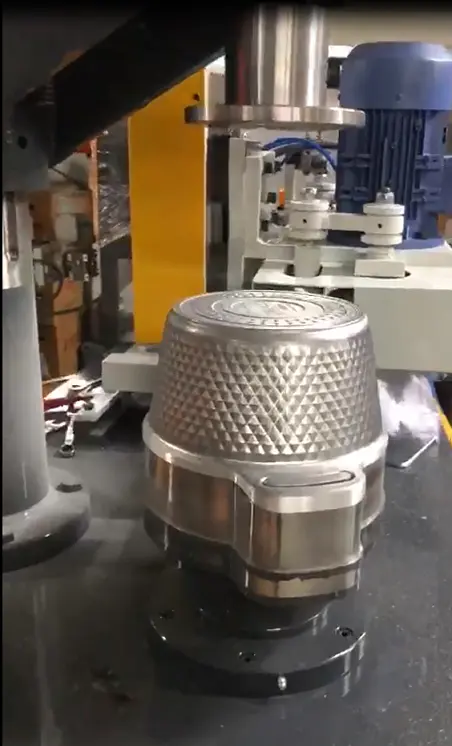

We manufacture Power Deburring Tools for Metal to round the sheet metal edges. These machines are used in metalworking industries

Power deburring tools for metal are handheld or bench-mounted tools designed to remove burrs, sharp edges, and other imperfections from metal workpieces. These tools typically use rotating cutting bits, abrasive wheels, or brushes to perform the deburring operation. Here are some common types of power deburring tools for metal:

- Handheld Electric Deburring Tools: These tools are compact and lightweight, designed to be operated by hand. They often have a rotary motor that drives a cutting bit or an abrasive wheel. Handheld electric deburring tools are versatile and can be used on various metal surfaces, including edges, holes, and internal corners.

- Bench-mounted Deburring Machines: Bench-mounted deburring machines are larger and more powerful than handheld tools. They are designed to be mounted on a workbench or stand. These machines typically have a motorized spindle that drives a variety of deburring attachments, such as cutting bits, abrasive wheels, or wire brushes. Bench-mounted deburring machines are suitable for larger workpieces or when more precision and control are required.

- Pneumatic Deburring Tools: Pneumatic deburring tools are powered by compressed air and are commonly used in industrial settings. They offer high power and speed, making them suitable for heavy-duty deburring applications. Pneumatic deburring tools often feature rotary cutting bits or abrasive wheels for efficient material removal.

- Rotary Deburring Tools: Rotary deburring tools consist of a rotary motor and a variety of cutting bits or abrasive wheels. These tools are designed to be versatile and can handle different types of metal surfaces, including flat, curved, or irregular shapes. Rotary deburring tools are commonly used for edge deburring, hole deburring, and general metal finishing tasks.

- Die Grinder: A die grinder is a handheld power tool that can be equipped with various deburring attachments, such as carbide burrs or abrasive wheels. Die grinders are known for their high speed and precision, making them suitable for intricate deburring tasks on metal workpieces.

When selecting a power deburring tool for metal, consider the following factors:

- Power and Speed: Choose a tool with sufficient power and speed to effectively remove burrs and achieve the desired surface finish on the metal workpiece.

- Tool Size and Ergonomics: Consider the size, weight, and ergonomics of the tool to ensure comfortable and easy handling during extended use.

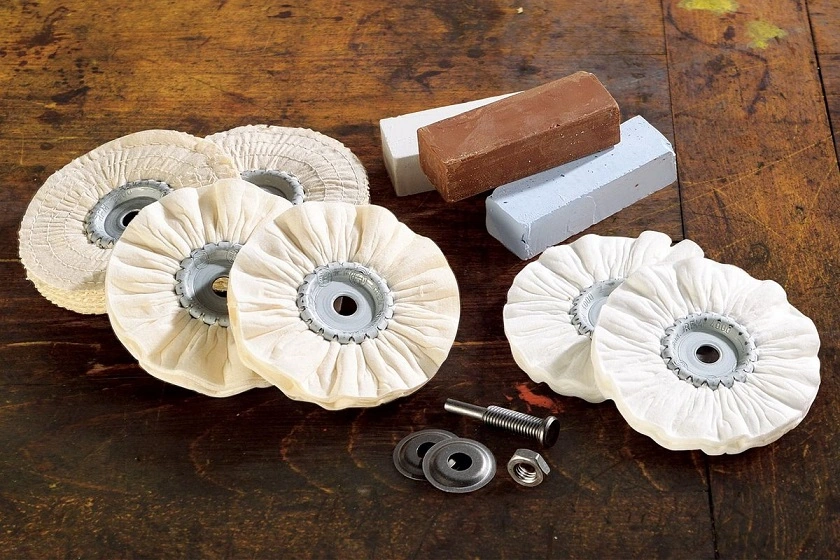

- Deburring Attachments: Different deburring tools support various attachments, such as cutting bits, abrasive wheels, wire brushes, or carbide burrs. Ensure that the tool you choose is compatible with the specific attachments required for your deburring applications.

- Safety Features: Look for tools with appropriate safety features, such as guards, safety switches, or vibration dampening, to protect the operator during use.

- Durability and Reliability: Consider the build quality and reputation of the brand to ensure a durable and reliable tool that can withstand the demands of deburring metal workpieces.

Always follow proper safety guidelines, wear appropriate personal protective equipment (PPE), and refer to the manufacturer’s instructions when operating power deburring tools for metal.

Power Deburring Tools for Metal

Power deburring tools are specialized machines that use abrasive belts, discs, or wheels to remove burrs, sharp edges, and imperfections from metal parts. These tools are essential for improving the safety, functionality, and aesthetics of metal components in various industries.

Types of Power Deburring Tools for Metal:

- Rotary Deburring Tools:

These tools utilize rotating abrasive discs or belts to remove burrs from metal parts. They are versatile and can be used on a wide range of materials, including steel, aluminum, and stainless steel. Rotary deburring tools are available in handheld and stationary models.

- Grinders:

Grinders are powerful tools that use coarse abrasive wheels to remove burrs and heavy imperfections from metal parts. They are often used for initial deburring or for deburring large or thick metal parts.

- Belt Sanders:

Belt sanders use continuous belts of abrasive material to smooth out rough edges and remove burrs from metal parts. They are particularly effective for finishing work and achieving a consistent surface finish.

- Stationary Deburring Machines:

Stationary deburring machines offer precise and consistent deburring for high-volume production or for deburring complex shapes. These machines may utilize rotating cutters, abrasive belts, or a combination of both.

- Ultrasonic Deburring Systems:

Ultrasonic deburring systems use high-frequency vibrations to remove burrs from delicate or precision metal parts. This method is gentle and non-abrasive, making it suitable for parts with intricate geometries or sensitive surfaces.

Choosing the Right Power Deburring Tool for Metal:

The choice of power deburring tool for metal depends on several factors, including:

- Size and shape of the metal part: The tool should be able to accommodate the size and shape of the part comfortably.

- Material of the metal part: The abrasive material used in the tool should be compatible with the material of the part.

- Desired level of precision: The tool should be able to achieve the desired level of precision for the application.

- Production volume: If high-volume production is required, a stationary machine may be more efficient.

- Safety features: The tool should incorporate adequate safety features to protect the operator from potential hazards.

Benefits of Using Power Deburring Tools for Metal:

- Efficiency: Power deburring tools can remove burrs and imperfections much faster than hand tools.

- Precision: Power deburring tools can achieve a higher level of precision than hand tools.

- Consistency: Power deburring tools can provide consistent results, even for high-volume production.

- Safety: Power deburring tools can reduce the risk of injuries to operators by automating the deburring process.

Applications of Power Deburring Tools for Metal:

- Automotive industry: Deburring engine components, car bodies, and other automotive parts.

- Aerospace manufacturing: Deburring precision metal components for aircraft and spacecraft.

- Construction: Deburring metal components for buildings, bridges, and other structures.

- Electronics manufacturing: Deburring metal components for circuit boards, electronic devices, and other electronics.

- Consumer goods manufacturing: Deburring metal components for appliances, furniture, and other consumer products.

Power deburring tools are essential tools for any business that works with metal parts. They can improve the safety, functionality, and aesthetics of metal components, while also increasing efficiency and reducing labor costs. By choosing the right power deburring tool for the job, businesses can ensure that their metal parts meet the highest standards of quality.

Handheld Electric Deburring Tools

Handheld electric deburring tools are portable and versatile tools used to remove burrs, sharp edges, and other imperfections from metal workpieces. These tools are typically compact and lightweight, making them easy to maneuver and operate by hand. Here are some key features and considerations for handheld electric deburring tools:

- Power Source: Handheld electric deburring tools are powered by electricity and usually have a cord for connection to a power outlet. Some models may have a rechargeable battery for cordless operation, offering greater mobility and flexibility.

- Motor Power and Speed: Consider the power rating of the motor, usually expressed in watts or horsepower, to ensure sufficient power for the intended deburring applications. The speed of the tool is typically measured in rotations per minute (RPM), and higher RPMs allow for faster material removal. Variable speed options are also available on some models, providing greater control over the deburring process.

- Deburring Attachments: Handheld electric deburring tools support various types of attachments to suit different deburring needs. Common attachments include cutting bits, abrasive wheels, wire brushes, or carbide burrs. Ensure that the tool you choose is compatible with the specific attachments required for your deburring applications.

- Ergonomics and Grip: Consider the ergonomics of the tool, including the handle design and grip comfort. Look for tools with ergonomic handles and rubberized grips that provide a comfortable and secure hold during extended use. A well-designed tool reduces operator fatigue and enhances control.

- Durability and Build Quality: Look for handheld electric deburring tools made from durable materials that can withstand the demands of deburring tasks. Consider tools with sturdy construction and high-quality components for long-lasting performance.

- Safety Features: Ensure that the tool has appropriate safety features, such as guards, safety switches, or vibration dampening, to protect the operator during use. Safety features help prevent accidents and ensure operator safety.

- Noise and Vibration Levels: Check the noise and vibration levels of the tool, as excessive noise and vibration can be fatiguing and uncomfortable during prolonged use. Tools with low vibration levels reduce operator discomfort and allow for more precise control.

- Compatibility with Workpiece Size and Shape: Consider the size and shape of the workpieces you plan to deburr and ensure that the tool can effectively reach and maneuver around the desired areas. Some handheld deburring tools are designed specifically for certain workpiece sizes or shapes.

- Price and Brand: Compare different brands and models of handheld electric deburring tools based on their features, durability, and price. Opt for reputable brands known for manufacturing reliable and efficient tools.

Always follow proper safety guidelines, wear appropriate personal protective equipment (PPE), and refer to the manufacturer’s instructions when operating handheld electric deburring tools. Regular maintenance and cleaning of the tool will ensure optimal performance and longevity.

Bench-mounted Deburring Machines

Bench-mounted deburring machines are stationary machines designed to remove burrs, sharp edges, and other imperfections from metal workpieces. These machines are typically mounted on a workbench or stand, providing stability and precision during the deburring process. Here are some key features and considerations for bench-mounted deburring machines:

- Construction and Stability: Bench-mounted deburring machines are constructed with a sturdy frame and a stable base to ensure vibration-free operation. Look for machines made from durable materials, such as cast iron or steel, that can withstand the demands of deburring tasks.

- Motor Power and Speed: Consider the power rating of the motor, usually expressed in watts or horsepower, to ensure sufficient power for the intended deburring applications. The speed of the machine is typically measured in rotations per minute (RPM), and higher RPMs allow for faster material removal. Variable speed options are also available on some models, providing greater control over the deburring process.

- Deburring Attachments: Bench-mounted deburring machines support a variety of attachments to suit different deburring needs. These can include cutting bits, abrasive wheels, wire brushes, or specialized deburring brushes. Ensure that the machine you choose is compatible with the specific attachments required for your deburring applications.

- Workpiece Support: Bench-mounted deburring machines often feature workpiece support elements, such as adjustable tables or fences, to position and secure the workpiece during the deburring process. Look for machines with sturdy and adjustable support mechanisms that allow for precise positioning and hold the workpiece securely in place.

- Safety Features: Ensure that the machine has appropriate safety features, such as guards, safety switches, or emergency stop buttons, to protect the operator during use. These safety features help prevent accidents and ensure operator safety.

- Dust Collection and Chip Management: Some bench-mounted deburring machines have provisions for dust collection or chip management systems. These systems help remove debris and dust generated during the deburring process, improving visibility and maintaining a clean work area.

- Size and Capacity: Consider the size and capacity of the machine in relation to the workpieces you plan to deburr. Ensure that the machine can accommodate the size and quantity of the workpieces effectively.

- Ease of Use and Adjustability: Look for bench-mounted deburring machines that are user-friendly and easy to adjust. Machines with intuitive controls and ergonomic design features make the deburring process more efficient and comfortable.

- Durability and Build Quality: Consider machines made from high-quality materials and components for long-lasting performance. Look for reputable brands known for manufacturing durable and reliable deburring machines.

- Price and Brand: Compare different brands and models of bench-mounted deburring machines based on their features, durability, and price. Opt for reputable brands that offer good customer support and after-sales service.

Always follow proper safety guidelines, wear appropriate personal protective equipment (PPE), and refer to the manufacturer’s instructions when operating bench-mounted deburring machines. Regular maintenance and cleaning of the machine will ensure optimal performance and longevity.

Pneumatic Deburring Tools

Pneumatic deburring tools are handheld power tools that use compressed air as their power source to remove burrs, sharp edges, and other imperfections from metal workpieces. These tools are known for their high power-to-weight ratio and are commonly used in industrial applications. Here are some key features and considerations for pneumatic deburring tools:

- Power Source: Pneumatic deburring tools require a compressed air source to operate. They are connected to an air compressor through an air hose and utilize the compressed air to drive the tool’s internal mechanisms.

- Air Pressure and Flow: Pneumatic deburring tools operate at specific air pressure and flow rates. It’s important to ensure that the air compressor can provide the necessary pressure and flow required by the tool. Consult the manufacturer’s guidelines for the recommended air pressure and flow specifications.

- Motor Power and Speed: Pneumatic deburring tools have a pneumatic motor that is powered by the compressed air. The power and speed of the tool are determined by the air pressure and flow rate. Higher air pressure and flow result in increased power and speed, allowing for efficient material removal.

- Deburring Attachments: Pneumatic deburring tools support various types of deburring attachments, such as cutting bits, abrasive wheels, or wire brushes. These attachments are driven by the tool’s motor and provide the cutting or grinding action necessary for deburring. Ensure that the tool is compatible with the specific attachments required for your deburring applications.

- Ergonomics and Grip: Consider the ergonomics and grip comfort of the pneumatic deburring tool. Look for tools with ergonomic handles and rubberized grips that provide a comfortable and secure hold during extended use. This ensures operator comfort and control.

- Safety Features: Pneumatic deburring tools should have appropriate safety features, such as guards, safety switches, or trigger locks, to protect the operator during use. These features help prevent accidents and ensure operator safety.

- Noise and Vibration Levels: Pneumatic tools can generate noise and vibration during operation. Consider the noise and vibration levels of the tool and use appropriate hearing protection and anti-vibration gloves when operating.

- Durability and Build Quality: Look for pneumatic deburring tools made from durable materials that can withstand the demands of industrial applications. Consider tools with sturdy construction and high-quality components for long-lasting performance.

- Maintenance and Lubrication: Pneumatic tools require regular maintenance, including proper lubrication, to ensure optimal performance and longevity. Follow the manufacturer’s guidelines for maintenance procedures and use compatible lubricants for the tool’s internal components.

- Price and Brand: Compare different brands and models of pneumatic deburring tools based on their features, durability, and price. Opt for reputable brands known for manufacturing reliable and efficient pneumatic tools.

Always follow proper safety guidelines, wear appropriate personal protective equipment (PPE), and refer to the manufacturer’s instructions when operating pneumatic deburring tools. Regular maintenance and cleaning of the tool will ensure optimal performance and longevity.

Rotary Deburring Tools

Rotary deburring tools are versatile handheld power tools designed to remove burrs, sharp edges, and other imperfections from metal workpieces. These tools use a rotary motion to perform the deburring operation, and they are available in various configurations and types. Here are some key features and considerations for rotary deburring tools:

- Rotary Motion: Rotary deburring tools utilize a rotating motion to remove burrs and smooth edges. The rotary motion can be achieved through an electric motor or by attaching the tool to a rotary power source, such as a drill or rotary tool.

- Deburring Attachments: Rotary deburring tools support a range of deburring attachments, including cutting bits, abrasive wheels, wire brushes, or specialized deburring brushes. These attachments are mounted on the rotary tool and provide the cutting or grinding action necessary for deburring. Ensure that the tool is compatible with the specific attachments required for your deburring applications.

- Power Source: Rotary deburring tools can be powered by electricity, battery, or by attaching them to a rotary power source, such as a drill or rotary tool. Consider the power source that best suits your needs in terms of mobility, convenience, and available power options.

- Motor Power and Speed: If the rotary deburring tool has its own motor, consider the power rating (watts or horsepower) and speed (rotations per minute, or RPM) of the motor. Higher motor power and speed allow for more efficient material removal and faster deburring.

- Ergonomics and Grip: Look for rotary deburring tools with ergonomic designs and comfortable grips. These features ensure operator comfort and control during extended use.

- Safety Features: Rotary deburring tools should have appropriate safety features, such as guards, safety switches, or vibration dampening, to protect the operator during use. These features help prevent accidents and ensure operator safety.

- Versatility: Rotary deburring tools are typically designed to handle various metal surfaces, including flat, curved, or irregular shapes. Consider the versatility of the tool and its ability to access different areas of the workpiece.

- Noise and Vibration Levels: Some rotary deburring tools can generate noise and vibration during operation. Consider the noise and vibration levels of the tool and use appropriate hearing protection and anti-vibration gloves when operating.

- Durability and Build Quality: Look for rotary deburring tools made from durable materials that can withstand the demands of deburring tasks. Consider tools with sturdy construction and high-quality components for long-lasting performance.

- Price and Brand: Compare different brands and models of rotary deburring tools based on their features, durability, and price. Opt for reputable brands known for manufacturing reliable and efficient rotary deburring tools.

Always follow proper safety guidelines, wear appropriate personal protective equipment (PPE), and refer to the manufacturer’s instructions when operating rotary deburring tools. Regular maintenance and cleaning of the tool will ensure optimal performance and longevity.

Die Grinder

A die grinder is a handheld power tool that is used for a variety of grinding, polishing, and deburring tasks. It is commonly used in metalworking, woodworking, and other industries where precise material removal is required. Here are some key features and considerations for die grinders:

- Power Source: Die grinders are typically powered by electricity or compressed air. Electric die grinders are corded or cordless, depending on the model, while pneumatic die grinders require a compressed air source and an air hose.

- Motor Power and Speed: Consider the power rating (expressed in watts or horsepower) and the speed (measured in rotations per minute, or RPM) of the motor. Higher power and speed allow for faster material removal and more efficient grinding.

- Collet Size: Die grinders have a collet or chuck mechanism that holds the grinding or cutting attachments. The collet size determines the maximum diameter of the attachment that can be used with the grinder. Common collet sizes include 1/4 inch and 1/8 inch.

- Variable Speed: Some die grinders offer variable speed control, allowing you to adjust the RPM according to the specific application or material being worked on. Variable speed control provides greater versatility and control.

- Ergonomics and Grip: Look for die grinders with ergonomic designs and comfortable grips. These features ensure operator comfort and control during extended use.

- Grinding Attachments: Die grinders support various grinding attachments, such as grinding wheels, burrs, sanding discs, and polishing pads. Ensure that the grinder is compatible with the specific attachments required for your grinding or deburring applications.

- Safety Features: Die grinders should have appropriate safety features, such as guards, safety switches, or vibration dampening, to protect the operator during use. These features help prevent accidents and ensure operator safety.

- Noise and Vibration Levels: Die grinders can generate noise and vibration during operation. Consider the noise and vibration levels of the tool and use appropriate hearing protection and anti-vibration gloves when operating.

- Durability and Build Quality: Look for die grinders made from durable materials that can withstand the demands of grinding tasks. Consider tools with sturdy construction and high-quality components for long-lasting performance.

- Price and Brand: Compare different brands and models of die grinders based on their features, durability, and price. Opt for reputable brands known for manufacturing reliable and efficient die grinders.

Always follow proper safety guidelines, wear appropriate personal protective equipment (PPE), and refer to the manufacturer’s instructions when operating a die grinder. Regular maintenance and cleaning of the tool will ensure optimal performance and longevity.

Deburring Tool for Metal

https://www.youtube.com/embed/mMRmnQuYgjE?feature=oembedDeburring Tool for Metal

Deburring tools are essential for removing burrs, sharp edges, and imperfections from metal components. These tools are crucial for maintaining the safety, functionality, and aesthetics of metal products across various industries.

Types of Deburring Tools for Metal:

- Hand-Held Deburring Tools: These tools provide portability and convenient deburring for smaller metal parts or in situations where access is limited. Common hand-held deburring tools include:

- Files: Files with varying coarseness levels are effective for removing burrs and smoothing out rough edges on metal.

- Deburring Knives: Knives with rounded blades are specifically designed to trim and remove burrs from metal edges.

- Deburring Wheels: Deburring wheels with abrasive grit are effective for deburring metal edges.

- Power Deburring Tools: These tools offer greater efficiency and power for deburring larger metal components or in high-volume production. Examples include:

- Rotary Deburring Tools: Utilize rotating abrasive discs or belts to quickly remove burrs from metal parts.

- Sanders: Sanders with appropriate abrasive belts can be used for deburring and surface finishing of metal components.

- Stationary Deburring Machines: For high-precision deburring or deburring complex shapes, specialized stationary machines offer consistent and precise results. These machines may utilize rotating cutters, abrasive belts, or a combination of both.

- Ultrasonic Deburring Systems: For precision deburring of delicate metal parts or complex geometries, ultrasonic deburring offers a gentle and effective method.

Choosing the Right Deburring Tool for Metal

The choice of deburring tool for metal depends on several factors, including:

- Size and shape of the metal part: The tool should be able to accommodate the size and shape of the part comfortably.

- Material of the metal part: The abrasive material used in the tool should be compatible with the material of the part.

- Desired level of precision: The tool should be able to achieve the desired level of precision for the application.

- Production volume: If high-volume production is required, a stationary machine may be more efficient.

- Safety features: The tool should incorporate adequate safety features to protect the operator from potential hazards.

Benefits of Using Deburring Tools for Metal:

- Improved safety: Deburring tools can reduce the risk of injuries to operators by removing sharp edges and burrs.

- Improved functionality: Rounded edges can prevent snagging and protect other components from damage.

- Enhanced aesthetics: A smooth, burr-free surface improves the overall appearance of metal products.

- Increased efficiency: Power deburring tools and stationary machines can significantly reduce deburring time.

Applications of Deburring Tools for Metal:

- Automotive industry: Deburring car bodies, engine components, and other automotive parts.

- Aerospace manufacturing: Deburring precision metal components for aircraft and spacecraft.

- Construction: Deburring metal components for buildings, bridges, and other structures.

- Electronics manufacturing: Deburring metal components for circuit boards, electronic devices, and other electronics.

- Consumer goods manufacturing: Deburring metal components for appliances, furniture, and other consumer products.

Deburring tools play an essential role in maintaining the quality and safety of metal components across various industries. By effectively removing burrs and imperfections, deburring enhances the functionality, aesthetics, and overall value of metal products.

Metal deburring, grinding, and rounding are common applications in metalworking processes aimed at smoothing rough edges, removing burrs, and achieving a uniform finish on metal parts. Here’s a brief overview of each:

- Deburring: This process involves removing sharp edges or burrs left on metal parts after machining, cutting, or forming operations. It improves safety, functionality, and aesthetics of the parts.

- Grinding: Grinding is used to achieve precise dimensional control and surface finish. It involves using abrasive wheels or belts to remove material from a workpiece, often to prepare surfaces for further finishing or to achieve specific tolerances.

- Rounding: Rounding, also known as edge rounding, is done to soften sharp edges or corners on metal parts. It improves part handling, reduces the risk of injury, and can be aesthetically pleasing.

