Edge cutting trimming and forming machines are specialized machines used to deburr, smooth, trim, and shape edges of various materials, particularly metals, plastics, and wood. They employ a combination of cutting, grinding, and forming processes to achieve the desired edge finish and profile.

Types of Edge Cutting Trimming and Forming Machines

Edge cutting trimming and forming machines come in various configurations to suit specific applications and materials. Common types include:

- Benchtop Machines: These compact and portable machines are ideal for small-scale edge finishing tasks, such as deburring and trimming small components.

- Floor-standing Machines: These larger and more powerful machines are designed for heavy-duty edge finishing applications, such as trimming and shaping large sheets of metal or plastic.

Components of Edge Cutting Trimming and Forming Machines

Edge cutting trimming and forming machines typically consist of the following components:

- Cutting Tool: The cutting tool is the primary element that removes material from the edge. It may be a rotating blade, a grinding wheel, or a milling cutter, depending on the material and desired finish.

- Guide Rails: The guide rails provide precise positioning and movement of the workpiece during edge finishing.

- Forming Tool: The forming tool, if used, shapes the edge of the workpiece to the desired profile. It may be a roller, a press, or a forming die, depending on the application.

- Workpiece Support: The workpiece support securely holds the workpiece in place during edge finishing.

- Control System: The control system regulates the movement of the cutting and forming tools, ensuring precision and repeatability.

Working Principle of Edge Cutting Trimming and Forming Machines

Edge cutting trimming and forming machines operate on the principle of controlled material removal and shaping. The cutting tool precisely removes unwanted material from the edge, while the forming tool shapes the edge into the desired profile. The guide rails ensure accurate positioning and movement of the workpiece, while the control system regulates the entire process.

Applications of Edge Cutting Trimming and Forming Machines

Edge cutting trimming and forming machines are widely used in various industries for a range of applications:

- Metal Fabrication: Deburring, trimming, and shaping metal components for various applications, such as automotive parts, machinery components, and architectural elements.

- Plastics Manufacturing: Deburring, trimming, and shaping plastic sheets and components for various applications, such as packaging, electronics, and automotive parts.

- Woodworking: Deburring, trimming, and shaping wooden components for various applications, such as furniture, cabinetry, and decorative woodwork.

- Medical Device Manufacturing: Deburring, trimming, and shaping medical devices and implants to achieve a smooth, sterile surface that meets medical standards.

- Jewelry Making: Trimming and shaping gemstones, precious metals, and jewelry components to achieve precise dimensions and a polished finish.

Benefits of Edge Cutting Trimming and Forming Machines

Edge cutting trimming and forming machines offer several advantages, including:

- Accuracy and Precision: They provide precise edge finishing with minimal material removal, ensuring consistent results.

- Fast and Efficient: They can quickly deburr, trim, and shape edges of various materials, reducing production time.

- Versatility: They can handle a wide range of materials, from soft plastics to hard metals, and can achieve various edge profiles.

- Rugged Construction: They are typically made from durable materials and are designed to withstand heavy-duty use.

- Automated Processes: Some machines can be automated, further reducing labor costs and improving efficiency.

Safety Considerations when Using Edge Cutting Trimming and Forming Machines

When using edge cutting trimming and forming machines, safety precautions are essential to prevent injuries and maintain a safe working environment:

- Personal Protective Equipment: Wear safety glasses, gloves, and a respirator to protect from flying debris and metal splinters.

- Safe Material Handling: Handle materials carefully to avoid cuts and abrasions.

- Secure Workpiece Fixture: Ensure the workpiece is securely held in place to prevent it from moving during operation.

- Adequate Ventilation: Provide adequate ventilation in the working area to remove dust and fumes.

- Proper Machine Operation: Follow the manufacturer’s instructions and guidelines for safe operation.

Edge Cutting Trimming and Forming Machine

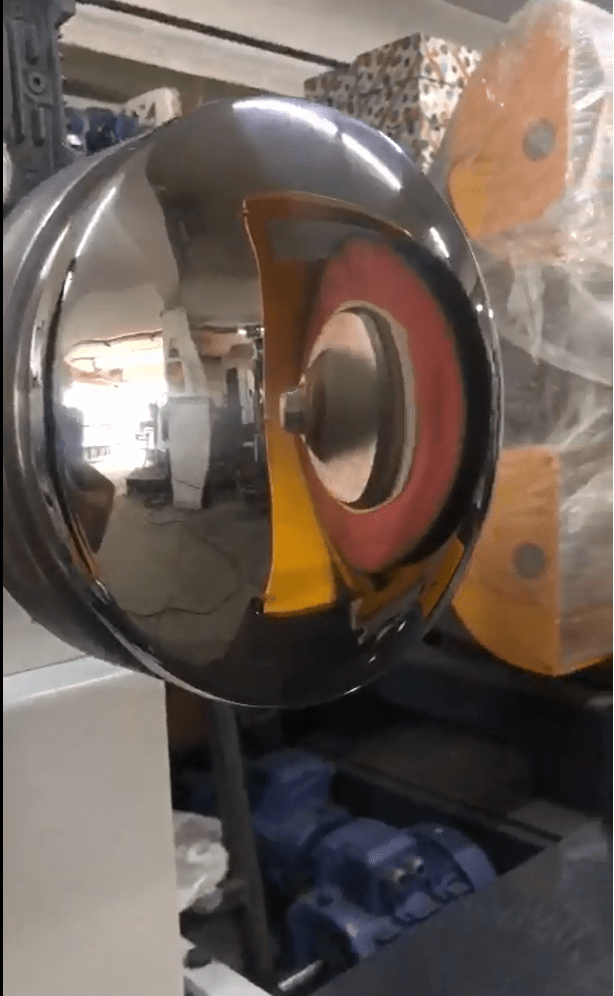

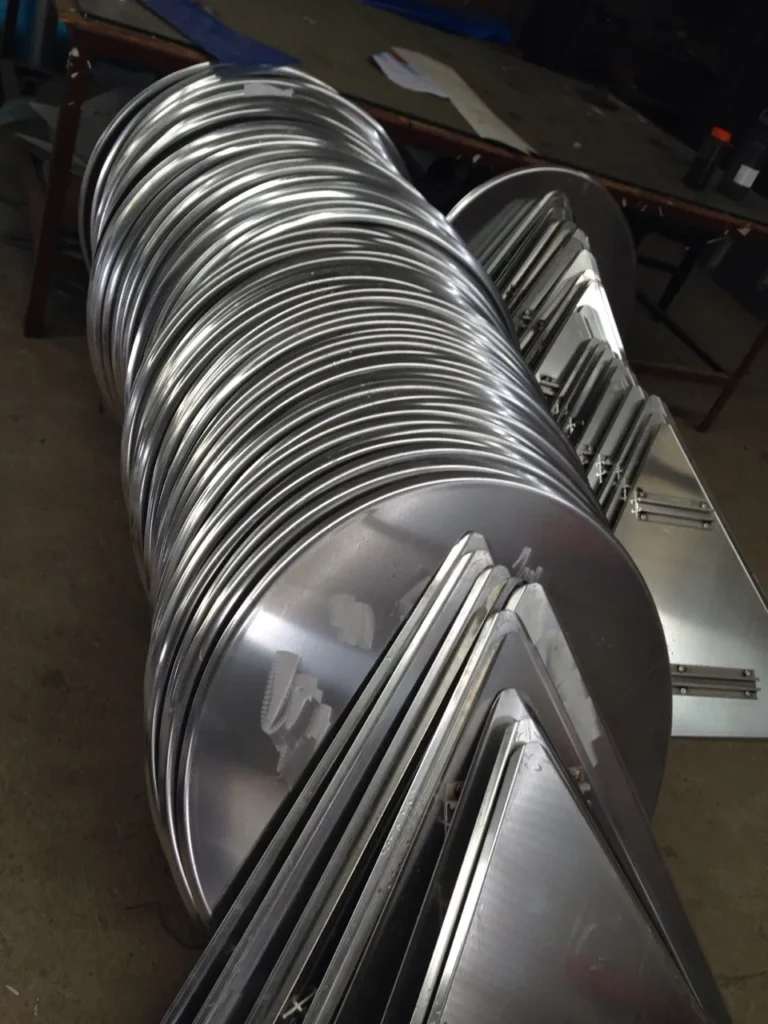

Edge Cutting Trimming and Forming Machine, aka Corner Rounder Machine, is used to cut, bend or round sharp edges of a metal cup-shaped part such as fire extinguisher or cookware production

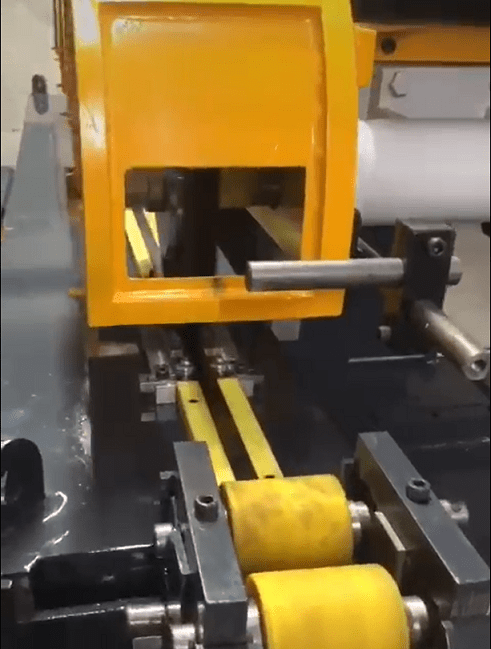

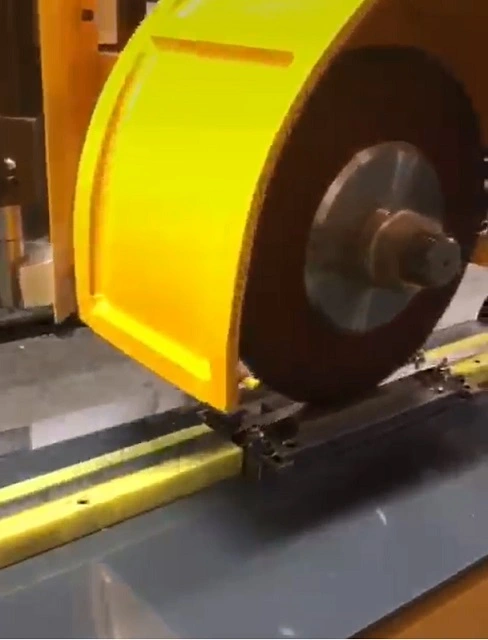

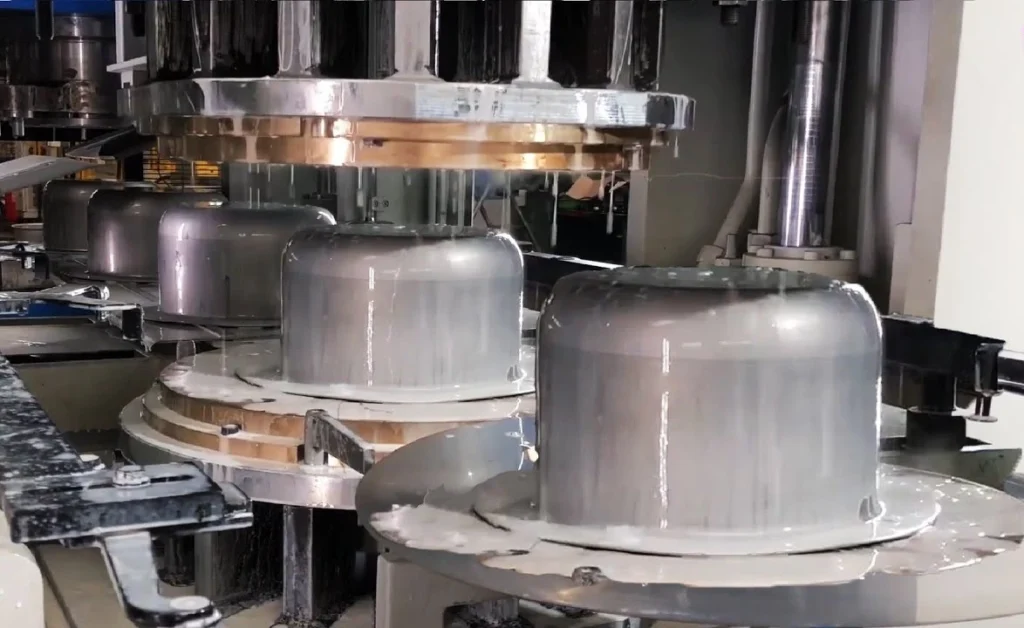

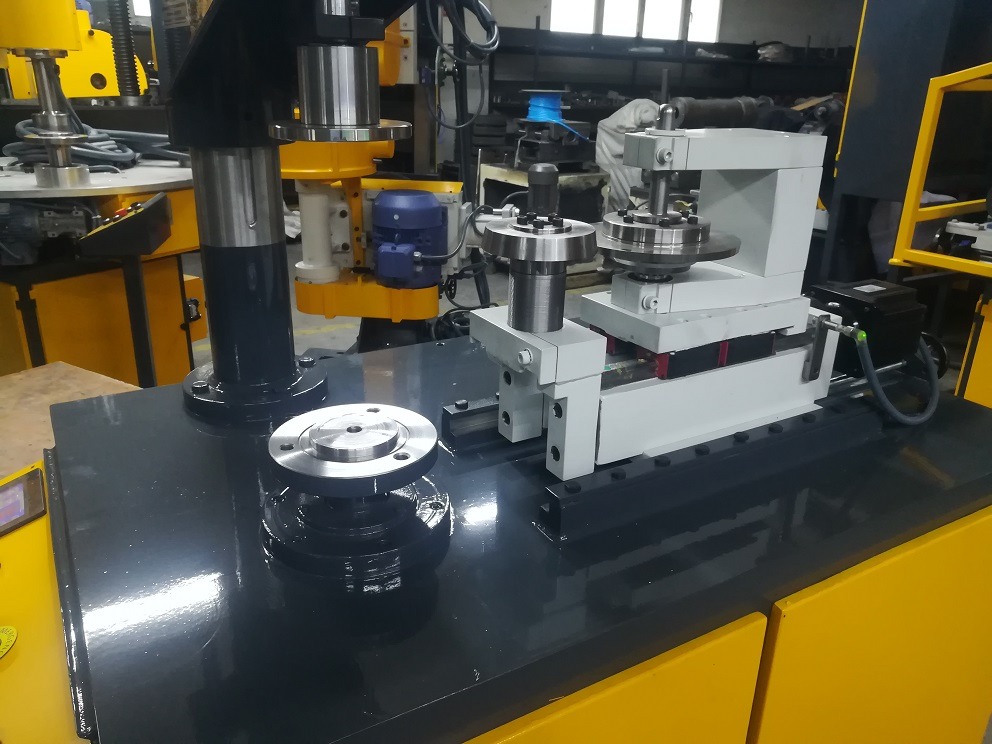

These cutting and trimming of edges are carried out by our ECM-100, ECM-200, and ECM-300 machines, specially designed to cut the edges of round parts in serial production. In our machinery, cutting of edges and bending them inside are carried out in one cycle which shortens the cycle time of one part and makes economy in the production of the machine

Our order rounder machines are made as a welded sheet construction and complete painted, with an electrical board, controlled by a PLC

Edge Cutting Trimming and Forming Machine is a specialized machine used for cutting, trimming, and forming the edges of various materials such as metal, plastic, and wood. It is commonly used in the manufacturing industry for mass production of products such as panels, boards, and sheets.

The machine is equipped with sharp blades that can accurately cut and trim the edges of the material. It is also designed with different forming tools that can shape the edges of the material into various forms and profiles.

The operation of the Edge Cutting Trimming and Forming Machine is simple and efficient. The operator loads the material onto the machine and selects the appropriate cutting, trimming, or forming tool. The machine automatically performs the required operation according to the selected tool, and the finished product is discharged from the machine.

This machine is widely used in the manufacturing industry, including industries such as automotive, aerospace, construction, and furniture. It is particularly useful for cutting, trimming, and forming the edges of materials used in these industries.

Edge curling operation with the Edge Cutting Trimming and Forming Machine for sheet metals

Edge curling, also known as edge rolling or edge forming, is a metalworking process that creates a rolled or curled edge on sheet metal components. It is commonly used for various purposes, including:

- Reinforcing edges: Curling strengthens the edges of sheet metal components, making them more resistant to damage and wear.

- Creating a smooth finish: Curling eliminates sharp edges and creates a smooth, rounded edge that is safer to handle and aesthetically pleasing.

- Preparing for welding: Curling can prepare the edges of sheet metal components for welding by aligning them and providing a consistent surface for the weld bead.

Edge curling can be performed using various tools and techniques, but one of the most efficient and versatile methods is using an edge cutting trimming and forming machine. These machines are equipped with specialized tooling that can precisely curl edges of various sizes and materials.

Edge Curling Operation with an Edge Cutting Trimming and Forming Machine

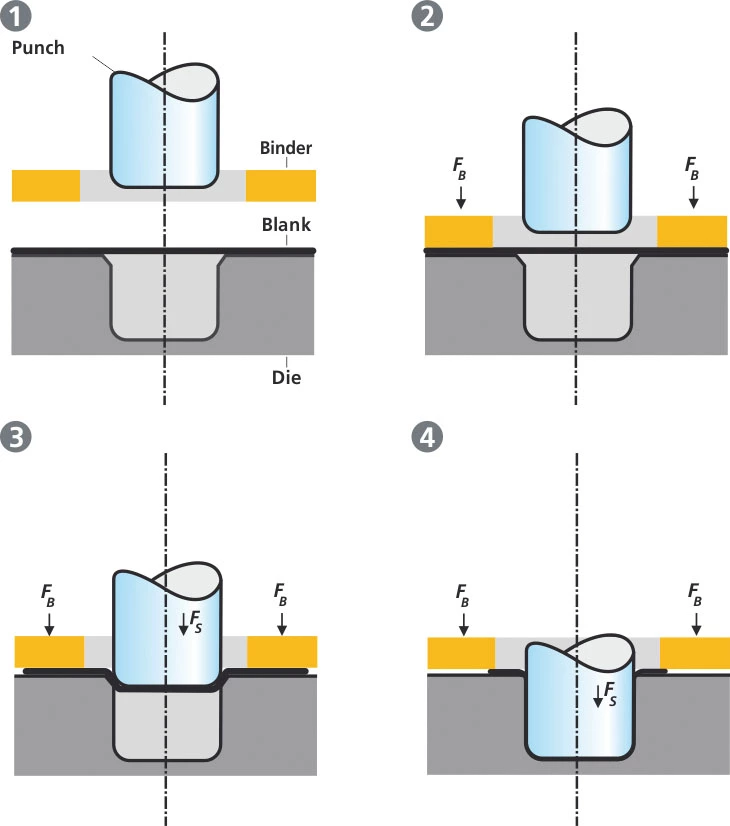

The edge curling operation with an edge cutting trimming and forming machine typically involves the following steps:

- Material Preparation: Ensure the sheet metal is clean, free from burrs, and of uniform thickness.

- Workpiece Positioning: Securely position the sheet metal on the machine’s workpiece support, ensuring it is aligned with the curling tool.

- Tool Adjustment: Adjust the curling tool’s position and pressure settings according to the thickness and material of the sheet metal.

- Edge Curling: Activate the machine to curl the edge of the sheet metal. The machine’s guide rails will ensure precise movement, and the curling tool will apply the appropriate pressure to achieve the desired curl radius.

- Inspection: Inspect the curled edge for uniformity, consistency, and adherence to the desired specifications.

Benefits of Using an Edge Cutting Trimming and Forming Machine for Edge Curling

Edge cutting trimming and forming machines offer several advantages for edge curling operations:

- Accuracy and Precision: They provide precise edge curling with consistent results, ensuring the desired curl radius and edge profile.

- Versatility: They can handle a wide range of sheet metal thicknesses and materials, from thin aluminum to thick steel.

- Efficiency: They can quickly curl edges of various sizes, reducing production time and increasing productivity.

- Reduced Human Error: They automate the edge curling process, minimizing the risk of human error and ensuring consistent quality.

- Safety: They provide safety features, such as guards and interlocks, to protect operators from potential hazards.

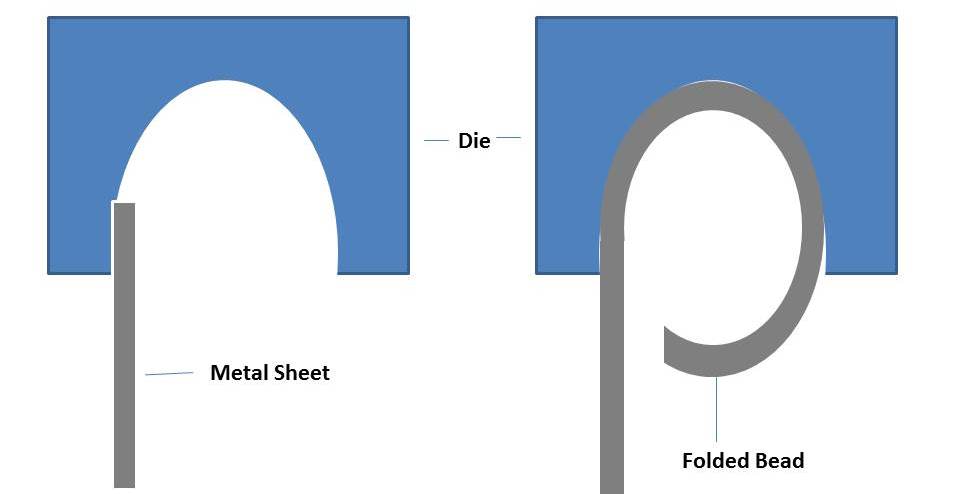

Edge curling is a special metalworking operation, to make the edges of a round or a flat sheet metal into hollow rings and this operation is carried out when there is a need of fixing one part on the other with air or watertight closure for safe handling. The rims of the round metal part are first cut (or also called trimmed) and then can be bent outside or inside by a special metal tool called “sheet metal curling tool”. In this way, the part has a better finishing and the rims have no longer the risk of cutting by usage.

The curling usually takes a few seconds more time in comparison to edge cutting operation. The operator needs to remove the edge cutting tool and put on the edge curling tool to go on with the curling.

Edge curling operation can be applied on metals such as:

- Stainless steel

- Black steel

- Aluminum

- Copper

- Tin

- Zinc

The edge curling (or edge closing) is also widely applied in bakeware production facilities. The stainless steel cake, aluminum or alusteel cake molds (or more generally bake molds) are also manufactured by a drawing hydraulic press and the rims of these molds are trimmed first by an edge trimming machine and then curled inside or outside depending on the application.

The curling of sheet metals can be applied to the parts as below

- Cake molds

- Teapots and coffee pots

- Milk canisters

- Water heater bodies

- Kettles

- Bakery products

What is curling in sheet metal?

Curling in sheet metal is a metalforming process that creates a rolled or curled edge on sheet metal components. It is a versatile and widely used technique that serves various purposes, including:

- Reinforcing edges: Curling strengthens the edges of sheet metal components, making them more resistant to damage and wear. This is particularly important for components subjected to frequent handling or potential impacts.

- Eliminating sharp edges: Curling eliminates sharp edges that can pose safety hazards or cause discomfort during handling. The rounded edge created by curling provides a smoother, safer finish.

- Enhancing aesthetics: Curling can enhance the aesthetic appearance of sheet metal components by creating a clean, uniform edge. This is often desirable for components that are visible or have decorative elements.

- Preparing for welding: Curling can prepare the edges of sheet metal components for welding by aligning them and providing a consistent surface for the weld bead. This can improve the quality and strength of the welded joint.

- Guiding fluid flow: In applications where sheet metal components are used to guide fluid flow, curling can help create a smooth, consistent internal profile that minimizes turbulence and enhances fluid flow characteristics.

Methods of Curling Sheet Metal

There are several methods for curling sheet metal, each with its own advantages and limitations. Some of the most common methods include:

- Manual Curling: Manual curling involves using hand tools, such as curling pliers or a hammer and dolly, to bend the edge of the sheet metal. While this method is simple and inexpensive, it can be time-consuming and may not provide the precision and consistency required for critical applications.

- Roll Forming: Roll forming utilizes a series of rollers to gradually bend the edge of the sheet metal into the desired curl radius. This method offers high precision and consistency, but it requires specialized equipment and may not be suitable for small-scale or complex shapes.

- Press Forming: Press forming utilizes a press brake or other stamping equipment to press the edge of the sheet metal into a die that forms the desired curl shape. This method is suitable for high-volume production and can produce complex curl profiles.

- Edge Cutting Trimming and Forming Machines: Edge cutting trimming and forming machines are versatile machines that can perform a variety of edge finishing operations, including curling. These machines offer a combination of precision, efficiency, and versatility, making them a popular choice for various sheet metal applications.

Factors Affecting Curling Process

The curling process is influenced by several factors, including:

- Sheet Metal Thickness: Thinner sheet metal is generally easier to curl than thicker sheet metal, as it requires less force and is more pliable.

- Sheet Metal Material: The material of the sheet metal also affects the curling process. Softer materials, such as aluminum, are generally easier to curl than harder materials, such as steel.

- Curl Radius: The desired curl radius affects the curling process. Smaller curl radii require more precise tooling and control, while larger curl radii are more forgiving.

- Lubrication: Lubrication can be applied to the sheet metal to reduce friction and prevent galling during the curling process.

- Tooling: The type and quality of the curling tool significantly impact the curling process. Proper tool selection and maintenance are essential for achieving consistent results.

- Machine Settings: Machine settings, such as speed, pressure, and feed rate, must be adjusted appropriately for the specific sheet metal thickness, material, and curl radius.

Curling is a valuable technique in sheet metal fabrication, offering a range of benefits and applications. By understanding the curling process, factors affecting it, and the appropriate methods and equipment, manufacturers can effectively curl sheet metal components to achieve the desired strength, aesthetics, functionality, and consistency.

Curling is one of the sheet metal forming applications to make the flat or round rims (edges) of a part hollow and circular roll. After the curling, the outer geometry of the edge changes completely. The thickness of the edge becomes the diameter of the hollow roll.

The curling operations can be made on the center of the roll or off the center of the roll. These two applications need separate machine tool designs

The curling tool moves vertically on the sheet metal edge of the part while the part rotates about its own axis. The curling tool has a special hemisphere geometry and needs to be manufactured with a harder material than the part itself to withstand the wear and friction. The curling tool moves up and the contact of the part edge must be on the edge of the curling tool inside, maximum closest to the hemisphere finishing corner. the diameter of this hemisphere determines the outer diameter of the curling roll of the sheet metal part.

The speed of the upward movement of the curling tool (or curling die) is critical. This speed is calculated according to the yield strength of the material of the part. The bigger the yield strength, the slower the curling die needs to move upward in order no to damage the part edge

In our edge cutting trimming beading or curling machines, the movement and the speed of the curling die is controlled by a servo motor (which is also controlled by a PLC) to make the process go smoother.

The Edge Cutting Trimming and Forming Machine is a specialized machine used in the production of metal parts, particularly for sheet metal fabrication. It is designed to cut, trim, and form the edges of metal parts, resulting in a clean and smooth finish. The machine uses a series of cutting and forming tools to shape the edges of the metal parts into the desired configuration.

The Edge Cutting Trimming and Forming Machine is commonly used in industries such as automotive manufacturing, aerospace, construction, and metal fabrication. It is particularly useful in applications where the edges of the metal parts need to be precise and uniform, such as in the production of sheet metal components for automotive body parts or aircraft wings.

The machine consists of several components, including a cutting blade, a forming tool, a workpiece holder, and a control system. The cutting blade is used to cut the metal sheet to the required size, while the forming tool is used to shape the edges of the metal part into the desired configuration. The workpiece holder is used to securely hold the metal sheet in place while the machine operates, and the control system manages the operation of the machine and ensures that the metal parts are cut and formed correctly.

Overall, the Edge Cutting Trimming and Forming Machine is a versatile and essential tool in the metal fabrication industry, allowing for the production of high-quality metal parts with precise and uniform edges.

How does the Edge Cutting Trimming and Forming Machine work?

The Edge Cutting Trimming and Forming Machine is a versatile machine that performs multiple operations on sheet metal components, including edge cutting, trimming, and forming. It is a valuable tool in various industries, including metal fabrication, electronics manufacturing, and automotive production.

Working Principle

The Edge Cutting Trimming and Forming Machine operates primarily on the principles of controlled material removal and shaping. The machine utilizes a combination of cutting and forming tools that precisely remove unwanted material and shape the edges of sheet metal components to the desired profile.

- Edge Cutting: The cutting tool, typically a rotating blade, removes excess material from the edges of the sheet metal component. The blade’s movement is controlled by guide rails to ensure precise and consistent cutting.

- Trimming: Trimming involves removing any imperfections or irregularities from the cut edge. This ensures a clean, finished edge that is free of burrs or unevenness.

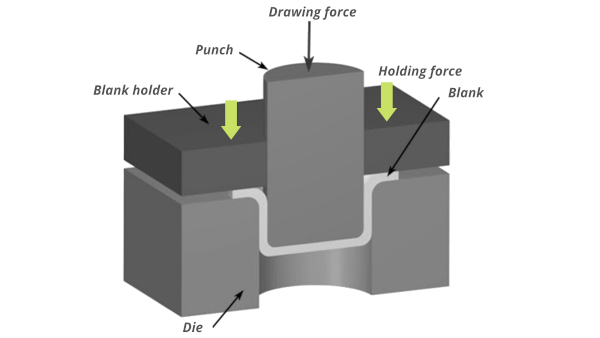

- Forming: The forming tool, which may be a roller, press, or forming die, shapes the edge of the sheet metal component into the desired profile. This could involve creating a rolled or curled edge, a flanged edge, or a beaded edge.

Control System

The Edge Cutting Trimming and Forming Machine is equipped with a control system that regulates the movement of the cutting and forming tools and ensures precision and repeatability. The control system may consist of servo motors, encoders, and a programmable logic controller (PLC).

Versatility

The Edge Cutting Trimming and Forming Machine can handle a wide range of sheet metal thicknesses and materials, from thin aluminum to thick steel. It can also be used with various tooling configurations to achieve different edge profiles and shapes.

Applications

Edge Cutting Trimming and Forming Machines are used in various applications, including:

- **Deburring and trimming metal components for various applications, such as automotive parts, machinery components, and architectural elements.

- **Shaping edges of plastic sheets and components for various applications, such as packaging, electronics, and automotive parts.

- **Creating rolled or curled edges on sheet metal components for reinforcement, aesthetics, or fluid flow optimization.

- **Flanging edges of sheet metal components to provide a stronger joint or accommodate welding.

- **Creating beaded edges on sheet metal components for decorative purposes or to enhance rigidity.

Benefits

Edge Cutting Trimming and Forming Machines offer several benefits, including:

- Accuracy and precision: They provide precise edge finishing with consistent results, ensuring the desired edge profile and dimensional accuracy.

- Versatility: They can handle a wide range of materials and thicknesses, making them suitable for various applications.

- Efficiency: They can quickly process workpieces, reducing production time and increasing productivity.

- Reduced human error: They automate the edge finishing process, minimizing the risk of human error and ensuring consistent quality.

- Safety: They provide safety features, such as guards and interlocks, to protect operators from potential hazards.

Edge Cutting Trimming and Forming Machines are essential tools in sheet metal fabrication, enabling manufacturers to produce high-quality components with precise edge finishes, enhanced strength, and improved aesthetics.

The Edge Cutting Trimming and Forming Machine is designed to trim and form the edges of sheet metal parts. It works by using a set of cutting and forming tools that are mounted on a horizontal axis. The sheet metal part is placed on a support table, and then it is pushed against the cutting and forming tools. The cutting tools are used to trim the excess metal from the edges of the sheet, while the forming tools are used to create the desired shape or contour of the edge.

The machine is controlled by a computer program that controls the movement of the cutting and forming tools. The program is designed to take into account the dimensions and shape of the sheet metal part, as well as the desired shape and contour of the edge. Once the program is set, the machine can perform the cutting, forming, and trimming operations automatically, with a high degree of precision and accuracy.

Industries working with our machinery

Trimming and beading machines are versatile tools that are used in a wide range of industries. Here are some of the most common industries that use trimming and beading machines:

Automotive Industry

The automotive industry is one of the largest users of trimming and beading machines. These machines are used to trim and bead car body panels, fenders, doors, and other sheet metal components. Trimming ensures precise dimensions and eliminates rough edges, while beading strengthens the sheet metal and provides reference points for alignment during assembly and welding.

Aerospace Industry

The aerospace industry also relies heavily on trimming and beading machines. These machines are used to fabricate lightweight and high-strength components for aircraft and spacecraft. The precise and consistent trimming and beading operations ensure the structural integrity of these critical components.

Appliance Manufacturing

Appliance manufacturing is another major user of trimming and beading machines. These machines are used to trim and bead the sheet metal components of refrigerators, washing machines, and other household appliances. Trimming and beading help to strengthen the appliances, improve their appearance, and facilitate assembly.

HVAC Industry

The HVAC industry uses trimming and beading machines to fabricate ductwork, fans, and other sheet metal components. Trimming ensures that the components fit together properly, while beading strengthens the components and provides rigidity.

Construction Industry

The construction industry uses trimming and beading machines to fabricate roofing panels, siding, and other sheet metal components for buildings. Trimming and beading help to ensure that the components are weatherproof and durable.

Metal Fabrication Industries

Trimming and beading machines are widely used in various metal fabrication industries, including electrical equipment manufacturing, medical device manufacturing, and industrial machinery manufacturing. These machines are used to trim and bead a wide range of sheet metal components for various applications.

In addition to these specific industries, trimming and beading machines are also used in a variety of other applications, including:

- Sign Manufacturing

- Furniture Manufacturing

- Toy Manufacturing

- Food and Beverage Processing Equipment Manufacturing

- Medical Device Manufacturing

The versatility and effectiveness of trimming and beading machines make them essential tools for a wide range of industries. These machines play a crucial role in producing high-quality, durable, and precisely dimensioned sheet metal components for a variety of applications.

- Cookware Kitchenware

- Defense

- Water Tank Manufacturing

- Solar Power Generator Manufacturing

- Electrical Motor Fan Cover Manufacturing

- Fire Extinguisher Manufacturing

- Exhaust Pipe Manufacturing

- LPG & LNG Tank Manufacturing

Trimming beading machines are specialized pieces of equipment used in various manufacturing industries to cut, shape, and form beads along the edges of metal sheets and other materials. These machines serve the critical function of enhancing the structural integrity and aesthetic appeal of products by creating precise and consistent beading.

Trimming beading machines are essential in processes where the appearance and durability of the edges are paramount. They are commonly employed in industries such as automotive, aerospace, HVAC, and consumer goods manufacturing, where precision and efficiency are crucial.

Importance in Industrial Applications

The primary importance of trimming beading machines lies in their ability to streamline manufacturing processes by automating edge-forming tasks that would otherwise be labor-intensive and prone to human error. By improving consistency and reducing waste, these machines contribute significantly to the overall productivity and cost-effectiveness of production lines.

Furthermore, trimming beading machines enhance the quality of finished products, ensuring they meet stringent industry standards and customer expectations. Their ability to produce uniform edges and beads also plays a vital role in the assembly and functionality of components, particularly in high-stakes industries like aerospace and automotive manufacturing.

Overview of the Content

This comprehensive guide aims to provide an in-depth exploration of trimming beading machines, covering their components, working principles, types, applications, technical specifications, maintenance, and emerging trends. By understanding these aspects, industry professionals can make informed decisions about implementing and optimizing trimming beading machines within their operations.

Components of Trimming Beading Machines

Base and Frame

The base and frame of a trimming beading machine form its structural backbone, providing stability and support for all other components. Typically constructed from robust materials such as steel or cast iron, the frame ensures the machine can withstand the stresses of operation and maintain precision over time.

Materials Used

- Steel: Known for its durability and resistance to deformation, steel is commonly used in high-performance trimming beading machines. It offers excellent rigidity and longevity.

- Cast Iron: Preferred for its vibration-damping properties, cast iron frames help minimize noise and improve accuracy during operation.

Structural Design

- The structural design of trimming beading machines varies based on the specific model and intended application. Key considerations include the machine’s footprint, ease of access for maintenance, and adaptability to different manufacturing environments.

Cutting and Beading Tools

The cutting and beading tools are critical to the machine’s functionality, responsible for shaping and forming the edges of materials. These tools come in various shapes and sizes, tailored to the specific beading patterns and material thicknesses required.

Types and Materials

- High-Speed Steel (HSS): Known for its hardness and heat resistance, HSS is commonly used for cutting tools that need to maintain sharpness under demanding conditions.

- Carbide: Offering superior wear resistance and durability, carbide tools are ideal for high-volume production runs and materials that are difficult to machine.

Maintenance and Replacement

- Regular maintenance of cutting and beading tools is essential to ensure consistent performance. This includes sharpening or replacing worn tools and adjusting alignment to prevent defects in the finished products.

Drive Mechanism

The drive mechanism powers the machine’s operations, converting electrical energy into mechanical motion. It is a crucial component that directly influences the machine’s efficiency and performance.

Motor Types

- AC Motors: Widely used in trimming beading machines for their reliability and simplicity. AC motors offer consistent performance and are suitable for applications where speed control is not critical.

- Servo Motors: Preferred for applications requiring precise control and variable speeds. Servo motors enable dynamic adjustments to the machine’s operations, enhancing versatility and efficiency.

Energy Efficiency Considerations

- Modern trimming beading machines are designed with energy efficiency in mind, incorporating features like variable frequency drives (VFDs) to optimize power consumption and reduce operational costs.

Control Systems

Control systems govern the operation of trimming beading machines, allowing operators to configure settings, monitor performance, and ensure safety. These systems range from basic manual controls to sophisticated automated interfaces.

Manual vs. Automated Systems

- Manual Systems: Suitable for smaller operations or applications requiring frequent adjustments. Manual controls offer simplicity and direct operator oversight.

- Automated Systems: Essential for large-scale production environments, automated systems provide consistent performance, reduce human error, and enable integration with other machinery.

Integration with Industry 4.0 Technologies

- Trimming beading machines are increasingly adopting Industry 4.0 technologies, such as IoT sensors and data analytics, to enhance operational efficiency and enable predictive maintenance.

Working Principles

Detailed Description of the Trimming Process

The trimming process involves cutting away excess material from the edges of a workpiece to achieve a desired shape or size. Trimming beading machines utilize specialized tools to perform this task with high precision and consistency.

- Material Feeding: The workpiece is fed into the machine, either manually or automatically, and positioned for trimming.

- Tool Engagement: Cutting tools engage the workpiece, removing excess material while following the predefined path and pattern.

- Material Removal: The machine’s cutting tools execute the trimming operation, guided by precise control systems to ensure uniformity.

- Quality Inspection: The trimmed edges are inspected for accuracy and quality, with adjustments made as necessary.

Beading Techniques and Variations

Beading is the process of forming beads along the edges of a workpiece, enhancing both its structural integrity and aesthetic appeal. Different techniques and variations are employed based on the material and intended application.

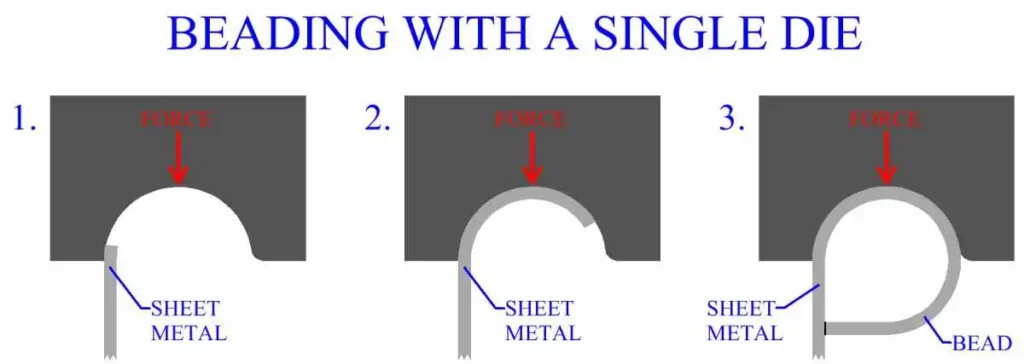

- Single Bead Formation: The simplest form of beading, involving a single continuous bead along the edge.

- Double Bead Formation: Utilized when additional strength or a decorative effect is desired, double beads consist of two parallel beads along the edge.

- Custom Bead Patterns: Some machines allow for custom bead patterns, tailored to specific design requirements or functional needs.

Workflow and Operational Steps

The workflow of a trimming beading machine is designed to maximize efficiency and ensure consistent output. Key operational steps include:

- Setup and Calibration: Operators configure the machine settings, such as tool alignment and material thickness, to match the requirements of the production run.

- Material Loading: Workpieces are loaded onto the machine, either manually or through automated systems, and positioned for processing.

- Trimming and Beading: The machine executes the trimming and beading operations, following the specified parameters and patterns.

- Quality Control: Finished pieces undergo quality control checks to verify dimensional accuracy and bead integrity.

- Adjustment and Maintenance: Regular adjustments and maintenance are performed to ensure optimal performance and address any issues that arise during operation.

Common Challenges and Solutions

Trimming beading machines can encounter various challenges during operation, which can impact performance and product quality. Common issues and their solutions include:

- Tool Wear and Dullness: Regular tool maintenance, including sharpening and replacement, is essential to maintain cutting precision and prevent defects.

- Material Deformation: Proper machine calibration and tool alignment help prevent material deformation during trimming and beading processes.

- Machine Downtime: Implementing predictive maintenance and monitoring systems can reduce downtime and improve overall equipment efficiency.

- Quality Variability: Consistent quality control checks and process adjustments help ensure uniformity and adherence to specifications.

Types of Trimming Beading Machines

Trimming beading machines are available in various types, each suited to specific applications and production needs. Understanding the differences between these machines is crucial for selecting the right equipment for a given operation.

Manual Trimming Beading Machines

Features and Use Cases

- Manual trimming beading machines are operated entirely by human intervention, making them suitable for small-scale production or applications requiring frequent adjustments. These machines offer simplicity and ease of use, often utilized in workshops or small manufacturing facilities.

Advantages and Disadvantages

- Advantages:

- Cost-effective for low-volume production

- Flexibility to handle various materials and bead patterns

- Simple operation and maintenance

- Disadvantages:

- Limited throughput and productivity

- Higher labor costs due to manual operation

- Inconsistent quality due to human error

Semi-Automatic Trimming Beading Machines

Features and Use Cases

- Semi-automatic trimming beading machines combine manual input with automated processes, offering a balance between flexibility and efficiency. These machines are ideal for medium-scale production environments where speed and precision are important.

Advantages and Disadvantages

- Advantages:

- Improved productivity compared to manual machines

- Enhanced consistency and accuracy

- Reduced operator fatigue and error

- Disadvantages:

- Higher initial investment compared to manual machines

- Requires skilled operators for setup and adjustment

- Limited scalability for large-scale production

Fully Automatic Trimming Beading Machines

Features and Use Cases

- Fully automatic trimming beading machines offer the highest level of automation and efficiency, designed for large-scale production environments. These machines are equipped with advanced control systems and automation features, enabling continuous and consistent operation.

Advantages and Disadvantages

- Advantages:

- Maximum productivity and throughput

- Consistent quality and precision

- Integration with other automated systems and Industry 4.0 technologies

- Disadvantages:

- High initial cost and complexity

- Requires skilled technicians for maintenance and troubleshooting

- Limited flexibility for custom or small-batch production

Applications in Various Industries

Trimming beading machines play a vital role in a wide range of industries, each benefiting from the precision and efficiency these machines offer. Here, we explore some of the key industries and their specific applications.

Automotive Industry

Specific Use Cases

- In the automotive industry, trimming beading machines are used for forming edges on components such as fenders, doors, hoods, and other body panels. These machines ensure that parts meet the strict dimensional tolerances required for assembly and safety.

Benefits in Automotive Manufacturing

- Improved part quality and consistency, reducing rework and waste

- Enhanced structural integrity of components, contributing to vehicle safety

- Increased production speed and efficiency, supporting high-volume manufacturing

Aerospace Industry

Specific Use Cases

- Aerospace manufacturing demands precision and reliability, making trimming beading machines essential for producing parts such as fuselage panels, wing components, and engine casings. These machines contribute to the stringent quality standards of the aerospace industry.

Benefits in Aerospace Manufacturing

- High precision and repeatability, ensuring compliance with aerospace standards

- Reduction in material waste and production costs

- Support for complex geometries and advanced materials

HVAC Industry

Specific Use Cases

- In the HVAC industry, trimming beading machines are used to form edges and beads on ductwork, vents, and other components. These machines help produce parts that are essential for efficient heating, ventilation, and air conditioning systems.

Benefits in HVAC Manufacturing

- Consistent part quality and fit, reducing installation time and costs

- Enhanced durability and performance of HVAC components

- Support for custom designs and specifications

Consumer Goods Industry

Specific Use Cases

- The consumer goods industry utilizes trimming beading machines for a variety of products, including appliances, electronics, and packaging. These machines help create aesthetically pleasing and functional components.

Benefits in Consumer Goods Manufacturing

- Improved product appearance and appeal

- Increased manufacturing efficiency and speed

- Support for diverse materials and product designs

Technical Specifications and Standards

Understanding the technical specifications and standards of trimming beading machines is crucial for selecting the right equipment and ensuring compliance with industry requirements.

International Standards and Compliance

Trimming beading machines must adhere to international standards to ensure safety, quality, and interoperability. Key standards include:

- ISO 9001: Quality management systems standard that ensures consistent product quality and customer satisfaction.

- ISO 12100: Safety of machinery – General principles for design, providing guidelines for reducing risks associated with machine operation.

- CE Marking: Conformity with European health, safety, and environmental protection standards.

Key Technical Specifications

Trimming beading machines have various technical specifications that influence their performance and suitability for specific applications. Key specifications include:

- Maximum Material Thickness: The thickest material the machine can handle, typically measured in millimeters or inches.

- Beading Speed: The rate at which the machine can form beads, often measured in meters per minute.

- Cutting Force: The amount of force exerted by the machine’s cutting tools, affecting its ability to handle different materials.

- Power Requirements: The electrical power needed for operation, influencing energy consumption and infrastructure needs.

Customization Options

Manufacturers often offer customization options to tailor trimming beading machines to specific requirements. Common customization options include:

- Tooling Variations: Custom tools and dies to accommodate unique bead patterns and material specifications.

- Automation Features: Integration of advanced control systems and automation technologies for enhanced performance.

- Material Handling Systems: Customized feeding and handling systems to improve workflow and reduce manual intervention.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting are essential to ensuring the longevity and performance of trimming beading machines. Here, we outline key maintenance practices and common issues that operators may encounter.

Routine Maintenance Procedures

Regular maintenance helps prevent unexpected downtime and ensures consistent machine performance. Key maintenance procedures include:

- Tool Inspection and Replacement: Regularly inspect cutting and beading tools for wear and damage. Sharpen or replace tools as needed to maintain cutting precision.

- Lubrication: Ensure all moving parts are properly lubricated to reduce friction and wear.

- Alignment Checks: Verify tool alignment and calibration to prevent defects and ensure uniformity.

- Electrical System Inspection: Check electrical connections and components for signs of wear or damage, addressing issues promptly to prevent malfunctions.

Common Issues and Solutions

Trimming beading machines may encounter various issues during operation. Understanding these problems and their solutions is crucial for maintaining productivity and quality.

- Tool Wear and Dullness: Dull or worn tools can lead to poor cutting performance and defects. Regularly sharpen or replace tools to maintain quality.

- Material Jams: Misalignment or improper feeding can cause material jams, leading to downtime and damage. Ensure proper setup and alignment to prevent jams.

- Machine Vibration: Excessive vibration can impact precision and tool life. Check for loose components and ensure the machine is properly anchored to reduce vibration.

- Inconsistent Quality: Variability in bead quality and dimensions can arise from improper calibration or tool wear. Regularly inspect and adjust settings to maintain consistency.

Safety Considerations

Safety is paramount when operating trimming beading machines. Key safety considerations include:

- Personal Protective Equipment (PPE): Operators should wear appropriate PPE, such as gloves, safety glasses, and hearing protection, to minimize injury risk.

- Machine Guarding: Ensure all machine guards and safety features are in place and functional to prevent accidental contact with moving parts.

- Emergency Stops: Verify that emergency stop mechanisms are operational and accessible in case of emergencies.

- Training and Education: Provide thorough training to operators and maintenance personnel on safe machine operation and emergency procedures.

Latest Innovations and Trends

The field of trimming beading machines is continually evolving, with new technologies and trends shaping the future of manufacturing. Here, we explore some of the latest innovations and emerging trends in the industry.

Technological Advances

Advancements in technology are driving significant improvements in trimming beading machines, enhancing their capabilities and performance.

- Smart Sensors and IoT Integration: Trimming beading machines are increasingly incorporating smart sensors and IoT connectivity to monitor performance, predict maintenance needs, and optimize operations.

- Advanced Control Systems: New control systems offer greater precision and flexibility, enabling operators to achieve complex bead patterns and adapt to changing production requirements.

- Automation and Robotics: The integration of automation and robotics is transforming trimming beading machines, reducing manual labor, and increasing throughput.

Future Trends in Trimming Beading Machines

Several trends are shaping the future of trimming beading machines, influencing how they are designed and utilized.

- Sustainability and Energy Efficiency: Manufacturers are focusing on sustainability, developing machines with lower energy consumption and reduced environmental impact.

- Customization and Flexibility: As demand for custom products grows, trimming beading machines are becoming more adaptable, with features that support rapid reconfiguration and customization.

- Digitalization and Industry 4.0: The digital transformation of manufacturing is driving the adoption of Industry 4.0 technologies, enabling data-driven decision-making and enhanced machine performance.

Case Studies and Examples

Real-world examples and case studies demonstrate the impact of trimming beading machines in various industries, highlighting their benefits and applications.

- Automotive Manufacturing: A leading automotive manufacturer implemented advanced trimming beading machines to improve production efficiency and reduce defects, achieving significant cost savings and quality improvements.

- Aerospace Industry: An aerospace supplier adopted IoT-enabled trimming beading machines to enhance traceability and optimize maintenance, resulting in reduced downtime and improved compliance with industry standards.

- HVAC Production: A major HVAC manufacturer integrated automated trimming beading machines to increase production capacity and reduce manual labor, leading to faster lead times and higher product quality.

Choosing the Right Trimming Beading Machine

Selecting the right trimming beading machine is crucial for achieving optimal performance and meeting specific production needs. Here, we outline key factors to consider and offer guidance on the selection process.

Factors to Consider

When choosing a trimming beading machine, several factors should be considered to ensure the equipment meets operational requirements.

- Production Volume: Assess the production volume and throughput requirements to determine the appropriate machine type and capacity.

- Material Specifications: Consider the types of materials and thicknesses the machine will handle, ensuring compatibility with the equipment’s capabilities.

- Beading Patterns: Evaluate the complexity and variety of bead patterns needed, selecting machines that offer the necessary tooling and flexibility.

- Automation Needs: Determine the level of automation required, balancing productivity gains with cost considerations and operator expertise.

Cost vs. Benefit Analysis

Conducting a cost vs. benefit analysis helps evaluate the financial implications of investing in a trimming beading machine.

- Initial Investment: Assess the upfront cost of the machine, including installation and setup expenses.

- Operational Costs: Consider ongoing operational costs, such as energy consumption, maintenance, and labor.

- Return on Investment (ROI): Calculate the expected ROI by evaluating the machine’s impact on productivity, quality, and cost savings.

Vendor Selection and Partnerships

Choosing the right vendor and establishing strong partnerships are essential for acquiring quality equipment and support.

- Reputation and Experience: Evaluate potential vendors based on their reputation, experience, and track record in the industry.

- Technical Support and Service: Ensure the vendor offers comprehensive technical support, training, and maintenance services to maximize machine performance and uptime.

- Customization and Flexibility: Consider vendors that offer customization options and flexible solutions tailored to specific production needs.

Conclusion

Recap of Key Points

Trimming beading machines are essential tools in modern manufacturing, offering precision, efficiency, and versatility across a range of industries. Understanding their components, working principles, and applications is crucial for making informed decisions and optimizing production processes.

Final Thoughts on Trimming Beading Machines

As technology continues to advance, trimming beading machines are poised to play an increasingly important role in the manufacturing landscape. By embracing innovation and adopting best practices, manufacturers can leverage these machines to enhance quality, productivity, and competitiveness in their respective industries.

Components of Trimming Beading Machines

To provide a detailed exploration of the components of a trimming beading machine, we’ll delve deeper into each part, discussing their functions, materials, and importance. Here’s an expanded version of the Components of Trimming Beading Machines section:

Trimming beading machines consist of several integral components, each playing a crucial role in ensuring precise operation and high-quality output. Understanding these components can aid in the proper selection, operation, and maintenance of the machines.

Base and Frame

Functionality and Importance

The base and frame of a trimming beading machine serve as the foundation, providing structural support and stability. A well-designed frame is essential to withstand operational stresses and vibrations, ensuring accurate and consistent performance.

Materials Used

- Steel: Often used for its high tensile strength and durability. Steel frames provide rigidity, helping to maintain precision even under heavy loads.

- Cast Iron: Valued for its excellent vibration-damping properties. Cast iron is commonly used in applications where reducing machine noise and vibration is critical to maintaining accuracy.

- Aluminum Alloys: Used in some lightweight machines, aluminum alloys offer corrosion resistance and ease of handling, though they may lack the rigidity of steel or cast iron.

Structural Design

- Box-Type Frames: Provide superior rigidity and support. Box-type frames are designed to minimize deformation and ensure precise alignment of components.

- Open-Type Frames: Offer ease of access for maintenance and adjustments. Open frames are suitable for applications where quick changes and flexibility are required.

- Welded vs. Bolted Structures: Welded structures provide a solid and seamless frame, while bolted structures offer flexibility in assembly and disassembly for maintenance.

Cutting and Beading Tools

Role in Operation

Cutting and beading tools are at the heart of the trimming beading machine’s functionality. They are responsible for removing excess material and forming beads along the edges of workpieces.

Types of Tools

- Rotary Cutters: Used for continuous cutting operations, rotary cutters offer high speed and precision, ideal for long production runs.

- Punch and Die Sets: Employed for stamping and forming operations, punch and die sets provide versatility in creating complex bead patterns and shapes.

- Roller Dies: Utilized in forming continuous beads along the length of a workpiece. Roller dies offer consistent pressure and control, ensuring uniform bead formation.

Materials for Cutting Tools

- High-Speed Steel (HSS): Known for its hardness and ability to maintain a sharp edge at high temperatures. HSS is suitable for a wide range of cutting applications.

- Carbide: Offers superior wear resistance and durability, making it ideal for high-volume production and difficult-to-machine materials.

- Ceramic and Diamond Coatings: Used for specialized applications requiring extreme hardness and wear resistance. These coatings can extend the life of cutting tools and improve performance.

Maintenance and Replacement

Regular maintenance of cutting and beading tools is essential to ensure optimal performance. This includes:

- Tool Inspection: Conduct routine inspections to identify signs of wear or damage. Replace tools that have become dull or chipped.

- Sharpening: Maintain sharp edges on cutting tools to ensure precise cuts and prevent material deformation.

- Alignment and Calibration: Regularly check tool alignment and calibration to prevent defects and ensure uniformity in bead formation.

Drive Mechanism

Functionality and Importance

The drive mechanism powers the operation of trimming beading machines, converting electrical energy into mechanical motion. It directly influences the machine’s efficiency and performance.

Motor Types

- AC Motors: Commonly used for their reliability and low maintenance requirements. AC motors provide consistent performance and are suitable for applications where speed control is not critical.

- DC Motors: Offer precise speed control and are used in applications requiring variable speeds. DC motors can be paired with controllers to fine-tune performance.

- Servo Motors: Provide high precision and dynamic control, enabling rapid adjustments to speed and position. Servo motors are ideal for applications requiring complex bead patterns and high-speed operations.

- Stepper Motors: Offer precise positioning and repeatability. Stepper motors are used in applications where incremental movements and accuracy are essential.

Energy Efficiency Considerations

- Variable Frequency Drives (VFDs): Used to optimize energy consumption by adjusting the motor’s speed and torque to match the operational needs. VFDs can significantly reduce energy costs and extend the life of the drive system.

- Regenerative Drives: Capture and reuse energy generated during deceleration, further improving energy efficiency and reducing operational costs.

Control Systems

Role in Operation

Control systems govern the operation of trimming beading machines, allowing operators to configure settings, monitor performance, and ensure safety. These systems range from basic manual controls to sophisticated automated interfaces.

Types of Control Systems

- Manual Controls: Suitable for smaller operations or applications requiring frequent adjustments. Manual controls offer simplicity and direct operator oversight.

- Programmable Logic Controllers (PLCs): Provide automation and flexibility, enabling operators to program complex operations and adjust settings on the fly. PLCs are widely used in industrial applications for their reliability and ease of use.

- Computer Numerical Control (CNC): Offers high precision and control, allowing for complex and repeatable operations. CNC systems are ideal for high-volume production and applications requiring intricate bead patterns.

- Human-Machine Interfaces (HMIs): Facilitate interaction between operators and machines, providing real-time data and control over machine settings. HMIs enhance usability and improve operational efficiency.

Integration with Industry 4.0 Technologies

Trimming beading machines are increasingly adopting Industry 4.0 technologies to enhance operational efficiency and enable predictive maintenance. Key advancements include:

- IoT Connectivity: Sensors and IoT devices provide real-time monitoring and data collection, enabling operators to track performance, detect anomalies, and predict maintenance needs.

- Data Analytics and Machine Learning: Advanced analytics and machine learning algorithms optimize machine performance by analyzing operational data and identifying trends or inefficiencies.

- Remote Monitoring and Control: Operators can access and control machines remotely, improving flexibility and enabling rapid response to issues.

Conclusion

The components of trimming beading machines play vital roles in ensuring precision, efficiency, and durability. By understanding these components, manufacturers can optimize their machines for specific applications, improve operational efficiency, and reduce downtime. Proper selection, maintenance, and integration of these components are essential for maximizing the performance and lifespan of trimming beading machines.

Tool Maintenance Tips for Trimming Beading Machines

Maintaining the tools of a trimming beading machine is essential for ensuring long-term efficiency, precision, and reliability. Regular maintenance not only prolongs the lifespan of the tools but also ensures consistent quality of the finished products. Here are some detailed tool maintenance tips:

1. Regular Inspection and Assessment

Visual Inspection

- Daily Checks: Conduct visual inspections of cutting and beading tools at the start and end of each shift to identify any visible signs of wear, damage, or misalignment.

- Surface Examination: Look for chips, cracks, or signs of wear on the cutting edges and surfaces, as these can affect the tool’s performance and the quality of the beading.

Performance Monitoring

- Quality Checks: Routinely check the quality of the finished products for any signs of tool-related issues, such as burrs, uneven edges, or inconsistent beading.

- Operational Sounds: Listen for unusual noises during operation, which may indicate tool misalignment or wear.

2. Proper Cleaning and Lubrication

Cleaning Procedures

- Remove Debris: Regularly clean tools to remove metal shavings, dust, and other debris that can accumulate and affect performance.

- Use Appropriate Solvents: Employ non-corrosive cleaning solvents to remove stubborn residues without damaging the tool’s surface.

Lubrication

- Lubricant Selection: Use the correct type of lubricant for the specific tool material, such as oil-based lubricants for steel tools or dry lubricants for carbide tools.

- Regular Application: Apply lubricants at regular intervals to reduce friction, prevent overheating, and protect against corrosion.

3. Sharpening and Reconditioning

Sharpening Techniques

- Proper Tools: Use appropriate sharpening tools, such as diamond stones or grinding wheels, to maintain the cutting edge.

- Sharpening Angles: Follow the manufacturer’s recommendations for sharpening angles to ensure optimal cutting performance.

- Frequency: Establish a regular sharpening schedule based on tool usage and material hardness to maintain sharp edges.

Reconditioning Services

- Professional Reconditioning: Consider professional reconditioning services for heavily worn or damaged tools to restore them to their original specifications.

- Tool Replacement: Replace tools that have reached the end of their usable life to maintain performance and quality.

4. Alignment and Calibration

Tool Alignment

- Proper Setup: Ensure that tools are correctly aligned before each operation to prevent uneven wear and ensure accurate cuts and beads.

- Alignment Tools: Use precision alignment tools and gauges to verify proper tool positioning and alignment.

Calibration

- Regular Calibration: Regularly calibrate the machine and its components to ensure that tools operate within specified tolerances.

- Documentation: Keep detailed records of calibration activities and adjustments for quality control and maintenance purposes.

5. Storage and Handling

Tool Storage

- Protective Cases: Store tools in protective cases or racks to prevent damage when not in use.

- Controlled Environment: Maintain a clean, dry, and temperature-controlled environment to prevent corrosion and material degradation.

Handling Practices

- Proper Handling: Use appropriate handling techniques to prevent dropping or mishandling tools, which can lead to damage.

- Training: Train operators and maintenance personnel on proper handling and storage procedures to minimize accidental damage.

6. Documentation and Training

Maintenance Records

- Detailed Logs: Keep detailed records of all maintenance activities, including inspections, cleaning, sharpening, and replacements. This information can help track tool performance and identify patterns or issues.

- Tool Usage Records: Document tool usage, including hours of operation and materials processed, to anticipate maintenance needs and schedule downtime effectively.

Training and Education

- Operator Training: Provide comprehensive training for operators and maintenance personnel on proper tool care and maintenance procedures.

- Continuous Education: Stay updated on the latest tool maintenance techniques and technologies to improve maintenance practices and enhance tool longevity.

Conclusion

Effective tool maintenance is crucial for maximizing the performance and lifespan of trimming beading machines. By implementing these maintenance tips, manufacturers can ensure consistent product quality, reduce downtime, and extend the life of their tools. Regular inspections, proper cleaning and lubrication, alignment, and training are essential components of a comprehensive maintenance strategy.

Application Areas of Trimming Beading Machines

Trimming beading machines play a crucial role across various industries due to their ability to efficiently trim and bead the edges of metal and other materials. They are essential for achieving precision, consistency, and quality in manufacturing processes. Below, we delve into the primary application areas where these machines are indispensable:

1. Automotive Industry

Role and Importance

The automotive industry relies heavily on trimming beading machines to ensure the structural integrity and aesthetic quality of vehicle components. These machines are used to trim and form beads on various parts, contributing to the overall safety and appearance of vehicles.

Specific Applications

- Body Panels: Trimming beading machines are used to trim and bead the edges of doors, hoods, fenders, and trunk lids. This ensures a smooth fit and finish, reducing the risk of sharp edges and improving the vehicle’s aesthetic appeal.

- Exhaust Systems: Beading is essential for exhaust system components to ensure proper sealing and assembly. Trimming beading machines create precise beads that help maintain joint integrity under varying temperatures and pressures.

- Interior Components: These machines are used to create beaded edges on interior panels and trim pieces, enhancing the aesthetic quality and durability of the interior components.

Benefits

- Improved Safety: Proper beading enhances the strength and stability of components, contributing to vehicle safety.

- Aesthetic Appeal: Beading provides a polished and professional appearance, enhancing the overall look of the vehicle.

- Cost Efficiency: Automated trimming and beading reduce labor costs and increase production efficiency, enabling manufacturers to meet high-volume demands.

2. Aerospace Industry

Role and Importance

The aerospace industry demands the highest precision and quality standards, making trimming beading machines essential for manufacturing components that must withstand extreme conditions and stresses.

Specific Applications

- Fuselage Panels: Trimming beading machines are used to trim and bead the edges of fuselage panels, ensuring a precise fit and alignment during assembly. Beading enhances the panels’ structural integrity and resistance to aerodynamic forces.

- Wing Components: Beading is applied to wing components, such as flaps and ailerons, to improve their strength and performance. The precision of trimming beading machines ensures the components meet strict aerospace standards.

- Engine Components: In engine manufacturing, trimming beading machines are used to create precise beads on engine casings and ducts, improving thermal and mechanical performance.

Benefits

- Precision and Accuracy: Trimming beading machines provide the precision necessary to meet the stringent requirements of the aerospace industry.

- Enhanced Performance: Beaded components offer improved strength and aerodynamic performance, contributing to the overall efficiency of aircraft.

- Reliability: The consistent quality of beaded components ensures reliability and safety in critical aerospace applications.

3. HVAC Industry

Role and Importance

The HVAC (Heating, Ventilation, and Air Conditioning) industry utilizes trimming beading machines to manufacture components that require precise sealing and structural integrity.

Specific Applications

- Ductwork: Trimming beading machines are used to bead the edges of ductwork components, ensuring a tight seal and preventing air leaks. Proper beading also enhances the structural stability of ducts.

- Vents and Grilles: Beading is applied to vents and grilles to improve their strength and appearance. Trimming beading machines ensure a consistent fit and finish, contributing to the overall quality of HVAC systems.

- Heat Exchangers: In heat exchanger manufacturing, trimming beading machines create beads that enhance the thermal performance and durability of components.

Benefits

- Energy Efficiency: Beaded components improve sealing and reduce air leakage, enhancing the energy efficiency of HVAC systems.

- Durability: The structural integrity provided by beading ensures the long-term durability of HVAC components.

- Quality Assurance: Trimming beading machines deliver consistent quality, enabling manufacturers to meet industry standards and customer expectations.

4. Consumer Goods Industry

Role and Importance

In the consumer goods industry, trimming beading machines are employed to enhance the quality and appearance of a wide range of products, from household appliances to electronics.

Specific Applications

- Appliances: Trimming beading machines are used to create beaded edges on appliances such as refrigerators, ovens, and washing machines. This improves the aesthetic appeal and durability of the products.

- Electronics Enclosures: Beading is applied to electronic enclosures and casings to enhance their strength and provide a polished appearance. Trimming beading machines ensure a precise fit and finish, critical for protecting sensitive electronic components.

- Packaging: In packaging manufacturing, trimming beading machines create beads that improve the strength and sealing of containers, ensuring the protection and integrity of packaged goods.

Benefits

- Aesthetic Enhancement: Beading enhances the visual appeal of consumer products, contributing to customer satisfaction and brand image.

- Structural Integrity: Beaded edges provide added strength and resistance to wear and tear, extending the lifespan of consumer goods.

- Manufacturing Efficiency: Trimming beading machines increase production efficiency, allowing manufacturers to meet high demand while maintaining quality.

5. Metalworking Industry

Role and Importance

The metalworking industry utilizes trimming beading machines for a variety of applications where precision and consistency are paramount.

Specific Applications

- Sheet Metal Fabrication: Trimming beading machines are used to trim and bead sheet metal components for a range of applications, from construction to transportation.

- Custom Metal Components: Beading is applied to custom metal parts to enhance their strength and performance. Trimming beading machines enable the production of intricate and precise designs.

- Architectural Metalwork: In architectural metalwork, trimming beading machines create beaded edges on decorative elements, ensuring a high-quality finish.

Benefits

- Precision and Consistency: Trimming beading machines provide the accuracy required for complex metalworking applications.

- Versatility: These machines can handle a wide range of materials and thicknesses, accommodating diverse metalworking needs.

- Quality Assurance: The consistent quality of beaded metal components ensures they meet industry standards and project specifications.

6. Food and Beverage Industry

Role and Importance

In the food and beverage industry, trimming beading machines are used to manufacture components that require precise sealing and hygiene standards.

Specific Applications

- Food Containers: Trimming beading machines are used to create beaded edges on food containers, ensuring a tight seal and preventing contamination.

- Beverage Cans: Beading is applied to beverage cans to enhance their strength and resistance to pressure changes. Trimming beading machines ensure a uniform and reliable seal.

- Processing Equipment: In food processing equipment manufacturing, trimming beading machines create beads that improve the structural integrity and hygiene of components.

Benefits

- Food Safety: Beaded components provide secure sealing, preventing contamination and ensuring food safety.

- Durability: The added strength provided by beading ensures the longevity and reliability of food and beverage packaging.

- Efficiency: Trimming beading machines increase production efficiency, enabling manufacturers to meet high demand while maintaining quality and safety standards.

7. Medical Device Manufacturing

Role and Importance

The medical device manufacturing industry requires precision and reliability, making trimming beading machines essential for producing components that must meet strict standards.

Specific Applications

- Surgical Instruments: Trimming beading machines are used to create beaded edges on surgical instruments, enhancing their strength and safety.

- Medical Equipment Casings: Beading is applied to medical equipment casings to improve their structural integrity and provide a polished appearance.

- Implantable Devices: In the manufacturing of implantable devices, trimming beading machines create beads that ensure precision and compatibility with human tissue.

Benefits

- Precision and Accuracy: Trimming beading machines provide the precision necessary to meet the stringent requirements of medical device manufacturing.

- Reliability: Beaded components ensure reliability and safety in critical medical applications.

- Quality Assurance: The consistent quality of beaded medical components ensures they meet industry standards and regulatory requirements.

Conclusion

Trimming beading machines are versatile tools that play a vital role in various industries, from automotive to medical device manufacturing. Their ability to enhance the precision, consistency, and quality of components makes them indispensable for modern manufacturing processes. By understanding the specific applications and benefits of trimming beading machines, manufacturers can optimize their operations, improve product quality, and meet the demands of their respective industries.

Trimming Beading Tools

Trimming beading tools are critical components of trimming beading machines, directly responsible for cutting and forming beads on workpieces. Their design, material, and maintenance play a crucial role in determining the quality and efficiency of the trimming and beading process. Here’s an in-depth look at trimming beading tools, including their types, materials, maintenance, and considerations for selection:

Types of Trimming Beading Tools

Trimming beading tools come in various shapes and forms, each designed for specific tasks and applications. The choice of tools depends on the material being processed, the desired bead pattern, and the machine’s capabilities.

1. Rotary Cutters

Functionality

- Rotary cutters are used for continuous cutting operations and are ideal for long production runs.

- They provide high-speed cutting and precision, making them suitable for trimming operations that require clean and straight edges.

Applications

- Automotive body panels

- Sheet metal fabrication

- Packaging components

2. Punch and Die Sets

Functionality

- Punch and die sets are used for stamping and forming operations, allowing for the creation of complex bead patterns and shapes.

- They offer versatility and can be customized to meet specific design requirements.

Applications

- Complex bead patterns in aerospace components

- Decorative metalwork

- Custom metal parts

3. Roller Dies

Functionality

- Roller dies are utilized in forming continuous beads along the length of a workpiece.

- They apply consistent pressure and control, ensuring uniform bead formation.

Applications

- HVAC ductwork

- Metal enclosures

- Architectural metalwork

4. Serrated Cutters

Functionality

- Serrated cutters feature a toothed edge that is designed for gripping and cutting through tougher materials.

- They are often used in applications where a smooth finish is not critical but where material grip and precision are required.

Applications

- Heavy-duty metal cutting

- Thicker materials such as steel or titanium

5. Profile Tools

Functionality

- Profile tools are used to create specific bead profiles and shapes, including U-beads, V-beads, and more complex designs.

- These tools are customized to match the desired profile and are critical for applications requiring specific geometric shapes.

Applications

- Automotive trim components

- Custom metal profiles

- Precision sheet metal work

Materials for Trimming Beading Tools

The choice of material for trimming beading tools affects their performance, durability, and suitability for different applications. Key materials include:

1. High-Speed Steel (HSS)

Characteristics

- Known for its hardness and ability to maintain a sharp edge at high temperatures.

- Offers good wear resistance and is suitable for a wide range of cutting applications.

Advantages

- Cost-effective for general-purpose trimming and beading.

- Easy to sharpen and recondition.

Limitations

- May wear quickly in high-volume production or with abrasive materials.

2. Carbide

Characteristics

- Carbide tools offer superior wear resistance and durability, making them ideal for high-volume production and difficult-to-machine materials.

- Maintains sharpness and precision over extended periods.

Advantages

- Long tool life and reduced downtime for tool changes.

- Suitable for hard and abrasive materials.

Limitations

- Higher initial cost compared to HSS tools.

- More challenging to recondition and sharpen.

3. Ceramic and Diamond Coatings

Characteristics

- Ceramic and diamond coatings provide extreme hardness and wear resistance.

- Used for specialized applications requiring the highest levels of durability and precision.

Advantages

- Exceptional tool life and performance in demanding applications.

- Resistance to heat and wear, reducing tool degradation.

Limitations

- Very high cost, typically reserved for critical applications.

- Requires specialized equipment for sharpening and maintenance.

4. Tool Steel

Characteristics

- Tool steel is a versatile material that offers a good balance of strength, toughness, and wear resistance.

- Suitable for a variety of tool types and applications.

Advantages

- Cost-effective and easy to machine and customize.

- Provides a good balance between durability and flexibility.

Limitations

- May not perform as well as carbide or ceramic in highly abrasive conditions.

Maintenance of Trimming Beading Tools

Proper maintenance of trimming beading tools is essential for ensuring consistent performance and longevity. Here are some key maintenance practices:

1. Regular Inspection and Assessment

- Visual Inspections: Conduct regular visual inspections to identify signs of wear, damage, or misalignment.

- Performance Monitoring: Monitor tool performance by checking the quality of the finished products for any signs of tool-related issues, such as burrs or uneven edges.

2. Cleaning and Lubrication

- Cleaning Procedures: Regularly clean tools to remove metal shavings, dust, and debris that can accumulate and affect performance.

- Lubrication: Apply appropriate lubricants to reduce friction, prevent overheating, and protect against corrosion. Ensure that the correct type of lubricant is used for the specific tool material.

3. Sharpening and Reconditioning

- Sharpening Techniques: Use the appropriate sharpening tools, such as diamond stones or grinding wheels, to maintain the cutting edge. Follow manufacturer recommendations for sharpening angles.

- Reconditioning Services: Consider professional reconditioning services for heavily worn or damaged tools to restore them to their original specifications.

4. Alignment and Calibration

- Tool Alignment: Ensure that tools are correctly aligned before each operation to prevent uneven wear and ensure accurate cuts and beads.

- Calibration: Regularly calibrate the machine and its components to ensure that tools operate within specified tolerances.

5. Storage and Handling

- Proper Storage: Store tools in protective cases or racks to prevent damage when not in use. Maintain a clean, dry, and temperature-controlled environment.

- Handling Practices: Use appropriate handling techniques to prevent dropping or mishandling tools. Train operators on proper handling and storage procedures.

Considerations for Selecting Trimming Beading Tools

Selecting the right trimming beading tools requires careful consideration of several factors to ensure optimal performance and quality:

1. Material Compatibility

- Choose tools made from materials that are compatible with the workpiece material to ensure effective cutting and beading.

- Consider the hardness, abrasiveness, and thickness of the material when selecting tool materials and coatings.

2. Tool Geometry

- Select tools with the appropriate geometry for the desired bead profile and cutting requirements.