We manufacture a Deburring Aluminium Sheet to deburr the sheet metal edges of Aluminium and Stainless Steel. These machines are used in metalworking industries

When deburring aluminum sheets, there are several methods you can use to remove burrs and smooth out the edges. Here are some common techniques:

- Hand Deburring Tools: You can use handheld deburring tools like files, deburring knives, or deburring blocks to manually remove burrs from the edges of the aluminum sheet. These tools allow for precise control and are suitable for smaller or intricate areas.

- Sandpaper or Emery Cloth: Use fine-grit sandpaper or emery cloth to gently sand away the burrs and smooth out the edges of the aluminum sheet. Start with a coarser grit and gradually move to finer grits for a smoother finish.

- Deburring Wheels or Brushes: Attach a deburring wheel or brush to a rotary tool or bench-mounted deburring machine to remove burrs from the aluminum sheet. These tools work well for larger surfaces and can be more efficient for larger quantities of aluminum sheets.

- Vibratory or Tumbling Deburring: If you have multiple aluminum sheets to deburr, you can consider using a vibratory or tumbling deburring machine. These machines use abrasive media and tumbling action to remove burrs and produce a smoother finish. This method is suitable for batch processing and can save time and effort.

- Chemical Deburring: Chemical deburring involves the use of special chemicals to dissolve the burrs from the aluminum sheet. This method is often used for complex or hard-to-reach areas. It is important to follow the manufacturer’s instructions and use appropriate safety measures when using chemical deburring solutions.

Remember to always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, when deburring aluminum sheets. Additionally, ensure proper ventilation when using chemical deburring methods.

It’s a good practice to test the deburring technique on a scrap or inconspicuous area of the aluminum sheet before working on the final piece to ensure the desired results.

Deburring Aluminium Sheet

Deburring aluminium sheet is an essential process in metalworking to remove sharp edges, burrs, and imperfections from the edges of aluminum sheets. These imperfections can arise from various metalworking processes, such as cutting, stamping, or forming. Deburring is crucial for several reasons:

Safety: Sharp edges and burrs on aluminum sheets pose a significant safety hazard, increasing the risk of cuts, lacerations, and other injuries. Removing these hazards enhances worker safety and reduces the risk of accidents.

Aesthetics: Rounded edges and a smooth surface improve the overall appearance of aluminum sheet components, making them more visually appealing and aesthetically pleasing. This is particularly important for products that will be visible in the final product, such as appliance panels or architectural components.

Functionality: Rounded edges can prevent snagging, tearing, or abrasion of materials that come into contact with the aluminum sheet. This is important for parts that need to move smoothly, such as conveyor belts, machinery components, or packaging materials.

Methods for Deburring Aluminium Sheet:

- Hand Deburring Tools:

For small aluminum sheets or in situations where access is limited, hand-held tools offer a convenient option. Common hand-held deburring tools include:

- Files: Files with varying coarseness levels can be used to remove burrs and smooth out rough edges.

- Deburring Knives: Knives with rounded blades are specifically designed to trim and remove burrs from aluminum sheets.

- Deburring Wheels: Deburring wheels with abrasive grit are effective for deburring aluminum sheets.

- Power Deburring Tools:

For larger aluminum sheets or high-volume production, power tools provide a more efficient and powerful solution. Examples include:

- Rotary Deburring Tools: These tools utilize rotating abrasive discs or belts to quickly remove burrs from aluminum sheets.

- Sanders: Sanders with appropriate abrasive belts can be used for deburring and surface finishing of aluminum sheets.

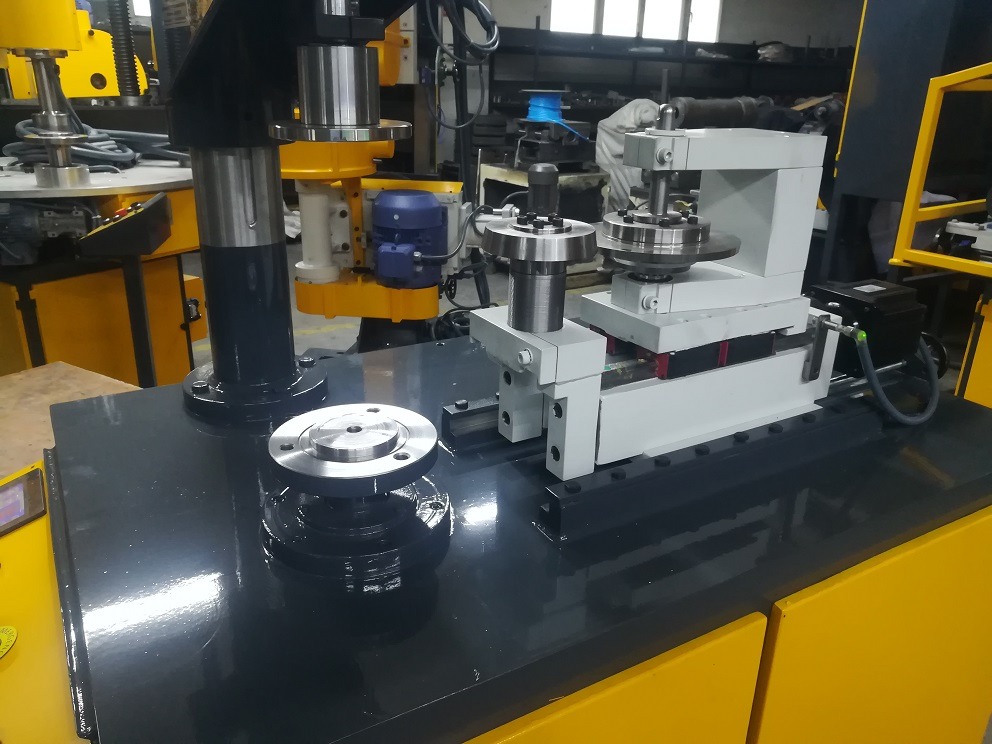

- Stationary Deburring Machines:

For high-precision deburring or deburring complex shapes, specialized stationary machines offer consistent and precise results. These machines may utilize rotating cutters, abrasive belts, or a combination of both.

Factors to Consider When Choosing a Deburring Method:

- Sheet Size and Thickness: The size and thickness of the aluminum sheet will determine the tool’s capacity and suitability.

- Desired Level of Precision: The required level of precision will dictate whether a hand-held tool, a power tool, or a specialized machine is more appropriate.

- Accessibility of Edges: The accessibility of the edges will influence whether a handheld or stationary tool is more suitable.

- Production Volume: For high-volume production, a power tool or a specialized machine may be necessary.

- Cost Considerations: The cost of different deburring methods and tools should be evaluated based on production volume and desired precision.

Conclusion:

Deburring aluminium sheet is an essential step in metalworking to ensure the safety, aesthetics, and functionality of aluminum components. The choice of deburring method depends on factors such as sheet size, precision requirements, accessibility, production volume, and cost considerations. By effectively removing burrs and imperfections, deburring enhances the quality and safety of aluminum products across various industries.

Hand Deburring Tools

Hand deburring tools are manual tools designed to remove burrs and sharp edges from various materials, including metal, plastic, and wood. They offer precise control and are commonly used for small-scale or intricate deburring tasks. Here are some commonly used hand deburring tools:

- Deburring Knife: A deburring knife is a small, handheld tool with a sharp blade specifically designed for removing burrs. It allows for precise cutting and scraping of burrs from the edges of the material.

- Deburring File: Deburring files have fine teeth or abrasive surfaces that can be used to file down burrs and smooth out rough edges. They come in various shapes and sizes, including flat, half-round, round, and needle files, to suit different deburring requirements.

- Deburring Tool with Blades: These handheld tools feature interchangeable blades designed to remove burrs from different materials and contours. The blades are inserted into the tool and can be rotated or replaced as needed.

- Deburring Block or Stone: Deburring blocks or stones are typically made of abrasive materials, such as silicon carbide or aluminum oxide. They are used by rubbing the block or stone against the edges of the material to remove burrs and create a smooth surface.

- Countersink Tool: While primarily used for creating countersunk holes, countersink tools can also be used for deburring. They have a conical-shaped cutting edge that can be run along the edges of the material to remove burrs and chamfer the surface.

- Handheld Sanding or Emery Cloth: Sanding or emery cloth can be wrapped around a finger or held in hand to manually sand down burrs and smooth out edges. Different grits of sandpaper or emery cloth can be used depending on the level of deburring required.

