Here you may find some brief information about Deep Drawing Applications and industries where deep drawing is applied. Free Consultation

Deep Drawing

Deep drawing is a metal-forming process that is commonly used in the manufacturing of various products. Some common applications of deep drawing include:

- Automotive parts: Deep drawing is used to manufacture various automotive components such as fuel tanks, exhaust systems, and suspension components.

- Kitchenware: Deep drawing is commonly used to manufacture pots, pans, and other kitchenware items from stainless steel, aluminum, and other metals.

- Aerospace industry: Deep drawing is used in the manufacturing of various aerospace components such as fuel tanks, rocket casings, and engine components.

- Electronics industry: Deep drawing is used in the manufacturing of various electronic components such as heat sinks, computer casings, and mobile phone casings.

- Medical industry: Deep drawing is used in the manufacturing of various medical devices such as syringe bodies, catheter components, and implantable devices.

- Packaging industry: Deep drawing is used in the manufacturing of various packaging components such as cans, containers, and bottles.

- Defense industry: Deep drawing is used in the manufacturing of various defense components such as ammunition casings, shell casings, and missile components.

Overall, deep drawing is a versatile metal-forming process that can be used in a wide range of applications across various industries. Its ability to form complex shapes and tight tolerances makes it an ideal choice for many manufacturing applications.

Deep Drawing Automotive Parts

Deep drawing is widely used in the automotive industry for the production of various components such as fuel tanks, exhaust systems, engine components, and suspension components. Some examples of automotive parts that are produced using deep drawing include:

- Fuel tanks: Deep drawing is commonly used in the production of fuel tanks for automobiles, motorcycles, and other vehicles. The process allows for the production of complex shapes and sizes, which is critical for accommodating the various space constraints within vehicles.

- Exhaust systems: Deep drawing is used in the manufacturing of exhaust systems for automobiles and other vehicles. The process allows for the production of various exhaust components such as mufflers, resonators, and catalytic converters.

- Engine components: Deep drawing is used in the production of various engine components such as cylinder heads, engine blocks, and crankshafts. The process allows for the production of components with high accuracy and tight tolerances, which is critical for engine performance and efficiency.

- Suspension components: Deep drawing is used in the production of various suspension components such as shock absorber housings and strut towers. The process allows for the production of components with high strength and durability, which is critical for vehicle safety and performance.

Overall, deep drawing is an essential metal forming process in the automotive industry, allowing for the production of various complex components with high accuracy and tight tolerances. The ability to produce these components efficiently and cost-effectively is critical for the overall success of the automotive industry.

Deep Drawing Kitchenware

Deep drawing is commonly used in the production of kitchenware items, as it allows for the creation of complex shapes and designs. Some examples of kitchenware items that are produced using deep drawing include:

- Cookware: Deep drawing is used in the production of various types of cookware such as pots, pans, and casseroles. The process allows for the production of components with high strength and durability, which is critical for cooking applications.

- Bakeware: Deep drawing is used in the production of various types of bakeware such as baking sheets, cake pans, and muffin tins. The process allows for the production of components with high accuracy and tight tolerances, which is critical for baking applications.

- Kitchen sinks: Deep drawing is used in the production of various types of kitchen sinks. The process allows for the production of sinks with complex shapes and designs, which is critical for accommodating various kitchen layouts and styles.

- Utensils: Deep drawing is used in the production of various types of utensils such as spoons, forks, and ladles. The process allows for the production of components with high accuracy and tight tolerances, which is critical for handling food and liquids.

Overall, deep drawing is an important metal forming process in the production of kitchenware items, allowing for the creation of complex shapes and designs with high accuracy and tight tolerances. The ability to produce these items efficiently and cost-effectively is critical for the overall success of the kitchenware industry.

Deep Drawing for the Aerospace Industry

Deep drawing is also used in the aerospace industry for the production of a variety of parts and components. Some examples of aerospace parts that are produced using deep drawing include:

- Fuel tanks: Deep drawing is used to produce fuel tanks for aircraft, missiles, and spacecraft. The process allows for the creation of tanks with complex shapes and tight tolerances, which is critical for maximizing fuel capacity and efficiency.

- Engine components: Deep drawing is used to produce various engine components such as compressor blades, diffusers, and turbine discs. The process allows for the creation of components with high strength and durability, which is critical for withstanding the extreme operating conditions of aerospace engines.

- Structural components: Deep drawing is used to produce structural components such as fuselage panels, wing skins, and tail sections. The process allows for the creation of components with high accuracy and tight tolerances, which is critical for ensuring proper fit and function.

- Electrical components: Deep drawing is used to produce various electrical components such as connectors, housings, and terminals. The process allows for the creation of components with high precision and reliability, which is critical for maintaining proper electrical performance.

Overall, deep drawing is an important metal forming process in the aerospace industry, allowing for the creation of complex parts and components with high precision, reliability, and durability. The ability to produce these components efficiently and cost-effectively is critical for the overall success of the aerospace industry.

Deep Drawing for the Electronics Industry

Deep drawing is also used in the electronics industry for the production of various components and parts. Some examples of electronics parts that are produced using deep drawing include:

- Connectors: Deep drawing is used to produce connectors for electronic devices such as smartphones, laptops, and cameras. The process allows for the creation of connectors with complex shapes and tight tolerances, which is critical for ensuring proper connectivity and reliability.

- Housings: Deep drawing is used to produce housings for electronic devices such as hard disk drives, routers, and switches. The process allows for the creation of housings with high precision and accuracy, which is critical for ensuring proper fit and function.

- Heat sinks: Deep drawing is used to produce heat sinks for electronic devices such as computer processors and power amplifiers. The process allows for the creation of heat sinks with complex shapes and designs, which is critical for maximizing heat dissipation and performance.

- Antennas: Deep drawing is used to produce antennas for electronic devices such as smartphones, tablets, and GPS systems. The process allows for the creation of antennas with high precision and reliability, which is critical for ensuring proper signal strength and connectivity.

Overall, deep drawing is an important metal forming process in the electronics industry, allowing for the creation of complex parts and components with high precision, accuracy, and reliability. The ability to produce these components efficiently and cost-effectively is critical for the overall success of the electronics industry.

Dee Drawing for the Electronics Industry

Deep drawing is widely used in the medical industry for the production of various components and devices. Some examples of medical devices that are produced using deep drawing include:

- Surgical instruments: Deep drawing is used to produce various surgical instruments such as forceps, clamps, scissors, and needle holders. The process allows for the creation of instruments with complex shapes and designs, which is critical for their proper function and reliability.

- Implantable medical devices: Deep drawing is used to produce various implantable medical devices such as stents, catheters, and pacemakers. The process allows for the creation of devices with high precision and accuracy, which is critical for their proper fit and function.

- Medical tubing: Deep drawing is used to produce medical tubing used in various medical applications such as blood transfusions, dialysis, and intravenous therapy. The process allows for the creation of tubing with precise dimensions and tolerances, which is critical for ensuring proper flow and compatibility with other medical devices.

- Medical equipment housings: Deep drawing is used to produce housings for various medical equipment such as ultrasound machines, X-ray machines, and CT scanners. The process allows for the creation of housings with high precision and accuracy, which is critical for their proper fit and function.

Overall, deep drawing is an important metal forming process in the medical industry, allowing for the creation of complex parts and devices with high precision, accuracy, and reliability. The ability to produce these components and devices efficiently and cost-effectively is critical for the overall success of the medical industry.

Dee Drawing for the Packaging Industry

Deep drawing is commonly used in the packaging industry for the production of various containers, lids, and caps for food, beverage, and other consumer products. Some examples of packaging products that are produced using deep drawing include:

- Aluminum cans: Deep drawing is used to produce aluminum cans for beverages such as soda, beer, and energy drinks. The process allows for the creation of cans with precise dimensions and tolerances, which is critical for ensuring proper sealing and preservation of the product.

- Plastic containers: Deep drawing is used to produce plastic containers for food, cosmetics, and other consumer products. The process allows for the creation of containers with complex shapes and designs, which is critical for their proper function and aesthetics.

- Metal lids and caps: Deep drawing is used to produce metal lids and caps for various containers such as jars and bottles. The process allows for the creation of lids and caps with precise dimensions and tolerances, which is critical for ensuring proper sealing and preservation of the product.

- Packaging trays: Deep drawing is used to produce packaging trays for food and other consumer products. The process allows for the creation of trays with precise dimensions and tolerances, which is critical for ensuring proper fit and compatibility with other packaging materials.

Overall, deep drawing is an important metal forming process in the packaging industry, allowing for the creation of containers, lids, and caps with high precision, accuracy, and aesthetics. The ability to produce these products efficiently and cost-effectively is critical for the overall success of the packaging industry.

Deep Drawing for the Defense Industry

Deep drawing is also used in the defense industry for the production of various components and parts. Some examples of deep drawing applications in the defense industry include:

- Missile components: Deep drawing is used to produce missile components such as casings, warheads, and fins. These components are often made from high-strength materials such as titanium and require complex shapes and designs, which can be achieved through the deep drawing process.

- Aircraft parts: Deep drawing is used to produce various aircraft parts such as fuselage skins, wing skins, and engine components. These parts require high precision and accuracy, which can be achieved through the deep drawing process.

- Ammunition casings: Deep drawing is used to produce ammunition casings for various types of ammunition, including bullets, shells, and cartridges. The deep drawing process allows for the production of casings with precise dimensions and tolerances, which is critical for their proper function.

- Armor components: Deep drawing is used to produce armor components such as vehicle body panels, helmets, and body armor. These components require high strength and durability, which can be achieved through the deep drawing process.

Overall, deep drawing is an important metal forming process in the defense industry, allowing for the production of components and parts with high precision, strength, and durability. The ability to produce these products efficiently and cost-effectively is critical for the overall success of the defense industry.

Hydraulic presses are powerful machines used to apply a significant amount of force to an object through hydraulic fluid pressure. They are essential in various industrial applications, providing the necessary force for processes such as metal forming, stamping, bending, and molding. The versatility and efficiency of hydraulic presses make them indispensable tools in manufacturing and production lines. This document will explore the different types of hydraulic presses, their application areas, components, operational principles, manufacturing process, and the challenges and advancements in the industry.

Types of Hydraulic Presses

Hydraulic presses come in various designs, each suited to specific applications and requirements. The primary types of hydraulic presses include C-frame presses, H-frame presses, four-column presses, straightening presses, arbor presses, laminating presses, and transfer presses.

C-frame presses, also known as gap-frame presses, have a C-shaped frame that provides three-sided access to the work area. This design is ideal for applications requiring easy loading and unloading of materials.

H-frame presses, or two-post presses, have a robust H-shaped frame that offers excellent stability and strength. They are commonly used for heavy-duty tasks such as metal forming and straightening.

Four-column presses, or four-post presses, have four vertical columns that provide superior support and uniform force distribution. These presses are suitable for large-scale applications requiring high precision and repeatability.

Straightening presses are specialized hydraulic presses used to straighten bent or distorted metal components. They are widely used in the automotive and construction industries.

Arbor presses are smaller, manually operated hydraulic presses used for light-duty tasks such as assembly, riveting, and broaching. They are commonly found in workshops and small manufacturing facilities.

Laminating presses are used to bond multiple layers of material together under heat and pressure. These presses are essential in industries such as electronics, where laminated components are common.

Transfer presses are automated hydraulic presses that move the workpiece through multiple stations for different operations. They are highly efficient and used in high-volume production environments.

Application Areas

Hydraulic presses are employed in various industries, thanks to their ability to deliver consistent and precise force. Key application areas include:

Metal forming and forging: Hydraulic presses are crucial in shaping and forming metal parts through processes such as stamping, bending, and deep drawing. They are essential in the production of automotive parts, machinery components, and structural elements.

Automotive industry: In the automotive sector, hydraulic presses are used for manufacturing various parts, including body panels, chassis components, and engine parts. They play a critical role in ensuring the structural integrity and performance of vehicles.

Aerospace industry: The aerospace industry relies on hydraulic presses for forming and shaping high-strength materials used in aircraft components. Precision and reliability are paramount in this industry, making hydraulic presses indispensable.

Plastic and rubber molding: Hydraulic presses are used in the molding of plastic and rubber components, including automotive parts, household goods, and medical devices. They ensure consistent product quality and precision.

Electrical and electronics industry: In the electronics sector, hydraulic presses are used for laminating circuit boards, forming connectors, and assembling electronic components. They provide the necessary force and precision for delicate operations.

Medical device manufacturing: Hydraulic presses are used in the production of medical devices, including surgical instruments, implants, and diagnostic equipment. They ensure the high precision and quality required in the medical field.

Packaging industry: Hydraulic presses are employed in the packaging industry for forming and shaping packaging materials, such as cardboard, plastic, and metal. They help produce packaging solutions that are strong, durable, and aesthetically pleasing.

Components of a Hydraulic Press

A hydraulic press comprises several key components that work together to generate and control the applied force. The main components include the frame, hydraulic cylinder, hydraulic pump, control valves, hydraulic fluid, pressure gauges and sensors, and die and tooling.

The frame is the main structure of the hydraulic press, providing stability and support for all other components. It is typically made of high-strength steel to withstand the significant forces generated during operation.

The hydraulic cylinder is the core component that generates the pressing force. It consists of a cylindrical chamber, a piston, and a piston rod. When hydraulic fluid is pumped into the cylinder, it moves the piston, which in turn applies force to the workpiece.

The hydraulic pump is responsible for generating the hydraulic fluid pressure needed to move the piston. It draws hydraulic fluid from a reservoir and delivers it to the cylinder under high pressure.

Control valves regulate the flow of hydraulic fluid to and from the cylinder, controlling the movement and force of the press. These valves can be manually operated or automated, depending on the press design.

Hydraulic fluid, typically oil, is the medium through which force is transmitted in the hydraulic system. It must have suitable properties, such as viscosity and lubricity, to ensure efficient operation and protect system components.

Pressure gauges and sensors monitor the hydraulic fluid pressure within the system. They provide real-time feedback to the operator or control system, ensuring safe and accurate press operation.

Die and tooling are the interchangeable components that come into direct contact with the workpiece. They are designed to shape, form, or cut the material as required by the specific application.

How Hydraulic Presses Work

Hydraulic presses operate based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows hydraulic presses to generate significant force with relatively small input pressure.

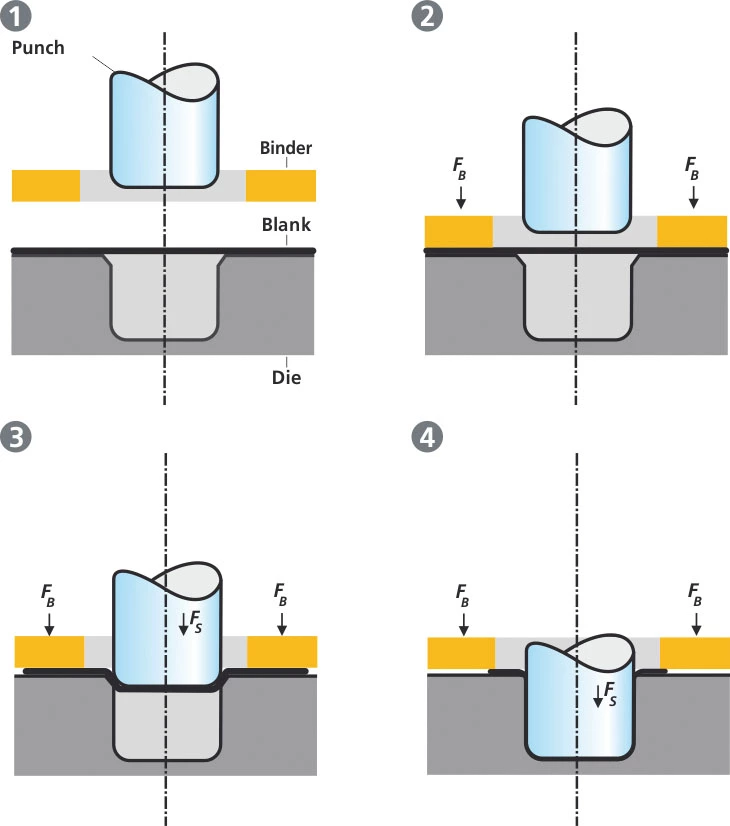

The operation of a hydraulic press begins with the hydraulic pump drawing fluid from the reservoir and delivering it to the cylinder. The control valves regulate the flow of fluid, directing it into the cylinder to move the piston. As the piston moves, it applies force to the workpiece placed between the die and tooling.

The hydraulic fluid plays a crucial role in this process, as it transmits the applied pressure and lubricates the system components. The pressure gauges and sensors continuously monitor the fluid pressure, providing feedback to ensure the press operates within safe limits.

The force generated by the hydraulic press can be precisely controlled by adjusting the hydraulic fluid pressure and the position of the control valves. This allows for accurate and repeatable operations, essential for high-quality manufacturing.

Manufacturing of Hydraulic Presses

The manufacturing of hydraulic presses involves several stages, from design and engineering to assembly and quality control. Each stage is critical to ensuring the press’s performance, reliability, and safety.

Design and engineering: The process begins with the design and engineering phase, where specifications for the press are developed based on the intended application. This includes selecting suitable materials, determining the required force and stroke, and designing the frame and hydraulic system.

Material selection: High-quality materials, such as high-strength steel for the frame and durable alloys for the hydraulic components, are selected to ensure the press’s longevity and performance.

Fabrication of components: The individual components of the hydraulic press, including the frame, cylinder, and pump, are fabricated using precision machining and manufacturing techniques. This ensures that each component meets the required tolerances and specifications.

Assembly process: The fabricated components are then assembled into the complete hydraulic press. This involves mounting the cylinder, pump, and control valves onto the frame, connecting the hydraulic lines, and installing the die and tooling.

Quality control and testing: Rigorous quality control measures are implemented throughout the manufacturing process to ensure the press meets all specifications and standards. This includes pressure testing the hydraulic system, verifying the accuracy of the control valves, and performing operational tests to ensure the press functions correctly.

Advancements and Innovations

The hydraulic press industry is continually evolving, driven by advancements in technology and increasing demands for efficiency and precision. Key innovations include automation and control systems, energy efficiency improvements, and smart hydraulic presses.

Automation and control systems: Modern hydraulic presses are often equipped with advanced control systems that automate the pressing process. This includes programmable logic controllers (PLCs), human-machine interfaces (HMIs), and sensors that monitor and adjust the press’s operation in real time. Automation improves efficiency, reduces the risk of human error, and enhances the consistency of the finished products.

Energy efficiency improvements: Manufacturers are focusing on developing hydraulic presses that consume less energy and have a smaller environmental footprint. This includes using variable displacement pumps, energy recovery systems, and optimizing the hydraulic system’s design to minimize energy losses.

Smart hydraulic presses: The integration of IoT (Internet of Things) technology into hydraulic presses has led to the development of smart presses. These presses can communicate with other machines and systems, providing real-time data on their status, performance, and maintenance needs. This connectivity allows for predictive maintenance, reducing downtime and extending the press’s lifespan.

Challenges in Hydraulic Press Manufacturing

The manufacturing of hydraulic presses presents several challenges, including precision and quality requirements, cost management, technological advancements, and environmental considerations.

Precision and quality requirements: Hydraulic presses must deliver consistent and precise force, which requires high levels of accuracy in the manufacturing process. Ensuring each component meets the required tolerances and specifications is critical to the press’s performance and reliability.

Cost management: The cost of materials, labor, and energy can significantly impact the overall cost of manufacturing hydraulic presses. Manufacturers must balance quality and cost to remain competitive in the market.

Technological advancements: Keeping up with technological advancements is essential for manufacturers to meet the evolving demands of the industry. This requires continuous investment in research and development to incorporate new technologies and improve existing designs.

Environmental considerations: Environmental regulations and sustainability concerns are increasingly important in hydraulic press manufacturing. Manufacturers must develop eco-friendly presses that consume less energy, use recyclable materials, and minimize their environmental impact.

Conclusion

Hydraulic presses are essential machines in various industries, providing the necessary force for processes such as metal forming, stamping, and molding. Understanding the different types of hydraulic presses, their components, and how they work is crucial for effective application and operation.

The manufacturing process of hydraulic presses involves careful design and engineering, material selection, precision fabrication, and rigorous quality control. Despite the challenges, advancements in technology and innovations are driving the industry forward, leading to more efficient, precise, and environmentally friendly hydraulic presses.

As industries continue to evolve, the hydraulic press industry must adapt and innovate to meet the demands of efficiency, precision, and sustainability. Through continuous research and development, manufacturers can enhance the performance and reliability of hydraulic presses, contributing to the success of various industrial applications.