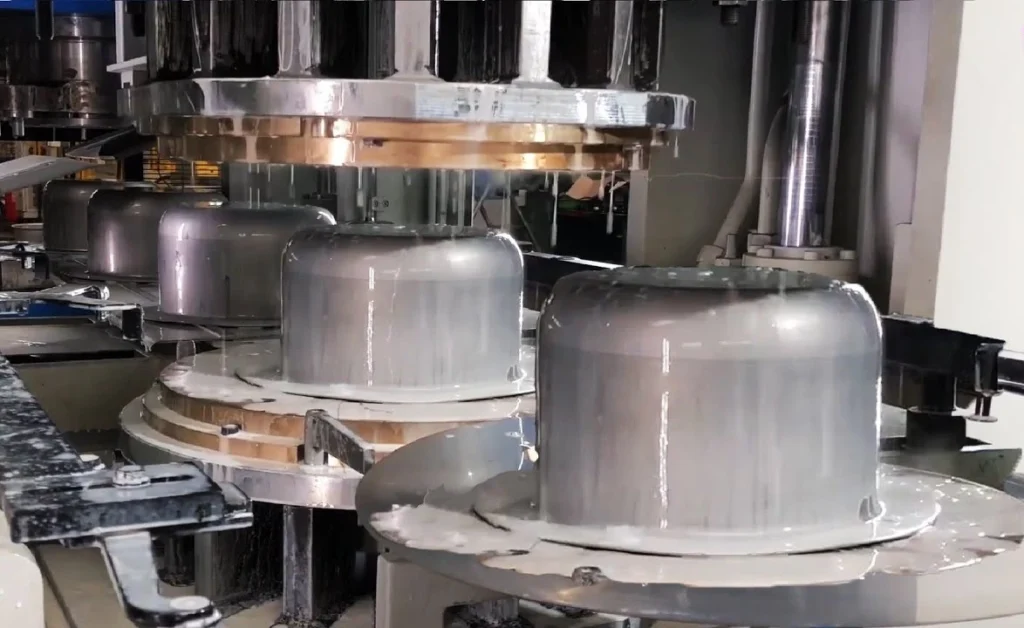

We manufacture hydraulic press with a deep drawing process. Deep drawing process & Deep drawing press & Double action deep drawing press & Triple action deep drawing press

Sheet metal forming is one of the most important production methods used in different industries such as producing industrial parts, office, and home appliances, automobile bodies, airplane parts, etc. Deep drawing is one of the frequently applied methods in sheet metal forming.

Deep Drawing Operation

Deep drawing operation is based on producing engineering parts with specific shapes through major plastic deformation of flat metal sheets. An external force on a metal sheet does this plastic deformation. This external force has to be large enough to place the material in the plastic zone and

to ensure that after displacing the external force, the metal part doesn’t spring back or elastically deform again.

The final quality of the parts produced through this operation is based on the final wall thickness and being wrinkle-free and fracture-free

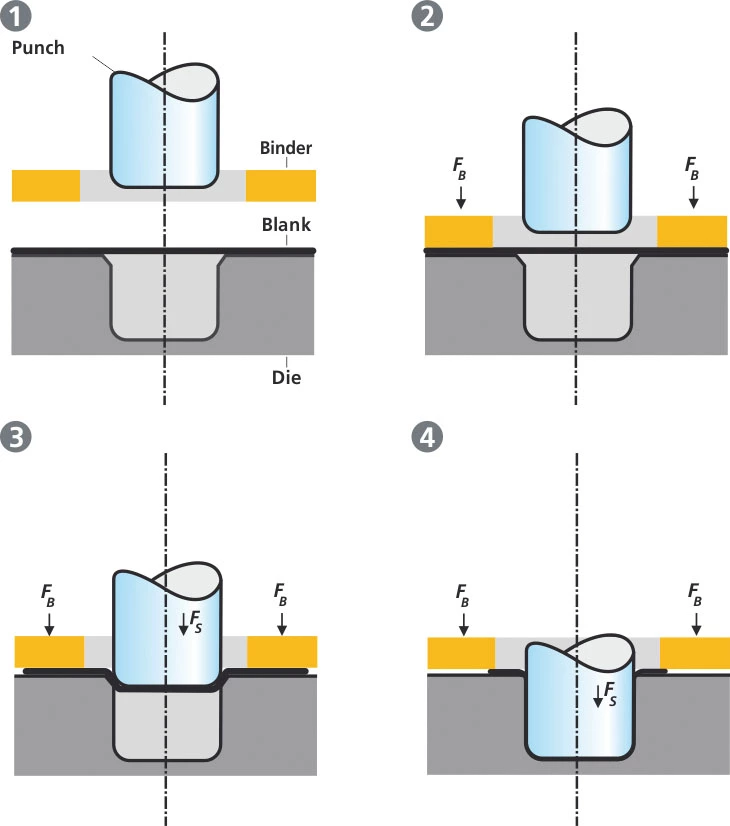

The flat blank for use in the analysis of deep drawing may be divided into three zones, X, Y, and Z [13], as shown in Fig. 1.1 As the punch is lowered

into the die opening, several distinct phenomena occur. X, the outer annular zone consists of material in contact with the die. Y, the inner

annular zone is not initially in contact with either the punch or the die, and Z, the circular zone is only in contact with the flat bottom of the punch.

As the deep-drawing operation proceeds, the outer flange portion of the blank, zone X will be subjected to a radial drawing tensile stress as it is drawn progressively inwards towards the die profile and the effect of continuously decreasing the radius in this zone is to induce compressive hoop stress, resulting in an increase in material thickness [3]. Then when the magnitude of these stresses exceeds a certain critical value, wrinkling and buckling of the flange may occur if the blank holder pressure is not high enough.

The material in the inner parts of zone X is thinned by plastic bending under tensile stress as it passes over the die profile. The inner parts of zone X are thinned further by the tension between the punch and die, resulting in an increase in thickness for the outer parts of zone X. Zone Y is subject to bending and sliding over the die profile, stretching in tension between the punch and die and finally to bending and sliding over the punch profile. Zone Z is subject to stretching and sliding over the punch head

Deep Drawing Process Steps

In summary, five processes take place during the course of deep drawing.

- Pure radial drawing between the die and blank holder in zone X, causing the blank to thicken due to the resultant hoop stress.

- Bending and sliding over the die profile, r2, will cause some thinning of the metal.

- Initial stretching in zone Y. This will cause thinning of the material at the intersection of the bottom of the cup and its side wall. If a cup fails to form it is invariably due to tensile failure in zone Y.

Bending and sliding over the punch profile radius, r1, thinning to some degree occurs here. Stretching and sliding over the punch nose in zone

Defects in Deep Drawing Progress

A number of defects may occur in deep-drawn parts. Figure 1.2 shows the type of defects that may be found after drawing cups. The description of

such defects is discussed below:

Earing:

It occurs in deep-drawn parts made from anisotropic materials. Because of planar anisotropy, the sheet metal may be stronger in one direction than in other directions in the plane of the sheet. This causes the formation of ears in the upper edge of a deep-drawn cup even when a circular blank is

used. In practice, enough extra metal is left on the drawn cup so that the ears can be trimmed.

Wrinkling in the flange

Wrinkling in deep drawn parts consists of a series of ridges that form radially in the flange due to compressive forces. Wrinkling in the wall occurs when ridges in the flange are drawn into the vertical wall of the cup.

Wrinkling in the wall

It occurs when ridges in the flange are drawn into the vertical wall of the cup.

Tearing

It occurs near the base of the drawn cup and results from high stresses in the vertical wall that cause thinning and failure of the metal at that location.

Surface scratches

It occurs in a drawn part if the punch and die surfaces are not smooth or if lubrication is not enough.

Parts of a Hydraulic Press with the Deep Drawing Process

Top Plate of a Deep Drawing Press

It is the plate that is situated at the top of the machine. It will be made up of MS material. This plate will support the

one cylinder which is used for punching the workpiece. This plate will also support two small cylinders which are situated beside the punching cylinder. It will hold four pillars which will be fixed with the help of bolts. It will support the whole weight of three cylinders which are used for different purposes in the machine. It also will help to correct the alignment of the base plate and pressure plate with four rods at its end.

Base Plate

It is a plate that is situated on the frame. It will take all load off the machine. It is connected to the top plate with the help of four pillars. The pillars are situated at their ends. It has a T slot cut into it. This T slot helps for mounting the die set on it. It is the plate on which the workpiece is actually placed and then the punching operation takes place. An ejection system will be provided below it to eject the workpiece from the die set.

Pressure Plate

The pressure plate is a little less in dimension than the base plate or top plate as it has to move up and down in the machine. This plate will move up and down with the help of two piston rods which will hold it at the two ends. This plate will hold the metal sheet and then the punch will come down and punch the metal sheet. It has a center hole through which the punch moves up and down. This is an important part of the system as it has to hold the metal sheet. Due to this plate, there are fewer chances of wrinkles on the workpiece.

Pillars

There is a total of four pillars in this machine. These pillars are mounted between the top plate and the bottom plate. They are fixed with top and bottom plates with bolt arrangement. They support the whole weight of cylinders and the top plate. They reduce vibrations of the machine to transfer to the base plate and ultimately to the die set. This avoids any variation in the workpiece.

Frame

This is the component of the system that takes all load of the machine. This takes a load of hydraulic cylinders, base plate, top plate, and pillars. It also holds an ejection system which helps in the ejection of the workpiece from the die set.

C-Clamp

This component of the system helps in the ejection of the workpiece from the die. It also limits the movement of the pressure plate. This C- clamp is connected to the piston rod of the punching cylinder. It also has one limiting movement mechanism. With this mechanism the armature of C-clamp is made contact with a pressure switch is used to stop the Clamp.

Double Action Deep Drawing Hydraulic Press Machine Automation plane uses a hydraulic cylinder for both direction movement and stroke, a hydraulic motor is used to drive the hydraulic cylinder, and a pleasure switch to control the movement of the press pad and punch. Solenoid valves are widely used on compressed air or hydraulic fluid for powering actuators on mechanical components.

While motors are used to supply continuous rotary motion, actuators are typically a better choice for intermittently creating a limited range of movement for a mechanical component, such as moving various mechanical arms, opening or closing valves, raising heavy press rolls, and applying pressure to presses.

Control circuits are often drawn using ladder logic, so named because the wiring diagram resembles a ladder. First of all base plate is mounted on the frame. The base plate is welded to the frame. Then take four pillars and they were situated vertically on the base plate and in they are fitted to the base plate with help of a bolt and lock nut.

Over that pillar, the top plate is situated and it is fixed with the nut and bolt. After that, the round plate is welded to the top plate at its center. Over that round plate cylinder of 20 tones is fixed with nut and bolt. Which are situated in the holes on the circumference of the round plate. After this situation of the center cylinder is used for the punching operation. Then and edges of the top plate square blocks are welded and over that block cylinder of 2.5 tones is fixed. With the same process that of the center cylinder.

After that piston of the cylinder which is of 2.5 tones brought down and the pressure plate is fixed with it at the edges and with help of a square block. In that Allen bolts and nuts. After that clamp is situated in the center cylinder piston by cutting and milling it into that shape. Another part of the c-clamp is assembling the top of the ejection system. Which is situated below the base plate Pressure switch is situated on the top plate to limit the movement of the c-clamp in the upward and downward direction.

The hydraulic system is brought near the machine and its pipes and ports are connected to the vales of the cylinder. There is a system of switches. The white switch is for the downward movement of the center piston which acts as the punch.

And the black switch is for the downward movement of the pressure plate with the help of the downward movement of side pistons. The red switch is for the upward movement center piston which acts as a punch. The blue switch is for the upward movement side piston which acts to move the pressure plate.

Sequential Control

Sequential control may be either a fixed sequence or a logical one that will perform different actions depending on various system states. An example of an adjustable but otherwise fixed sequence is a timer on a pressure switch. In a typical hard-wired motor start and stop circuit (called

a control circuit) a motor is started by pushing a “Start” or “Run” button that activates a pair of electrical relays.

The “lock-in” relay locks in contacts that keep the control circuit energized when the push button is released. (The start button is a normally open contact and the stop button is normally closed contact.) Another relay energizes a switch that powers the device that throws the motor starter switch (three sets of contacts for three-phase industrial power) in the main power circuit.

All contacts are held engaged by their respective electromagnets until a “stop” or “off” button is pressed that de-energizes the lock-in relay. (Note- Large motors use high voltage and experience high in-rush current, making speed important in making and breaking contact. This can be dangerous for personnel and property with manual switches.

Conventional deep drawing can be achieved without a blank holder as indicated in Figure 1, or with a blank holder as shown in Figure 2 (Malinin 1975; Popov 1977). Normally, the first method employs conventional drawing punches which consist of matrix 1 and punch 2. It is used for manufacturing shallow vessels or thin-walled articles with no folds or corrugation. Figure 1-b presents the second stage of deep drawing without a blank holder.

Blank holder 3 is used in the second method of the deep drawing shown on Figure 2. The collar section of the workpiece is pressed against the matrix by the blank holder in order to prevent corrugation from forming on the material, as the material is forced downwards through the matrix hole under the punch pressure. Figure 2-a shows the first stage of deep drawing by punching a flat workpiece whereas Figure 2-b shows the second stage of drawing the hollow workpiece.

Drawing dies 1 in Figure 3, whose chamber is filled with oil beforehand, overcomes the opposing compression of the hydraulic clamp 2 and initiates drawing of the blank part over punch 3. Due to the progressively growing pressure within chamber 1 oil starts flowing along channel 5 and then into channel 4 thus exerting radial pressure along the periphery of the blank part. Upon the consequent downward stroke of puncheon 6, the blank part is inserted into its receptive aperture

This causes oil pressure to increase thus exerting pressure against the lower base of punch 3 which is pushed upward and impacts this section of the blank that is inserted between puncheon 6 and mold 1. The opposing motion of punch 3, mold 1 and clamp 2 which is in permanent contact in relation to puncheon 6 is adjusted and synchronized electro-hydraulically. A general view of the test unit with its attachments and instrumentation is shown in Figure 5.

Hydraulic presses are powerful machines used to apply a significant amount of force to an object through hydraulic fluid pressure. They are essential in various industrial applications, providing the necessary force for processes such as metal forming, stamping, bending, and molding. The versatility and efficiency of hydraulic presses make them indispensable tools in manufacturing and production lines. This document will explore the different types of hydraulic presses, their application areas, components, operational principles, manufacturing process, and the challenges and advancements in the industry.

Types of Hydraulic Presses

Hydraulic presses come in various designs, each suited to specific applications and requirements. The primary types of hydraulic presses include C-frame presses, H-frame presses, four-column presses, straightening presses, arbor presses, laminating presses, and transfer presses.

C-frame presses, also known as gap-frame presses, have a C-shaped frame that provides three-sided access to the work area. This design is ideal for applications requiring easy loading and unloading of materials.

H-frame presses, or two-post presses, have a robust H-shaped frame that offers excellent stability and strength. They are commonly used for heavy-duty tasks such as metal forming and straightening.

Four-column presses, or four-post presses, have four vertical columns that provide superior support and uniform force distribution. These presses are suitable for large-scale applications requiring high precision and repeatability.

Straightening presses are specialized hydraulic presses used to straighten bent or distorted metal components. They are widely used in the automotive and construction industries.

Arbor presses are smaller, manually operated hydraulic presses used for light-duty tasks such as assembly, riveting, and broaching. They are commonly found in workshops and small manufacturing facilities.

Laminating presses are used to bond multiple layers of material together under heat and pressure. These presses are essential in industries such as electronics, where laminated components are common.

Transfer presses are automated hydraulic presses that move the workpiece through multiple stations for different operations. They are highly efficient and used in high-volume production environments.

Application Areas

Hydraulic presses are employed in various industries, thanks to their ability to deliver consistent and precise force. Key application areas include:

Metal forming and forging: Hydraulic presses are crucial in shaping and forming metal parts through processes such as stamping, bending, and deep drawing. They are essential in the production of automotive parts, machinery components, and structural elements.

Automotive industry: In the automotive sector, hydraulic presses are used for manufacturing various parts, including body panels, chassis components, and engine parts. They play a critical role in ensuring the structural integrity and performance of vehicles.

Aerospace industry: The aerospace industry relies on hydraulic presses for forming and shaping high-strength materials used in aircraft components. Precision and reliability are paramount in this industry, making hydraulic presses indispensable.

Plastic and rubber molding: Hydraulic presses are used in the molding of plastic and rubber components, including automotive parts, household goods, and medical devices. They ensure consistent product quality and precision.

Electrical and electronics industry: In the electronics sector, hydraulic presses are used for laminating circuit boards, forming connectors, and assembling electronic components. They provide the necessary force and precision for delicate operations.

Medical device manufacturing: Hydraulic presses are used in the production of medical devices, including surgical instruments, implants, and diagnostic equipment. They ensure the high precision and quality required in the medical field.

Packaging industry: Hydraulic presses are employed in the packaging industry for forming and shaping packaging materials, such as cardboard, plastic, and metal. They help produce packaging solutions that are strong, durable, and aesthetically pleasing.

Components of a Hydraulic Press

A hydraulic press comprises several key components that work together to generate and control the applied force. The main components include the frame, hydraulic cylinder, hydraulic pump, control valves, hydraulic fluid, pressure gauges and sensors, and die and tooling.

The frame is the main structure of the hydraulic press, providing stability and support for all other components. It is typically made of high-strength steel to withstand the significant forces generated during operation.

The hydraulic cylinder is the core component that generates the pressing force. It consists of a cylindrical chamber, a piston, and a piston rod. When hydraulic fluid is pumped into the cylinder, it moves the piston, which in turn applies force to the workpiece.

The hydraulic pump is responsible for generating the hydraulic fluid pressure needed to move the piston. It draws hydraulic fluid from a reservoir and delivers it to the cylinder under high pressure.

Control valves regulate the flow of hydraulic fluid to and from the cylinder, controlling the movement and force of the press. These valves can be manually operated or automated, depending on the press design.

Hydraulic fluid, typically oil, is the medium through which force is transmitted in the hydraulic system. It must have suitable properties, such as viscosity and lubricity, to ensure efficient operation and protect system components.

Pressure gauges and sensors monitor the hydraulic fluid pressure within the system. They provide real-time feedback to the operator or control system, ensuring safe and accurate press operation.

Die and tooling are the interchangeable components that come into direct contact with the workpiece. They are designed to shape, form, or cut the material as required by the specific application.

How Hydraulic Presses Work

Hydraulic presses operate based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows hydraulic presses to generate significant force with relatively small input pressure.

The operation of a hydraulic press begins with the hydraulic pump drawing fluid from the reservoir and delivering it to the cylinder. The control valves regulate the flow of fluid, directing it into the cylinder to move the piston. As the piston moves, it applies force to the workpiece placed between the die and tooling.

The hydraulic fluid plays a crucial role in this process, as it transmits the applied pressure and lubricates the system components. The pressure gauges and sensors continuously monitor the fluid pressure, providing feedback to ensure the press operates within safe limits.

The force generated by the hydraulic press can be precisely controlled by adjusting the hydraulic fluid pressure and the position of the control valves. This allows for accurate and repeatable operations, essential for high-quality manufacturing.

Manufacturing of Hydraulic Presses

The manufacturing of hydraulic presses involves several stages, from design and engineering to assembly and quality control. Each stage is critical to ensuring the press’s performance, reliability, and safety.

Design and engineering: The process begins with the design and engineering phase, where specifications for the press are developed based on the intended application. This includes selecting suitable materials, determining the required force and stroke, and designing the frame and hydraulic system.

Material selection: High-quality materials, such as high-strength steel for the frame and durable alloys for the hydraulic components, are selected to ensure the press’s longevity and performance.

Fabrication of components: The individual components of the hydraulic press, including the frame, cylinder, and pump, are fabricated using precision machining and manufacturing techniques. This ensures that each component meets the required tolerances and specifications.

Assembly process: The fabricated components are then assembled into the complete hydraulic press. This involves mounting the cylinder, pump, and control valves onto the frame, connecting the hydraulic lines, and installing the die and tooling.

Quality control and testing: Rigorous quality control measures are implemented throughout the manufacturing process to ensure the press meets all specifications and standards. This includes pressure testing the hydraulic system, verifying the accuracy of the control valves, and performing operational tests to ensure the press functions correctly.

Advancements and Innovations

The hydraulic press industry is continually evolving, driven by advancements in technology and increasing demands for efficiency and precision. Key innovations include automation and control systems, energy efficiency improvements, and smart hydraulic presses.

Automation and control systems: Modern hydraulic presses are often equipped with advanced control systems that automate the pressing process. This includes programmable logic controllers (PLCs), human-machine interfaces (HMIs), and sensors that monitor and adjust the press’s operation in real time. Automation improves efficiency, reduces the risk of human error, and enhances the consistency of the finished products.

Energy efficiency improvements: Manufacturers are focusing on developing hydraulic presses that consume less energy and have a smaller environmental footprint. This includes using variable displacement pumps, energy recovery systems, and optimizing the hydraulic system’s design to minimize energy losses.

Smart hydraulic presses: The integration of IoT (Internet of Things) technology into hydraulic presses has led to the development of smart presses. These presses can communicate with other machines and systems, providing real-time data on their status, performance, and maintenance needs. This connectivity allows for predictive maintenance, reducing downtime and extending the press’s lifespan.

Challenges in Hydraulic Press Manufacturing

The manufacturing of hydraulic presses presents several challenges, including precision and quality requirements, cost management, technological advancements, and environmental considerations.

Precision and quality requirements: Hydraulic presses must deliver consistent and precise force, which requires high levels of accuracy in the manufacturing process. Ensuring each component meets the required tolerances and specifications is critical to the press’s performance and reliability.

Cost management: The cost of materials, labor, and energy can significantly impact the overall cost of manufacturing hydraulic presses. Manufacturers must balance quality and cost to remain competitive in the market.

Technological advancements: Keeping up with technological advancements is essential for manufacturers to meet the evolving demands of the industry. This requires continuous investment in research and development to incorporate new technologies and improve existing designs.

Environmental considerations: Environmental regulations and sustainability concerns are increasingly important in hydraulic press manufacturing. Manufacturers must develop eco-friendly presses that consume less energy, use recyclable materials, and minimize their environmental impact.

Conclusion

Hydraulic presses are essential machines in various industries, providing the necessary force for processes such as metal forming, stamping, and molding. Understanding the different types of hydraulic presses, their components, and how they work is crucial for effective application and operation.

The manufacturing process of hydraulic presses involves careful design and engineering, material selection, precision fabrication, and rigorous quality control. Despite the challenges, advancements in technology and innovations are driving the industry forward, leading to more efficient, precise, and environmentally friendly hydraulic presses.

As industries continue to evolve, the hydraulic press industry must adapt and innovate to meet the demands of efficiency, precision, and sustainability. Through continuous research and development, manufacturers can enhance the performance and reliability of hydraulic presses, contributing to the success of various industrial applications.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching