Deep Drawing Manufacturing Process: The deep drawing process is a critical metal forming technique used across various industries, from automotive to aerospace, for producing high-quality, precision metal parts. A central element in the success of the deep drawing process is the hydraulic press, a versatile and highly controlled machine that allows manufacturers to achieve the desired shapes with precision, repeatability, and efficiency. Hydraulic presses offer superior control over pressure, speed, and force, which are crucial for the deep drawing process to be defect-free and efficient.

Introduction to Deep Drawing and Hydraulic Presses

Deep drawing is a metal forming process that transforms flat sheet metal into hollow, cylindrical, or box-shaped components by drawing the metal into a die cavity. The process relies on the application of mechanical force, which stretches and compresses the material into a final shape. Deep drawing is essential in industries like automotive, aerospace, consumer goods, and packaging, where complex, hollow shapes are needed.

This process is highly versatile, allowing for the production of intricate geometries and seamless parts with uniform wall thickness. Products such as automotive body panels, fuel tanks, kitchen sinks, and beverage cans are all examples of components created through deep drawing.

1.2 Importance of Hydraulic Presses in Metal Forming

Hydraulic presses are crucial in metal forming due to their ability to deliver high precision, force control, and flexibility. Unlike mechanical presses that rely on rotational motion to generate force, hydraulic presses use fluid pressure to deliver controlled, uniform force over longer strokes, making them ideal for processes like deep drawing, which require gradual and controlled material deformation.

Hydraulic presses offer several advantages:

- Force and Speed Control: The ability to control both the force and speed during the press cycle allows for superior material flow control and minimizes defects such as wrinkling or tearing.

- Flexibility: Hydraulic presses can handle a wide range of materials, including aluminum, steel, titanium, and nickel alloys, with precise adjustments for material thickness and forming depth.

- High Force Output: Hydraulic presses can generate high force output with smaller machines, making them suitable for deep drawing complex parts.

1.3 Deep Drawing with Hydraulic Presses

In deep drawing, hydraulic presses play a pivotal role in shaping materials with high precision. The deep drawing process requires careful control of both the punch force and blank holder force to ensure smooth material flow into the die cavity without causing defects like wrinkling, thinning, or tearing.

Hydraulic presses excel in this role due to their:

- Constant Force Application: Hydraulic presses can apply consistent force throughout the entire stroke, which is essential for achieving uniform material thickness and precise shapes.

- Controlled Material Flow: The gradual application of force in hydraulic presses ensures that the material is drawn smoothly into the die without sudden changes in deformation, reducing the risk of defects.

The superior control and flexibility offered by hydraulic presses make them the preferred choice for deep drawing applications, particularly when forming complex geometries or working with materials that are prone to springback or galling.

Fundamentals of Hydraulic Presses

2.1 Working Principles of Hydraulic Presses

Hydraulic presses operate on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. A hydraulic press consists of a hydraulic cylinder containing fluid (usually oil), a piston, and a ram. The press applies pressure to the fluid using a pump or compressor, which generates the force needed to move the piston. This force is transferred through the ram to the material being shaped.

The press’s force output is determined by the size of the hydraulic piston and the pressure of the fluid. Hydraulic presses can generate immense forces with relatively small power input, which makes them suitable for heavy-duty metal forming processes like deep drawing.

Key steps in hydraulic press operation:

- Fluid Compression: Hydraulic fluid is pressurized by a pump.

- Force Transmission: The pressurized fluid moves the piston, which exerts force on the ram.

- Deformation: The ram pushes against the workpiece, deforming it into the shape of the die.

2.2 Components of a Hydraulic Press

The main components of a hydraulic press used in deep drawing include:

- Hydraulic Cylinder: The cylinder houses the hydraulic fluid and piston. When pressurized, the fluid moves the piston, generating force.

- Piston and Ram: The piston is attached to the ram, which transfers the force to the punch or die. The ram pushes the workpiece into the die cavity to form the part.

- Press Frame: The frame supports the entire structure, including the hydraulic cylinder, ram, and die set. Hydraulic presses come in various frame designs, such as C-frame, H-frame, or four-column presses, depending on the application.

- Pump and Motor: These components pressurize the hydraulic fluid, generating the necessary force to move the piston. Hydraulic presses use either manual pumps (for smaller operations) or electric motors (for industrial presses).

- Control Systems: Modern hydraulic presses are equipped with control systems that allow operators to adjust parameters such as punch speed, force, and stroke length.

2.3 Types of Hydraulic Presses Used in Deep Drawing

Hydraulic presses come in various types, each offering unique advantages depending on the complexity of the part, material, and production requirements. The most common types used in deep drawing are:

- Single-Action Hydraulic Presses: These presses apply force from a single cylinder, making them ideal for shallow drawing operations. They are commonly used for parts with simple geometries.

- Double-Action Hydraulic Presses: These presses have two cylinders: one for the punch and one for the blank holder. This configuration provides superior control over both punch force and blank holder force, allowing for deeper drawing operations and more complex geometries.

- Triple-Action Hydraulic Presses: In addition to the punch and blank holder cylinders, triple-action presses feature a third cylinder that controls ejection or additional material holding. These presses are ideal for highly complex, deep-drawn parts that require multiple stages of material handling.

2.4 Comparison Between Hydraulic Presses and Mechanical Presses

While mechanical presses are often used in metal forming processes such as stamping and bending, hydraulic presses offer significant advantages for deep drawing due to their superior force control and flexibility. Key differences include:

- Force Application: Hydraulic presses can apply constant force throughout the stroke, while mechanical presses deliver peak force at the bottom of the stroke. This makes hydraulic presses more suitable for deep drawing, where precise force control is needed at different stages of deformation.

- Speed: Mechanical presses operate at higher speeds, making them ideal for high-volume production of shallow parts. Hydraulic presses operate more slowly, but their precision makes them ideal for deep drawing complex parts or parts that require large forming depths.

- Stroke Length: Hydraulic presses offer variable stroke lengths, allowing them to accommodate parts with different forming depths. Mechanical presses have a fixed stroke length, limiting their ability to handle deep drawing operations.

- Flexibility: Hydraulic presses can easily be adjusted to accommodate different materials, part sizes, and geometries, while mechanical presses are optimized for specific production runs. This makes hydraulic presses more versatile for a wide range of deep drawing applications.

The Deep Drawing Process with Hydraulic Presses

3.1 Material Flow and Plastic Deformation in Deep Drawing

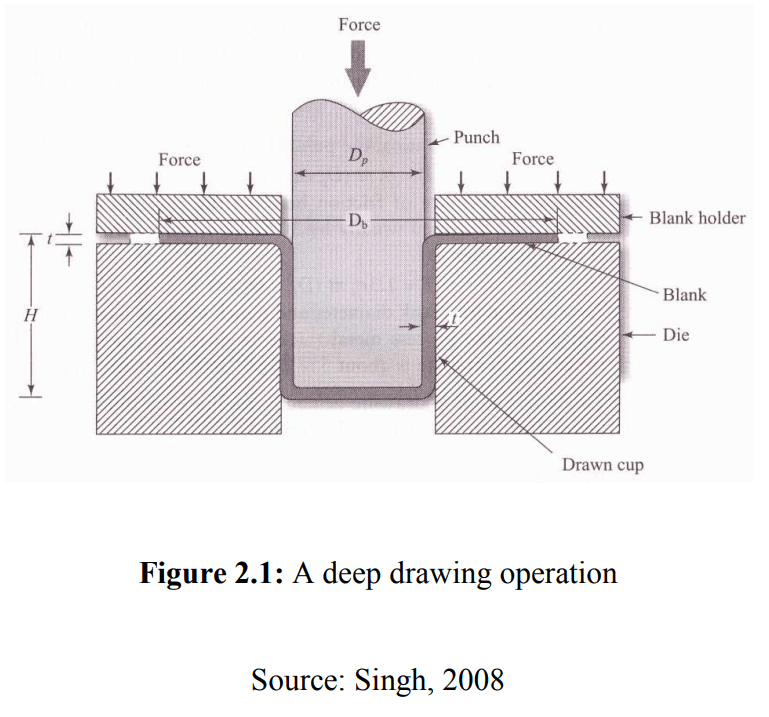

In the deep drawing process, a flat sheet metal blank is placed over a die cavity, and a punch is used to press the blank into the die. The material undergoes plastic deformation, meaning it is permanently reshaped without cracking. As the punch moves downward, the material flows radially inward toward the center of the blank and is pulled into the die cavity, forming a hollow shape.

Hydraulic presses play a critical role in controlling the material flow during deep drawing. The gradual and controlled application of force prevents defects such as wrinkling, tearing, and excessive thinning, which can occur when the material is overstressed or deformed too quickly.

3.2 Stages of the Deep Drawing Process in Hydraulic Presses

The deep drawing process involves several stages, each of which must be carefully controlled to ensure the material deforms uniformly without failure:

- Blank Placement: A flat metal blank is placed over the die cavity. The blank must be perfectly aligned to prevent uneven deformation.

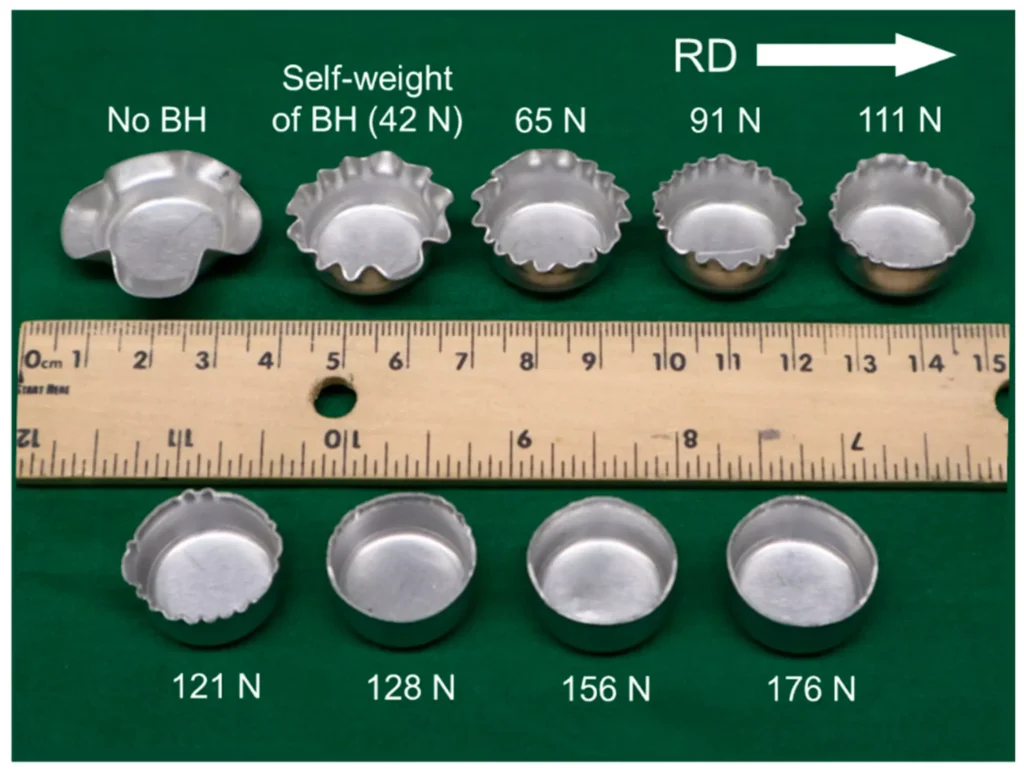

- Clamping: The blank holder applies pressure to the edges of the blank to prevent it from wrinkling as it is drawn into the die. In hydraulic presses, the blank holder force can be adjusted dynamically to accommodate different materials and part geometries.

- Drawing: The punch moves downward, pressing the blank into the die cavity. The hydraulic press provides precise control over punch speed and force, ensuring the material flows smoothly into the die without sudden deformation or tearing.

- Redrawing (if necessary): For parts with significant depth or complex geometries, the initial drawing operation may not be sufficient to achieve the desired shape. In these cases, the part may be redrawn using additional dies to gradually increase the depth and refine the shape.

- Trimming and Finishing: After the part has been drawn, excess material may need to be trimmed from the edges, and finishing processes such as deburring or polishing may be required to achieve the desired surface quality.

3.3 Punch, Die, and Blank Holder Mechanics in Hydraulic Deep Drawing

Punch: The punch is the tool that presses the blank into the die cavity. Its shape and dimensions determine the internal geometry of the drawn part. In hydraulic presses, the punch force can be precisely controlled to prevent overstressing the material and causing defects such as tearing or excessive thinning.

Die: The die provides the external shape of the part. The material is drawn into the die cavity by the punch, conforming to its shape. Hydraulic presses can accommodate various die designs, allowing for the production of parts with complex geometries, such as deep-drawn cups, tanks, and enclosures.

Blank Holder: The blank holder plays a critical role in preventing wrinkling during the deep drawing process. By applying pressure to the edges of the blank, the blank holder ensures that the material flows smoothly into the die without folding or wrinkling. In hydraulic presses, the blank holder force can be adjusted throughout the drawing process to optimize material flow.

3.4 Advantages of Using Hydraulic Presses for Deep Drawing

Hydraulic presses offer several advantages for deep drawing, making them the preferred choice for many industries:

- Precise Force Control: The ability to control both punch force and blank holder force allows for precise management of material flow, minimizing the risk of defects such as wrinkling or tearing.

- Variable Speed Control: Hydraulic presses can operate at different speeds throughout the press stroke, allowing for gradual deformation and reducing the risk of overstressing the material.

- Deep Forming Capability: Hydraulic presses can handle large stroke lengths, making them ideal for deep drawing operations that require significant forming depths.

- Versatility: Hydraulic presses can accommodate a wide range of materials, including aluminum, steel, copper, and titanium, making them suitable for applications in industries ranging from automotive to aerospace.

Pressure Control and Force Distribution in Hydraulic Presses

4.1 Importance of Pressure Control in Deep Drawing

In deep drawing, maintaining precise pressure control is critical to ensuring that the material deforms smoothly and uniformly without tearing or wrinkling. Hydraulic presses excel in pressure control because they allow for fine adjustments to be made throughout the drawing process, ensuring that the correct amount of force is applied at each stage.

Inconsistent pressure during deep drawing can lead to defects such as:

- Wrinkling: Occurs when the blank holder force is too low, allowing excess material to fold or buckle as it is drawn into the die.

- Tearing: Occurs when the punch force is too high or applied too quickly, causing the material to overstretch and crack.

- Thinning: Results from uneven force distribution, causing localized areas of the material to become too thin, which weakens the part.

Hydraulic presses mitigate these risks by offering precise control over both the punch force and blank holder force, allowing for smooth, controlled material flow.

4.2 Force Distribution Mechanisms in Hydraulic Presses

Hydraulic presses distribute force evenly across the entire surface of the workpiece, ensuring that the material deforms uniformly. This is particularly important in deep drawing, where the material is subjected to both tensile and compressive stresses.

- Tensile Stresses: As the material is drawn into the die, the edges of the blank experience tensile stresses, which stretch the material.

- Compressive Stresses: In the flange area near the blank holder, the material is compressed as it flows into the die cavity.

Hydraulic presses control the distribution of these stresses by adjusting the punch force, blank holder force, and drawing speed, ensuring that the material flows smoothly without overstressing any particular area.

4.3 Relationship Between Pressure, Force, and Material Behavior

The behavior of the material during deep drawing is influenced by the relationship between pressure, force, and material properties. Hydraulic presses allow manufacturers to tailor the process parameters based on the material being used.

- Yield Strength: Materials with lower yield strength, such as aluminum or low-carbon steel, require less punch force to deform. Hydraulic presses can adjust the force to prevent overstressing these materials.

- Ductility: Ductile materials can undergo significant plastic deformation before failing, making them ideal for deep drawing. Hydraulic presses allow for gradual force application, preventing brittle failure in materials with lower ductility.

- Strain Hardening: Some materials become stronger as they are deformed, a phenomenon known as strain hardening. Hydraulic presses can adjust the force during the drawing process to account for this change in material strength.

4.4 Precision Control of Punch Force and Blank Holder Force

Hydraulic presses provide precision control over both the punch force and blank holder force, allowing manufacturers to optimize the deep drawing process for different materials and part geometries.

- Punch Force Control: The punch force must be carefully controlled to ensure that the material flows smoothly into the die without tearing or excessive thinning. Hydraulic presses allow for fine adjustments to the punch force throughout the stroke, ensuring that the material is deformed evenly.

- Blank Holder Force Control: The blank holder force prevents wrinkling by applying pressure to the edges of the blank. In hydraulic presses, the blank holder force can be dynamically adjusted during the drawing process, allowing for real-time optimization of material flow and preventing defects.

This level of control is particularly important for deep drawing applications where the part geometry is complex or the material has variable properties, such as anisotropy (directional dependence of material properties).

Hydraulic Press Configurations for Deep Drawing

Hydraulic presses come in various configurations, each designed to meet the specific requirements of different deep drawing applications. The choice of press configuration depends on factors such as the complexity of the part, the material being formed, and the production volume.

5.1 Single-Action Hydraulic Presses

Single-action hydraulic presses apply force from a single hydraulic cylinder, which controls the movement of the punch. These presses are typically used for shallow drawing operations, where the part geometry is relatively simple, and the forming depth is not significant.

Advantages of single-action hydraulic presses:

- Cost-Effective: Single-action presses are simpler and less expensive than double- or triple-action presses, making them ideal for smaller production runs or parts with simple geometries.

- Ease of Operation: These presses are straightforward to operate and require less complex tooling than multi-action presses.

However, single-action presses have limitations in terms of force control and blank holder management, making them less suitable for deep drawing operations where more precise control over material flow is required.

5.2 Double-Action Hydraulic Presses

Double-action hydraulic presses feature two independent hydraulic cylinders: one for controlling the punch and another for controlling the blank holder. This configuration provides superior control over both the punch force and blank holder force, making it ideal for deeper drawing operations and more complex geometries.

Advantages of double-action hydraulic presses:

- Precise Blank Holder Control: By independently controlling the blank holder force, double-action presses can prevent wrinkling and ensure smooth material flow into the die.

- Deeper Drawing Capability: The ability to control both the punch and blank holder forces allows for deeper draws, making these presses suitable for producing parts with significant forming depths.

- Improved Material Flow: The dynamic control of punch and blank holder forces allows for better management of material flow, reducing the risk of defects such as tearing or thinning.

Double-action hydraulic presses are commonly used in industries such as automotive and aerospace, where parts with complex geometries and deep forming depths are required.

5.3 Triple-Action Hydraulic Presses

Triple-action hydraulic presses add a third hydraulic cylinder to control the ejection of the part or to apply additional force to the blank. These presses are used for highly complex deep drawing applications where additional force or material handling is required.

Advantages of triple-action hydraulic presses:

- Complex Part Handling: The third cylinder allows for more complex material handling and ejection processes, making these presses ideal for producing parts with intricate geometries or multi-stage drawing operations.

- Multiple Force Control: Triple-action presses offer the most control over the deep drawing process, allowing for independent control of the punch, blank holder, and ejection forces.

Triple-action hydraulic presses are used in advanced manufacturing applications where parts with complex shapes and multiple forming stages are required, such as in the production of automotive body panels, aircraft fuselage sections, and medical device enclosures.

5.4 Special Configurations for Complex Deep Drawing Applications

For highly specialized deep drawing applications, hydraulic presses can be customized with additional features and configurations to meet specific requirements. Some examples include:

- Multi-Slide Presses: These presses feature multiple slides that move independently, allowing for the simultaneous drawing of complex parts with multiple features, such as flanges, ribs, or undercuts.

- Hydro-Mechanical Presses: These presses combine the force of a hydraulic press with the precision of mechanical control, allowing for highly accurate forming of complex parts.

- Multi-Stage Presses: These presses are designed to perform multiple drawing operations in a single cycle, reducing the need for secondary operations and improving production efficiency.

These specialized configurations allow manufacturers to tackle even the most challenging deep drawing applications, producing parts with complex geometries, tight tolerances, and high-quality finishes.

Hydraulic Fluids and Lubrication in Deep Drawing Presses

6.1 Role of Hydraulic Fluids in Press Operation

Hydraulic presses rely on hydraulic fluid to generate and transmit force. The fluid is pressurized by a pump, and this pressure is used to move the piston and generate the force needed for the deep drawing process. The selection of hydraulic fluid is critical to the performance, efficiency, and longevity of the press.

Functions of hydraulic fluids in deep drawing presses:

- Force Transmission: Hydraulic fluids transmit the force generated by the pump to the piston, which moves the punch or blank holder.

- Heat Dissipation: During operation, hydraulic fluids absorb heat generated by friction and pressure, helping to keep the press components cool and preventing overheating.

- Lubrication: Hydraulic fluids also lubricate the moving parts of the press, reducing wear and extending the life of the components.

6.2 Types of Hydraulic Fluids for Deep Drawing

The performance of a hydraulic press is directly influenced by the type of hydraulic fluid used. There are several types of hydraulic fluids, each with specific properties that make them suitable for different applications:

- Mineral-Based Hydraulic Fluids: These are the most common type of hydraulic fluid and are derived from petroleum. They offer excellent lubricating properties and are suitable for most hydraulic press applications.

- Synthetic Hydraulic Fluids: These fluids are engineered to provide superior performance in extreme conditions, such as high temperatures or high pressures. They are often used in high-performance hydraulic presses where precise force control and heat resistance are critical.

- Fire-Resistant Hydraulic Fluids: These fluids are formulated to reduce the risk of fire in high-temperature environments. They are commonly used in industries such as aerospace and automotive manufacturing, where safety is a top priority.

- Bio-Based Hydraulic Fluids: These environmentally friendly fluids are derived from renewable sources and are designed to reduce the environmental impact of hydraulic press operations. They are increasingly being used in industries that prioritize sustainability.

6.3 Lubrication in the Deep Drawing Process

Lubrication plays a critical role in the deep drawing process, as it helps reduce friction between the blank, punch, and die. Proper lubrication ensures smooth material flow, minimizes tool wear, and reduces the risk of defects such as galling, surface scratches, or thinning.

Types of lubricants used in deep drawing:

- Oil-Based Lubricants: Oil-based lubricants are commonly used in deep drawing applications to reduce friction and prevent the material from sticking to the die or punch. These lubricants are particularly effective when drawing materials like steel and stainless steel.

- Water-Based Lubricants: Water-based lubricants offer good cooling properties and are used in applications where heat dissipation is important. They are commonly used when drawing aluminum and other lightweight materials.

- Dry Film Lubricants: Dry film lubricants, such as graphite or molybdenum disulfide, provide a solid, non-stick layer that reduces friction without the need for liquid lubrication. These lubricants are often used in deep drawing applications where cleanliness or surface finish is critical.

6.4 Preventing Galling and Wear in Hydraulic Presses

Galling is a common issue in deep drawing, where material from the blank adheres to the punch or die, causing scratches and surface defects on the part. Galling occurs due to excessive friction between the blank and the tooling.

To prevent galling and wear, manufacturers use a combination of:

- Proper Lubrication: Ensuring that the right type and amount of lubricant are used is essential for reducing friction and preventing galling.

- Tool Coatings: Tooling can be coated with materials like titanium nitride (TiN) or diamond-like carbon (DLC) to reduce friction and wear.

- Optimized Press Parameters: Controlling the punch speed, force, and lubrication flow can help reduce the risk of galling and extend the life of the tooling.

By carefully selecting hydraulic fluids and lubricants, manufacturers can optimize the performance of their hydraulic presses and reduce the risk of defects during the deep drawing process.

Materials Suitable for Deep Drawing with Hydraulic Presses

The material selection for deep drawing is crucial, as different metals exhibit unique behaviors under the stresses and strains of the process. Hydraulic presses are versatile machines that can handle a wide variety of materials, each with its own forming characteristics.

7.1 Steel, Aluminum, and Stainless Steel

Steel: Low-carbon steel is one of the most commonly used materials in deep drawing due to its excellent ductility and formability. It can be easily drawn into complex shapes with minimal risk of tearing or wrinkling. Low-carbon steel is widely used in the automotive industry for components such as body panels and fuel tanks.

- Hydraulic Press Considerations: When deep drawing steel, the hydraulic press must provide sufficient force to deform the material without causing excessive thinning or tearing. Proper lubrication is also essential to prevent galling and surface defects.

Aluminum: Aluminum is a lightweight material with good corrosion resistance, making it ideal for applications where weight savings and durability are important, such as in aerospace and automotive applications. Aluminum’s high ductility allows it to be drawn into deep, complex shapes, but it is also prone to springback, which can complicate the deep drawing process.

- Hydraulic Press Considerations: Aluminum requires precise control of punch force and speed to prevent defects such as wrinkling or earing. Hydraulic presses with variable speed control are ideal for drawing aluminum, as they allow for gradual force application and smooth material flow.

Stainless Steel: Stainless steel is known for its strength, corrosion resistance, and ability to withstand high temperatures, making it suitable for industries such as medical devices and food processing. However, its higher strength and tendency to work harden make it more difficult to draw than materials like aluminum or low-carbon steel.

- Hydraulic Press Considerations: Stainless steel requires higher punch forces to deform, and the blank holder force must be carefully controlled to prevent wrinkling. Lubrication and tool coatings are also critical to prevent galling when drawing stainless steel.

7.2 Copper, Brass, and Other Alloys

Copper: Copper is highly ductile and exhibits excellent formability, making it suitable for deep drawing applications that require complex shapes, such as electrical connectors and plumbing fittings. Copper’s high thermal and electrical conductivity also makes it a popular choice for heat exchangers and electronic components.

- Hydraulic Press Considerations: When deep drawing copper, the hydraulic press must provide precise control over punch speed and force to prevent wrinkling and ensure smooth material flow. Copper is prone to work hardening, so intermediate annealing may be necessary for deeper draws.

Brass: Brass is an alloy of copper and zinc that offers excellent corrosion resistance and a decorative finish. It is often used in applications such as decorative hardware, musical instruments, and plumbing components. Brass is relatively easy to form and can be drawn into deep, complex shapes with minimal risk of tearing.

- Hydraulic Press Considerations: Brass can be drawn using lower punch forces than steel or stainless steel, but the press must still provide precise control over material flow to prevent defects.

7.3 Titanium and Nickel Alloys

Titanium: Titanium is prized for its high strength-to-weight ratio, corrosion resistance, and biocompatibility. It is commonly used in industries such as aerospace, medical devices, and chemical processing. However, titanium’s high strength and tendency to spring back after deformation make it challenging to form using traditional methods.

- Hydraulic Press Considerations: Titanium requires higher punch forces than most materials, and the press must be capable of applying constant, controlled force throughout the stroke to prevent springback and achieve the desired part geometry. Hydraulic presses with servo control are ideal for deep drawing titanium, as they offer the flexibility and precision needed for complex parts.

Nickel Alloys: Nickel-based alloys, such as Inconel and Hastelloy, offer excellent heat resistance and corrosion resistance, making them suitable for high-temperature applications in industries such as aerospace and chemical processing. These alloys are difficult to form due to their high strength and work hardening properties.

- Hydraulic Press Considerations: Nickel alloys require high punch forces and careful control of material flow to prevent cracking or tearing. Hydraulic presses with real-time force monitoring and feedback systems are ideal for drawing nickel alloys, as they allow for precise adjustments to the punch and blank holder forces throughout the process.

7.4 How Material Properties Influence the Role of Hydraulic Presses

The success of the deep drawing process depends on selecting the right material and optimizing the press parameters based on the material’s properties. Key material properties that influence the role of hydraulic presses include:

- Ductility: Materials with high ductility, such as aluminum and copper, can be easily drawn into complex shapes with minimal risk of tearing. Hydraulic presses allow for fine-tuned control of punch speed and force, which is critical when working with ductile materials.

- Yield Strength: Materials with lower yield strength, such as low-carbon steel, require less punch force to deform, allowing for faster cycle times and less wear on the tooling. Hydraulic presses can adjust the force based on the material’s yield strength, ensuring optimal forming conditions.

- Work Hardening: Some materials, such as stainless steel and nickel alloys, exhibit work hardening, meaning they become stronger and more resistant to deformation as they are drawn. Hydraulic presses can adjust the force throughout the process to account for this increase in strength, ensuring that the material is fully formed without cracking or tearing.

- Springback: Materials such as aluminum and titanium tend to spring back after being deformed, which can make it difficult to achieve precise part geometries. Hydraulic presses with servo control can apply continuous, controlled force to minimize springback and ensure that the part conforms to the die.

By selecting the appropriate material and optimizing the hydraulic press parameters, manufacturers can achieve high-quality, defect-free parts in a wide range of deep drawing applications.

Common Defects in Hydraulic Deep Drawing and Their Prevention

While hydraulic presses offer precise control over the deep drawing process, defects can still occur if the process parameters are not optimized. Understanding the common defects in hydraulic deep drawing and how to prevent them is essential for producing high-quality parts.

8.1 Wrinkling, Tearing, and Thinning

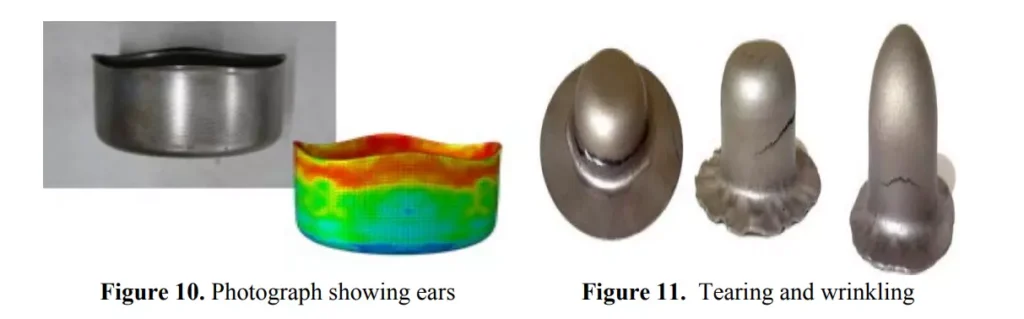

Wrinkling: Wrinkling occurs when the material is compressed and folds or buckles instead of being drawn smoothly into the die. This defect is typically seen in the flange area and can compromise the structural integrity and surface quality of the part.

- Prevention: To prevent wrinkling, the blank holder force must be carefully controlled. If the blank holder force is too low, the material will flow too freely, leading to wrinkling. Hydraulic presses allow for dynamic control of the blank holder force, ensuring that the material is properly supported throughout the drawing process.

Tearing: Tearing occurs when the material is overstretched and cracks during the drawing process. This defect is usually caused by excessive punch force, incorrect material selection, or improper lubrication.

- Prevention: To prevent tearing, the punch force must be carefully controlled to avoid overstressing the material. Hydraulic presses provide precision force control, allowing for fine adjustments to the punch force throughout the stroke. Additionally, selecting a material with sufficient ductility and using the appropriate lubricant can help reduce the risk of tearing.

Thinning: Thinning occurs when the material is stretched too much in certain areas, leading to a reduction in thickness. This weakens the part and increases the risk of failure during use.

- Prevention: Thinning can be minimized by controlling the punch force and blank holder force to ensure that the material flows evenly into the die. Hydraulic presses allow for real-time adjustments to the press parameters, ensuring that the material is drawn uniformly without excessive thinning.

8.2 Earing and Non-Uniform Thickness Distribution

Earing: Earing is a defect that occurs due to anisotropy in the material’s grain structure, causing uneven deformation during deep drawing. This results in the formation of ears or flanges around the edges of the part, which must be trimmed in a secondary operation.

- Prevention: To minimize earing, materials with low anisotropy should be selected, and the blank should be aligned with the material’s grain direction. Hydraulic presses can also help reduce earing by controlling the punch force and blank holder force to ensure uniform material flow.

Non-Uniform Thickness Distribution: Non-uniform thickness distribution occurs when the material is unevenly stretched during the drawing process, resulting in areas of the part that are too thin or too thick.

- Prevention: Ensuring that the punch force and blank holder force are properly balanced is essential for achieving uniform thickness distribution. Hydraulic presses with real-time force monitoring and feedback systems can dynamically adjust the press parameters to ensure that the material is deformed evenly.

8.3 Preventive Measures Using Hydraulic Presses

Hydraulic presses offer several features that help prevent defects during the deep drawing process, including:

- Dynamic Force Control: Hydraulic presses allow for real-time adjustments to both the punch force and blank holder force, ensuring that the material is deformed smoothly without overstressing any particular area.

- Variable Speed Control: By adjusting the punch speed throughout the stroke, hydraulic presses can prevent defects such as tearing or thinning, which can occur if the material is drawn too quickly.

- Precision Lubrication: Proper lubrication is essential for reducing friction and preventing defects such as galling or surface scratches. Hydraulic presses can be equipped with automatic lubrication systems to ensure that the correct amount of lubricant is applied throughout the drawing process.

8.4 Real-Time Monitoring and Defect Detection

Modern hydraulic presses are equipped with real-time monitoring systems that use sensors and feedback loops to track key process parameters such as punch force, blank holder force, and material flow. These systems allow manufacturers to detect potential defects before they occur and make real-time adjustments to the press parameters to prevent them.

Common real-time monitoring features include:

- Force Monitoring: Sensors measure the punch force and blank holder force throughout the stroke, allowing for fine-tuned control of material flow and deformation.

- Position Monitoring: Sensors track the position of the punch and blank holder, ensuring that the material is being drawn evenly into the die.

- Lubrication Monitoring: Sensors monitor the application of lubricants to ensure that the correct amount is being applied to prevent galling and surface defects.

By incorporating real-time monitoring and feedback systems into hydraulic presses, manufacturers can optimize the deep drawing process and reduce the risk of defects.

Automation and Smart Control Systems in Hydraulic Presses

9.1 Role of Automation in Modern Hydraulic Presses

Automation has transformed the way hydraulic presses are used in manufacturing, enabling greater precision, efficiency, and flexibility in the deep drawing process. Modern hydraulic presses are equipped with computer numerical control (CNC) systems, servo motors, and smart sensors that allow for real-time adjustments to process parameters, ensuring consistent, high-quality parts.

Benefits of automation in hydraulic presses include:

- Increased Productivity: Automated hydraulic presses can operate continuously with minimal human intervention, reducing cycle times and increasing production efficiency.

- Enhanced Precision: Automation allows for precise control over punch force, blank holder force, and punch speed, ensuring that each part is formed to exact specifications.

- Consistency and Repeatability: Automated presses produce consistent, repeatable results, reducing the risk of defects and ensuring that each part meets the required quality standards.

9.2 Servo-Controlled Hydraulic Presses

Servo-controlled hydraulic presses use servo motors to control the movement of the hydraulic piston, allowing for precise control over punch force, speed, and position. Servo-controlled presses offer several advantages over traditional hydraulic presses, including:

- Real-Time Adjustments: Servo motors allow for real-time adjustments to the press parameters, enabling manufacturers to fine-tune the process for different materials and part geometries.

- Energy Efficiency: Servo-controlled presses are more energy-efficient than traditional hydraulic presses, as the servo motors only use energy when needed, reducing overall energy consumption.

- High Precision: The precise control offered by servo motors ensures that the punch force and blank holder force are applied with high accuracy, reducing the risk of defects and improving part quality.

Servo-controlled hydraulic presses are ideal for applications that require high precision and flexibility, such as deep drawing parts with complex geometries or tight tolerances.

9.3 Smart Sensors and Feedback Systems

Modern hydraulic presses are equipped with smart sensors that monitor key process parameters in real time, such as force, speed, position, and temperature. These sensors provide valuable data that can be used to optimize the deep drawing process and prevent defects.

- Force Sensors: Measure the punch force and blank holder force throughout the stroke, ensuring that the correct amount of force is applied at each stage of the drawing process.

- Position Sensors: Track the movement of the punch and blank holder, ensuring that the material is drawn evenly into the die and preventing defects such as wrinkling or thinning.

- Temperature Sensors: Monitor the temperature of the hydraulic fluid and the workpiece, ensuring that the process operates within the optimal temperature range.

These sensors are connected to a feedback system that allows the press to make real-time adjustments to the process parameters, ensuring consistent, high-quality parts.

9.4 Integration of Industry 4.0 in Hydraulic Deep Drawing

Industry 4.0 refers to the integration of digital technologies, automation, and data analytics into manufacturing processes. In hydraulic deep drawing, Industry 4.0 technologies such as smart sensors, real-time monitoring, and predictive maintenance are transforming the way parts are produced.

Key Industry 4.0 technologies in hydraulic deep drawing include:

- Real-Time Data Monitoring: Sensors collect data on key process parameters, such as punch force, speed, and material flow. This data can be analyzed in real time to optimize the process and prevent defects.

- Predictive Maintenance: By monitoring the condition of the press components, such as the hydraulic cylinder, piston, and seals, predictive maintenance systems can alert operators when maintenance is needed, reducing downtime and preventing costly breakdowns.

- Digital Twins: A digital twin is a virtual model of the hydraulic press and the deep drawing process. By simulating the process in a virtual environment, engineers can test different press parameters and tooling designs before implementing them in production.

The integration of Industry 4.0 technologies into hydraulic deep drawing allows manufacturers to achieve greater precision, efficiency, and flexibility, while reducing the risk of defects and downtime.

Simulation and Finite Element Analysis (FEA) in Hydraulic Deep Drawing

10.1 Importance of FEA in Hydraulic Press Design

Finite Element Analysis (FEA) is a powerful computational tool used to simulate the behavior of materials during the deep drawing process. FEA allows engineers to predict how the material will deform under various conditions and optimize the design of the hydraulic press, tooling, and process parameters to prevent defects.

The benefits of FEA in hydraulic deep drawing include:

- Optimized Tooling Design: FEA simulations can be used to optimize the design of the punch, die, and blank holder, ensuring that the material flows smoothly into the die without tearing or wrinkling.

- Defect Prevention: FEA allows engineers to identify potential defects, such as thinning or wrinkling, before they occur in production, enabling them to adjust the process parameters to prevent these defects.

- Material Behavior Prediction: FEA simulations can predict how different materials will behave during the deep drawing process, allowing engineers to select the optimal material for the application.

10.2 Predicting Material Flow and Defect Prevention

One of the most important applications of FEA in hydraulic deep drawing is the prediction of material flow. By simulating the flow of the material into the die cavity, FEA can help engineers identify areas where the material may become overstressed, leading to defects such as tearing or thinning.

FEA also allows engineers to test different process parameters, such as punch force, blank holder force, and punch speed, to determine the optimal settings for each material and part geometry.

In addition to predicting material flow, FEA can be used to prevent common deep drawing defects such as:

- Wrinkling: FEA simulations can identify areas of the part that are prone to wrinkling and allow engineers to adjust the blank holder force or material thickness to prevent this defect.

- Tearing: FEA can simulate the tensile stresses in the material during the drawing process, helping engineers adjust the punch force or tooling design to prevent tearing.

- Thinning: By analyzing the strain distribution in the material, FEA can identify areas where the material is at risk of becoming too thin, allowing engineers to adjust the process parameters to ensure uniform thickness.

10.3 Case Studies of FEA in Hydraulic Deep Drawing

Several case studies have demonstrated the effectiveness of FEA in optimizing the deep drawing process and preventing defects. For example, in the automotive industry, FEA has been used to optimize the design of body panels and fuel tanks, reducing material waste and improving part quality. In the aerospace industry, FEA has been used to optimize the deep drawing of aircraft fuselage sections, ensuring that the parts meet the stringent quality and safety standards required in the industry.

10.4 Simulation Tools Used in Hydraulic Press Applications

There are several simulation tools available for performing FEA in hydraulic deep drawing applications. Some of the most commonly used tools include:

- ABAQUS: A powerful FEA software that is widely used in the automotive, aerospace, and manufacturing industries for simulating the deep drawing process.

- ANSYS: Another popular FEA software that offers advanced simulation capabilities for predicting material behavior, optimizing tooling design, and preventing defects in hydraulic deep drawing applications.

- LS-DYNA: A versatile FEA software that is used for simulating complex metal forming processes, including deep drawing, hydroforming, and stamping.

These simulation tools provide valuable insights into the deep drawing process, allowing engineers to optimize the hydraulic press, tooling, and process parameters for improved part quality and reduced defect rates.

Hydraulic Presses in Different Industry Applications

Hydraulic presses play a crucial role in a wide range of industries, enabling the production of high-quality parts with complex geometries, tight tolerances, and uniform thickness. The versatility of hydraulic presses makes them suitable for deep drawing applications in industries such as automotive, aerospace, consumer goods, and medical devices.

11.1 Automotive Industry: Body Panels, Fuel Tanks, and Exhaust Components

The automotive industry is one of the largest users of hydraulic presses for deep drawing. Hydraulic presses are used to produce body panels, fuel tanks, exhaust components, and other critical parts that require high strength, durability, and lightweight properties.

Key advantages of hydraulic presses in the automotive industry include:

- High Precision: Hydraulic presses provide the precision needed to produce parts with complex geometries and tight tolerances, such as automotive body panels.

- Uniform Thickness: The ability to control the punch force and blank holder force ensures that the material is drawn evenly into the die, resulting in parts with uniform thickness and high structural integrity.

- Lightweight Materials: Hydraulic presses can handle lightweight materials such as aluminum and high-strength steel, which are commonly used in the automotive industry to reduce vehicle weight and improve fuel efficiency.

11.2 Aerospace Industry: Fuselage Panels, Structural Components, and Engine Parts

The aerospace industry requires parts that are both lightweight and strong, making hydraulic presses ideal for producing components such as fuselage panels, structural components, and engine parts.

Key advantages of hydraulic presses in the aerospace industry include:

- Complex Geometries: Hydraulic presses can produce parts with complex shapes, such as aircraft fuselage sections, which require deep drawing operations with tight tolerances.

- High-Strength Materials: Hydraulic presses can handle high-strength materials such as titanium and nickel alloys, which are commonly used in aerospace applications due to their excellent strength-to-weight ratio and corrosion resistance.

- Precision and Repeatability: The precision and repeatability of hydraulic presses ensure that aerospace components meet the stringent quality and safety standards required in the industry.

11.3 Consumer Goods: Cookware, Packaging, and Electronics Enclosures

Hydraulic presses are widely used in the consumer goods industry to produce products such as cookware, packaging, and electronics enclosures. The ability of hydraulic presses to produce parts with smooth surfaces, uniform thickness, and complex geometries makes them ideal for these applications.

Key advantages of hydraulic presses in the consumer goods industry include:

- Smooth Surface Finishes: Hydraulic presses provide the smooth surface finishes needed for products such as cookware and consumer electronics enclosures, where aesthetics and quality are important.

- Complex Shapes: Hydraulic presses can produce parts with complex shapes, such as packaging and electronics enclosures, which require deep drawing operations with intricate features.

- High-Volume Production: Hydraulic presses are capable of producing large volumes of parts with consistent quality, making them ideal for mass production of consumer goods.

11.4 Medical Devices: Surgical Instruments and Device Housings

The medical device industry requires parts that are both biocompatible and precise, making hydraulic presses ideal for producing components such as surgical instruments, implants, and device housings.

Key advantages of hydraulic presses in the medical device industry include:

- Biocompatible Materials: Hydraulic presses can handle stainless steel and titanium, which are commonly used in medical devices due to their biocompatibility and corrosion resistance.

- Tight Tolerances: The precision of hydraulic presses ensures that medical device components are produced with tight tolerances, which are critical for ensuring the safety and efficacy of the devices.

- Smooth Surface Finishes: Hydraulic presses provide the smooth surface finishes needed for medical devices, where cleanliness and surface quality are critical.

Advantages and Limitations of Hydraulic Presses in Deep Drawing

While hydraulic presses offer many advantages for deep drawing, they also have some limitations. Understanding the benefits and challenges of using hydraulic presses is essential for selecting the right equipment for deep drawing applications.

12.1 Benefits of Hydraulic Presses: Precision, Versatility, and Control

Hydraulic presses offer several key advantages for deep drawing, including:

- Precision Force Control: Hydraulic presses allow for precise control over both the punch force and blank holder force, ensuring that the material is deformed smoothly without overstressing any particular area.

- Variable Speed Control: The ability to control the punch speed throughout the stroke allows for gradual deformation, reducing the risk of defects such as tearing or thinning.

- Versatility: Hydraulic presses can handle a wide range of materials, including steel, aluminum, stainless steel, and titanium, making them suitable for a variety of industries and applications.

- Deep Forming Capability: Hydraulic presses can accommodate large stroke lengths, making them ideal for deep drawing operations that require significant forming depths.

- Complex Geometries: Hydraulic presses can produce parts with complex geometries, such as deep-drawn cups, tanks, and enclosures, which would be difficult to achieve with other forming methods.

12.2 Challenges and Limitations of Hydraulic Presses

Despite their many advantages, hydraulic presses also have some limitations:

- Slower Production Speeds: Hydraulic presses operate more slowly than mechanical presses, making them less suitable for high-volume production of shallow parts.

- Higher Energy Consumption: Hydraulic presses can consume more energy than mechanical presses, particularly when operating at high forces or with large stroke lengths.

- Maintenance Requirements: Hydraulic presses require regular maintenance to ensure the proper functioning of the hydraulic system, including the pumps, cylinders, and seals.

12.3 Comparison with Mechanical and Servo Presses

While hydraulic presses are ideal for deep drawing, other types of presses, such as mechanical presses and servo presses, may be more suitable for certain applications. Key differences include:

- Mechanical Presses: Mechanical presses operate at higher speeds and are ideal for high-volume production of shallow parts. However, they lack the precise force control and flexibility of hydraulic presses, making them less suitable for deep drawing applications.

- Servo Presses: Servo presses offer the precision and flexibility of hydraulic presses, combined with the speed and efficiency of mechanical presses. They are ideal for applications that require high precision and flexibility, such as deep drawing parts with complex geometries.

12.4 Overcoming Challenges in Hydraulic Press Operations

To overcome the challenges associated with hydraulic presses, manufacturers can implement several strategies:

- Optimizing Energy Consumption: Using servo-controlled hydraulic presses can reduce energy consumption by only using energy when needed, making the process more energy-efficient.

- Implementing Predictive Maintenance: By using predictive maintenance systems, manufacturers can reduce downtime and prevent costly breakdowns, ensuring that the hydraulic press operates efficiently.

- Automating the Process: Implementing automation and smart control systems can increase productivity and reduce the risk of defects, making hydraulic presses more efficient and reliable for deep drawing applications.

Future Trends in Hydraulic Press Technology

As manufacturing processes continue to evolve, hydraulic presses are also advancing to meet the demands of modern production. Several key trends are shaping the future of hydraulic press technology in deep drawing.

13.1 Advancements in Hydraulic Press Design

Modern hydraulic presses are being designed with improved energy efficiency, precision, and flexibility in mind. New press designs incorporate features such as servo motors, smart sensors, and feedback systems to optimize the deep drawing process and reduce the risk of defects.

Key advancements in hydraulic press design include:

- Servo-Controlled Hydraulic Presses: These presses use servo motors to control the movement of the hydraulic piston, providing greater precision and energy efficiency than traditional hydraulic presses.

- Modular Press Designs: Modular press designs allow manufacturers to easily upgrade or customize their hydraulic presses to meet the needs of specific applications, improving flexibility and reducing downtime.

13.2 Integration of Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) into hydraulic press operations is transforming the way parts are produced. AI and ML algorithms can analyze data from the deep drawing process to identify patterns, optimize process parameters, and predict potential defects before they occur.

Key applications of AI and ML in hydraulic press technology include:

- Process Optimization: AI algorithms can analyze data from sensors and feedback systems to optimize the punch force, blank holder force, and punch speed in real time, ensuring that the deep drawing process operates at peak efficiency.

- Defect Prediction: ML algorithms can analyze historical data from the deep drawing process to predict potential defects, such as tearing or wrinkling, and recommend adjustments to the process parameters to prevent these defects from occurring.

13.3 The Rise of Eco-Friendly Hydraulic Presses

As sustainability becomes increasingly important in manufacturing, hydraulic presses are being designed with environmentally friendly features that reduce their energy consumption and environmental impact. These eco-friendly hydraulic presses incorporate features such as energy-efficient motors, recyclable hydraulic fluids, and low-energy cooling systems to minimize their environmental footprint.

Key trends in eco-friendly hydraulic press design include:

- Energy Efficiency: Hydraulic presses are being designed with energy-efficient features, such as servo motors and variable speed drives, that reduce energy consumption and improve overall efficiency.

- Sustainable Materials: Hydraulic presses are increasingly being designed to use recyclable hydraulic fluids and biodegradable lubricants, reducing the environmental impact of the deep drawing process.

13.4 The Future of Smart Factories and Hydraulic Press Automation

The future of hydraulic press technology lies in the integration of smart factory concepts, where hydraulic presses are connected to a network of sensors, machines, and data analytics tools that allow for fully automated, intelligent manufacturing.

Key features of smart factories include:

- Connected Machines: Hydraulic presses will be connected to other machines and systems within the factory, allowing for seamless data exchange and real-time optimization of the deep drawing process.

- Autonomous Operation: With the integration of AI and machine learning, hydraulic presses will be able to operate autonomously, making real-time adjustments to process parameters and preventing defects without the need for human intervention.

- Predictive Analytics: Smart factories will use predictive analytics to monitor the condition of the hydraulic press and its components, allowing for predictive maintenance and reducing downtime.

The future of hydraulic press technology in deep drawing is one of increased precision, efficiency, and automation. As smart factories become the norm, hydraulic presses will play a central role in enabling manufacturers to produce high-quality parts with greater flexibility and sustainability.

Conclusion: The Central Role of Hydraulic Presses in Deep Drawing

Hydraulic presses play a central role in the deep drawing process, providing the precision, control, and flexibility needed to produce high-quality, defect-free parts. Their ability to generate precise force and control material flow makes them ideal for deep drawing applications in industries such as automotive, aerospace, consumer goods, and medical devices.

The advantages of hydraulic presses in deep drawing include:

- Precise Force Control: Hydraulic presses allow for fine-tuned control over both the punch force and blank holder force, ensuring smooth material flow and reducing the risk of defects.

- Versatility: Hydraulic presses can handle a wide range of materials and part geometries, making them suitable for a variety of industries and applications.

- Deep Forming Capability: Hydraulic presses can accommodate large stroke lengths, allowing for the production of parts with significant forming depths.

As technology continues to evolve, hydraulic presses are becoming more advanced, incorporating features such as servo control, smart sensors, and automation to optimize the deep drawing process and improve part quality. The integration of Industry 4.0 technologies, such as artificial intelligence and machine learning, is further enhancing the capabilities of hydraulic presses, enabling manufacturers to produce parts with greater precision, efficiency, and sustainability.

In conclusion, hydraulic presses are an essential tool in the deep drawing process, providing manufacturers with the control, precision, and flexibility needed to produce high-quality parts for a wide range of industries. As hydraulic press technology continues to advance, the deep drawing process will become even more efficient, reliable, and sustainable, ensuring its continued importance in modern manufacturing.

Materials Commonly Used in Deep Drawing

The deep drawing process is a key technique in metal forming that transforms flat sheet metal blanks into hollow, cylindrical, or complex shapes. Used widely in industries such as automotive, aerospace, packaging, and consumer goods, the deep drawing process relies heavily on the selection of appropriate materials that can withstand the stresses and strains involved in the deformation. The success of deep drawing depends on the material’s ability to undergo significant plastic deformation without cracking or failing, making the choice of material critical to the manufacturing process.

Introduction to Deep Drawing and Material Selection

1.1 Overview of Deep Drawing

Deep drawing is a highly specialized sheet metal forming process in which a flat sheet, or blank, is mechanically forced into a die cavity to create a hollow, cup-shaped, or cylindrical part. This process is characterized by the significant amount of plastic deformation that occurs as the blank is pulled into the die, causing it to stretch and flow into the desired shape.

Deep drawing is commonly used to produce parts like automotive body panels, kitchen sinks, fuel tanks, and beverage cans, making it an essential process in high-volume production. The success of the deep drawing process depends not only on the design of the dies and punches but also on the material’s ability to undergo extensive deformation without failure.

1.2 Importance of Material Selection in Deep Drawing

The choice of material is one of the most critical decisions in deep drawing. Different materials exhibit varying degrees of formability, strength, and ductility, which directly influence their behavior during the deep drawing process. Materials with high ductility can stretch and flow more easily, while those with high tensile strength resist deformation, potentially leading to cracking or tearing.

Selecting the right material involves balancing several factors, including:

- Ductility: The material’s ability to deform without cracking.

- Tensile Strength: The resistance to pulling forces, which helps the material withstand the stresses of the deep drawing process.

- Work Hardening: How the material’s hardness increases as it is deformed.

- Surface Finish: Materials with smoother surfaces tend to have better flow characteristics, reducing friction during deep drawing.

1.3 Criteria for Material Selection

When selecting a material for deep drawing, several key criteria must be considered:

- Formability: The material’s ability to stretch without tearing, which is critical for producing complex shapes.

- Thickness: Thicker materials can generally withstand deeper draws but may require higher forces.

- Lubrication Compatibility: Some materials require specific lubricants to prevent galling, wrinkling, or surface defects.

- Cost and Availability: The material’s cost and availability can significantly impact the overall production process.

- Corrosion Resistance: Depending on the application, materials like stainless steel or aluminum may be preferred for their corrosion resistance.

Understanding how different materials behave during deep drawing helps manufacturers optimize the process to avoid defects, reduce material waste, and improve production efficiency.

Steel and Its Alloys in Deep Drawing

2.1 Low-Carbon Steel

Low-carbon steel is one of the most commonly used materials in deep drawing due to its excellent formability and low cost. It contains a carbon content of less than 0.3%, which provides good ductility and makes it easier to deform without cracking or tearing.

Properties of Low-Carbon Steel:

- Ductility: Low-carbon steel has excellent ductility, allowing it to undergo significant plastic deformation during deep drawing without failing.

- Tensile Strength: While low-carbon steel has moderate tensile strength, it is sufficient for most deep drawing applications, such as producing automotive body panels or household appliances.

- Cost-Effectiveness: Low-carbon steel is relatively inexpensive compared to other materials like stainless steel or aluminum, making it a cost-effective choice for high-volume production.

2.2 High-Strength Low-Alloy (HSLA) Steel

High-Strength Low-Alloy (HSLA) steel is an enhanced form of carbon steel that contains small amounts of alloying elements, such as vanadium, niobium, or titanium, which increase the material’s strength without significantly reducing its formability.

HSLA steel is used in applications where higher strength is needed but weight reduction is also important. Automotive manufacturers often use HSLA steel to produce structural components like reinforcements and impact-resistant parts.

Properties of HSLA Steel:

- Higher Strength: HSLA steel offers greater strength compared to low-carbon steel, allowing for the production of thinner and lighter components without sacrificing structural integrity.

- Formability: Despite its higher strength, HSLA steel retains good formability, although the deep drawing process may require higher forces and more precise control.

- Applications: HSLA steel is commonly used in the automotive and construction industries, where weight savings and strength are critical factors.

2.3 Stainless Steel

Stainless steel is a widely used material in deep drawing, particularly in applications requiring corrosion resistance and high strength. Stainless steel is an alloy that contains at least 10.5% chromium, which forms a passive layer of chromium oxide on the surface, protecting the material from corrosion.

Types of Stainless Steel Used in Deep Drawing:

- Austenitic Stainless Steel (300 Series): Austenitic stainless steel, such as 304 and 316, is the most common type used in deep drawing due to its excellent formability, corrosion resistance, and non-magnetic properties. It is widely used in kitchenware, medical devices, and automotive exhaust systems.

- Ferritic Stainless Steel (400 Series): Ferritic stainless steel, such as 430, offers good corrosion resistance and is used in applications where magnetic properties are not a concern, such as in household appliances and automotive trim.

Challenges of Stainless Steel in Deep Drawing:

- Higher Work Hardening: Stainless steel tends to work harden more quickly than other materials, which can increase the risk of cracking or tearing during deep drawing. Proper lubrication and precise control of the punch force are essential to prevent these defects.

- Surface Finish: Stainless steel has a smooth surface finish, which can reduce friction during deep drawing, but it may require special lubricants to prevent galling.

2.4 Applications of Steel in Deep Drawing

Steel, including low-carbon steel, HSLA steel, and stainless steel, is used in a wide range of industries for deep drawing applications:

- Automotive Industry: Low-carbon steel is used for body panels, while HSLA steel is used for structural components and reinforcements.

- Consumer Goods: Stainless steel is used in kitchen appliances, sinks, and cookware due to its corrosion resistance and aesthetic appeal.

- Aerospace and Medical: High-strength stainless steel is used in aircraft components and medical devices, where durability and corrosion resistance are critical.

Aluminum and Aluminum Alloys

3.1 Pure Aluminum

Aluminum is a lightweight metal that offers excellent corrosion resistance, making it an ideal choice for deep drawing in industries where weight savings and durability are important, such as aerospace, automotive, and packaging. Pure aluminum has relatively low strength but high ductility, allowing it to be drawn into complex shapes without cracking.

Properties of Pure Aluminum:

- Lightweight: Aluminum is significantly lighter than steel, which makes it attractive for applications where reducing weight is critical, such as in automotive and aerospace manufacturing.

- Corrosion Resistance: Aluminum forms a natural oxide layer on its surface, which provides good resistance to corrosion, especially in marine and outdoor environments.

- Ductility: Pure aluminum is highly ductile, allowing it to be formed into deep, complex shapes without the risk of tearing or cracking.

3.2 Aluminum Alloys for Deep Drawing

While pure aluminum is highly ductile, it lacks the strength needed for certain applications. As a result, aluminum alloys are often used in deep drawing to improve strength without compromising formability. Some of the most common aluminum alloys used in deep drawing include:

- Aluminum 1100: This alloy is almost pure aluminum and offers excellent formability. It is used in deep drawing applications where corrosion resistance and ductility are more important than strength, such as food and chemical processing equipment.

- Aluminum 3003: This is a non-heat-treatable alloy that provides a good balance of strength and formability. It is commonly used in the production of cooking utensils, heat exchangers, and storage tanks.

- Aluminum 5052: This alloy has higher strength than 1100 or 3003 and is often used in deep drawing applications that require both strength and corrosion resistance, such as marine components, fuel tanks, and aircraft parts.

3.3 Formability of Aluminum

Aluminum is highly formable, but it does present certain challenges during the deep drawing process:

- Springback: Aluminum has a tendency to spring back after being deformed, which can complicate the process of achieving precise geometries. This issue can be mitigated by using a hydraulic press with precise force control or by designing the die to compensate for springback.

- Work Hardening: Aluminum work hardens less than steel, which means it can be drawn into deeper shapes without becoming overly stiff. However, repeated forming operations may still lead to work hardening, which requires intermediate annealing to soften the material.

3.4 Applications of Aluminum in Deep Drawing

Aluminum and its alloys are used in a wide variety of deep drawing applications across several industries:

- Aerospace: Aluminum’s lightweight properties make it ideal for aircraft fuselage panels, wing components, and engine parts.

- Automotive: Aluminum is used to produce body panels, heat shields, and fuel tanks in automobiles, where weight savings are critical for improving fuel efficiency and reducing emissions.

- Packaging: Aluminum is the material of choice for beverage cans, food containers, and cosmetic packaging due to its lightweight, corrosion resistance, and ability to be formed into deep, thin-walled containers.

Copper and Copper Alloys

4.1 Copper and Its Properties

Copper is a highly conductive material with excellent thermal and electrical properties, making it an ideal choice for deep drawing applications that require heat dissipation or electrical conductivity. Copper’s ductility allows it to be drawn into complex shapes without the risk of cracking, although it can harden during the process, requiring intermediate annealing.

Properties of Copper:

- High Ductility: Copper is highly ductile, making it suitable for deep drawing into intricate shapes, such as electrical connectors, heat sinks, and plumbing fixtures.

- Thermal and Electrical Conductivity: Copper’s excellent conductivity makes it ideal for applications in the electrical and electronics industries, where heat dissipation and electrical performance are critical.

- Corrosion Resistance: Copper has good resistance to corrosion in many environments, although it can develop a patina over time.

4.2 Brass in Deep Drawing

Brass is an alloy of copper and zinc, and it is widely used in deep drawing due to its excellent formability and aesthetic appeal. Brass combines the ductility of copper with the added strength of zinc, making it suitable for producing decorative hardware, musical instruments, and plumbing components.

Properties of Brass:

- Good Formability: Brass can be drawn into complex shapes with ease, making it ideal for deep-drawn decorative items such as vases, lamps, and jewelry.

- Corrosion Resistance: Brass offers good corrosion resistance, particularly in marine environments, making it suitable for valves, fittings, and other components exposed to moisture.

4.3 Bronze in Deep Drawing

Bronze is another copper alloy, typically made with tin and other elements like aluminum or phosphorus. Bronze is known for its strength, corrosion resistance, and aesthetic appearance. It is used in applications where durability and a decorative finish are important.

Properties of Bronze:

- Durability: Bronze is stronger than copper and brass, making it suitable for deep drawing applications that require higher strength, such as bushings, bearings, and springs.

- Wear Resistance: Bronze has good wear resistance, which makes it suitable for marine hardware and industrial components.

4.4 Applications of Copper and Copper Alloys

Copper and its alloys are widely used in deep drawing applications, particularly in industries that require conductive materials or decorative finishes:

- Electronics and Electrical: Copper is used for electrical connectors, terminals, and heat sinks due to its excellent electrical conductivity.

- Plumbing: Copper and brass are used in plumbing fittings, valves, and pipes, where corrosion resistance and ease of forming are important.

- Consumer Goods: Brass is used in decorative hardware, musical instruments, and home furnishings, where its aesthetic appeal and formability make it an attractive choice.

Nickel and Nickel Alloys

5.1 Nickel’s Properties in Deep Drawing

Nickel is a versatile metal known for its high-temperature resistance, corrosion resistance, and strength. Nickel and its alloys, such as Inconel and Hastelloy, are used in deep drawing applications where parts must withstand extreme conditions, including high temperatures, pressure, and aggressive environments.

Properties of Nickel:

- Corrosion Resistance: Nickel is highly resistant to oxidation and corrosion, making it suitable for deep drawing parts that are exposed to harsh environments, such as chemical processing equipment or oil and gas components.

- High-Temperature Performance: Nickel alloys retain their strength and structural integrity at elevated temperatures, making them ideal for applications in turbine engines, heat exchangers, and exhaust systems.

- Formability: Although nickel is stronger than many other metals used in deep drawing, it still offers good formability when processed correctly, although it may require higher drawing forces and precision control during the forming process.

5.2 Inconel and Hastelloy

Inconel and Hastelloy are two of the most common nickel-based alloys used in deep drawing. These alloys are prized for their ability to maintain mechanical strength at high temperatures and their resistance to oxidation and corrosion.

- Inconel: Inconel is commonly used in aerospace and power generation applications due to its high-temperature stability and oxidation resistance. It is often used to produce deep-drawn parts such as exhaust systems, turbine blades, and heat shields.

- Hastelloy: Hastelloy is known for its superior resistance to corrosive environments, particularly in chemical processing industries. It is used in deep drawing applications where parts are exposed to acids, chlorides, and other aggressive chemicals.

5.3 Applications of Nickel Alloys in High-Temperature Environments

Nickel and its alloys are commonly used in deep drawing applications where high temperatures and corrosive environments are prevalent:

- Aerospace: Nickel alloys are used to produce engine components, exhaust systems, and heat exchangers that must withstand extreme temperatures and high-stress conditions.

- Chemical Processing: Hastelloy and other nickel alloys are used to produce components such as valves, pumps, and reactor vessels that are exposed to corrosive chemicals.

- Oil and Gas: Nickel alloys are used in drilling equipment, pipes, and valves that operate in high-pressure, high-temperature, and corrosive environments.

Titanium and Titanium Alloys

6.1 Properties of Titanium in Deep Drawing

Titanium is a highly desirable material for deep drawing due to its combination of high strength, lightweight, and excellent corrosion resistance. Titanium’s high strength-to-weight ratio makes it ideal for applications where weight reduction is critical, such as in aerospace and medical devices. However, titanium can be more challenging to form than materials like aluminum or steel, due to its springback and tendency to gall during the forming process.

Properties of Titanium:

- High Strength-to-Weight Ratio: Titanium offers excellent strength while being significantly lighter than steel, making it ideal for applications where both strength and lightweight properties are required.

- Corrosion Resistance: Titanium is highly resistant to corrosion, particularly in marine environments and chemical processing.

- Biocompatibility: Titanium is biocompatible, making it the material of choice for medical implants and surgical instruments.

6.2 Titanium’s Strength and Weight Benefits

One of the key advantages of titanium in deep drawing is its ability to provide high strength with low weight. This makes titanium an ideal material for industries such as aerospace, where reducing weight is crucial for improving fuel efficiency and performance. Titanium’s high strength allows it to be formed into thin-walled, deep-drawn parts that can withstand extreme conditions without adding unnecessary weight.

6.3 Applications in Aerospace and Medical Devices

Aerospace: Titanium is widely used in the aerospace industry for deep drawing components such as fuselage panels, engine parts, and heat shields. Its lightweight properties and ability to withstand high temperatures make it ideal for aircraft and spacecraft applications.

Medical Devices: Titanium’s biocompatibility and corrosion resistance make it the material of choice for deep drawing surgical instruments, orthopedic implants, and prosthetics. Titanium’s strength allows it to be drawn into thin-walled parts that are both durable and lightweight, ensuring patient comfort and long-term performance.

Zinc and Zinc Alloys

7.1 Zinc’s Role in Deep Drawing

Zinc is used in deep drawing applications where corrosion resistance and cost-effectiveness are important. While zinc itself is not often used as a primary material in deep drawing, it is commonly applied as a coating to steel in the form of galvanized steel, which combines the strength of steel with the corrosion resistance of zinc.

Properties of Zinc:

- Corrosion Resistance: Zinc’s primary benefit in deep drawing applications is its ability to protect steel from corrosion, particularly in outdoor and marine environments.