These processes are essential in various industries such as automotive, aerospace, manufacturing, and precision engineering, where metal parts must meet high standards of quality, safety, and performance.

- Deburring:

- Purpose: Deburring removes burrs, which are unwanted rough edges or protrusions on metal parts that result from machining, cutting, or forming processes.

- Methods: Deburring can be achieved through various methods such as manual deburring tools, abrasive stones, brushes, tumbling machines (vibratory or centrifugal), or chemical deburring solutions.

- Importance: Removing burrs improves the functional and aesthetic quality of metal parts. It also enhances safety by eliminating sharp edges that could cause injuries during handling or assembly.

- Grinding:

- Purpose: Grinding is used to achieve precise dimensional control, improve surface finish, and remove excess material from metal parts.

- Types: There are several types of grinding processes, including surface grinding, cylindrical grinding, centerless grinding, and internal grinding, each suited for specific part geometries and surface requirements.

- Equipment: Grinding machines use abrasive wheels (grinding wheels or belts) that rotate at high speeds to grind away material from the workpiece.

- Applications: Grinding is crucial for preparing surfaces for further finishing operations (such as polishing or plating), achieving tight tolerances, or removing defects like surface imperfections or weld seams.

- Rounding (Edge Rounding):

- Purpose: Rounding, or edge rounding, involves smoothing sharp edges or corners on metal parts.

- Methods: This can be done through mechanical methods like deburring tools with radius edges, vibratory or centrifugal tumbling processes with rounded media, or automated edge rounding machines.

- Benefits: Rounding improves part handling safety by reducing the risk of cuts or scratches. It also enhances the part’s appearance and can be critical for components that interact with other parts or personnel during assembly or use.

These processes are fundamental in metalworking industries where precision, quality, and safety are paramount. They ensure that metal parts meet exacting standards for functionality, durability, and aesthetics demanded by various applications, from automotive and aerospace to electronics and consumer goods manufacturing.

Deburring

Deburring is a critical process in metalworking that involves the removal of burrs, which are unwanted rough edges or protrusions on metal parts. These burrs typically occur as a result of machining, cutting, or forming operations such as drilling, milling, stamping, or punching.

Importance of Deburring:

- Safety: Removing burrs eliminates sharp edges that can cause injuries during handling or assembly of parts.

- Functionality: Deburring ensures that parts fit together properly without interference from protrusions or rough edges.

- Aesthetics: Smooth edges improve the appearance of parts and enhance overall product quality.

- Performance: Burrs can affect the performance of moving parts or components that require precise tolerances.

Methods of Deburring:

- Manual Deburring Tools: Hand tools such as files, deburring knives, scrapers, or abrasive pads are used to manually remove burrs from small or intricate parts.

- Abrasive Stones and Brushes: Rotary tools equipped with abrasive stones or brushes can be used to remove burrs from larger or more accessible surfaces.

- Tumbling Machines: Vibratory or centrifugal tumbling machines use abrasive media (such as ceramic or plastic pellets) to deburr multiple parts simultaneously. This method is effective for small to medium-sized parts with complex geometries.

- Chemical Deburring: Chemical solutions or processes can be employed to selectively dissolve burrs, particularly in internal passages or complex shapes where mechanical methods may be challenging.

Deburring Considerations:

- Material Type: Different metals (e.g., aluminum, steel, titanium) require specific deburring techniques due to variations in hardness and machinability.

- Part Geometry: Deburring methods are chosen based on the size, shape, and accessibility of the burrs and the part itself.

- Quality Control: Inspecting parts after deburring ensures that all burrs are removed and that the part meets required specifications.

Deburring is essential in industries such as aerospace, automotive, electronics, and precision engineering, where high-quality, safe, and functional metal components are crucial.

Grinding

Grinding is a machining process used to remove material from a workpiece to achieve desired dimensions and surface finish. It is a versatile process widely used in various industries for both roughing and finishing operations on metal and other materials.

Purpose of Grinding

- Dimensional Control: Grinding allows for precise control over the dimensions of a workpiece, achieving tight tolerances that are difficult to achieve through other machining processes.

- Surface Finish: By using abrasive grains bonded into wheels or belts, grinding can produce smooth surfaces with low roughness values, enhancing the appearance and functionality of the parts.

- Material Removal: Grinding efficiently removes excess material, such as weld beads, casting flash, or stock material from forgings or billets, preparing the workpiece for subsequent operations.

Types of Grinding Processes:

- Surface Grinding: Involves grinding flat surfaces to achieve a smooth finish. It is commonly used for finishing hardened steel, cast iron, and similar materials.

- Cylindrical Grinding: Used to grind the outside diameter of cylindrical workpieces. It is ideal for creating precise roundness and surface finishes on shafts, rods, and other cylindrical components.

- Centerless Grinding: A type of cylindrical grinding where the workpiece is supported between two wheels: the grinding wheel and a regulating wheel. It is used for high-volume production of cylindrical parts with consistent dimensional accuracy.

- Internal Grinding: Grinding the inside diameter of a workpiece. It is used to create precise bores or holes with a smooth surface finish.

Equipment and Tools:

- Grinding Machines: Include surface grinders, cylindrical grinders, centerless grinders, and internal grinders, each designed for specific grinding applications.

- Grinding Wheels: Made from abrasive grains bonded together in various shapes and sizes. Types include aluminum oxide, silicon carbide, and diamond, each suited to different materials and applications.

Applications of Grinding:

- Manufacturing: Grinding is essential in the production of precision components for automotive, aerospace, medical devices, and consumer electronics.

- Tool and Die Making: Used for sharpening cutting tools and dies to maintain sharp edges and precise dimensions.

- Repair and Maintenance: Grinding is also employed for repairing worn or damaged parts by restoring their original dimensions and surface finish.

Grinding is a fundamental machining process that plays a crucial role in achieving the required dimensional accuracy, surface quality, and overall performance of metal parts in modern manufacturing.

Rounding

Rounding, also known as edge rounding or radiusing, is a finishing process used to smooth sharp edges and corners on metal parts. This process is essential for improving safety, enhancing aesthetics, and ensuring proper functionality of the parts, especially in applications where handling and contact with personnel or other components are involved.

Purpose and Benefits of Rounding:

- Safety: Rounded edges reduce the risk of injuries during handling, assembly, or use by eliminating sharp points or edges that could cause cuts or abrasions.

- Aesthetics: Smooth, rounded edges enhance the appearance of metal parts, making them more visually appealing and professional in finished products.

- Functionality: Rounding can improve the performance of parts by reducing stress concentrations at corners, which can extend the service life of components subjected to cyclic loading or wear.

Methods of Rounding:

- Manual Methods: Hand tools such as files, deburring tools with radiused edges, or abrasive pads can be used for small-scale rounding operations on accessible edges and corners.

- Machine Rounding: Automated edge rounding machines or dedicated deburring machines equipped with specialized tools can efficiently round edges and corners of larger or complex-shaped parts.

- Tumbling Processes: Vibratory or centrifugal tumbling machines using abrasive media (e.g., ceramic or plastic pellets) can uniformly round edges of multiple parts simultaneously. This method is effective for small to medium-sized parts with consistent edge profiles.

Considerations for Rounding:

- Part Geometry: The shape and size of the part influence the choice of rounding method. Complex geometries may require specialized equipment or multiple processes to achieve uniform rounding.

- Material Compatibility: Different metals (e.g., aluminum, stainless steel, titanium) and alloys have varying hardness and machinability characteristics, which may affect the choice of rounding tools and methods.

- Surface Finish Requirements: Rounding should maintain or improve the overall surface finish of the part, ensuring it meets functional and aesthetic specifications.

Applications of Rounding:

- Consumer Products: Rounding is crucial in industries such as furniture manufacturing, where rounded edges on metal components improve safety and user comfort.

- Automotive and Aerospace: Parts like brackets, panels, and housings benefit from rounded edges to prevent injuries during assembly and maintenance operations.

- Medical Devices: Ensuring smooth, rounded edges on surgical instruments and equipment enhances patient safety and ease of handling.

Rounding plays a vital role in enhancing the usability, safety, and appearance of metal parts across various industries, contributing to overall product quality and customer satisfaction.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching