We manufacture machinery for the cooking industry and explain here How are Metal Pots Made in different forms. These machines are used in metalworking industries for production.

The manufacturing process for metal pots involves several steps, each designed to transform raw materials into functional and durable cookware. Here’s a simplified overview of the process:

- Material Preparation: The process begins with selecting the appropriate metal alloy, typically aluminum, stainless steel, or cast iron. The alloy is melted and heated to a specific temperature, ensuring its optimal fluidity for shaping.

- Casting or Forging: The molten metal is then poured into molds or shaped using forging techniques. Casting is commonly used for producing pots with complex shapes and intricate designs, while forging is preferred for creating thicker and more durable pots.

- Trimming and Shaping: Once the pot’s initial form is established, excess material is trimmed and the pot is shaped to achieve the desired dimensions and contours. This stage involves precision cutting, grinding, and polishing to ensure a smooth and seamless finish.

- Handle Attachment: Handles are typically made from heat-resistant materials like Bakelite or stainless steel. They are securely attached to the pot using rivets, welding, or adhesives.

- Surface Finishing: The pot undergoes various surface treatments to enhance its appearance, durability, and functionality. These treatments may include polishing, anodizing (for aluminum), or enameling (for cast iron).

- Quality Control and Inspection: Each pot is subjected to rigorous quality control checks to ensure it meets the manufacturer’s standards for material integrity, dimensions, surface finish, and overall functionality.

- Packaging and Shipping: The finished pots are carefully packaged to protect them during transportation and shipped to retailers or distributors for sale to consumers.

The specific manufacturing methods and techniques used may vary depending on the type of metal pot being produced, the desired qualities of the pot, and the manufacturer’s expertise. However, the overall process follows a similar sequence of steps, transforming raw materials into high-quality cookware that is both functional and aesthetically pleasing.

How are Metal Pots Made

The manufacturing process for metal pots involves several steps, from shaping the raw material to applying the final finishes. Here’s a general overview of the process:

- Material Preparation:a. Melting: The raw metal, typically aluminum or stainless steel, is melted in a furnace at high temperatures to turn it into a liquid state.b. Purification: The molten metal may undergo purification processes to remove impurities and ensure the desired quality.

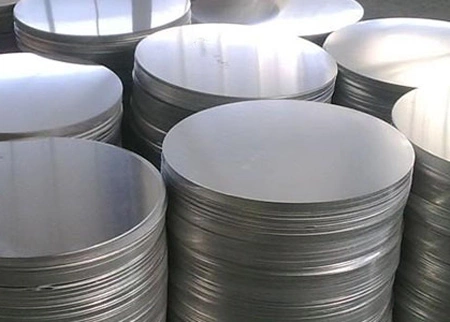

- Shaping and Forming:a. Casting: The molten metal is poured into molds of the desired pot shape. The mold cools, allowing the metal to solidify into the desired form.b. Spinning: For some pot shapes, spinning is used. A spinning chuck rotates a metal disc, and a roller is applied to gradually form the disc into the desired shape.c. Stamping: In some cases, stamping is used to create flat or shallow pots. Metal sheets are fed into a stamping press, where they are cut and formed into the desired shape.

- Trimming and Finishing:a. Trimming: Excess metal is trimmed from the edges of the pot to create a clean and consistent shape.b. Sanding: The pot may be sanded to remove any rough spots or imperfections and create a smooth surface.

- Handle Attachment:a. Drilling: Holes are drilled in the pot for handle attachment.b. Handle Riveting or Welding: Handles are attached to the pot using rivets or welding techniques, ensuring a secure and durable connection.

- Polishing:a. Buffing: The pot may undergo buffing to create a shiny and polished surface. This enhances the pot’s appearance and protects it from corrosion.

- Cleaning:a. Thorough Cleaning: The pot is thoroughly cleaned to remove any debris, residues, or polishing compounds from the manufacturing process.

- Inspection:a. Quality Control: The pots undergo quality control checks to ensure they meet the desired specifications for shape, size, finish, and overall quality.

- Packaging and Shipping:a. Protective Packaging: The pots are carefully packaged with protective materials to prevent damage during shipping.b. Shipping: The packaged pots are shipped to retailers or distributors for distribution and sale.

This is a simplified overview of the metal pot manufacturing process. The specific steps and techniques may vary depending on the type of pot, the materials used, and the manufacturer’s preferences.

Types of Cookware

Cookware comes in various types, each with unique properties and manufacturing processes. The primary types include stainless steel, aluminum, cast iron, copper, non-stick, and ceramic cookware.

Stainless steel cookware is known for its durability, resistance to rust and corrosion, and non-reactive properties. It is often used in professional kitchens and for high-quality home cookware.

Aluminum cookware is lightweight, conducts heat well, and is typically more affordable than other types. It is often anodized or coated to prevent reaction with acidic foods.

Cast iron cookware is renowned for its excellent heat retention and even cooking. It is durable and can be used on various heat sources, including induction cooktops.

Copper cookware provides superior heat conductivity, allowing precise temperature control. It is often lined with stainless steel or tin to prevent reactions with food.

Non-stick cookware features a coating that prevents food from sticking, making it easy to clean. It is popular for low-fat cooking but requires careful handling to avoid damaging the coating.

Ceramic cookware is valued for its non-reactive surface and even heating. It is often used for baking and roasting due to its ability to withstand high temperatures.

Raw Materials and Sourcing

The selection and sourcing of raw materials are critical in cookware manufacturing. The quality of the final product depends heavily on the quality of the materials used.

For stainless steel cookware, high-grade stainless steel alloys such as 18/10 (18% chromium, 10% nickel) are commonly used. These alloys offer excellent durability and resistance to corrosion.

Aluminum cookware typically uses pure aluminum or aluminum alloys. Pure aluminum is soft and lightweight, while alloys provide added strength and durability.

Cast iron cookware is made from iron alloys with a high carbon content. The iron is melted and poured into molds to create the desired shapes.

Copper cookware uses high-purity copper, often with a lining of stainless steel or tin to prevent reactions with food.

Non-stick cookware starts with a base of aluminum or stainless steel, to which a non-stick coating such as PTFE (polytetrafluoroethylene) is applied.

Ceramic cookware is made from natural clay, which is shaped and fired at high temperatures to create a hard, non-porous surface.

Quality control of raw materials involves rigorous testing and inspection to ensure they meet industry standards. Environmental considerations also play a role in material selection, with manufacturers increasingly opting for sustainable and eco-friendly options.

Manufacturing Process

The manufacturing process of cookware involves several stages, each crucial for producing high-quality products.

Forming

Forming is the initial stage where the raw materials are shaped into cookware.

Casting: Involves pouring molten metal into molds to create the desired shape. This method is commonly used for cast iron and some types of aluminum cookware.

Stamping: Uses heavy machinery to stamp out shapes from sheets of metal. This process is often used for stainless steel and aluminum cookware.

Spinning: Involves rotating a metal disc and shaping it over a form using a lathe. This method is used for making items like pots and pans from stainless steel and aluminum.

Surface Preparation

Surface preparation ensures the cookware’s surface is smooth and ready for coating or finishing.

Grinding: Removes any rough edges and surface imperfections using abrasive wheels.

Polishing: Uses finer abrasives to create a smooth, shiny surface on the cookware.

Sandblasting: Blasts the surface with fine particles to clean and texture it, preparing it for further finishing.

Coating and Finishing

Coating and finishing enhance the cookware’s performance and appearance.

Non-stick Coating Application: Involves applying a non-stick layer, usually PTFE, to the cookware surface. The coating is then baked to cure it.

Enameling: Applies a glass-like coating to metal cookware, providing a durable, non-reactive surface. This process is commonly used for cast iron and steel cookware.

Anodizing: Involves electrochemically treating aluminum to create a hard, non-reactive surface. Anodized aluminum cookware is known for its durability and resistance to corrosion.

Assembly and Attachment

Handles and knobs are attached to the cookware, ensuring they are secure and ergonomic.

Handles and Knobs: Made from materials such as stainless steel, plastic, or silicone, are attached using riveting, welding, or screwing.

Riveting and Welding: Securely attach handles and other components to the cookware, ensuring they can withstand regular use.

Quality Control and Testing

Quality control is critical in cookware manufacturing to ensure the final products meet safety and performance standards.

Inspection Procedures: Involve visual and mechanical inspection of cookware to detect any defects or irregularities.

Performance Testing: Includes tests for heat distribution, durability, and resistance to scratching and corrosion.

Safety Standards Compliance: Ensures that the cookware meets all relevant safety standards and regulations, such as those set by the FDA or other regulatory bodies.

Technological Advancements in Cookware Manufacturing

Technological advancements are continually improving the efficiency, quality, and sustainability of cookware manufacturing.

Automation and Robotics: Modern manufacturing facilities often use automated systems and robotics to handle repetitive tasks, improving consistency and reducing labor costs.

Advanced Materials: Research into new materials and coatings has led to the development of cookware with improved performance, such as better non-stick properties and enhanced durability.

Sustainable Manufacturing Practices: Manufacturers are increasingly adopting eco-friendly practices, such as using recycled materials, reducing energy consumption, and minimizing waste.

Smart Cookware: The integration of smart technology into cookware, such as temperature sensors and connectivity features, is a growing trend, providing users with more control and information during cooking.

Challenges in Cookware Manufacturing

Cookware manufacturing faces several challenges, including maintaining quality and consistency, cost management, technological advancements, and environmental regulations.

Maintaining Quality and Consistency: Ensuring that every piece of cookware meets high standards of quality and performance is challenging, particularly in high-volume production.

Cost Management: Balancing the costs of materials, labor, and production while remaining competitive in the market requires careful planning and efficiency.

Technological Advancements: Keeping up with rapid technological changes and integrating new technologies into existing manufacturing processes can be demanding.

Environmental Regulations: Compliance with environmental regulations requires manufacturers to adopt sustainable practices and invest in eco-friendly technologies, which can be costly and complex.

Future Trends in Cookware Manufacturing

The future of cookware manufacturing is likely to be shaped by innovations in materials, enhanced functionality, and sustainability.

Innovations in Materials: Continued research into new materials and coatings will likely result in cookware with superior performance, such as improved heat distribution and non-stick properties.

Enhanced Functionality and Features: Cookware with added features, such as smart technology, will provide users with more control and convenience during cooking.

Eco-friendly and Sustainable Products: As consumers become more environmentally conscious, demand for eco-friendly cookware made from sustainable materials and produced using green manufacturing practices will likely increase.

Conclusion

Cookware manufacturing is a complex and multifaceted industry that produces essential tools for cooking. Understanding the various types of cookware, raw materials, manufacturing processes, and technological advancements is crucial for producing high-quality products. Despite challenges such as maintaining quality, managing costs, and complying with environmental regulations, the industry continues to evolve and innovate. Future trends in materials, functionality, and sustainability promise to drive the industry forward, ensuring that cookware remains a vital part of daily life and culinary excellence.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching