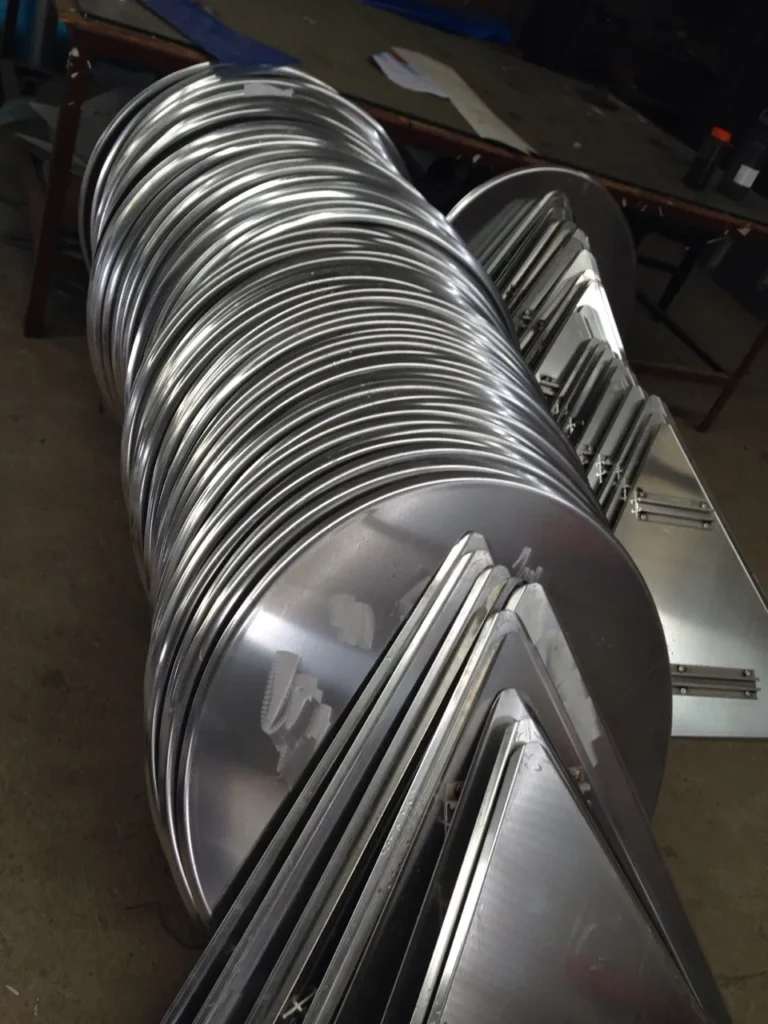

The Road Sign Trimming Beading Machine is used for trimming beading cutting and curling round sheet metal parts. It is also used for square and rectangular-shaped objects.

Multi-head hydraulic or pneumatic trimming, curling, and beading machine is a new type of shear type trimming curling and beading machine. It can also be used for square objects as well as round parts.

A Trimming beading machine is a vital machine used to trim and bead the edges of the parts after deep drawing. The road sign trimming beading machine is a must-have for any business that specializes in making road signs. A Trimming beading machine is a vital machine used to trim and bead the edges of the parts after deep drawing.

The Design of the Road Sign Trimming Beading Machine

It is designed to efficiently trim and bend metal sheets into the desired shape for road signs. It also has the capability to bead the edges of the metal for added strength and durability. With its advanced features, it makes the process of making road signs easier and faster than ever before.

Road sign trimming beading machines are becoming increasingly popular as a way to produce road signs quickly and accurately. These machines help to reduce the time spent on making road signs by automating the trimming and beading process. With this machine, you can easily produce different types of road signs such as warning, speed limit, no parking, etc. They are also able to provide more consistent results than manual methods, resulting in better-quality signs.

Road sign trimming bench beading machine also helps to ensure accuracy in the final product, reducing errors that could lead to costly re-work or even safety issues. With its many advantages, it is no wonder that the use of a trimming and beading machine is becoming increasingly commonplace in the road sign-making industry.

As EMS-Metalworking, we can both manufacture road sign trimming beading machines and sell used trimming beading machines. We have also after-sales service. In the customer’s factory or in our factory, we can provide road striping training.

Road Sign Trimming Beading Machine

A road sign trimming and beading machine is a specialized piece of equipment used in the manufacturing and fabrication of road signs. These machines are designed to trim the edges of road sign blanks to the required shape and to add a beaded edge for improved rigidity and safety. Here are key details about road sign trimming and beading machines:

1. Trimming Function:

- The primary function of these machines is to trim the edges of road sign blanks to the desired shape. Road signs come in various shapes and sizes, and the machine’s cutting tool can be adjusted to match the specific sign design.

2. Beading Function:

- In addition to trimming, these machines are equipped with a beading function. Beading involves adding a raised, rounded edge (bead) to the perimeter of the sign.

- The bead provides reinforcement to the sign, making it more rigid and less prone to bending or warping.

3. Material Compatibility:

- Road sign trimming and beading machines are designed to work with a range of materials commonly used for road signs, including aluminum, aluminum composite, and other metals.

- The machine’s settings and tooling must be appropriate for the material being processed.

4. Tooling:

- These machines use specialized cutting tools for trimming and beading. The cutting tools can be customized to achieve specific edge profiles and bead shapes.

- Proper tool maintenance and sharpening are essential for achieving clean and accurate cuts.

5. Feed System:

- Road sign blanks are typically fed into the machine manually or using an automated feed system, depending on the machine’s design.

- Automated feed systems can improve efficiency and reduce operator fatigue.

6. Controls:

- The machine’s controls allow operators to adjust settings such as cutting depth, feed rate, and bead size to achieve the desired results.

- Some advanced models may feature digital controls for precise adjustments.

7. Safety Features:

- Safety features are important to protect operators during machine operation. These may include emergency stop buttons, safety interlocks, and guarding to prevent accidental contact with moving parts.

8. Production Speed:

- Production speed depends on the machine’s design and capabilities. High-capacity models are capable of processing a large number of sign blanks per hour.

9. Application:

- Road sign trimming and beading machines are used by manufacturers of road signs, traffic control equipment, and related products to ensure that signs meet regulatory standards and are durable for outdoor use.

10. Footprint: – The size and footprint of these machines can vary, so consideration of available workspace is essential when selecting a machine for a manufacturing facility.

Road sign trimming and beading machines play a critical role in the production of road signs, ensuring that they meet safety and durability requirements. When choosing such a machine, it’s important to consider the specific sign designs and materials you’ll be working with, as well as the production volume and available workspace. Proper training and maintenance are also crucial to ensure the machine’s performance and safety.

Trimming beading machines are specialized equipment used in various industries to trim and bead the edges of metal sheets and components. These machines are essential in the manufacturing process, providing precision, efficiency, and consistency in the finishing of metal products. Trimming involves removing excess material from the edges of metal sheets, while beading adds a raised or recessed profile to the edges, enhancing the structural integrity and aesthetic appeal of the final product. This document explores the different types of trimming beading machines, their components, operational principles, application areas, manufacturing processes, challenges, and future trends in the industry.

Types of Trimming Beading Machines

Trimming beading machines come in various designs, each suited to specific applications and levels of automation. The primary types include manual, semi-automatic, fully automatic, and CNC trimming beading machines.

Manual trimming beading machines are operated by hand and are suitable for small-scale or low-volume production. They are simple, cost-effective, and ideal for workshops and small manufacturing units.

Semi-automatic trimming beading machines combine manual operation with automated functions to increase efficiency and consistency. They require some level of operator intervention but can handle higher production volumes than manual machines.

Fully automatic trimming beading machines are designed for high-volume production and minimal operator intervention. These machines use advanced control systems and automation technologies to perform trimming and beading operations with high precision and speed.

CNC (Computer Numerical Control) trimming beading machines represent the most advanced type, offering unparalleled precision and flexibility. These machines are programmed using computer software, allowing for complex trimming and beading patterns with minimal manual input.

Components of Trimming Beading Machines

Trimming beading machines consist of several key components that work together to perform the trimming and beading operations. These components include the frame and base, cutting tools, beading tools, motors and drives, control systems, and safety features.

The frame and base provide structural support and stability for the machine. They are typically made from high-strength steel or aluminum to withstand the forces generated during operation.

Cutting tools are used to trim the excess material from the edges of metal sheets. These tools can be various types of blades or shears, depending on the specific application and material being processed.

Beading tools create the desired raised or recessed profiles on the edges of the metal sheets. These tools can be rollers, dies, or specialized beading heads designed to produce specific bead shapes.

Motors and drives power the cutting and beading tools, providing the necessary force and motion to perform the operations. They are typically electric motors, but pneumatic or hydraulic drives can also be used in certain applications.

Control systems regulate the operation of the trimming beading machine, ensuring precise and consistent performance. These systems can range from simple manual controls to advanced computer numerical control (CNC) systems.

Safety features are essential components of trimming beading machines, protecting operators from potential hazards. These features can include emergency stop buttons, safety guards, and sensors that detect and prevent unsafe operating conditions.

How Trimming Beading Machines Work

Trimming beading machines operate based on principles of cutting and forming metal sheets. The trimming process involves removing excess material from the edges of the metal sheets using cutting tools. The beading process adds raised or recessed profiles to the edges, enhancing the structural integrity and aesthetic appeal of the final product.

The trimming process begins with the metal sheet being fed into the machine. The cutting tools, driven by motors and guided by control systems, trim the excess material from the edges. The trimmed edges are then passed through the beading tools, which create the desired bead profiles.

Control mechanisms ensure precise and consistent performance of the trimming and beading operations. In manual and semi-automatic machines, operators guide the material and adjust the settings as needed. In fully automatic and CNC machines, advanced control systems and sensors regulate the entire process, allowing for high precision and repeatability.

Application Areas

Trimming beading machines are used in various industries, thanks to their ability to enhance the quality and durability of metal products. Key application areas include:

Automotive industry: In the automotive sector, trimming beading machines are used to manufacture components such as body panels, chassis parts, and trim pieces. The machines ensure precise dimensions and smooth edges, contributing to the overall quality and safety of vehicles.

Aerospace industry: The aerospace industry relies on trimming beading machines to produce high-precision components for aircraft and spacecraft. The machines help create parts that meet stringent quality and safety standards.

HVAC (Heating, Ventilation, and Air Conditioning): Trimming beading machines are used to manufacture ductwork, fittings, and other components for HVAC systems. The machines ensure smooth edges and precise dimensions, which are crucial for efficient airflow and system performance.

Metalworking and fabrication: In metalworking and fabrication, trimming beading machines are used to finish a wide range of metal products, including enclosures, brackets, and structural components. The machines enhance the quality and appearance of the finished products.

Consumer goods manufacturing: Trimming beading machines are used in the production of consumer goods such as appliances, furniture, and decorative items. The machines ensure smooth edges and aesthetically pleasing finishes, enhancing the overall quality of the products.

Manufacturing of Trimming Beading Machines

The manufacturing of trimming beading machines involves several stages, from design and engineering to assembly and quality control.

Design and engineering: The process begins with the design and engineering phase, where specifications for the trimming beading machine are developed based on the intended application. This includes selecting suitable materials, determining the required force and speed, and designing the machine’s structure and components.

Material selection: High-quality materials, such as hardened steel for cutting and beading tools and durable alloys for the machine frame, are selected to ensure longevity and performance.

Fabrication of components: The individual components of the trimming beading machine, including the frame, cutting tools, beading tools, motors, and control systems, are fabricated using precision machining and manufacturing techniques.

Assembly process: The fabricated components are then assembled into the complete trimming beading machine. This involves mounting the components onto the machine frame, connecting the power and control systems, and installing the necessary safety features.

Quality control and testing: Rigorous quality control measures are implemented throughout the manufacturing process to ensure the trimming beading machine meets all specifications and standards. This includes performance testing, verifying the accuracy of the control systems, and conducting operational tests to ensure the machine functions correctly.

Advancements and Innovations

The trimming beading machine industry is continually evolving, driven by advancements in technology and increasing demands for efficiency and precision. Key innovations include automation and robotics, CNC technology, energy efficiency improvements, and smart trimming beading machines.

Automation and robotics: Modern trimming beading machines are often equipped with advanced control systems and robotics that automate the trimming and beading processes. This includes programmable logic controllers (PLCs), human-machine interfaces (HMIs), and robotic arms that handle the metal sheets. Automation improves efficiency, reduces the risk of human error, and enhances the consistency of the finished products.

CNC technology: The integration of CNC technology into trimming beading machines allows for unparalleled precision and flexibility. CNC machines can be programmed to perform complex trimming and beading patterns with minimal manual input, making them ideal for high-precision and high-volume production.

Energy efficiency improvements: Manufacturers are focusing on developing trimming beading machines that consume less energy and have a smaller environmental footprint. This includes using energy-efficient motors, optimizing the machine’s design to minimize energy losses, and incorporating energy recovery systems.

Smart trimming beading machines: The integration of IoT (Internet of Things) technology into trimming beading machines has led to the development of smart machines. These machines can communicate with other equipment and systems, providing real-time data on their status, performance, and maintenance needs. This connectivity allows for predictive maintenance, reducing downtime and extending the machine’s lifespan.

Challenges in Manufacturing Trimming Beading Machines

The manufacturing of trimming beading machines presents several challenges, including precision and quality requirements, cost management, technological advancements, and environmental considerations.

Precision and quality requirements: Trimming beading machines must deliver consistent and precise results, which requires high levels of accuracy in the manufacturing process. Ensuring each component meets the required tolerances and specifications is critical to the machine’s performance and reliability.

Cost management: The cost of materials, labor, and energy can significantly impact the overall cost of manufacturing trimming beading machines. Manufacturers must balance quality and cost to remain competitive in the market.

Technological advancements: Keeping up with technological advancements is essential for manufacturers to meet the evolving demands of the industry. This requires continuous investment in research and development to incorporate new technologies and improve existing designs.

Environmental considerations: Environmental regulations and sustainability concerns are increasingly important in trimming beading machine manufacturing. Manufacturers must develop eco-friendly machines that consume less energy, use recyclable materials, and minimize their environmental impact.

Conclusion

Trimming beading machines are essential tools in various industries, providing the necessary processes to enhance the quality and durability of metal products. Understanding the different types of trimming beading machines, their components, and how they work is crucial for effective application and operation.

The manufacturing process of trimming beading machines involves careful design and engineering, material selection, precision fabrication, and rigorous quality control. Despite the challenges, advancements in technology and innovations are driving the industry forward, leading to more efficient, precise, and environmentally friendly trimming beading machines.

As industries continue to evolve, the trimming beading machine industry must adapt and innovate to meet the demands of efficiency, precision, and sustainability. Through continuous research and development, manufacturers can enhance the performance and reliability of trimming beading machines, contributing to the success of various industrial applications.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching