Dutch oven manufacturers may begin targeting international markets where cooking styles and preferences vary. For example, Dutch ovens can be marketed to countries with strong stewing, roasting, and slow-cooking traditions. Countries in Asia, Africa, and South America with rich culinary histories may see a rising demand for versatile cookware that can handle a variety of cooking techniques, especially those that involve slow-cooked or one-pot meals. As a result, cookware brands may need to adjust their designs to better suit these regional preferences, possibly introducing new sizes, materials, or finishes that are more appropriate for different types of cuisine.

Finally, there is an increasing demand for cookware that matches modern kitchen aesthetics. As kitchens become more open and integrated into living spaces, cookware is no longer just a tool but also part of the home’s décor. Dutch ovens, in particular, are often displayed on stovetops or hanging in kitchens, so their design and appearance must complement modern interior design trends. Brands are therefore focusing on sleek, minimalist designs, along with a broader range of color options, finishes, and texture variations. These design elements cater to consumers who value both the function and aesthetics of their cookware.

In conclusion, the future of Dutch oven manufacturing will likely see ongoing innovation in both materials and production methods. As consumer preferences shift toward sustainability, customization, and technology-enhanced cooking, manufacturers will continue to adapt. By staying attuned to trends like premium craftsmanship, eco-friendly practices, direct-to-consumer sales, and health-conscious cooking, Dutch oven manufacturers can remain competitive in a market that increasingly values quality, performance, and style. With each new iteration of design and functionality, Dutch ovens will continue to be essential pieces of cookware for home chefs, professional kitchens, and outdoor cooking enthusiasts alike.

How to manufacture Sheet Metal Double Boiler

Manufacturing a sheet metal double boiler involves several stages, including material selection, shaping, assembly, surface treatment, and final quality checks. A double boiler is typically composed of two stacked pots, with the bottom pot holding water that is heated to cook food in the top pot via indirect heat. This manufacturing process combines both metalworking and design considerations to ensure that the final product is durable, functional, and safe for cooking purposes.

Material Selection

The first step is choosing the right materials. The primary materials used for manufacturing a double boiler are stainless steel, aluminum, or copper. Stainless steel is often preferred for its durability, resistance to corrosion, and ease of cleaning, making it ideal for cookware. Aluminum is lightweight and provides good thermal conductivity, though it’s more prone to scratches. Copper is often used for its superior heat conductivity but requires additional care due to its tendency to react with acidic foods.

For the base and outer layer, stainless steel is commonly selected due to its robustness. For the inner cooking surface (the top pot), a non-reactive and heat-conductive material like stainless steel or aluminum is ideal.

Cutting and Shaping the Sheet Metal

Once the material is selected, the next step is to cut the sheet metal into the desired shapes. The base of the double boiler is typically a bowl or pot, and the top piece is often slightly smaller to fit comfortably within the bottom. The metal sheets are cut to size using a laser cutter, plasma cutter, or shearing machine for precision.

The bottom pot is usually circular, so the metal sheets are cut into discs. The dimensions of the discs depend on the specific design and size of the double boiler. The top pot (the one that holds the food) is also cut to the correct size and shape, which might involve both circular and slightly angled cuts to allow for a snug fit into the bottom boiler.

Forming the Body

Once the sheet metal pieces are cut to size, the next stage involves shaping them into the desired form. This is typically done through press forming, spinning, or deep drawing, depending on the specific shape and thickness of the metal.

- Press Forming: The sheets are placed into a die, and a press is used to push the metal into the mold, creating the base and sides of the pots. This is often used for creating smooth, uniform shapes.

- Spinning: For more complex or circular designs, the sheet metal is placed on a spinning lathe, and the metal is gradually shaped by rotating it against a tool. This is often used for the pot’s sides.

- Deep Drawing: If the double boiler requires deeper sides, deep drawing can be used, which involves pulling the metal into a mold to form deeper, uniform walls.

The metal is worked to the desired thickness, ensuring it’s both sturdy and heat-resistant, especially around areas that will be exposed to the heat source, such as the bottom of the boiler.

Assembling the Double Boiler

Once the top and bottom pieces are shaped, the next step is to assemble them. The top and bottom pieces are typically designed to fit together with a small gap between them for the water to circulate and provide indirect heat. This gap is crucial for the double boiler’s functionality, as the purpose is for steam from the heated water to cook the food without direct contact with heat.

- Fitting the top and bottom pots: The top pot is positioned inside the bottom pot. The top pot should fit snugly to prevent food from spilling out, but it must also allow steam to circulate around the sides.

- Adding a handle: A heat-resistant handle is often added to the bottom pot (and sometimes to the top pot, depending on the design). The handle can be welded, riveted, or screwed in place. It must be durable enough to handle the weight of the filled pot and allow for safe lifting during cooking.

- Attaching the lid: The double boiler may or may not include a lid for the top pot. If included, the lid is typically made from the same material as the pot and is designed to fit tightly to trap steam inside. The lid may have a handle attached to make it easy to remove. The lid design may include ventilation holes for steam escape or a domed shape to facilitate the condensation of steam back into the cooking vessel.

Surface Treatment

After the basic shape and assembly are complete, the next step is surface treatment. Depending on the material chosen, the double boiler might undergo various processes:

- Polishing: Stainless steel or aluminum double boilers are typically polished to a smooth, shiny finish using a buffing machine. This helps improve the appearance of the cookware and makes it easier to clean.

- Coating: In some cases, the double boiler may undergo a coating process. This could be a non-stick coating for the cooking surface of the top pot, or an enameled coating for added durability and ease of cleaning. Ceramic or vitreous enamel coatings are often used on the inner cooking surface to ensure even heat distribution and to prevent food from sticking.

- Anodizing: For aluminum double boilers, anodizing may be used to harden the surface and improve corrosion resistance. This involves an electrochemical process that creates a protective oxide layer on the aluminum.

Quality Control and Testing

Before packaging, the double boiler undergoes quality control checks. These checks ensure that:

- The pots fit together correctly and that there is enough space for steam circulation between the two.

- The handles are securely attached and that they are heat-resistant.

- The lids, if included, fit properly and seal tightly.

- The cookware has no sharp edges, ensuring it’s safe to handle.

- The surface finish is consistent, smooth, and free of imperfections.

- The product meets any required safety standards (such as for non-toxic materials in cookware).

Additionally, some double boilers undergo functional testing to ensure that they perform as expected. This might include heating the pots with water and verifying that the top pot effectively uses the steam from the bottom pot to cook food at the correct temperature.

Packaging

Once the double boilers have passed all inspections, they are cleaned one final time, often to remove any polishing compounds, oils, or manufacturing residues. After cleaning, the cookware is carefully packaged in protective packaging (such as foam inserts or cardboard dividers) to ensure they aren’t damaged during transportation. The packaging is designed to prevent scratches or dents during shipping.

Some manufacturers may also include instruction manuals or care guides to help customers use and maintain the double boiler. These guides often include recommendations for seasoning (if necessary), cleaning methods, and general cooking tips.

Final Distribution

The packaged double boilers are now ready for distribution. Many are sold through traditional retail channels, such as department stores, cookware shops, and online marketplaces. Some manufacturers also sell directly to consumers via their own websites or in exclusive outlets.

Conclusion

The manufacture of a sheet metal double boiler requires careful attention to material selection, shaping, and assembly processes to ensure the product performs effectively and meets high standards of safety and functionality. Whether made from stainless steel, aluminum, or copper, the design and construction of the double boiler aim to provide even, indirect heat for cooking delicate dishes like melted chocolate, custards, and sauces. By combining modern manufacturing techniques with traditional cookware needs, manufacturers can create double boilers that are both practical and long-lasting, ensuring they remain an essential tool in both home kitchens and professional cooking environments.

The process of manufacturing a sheet metal double boiler continues with the final stages of packaging and distribution, after all construction and testing are complete. The final step in the process involves cleaning the cookware to remove any residues from the manufacturing process, such as oils, polishing compounds, or protective coatings. This ensures that the double boiler is ready for immediate use by the consumer, without any contaminants that could affect its performance or safety.

Once cleaned, the double boiler is carefully packaged. Protective packaging materials such as foam inserts, bubble wrap, or cardboard dividers are used to prevent the cookware from being scratched, dented, or damaged during shipping. The packaging is designed to hold the double boiler securely in place, keeping it safe from any external forces during transportation. Some manufacturers also include care guides, user instructions, or warranty information within the packaging to help the consumer use and maintain the cookware properly. These guides often provide tips on seasoning, cleaning, and ensuring the longevity of the double boiler.

When it comes to the distribution phase, the packaged double boilers are sent out for retail or direct-to-consumer sales. In many cases, the double boilers are sold through department stores, cookware specialty shops, and online marketplaces. Some manufacturers also offer direct sales through their own websites, where they may market the product in different colors or sizes to appeal to a wide range of customer preferences. The use of online sales platforms has allowed manufacturers to reach a global market, increasing accessibility and convenience for consumers who prefer to shop from home.

Throughout the entire manufacturing process, quality control is crucial. The final product must be able to perform as intended, ensuring that it provides the benefits of indirect heat cooking without issues such as warping, handle detachment, or uneven heat distribution. Therefore, the final double boilers undergo several quality checks to confirm that the pots fit together properly, the handles are securely attached, the lid seals effectively, and the overall structure is free of defects. The surface finish is also inspected for consistency, ensuring that it is smooth and free from imperfections.

Once distributed, the double boiler’s performance will be evaluated by consumers through feedback, which can influence future product designs. If any issues arise, such as poor heat retention or a malfunctioning lid, the manufacturer may make adjustments to the design, material selection, or production process to improve the next batch. These improvements are often based on direct feedback from customers or ongoing research into better manufacturing techniques and materials.

Additionally, there is a growing focus on sustainability within the cookware industry. Some manufacturers are opting to use recycled metals, reducing their environmental footprint and promoting eco-friendly practices. By producing cookware with minimal waste and ensuring it’s durable enough to last for many years, manufacturers can help reduce the need for frequent replacements and contribute to more sustainable consumer habits.

The modern consumer is also becoming increasingly conscious of the materials used in their cookware, with many seeking non-toxic, PFOA-free products. This has led some manufacturers to move away from traditional non-stick coatings and instead focus on alternative materials like ceramic or enameled coatings that provide the same non-stick properties without the associated health concerns. These coatings are applied carefully, and the double boiler may undergo additional heat treatment or baking in a kiln to ensure the coating adheres properly and creates a durable, smooth surface that is safe for food preparation.

In conclusion, the manufacture of a sheet metal double boiler requires a combination of advanced metalworking techniques, attention to design and functionality, and a focus on safety and quality. The process involves selecting the right materials, cutting and shaping the metal, assembling the components, and applying finishing touches like coatings or polishing. After the double boiler passes quality checks, it is packaged and distributed, where it enters the consumer market, ready for use in preparing delicate dishes like sauces, custards, and melted chocolate. Through continuous innovation and adherence to consumer needs, manufacturers can ensure that their double boilers provide consistent performance, durability, and value, solidifying their place in kitchens worldwide.

After the double boiler is distributed and in use, the lifecycle of the product continues to be important for both the manufacturer and the consumer. Ensuring that the cookware remains functional and durable over time is crucial for building brand loyalty and reducing the need for frequent replacements. Manufacturers who produce high-quality, long-lasting cookware can establish trust with consumers, who appreciate products that hold up to regular use.

As part of this ongoing lifecycle, many cookware brands offer customer service programs that support consumers with guidance on maintenance, care, and repair. For instance, if a double boiler experiences issues such as warping due to improper use or a lid that no longer seals properly, the manufacturer might offer repair services or even replacement parts. Some brands may also offer extended warranties or guarantees, which further reassures customers of the quality and longevity of their product. Additionally, cookware brands can offer online resources such as instructional videos, FAQs, or forums where users can share tips and troubleshoot any issues they may encounter.

From a sustainability standpoint, cookware manufacturers are increasingly seeking ways to extend the product’s lifecycle beyond the point of purchase. This might include designing products that can be easily repaired or reused rather than discarded. For example, removable handles or easily replaceable lids can help extend the lifespan of a double boiler, reducing waste. Furthermore, many manufacturers are looking at ways to ensure that their products are made from recyclable materials that can be reprocessed at the end of their lifespan, contributing to a circular economy.

The growing awareness of environmental impact also means that consumers are becoming more conscientious about their purchases. They may prioritize cookware from manufacturers who adopt eco-friendly manufacturing processes, such as reducing energy consumption, utilizing renewable energy sources, or sourcing sustainable raw materials. Cookware made with recycled metals or sustainable coatings is becoming increasingly popular, aligning with the broader trend of sustainable consumerism. Brands that actively communicate their commitment to sustainability can attract environmentally-conscious buyers, creating a competitive edge in the market.

In terms of future trends in double boiler manufacturing, there may be further innovations in material science. For example, manufacturers could explore new alloys or composite materials that combine the best properties of metals like stainless steel, aluminum, and copper, resulting in cookware that is lighter, more heat-efficient, and resistant to corrosion. Advanced non-stick coatings, such as those derived from natural minerals or biodegradable substances, may also become more prevalent as consumer demand for non-toxic products increases.

Smart cookware is another area of innovation that could influence the future of double boiler design. By incorporating sensors into the double boiler, manufacturers could create products that help users achieve perfect results every time. These sensors could monitor temperature and humidity levels, ensuring that the water temperature in the bottom pot is maintained within an optimal range for cooking. This would make the double boiler even more user-friendly, particularly for home cooks who are less familiar with the nuances of indirect heat cooking.

Customization is another area where manufacturers might explore in response to consumer demand. Offering customers the ability to select different sizes, colors, or finishes for their double boiler would allow for greater personalization, catering to a wide range of tastes and kitchen aesthetics. As kitchens continue to evolve into social and communal spaces, many consumers now view cookware not just as functional tools but as design elements that contribute to the overall look and feel of the kitchen.

In the context of global market trends, the growing popularity of cooking at home and gourmet cooking has made high-quality kitchen tools, like double boilers, more desirable. The rise of food influencers, cooking shows, and recipe blogs has increased interest in learning professional cooking techniques at home, further pushing the demand for specialized cookware. For example, double boilers are used in many culinary practices such as melting chocolate, making custards, or preparing delicate sauces, and this growing interest in complex, high-end home cooking will likely keep the demand for double boilers strong.

As cookware becomes more specialized, educational content will play a significant role in its success. Manufacturers might offer recipe books, online tutorials, or cooking classes that teach users how to maximize the potential of their double boilers. Providing a complete cooking experience, where customers not only buy the product but also learn how to use it effectively, could enhance customer loyalty and satisfaction.

Finally, innovation in manufacturing methods will continue to evolve. 3D printing could revolutionize the way cookware is designed and produced. By using 3D printing, manufacturers can create complex shapes with less waste and in less time. For example, a double boiler with intricate internal designs for improved steam circulation could be made with 3D printing, which would allow for greater efficiency and customization at a lower cost.

As the manufacturing and usage of sheet metal double boilers continue to evolve, it’s clear that the key to success lies in balancing traditional craftsmanship with modern innovations. By keeping pace with changing consumer expectations, adopting sustainable practices, and embracing new technologies, manufacturers can ensure that double boilers remain a staple in kitchens for years to come, meeting the needs of both amateur and professional cooks alike.

Continuing to build on the ongoing evolution of the cookware industry, the importance of consumer feedback cannot be overstated. Manufacturers who actively engage with their customers, gather reviews, and act on suggestions can improve both their products and customer relationships. Offering a platform where consumers can directly communicate with the company or share their experiences helps in refining designs and identifying potential improvements. For example, feedback on the ergonomics of handles, the effectiveness of the steam release system, or the heat distribution in the double boiler can inform future product iterations. Manufacturers might also introduce a customer loyalty program or subscription services, where consumers who regularly use their products can get discounts or exclusive access to new releases. This can foster a strong community around the brand and increase customer retention.

Additionally, globalization continues to influence how cookware, including double boilers, is manufactured and sold. With access to global supply chains, manufacturers have the ability to source materials from various parts of the world, allowing them to select the best raw materials at competitive prices. This has also enabled brands to enter new markets, reaching customers who may have previously been inaccessible. For instance, expanding into emerging markets with growing middle classes, such as parts of Asia, Africa, or South America, can lead to a broader customer base. In these markets, local culinary traditions may drive the demand for specific features in cookware, such as heat-resistant materials or pots designed for use over open flames, which could influence how double boilers are produced.

As digital transformation continues to reshape industries, manufacturers in the cookware sector are increasingly embracing smart technologies. For instance, integrating IoT (Internet of Things) sensors into double boilers could allow users to monitor temperature, water levels, and cooking progress via smartphone apps. This type of connected cookware would not only make cooking more efficient but also offer a level of convenience that caters to modern lifestyles, where time and multitasking are precious. Features like automatic shutoff if the water evaporates or alerts when the food in the top pot reaches the desired temperature could further enhance the cooking experience.

In terms of the materials science used in double boiler manufacturing, we might see the emergence of more advanced alloys or hybrid metals. For example, manufacturers may use a composite metal that combines the best attributes of stainless steel, aluminum, and copper, providing better heat distribution, strength, and lighter weight. Nanotechnology could also come into play to improve non-stick coatings or increase the durability of the cookware surface. These technologies could help further refine the cooking performance of double boilers, making them even more user-friendly and resistant to wear and tear.