- Wire Brush: Wire brushes with bristles made of stainless steel or brass can be used to remove burrs and clean the surface of the material. They are particularly useful for removing burrs from harder metals.

When using hand deburring tools, ensure you have a secure grip, work in a well-lit area, and wear appropriate personal protective equipment (PPE) such as safety glasses and gloves. It’s recommended to start with a light touch and gradually increase pressure as needed to avoid damaging the material.

Sandpaper or Emery Cloth

Sandpaper and emery cloth are abrasive materials commonly used for deburring, sanding, and smoothing surfaces. They are available in various grits and can be used by hand or with a sanding block. Here’s how you can use sandpaper or emery cloth for deburring:

- Select the Right Grit: Sandpaper and emery cloth are available in different grit sizes, which determine the coarseness of the abrasive particles. For deburring, start with a coarser grit to remove the burrs and then gradually move to finer grits for a smoother finish. The specific grits to use depend on the material and the extent of the burrs.

- Secure the Material: Place the aluminum sheet or workpiece on a stable surface or secure it in a vise to prevent movement during the deburring process. This ensures stability and helps achieve even results.

- Wrap the Sandpaper or Emery Cloth: If using by hand, wrap the sandpaper or emery cloth around your fingers or a sanding block, ensuring it is taut but not overly tight. If using a sanding block, secure the abrasive material to the block using clips or adhesive.

- Apply Light Pressure: Hold the sandpaper or emery cloth firmly but apply light pressure while rubbing it along the burrs and edges of the aluminum sheet. Move in a back-and-forth or circular motion, following the contours of the material. Avoid excessive pressure that can cause gouging or uneven sanding.

- Check Progress: Regularly check the progress by running your fingers over the surface to feel for any remaining burrs. Inspect the area under good lighting to ensure all burrs have been removed and the surface is smooth.

- Gradually Progress to Finer Grits: As the burrs are removed, switch to progressively finer grits of sandpaper or emery cloth to refine the surface. This helps achieve a smoother finish and removes any scratches or marks left by coarser grits.

- Clean the Surface: After deburring, clean the aluminum sheet to remove any debris or abrasive particles. Use a clean cloth or compressed air to ensure the surface is free from residue.

Remember to wear appropriate personal protective equipment (PPE), such as safety glasses and a dust mask, to protect yourself from particles generated during the deburring process. Additionally, work in a well-ventilated area or consider using a dust collection system to minimize airborne dust.

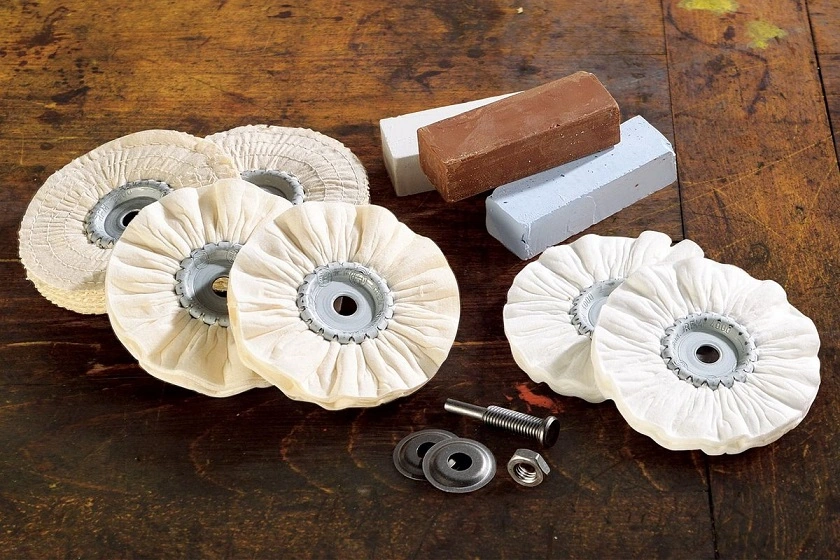

Deburring Wheels or Brushes

Deburring wheels and brushes are rotary tools designed to remove burrs, sharp edges, and other imperfections from various materials. They are commonly used in metalworking, woodworking, and fabrication industries. Here’s an overview of deburring wheels and brushes:

Deburring Wheels: Deburring wheels are typically made of abrasive materials such as bonded abrasive particles, non-woven nylon fibers, or wire bristles. They are attached to rotary tools such as bench grinders, angle grinders, or handheld rotary tools. Deburring wheels come in different shapes, sizes, and abrasive densities to suit various applications.

- Abrasive Wheels: These wheels are made of abrasive materials like aluminum oxide, silicon carbide, or diamond particles. They are effective for removing burrs, grinding, and smoothing edges. The coarseness of the abrasive determines the aggressiveness of the wheel.

- Non-Woven Wheels: Non-woven wheels are made of nylon fibers impregnated with abrasive particles. They are less aggressive than abrasive wheels and provide a more controlled deburring action. Non-woven wheels are suitable for finer deburring and blending operations.

- Wire Wheels: Wire wheels consist of wire bristles in various configurations such as crimped or twisted. They are used for aggressive deburring, cleaning, and rust removal. Wire wheels are available in different wire thicknesses and densities to suit the application.

Deburring Brushes: Deburring brushes are handheld or machine-mounted brushes with bristles made of various materials such as steel wire, stainless steel, or nylon. They are used for targeted deburring and surface conditioning. Deburring brushes come in different shapes, including cup brushes, wheel brushes, and end brushes.

- Wire Brushes: Wire brushes with steel or stainless steel bristles are effective for heavy-duty deburring, rust removal, and cleaning applications. They can be used on different materials, including metal, wood, or plastic.

- Nylon Brushes: Nylon brushes are gentler than wire brushes and are suitable for lighter deburring, cleaning, and surface conditioning tasks. They can be used on delicate materials like aluminum or plastic without causing damage.

When using deburring wheels or brushes, consider the following tips:

- Ensure the wheel or brush is securely mounted on the rotary tool or machine.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and protective clothing.

- Keep a steady hand and maintain control over the tool to avoid unintended damage or injury.

- Use the appropriate wheel or brush for the material and type of deburring required.

- Follow the manufacturer’s guidelines for operating speed, pressure, and technique.

- Regularly inspect and replace worn-out wheels or brushes to maintain optimal performance.

Note: It is important to consider the specific requirements of your deburring application and select the appropriate type of deburring wheel or brush accordingly.

Vibratory or Tumbling Deburring

Vibratory or tumbling deburring is a mass finishing process used to remove burrs, sharp edges, and surface imperfections from small to medium-sized parts in bulk. It involves placing the parts along with abrasive media and a deburring compound into a vibratory or tumbling machine. Here’s an overview of vibratory and tumbling deburring:

Vibratory Deburring:

- Process: Vibratory deburring involves placing the parts and abrasive media in a vibratory bowl or tub. The vibratory machine generates vibrations that cause the media and parts to rub against each other, effectively removing burrs and imparting a smooth finish.

- Media: Various types of abrasive media can be used in vibratory deburring, such as ceramic media, plastic media, or stainless steel media. The media selection depends on the material and desired level of deburring.

- Deburring Compound: A deburring compound, also known as a burnishing compound or soap, is often added to the vibratory machine. It enhances the deburring action by providing lubrication and aiding in the removal of burrs.

- Process Control: The duration of the vibratory deburring process can vary depending on the type and quantity of parts, the level of deburring required, and the condition of the media. The process can be monitored and controlled to achieve consistent results.

Tumbling Deburring:

- Process: Tumbling deburring involves placing the parts, abrasive media, and deburring compound into a rotating drum or barrel. The barrel tumbles the contents, causing the parts and media to interact and remove burrs and surface imperfections.

- Media: Similar to vibratory deburring, various types of abrasive media are used in tumbling deburring, including ceramic, plastic, or stainless steel media. The media choice depends on the material and desired deburring outcome.

- Deburring Compound: A deburring compound is often added to the tumbling process to enhance the deburring action and improve the overall surface finish.

- Process Control: Tumbling deburring time can be adjusted based on the part size, complexity, and deburring requirements. The speed of the barrel rotation and the amount of media and compound used can also be controlled to achieve desired results.

Advantages of Vibratory and Tumbling Deburring:

- Suitable for batch processing and deburring multiple parts simultaneously.

- Provides consistent and uniform deburring results.

- Can handle a variety of part shapes, sizes, and materials.

- Helps remove burrs in hard-to-reach areas.

- Can impart a smoother and polished finish on the parts.

Considerations:

- The selection of the appropriate abrasive media, deburring compound, and process parameters depends on the specific part requirements and desired finish.

- It is important to follow safety guidelines and wear appropriate PPE when working with vibratory or tumbling deburring machines.

- Regularly check the condition of the media, compound, and machine parts to maintain optimal performance and avoid contamination.

It’s recommended to consult with deburring equipment manufacturers or experts to determine the most suitable vibratory or tumbling deburring process for your specific parts and requirements.

Chemical Deburring

Chemical deburring is a process used to remove burrs and sharp edges from metal parts using chemical solutions. It is particularly useful for complex or hard-to-reach areas where traditional mechanical deburring methods may be challenging or ineffective. Here’s an overview of the chemical deburring process:

- Process Preparation: The metal parts to be deburred are thoroughly cleaned and prepared for the chemical deburring process. This involves removing any oils, grease, or contaminants from the parts to ensure optimal chemical interaction.

- Chemical Deburring Solution: A specially formulated chemical deburring solution is used for the process. The solution typically contains a combination of acids or alkaline compounds that selectively dissolve the burrs without significantly affecting the base metal.

- Immersion or Spray Method: The parts are either immersed in the chemical deburring solution or subjected to a spray application, depending on the size, complexity, and nature of the parts. Immersion involves placing the parts in a tank filled with the solution, while spray application involves applying the solution onto the parts using spray nozzles.

- Reaction Time: The parts are left in contact with the chemical deburring solution for a specific duration, allowing the solution to dissolve the burrs. The reaction time depends on factors such as the type and thickness of the burrs, the material of the parts, and the concentration of the deburring solution.

- Rinse and Neutralization: After the deburring process, the parts are thoroughly rinsed to remove any residual deburring solution. This is typically done using water or a neutralizing solution to ensure the complete removal of the deburring chemicals.

- Drying and Post-Treatment: Once rinsed, the parts are dried using appropriate methods such as air drying, hot air drying, or other drying techniques. Depending on the specific requirements, additional post-treatment steps may be carried out, such as surface conditioning, passivation, or protective coating application.

Advantages of Chemical Deburring:

- Effective for deburring complex or intricate parts with hard-to-reach areas.

- Consistent and uniform removal of burrs, even in challenging geometries.

- Can be applied to a wide range of metal materials.

- Minimizes the risk of damage or distortion to the parts, compared to mechanical methods.

- Can be automated for high-volume production.

Considerations:

- Chemical deburring requires careful handling of the deburring solution and adherence to safety protocols, including the use of appropriate personal protective equipment (PPE).

- The selection of the deburring solution and process parameters should be based on the specific material and burr characteristics.

- Environmental considerations should be taken into account, including proper disposal or treatment of the used deburring solution.

It is recommended to consult with chemical deburring solution manufacturers or experts to ensure the appropriate selection and implementation of the chemical deburring process for your specific parts and requirements.

Deburring Tool for Metal

https://www.youtube.com/embed/mMRmnQuYgjE?feature=oembedDeburring Tool for Metal

Deburring tools are essential for removing burrs, sharp edges, and imperfections from metal components. These tools are crucial for maintaining the safety, functionality, and aesthetics of metal products across various industries.

Types of Deburring Tools for Metal:

- Hand-Held Deburring Tools: These tools provide portability and convenient deburring for smaller metal parts or in situations where access is limited. Common hand-held deburring tools include:

- Files: Files with varying coarseness levels are effective for removing burrs and smoothing out rough edges on metal.

- Deburring Knives: Knives with rounded blades are specifically designed to trim and remove burrs from metal edges.

- Deburring Wheels: Deburring wheels with abrasive grit are effective for deburring metal edges.

- Power Deburring Tools: These tools offer greater efficiency and power for deburring larger metal components or in high-volume production. Examples include:

- Rotary Deburring Tools: Utilize rotating abrasive discs or belts to quickly remove burrs from metal parts.

- Sanders: Sanders with appropriate abrasive belts can be used for deburring and surface finishing of metal components.

- Stationary Deburring Machines: For high-precision deburring or deburring complex shapes, specialized stationary machines offer consistent and precise results. These machines may utilize rotating cutters, abrasive belts, or a combination of both.

- Ultrasonic Deburring Systems: For precision deburring of delicate metal parts or complex geometries, ultrasonic deburring offers a gentle and effective method.

Choosing the Right Deburring Tool for Metal

The choice of deburring tool for metal depends on several factors, including:

- Size and shape of the metal part: The tool should be able to accommodate the size and shape of the part comfortably.

- Material of the metal part: The abrasive material used in the tool should be compatible with the material of the part.

- Desired level of precision: The tool should be able to achieve the desired level of precision for the application.

- Production volume: If high-volume production is required, a stationary machine may be more efficient.

- Safety features: The tool should incorporate adequate safety features to protect the operator from potential hazards.

Benefits of Using Deburring Tools for Metal:

- Improved safety: Deburring tools can reduce the risk of injuries to operators by removing sharp edges and burrs.

- Improved functionality: Rounded edges can prevent snagging and protect other components from damage.

- Enhanced aesthetics: A smooth, burr-free surface improves the overall appearance of metal products.

- Increased efficiency: Power deburring tools and stationary machines can significantly reduce deburring time.

Applications of Deburring Tools for Metal:

- Automotive industry: Deburring car bodies, engine components, and other automotive parts.

- Aerospace manufacturing: Deburring precision metal components for aircraft and spacecraft.

- Construction: Deburring metal components for buildings, bridges, and other structures.

- Electronics manufacturing: Deburring metal components for circuit boards, electronic devices, and other electronics.

- Consumer goods manufacturing: Deburring metal components for appliances, furniture, and other consumer products.

Deburring tools play an essential role in maintaining the quality and safety of metal components across various industries. By effectively removing burrs and imperfections, deburring enhances the functionality, aesthetics, and overall value of metal products.

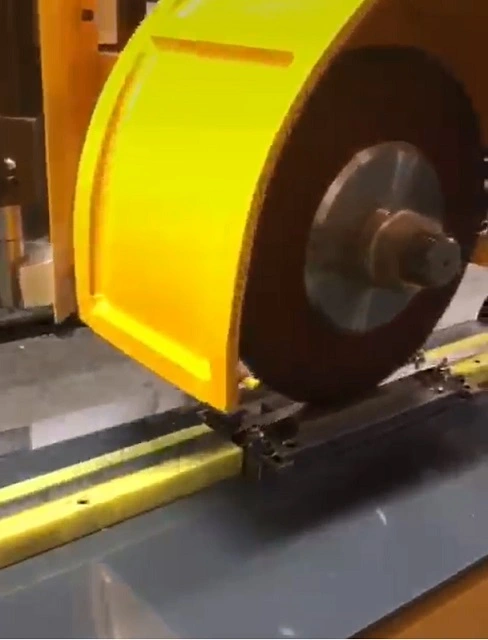

Metal deburring, grinding, and rounding are common applications in metalworking processes aimed at smoothing rough edges, removing burrs, and achieving a uniform finish on metal parts. Here’s a brief overview of each:

- Deburring: This process involves removing sharp edges or burrs left on metal parts after machining, cutting, or forming operations. It improves safety, functionality, and aesthetics of the parts.

- Grinding: Grinding is used to achieve precise dimensional control and surface finish. It involves using abrasive wheels or belts to remove material from a workpiece, often to prepare surfaces for further finishing or to achieve specific tolerances.

- Rounding: Rounding, also known as edge rounding, is done to soften sharp edges or corners on metal parts. It improves part handling, reduces the risk of injury, and can be aesthetically pleasing.

These processes are essential in various industries such as automotive, aerospace, manufacturing, and precision engineering, where metal parts must meet high standards of quality, safety, and performance.

- Deburring:

- Purpose: Deburring removes burrs, which are unwanted rough edges or protrusions on metal parts that result from machining, cutting, or forming processes.

- Methods: Deburring can be achieved through various methods such as manual deburring tools, abrasive stones, brushes, tumbling machines (vibratory or centrifugal), or chemical deburring solutions.

- Importance: Removing burrs improves the functional and aesthetic quality of metal parts. It also enhances safety by eliminating sharp edges that could cause injuries during handling or assembly.

- Grinding:

- Purpose: Grinding is used to achieve precise dimensional control, improve surface finish, and remove excess material from metal parts.

- Types: There are several types of grinding processes, including surface grinding, cylindrical grinding, centerless grinding, and internal grinding, each suited for specific part geometries and surface requirements.

- Equipment: Grinding machines use abrasive wheels (grinding wheels or belts) that rotate at high speeds to grind away material from the workpiece.

- Applications: Grinding is crucial for preparing surfaces for further finishing operations (such as polishing or plating), achieving tight tolerances, or removing defects like surface imperfections or weld seams.

- Rounding (Edge Rounding):

- Purpose: Rounding, or edge rounding, involves smoothing sharp edges or corners on metal parts.

- Methods: This can be done through mechanical methods like deburring tools with radius edges, vibratory or centrifugal tumbling processes with rounded media, or automated edge rounding machines.

- Benefits: Rounding improves part handling safety by reducing the risk of cuts or scratches. It also enhances the part’s appearance and can be critical for components that interact with other parts or personnel during assembly or use.

These processes are fundamental in metalworking industries where precision, quality, and safety are paramount. They ensure that metal parts meet exacting standards for functionality, durability, and aesthetics demanded by various applications, from automotive and aerospace to electronics and consumer goods manufacturing.

Deburring

Deburring is a critical process in metalworking that involves the removal of burrs, which are unwanted rough edges or protrusions on metal parts. These burrs typically occur as a result of machining, cutting, or forming operations such as drilling, milling, stamping, or punching.

Importance of Deburring:

- Safety: Removing burrs eliminates sharp edges that can cause injuries during handling or assembly of parts.

- Functionality: Deburring ensures that parts fit together properly without interference from protrusions or rough edges.

- Aesthetics: Smooth edges improve the appearance of parts and enhance overall product quality.

- Performance: Burrs can affect the performance of moving parts or components that require precise tolerances.

Methods of Deburring:

- Manual Deburring Tools: Hand tools such as files, deburring knives, scrapers, or abrasive pads are used to manually remove burrs from small or intricate parts.

- Abrasive Stones and Brushes: Rotary tools equipped with abrasive stones or brushes can be used to remove burrs from larger or more accessible surfaces.

- Tumbling Machines: Vibratory or centrifugal tumbling machines use abrasive media (such as ceramic or plastic pellets) to deburr multiple parts simultaneously. This method is effective for small to medium-sized parts with complex geometries.

- Chemical Deburring: Chemical solutions or processes can be employed to selectively dissolve burrs, particularly in internal passages or complex shapes where mechanical methods may be challenging.

Deburring Considerations:

- Material Type: Different metals (e.g., aluminum, steel, titanium) require specific deburring techniques due to variations in hardness and machinability.

- Part Geometry: Deburring methods are chosen based on the size, shape, and accessibility of the burrs and the part itself.

- Quality Control: Inspecting parts after deburring ensures that all burrs are removed and that the part meets required specifications.

Deburring is essential in industries such as aerospace, automotive, electronics, and precision engineering, where high-quality, safe, and functional metal components are crucial.

Grinding

Grinding is a machining process used to remove material from a workpiece to achieve desired dimensions and surface finish. It is a versatile process widely used in various industries for both roughing and finishing operations on metal and other materials.

Purpose of Grinding

- Dimensional Control: Grinding allows for precise control over the dimensions of a workpiece, achieving tight tolerances that are difficult to achieve through other machining processes.

- Surface Finish: By using abrasive grains bonded into wheels or belts, grinding can produce smooth surfaces with low roughness values, enhancing the appearance and functionality of the parts.

- Material Removal: Grinding efficiently removes excess material, such as weld beads, casting flash, or stock material from forgings or billets, preparing the workpiece for subsequent operations.

Types of Grinding Processes:

- Surface Grinding: Involves grinding flat surfaces to achieve a smooth finish. It is commonly used for finishing hardened steel, cast iron, and similar materials.

- Cylindrical Grinding: Used to grind the outside diameter of cylindrical workpieces. It is ideal for creating precise roundness and surface finishes on shafts, rods, and other cylindrical components.

- Centerless Grinding: A type of cylindrical grinding where the workpiece is supported between two wheels: the grinding wheel and a regulating wheel. It is used for high-volume production of cylindrical parts with consistent dimensional accuracy.

- Internal Grinding: Grinding the inside diameter of a workpiece. It is used to create precise bores or holes with a smooth surface finish.

Equipment and Tools:

- Grinding Machines: Include surface grinders, cylindrical grinders, centerless grinders, and internal grinders, each designed for specific grinding applications.

- Grinding Wheels: Made from abrasive grains bonded together in various shapes and sizes. Types include aluminum oxide, silicon carbide, and diamond, each suited to different materials and applications.

Applications of Grinding:

- Manufacturing: Grinding is essential in the production of precision components for automotive, aerospace, medical devices, and consumer electronics.

- Tool and Die Making: Used for sharpening cutting tools and dies to maintain sharp edges and precise dimensions.

- Repair and Maintenance: Grinding is also employed for repairing worn or damaged parts by restoring their original dimensions and surface finish.

Grinding is a fundamental machining process that plays a crucial role in achieving the required dimensional accuracy, surface quality, and overall performance of metal parts in modern manufacturing.

Rounding

Rounding, also known as edge rounding or radiusing, is a finishing process used to smooth sharp edges and corners on metal parts. This process is essential for improving safety, enhancing aesthetics, and ensuring proper functionality of the parts, especially in applications where handling and contact with personnel or other components are involved.

Purpose and Benefits of Rounding:

- Safety: Rounded edges reduce the risk of injuries during handling, assembly, or use by eliminating sharp points or edges that could cause cuts or abrasions.

- Aesthetics: Smooth, rounded edges enhance the appearance of metal parts, making them more visually appealing and professional in finished products.

- Functionality: Rounding can improve the performance of parts by reducing stress concentrations at corners, which can extend the service life of components subjected to cyclic loading or wear.

Methods of Rounding:

- Manual Methods: Hand tools such as files, deburring tools with radiused edges, or abrasive pads can be used for small-scale rounding operations on accessible edges and corners.

- Machine Rounding: Automated edge rounding machines or dedicated deburring machines equipped with specialized tools can efficiently round edges and corners of larger or complex-shaped parts.

- Tumbling Processes: Vibratory or centrifugal tumbling machines using abrasive media (e.g., ceramic or plastic pellets) can uniformly round edges of multiple parts simultaneously. This method is effective for small to medium-sized parts with consistent edge profiles.

Considerations for Rounding:

- Part Geometry: The shape and size of the part influence the choice of rounding method. Complex geometries may require specialized equipment or multiple processes to achieve uniform rounding.

- Material Compatibility: Different metals (e.g., aluminum, stainless steel, titanium) and alloys have varying hardness and machinability characteristics, which may affect the choice of rounding tools and methods.

- Surface Finish Requirements: Rounding should maintain or improve the overall surface finish of the part, ensuring it meets functional and aesthetic specifications.

Applications of Rounding:

- Consumer Products: Rounding is crucial in industries such as furniture manufacturing, where rounded edges on metal components improve safety and user comfort.

- Automotive and Aerospace: Parts like brackets, panels, and housings benefit from rounded edges to prevent injuries during assembly and maintenance operations.

- Medical Devices: Ensuring smooth, rounded edges on surgical instruments and equipment enhances patient safety and ease of handling.

Rounding plays a vital role in enhancing the usability, safety, and appearance of metal parts across various industries, contributing to overall product quality and customer satisfaction.

Surface finishing operations are essential processes applied to sheet metal parts to enhance their appearance, functionality, and durability. These operations involve the removal of imperfections, smoothing of surfaces, and application of protective coatings. The importance of surface finishing cannot be overstated, as it directly impacts the performance, longevity, and aesthetic appeal of the final product.

- Key Objectives of Surface Finishing:

- Improve aesthetic appearance.

- Enhance corrosion resistance.

- Reduce friction and wear.

- Remove surface defects.

- Prepare surfaces for further processing.

Overview of Surface Finishing Techniques

Surface finishing techniques encompass a wide range of processes, each tailored to achieve specific results. The primary techniques include deburring, polishing, and buffing, each serving a unique purpose in the finishing workflow.

- Deburring: The process of removing burrs—tiny protrusions or unwanted materials—from the edges of sheet metal parts.

- Polishing: Involves smoothing and shining the surface to achieve a reflective finish.

- Buffing: A finishing process that further enhances the shine and smoothness of the surface.

Applications in Industry

Surface finishing operations are vital across various industries, including automotive, aerospace, electronics, and consumer goods. The demand for high-quality finishes in these sectors drives innovation and the development of advanced finishing techniques.

- Automotive: Enhancing the appearance and durability of car components.

- Aerospace: Ensuring precision and performance in aircraft parts.

- Electronics: Improving the aesthetic and functional quality of devices.

- Consumer Goods: Increasing the appeal and longevity of products.

Section 2: Deburring in Sheet Metal Parts

Definition and Types of Burrs

Deburring is the process of removing small, unwanted protrusions or burrs that form on the edges of sheet metal parts during manufacturing processes like cutting, drilling, and stamping. Burrs can negatively affect the performance, safety, and appearance of metal parts, making deburring a critical step in the production cycle.

- Types of Burrs:

- Poisson Burr: Caused by material deformation, often appears as a thin edge.

- Roll-Over Burr: Occurs when material is pushed over the edge of a part.

- Tear Burr: Created by tearing of material, resulting in irregular edges.

- Cut-Off Burr: Occurs at the end of the cutting process, often requiring specific removal techniques.

Methods of Burr Removal

The selection of a deburring method depends on factors such as the type of burr, material properties, and desired surface finish. Below are common deburring methods:

Manual Deburring

- Tools Used: Files, scrapers, abrasive pads, and brushes.

- Advantages:

- Cost-effective for small-scale production.

- Provides control over the finishing process.

- Disadvantages:

- Labor-intensive and time-consuming.

- Inconsistent results due to human error.

Mechanical Deburring

- Methods:

- Tumbling: Parts are placed in a tumbler with abrasive media that polishes the edges.

- Vibratory Finishing: Uses vibrations to agitate parts and media for deburring.

- Grinding: Utilizes rotating abrasive wheels to remove burrs.

- Advantages:

- Suitable for large-scale production.

- Consistent and repeatable results.

- Disadvantages:

- May require additional equipment and space.

- Potential for media contamination.

Thermal Deburring

- Process: Involves exposing parts to a controlled explosion of gas to burn away burrs.

- Advantages:

- Effective for hard-to-reach areas.

- Fast and efficient for complex parts.

- Disadvantages:

- High initial setup cost.

- Limited to specific materials.

Electrochemical Deburring

- Process: Involves the use of electrolytic solutions to dissolve burrs.

- Advantages:

- Precise and controlled removal.

- Minimal tool wear.

- Disadvantages:

- Requires careful handling of chemicals.

- High operational costs.

Tools and Equipment Used

- Manual Tools: Files, sandpaper, brushes.

- Mechanical Equipment: Tumblers, grinders, vibratory finishers.

- Advanced Equipment: Thermal deburring machines, electrochemical setups.

Challenges in Deburring

- Material Compatibility: Different materials require specific deburring techniques.

- Cost Considerations: Balancing cost and efficiency in high-volume production.

- Quality Control: Ensuring consistent results across batches.

Case Studies

Case Study 1: Automotive Component Deburring

- Objective: Improve the precision and safety of automotive parts.

- Method Used: Mechanical deburring with vibratory finishing.

- Outcome: Enhanced safety and performance of components, reduced production time.

Case Study 2: Aerospace Part Deburring

- Objective: Achieve high precision and reliability in aircraft parts.

- Method Used: Electrochemical deburring for intricate components.

- Outcome: Improved accuracy and reliability, meeting industry standards.

Section 3: Polishing of Sheet Metal Parts

Definition and Purpose

Polishing is a surface finishing process aimed at smoothing and shining metal parts to achieve a reflective finish. It enhances the appearance and functionality of metal parts by removing scratches, pits, and other imperfections.

- Purpose of Polishing:

- Improve aesthetic appeal.

- Increase corrosion resistance.

- Enhance surface smoothness and reflectivity.

- Prepare surfaces for further coating or finishing processes.

Polishing Techniques

Various polishing techniques are employed based on the desired finish and application requirements.

Mechanical Polishing

- Process: Involves the use of abrasive materials to remove surface irregularities.

- Techniques:

- Belt Polishing: Uses abrasive belts for continuous polishing.

- Disk Polishing: Utilizes rotating disks with abrasive pads.

- Buffing Wheels: Employs rotating cloth wheels with polishing compounds.

- Advantages:

- Cost-effective and versatile.

- Suitable for various metals and shapes.

- Disadvantages:

- Limited precision for complex geometries.

- Requires skilled operators for optimal results.

Electropolishing

- Process: Involves the use of an electrolytic bath to dissolve the surface layer of metal, resulting in a smooth and shiny finish.

- Advantages:

- Superior surface finish and reflectivity.

- Removes microscopic imperfections.

- Enhances corrosion resistance.

- Disadvantages:

- High setup and operational costs.

- Limited to specific metals and applications.

Tools and Equipment Used

- Abrasive Belts and Disks: Used for mechanical polishing.

- Buffing Wheels and Compounds: For fine finishing.

- Electropolishing Equipment: Includes electrolytic baths and power supplies.

Comparison of Different Polishing Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Mechanical | Cost-effective, versatile | Limited precision for complex parts |

| Electropolishing | Superior finish, corrosion resistance | High cost, limited material compatibility |

Applications in Various Industries

- Automotive: Enhancing the appearance of exterior and interior components.

- Medical Devices: Ensuring the smoothness and biocompatibility of implants and tools.

- Aerospace: Improving the aerodynamics and aesthetics of aircraft parts.

- Consumer Electronics: Enhancing the visual appeal of devices and components.

Challenges and Solutions

- Surface Uniformity: Achieving consistent finishes across complex geometries.

- Material Constraints: Adapting techniques for various metals and alloys.

- Environmental Concerns: Managing waste and emissions from polishing processes.

Section 4: Buffing Process for Sheet Metal Parts

Definition and Difference from Polishing

Buffing is a surface finishing process that involves the use of soft cloth wheels and polishing compounds to achieve a high-gloss finish on metal surfaces. While similar to polishing, buffing focuses on enhancing the final appearance rather than removing significant surface imperfections.

- Difference from Polishing:

- Polishing: Involves removing surface material to smooth and refine.

- Buffing: Focuses on creating a high-gloss, reflective finish.

Buffing Techniques

Different buffing techniques are employed based on the desired finish and complexity of the parts.

Manual Buffing

- Process: Involves the use of hand-held buffing wheels and compounds.

- Advantages:

- Flexibility for small-scale production.

- Control over the finishing process.

- Disadvantages:

- Labor-intensive and time-consuming.

- Inconsistent results due to human error.

Automatic Buffing

- Process: Utilizes automated machines and robotic arms for buffing.

- Advantages:

- Suitable for large-scale production.

- Consistent and repeatable results.

- Disadvantages:

- High initial setup cost.

- Limited flexibility for intricate parts.

Buffing Compounds and Materials

Buffing compounds are essential for achieving desired finishes and vary based on the material and application.

- Types of Buffing Compounds:

- Tripoli: Used for initial cutting and smoothing.

- Rouge: Provides a high-gloss finish.

- White Diamond: Removes light scratches and enhances shine.

- Materials Used:

- Cloth Wheels: Made from cotton, flannel, or sisal.

- Buffing Pads: Available in various grades for different finishes.

Tools and Equipment Used

- Buffing Machines: Includes bench grinders and automated buffing stations.

- Buffing Wheels and Pads: Available in different sizes and materials.

- Polishing Compounds: Formulated for specific applications and finishes.

Applications in Various Industries

- Jewelry: Enhancing the luster and appeal of metal pieces.

- Automotive: Achieving high-gloss finishes on body panels and trim.

- Furniture: Polishing metal components for aesthetic appeal.

- Consumer Goods: Improving the appearance of household items and appliances.

Advantages and Limitations

- Advantages:

- Enhances aesthetic appeal and surface smoothness.

- Suitable for various metals and applications.

- Limitations:

- Limited material removal capability.

- Requires careful handling to avoid surface damage.

Section 5: Comparison of Deburring, Polishing, and Buffing

Differences in Techniques and Applications

| Process | Purpose | Applications |

|---|---|---|

| Deburring | Remove burrs and imperfections | Manufacturing, machining |

| Polishing | Smooth and shine surfaces | Automotive, aerospace, electronics |

| Buffing | Enhance gloss and appearance | Jewelry, consumer goods, automotive |

Suitability for Different Types of Sheet Metal

- Deburring: Essential for parts with sharp edges and complex geometries.

- Polishing: Suitable for achieving reflective finishes on flat and contoured surfaces.

- Buffing: Ideal for enhancing the appearance of decorative and high-visibility parts.

Cost and Time Considerations

- Deburring: Cost-effective for high-volume production, but may require specialized equipment.

- Polishing: Balances cost with desired finish quality, may involve multiple steps.

- Buffing: Cost-effective for achieving high-gloss finishes, but may require additional polishing.

Environmental and Safety Considerations

- Deburring: Potential for media and chemical contamination, requires proper disposal.

- Polishing: Generates dust and waste, necessitating effective ventilation and filtration.

- Buffing: Involves the use of chemicals, requires protective equipment and safety measures.

Section 6: Advancements in Surface Finishing Technologies

Automation and Robotics

The integration of automation and robotics in surface finishing operations has revolutionized the industry, offering improved efficiency, precision, and consistency.

- Benefits of Automation:

- Reduced labor costs and human error.

- Enhanced precision and repeatability.

- Increased production speed and efficiency.

- Applications:

- Robotic deburring for intricate parts.

- Automated polishing systems for large components.

- Intelligent buffing machines with adaptive control.

Innovative Materials and Techniques

Advancements in materials and techniques continue to drive improvements in surface finishing processes.

- Innovative Materials:

- Advanced Abrasives: Developments in abrasive materials enhance cutting and polishing efficiency.

- Eco-Friendly Compounds: Formulations that reduce environmental impact and improve safety.

- New Techniques:

- Laser Deburring: Uses laser beams to remove burrs with precision.

- Nano-Polishing: Employs nanotechnology for superior surface finishes.

Impact of Industry 4.0

Industry 4.0 is reshaping surface finishing operations through the integration of smart technologies and data-driven approaches.

- Key Aspects of Industry 4.0:

- IoT Connectivity: Enables real-time monitoring and control of finishing processes.

- Data Analytics: Provides insights into process optimization and quality control.

- AI and Machine Learning: Enhances decision-making and process automation.

Case Studies on Modern Applications

Case Study 1: Automotive Industry

- Objective: Improve production efficiency and finish quality.

- Solution: Implementation of robotic polishing systems with IoT connectivity.

- Outcome: Increased production speed, reduced defects, and enhanced finish quality.

Case Study 2: Aerospace Industry

- Objective: Achieve high precision and consistency in aircraft parts.

- Solution: Integration of AI-driven deburring and polishing systems.

- Outcome: Improved accuracy, reduced waste, and compliance with industry standards.

Section 7: Best Practices and Quality Control

Quality Standards and Certifications

Adhering to quality standards and certifications ensures the reliability and performance of surface-finished parts.

- Key Standards:

- ISO 9001: Quality management systems for consistent product quality.

- ISO 14001: Environmental management standards for sustainable practices.

- NADCAP: Aerospace industry standards for process quality and control.

Inspection Techniques

Effective inspection techniques are crucial for maintaining the quality and consistency of finished parts.

- Visual Inspection: Identifying surface defects and irregularities.

- Dimensional Inspection: Measuring critical dimensions and tolerances.

- Surface Roughness Testing: Assessing surface smoothness and texture.

- Non-Destructive Testing: Evaluating structural integrity without damaging parts.

Process Optimization

Optimizing surface finishing processes enhances efficiency and reduces costs.

- Key Strategies:

- Lean Manufacturing: Minimizing waste and improving workflow.

- Continuous Improvement: Implementing feedback loops for process refinement.

- Process Automation: Utilizing technology for increased efficiency and precision.

Safety Measures and Precautions

Ensuring safety in surface finishing operations is paramount to protect workers and the environment.

- Safety Precautions:

- Personal Protective Equipment (PPE): Gloves, masks, goggles, and protective clothing.

- Ventilation and Filtration: Effective air quality management to reduce dust and fumes.

- Training and Education: Ongoing training programs for workers to ensure safe practices.

Section 8: Conclusion

Summary of Key Points

- Surface finishing operations, including deburring, polishing, and buffing, are essential for enhancing the appearance, functionality, and durability of sheet metal parts.

- Deburring removes burrs and imperfections, while polishing smooths and shines surfaces, and buffing enhances gloss and appearance.

- Advancements in technology, automation, and materials continue to drive improvements in surface finishing processes.

Future Trends in Surface Finishing

The future of surface finishing operations will be shaped by continued advancements in automation, materials, and sustainability.

- Emerging Trends:

- Green Technologies: Development of eco-friendly compounds and processes.

- Advanced Robotics: Increased use of robotics for precision and efficiency.

- Smart Manufacturing: Integration of IoT and AI for data-driven process optimization.

Final Thoughts

Surface finishing operations are a vital component of modern manufacturing, contributing to the quality and performance of sheet metal parts across various industries. By staying abreast of technological advancements and best practices, manufacturers can achieve superior finishes and meet the evolving demands of the market.

Types of Polishing

Polishing is primarily categorized into mechanical and chemical methods, each serving different purposes and achieving unique results.

1. Mechanical Polishing

Mechanical polishing involves using abrasive tools and materials to physically remove surface material and achieve a smooth, reflective finish.

a. Belt Polishing

- Process: Uses abrasive belts that continuously rotate around rollers to polish the surface of the metal.

- Applications: Ideal for flat surfaces and edges.

- Advantages: Cost-effective, easy to set up, and suitable for removing larger imperfections.

- Commonly Used Materials:

- Aluminum Oxide: A widely used abrasive for general-purpose polishing.

- Silicon Carbide: Suitable for hard metals and provides a fine finish.

b. Disk Polishing

- Process: Utilizes rotating disks with abrasive pads to polish surfaces.

- Applications: Suitable for curved and irregular surfaces.

- Advantages: Provides uniform pressure and can reach tight spots.

- Commonly Used Materials:

- Diamond Abrasives: Known for cutting efficiency and durability, especially on hard metals.

- Ceramic Abrasives: Used for rapid stock removal and fine finishes.

c. Buffing Wheels

- Process: Employs cloth wheels coated with polishing compounds to achieve a high-gloss finish.

- Applications: Suitable for finishing and enhancing shine on metal surfaces.

- Advantages: Produces a mirror-like finish, ideal for aesthetic applications.

- Commonly Used Materials:

- Cotton and Flannel Wheels: Provide softness and flexibility, allowing for smooth finishes.

- Sisal Wheels: Used for cutting and initial buffing stages due to their firmness.

d. Vibratory Polishing

- Process: Involves placing parts in a vibrating container filled with abrasive media and compounds.

- Applications: Ideal for small and complex parts that require even polishing.

- Advantages: Provides consistent finishes, handles large volumes, and reduces manual labor.

- Commonly Used Materials:

- Ceramic Media: Effective for heavy cutting and smoothing.

- Plastic Media: Used for delicate parts and achieving fine finishes.

2. Chemical and Electrochemical Polishing

Chemical and electrochemical polishing methods involve the use of chemical reactions to remove surface material and achieve a smooth finish.

a. Electropolishing

- Process: Uses an electrolytic bath to dissolve the surface layer of metal, smoothing and leveling the surface.

- Applications: Commonly used in industries requiring high precision and cleanliness, such as medical and food processing.

- Advantages: Removes microscopic burrs, enhances corrosion resistance, and improves surface reflectivity.

- Commonly Used Materials:

- Electrolytic Solutions: Acidic solutions containing phosphoric and sulfuric acids.

- Anodes and Cathodes: Typically made from stainless steel or titanium for durability.

b. Chemical Polishing

- Process: Involves submerging the metal in a chemical solution that selectively removes surface material.

- Applications: Suitable for intricate shapes and areas difficult to reach with mechanical methods.

- Advantages: Provides uniform finishes and is effective for complex geometries.

- Commonly Used Materials:

- Acidic Solutions: Mixtures of nitric, hydrochloric, and sulfuric acids tailored to specific metals.

- Additives: Agents that control the polishing rate and improve surface quality.

3. Abrasive Polishing

Abrasive polishing uses fine abrasive particles to refine the surface, removing minor scratches and achieving a high level of smoothness.

a. Sandblasting

- Process: Propels fine abrasive particles against the surface of the metal to remove contaminants and smoothen the surface.

- Applications: Suitable for preparing surfaces for painting or coating.

- Advantages: Fast and effective for large surfaces and tough residues.

- Commonly Used Materials:

- Silica Sand: Traditional abrasive for general-purpose sandblasting.

- Glass Beads: Provides a smoother finish and is less aggressive than sand.

- Garnet: Known for its hardness and sharpness, ideal for heavy-duty applications.

b. Lapping

- Process: Involves using a lapping plate and abrasive slurry to achieve a fine, flat surface finish.

- Applications: Used in precision applications requiring tight tolerances, such as in optics and semiconductor industries.

- Advantages: Produces extremely flat surfaces and fine finishes.

- Commonly Used Materials:

- Diamond Slurry: Provides precision and is used for hard materials.

- Aluminum Oxide Slurry: Suitable for softer materials and less abrasive applications.

c. Micro-Abrasive Blasting

- Process: Uses a controlled stream of micro-abrasive particles to remove fine surface layers.

- Applications: Ideal for delicate and detailed parts requiring precision.

- Advantages: Highly controlled process, reduces risk of surface damage.

- Commonly Used Materials:

- Aluminum Oxide Powder: Common for general applications and provides a good balance of cutting and polishing.

- Sodium Bicarbonate: Gentle abrasive for sensitive materials.

Materials Used in Polishing

The choice of materials used in polishing depends on the type of metal, desired finish, and specific polishing method. Below are commonly used materials and compounds in metal polishing:

1. Abrasive Materials

- Aluminum Oxide: A versatile and widely used abrasive for various metals, including steel and aluminum. It provides a good balance between cutting and finishing capabilities.

- Silicon Carbide: Known for its hardness and sharpness, it is used for polishing hard metals and achieving a smooth surface.

- Diamond Abrasives: Offers superior cutting efficiency and is ideal for polishing hard and brittle metals, such as tungsten and ceramics.

- Ceramic Abrasives: Used for heavy-duty applications, offering high material removal rates and durability.

2. Polishing Compounds

Polishing compounds are essential in achieving the desired finish and are formulated for specific metals and applications.

a. Tripoli Compound

- Description: A coarse compound used for initial cutting and smoothing of surfaces.

- Applications: Commonly used on softer metals like aluminum and brass to remove scratches and surface imperfections.

b. Rouge Compound

- Description: A fine polishing compound used for achieving a high-gloss finish.

- Applications: Ideal for polishing precious metals such as gold and silver, as well as achieving a mirror-like finish on stainless steel.

c. White Diamond Compound

- Description: A versatile compound used for polishing and refining surfaces.

- Applications: Suitable for use on plastics and metals, providing a bright finish and removing light scratches.

d. Green Chromium Oxide Compound

- Description: A compound containing chromium oxide, used for achieving a fine finish.

- Applications: Ideal for polishing stainless steel and other hard metals, providing a high level of smoothness and shine.

3. Polishing Pads and Wheels

Polishing pads and wheels come in various materials and are selected based on the desired finish and application requirements.

- Cotton Buffing Wheels: Soft and flexible, suitable for applying polishing compounds and achieving a smooth finish.

- Flannel Buffing Wheels: Provide a finer finish and are often used in the final buffing stage.

- Sisal Buffing Wheels: Firm and durable, used for cutting and initial buffing stages.

- Foam Polishing Pads: Used in conjunction with polishing compounds for fine finishing and detailing.

4. Chemical Solutions

Chemical solutions play a critical role in chemical and electrochemical polishing processes, providing the necessary reactions to achieve desired surface finishes.

- Electrolytic Solutions: Composed of acids like phosphoric and sulfuric acids, used in electropolishing to dissolve surface material and enhance smoothness.

- Chemical Polishing Solutions: Tailored mixtures of acids and additives designed for specific metals and applications, providing controlled material removal and surface refinement.

Conclusion

Polishing is a vital surface finishing process that enhances the appearance and functionality of metal parts. By understanding the various polishing methods and materials, manufacturers can achieve the desired finishes for different applications and industries. Whether through mechanical, chemical, or abrasive techniques, the choice of polishing materials and compounds plays a crucial role in achieving high-quality surface finishes.

Best Polishing Methods for Metal

Polishing metal surfaces is a critical step in many manufacturing processes, enhancing both the aesthetic appeal and functional properties of metal parts. The best polishing methods depend on various factors, including the type of metal, the desired finish, and specific application requirements. Below, we’ll explore some of the most effective polishing methods and their respective advantages, disadvantages, and suitable applications.

1. Mechanical Polishing

Mechanical polishing is one of the most commonly used methods due to its versatility and effectiveness in achieving smooth, shiny surfaces. This method involves using abrasive materials to physically remove surface imperfections.

a. Belt Polishing

Process: Belt polishing uses continuous abrasive belts to grind and polish metal surfaces. It is suitable for flat and slightly curved surfaces.

- Advantages:

- Cost-effective and suitable for high-volume production.

- Can handle a wide range of metals, including steel, aluminum, and brass.

- Efficient at removing larger surface imperfections.

- Disadvantages:

- Limited precision for intricate parts and complex geometries.

- May require additional finishing steps to achieve a mirror-like finish.

- Applications:

- Automotive parts such as body panels and bumpers.

- Large metal sheets and plates.

- Metal furniture components.

b. Disk Polishing

Process: Disk polishing involves rotating abrasive disks to smooth and shine metal surfaces. It is often used for smaller or more intricate parts.

- Advantages:

- Provides uniform pressure and consistent results.

- Suitable for complex shapes and small parts.

- Versatile for a range of metals and finishes.

- Disadvantages:

- Requires skilled operators to avoid over-polishing.

- Limited to flat and moderately curved surfaces.

- Applications:

- Jewelry and small metal components.

- Precision instruments and tools.

- Metal parts with intricate designs.

c. Vibratory Polishing

Process: Vibratory polishing involves placing metal parts in a vibrating container filled with abrasive media and compounds. The vibrations cause the media to polish the surfaces of the parts.

- Advantages:

- Ideal for large batches of small parts.

- Provides even polishing across surfaces.

- Reduces manual labor and operator fatigue.

- Disadvantages:

- Slower than other mechanical methods.

- Limited to smaller parts and components.

- Applications:

- Small automotive components.

- Hardware and fasteners.

- Jewelry and decorative items.

d. Buffing Wheels

Process: Buffing involves using cloth wheels and polishing compounds to achieve a high-gloss finish on metal surfaces. It is often used as a final finishing step.

- Advantages:

- Achieves a mirror-like, high-gloss finish.

- Suitable for a wide range of metals, including stainless steel and aluminum.

- Enhances the aesthetic appeal of metal surfaces.

- Disadvantages:

- Limited material removal capability.

- Requires careful handling to avoid surface damage.

- Applications:

- Automotive trim and decorative parts.

- Consumer electronics and appliances.

- Jewelry and luxury goods.

2. Chemical and Electrochemical Polishing

Chemical and electrochemical polishing methods use chemical reactions to smooth and refine metal surfaces, offering high precision and uniform finishes.

a. Electropolishing

Process: Electropolishing involves submerging metal parts in an electrolytic bath, where controlled electrical currents dissolve the surface layer of the metal, smoothing and leveling it.

- Advantages:

- Produces superior surface finishes with excellent reflectivity.

- Removes microscopic burrs and imperfections.

- Enhances corrosion resistance and passivation of metals.

- Disadvantages:

- High initial setup and operational costs.

- Limited to conductive materials like stainless steel, titanium, and aluminum.

- Applications:

- Medical devices and implants.

- Food processing equipment.

- Aerospace components.

b. Chemical Polishing

Process: Chemical polishing involves immersing metal parts in a chemical solution that selectively removes surface material, refining and smoothing the surface.

- Advantages:

- Uniform finishes on complex geometries.

- Suitable for delicate parts and thin-walled components.

- Reduces surface stress and improves fatigue resistance.

- Disadvantages:

- Requires precise control of chemical concentrations and temperature.

- Potential environmental and safety concerns with chemical handling.

- Applications:

- Intricate metal parts and components.

- Electronics and semiconductor industries.

- Decorative metal products.

3. Abrasive Polishing

Abrasive polishing methods involve using fine abrasive particles to achieve a smooth and refined surface finish, often used for precision applications.

a. Lapping

Process: Lapping uses a lapping plate and abrasive slurry to achieve flat, smooth surfaces with tight tolerances. It is often used for precision applications.

- Advantages:

- Achieves extremely flat and smooth surfaces.

- Suitable for high-precision parts and components.

- Provides tight tolerances and uniform finishes.

- Disadvantages:

- Requires specialized equipment and expertise.

- Limited to flat surfaces and precision applications.

- Applications:

- Optics and lenses.

- Semiconductor wafers.

- Precision mechanical components.

b. Micro-Abrasive Blasting

Process: Micro-abrasive blasting uses a controlled stream of micro-abrasive particles to remove fine surface layers and achieve precision finishes.

- Advantages:

- Highly controlled process for precision applications.

- Suitable for delicate and detailed parts.

- Minimizes surface damage and distortion.

- Disadvantages:

- Limited to small areas and precision applications.

- Requires specialized equipment and expertise.

- Applications:

- Aerospace and aviation components.

- Medical devices and instruments.

- Precision electronics and circuit boards.

Comparison of Polishing Methods

Here’s a table comparing the various polishing methods to highlight their advantages, disadvantages, and applications:

| Method | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Belt Polishing | Cost-effective, handles large surfaces | Limited precision, may require additional finishing | Automotive parts, large metal sheets |

| Disk Polishing | Uniform pressure, suitable for intricate parts | Skilled operation required, limited to flat surfaces | Jewelry, precision instruments, complex shapes |

| Vibratory Polishing | Even polishing, suitable for large batches | Slower process, limited to small parts | Small automotive components, hardware, jewelry |

| Buffing Wheels | Achieves high-gloss finish, enhances aesthetics | Limited material removal, requires careful handling | Automotive trim, consumer electronics, jewelry |

| Electropolishing | Superior finishes, removes microscopic burrs, enhances corrosion resistance | High setup costs, limited to conductive materials | Medical devices, food processing, aerospace components |

| Chemical Polishing | Uniform finishes on complex geometries, reduces surface stress | Precise control required, environmental concerns | Intricate parts, electronics, decorative products |

| Lapping | Extremely flat surfaces, tight tolerances | Requires specialized equipment, limited to flat surfaces | Optics, semiconductor wafers, precision components |

| Micro-Abrasive Blasting | Controlled process, suitable for delicate parts | Limited to small areas, requires specialized equipment | Aerospace components, medical devices, precision electronics |

Factors to Consider When Choosing a Polishing Method

Selecting the best polishing method for a specific application involves considering several key factors:

- Material Type: Different metals have varying properties, such as hardness and corrosion resistance, that affect their suitability for specific polishing methods. For example, stainless steel benefits from electropolishing due to its corrosion resistance, while softer metals like aluminum can be effectively polished using mechanical methods.

- Desired Finish: The intended appearance and surface quality of the finished product influence the choice of polishing method. For instance, a high-gloss finish may require buffing, while a matte finish could be achieved with abrasive blasting.

- Component Geometry: The shape and complexity of the metal parts play a crucial role in determining the most suitable polishing method. Intricate geometries may require chemical or electrochemical polishing for uniform finishes, while flat surfaces can be efficiently polished using mechanical methods.

- Production Volume: The scale of production impacts the choice of polishing method, with high-volume production benefiting from automated mechanical processes and small-batch or custom work requiring more manual techniques.

- Cost and Efficiency: The overall cost and efficiency of the polishing process, including equipment, labor, and materials, must be evaluated to determine the most cost-effective solution without compromising quality.

- Environmental and Safety Considerations: The environmental impact and safety of the polishing process, including waste management and operator safety, should be considered when selecting a method. Chemical processes may require special handling and disposal procedures, while mechanical methods can generate dust and noise.

Conclusion

Polishing is a vital process in the metalworking industry, significantly impacting the appearance and functionality of metal parts. By understanding the strengths and limitations of each polishing method, manufacturers can select the most appropriate technique to achieve the desired finish and meet specific application requirements. Whether through mechanical, chemical, or abrasive methods, the choice of polishing technique plays a critical role in producing high-quality, durable metal products.

What is Industrial Buffing?

Industrial buffing is a crucial process in the metal finishing industry, aimed at enhancing the appearance and functional properties of metal surfaces. It involves using buffing wheels and compounds to produce smooth, reflective finishes on various metal products. This section will explore the methods, materials, applications, and advancements in industrial buffing, providing a comprehensive understanding of this essential metalworking technique.

Industrial buffing is a surface finishing process used to achieve a high-gloss, mirror-like finish on metal surfaces. It involves using buffing wheels made from cloth, felt, or other materials, along with buffing compounds, to polish and smoothen the surface of metal parts. Buffing is often the final step in the finishing process, following grinding or polishing, to achieve the desired surface quality.

Objectives of Industrial Buffing

- Enhance Aesthetic Appeal: Buffing improves the visual appearance of metal parts by creating a reflective, glossy surface.

- Improve Surface Smoothness: The process removes fine scratches and imperfections, resulting in a smooth, even surface.

- Increase Corrosion Resistance: A polished surface can help reduce the risk of corrosion by minimizing surface irregularities where moisture could accumulate.

- Prepare for Further Coating: Buffing can prepare metal surfaces for additional coatings, such as paint or plating, by ensuring a smooth base.

Buffing Methods

Industrial buffing can be performed using various methods, each tailored to specific applications and desired finishes. Below are the primary methods used in industrial buffing:

1. Manual Buffing

Manual buffing involves skilled operators using hand-held buffing tools to polish metal surfaces. This method is often used for small-scale production or intricate parts requiring precise attention to detail.

- Advantages:

- Provides greater control over the buffing process.

- Suitable for complex shapes and detailed work.

- Allows for adjustments during the process to achieve the desired finish.

- Disadvantages:

- Labor-intensive and time-consuming.

- Inconsistent results due to human error.

- Limited to small production volumes.

- Applications:

- Jewelry and decorative items.

- Small automotive components.

- Custom metalwork.

2. Automated Buffing

Automated buffing employs machines and robotic systems to buff metal surfaces, offering consistent and efficient results for large-scale production.

- Advantages:

- High-speed production and consistent quality.

- Reduces labor costs and human error.

- Capable of handling large and complex parts.

- Disadvantages:

- High initial setup and equipment costs.

- Limited flexibility for intricate parts or custom finishes.

- Applications:

- Automotive parts and assemblies.

- Household appliances and electronics.

- Aerospace components.

3. Robotic Buffing

Robotic buffing utilizes robotic arms equipped with buffing tools to perform precise and efficient buffing operations, especially for complex geometries and large parts.

- Advantages:

- High precision and repeatability.

- Reduced human labor and increased safety.

- Capable of handling intricate and large-scale parts.

- Disadvantages:

- High capital investment for robotic systems.

- Requires programming and maintenance expertise.

- Applications:

- Aerospace and automotive industries.

- Large metal structures and equipment.

- High-volume production of standardized parts.

Buffing Compounds and Materials

The choice of buffing compounds and materials significantly influences the quality and efficiency of the buffing process. Various compounds are used based on the type of metal and desired finish.

Buffing Compounds

Buffing compounds are abrasive materials mixed with binders that help achieve the desired finish on metal surfaces. They come in different formulations, each suited for specific applications.

a. Tripoli Compound

- Description: A coarse compound used for initial cutting and smoothing of metal surfaces.

- Applications: Ideal for removing scratches and surface imperfections on softer metals like aluminum and brass.

b. Rouge Compound

- Description: A fine compound used to achieve a high-gloss, mirror-like finish.

- Applications: Suitable for polishing precious metals such as gold and silver, as well as stainless steel.

c. White Diamond Compound

- Description: A versatile compound used for polishing and refining metal surfaces.

- Applications: Effective on plastics and metals, providing a bright finish and removing light scratches.

d. Green Chromium Oxide Compound

- Description: A compound containing chromium oxide, used for achieving a fine finish.

- Applications: Ideal for polishing stainless steel and other hard metals, offering a high level of smoothness and shine.

Buffing Wheels and Materials

Buffing wheels are essential tools in the buffing process, available in various materials and configurations to suit different applications.

a. Cloth Buffing Wheels

- Description: Made from cotton or flannel, cloth wheels are soft and flexible, allowing for smooth finishes.

- Applications: Commonly used for applying buffing compounds and achieving a polished finish.

b. Sisal Buffing Wheels

- Description: Made from natural fibers, sisal wheels are firm and durable, making them suitable for initial cutting and buffing stages.

- Applications: Used for aggressive cutting and removing surface imperfections before finer buffing.

c. Felt Buffing Wheels

- Description: Dense and rigid, felt wheels are used for precision buffing and achieving high-gloss finishes.

- Applications: Ideal for detailed work and achieving mirror-like finishes on metals.

Applications of Industrial Buffing

Industrial buffing is used across various industries to enhance the appearance and functionality of metal parts. Here are some key applications:

1. Automotive Industry

- Applications:

- Buffing car body panels to achieve a smooth, glossy finish.

- Polishing chrome trim and accessories for enhanced aesthetic appeal.

- Smoothing engine components and parts for improved performance.

- Benefits:

- Improves the overall appearance and marketability of vehicles.

- Enhances corrosion resistance and durability of parts.

- Prepares surfaces for additional coatings or treatments.

2. Aerospace Industry

- Applications:

- Buffing aircraft components for improved aerodynamics and aesthetics.

- Polishing turbine blades and engine parts for enhanced performance.