A friction press for pots and pans typically refers to a type of machinery or equipment used in the manufacturing process of cookware like pots, pans, and other kitchen utensils. These presses are used to form and shape metal sheets into the desired cookware shapes and sizes. Here’s an overview of how a friction press can be used in the production of pots and pans:

Friction Press for Pots and Pans

- Materials Preparation: The manufacturing process begins with the preparation of the raw materials, which are typically metal sheets. These sheets are often made from materials like stainless steel, aluminum, or cast iron, depending on the desired properties of the cookware.

- Cutting and Blanking: The metal sheets are cut into the appropriate size and shape, a process known as blanking. This step creates the initial flat blanks that will be formed into pots and pans.

- Forming: The friction press is used to shape the flat metal blanks into the desired pot or pan shape. The forming process involves applying pressure to the metal using specialized dies and molds. These dies are placed in the press, and the blanks are positioned between them.

- Friction Press Operation: When the press is in operation, the upper and lower dies come together under pressure. The friction press generates the necessary force to deform the metal sheet into the desired shape. The force applied by the press is controlled to ensure precise shaping and consistent quality.

- Cooling and Tempering: After forming, the newly shaped pots and pans may undergo processes such as cooling and tempering to relieve internal stresses and enhance their durability.

- Finishing: Cookware is typically finished with processes like polishing, surface treatment (e.g., non-stick coatings for pans), and branding. These steps give the cookware its final appearance and functionality.

- Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the pots and pans meet the desired specifications, including size, shape, thickness, and finish.

- Packaging and Distribution: Once the pots and pans pass quality control, they are packaged and prepared for distribution to retailers or customers.

Friction presses used in the production of pots and pans are designed to provide precise control over the forming process, ensuring that each piece of cookware is consistent in shape and quality. The choice of materials, press settings, and the design of the dies play a crucial role in determining the final characteristics of the cookware.

These manufacturing processes are typically carried out in specialized factories or facilities equipped with the necessary machinery and skilled operators to produce high-quality pots and pans for consumer use.

Hot forging is a crucial process in the manufacturing industry, used to form and shape metals under high temperatures. One of the key machines in this process is the friction screw press. This piece of equipment is valued for its ability to apply precise and controlled pressure, making it indispensable in producing high-quality forged components. This article will delve into the intricacies of friction screw press hot forging, exploring its components, working principles, advantages, and applications in various industries.

What is Hot Forging?

Hot forging involves shaping metals at high temperatures, typically above their recrystallization point. This process enhances the metal’s ductility, making it easier to form complex shapes without cracking. The benefits of hot forging include improved mechanical properties, refined grain structure, and the ability to produce large and intricate components.

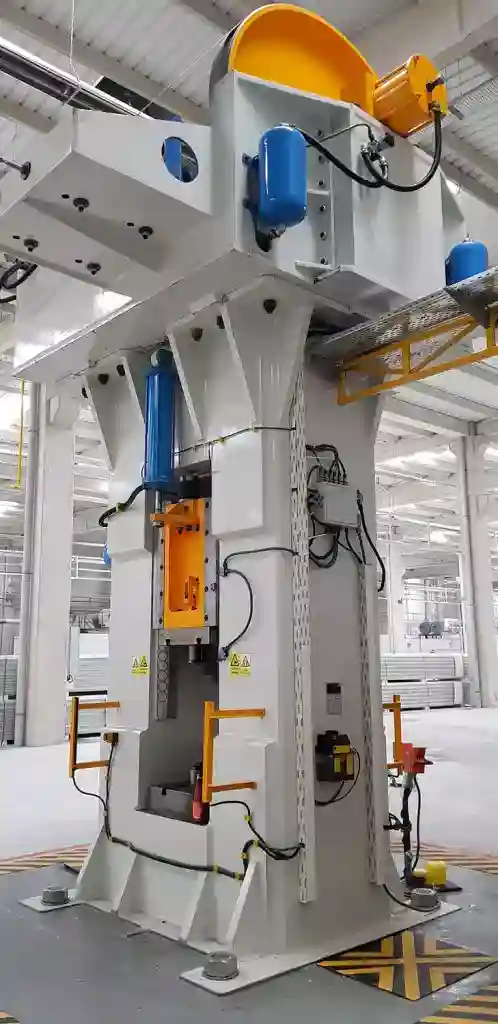

Friction Press: An Overview

A friction screw press, also known as a screw press, is a type of machine used extensively in hot forging. Its operation relies on a screw mechanism driven by a flywheel and friction clutch. The design and technology of friction screw presses have evolved significantly over the years, incorporating advancements that enhance their efficiency and precision.

Components of a Friction Screw Press

- Main Frame: The robust structure that supports all other components.

- Flywheel and Clutch: These control the rotational motion, converting it into linear force.

- Screw Mechanism: The core component that translates rotational energy into pressing force.

- Ram and Die Assembly: These parts directly interact with the workpiece to shape it.

- Control Systems: Modern presses include computerized controls for precision and safety.

How Friction Screw Press Works

The operation of a friction screw press can be broken down into several steps:

- Initial Setup: The workpiece is placed in the die.

- Engagement: The flywheel accelerates, and the clutch engages, transferring energy to the screw.

- Pressing: The screw drives the ram downward, applying force to shape the workpiece.

- Release: The clutch disengages, allowing the ram to return to its starting position.

- Final Product: The forged component is removed and inspected.

Advantages of Using Friction Screw Press for Hot Forging

- Precision and Control: The press provides accurate force application, essential for high-quality forging.

- Energy Efficiency: The design allows for efficient energy use, reducing operational costs.

- Versatility in Application: Suitable for a wide range of metals and component sizes.

- Durability and Maintenance: Built to withstand heavy-duty operations with minimal maintenance requirements.

Applications of Friction Screw Press Hot Forging

- Automotive Industry: Used in the production of engine components, gears, and axles.

- Aerospace Industry: Essential for creating high-strength, lightweight components.

- Construction and Heavy Machinery: Produces durable parts for heavy-duty applications.

- Other Industrial Applications: Applicable in the manufacturing of tools, agricultural equipment, and more.

Safety Considerations

Operating a friction screw press involves several safety risks. It’s crucial to adhere to strict safety protocols:

- Training: Operators must be adequately trained.

- Protective Equipment: Use of appropriate personal protective equipment (PPE).

- Regular Maintenance: Ensures the machinery operates safely.

- Emergency Procedures: Clear guidelines for handling emergencies.

Future Trends and Innovations

The future of friction screw press hot forging looks promising with ongoing technological advancements:

- Automation and AI: Integration of automated systems and artificial intelligence for enhanced precision.

- Eco-Friendly Technologies: Development of more energy-efficient and environmentally friendly processes.

- Material Innovations: Exploration of new materials that can be forged using friction screw presses.

Conclusion

Friction screw press hot forging is a pivotal process in modern manufacturing, offering numerous benefits in terms of precision, efficiency, and versatility. Its applications span various industries, contributing significantly to advancements in technology and industrial capabilities. As the industry continues to innovate, the role of friction screw presses in hot forging will remain vital, driving progress and setting new standards in manufacturing excellence.

Friction Press for Pots and Pans

Friction presses play a crucial role in the manufacturing of various metal products, including pots and pans. These machines offer precision, efficiency, and control, making them ideal for producing high-quality cookware. This article explores the use of friction presses in the manufacturing process of pots and pans, detailing their operation, advantages, and impact on the industry.

What is a Friction Press?

A friction press, also known as a screw press, is a type of mechanical press that utilizes a flywheel and a screw mechanism to apply pressure. This design allows for precise control over the force and speed of the pressing process, making it suitable for a wide range of forging applications, including the production of cookware.

Components of a Friction Press

- Main Frame: Provides structural support and stability.

- Flywheel and Clutch: Control the rotational motion and convert it into linear force.

- Screw Mechanism: Translates rotational energy into pressing force.

- Ram and Die Assembly: Interact with the workpiece to shape it.

- Control Systems: Ensure precision and safety during operation.

How Friction Presses are Used in Cookware Manufacturing

- Material Preparation: The raw material, usually a metal sheet, is cut to size.

- Heating: The metal sheet is heated to the appropriate forging temperature.

- Positioning: The heated metal sheet is placed in the die of the friction press.

- Pressing: The press applies force to shape the metal into the desired form of a pot or pan.

- Cooling and Finishing: The shaped cookware is cooled and undergoes finishing processes such as trimming and polishing.

Advantages of Using Friction Presses for Pots and Pans

- Precision and Control: Enables the production of high-quality cookware with consistent thickness and shape.

- Efficiency: The process is fast and can be automated, reducing production time.

- Versatility: Suitable for different types of metals and a variety of cookware designs.

- Durability: Friction presses are robust and can handle heavy-duty operations with minimal maintenance.

Applications in the Cookware Industry

Friction presses are used to manufacture various types of cookware, including:

- Pots: Different sizes and shapes for cooking.

- Pans: Frying pans, sauté pans, and more.

- Lids: Precisely fitting lids for pots and pans.

Safety Considerations

Operating friction presses involves several safety risks. It is crucial to adhere to strict safety protocols, including:

- Training: Operators must be adequately trained.

- Protective Equipment: Use of appropriate personal protective equipment (PPE).

- Regular Maintenance: Ensures the machinery operates safely.

- Emergency Procedures: Clear guidelines for handling emergencies.

Future Trends and Innovations

The future of friction presses in cookware manufacturing looks promising with ongoing technological advancements:

- Automation and AI: Integration of automated systems and artificial intelligence for enhanced precision.

- Eco-Friendly Technologies: Development of more energy-efficient and environmentally friendly processes.

- Material Innovations: Exploration of new materials that can be forged using friction presses.

Conclusion

Friction presses are essential in the manufacturing of high-quality cookware. Their precision, efficiency, and versatility make them ideal for producing pots, pans, and other kitchen essentials. As technology continues to advance, the role of friction presses in cookware manufacturing will remain vital, driving innovation and setting new standards in the industry.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching