We manufacture Finishing Machines for Vehicle Parts from design to assembly. Polishing Buffing Machines for Cookware. Discount Price from the Manufacturer

The manufacturing process employed determines the surface finish level. Some processes are inherently capable of producing better surfaces than others. The processes recognized for good surface finish are honing, lapping, polishing, and surface finishing.

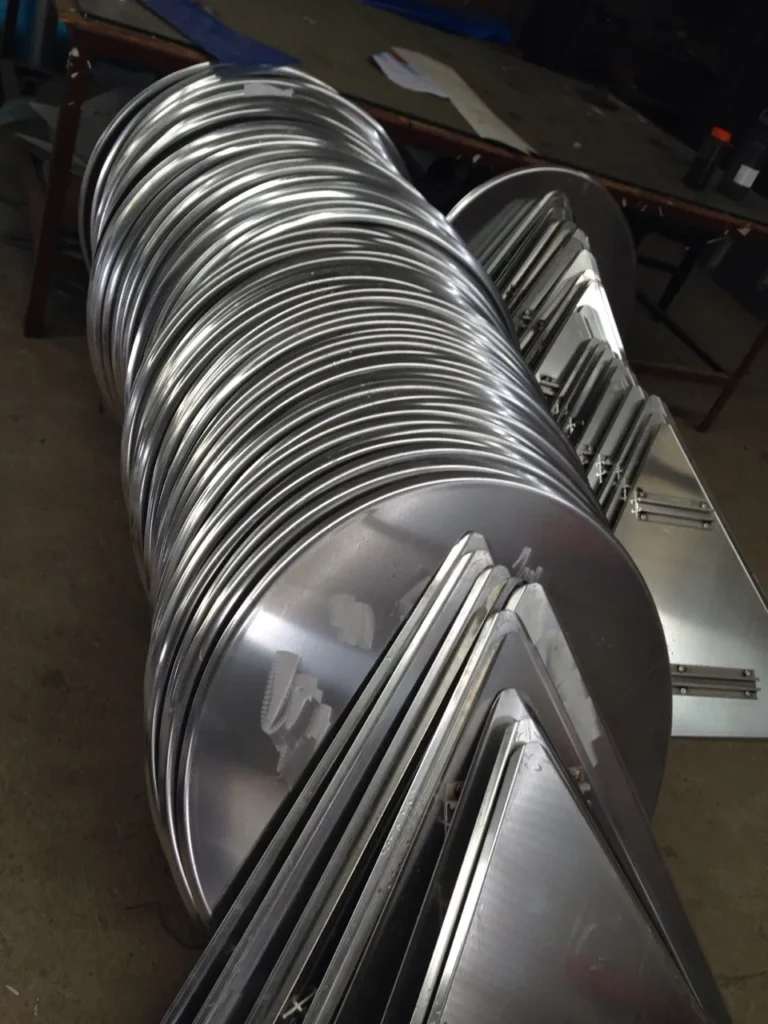

Finishing Machines for Vehicle Parts

Finishing machines play a crucial role in the automotive industry by polishing, buffing, and deburring various vehicle parts to achieve a desired surface finish, enhance functionality, and improve aesthetics. These machines are employed in various stages of the manufacturing process, from pre-treatment to final finishing, ensuring that vehicle parts meet stringent quality standards.

Types of Finishing Machines for Vehicle Parts:

- Vibratory Finishing Machines:

Vibratory finishing machines are widely used for mass finishing of small to medium-sized vehicle parts, such as engine components, transmission parts, and automotive accessories. These machines utilize a rotating tub filled with abrasive media, typically ceramic chips or plastic beads. As the tub rotates, the parts tumble within the media, creating friction and abrading the surfaces to achieve a uniform finish.

- Centrifugal Finishing Machines:

Centrifugal finishing machines are particularly effective for finishing complex-shaped or intricate vehicle parts. They employ centrifugal force to rotate the parts against abrasive media, resulting in rapid polishing and buffing. These machines are also suitable for achieving a more aggressive polishing effect on specific areas of the parts.

- Barrel Finishing Machines:

Barrel finishing machines are commonly used for finishing large batches of vehicle parts, such as castings, forgings, and machined components. They utilize a rotating barrel filled with abrasive media, and the parts tumble within the barrel as it rotates on its axis. Barrel finishing machines are effective for achieving a consistent finish across large quantities of parts.

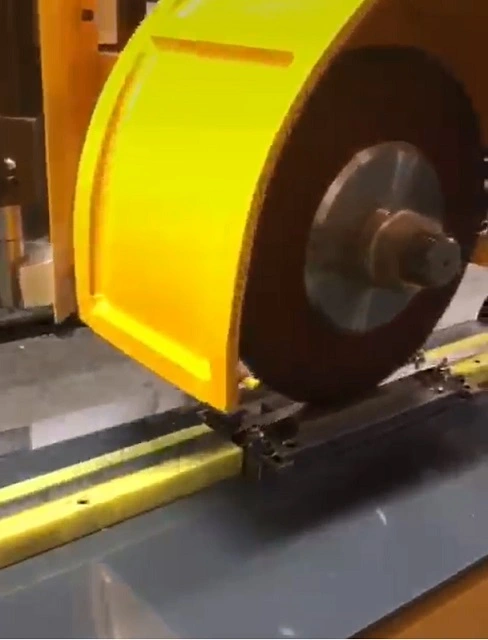

- Belt Finishing Machines:

Belt finishing machines are employed for polishing and buffing flat surfaces of vehicle parts, such as car panels, bumpers, and trim pieces. They utilize a series of abrasive belts that move continuously against the part surface, removing imperfections and achieving a smooth, consistent finish.

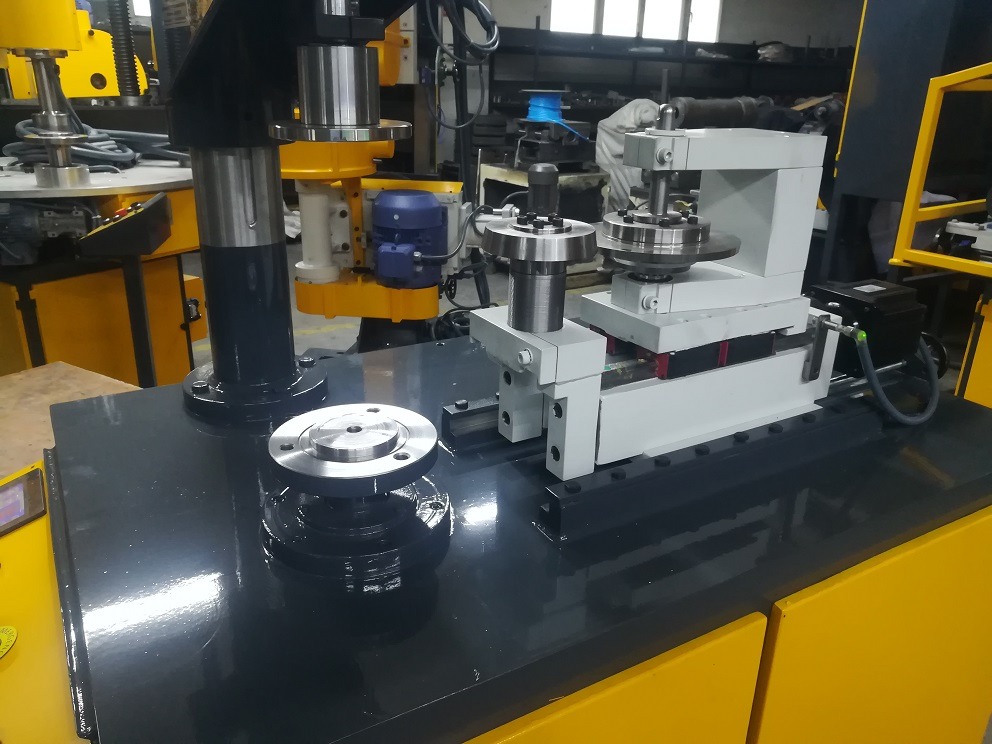

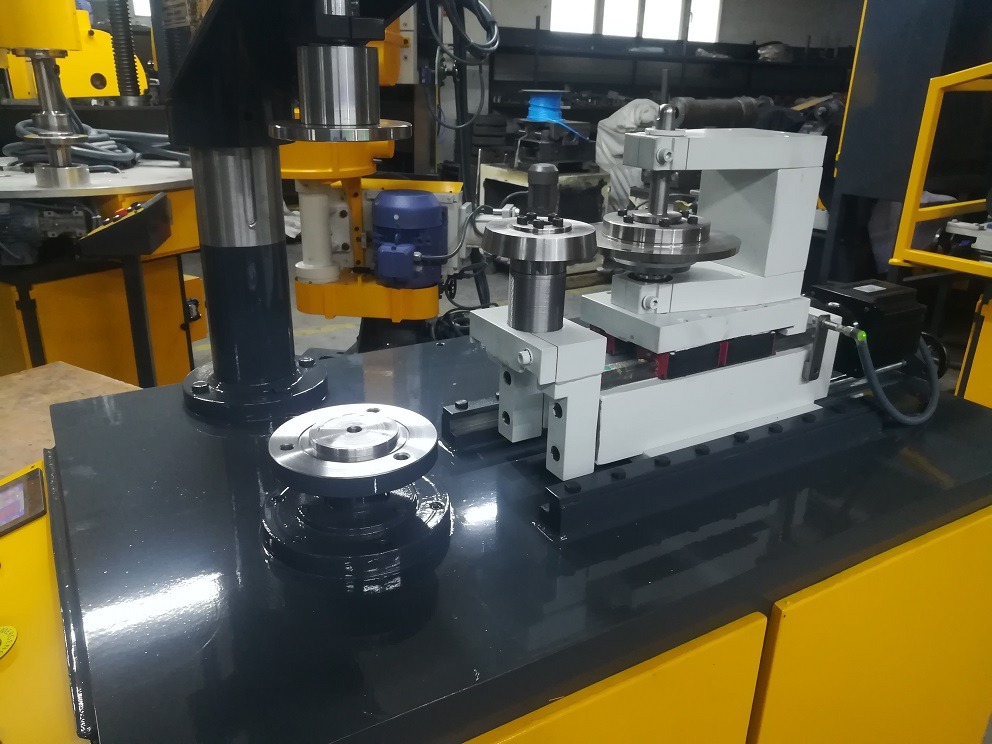

- Rotary Polishing Machines:

Rotary polishing machines are used for polishing and buffing curved surfaces of vehicle parts, such as headlights, taillights, and wheels. They utilize rotating polishing wheels or buffing compounds to remove scratches, haze, and other imperfections, restoring the part’s original shine.

Key Features of Finishing Machines for Vehicle Parts:

- Variable Speed Control: Adjustable speed control allows for tailoring the finishing process to the specific type of vehicle part and the desired finish.

- Precise Abrasive Media Selection: The choice of abrasive media is crucial for achieving the desired finish, considering the material properties of the vehicle part and the desired surface texture.

- Automated Control Systems: Advanced control systems ensure consistent finishing parameters, such as speed, pressure, and media flow, maintaining quality and minimizing variations.

- Dust and Fume Extraction Systems: These systems remove dust, debris, and fumes generated during the finishing process, maintaining a clean and safe work environment.

Benefits of Using Finishing Machines for Vehicle Parts:

- Enhanced Functionality: Finishing processes can improve the functionality of vehicle parts by removing burrs, imperfections, and surface irregularities that can affect performance or cause wear and tear.

- Improved Aesthetics: Finishing machines restore the shine and appearance of vehicle parts, enhancing the overall aesthetics of the vehicle and contributing to its perceived value.

- Corrosion Resistance: Finishing processes can create a smoother, more uniform surface, making it less susceptible to corrosion and environmental damage.

- Reduced Friction and Wear: Smoother surfaces reduce friction and wear, extending the lifespan of vehicle parts and improving overall vehicle performance.

- Enhanced Paint Adhesion: A clean, smooth surface provides better adhesion for paint and other coatings, improving the durability and longevity of the vehicle’s finish.

In conclusion, finishing machines are essential tools in the automotive industry, providing a range of benefits that enhance the quality, functionality, and aesthetics of vehicle parts. By employing these machines in various stages of the manufacturing process, automotive manufacturers ensure that their products meet the highest standards and deliver optimal performance to consumers.

Honing as Finishing Machines for Vehicle Parts

Honing is a surface finishing operation based on abrasive action performed by a set of bonded abrasive sticks. It is generally used to finish bores of cylinders of engines, hydraulic cylinders, gas barrels, bearings, etc. It can reduce the level of surface roughness below 32 μm. It produces a characteristics surface pattern across hatched which is a fit case to retain

lubrication layer to facilitate the move to moving parts, their best example is the IC engine.

The honing tool used to finish the internal surface is shown in Figure. The honing tool consists of a set of bonded abrasive sticks. The number of sticks mounted on a tool depends on its circumferential area. The number of sticks may be more than a dozen. The motion of a honing tool is a combination of rotation and reciprocation (linear).

The motion is managed in such a way that a given point on the abrasive stick does not trace the same path repeatedly. The honing speed may be kept up to 10 cm per sec. Lower speeds are recommended for a better surface finish. Manufacturing defects like slight eccentricity the way surface, light tapper, and less circulating can also be corrected by honing process. The process of honing is always supported by the flow of coolants. It flashes away the small chips and maintains a low and uniform temperature of tool and work.

Honing Machines as Finishing Machines for Vehicle Parts

Honing machines resemble vertical drilling machines in their construction.

The reciprocating motion of the spindle is obtained by hydraulic means. The rotary motion may be by a hydraulic motor or by a gear train. Depending upon the movement of the spindle or hones a machine may be vertical honing machine or a horizontal honing machine. Generally vertical honing machines are used. Horizontal honing machines are recommended for finishing the internal of long gun barrels.

Lapping

Lapping is also one of the abrasive processes used to produce finished

(smoothly accurate) surfaces. It gives a very high degree of accuracy and smoothness so it is used in the production of optical lenses, metallic bearing surfaces, measuring gauges, surface plates, and other measuring instruments.

All the metal parts that are subjected to fatigue loading or those surfaces that must be used to establish a seal with a mating part are often lapped. The process of lapping uses a bonded abrasive tool and a fluid suspension having very small-sized abrasive particles vibrating between the workpiece and the lapping tool.

The process of lapping is shown. The fluid with abrasive particles is referred to as a lapping compound. It appears as a chalky paste. Normally the fluid used in lapping compound is oil or kerosene.

The fluid should have slightly lubricating properties to make the action of abrasive and mild in nature. Abrasives used in lapping compounds are aluminiumoxide and silicon carbide. Their girt size is kept at 300 to 600 μm. It is hypothesized that two alternative cutting mechanisms are working in the process of lapping. In the first mechanism, the abrasive particles roll and slide between the lapping tool and workpiece.

These particles produce small cuts on both surfaces. Another mechanism supposed to work in lapping is that the abrasives become embedded in the lap surface to give cutting action like in the case of grinding.

Machine Lapping as Finishing Machines for Vehicle Parts

Machine lapping is recognized as a fast lapping process. Gudgeon pins with 25 mm diameter and 75 mm long can be lapped at the rate of 500 units per hour. Mechanical lapping machines have vertical construction with the work holder mounted on the lower table which is given oscillatory motion.

The upper lap is stationary and floating while the lower one revolves at 60 rpm. Some special purpose lapping machines are available for the lapping of small parts such as piston pins ball bearing races, etc. in machine lapping pressure upto 0.02 N/mm2 for soft material and 0.5 N/mm2 for hard material is applied.

Lapping Applications

Materials processed by lapping range from steel, and cast iron to non-ferrous metal like copper, brass, and lead. Wooden parts, made of hardwood, can also be finished using wood laps. Lapping removes material at a very slow rate. So lapping is generally followed by accurate machining of work pieces. Lapping is a costlier process so its applications are justified only when very Lapping Tool Lapping Compound Lense Blank (Work Piece)high grade of surface finishing is required. Lapped surfaces are well resistant to corrosion and wear, used in the manufacturing of high precision parts.

Polishing and Buffing as Finishing Machines for Vehicle Parts

Polishing and buffering are similar surface finishing operations. Polishing is used to remove scratches and burrs from a machined surface. It develops a very smooth surface by means of abrasive grains embedded in a polishing wheel rotating at high rpm. The rotating speed is equivalent to 2300 meters per minute. The rotating wheels are made of softer materials like canvas, leather, or paper. Thus, the wheels are enough flexible to finish the cavities and internal intricate shapes.

Polishing as Finishing Machines for Vehicle Parts

Polishing is carried out with the help of above-mentioned polishing wheels. Abrasive grains are bonded by gluing to the outside periphery of the wheel. After the abrasives have been worn down and used up, the wheel is replenished with new girts. Depending on the girt size polishing is divided into three categories.

- Rough Polishing: Girt size is maintained at 20 to 80.

- Finish Polishing: Girt size is kept at 80 to 120.

- Fine Finish: For polishing to give a very fine finish abrasive grit size is maintained above 120.

In the case of fine finishing process oil, tallow or beeswax is used as a lubricating agent. There is a limitation of the polishing process that the parts with irregular shapes, sharp corners, deep recesses, and sharp projections are difficult to polish.

Polishing Tool

Polishing can be done by hand, but for mass production work, specially designed semi-automatic and automatic polishing machines are available. Abrasive particles are Al2O3 or diamond. The carrier of abrasive particles have already been discussed. Polished surfaces may be buffed to obtain an even finer surface. Polishing does not improve dimensionless accuracy as done by lapping.

Difference between Polishing and Lapping

- Lapping and polishing differ in the following manner, polishing produces a shiny surface but lapping does not produce a bright shiny surface.

- Lapping removes metal from the surface to be finished, however, polishing removes a negligible amount of metal.

- Lapping involves cutting action but polishing consists of producing a kind of plastic flow of the surface crystals so that the high spots are made to fill the low spots.

Buffing

Buffing is similar to polishing in appearance, but its function is different. Buffing is used to provide attractive surfaces with high luster. Buffing is like a polishing operation in which the workpiece is brought in contact with a revolving cloth buffing wheel that usually has been charged with a very fine abrasive as shown in Figure.

Buffing status is somewhere in between polishing and lapping. A minor cutting action with a microchip is done in case of buffing. Buffing wheels are made of discs of liners, cotton, broadcloth, and canvas. These are made more or less firm by the amount of stitching used to fasten the layers of the cloth together. Buffing tools are enough flexible to polish up to the interior of intricate cavities. The buffing tools are named as BUFFING ROUGES.

There are semi-automatic buffing machines available consisting of a series of individually driver buffing wheels which can be adjusted to the desired position so as to buff different positions of the workpiece. The workpieces are held in fixtures on a suitable rotating worktable so as to move the buffing wheels. The application of buffing produces mirror-like finish. It is used for finishing of automobile parts, boats, bicycles, sports items, tools, furniture, fixtures, commercial and residential hardware, household utensils, and home appliances, etc

Super Finishing

Superfinishing is an alternative process similar to honing. This also uses

bonded abrasive stick moved with a reciprocating motion and pressed against the surface to to be finished. The relative motion between the abrasive stick and the workpiece is varied so that individual grains do not retrace the same path. Cutting fluid is used in the process for cooling of tool-workpiece interface.

Coolant also washes away the tiny chips produced in the process. The time needed for super finishing is very small. The workpiece may be super finished to a roughness of the order of 0.075 within 50 seconds. Sometimes the process of super finishing can be continued up to 3 minutes for very fine quality finish. Superfinishing can be differentiated from honing in the following ways:

- The superfinishing stroke length is comparatively shorter but the frequency is larger. It is up to 1500 strokes/minute.

- It requires low-pressure application as compared to honing process.

- During the process fed is given to the workpiece, and the fed rate in case of super finishing operation is smaller than honing.

- The grit size of the abrasive used in the case of super finishing is smaller than that used with hones.

- Major applications of super finishing are finishing computer memory drums, sewing machine parts, automotive cylinders, brake drums, bearing components, pistons piston rods, pins, axles, shafts, clutch plates, guide pins, etc.

Surface finishing operations are essential processes applied to sheet metal parts to enhance their appearance, functionality, and durability. These operations involve the removal of imperfections, smoothing of surfaces, and application of protective coatings. The importance of surface finishing cannot be overstated, as it directly impacts the performance, longevity, and aesthetic appeal of the final product.

- Key Objectives of Surface Finishing:

- Improve aesthetic appearance.

- Enhance corrosion resistance.

- Reduce friction and wear.

- Remove surface defects.

- Prepare surfaces for further processing.

Overview of Surface Finishing Techniques

Surface finishing techniques encompass a wide range of processes, each tailored to achieve specific results. The primary techniques include deburring, polishing, and buffing, each serving a unique purpose in the finishing workflow.

- Deburring: The process of removing burrs—tiny protrusions or unwanted materials—from the edges of sheet metal parts.

- Polishing: Involves smoothing and shining the surface to achieve a reflective finish.

- Buffing: A finishing process that further enhances the shine and smoothness of the surface.

Applications in Industry

Surface finishing operations are vital across various industries, including automotive, aerospace, electronics, and consumer goods. The demand for high-quality finishes in these sectors drives innovation and the development of advanced finishing techniques.

- Automotive: Enhancing the appearance and durability of car components.

- Aerospace: Ensuring precision and performance in aircraft parts.

- Electronics: Improving the aesthetic and functional quality of devices.

- Consumer Goods: Increasing the appeal and longevity of products.

Section 2: Deburring in Sheet Metal Parts

Definition and Types of Burrs

Deburring is the process of removing small, unwanted protrusions or burrs that form on the edges of sheet metal parts during manufacturing processes like cutting, drilling, and stamping. Burrs can negatively affect the performance, safety, and appearance of metal parts, making deburring a critical step in the production cycle.

- Types of Burrs:

- Poisson Burr: Caused by material deformation, often appears as a thin edge.

- Roll-Over Burr: Occurs when material is pushed over the edge of a part.

- Tear Burr: Created by tearing of material, resulting in irregular edges.

- Cut-Off Burr: Occurs at the end of the cutting process, often requiring specific removal techniques.

Methods of Burr Removal

The selection of a deburring method depends on factors such as the type of burr, material properties, and desired surface finish. Below are common deburring methods:

Manual Deburring

- Tools Used: Files, scrapers, abrasive pads, and brushes.

- Advantages:

- Cost-effective for small-scale production.

- Provides control over the finishing process.

- Disadvantages:

- Labor-intensive and time-consuming.

- Inconsistent results due to human error.

Mechanical Deburring

- Methods:

- Tumbling: Parts are placed in a tumbler with abrasive media that polishes the edges.

- Vibratory Finishing: Uses vibrations to agitate parts and media for deburring.

- Grinding: Utilizes rotating abrasive wheels to remove burrs.

- Advantages:

- Suitable for large-scale production.

- Consistent and repeatable results.

- Disadvantages:

- May require additional equipment and space.

- Potential for media contamination.

Thermal Deburring

- Process: Involves exposing parts to a controlled explosion of gas to burn away burrs.

- Advantages:

- Effective for hard-to-reach areas.

- Fast and efficient for complex parts.

- Disadvantages:

- High initial setup cost.

- Limited to specific materials.

Electrochemical Deburring

- Process: Involves the use of electrolytic solutions to dissolve burrs.

- Advantages:

- Precise and controlled removal.

- Minimal tool wear.

- Disadvantages:

- Requires careful handling of chemicals.

- High operational costs.

Tools and Equipment Used

- Manual Tools: Files, sandpaper, brushes.

- Mechanical Equipment: Tumblers, grinders, vibratory finishers.

- Advanced Equipment: Thermal deburring machines, electrochemical setups.

Challenges in Deburring

- Material Compatibility: Different materials require specific deburring techniques.

- Cost Considerations: Balancing cost and efficiency in high-volume production.

- Quality Control: Ensuring consistent results across batches.

Case Studies

Case Study 1: Automotive Component Deburring

- Objective: Improve the precision and safety of automotive parts.

- Method Used: Mechanical deburring with vibratory finishing.

- Outcome: Enhanced safety and performance of components, reduced production time.

Case Study 2: Aerospace Part Deburring

- Objective: Achieve high precision and reliability in aircraft parts.

- Method Used: Electrochemical deburring for intricate components.

- Outcome: Improved accuracy and reliability, meeting industry standards.

Section 3: Polishing of Sheet Metal Parts

Definition and Purpose

Polishing is a surface finishing process aimed at smoothing and shining metal parts to achieve a reflective finish. It enhances the appearance and functionality of metal parts by removing scratches, pits, and other imperfections.

- Purpose of Polishing:

- Improve aesthetic appeal.

- Increase corrosion resistance.

- Enhance surface smoothness and reflectivity.

- Prepare surfaces for further coating or finishing processes.

Polishing Techniques

Various polishing techniques are employed based on the desired finish and application requirements.

Mechanical Polishing

- Process: Involves the use of abrasive materials to remove surface irregularities.

- Techniques:

- Belt Polishing: Uses abrasive belts for continuous polishing.

- Disk Polishing: Utilizes rotating disks with abrasive pads.

- Buffing Wheels: Employs rotating cloth wheels with polishing compounds.

- Advantages:

- Cost-effective and versatile.

- Suitable for various metals and shapes.

- Disadvantages:

- Limited precision for complex geometries.

- Requires skilled operators for optimal results.

Electropolishing

- Process: Involves the use of an electrolytic bath to dissolve the surface layer of metal, resulting in a smooth and shiny finish.

- Advantages:

- Superior surface finish and reflectivity.

- Removes microscopic imperfections.

- Enhances corrosion resistance.

- Disadvantages:

- High setup and operational costs.

- Limited to specific metals and applications.

Tools and Equipment Used

- Abrasive Belts and Disks: Used for mechanical polishing.

- Buffing Wheels and Compounds: For fine finishing.

- Electropolishing Equipment: Includes electrolytic baths and power supplies.

Comparison of Different Polishing Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Mechanical | Cost-effective, versatile | Limited precision for complex parts |

| Electropolishing | Superior finish, corrosion resistance | High cost, limited material compatibility |

Applications in Various Industries

- Automotive: Enhancing the appearance of exterior and interior components.

- Medical Devices: Ensuring the smoothness and biocompatibility of implants and tools.

- Aerospace: Improving the aerodynamics and aesthetics of aircraft parts.

- Consumer Electronics: Enhancing the visual appeal of devices and components.

Challenges and Solutions

- Surface Uniformity: Achieving consistent finishes across complex geometries.

- Material Constraints: Adapting techniques for various metals and alloys.

- Environmental Concerns: Managing waste and emissions from polishing processes.

Section 4: Buffing Process for Sheet Metal Parts

Definition and Difference from Polishing

Buffing is a surface finishing process that involves the use of soft cloth wheels and polishing compounds to achieve a high-gloss finish on metal surfaces. While similar to polishing, buffing focuses on enhancing the final appearance rather than removing significant surface imperfections.

- Difference from Polishing:

- Polishing: Involves removing surface material to smooth and refine.

- Buffing: Focuses on creating a high-gloss, reflective finish.

Buffing Techniques

Different buffing techniques are employed based on the desired finish and complexity of the parts.

Manual Buffing

- Process: Involves the use of hand-held buffing wheels and compounds.

- Advantages:

- Flexibility for small-scale production.

- Control over the finishing process.

- Disadvantages:

- Labor-intensive and time-consuming.

- Inconsistent results due to human error.

Automatic Buffing

- Process: Utilizes automated machines and robotic arms for buffing.

- Advantages:

- Suitable for large-scale production.

- Consistent and repeatable results.

- Disadvantages:

- High initial setup cost.

- Limited flexibility for intricate parts.

Buffing Compounds and Materials

Buffing compounds are essential for achieving desired finishes and vary based on the material and application.

- Types of Buffing Compounds:

- Tripoli: Used for initial cutting and smoothing.

- Rouge: Provides a high-gloss finish.

- White Diamond: Removes light scratches and enhances shine.

- Materials Used:

- Cloth Wheels: Made from cotton, flannel, or sisal.

- Buffing Pads: Available in various grades for different finishes.

Tools and Equipment Used

- Buffing Machines: Includes bench grinders and automated buffing stations.

- Buffing Wheels and Pads: Available in different sizes and materials.

- Polishing Compounds: Formulated for specific applications and finishes.

Applications in Various Industries

- Jewelry: Enhancing the luster and appeal of metal pieces.

- Automotive: Achieving high-gloss finishes on body panels and trim.

- Furniture: Polishing metal components for aesthetic appeal.

- Consumer Goods: Improving the appearance of household items and appliances.

Advantages and Limitations

- Advantages:

- Enhances aesthetic appeal and surface smoothness.

- Suitable for various metals and applications.

- Limitations:

- Limited material removal capability.

- Requires careful handling to avoid surface damage.

Section 5: Comparison of Deburring, Polishing, and Buffing

Differences in Techniques and Applications

| Process | Purpose | Applications |

|---|---|---|

| Deburring | Remove burrs and imperfections | Manufacturing, machining |

| Polishing | Smooth and shine surfaces | Automotive, aerospace, electronics |

| Buffing | Enhance gloss and appearance | Jewelry, consumer goods, automotive |

Suitability for Different Types of Sheet Metal

- Deburring: Essential for parts with sharp edges and complex geometries.

- Polishing: Suitable for achieving reflective finishes on flat and contoured surfaces.

- Buffing: Ideal for enhancing the appearance of decorative and high-visibility parts.

Cost and Time Considerations

- Deburring: Cost-effective for high-volume production, but may require specialized equipment.

- Polishing: Balances cost with desired finish quality, may involve multiple steps.

- Buffing: Cost-effective for achieving high-gloss finishes, but may require additional polishing.

Environmental and Safety Considerations

- Deburring: Potential for media and chemical contamination, requires proper disposal.

- Polishing: Generates dust and waste, necessitating effective ventilation and filtration.

- Buffing: Involves the use of chemicals, requires protective equipment and safety measures.

Section 6: Advancements in Surface Finishing Technologies

Automation and Robotics

The integration of automation and robotics in surface finishing operations has revolutionized the industry, offering improved efficiency, precision, and consistency.

- Benefits of Automation:

- Reduced labor costs and human error.

- Enhanced precision and repeatability.

- Increased production speed and efficiency.

- Applications:

- Robotic deburring for intricate parts.

- Automated polishing systems for large components.

- Intelligent buffing machines with adaptive control.

Innovative Materials and Techniques

Advancements in materials and techniques continue to drive improvements in surface finishing processes.

- Innovative Materials:

- Advanced Abrasives: Developments in abrasive materials enhance cutting and polishing efficiency.

- Eco-Friendly Compounds: Formulations that reduce environmental impact and improve safety.

- New Techniques:

- Laser Deburring: Uses laser beams to remove burrs with precision.

- Nano-Polishing: Employs nanotechnology for superior surface finishes.

Impact of Industry 4.0

Industry 4.0 is reshaping surface finishing operations through the integration of smart technologies and data-driven approaches.

- Key Aspects of Industry 4.0:

- IoT Connectivity: Enables real-time monitoring and control of finishing processes.

- Data Analytics: Provides insights into process optimization and quality control.

- AI and Machine Learning: Enhances decision-making and process automation.

Case Studies on Modern Applications

Case Study 1: Automotive Industry

- Objective: Improve production efficiency and finish quality.

- Solution: Implementation of robotic polishing systems with IoT connectivity.

- Outcome: Increased production speed, reduced defects, and enhanced finish quality.

Case Study 2: Aerospace Industry

- Objective: Achieve high precision and consistency in aircraft parts.

- Solution: Integration of AI-driven deburring and polishing systems.

- Outcome: Improved accuracy, reduced waste, and compliance with industry standards.

Section 7: Best Practices and Quality Control

Quality Standards and Certifications

Adhering to quality standards and certifications ensures the reliability and performance of surface-finished parts.

- Key Standards:

- ISO 9001: Quality management systems for consistent product quality.

- ISO 14001: Environmental management standards for sustainable practices.

- NADCAP: Aerospace industry standards for process quality and control.

Inspection Techniques

Effective inspection techniques are crucial for maintaining the quality and consistency of finished parts.

- Visual Inspection: Identifying surface defects and irregularities.

- Dimensional Inspection: Measuring critical dimensions and tolerances.

- Surface Roughness Testing: Assessing surface smoothness and texture.

- Non-Destructive Testing: Evaluating structural integrity without damaging parts.

Process Optimization

Optimizing surface finishing processes enhances efficiency and reduces costs.

- Key Strategies:

- Lean Manufacturing: Minimizing waste and improving workflow.

- Continuous Improvement: Implementing feedback loops for process refinement.

- Process Automation: Utilizing technology for increased efficiency and precision.

Safety Measures and Precautions

Ensuring safety in surface finishing operations is paramount to protect workers and the environment.

- Safety Precautions:

- Personal Protective Equipment (PPE): Gloves, masks, goggles, and protective clothing.

- Ventilation and Filtration: Effective air quality management to reduce dust and fumes.

- Training and Education: Ongoing training programs for workers to ensure safe practices.

Section 8: Conclusion

Summary of Key Points

- Surface finishing operations, including deburring, polishing, and buffing, are essential for enhancing the appearance, functionality, and durability of sheet metal parts.

- Deburring removes burrs and imperfections, while polishing smooths and shines surfaces, and buffing enhances gloss and appearance.

- Advancements in technology, automation, and materials continue to drive improvements in surface finishing processes.

Future Trends in Surface Finishing

The future of surface finishing operations will be shaped by continued advancements in automation, materials, and sustainability.

- Emerging Trends:

- Green Technologies: Development of eco-friendly compounds and processes.

- Advanced Robotics: Increased use of robotics for precision and efficiency.

- Smart Manufacturing: Integration of IoT and AI for data-driven process optimization.

Final Thoughts

Surface finishing operations are a vital component of modern manufacturing, contributing to the quality and performance of sheet metal parts across various industries. By staying abreast of technological advancements and best practices, manufacturers can achieve superior finishes and meet the evolving demands of the market.

Types of Polishing

Polishing is primarily categorized into mechanical and chemical methods, each serving different purposes and achieving unique results.

1. Mechanical Polishing

Mechanical polishing involves using abrasive tools and materials to physically remove surface material and achieve a smooth, reflective finish.

a. Belt Polishing

- Process: Uses abrasive belts that continuously rotate around rollers to polish the surface of the metal.

- Applications: Ideal for flat surfaces and edges.

- Advantages: Cost-effective, easy to set up, and suitable for removing larger imperfections.

- Commonly Used Materials:

- Aluminum Oxide: A widely used abrasive for general-purpose polishing.

- Silicon Carbide: Suitable for hard metals and provides a fine finish.

b. Disk Polishing

- Process: Utilizes rotating disks with abrasive pads to polish surfaces.

- Applications: Suitable for curved and irregular surfaces.

- Advantages: Provides uniform pressure and can reach tight spots.

- Commonly Used Materials:

- Diamond Abrasives: Known for cutting efficiency and durability, especially on hard metals.

- Ceramic Abrasives: Used for rapid stock removal and fine finishes.

c. Buffing Wheels

- Process: Employs cloth wheels coated with polishing compounds to achieve a high-gloss finish.

- Applications: Suitable for finishing and enhancing shine on metal surfaces.

- Advantages: Produces a mirror-like finish, ideal for aesthetic applications.

- Commonly Used Materials:

- Cotton and Flannel Wheels: Provide softness and flexibility, allowing for smooth finishes.

- Sisal Wheels: Used for cutting and initial buffing stages due to their firmness.

d. Vibratory Polishing

- Process: Involves placing parts in a vibrating container filled with abrasive media and compounds.

- Applications: Ideal for small and complex parts that require even polishing.

- Advantages: Provides consistent finishes, handles large volumes, and reduces manual labor.

- Commonly Used Materials:

- Ceramic Media: Effective for heavy cutting and smoothing.

- Plastic Media: Used for delicate parts and achieving fine finishes.

2. Chemical and Electrochemical Polishing

Chemical and electrochemical polishing methods involve the use of chemical reactions to remove surface material and achieve a smooth finish.

a. Electropolishing

- Process: Uses an electrolytic bath to dissolve the surface layer of metal, smoothing and leveling the surface.

- Applications: Commonly used in industries requiring high precision and cleanliness, such as medical and food processing.

- Advantages: Removes microscopic burrs, enhances corrosion resistance, and improves surface reflectivity.

- Commonly Used Materials:

- Electrolytic Solutions: Acidic solutions containing phosphoric and sulfuric acids.

- Anodes and Cathodes: Typically made from stainless steel or titanium for durability.

b. Chemical Polishing

- Process: Involves submerging the metal in a chemical solution that selectively removes surface material.

- Applications: Suitable for intricate shapes and areas difficult to reach with mechanical methods.

- Advantages: Provides uniform finishes and is effective for complex geometries.

- Commonly Used Materials:

- Acidic Solutions: Mixtures of nitric, hydrochloric, and sulfuric acids tailored to specific metals.

- Additives: Agents that control the polishing rate and improve surface quality.

3. Abrasive Polishing

Abrasive polishing uses fine abrasive particles to refine the surface, removing minor scratches and achieving a high level of smoothness.

a. Sandblasting

- Process: Propels fine abrasive particles against the surface of the metal to remove contaminants and smoothen the surface.

- Applications: Suitable for preparing surfaces for painting or coating.

- Advantages: Fast and effective for large surfaces and tough residues.

- Commonly Used Materials:

- Silica Sand: Traditional abrasive for general-purpose sandblasting.

- Glass Beads: Provides a smoother finish and is less aggressive than sand.

- Garnet: Known for its hardness and sharpness, ideal for heavy-duty applications.

b. Lapping

- Process: Involves using a lapping plate and abrasive slurry to achieve a fine, flat surface finish.

- Applications: Used in precision applications requiring tight tolerances, such as in optics and semiconductor industries.

- Advantages: Produces extremely flat surfaces and fine finishes.

- Commonly Used Materials:

- Diamond Slurry: Provides precision and is used for hard materials.

- Aluminum Oxide Slurry: Suitable for softer materials and less abrasive applications.

c. Micro-Abrasive Blasting

- Process: Uses a controlled stream of micro-abrasive particles to remove fine surface layers.

- Applications: Ideal for delicate and detailed parts requiring precision.

- Advantages: Highly controlled process, reduces risk of surface damage.

- Commonly Used Materials:

- Aluminum Oxide Powder: Common for general applications and provides a good balance of cutting and polishing.

- Sodium Bicarbonate: Gentle abrasive for sensitive materials.

Materials Used in Polishing

The choice of materials used in polishing depends on the type of metal, desired finish, and specific polishing method. Below are commonly used materials and compounds in metal polishing:

1. Abrasive Materials

- Aluminum Oxide: A versatile and widely used abrasive for various metals, including steel and aluminum. It provides a good balance between cutting and finishing capabilities.

- Silicon Carbide: Known for its hardness and sharpness, it is used for polishing hard metals and achieving a smooth surface.

- Diamond Abrasives: Offers superior cutting efficiency and is ideal for polishing hard and brittle metals, such as tungsten and ceramics.

- Ceramic Abrasives: Used for heavy-duty applications, offering high material removal rates and durability.

2. Polishing Compounds

Polishing compounds are essential in achieving the desired finish and are formulated for specific metals and applications.

a. Tripoli Compound

- Description: A coarse compound used for initial cutting and smoothing of surfaces.

- Applications: Commonly used on softer metals like aluminum and brass to remove scratches and surface imperfections.

b. Rouge Compound

- Description: A fine polishing compound used for achieving a high-gloss finish.

- Applications: Ideal for polishing precious metals such as gold and silver, as well as achieving a mirror-like finish on stainless steel.

c. White Diamond Compound

- Description: A versatile compound used for polishing and refining surfaces.

- Applications: Suitable for use on plastics and metals, providing a bright finish and removing light scratches.

d. Green Chromium Oxide Compound

- Description: A compound containing chromium oxide, used for achieving a fine finish.

- Applications: Ideal for polishing stainless steel and other hard metals, providing a high level of smoothness and shine.

3. Polishing Pads and Wheels

Polishing pads and wheels come in various materials and are selected based on the desired finish and application requirements.

- Cotton Buffing Wheels: Soft and flexible, suitable for applying polishing compounds and achieving a smooth finish.

- Flannel Buffing Wheels: Provide a finer finish and are often used in the final buffing stage.

- Sisal Buffing Wheels: Firm and durable, used for cutting and initial buffing stages.

- Foam Polishing Pads: Used in conjunction with polishing compounds for fine finishing and detailing.

4. Chemical Solutions

Chemical solutions play a critical role in chemical and electrochemical polishing processes, providing the necessary reactions to achieve desired surface finishes.

- Electrolytic Solutions: Composed of acids like phosphoric and sulfuric acids, used in electropolishing to dissolve surface material and enhance smoothness.

- Chemical Polishing Solutions: Tailored mixtures of acids and additives designed for specific metals and applications, providing controlled material removal and surface refinement.

Conclusion

Polishing is a vital surface finishing process that enhances the appearance and functionality of metal parts. By understanding the various polishing methods and materials, manufacturers can achieve the desired finishes for different applications and industries. Whether through mechanical, chemical, or abrasive techniques, the choice of polishing materials and compounds plays a crucial role in achieving high-quality surface finishes.

Best Polishing Methods for Metal

Polishing metal surfaces is a critical step in many manufacturing processes, enhancing both the aesthetic appeal and functional properties of metal parts. The best polishing methods depend on various factors, including the type of metal, the desired finish, and specific application requirements. Below, we’ll explore some of the most effective polishing methods and their respective advantages, disadvantages, and suitable applications.

1. Mechanical Polishing

Mechanical polishing is one of the most commonly used methods due to its versatility and effectiveness in achieving smooth, shiny surfaces. This method involves using abrasive materials to physically remove surface imperfections.

a. Belt Polishing

Process: Belt polishing uses continuous abrasive belts to grind and polish metal surfaces. It is suitable for flat and slightly curved surfaces.

- Advantages:

- Cost-effective and suitable for high-volume production.

- Can handle a wide range of metals, including steel, aluminum, and brass.

- Efficient at removing larger surface imperfections.

- Disadvantages:

- Limited precision for intricate parts and complex geometries.

- May require additional finishing steps to achieve a mirror-like finish.

- Applications:

- Automotive parts such as body panels and bumpers.

- Large metal sheets and plates.

- Metal furniture components.

b. Disk Polishing

Process: Disk polishing involves rotating abrasive disks to smooth and shine metal surfaces. It is often used for smaller or more intricate parts.

- Advantages:

- Provides uniform pressure and consistent results.

- Suitable for complex shapes and small parts.

- Versatile for a range of metals and finishes.

- Disadvantages:

- Requires skilled operators to avoid over-polishing.

- Limited to flat and moderately curved surfaces.

- Applications:

- Jewelry and small metal components.

- Precision instruments and tools.

- Metal parts with intricate designs.

c. Vibratory Polishing

Process: Vibratory polishing involves placing metal parts in a vibrating container filled with abrasive media and compounds. The vibrations cause the media to polish the surfaces of the parts.

- Advantages:

- Ideal for large batches of small parts.

- Provides even polishing across surfaces.

- Reduces manual labor and operator fatigue.

- Disadvantages:

- Slower than other mechanical methods.

- Limited to smaller parts and components.

- Applications:

- Small automotive components.

- Hardware and fasteners.

- Jewelry and decorative items.

d. Buffing Wheels

Process: Buffing involves using cloth wheels and polishing compounds to achieve a high-gloss finish on metal surfaces. It is often used as a final finishing step.

- Advantages:

- Achieves a mirror-like, high-gloss finish.

- Suitable for a wide range of metals, including stainless steel and aluminum.

- Enhances the aesthetic appeal of metal surfaces.

- Disadvantages:

- Limited material removal capability.

- Requires careful handling to avoid surface damage.

- Applications:

- Automotive trim and decorative parts.

- Consumer electronics and appliances.

- Jewelry and luxury goods.

2. Chemical and Electrochemical Polishing

Chemical and electrochemical polishing methods use chemical reactions to smooth and refine metal surfaces, offering high precision and uniform finishes.

a. Electropolishing

Process: Electropolishing involves submerging metal parts in an electrolytic bath, where controlled electrical currents dissolve the surface layer of the metal, smoothing and leveling it.

- Advantages:

- Produces superior surface finishes with excellent reflectivity.

- Removes microscopic burrs and imperfections.

- Enhances corrosion resistance and passivation of metals.

- Disadvantages:

- High initial setup and operational costs.

- Limited to conductive materials like stainless steel, titanium, and aluminum.

- Applications:

- Medical devices and implants.

- Food processing equipment.

- Aerospace components.

b. Chemical Polishing

Process: Chemical polishing involves immersing metal parts in a chemical solution that selectively removes surface material, refining and smoothing the surface.

- Advantages:

- Uniform finishes on complex geometries.

- Suitable for delicate parts and thin-walled components.

- Reduces surface stress and improves fatigue resistance.

- Disadvantages:

- Requires precise control of chemical concentrations and temperature.

- Potential environmental and safety concerns with chemical handling.

- Applications:

- Intricate metal parts and components.

- Electronics and semiconductor industries.

- Decorative metal products.

3. Abrasive Polishing

Abrasive polishing methods involve using fine abrasive particles to achieve a smooth and refined surface finish, often used for precision applications.

a. Lapping

Process: Lapping uses a lapping plate and abrasive slurry to achieve flat, smooth surfaces with tight tolerances. It is often used for precision applications.

- Advantages:

- Achieves extremely flat and smooth surfaces.

- Suitable for high-precision parts and components.

- Provides tight tolerances and uniform finishes.

- Disadvantages:

- Requires specialized equipment and expertise.

- Limited to flat surfaces and precision applications.

- Applications:

- Optics and lenses.

- Semiconductor wafers.

- Precision mechanical components.

b. Micro-Abrasive Blasting

Process: Micro-abrasive blasting uses a controlled stream of micro-abrasive particles to remove fine surface layers and achieve precision finishes.

- Advantages:

- Highly controlled process for precision applications.

- Suitable for delicate and detailed parts.

- Minimizes surface damage and distortion.

- Disadvantages:

- Limited to small areas and precision applications.

- Requires specialized equipment and expertise.

- Applications:

- Aerospace and aviation components.

- Medical devices and instruments.

- Precision electronics and circuit boards.

Comparison of Polishing Methods

Here’s a table comparing the various polishing methods to highlight their advantages, disadvantages, and applications:

| Method | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Belt Polishing | Cost-effective, handles large surfaces | Limited precision, may require additional finishing | Automotive parts, large metal sheets |

| Disk Polishing | Uniform pressure, suitable for intricate parts | Skilled operation required, limited to flat surfaces | Jewelry, precision instruments, complex shapes |

| Vibratory Polishing | Even polishing, suitable for large batches | Slower process, limited to small parts | Small automotive components, hardware, jewelry |

| Buffing Wheels | Achieves high-gloss finish, enhances aesthetics | Limited material removal, requires careful handling | Automotive trim, consumer electronics, jewelry |

| Electropolishing | Superior finishes, removes microscopic burrs, enhances corrosion resistance | High setup costs, limited to conductive materials | Medical devices, food processing, aerospace components |

| Chemical Polishing | Uniform finishes on complex geometries, reduces surface stress | Precise control required, environmental concerns | Intricate parts, electronics, decorative products |

| Lapping | Extremely flat surfaces, tight tolerances | Requires specialized equipment, limited to flat surfaces | Optics, semiconductor wafers, precision components |

| Micro-Abrasive Blasting | Controlled process, suitable for delicate parts | Limited to small areas, requires specialized equipment | Aerospace components, medical devices, precision electronics |

Factors to Consider When Choosing a Polishing Method

Selecting the best polishing method for a specific application involves considering several key factors:

- Material Type: Different metals have varying properties, such as hardness and corrosion resistance, that affect their suitability for specific polishing methods. For example, stainless steel benefits from electropolishing due to its corrosion resistance, while softer metals like aluminum can be effectively polished using mechanical methods.

- Desired Finish: The intended appearance and surface quality of the finished product influence the choice of polishing method. For instance, a high-gloss finish may require buffing, while a matte finish could be achieved with abrasive blasting.

- Component Geometry: The shape and complexity of the metal parts play a crucial role in determining the most suitable polishing method. Intricate geometries may require chemical or electrochemical polishing for uniform finishes, while flat surfaces can be efficiently polished using mechanical methods.

- Production Volume: The scale of production impacts the choice of polishing method, with high-volume production benefiting from automated mechanical processes and small-batch or custom work requiring more manual techniques.

- Cost and Efficiency: The overall cost and efficiency of the polishing process, including equipment, labor, and materials, must be evaluated to determine the most cost-effective solution without compromising quality.

- Environmental and Safety Considerations: The environmental impact and safety of the polishing process, including waste management and operator safety, should be considered when selecting a method. Chemical processes may require special handling and disposal procedures, while mechanical methods can generate dust and noise.

Conclusion

Polishing is a vital process in the metalworking industry, significantly impacting the appearance and functionality of metal parts. By understanding the strengths and limitations of each polishing method, manufacturers can select the most appropriate technique to achieve the desired finish and meet specific application requirements. Whether through mechanical, chemical, or abrasive methods, the choice of polishing technique plays a critical role in producing high-quality, durable metal products.

What is Industrial Buffing?

Industrial buffing is a crucial process in the metal finishing industry, aimed at enhancing the appearance and functional properties of metal surfaces. It involves using buffing wheels and compounds to produce smooth, reflective finishes on various metal products. This section will explore the methods, materials, applications, and advancements in industrial buffing, providing a comprehensive understanding of this essential metalworking technique.

Industrial buffing is a surface finishing process used to achieve a high-gloss, mirror-like finish on metal surfaces. It involves using buffing wheels made from cloth, felt, or other materials, along with buffing compounds, to polish and smoothen the surface of metal parts. Buffing is often the final step in the finishing process, following grinding or polishing, to achieve the desired surface quality.

Objectives of Industrial Buffing

- Enhance Aesthetic Appeal: Buffing improves the visual appearance of metal parts by creating a reflective, glossy surface.

- Improve Surface Smoothness: The process removes fine scratches and imperfections, resulting in a smooth, even surface.

- Increase Corrosion Resistance: A polished surface can help reduce the risk of corrosion by minimizing surface irregularities where moisture could accumulate.

- Prepare for Further Coating: Buffing can prepare metal surfaces for additional coatings, such as paint or plating, by ensuring a smooth base.

Buffing Methods

Industrial buffing can be performed using various methods, each tailored to specific applications and desired finishes. Below are the primary methods used in industrial buffing:

1. Manual Buffing

Manual buffing involves skilled operators using hand-held buffing tools to polish metal surfaces. This method is often used for small-scale production or intricate parts requiring precise attention to detail.

- Advantages:

- Provides greater control over the buffing process.

- Suitable for complex shapes and detailed work.

- Allows for adjustments during the process to achieve the desired finish.

- Disadvantages:

- Labor-intensive and time-consuming.

- Inconsistent results due to human error.

- Limited to small production volumes.

- Applications:

- Jewelry and decorative items.

- Small automotive components.

- Custom metalwork.

2. Automated Buffing

Automated buffing employs machines and robotic systems to buff metal surfaces, offering consistent and efficient results for large-scale production.

- Advantages:

- High-speed production and consistent quality.

- Reduces labor costs and human error.

- Capable of handling large and complex parts.

- Disadvantages:

- High initial setup and equipment costs.

- Limited flexibility for intricate parts or custom finishes.

- Applications:

- Automotive parts and assemblies.

- Household appliances and electronics.

- Aerospace components.

3. Robotic Buffing

Robotic buffing utilizes robotic arms equipped with buffing tools to perform precise and efficient buffing operations, especially for complex geometries and large parts.

- Advantages:

- High precision and repeatability.

- Reduced human labor and increased safety.

- Capable of handling intricate and large-scale parts.

- Disadvantages:

- High capital investment for robotic systems.

- Requires programming and maintenance expertise.

- Applications:

- Aerospace and automotive industries.

- Large metal structures and equipment.

- High-volume production of standardized parts.

Buffing Compounds and Materials

The choice of buffing compounds and materials significantly influences the quality and efficiency of the buffing process. Various compounds are used based on the type of metal and desired finish.

Buffing Compounds

Buffing compounds are abrasive materials mixed with binders that help achieve the desired finish on metal surfaces. They come in different formulations, each suited for specific applications.

a. Tripoli Compound

- Description: A coarse compound used for initial cutting and smoothing of metal surfaces.

- Applications: Ideal for removing scratches and surface imperfections on softer metals like aluminum and brass.

b. Rouge Compound

- Description: A fine compound used to achieve a high-gloss, mirror-like finish.

- Applications: Suitable for polishing precious metals such as gold and silver, as well as stainless steel.

c. White Diamond Compound

- Description: A versatile compound used for polishing and refining metal surfaces.

- Applications: Effective on plastics and metals, providing a bright finish and removing light scratches.

d. Green Chromium Oxide Compound

- Description: A compound containing chromium oxide, used for achieving a fine finish.

- Applications: Ideal for polishing stainless steel and other hard metals, offering a high level of smoothness and shine.

Buffing Wheels and Materials

Buffing wheels are essential tools in the buffing process, available in various materials and configurations to suit different applications.

a. Cloth Buffing Wheels

- Description: Made from cotton or flannel, cloth wheels are soft and flexible, allowing for smooth finishes.

- Applications: Commonly used for applying buffing compounds and achieving a polished finish.

b. Sisal Buffing Wheels

- Description: Made from natural fibers, sisal wheels are firm and durable, making them suitable for initial cutting and buffing stages.

- Applications: Used for aggressive cutting and removing surface imperfections before finer buffing.

c. Felt Buffing Wheels

- Description: Dense and rigid, felt wheels are used for precision buffing and achieving high-gloss finishes.

- Applications: Ideal for detailed work and achieving mirror-like finishes on metals.

Applications of Industrial Buffing

Industrial buffing is used across various industries to enhance the appearance and functionality of metal parts. Here are some key applications:

1. Automotive Industry

- Applications:

- Buffing car body panels to achieve a smooth, glossy finish.

- Polishing chrome trim and accessories for enhanced aesthetic appeal.

- Smoothing engine components and parts for improved performance.

- Benefits:

- Improves the overall appearance and marketability of vehicles.

- Enhances corrosion resistance and durability of parts.

- Prepares surfaces for additional coatings or treatments.

2. Aerospace Industry

- Applications:

- Buffing aircraft components for improved aerodynamics and aesthetics.

- Polishing turbine blades and engine parts for enhanced performance.

- Smoothing fuselage and wing surfaces for reduced drag.

- Benefits:

- Increases the efficiency and reliability of aerospace components.

- Enhances safety and performance of aircraft.

- Meets stringent industry standards for quality and precision.

3. Jewelry and Decorative Products

- Applications:

- Buffing gold, silver, and platinum jewelry to achieve a high-gloss finish.

- Polishing decorative metal items such as sculptures and ornaments.

- Enhancing the appearance of metal art pieces and custom creations.

- Benefits:

- Improves the aesthetic appeal and value of jewelry and decorative items.

- Provides a luxurious and professional finish to products.

- Enhances the durability and wear resistance of metal pieces.

4. Electronics and Appliances

- Applications:

- Buffing metal casings and components for electronics and appliances.

- Polishing stainless steel surfaces for enhanced appearance and cleanliness.

- Smoothing metal parts for improved functionality and aesthetics.

- Benefits:

- Enhances the visual appeal and marketability of products.

- Improves the performance and longevity of electronic devices.

- Provides a polished and professional finish to consumer goods.

Advancements in Industrial Buffing

The field of industrial buffing has seen significant advancements in recent years, driven by technological innovations and industry demands for improved efficiency and quality. Here are some notable advancements:

1. Automation and Robotics

The integration of automation and robotics in industrial buffing processes has revolutionized the industry, offering improved precision, efficiency, and consistency.

- Benefits:

- Reduces labor costs and human error.

- Increases production speed and throughput.

- Provides consistent and repeatable results.

- Applications:

- Automated buffing systems for automotive and aerospace components.

- Robotic buffing for large and complex parts in various industries.

- Intelligent systems with adaptive control for customized finishes.

2. Innovative Materials and Compounds

Advancements in buffing materials and compounds have led to improved performance and environmental sustainability.

- Innovative Materials:

- Eco-Friendly Compounds: Formulations that reduce environmental impact and improve safety.

- Advanced Abrasives: Developments in abrasive materials enhance cutting and polishing efficiency.

- Applications:

- High-performance compounds for demanding industrial applications.

- Environmentally friendly solutions for sustainable manufacturing practices.

- Custom formulations for specific metals and finishes.

3. Industry 4.0 and Smart Technologies

Industry 4.0 is reshaping industrial buffing through the integration of smart technologies and data-driven approaches.

- Key Aspects:

- IoT Connectivity: Enables real-time monitoring and control of buffing processes.

- Data Analytics: Provides insights into process optimization and quality control.

- AI and Machine Learning: Enhances decision-making and process automation.

- Applications:

- Smart buffing systems for adaptive process control and optimization.

- Predictive maintenance and quality assurance through data-driven insights.

- Integration of IoT and AI for intelligent manufacturing solutions.

Challenges and Solutions in Industrial Buffing

Despite its advantages, industrial buffing also presents certain challenges that need to be addressed for optimal performance and quality. Here are some common challenges and their solutions:

1. Surface Uniformity

- Challenge: Achieving consistent finishes across complex geometries and large surfaces can be difficult, leading to variations in surface quality.

- Solution: Implementing automated and robotic systems ensures uniform pressure and consistent results, reducing variations in surface quality.

2. Material Compatibility

- Challenge: Different metals have varying properties, such as hardness and corrosion resistance, that affect their compatibility with specific buffing methods and materials.

- Solution: Selecting appropriate buffing compounds and materials for each metal type ensures optimal performance and finish quality.

3. Cost and Efficiency

- Challenge: Balancing cost and efficiency in high-volume production while maintaining quality can be challenging, especially with manual buffing processes.

- Solution: Investing in automated and robotic systems reduces labor costs and increases efficiency, allowing for cost-effective production without compromising quality.

4. Environmental and Safety Concerns

- Challenge: Managing waste and emissions from buffing processes, as well as ensuring operator safety, can be challenging, especially with chemical compounds and dust generation.

- Solution: Implementing effective ventilation and filtration systems, as well as using eco-friendly compounds, minimizes environmental impact and enhances safety.

Best Practices for Industrial Buffing

To achieve optimal results in industrial buffing, it is essential to follow best practices that ensure quality, efficiency, and safety. Here are some key best practices:

1. Quality Control and Inspection

Implementing robust quality control and inspection processes ensures the consistency and reliability of buffing results.

- Visual Inspection: Identifying surface defects and irregularities to ensure uniform finishes.

- Surface Roughness Testing: Assessing surface smoothness and texture to meet quality standards.

- Dimensional Inspection: Measuring critical dimensions and tolerances to ensure precision.

2. Process Optimization

Optimizing buffing processes enhances efficiency and reduces costs, ensuring high-quality results.

- Lean Manufacturing: Minimizing waste and improving workflow for efficient production.

- Continuous Improvement: Implementing feedback loops for process refinement and optimization.

- Process Automation: Utilizing technology for increased efficiency and precision.

3. Safety Measures and Precautions

Ensuring safety in industrial buffing operations is paramount to protect workers and the environment.

- Personal Protective Equipment (PPE): Providing gloves, masks, goggles, and protective clothing to ensure operator safety.

- Ventilation and Filtration: Implementing effective air quality management systems to reduce dust and fumes.

- Training and Education: Offering ongoing training programs for workers to ensure safe practices and awareness.

4. Maintenance and Upkeep

Regular maintenance and upkeep of buffing equipment and systems ensure optimal performance and longevity.

- Routine Inspections: Conducting regular inspections and maintenance to identify and address equipment issues.

- Cleaning and Lubrication: Keeping buffing tools and equipment clean and lubricated for smooth operation.

- Calibration and Adjustments: Ensuring equipment is calibrated and adjusted for precise and consistent results.

Conclusion

Industrial buffing is a vital process in the metalworking industry, offering numerous benefits in terms of appearance, functionality, and durability. By understanding the methods, materials, applications, and advancements in buffing, manufacturers can achieve high-quality finishes and meet the evolving demands of the market. Whether through manual, automated, or robotic methods, the choice of buffing technique plays a critical role in producing superior metal products. By adhering to best practices and addressing challenges, the industry can continue to innovate and improve the efficiency and quality of industrial buffing operations.

Types of Deburring Machines

A deburring machine is an essential tool in metal fabrication, designed to remove burrs and other imperfections from metal parts. Burrs are unwanted projections of material that often occur during machining, cutting, or stamping processes. These imperfections can negatively affect the performance, safety, and appearance of metal parts, making deburring an important step in the manufacturing process.

Below, we’ll explore the various types of deburring machines, their working principles, applications, advantages, and considerations for selecting the right machine for your needs.

Deburring machines come in various types, each suited for specific applications and materials. Here are some of the most common types of deburring machines used in the industry:

1. Vibratory Deburring Machines

Description

Vibratory deburring machines use a vibrating bowl filled with abrasive media and parts to remove burrs. The vibrations cause the media to rub against the parts, effectively deburring and polishing them.

Working Principle

- Parts and abrasive media are placed inside a vibrating chamber.

- The vibrations cause the media to move in a circular motion, rubbing against the parts.

- The abrasive action of the media removes burrs and smooths the surface of the parts.

Applications

- Suitable for small to medium-sized parts.

- Ideal for batch processing of components.

- Used in industries such as automotive, aerospace, and electronics.

Advantages

- Effective for complex shapes and geometries.

- Can process multiple parts simultaneously.

- Provides a consistent and uniform finish.

Disadvantages

- Limited to smaller parts and components.

- May require longer processing times for heavy burrs.

2. Centrifugal Disc Deburring Machines

Description

Centrifugal disc deburring machines use a rotating disc to generate high-speed motion, creating a sliding movement of abrasive media against the parts.

Working Principle

- Parts and abrasive media are placed in a stationary container with a rotating disc at the bottom.

- The rotation creates a centrifugal force that causes the media to slide against the parts.

- The abrasive action removes burrs and smooths the surfaces.

Applications

- Suitable for small to medium-sized parts with intricate shapes.

- Used in industries such as jewelry, electronics, and precision engineering.

Advantages

- Provides fast and efficient deburring.

- Produces smooth and polished finishes.

- Suitable for delicate and intricate parts.

Disadvantages

- Limited to smaller parts and components.

- May not be suitable for large or heavy parts.

3. Tumbling Deburring Machines

Description

Tumbling deburring machines use a rotating barrel filled with abrasive media and parts. The rotation causes the media to tumble against the parts, removing burrs and smoothing surfaces.

Working Principle

- Parts and abrasive media are placed in a rotating barrel or drum.

- The rotation causes the media and parts to tumble against each other.

- The abrasive action of the media removes burrs and polishes the surfaces.

Applications

- Suitable for small to medium-sized parts.

- Commonly used in industries such as automotive, aerospace, and consumer goods.

Advantages

- Cost-effective and simple to operate.

- Capable of processing large batches of parts.

- Provides consistent and uniform finishes.

Disadvantages

- Limited to smaller parts and components.

- May require longer processing times for heavy burrs.

4. Magnetic Deburring Machines

Description

Magnetic deburring machines use magnetic fields to agitate small steel pins or media, which in turn deburr and polish the surfaces of metal parts.

Working Principle

- Parts are placed in a chamber with small steel pins or media.

- Magnetic fields agitate the pins, causing them to move and interact with the parts.

- The mechanical action of the pins removes burrs and polishes surfaces.

Applications

- Suitable for small, delicate, and intricate parts.

- Commonly used in industries such as electronics, medical devices, and jewelry.

Advantages

- Gentle and precise deburring.

- Suitable for intricate and delicate parts.

- Can access hard-to-reach areas.

Disadvantages

- Limited to small parts and components.

- May require additional equipment for larger parts.

5. Brush Deburring Machines

Description

Brush deburring machines use rotating brushes made from abrasive materials to remove burrs and smooth surfaces.

Working Principle

- Parts are fed through the machine where rotating brushes make contact with the surfaces.

- The abrasive action of the brushes removes burrs and smooths the surfaces.

Applications

- Suitable for flat surfaces and edges.

- Used in industries such as automotive, aerospace, and metal fabrication.

Advantages

- Effective for flat surfaces and edges.

- Provides consistent and uniform finishes.

- Can be integrated into production lines.

Disadvantages

- Limited to flat surfaces and edges.

- May not be suitable for complex shapes or intricate parts.

6. Thermal Deburring Machines

Description

Thermal deburring machines use controlled explosions of gas to burn away burrs from metal parts.

Working Principle

- Parts are placed in a chamber filled with a mixture of gases.

- The gases are ignited, creating a controlled explosion that burns away burrs.

Applications

- Suitable for complex and intricate parts.

- Commonly used in industries such as automotive, aerospace, and precision engineering.

Advantages

- Effective for hard-to-reach areas and complex shapes.

- Provides a clean and burr-free finish.

- Fast and efficient process.

Disadvantages

- High initial setup and operational costs.

- Limited to specific materials and applications.

7. Electrochemical Deburring Machines

Description

Electrochemical deburring machines use electrolytic solutions to dissolve burrs from metal parts.

Working Principle

- Parts are submerged in an electrolytic bath with an electric current applied.

- The current causes the burrs to dissolve, leaving a smooth surface.

Applications

- Suitable for precision and intricate parts.

- Used in industries such as aerospace, medical devices, and electronics.

Advantages

- Precise and controlled deburring.

- Minimal tool wear and surface damage.

- Suitable for intricate and delicate parts.

Disadvantages

- Requires careful handling of chemicals.

- High operational costs.

Selecting the Right Deburring Machine

Choosing the right deburring machine involves considering several factors, including the type of metal, the size and complexity of the parts, and the desired finish. Here are some key considerations for selecting the right deburring machine:

1. Type of Metal

Different metals have varying properties that affect their deburring requirements. Consider the hardness, ductility, and conductivity of the metal when selecting a deburring machine.

2. Size and Complexity of Parts

The size and complexity of the parts influence the choice of deburring machine. Consider the geometry, size, and intricacy of the parts to determine the most suitable machine.

3. Desired Finish

The desired finish and surface quality of the parts play a crucial role in selecting the right deburring machine. Consider the level of smoothness, precision, and appearance required for the finished parts.

4. Production Volume

The scale of production impacts the choice of deburring machine. Consider the production volume and batch size to determine whether manual or automated machines are more suitable.

5. Cost and Efficiency

Evaluate the overall cost and efficiency of the deburring process, including equipment, labor, and materials, to determine the most cost-effective solution without compromising quality.

6. Environmental and Safety Considerations

Consider the environmental impact and safety of the deburring process, including waste management and operator safety, when selecting a machine. Some machines may require special handling and disposal procedures for chemicals or emissions.

Advantages of Deburring Machines

Deburring machines offer several advantages over manual deburring methods, making them essential tools in modern manufacturing processes. Here are some key advantages of using deburring machines:

1. Improved Efficiency and Productivity

Deburring machines automate the deburring process, significantly reducing the time and labor required compared to manual methods. This results in increased efficiency and productivity in manufacturing operations.

2. Consistent and Uniform Finishes

Deburring machines provide consistent and uniform finishes across batches, ensuring high-quality results with minimal variations in surface quality. This is particularly important for precision parts and components.

3. Reduced Labor Costs

Automated deburring machines reduce the need for manual labor, leading to lower labor costs and improved resource allocation in manufacturing operations.

4. Enhanced Safety

Deburring machines reduce the risk of operator injuries associated with manual deburring processes, such as cuts and abrasions. Additionally, automated machines minimize the exposure to hazardous materials and chemicals.

5. Versatility and Flexibility

Deburring machines offer versatility and flexibility in handling a wide range of parts and materials, making them suitable for various industries and applications.

6. Precision and Accuracy

Deburring machines provide precise and accurate deburring, ensuring high-quality finishes with minimal surface damage or tool wear.

Challenges and Solutions in Deburring

Despite their advantages, deburring machines also present certain challenges that need to be addressed for optimal performance and quality. Here are some common challenges and their solutions:

1. Material Compatibility

Challenge: Different materials require specific deburring techniques, which can impact the selection of deburring machines and abrasive media.

Solution: Select appropriate deburring machines and materials for each metal type to ensure optimal performance and finish quality.

2. Surface Uniformity

Challenge: Achieving consistent finishes across complex geometries and large surfaces can be difficult, leading to variations in surface quality.

Solution: Implement automated and robotic systems to ensure uniform pressure and consistent results, reducing variations in surface quality.

3. Cost and Efficiency

Challenge: Balancing cost and efficiency in high-volume production while maintaining quality can be challenging, especially with manual deburring processes.

Solution: Invest in automated and robotic systems to reduce labor costs and increase efficiency, allowing for cost-effective production without compromising quality.

4. Environmental and Safety Concerns

Challenge: Managing waste and emissions from deburring processes, as well as ensuring operator safety, can be challenging, especially with chemical compounds and dust generation.

Solution: Implement effective ventilation and filtration systems, as well as use eco-friendly compounds, to minimize environmental impact and enhance safety.

Best Practices for Using Deburring Machines

To achieve optimal results in deburring, it is essential to follow best practices that ensure quality, efficiency, and safety. Here are some key best practices for using deburring machines:

1. Quality Control and Inspection

Implement robust quality control and inspection processes to ensure the consistency and reliability of deburring results.

- Visual Inspection: Identify surface defects and irregularities to ensure uniform finishes.