Cutting Machine for Sheet Metal: Sheet metal cutting is a crucial process in various industries. The selection of a cutting machine depends on factors such as material thickness, desired cut quality, production volume, and budget. Here are some common types:

Shear Cutting Machines

- Manual shears: Hand-operated for small-scale cutting.

- Power shears: Electric or hydraulically powered for increased efficiency.

- Guillotine shears: Large industrial machines for straight-line cutting.

Punching Machines

- Create holes and shapes in sheet metal.

- Can be manual, mechanical, or CNC-controlled.

Plasma Cutting Machines

- Use high-temperature plasma to cut through conductive materials.

- Suitable for various thicknesses and materials.

- Offers high cutting speeds.

Laser Cutting Machines

- Employ a high-powered laser beam to cut intricate shapes.

- Known for precision and versatility.

- Ideal for thin to medium-thickness materials.

Water Jet Cutting Machines

- Uses a high-pressure water jet with abrasive particles to cut various materials.

- No heat-affected zone, making it suitable for delicate materials.

Other Cutting Methods

- Sawing: For thicker materials or irregular shapes.

- Grinding: For finishing and deburring edges.

Factors to Consider When Choosing a Cutting Machine

- Material type and thickness: Different machines excel at different materials and thicknesses.

- Cut quality: Laser and water jet cutting generally provide the highest precision.

- Production volume: High-volume production may require automated machines like CNC-controlled ones.

- Cost: Initial investment and operating costs vary significantly between different machine types.

A circle cutting machine is a tool used to cut circular shapes out of various materials, such as metal, plastic, paper, or fabric. Here are some parts and features commonly found in circle-cutting machines:

- Cutting blade: The blade is the most important part of the circle cutting machine, and it can be made of different materials such as steel or tungsten carbide. The blade rotates as the machine is in use, cutting out the circular shape from the material.

- Cutting guide: The cutting guide holds the material in place and guides the blade along the cutting path. The guide is adjustable to accommodate different circle sizes.

- Cutting depth adjustment: The cutting depth adjustment allows the user to control the depth of the cut, which can be helpful when working with different materials.

- Base plate: The base plate is the surface on which the material is placed during cutting. It is typically made of a durable material like metal or plastic.

- Pivot arm: The pivot arm connects the cutting blade to the base plate and allows for precise control over the cutting angle and direction.

- Motor: The motor powers the blade and allows it to rotate quickly and efficiently.

- Safety features: Circle cutting machines may have safety features such as blade guards or automatic shut-off mechanisms to prevent injury or damage to the machine.

Circle cutting machines are used in a variety of industries, including metalworking, woodworking, and crafting. They are useful for creating circular shapes for products such as gears, wheels, and decorative items.

A circle cutting machine, also known as a circle cutter or disc cutter, is a specialized tool used to cut circular shapes from various materials, including paper, cardboard, plastic, fabric, and even thin metal sheets. These machines are commonly employed in industrial settings, craft workshops, and DIY projects.

Types of Circle Cutting Machines

Circle cutting machines come in various types, each with its own unique features and applications:

- Handheld Circle Cutters: These compact and portable machines are commonly used for cutting circles from paper, cardboard, and other lightweight materials. They typically feature a rotating blade or a punch-and-die mechanism to cut circles.

- Rotary Circle Cutters: These machines utilize a rotating blade mounted on a track or arm, allowing for precise cutting of circles in a variety of sizes. They are often used for cutting circles from fabric, leather, and other flexible materials.

- Hydraulic Circle Cutters: These powerful machines employ hydraulic pressure to cut circles from thicker materials, such as plastic sheets, thin metal sheets, and rubber. They offer high precision and cutting force for heavy-duty applications.

- CNC Circle Cutting Machines: These computer-numerically controlled (CNC) machines utilize computer programming to cut circles with exceptional precision and accuracy. They are commonly used in industrial settings for cutting circles from a wide range of materials.

Safety Precautions when using Circle Cutting Machines

When operating circle cutting machines, it is crucial to follow safety precautions to prevent injuries and ensure proper operation:

- Wear Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and a cutting mat to protect yourself from sharp blades, flying debris, and potential cuts.

- Securely Clamp the Workpiece: Ensure the workpiece is firmly clamped to the machine’s work surface to prevent it from slipping or moving during cutting.

- Use the Correct Blade or Punch: Choose the appropriate blade or punch size and type for the material and desired circle size. Using the wrong blade or punch can damage the material or cause injury.

- Maintain Proper Blade or Punch Sharpness: Regularly sharpen or replace blades and punches to ensure they are sharp and maintain cutting efficiency. Dull blades can cause ragged edges and increase the risk of injury.

- Handle with Care: Always handle the machine with care, avoiding sudden movements or forceful actions that could lead to accidents.

- Never Touch the Moving Blade or Punch: Never touch the moving blade or punch while the machine is in operation.

- Turn Off the Machine Before Making Adjustments: Always turn off the machine before making any adjustments or changing the blade or punch.

- Store the Machine Properly: Store the machine in a safe, secure location when not in use, keeping it out of reach of children and unauthorized users.

By following these safety guidelines and operating the machine correctly, you can effectively utilize circle cutting machines to create precise circular shapes from various materials with minimal risk of injury.

Circle cutting machines are used in various industries, including:

- Metalworking: Circle cutting machines are commonly used in metalworking industries to cut circular shapes out of metals, such as steel, aluminum, and copper. They are used to make parts for machinery, automotive components, and other metal products.

- Woodworking: Circle cutting machines are also used in woodworking industries to cut circular shapes out of wood. They are used to make decorative wooden objects, such as clocks and signs, as well as to cut circular parts for furniture and other wooden products.

- Textile and apparel: Circle cutting machines are used in the textile and apparel industries to cut circular shapes out of fabric, leather, and other materials. They are used to make clothing, hats, bags, and other textile products.

- Craft and hobby: Circle cutting machines are popular among hobbyists and crafters, as they can be used to cut circular shapes out of a variety of materials. They are commonly used in scrapbooking, card making, and other paper crafts, as well as for creating decorative items like wreaths and ornaments.

- Manufacturing: Circle cutting machines are used in various manufacturing industries to cut circular shapes out of different materials. They are commonly used to make parts for machines and equipment, as well as for creating decorative and functional products.

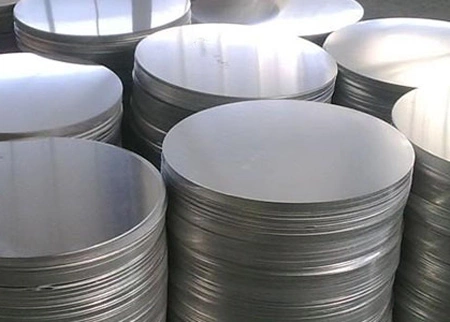

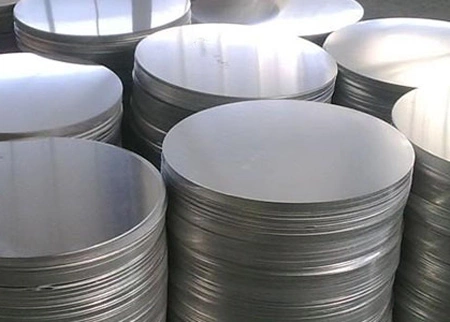

In factories, where hydraulic presses manufacture deep drawn parts, as blank, sheet metal circles need to be prepared beforehand. These circles can either be manufactured by a mechanical press in serial production or needs to be cut as a square first, then the corners need to be trimmed by a machine to turn these square sheets into circles. This machine is called a circle cutting machine

A circle cutting machine is a machine that is used to cut a circle into a sheet of steel. Circle cutters are mainly used in metalworking to cut round steel sheets into circles. They come in two types: manual and automatic.

The first type of circle cutting machine is the manual type. This type of machine has large handles on both sides which are turned by hand to rotate the blade and produce the circular cut out from the metal sheet. The second type of circle cutting machine is automatic, which is much more efficient than its manual counterpart because it does not require any human input or labor to operate it.

For this purpose, we design and manufacture circle cutting machines, to cut the corners of sheet metals, which are later sent to hydraulic drawing presses for further operation

The capacity of our circle cutting machines is exceptionally high where an operator can get as high as 30 pcs per minute

The main body of the circle cutting machine is solid welded steel and knives to cut the sheet are made from high carbon high chromium steel

Circle cutting machine

Circle cutting machines can easily be used with stainless steel, aluminum, copper, and tin sheets for various industrial applications. The steel circles later are used to deep draw parts with a hydraulic press. For long-duration high-quality parts you can contact us as your supplier from our main page

For a better analysis of our circle blank cutting machine, you can check our video below

Our circle cutting machines are hand-operated. Hand-operated operations are safer as the operator needs to control the machine with his hands and he will need to keep his hands on the control board to operate the machine. Circle cutter machines are essential in production facilities where there is a deep drawing press. Deep drawing presses use round sheets to form vase forms by deep drawings.

With our round corner cutting machines or sheet metal circle cutting machines you can have a capacity as high as 1 piece in 4 seconds. With this capacity, you can feed 2 hydraulic presses with one 1 circle cutting machine easily

Circle cutting machines are versatile tools used in various industries and applications for precisely cutting circular shapes from a wide range of materials. They are commonly employed in industrial settings, craft workshops, and DIY projects.

Industrial Applications

- Manufacturing: Circle cutting machines are used in various manufacturing processes, such as cutting circular gaskets, seals, and components from rubber, plastic, and thin metal sheets. They are also used to cut circular patterns in fabrics and textiles for clothing and industrial applications.

- Packaging: Circle cutting machines are essential in the packaging industry for cutting circular packaging materials, such as cardboard discs, labels, and packaging inserts. They ensure precise dimensions and consistent quality for product packaging.

- Graphic Design and Printing: Circle cutting machines are used in graphic design and printing studios to cut circular shapes from paper, cardboard, and other materials for creating promotional materials, signage, and decorative elements.

Craft and DIY Applications

- Scrapbooking and Paper Crafts: Circle cutting machines are popular among scrapbookers and paper crafters for cutting circular embellishments, decorative shapes, and photo mats. They provide a precise and efficient way to create custom elements for scrapbooking projects.

- Jewelry Making: Circle cutting machines are used in jewelry making to cut circular shapes from leather, felt, and other materials for creating jewelry components, such as pendants, earrings, and bracelets. They ensure consistent shapes and sizes for jewelry designs.

- Home Décor and DIY Projects: Circle cutting machines are versatile tools for DIY projects, such as cutting circular patterns from fabrics for quilting, sewing, and home décor accents. They can also be used to cut circular shapes from materials like felt, foam, and cork for crafting projects.

- Model Making and Architectural Design: Circle cutting machines are used in model making and architectural design to cut circular shapes from various materials, such as cardboard, balsa wood, and foam, for creating models and prototypes. They provide precision and accuracy for detailed work.

General Safety Guidelines

When operating circle cutting machines, safety is paramount. Always follow these general guidelines:

- Wear Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and a cutting mat to protect yourself from sharp blades, flying debris, and potential cuts.

- Securely Clamp the Workpiece: Ensure the workpiece is firmly clamped to the machine’s work surface to prevent it from slipping or moving during cutting.

- Use the Correct Blade or Punch: Choose the appropriate blade or punch size and type for the material and desired circle size. Using the wrong blade or punch can damage the material or cause injury.

- Maintain Proper Blade or Punch Sharpness: Regularly sharpen or replace blades and punches to ensure they are sharp and maintain cutting efficiency. Dull blades can cause ragged edges and increase the risk of injury.

- Handle with Care: Always handle the machine with care, avoiding sudden movements or forceful actions that could lead to accidents.

- Never Touch the Moving Blade or Punch: Never touch the moving blade or punch while the machine is in operation.

- Turn Off the Machine Before Making Adjustments: Always turn off the machine before making any adjustments or changing the blade or punch.

- Store the Machine Properly: Store the machine in a safe, secure location when not in use, keeping it out of reach of children and unauthorized users.

By adhering to these safety guidelines and operating the machine responsibly, you can effectively utilize circle cutting machines for various applications while minimizing the risk of injury.

Sheet Metal Circle Cutter Machine

How do you cut a circle in sheet metal?

Our sheet metal circle cutter machine can cut from as small as 2″ of circle blanks on sheet metal surfaces up to 12″ in diameter. The circle diameter to be cut can be arranged on the machine. The cutting tool is made from high-carbon cutting steel specially produced for metal cutting operations. The frame of the machine is complete welded steel and all the machinery goes through stress-relieving after the manufacturing is finished. Circle cutting machines are widely used in the cookware industry.

How do you cut big circles in metal?

with our sheet metal circle cutting machine, you can cut circle blanks from square metal sheets with sheet thickness starting from 0.1 mm up to 5 mm. The diameter also can be arranged from 5 cm up to 30 cm.

The circle cutting machine is a type of machine that can cut circles out of metal sheets. It is also called an automatic circle cutter or a steel circle cutter.

It is used to cut circles out of metal sheets. The machine has a circular blade that rotates around the circumference of the sheet. The operator sets the size and radius of the desired hole and then presses start to begin cutting.

The circle cutting machine is an automatic machine that cuts circles from flat steel sheets.

The circle cutting machine is a type of metalworking equipment that is used to cut circles in sheet metal. This equipment can be used for a variety of purposes, including manufacturing and construction. The round steel sheet, which is the most common material used in the process, can be cut into circles using this machine.

Adjustable Circle Cutter for Metal

An adjustable circle cutter typically consists of a central body that houses a pilot drill bit and an adjustable cutting blade.expand_more The pilot drill bit, usually made of high-speed steel (HSS) for durability, ensures the cutter stays centered while drilling into the metal. The cutting blade, also crafted from HSS for its ability to handle tough materials, is the workhorse of the tool.exclamation It can be adjusted outwards or inwards using a screw mechanism, allowing you to set the desired cutting diameter. Some models come with replaceable blades for extended use.

Operational Advantages

- Versatility: The key benefit of an adjustable circle cutter is its ability to cut various hole sizes within its range. This eliminates the need to purchase and carry multiple hole saws for different sized holes.

- Precision: When used correctly, adjustable circle cutters can produce clean, burr-free holes with minimal material distortion. The pilot drill bit helps maintain accuracy throughout the cutting process.

- Cost-Effective: Compared to buying multiple hole saws, an adjustable circle cutter offers a more economical solution for creating holes in various sizes.

- Drill Press Compatibility: Most adjustable circle cutters are designed for use with a drill press.expand_more The secure mounting of the drill press ensures stability and control while cutting, leading to cleaner cuts.exclamation

Factors to Consider When Choosing an Adjustable Circle Cutter

- Cutting Capacity: Adjustable circle cutters come with different maximum cutting diameters. Choose one that accommodates your typical hole size requirements. Common ranges include 1 inch to 6 inches, 2 inches to 12 inches, and even larger options for heavy-duty applications.

- Material Compatibility: While most adjustable circle cutters can handle sheet metal, brass, aluminum, and soft steel, some may not be suitable for very hard metals. Ensure the cutter you choose is rated for the type of metal you plan to work with.exclamation

- Shank Size: The shank is the part of the cutter that fits into the drill press chuck. Make sure the shank size of the cutter matches the chuck capacity of your drill press. Common shank sizes include 3/8 inch and 1/2 inch.

- Pilot Drill Bit Size: The pilot drill bit size should complement the cutting blade size.exclamation It ensures the cutter remains centered and prevents the metal from binding during the cutting process. Some adjustable circle cutters come with replaceable pilot drill bits.expand_more

Using an Adjustable Circle Cutter Safely and Effectively

- Clamp Your Workpiece Securely: Always ensure your metal sheet is firmly clamped to a stable work surface to prevent movement during cutting.expand_more

- Lubricate the Cutter: Use a cutting lubricant to reduce friction and extend the life of the blade.

- Start with a Pilot Hole (Optional): For thicker metals, drilling a pilot hole slightly smaller than the desired cut diameter can help center the adjustable circle cutter and make the cutting process smoother.

- Apply Moderate Pressure: Let the cutter do the work. Don’t force it through the metal, as this can cause the blade to bind or break.

- Maintain a Steady Speed: Use a moderate and consistent drill press speed for optimal cutting performance. Refer to the manufacturer’s instructions for recommended speeds based on the material and hole diameter.

With proper selection, use, and care, an adjustable circle cutter can become a valuable tool in your metalworking arsenal, saving you time, money, and effort while delivering clean and precise holes in your projects.

Which machine is used to cut rings or circular sheet metal?

There are two main machines used for cutting rings or circular sheet metal, each with its own advantages:

- Circular Shears: These machines are specifically designed for cutting out rings and discs from sheet metal. They typically have a stationary lower blade and a rotating upper blade that travels along a circular track. The metal sheet is fed between the blades, resulting in a clean, continuous cut. Circular shears can handle a wider range of metal thicknesses compared to some adjustable circle cutters.

- Adjustable Circle Cutters: As discussed previously, these versatile tools can be used to create circular holes in sheet metal. However, with some adjustments, they can also be used to cut out rings. This method involves making two cuts with the adjustable circle cutter: one for the inner diameter of the ring and another for the outer diameter. While less specialized than circular shears, adjustable circle cutters offer more flexibility in terms of creating holes of various sizes within their range.

Circular Shears

Circular shears, also known as rotary shears or ring shears, are specialized machines designed for efficiently and precisely cutting out rings and discs from sheet metal. They are ideal for high-volume production environments or applications requiring consistent, clean cuts in various ring sizes.

How They Work:

A circular shear typically has a sturdy base that houses the cutting mechanism. This mechanism consists of two key components:

- Lower Blade: This is a stationary, sharp blade secured to the base of the machine. It’s usually made from high-quality tool steel for durability.

- Upper Blade: This is a rotating blade mounted on an arm that travels along a circular track. The arm can be adjusted to set the desired cutting diameter for the ring. The upper blade is also crafted from tool steel for clean and efficient cutting.

Operation and Advantages:

- Simple Operation: Circular shears are relatively straightforward to operate. Once the sheet metal is positioned and the desired cutting diameter is set, the operator engages the machine. The upper blade rotates and presses against the sheet metal, shearing it cleanly along the pre-determined circular path.

- High Production Rate: Circular shears excel in production environments where repetitive cutting of rings is needed. They can handle a wider range of metal thicknesses compared to some adjustable circle cutters, making them suitable for heavier-duty applications.

- Clean and Accurate Cuts: The shearing action produces clean, burr-free edges on the cut rings. Additionally, the precise adjustment mechanism ensures consistent ring diameters throughout the cutting process.

- Versatility: While primarily used for rings, some circular shears offer the ability to make straight cuts as well. This adds to their overall functionality.

Choosing the Right Circular Shear:

When selecting a circular shear, consider the following factors:

- Cutting Capacity: Circular shears come with different maximum cutting diameters and throat depths (the maximum width of sheet metal they can handle). Choose one that accommodates your typical ring size and sheet metal thickness requirements.

- Material Compatibility: Ensure the shear is rated for the type of metal you plan to cut. Some models may be suitable for tougher materials like stainless steel.

- Power Source: Circular shears can be manually operated, powered by electric motors, or hydraulically driven. Electric and hydraulic models offer greater cutting force and efficiency for thicker metals.

- Additional Features: Some circular shears come with features like adjustable cutting speeds, digital displays for precise diameter settings, and foot pedals for hands-free operation.

Safety Considerations:

Always follow safety precautions when operating a circular shear, including wearing safety glasses, gloves, and proper clothing. Ensure the machine is properly secured and the sheet metal is firmly clamped in place before starting the cut.

In conclusion, circular shears are a powerful and efficient solution for cutting rings and discs from sheet metal. Their ability to handle high volumes, produce clean cuts, and accommodate various ring sizes makes them a valuable asset for metalworking professionals.

Adjustable Circle Cutter

Adjustable circle cutters, while not as specialized as circular shears, offer a versatile and cost-effective solution for creating holes in sheet metal. They can also be used, with a bit more work, to cut out rings.

How They Work:

An adjustable circle cutter is a more compact tool compared to a circular shear. It typically consists of:

- Central Body: This houses the mechanism for adjusting the cutting diameter.

- Pilot Drill Bit: Made from high-speed steel (HSS) for strength, it drills a pilot hole to center the cutter and prevent wandering.

- Adjustable Cutting Blade: Also crafted from HSS, this blade can be moved inwards or outwards using a screw mechanism to set the desired cutting diameter.

- Shank: This fits into the chuck of a drill press, providing stability and power for cutting.

Advantages:

- Versatility: The key benefit is the ability to cut various hole sizes within its range, eliminating the need for multiple hole saws.

- Cost-Effective: Compared to buying numerous hole saws, an adjustable circle cutter offers a more economical solution.

- Drill Press Compatibility: Most models are designed for use with a drill press, which provides stability and control for cleaner cuts.

- Can Cut Rings (with some effort): By making two cuts with the adjustable circle cutter (one for the inner and outer diameter), you can create rings from sheet metal.

Things to Consider When Choosing an Adjustable Circle Cutter:

- Cutting Capacity: Choose a cutter that accommodates your typical hole size requirements. Common ranges include 1 inch to 6 inches, 2 inches to 12 inches, and even larger options.

- Material Compatibility: Ensure the cutter is rated for the type of metal you plan to work with, such as sheet metal, brass, aluminum, or soft steel.

- Shank Size: Match the shank size of the cutter to the chuck capacity of your drill press (common sizes are 3/8 inch and 1/2 inch).

- Pilot Drill Bit Size: This should complement the cutting blade size for optimal centering and cutting performance. Some models come with replaceable pilot drill bits.

Using an Adjustable Circle Cutter Effectively:

- Clamp Your Workpiece Securely: Ensure the metal sheet is firmly clamped to prevent movement during cutting.

- Lubricate the Cutter: Use a cutting lubricant to reduce friction and extend blade life.

- Pilot Hole (Optional): For thicker metals, consider drilling a pilot hole slightly smaller than the desired cut for better centering and smoother cutting.

- Moderate Pressure: Let the cutter do the work. Don’t force it, as this can damage the blade.

- Maintain a Steady Speed: Use a moderate and consistent drill press speed for optimal results. Refer to the manufacturer’s instructions for recommended speeds based on material and hole diameter.

While not a replacement for a dedicated circular shear for high-volume ring cutting, adjustable circle cutters offer a practical and adaptable solution for various hole-making needs in sheet metal, with the added bonus of creating rings when required.

Cold forming machines are industrial machines used to shape and form metal materials at room temperature, without the application of heat. This process is typically used to produce parts with high precision and mechanical properties, including strength, hardness, and dimensional accuracy.

Here’s an overview of the key elements of cold forming machines:

Types of Cold Forming Processes:

- Stamping: The material is placed between dies and pressed into shape using a press machine. This is commonly used for producing flat parts.

- Roll Forming: The material is passed through a series of rollers to gradually form it into a desired shape. This is ideal for producing long lengths of materials, such as channels or profiles.

- Cold Heading: This is typically used to form fasteners such as bolts and screws. The process involves the deformation of the metal into a specific shape by compressing it in a die.

- Bending: Involves bending the metal to a required angle without heating it.

- Extrusion: In cold extrusion, the material is forced through a die to create long parts with consistent cross-sections.

Advantages of Cold Forming:

- Improved Material Properties: Cold forming increases the strength and hardness of the material due to work hardening.

- High Precision: The process can create parts with tight tolerances and fine detail.

- Cost Efficiency: It is often more cost-effective than hot forming because it eliminates the need for heating and the associated energy costs.

- Minimal Waste: Cold forming typically results in very little waste material, making it more efficient in terms of material usage.

Applications:

Cold forming is used in a wide range of industries, including automotive, aerospace, electronics, construction, and general manufacturing, to create components like gears, shafts, brackets, fasteners, and electrical connectors.

Cold forming machines are designed to shape metal materials at room temperature, utilizing pressure to mold or bend them into specific shapes. Unlike hot forming processes that require heating the material to high temperatures, cold forming relies on the metal’s ductility at ambient temperatures, which is particularly advantageous for maintaining material integrity and achieving high precision in the final products. This process is commonly used in industries where parts need to be made with high strength and durability, such as automotive, aerospace, and electronics.

In cold forming, the material is typically fed into a machine, where it undergoes various stages of deformation, such as stamping, rolling, heading, or bending. The shaping process is carried out through mechanical presses or rollers, which apply controlled force to the metal. One of the key benefits of cold forming is that it enhances the material’s mechanical properties. For example, the metal’s strength is often increased due to the work hardening that occurs during the process. Cold forming can also produce very precise and complex shapes, which is crucial for applications requiring tight tolerances or intricate details.

Additionally, cold forming can reduce material waste because it generally involves processes like stamping or extrusion, where the metal is used efficiently and little scrap is generated. It’s also a cost-effective method compared to other forming processes, as there’s no need for heating, which saves on energy and time. The resulting products tend to be highly durable, with improved surface finishes, and can be used for parts like gears, fasteners, and structural components.

The versatility of cold forming machines makes them suitable for a wide range of materials, including steel, aluminum, and other metals. Their applications are diverse, extending across different sectors, such as manufacturing parts for the automotive industry, aerospace components, electrical connectors, and hardware. The process continues to be a preferred choice for producing high-quality, high-strength metal parts in a highly efficient manner.

Cold forming machines are versatile and highly efficient, particularly in industries requiring high-volume production of complex metal parts. The machines typically use specialized dies and tooling to apply compressive force on the material, shaping it without the need for heat. This not only conserves energy but also helps maintain the metal’s original properties, such as hardness and tensile strength. For example, during cold heading, the metal is deformed in a series of dies to create components like bolts, nuts, and rivets, often with minimal waste.

One of the standout features of cold forming is its ability to produce parts with enhanced mechanical properties, particularly in terms of strength and hardness. This is because the process induces a phenomenon known as “work hardening,” where the metal becomes stronger as it is deformed, which can be beneficial for applications that require durable, high-performance components. This is especially true in industries like aerospace and automotive manufacturing, where parts must withstand high levels of stress and pressure.

The precision that cold forming offers is another key advantage. With the use of high-precision tools and equipment, cold forming can produce parts that meet tight tolerances and have intricate geometries. This is critical for applications such as electronics, where small, detailed components are often required, or for making complex fasteners used in automotive assemblies. The machines are capable of delivering consistent results over large production runs, which is essential for mass manufacturing operations.

Cold forming machines can handle a wide range of materials, from mild steel to high-strength alloys, and can be tailored to suit specific production needs. Whether using a mechanical press, a hydraulic press, or a rolling mill, manufacturers can select the type of cold forming machine that best fits the material and complexity of the part being produced. The process also allows for different variations of forming techniques, such as impact or shear forces, to achieve the desired shape and properties.

Overall, the appeal of cold forming machines lies in their ability to produce parts with high precision, enhanced material properties, and minimal waste, all while being energy efficient and cost-effective. Whether for mass production or custom parts, cold forming continues to be a fundamental process in modern manufacturing, enabling the creation of high-quality metal components used across a broad spectrum of industries.

Steel Bending Machine

A steel bending machine is a type of industrial equipment used to bend steel and other metal materials into various shapes and angles. The process is commonly employed in construction, manufacturing, and fabrication industries to create steel components that need to be formed into specific configurations, such as angles, curves, or circular shapes. Steel bending machines are designed to handle different grades and thicknesses of steel, ensuring high precision and repeatability for mass production or custom fabrication needs.

These machines typically use mechanical or hydraulic systems to apply controlled force to the steel, bending it around a die or mandrel. Depending on the design of the machine and the complexity of the bending operation, the process can either involve a single-axis bend (such as in pipe bending) or multi-axis bends for more complex shapes (as in structural beams or metal frames). Steel bending machines can also be used to create bends at precise angles, allowing for a high level of control over the final product.

One of the key features of steel bending machines is their ability to produce clean, accurate bends without causing excessive deformation or material stress. This is crucial in maintaining the structural integrity and appearance of the bent steel, particularly for applications where the steel will bear loads or be visible in the finished product. For example, in the construction of metal frames for buildings or bridges, precise bending is essential for ensuring the stability and strength of the structure.

Steel bending machines come in several different types, each suited for specific bending needs:

- Press Brake: One of the most common types, press brakes use a punch and die to apply force to the steel sheet, bending it into the desired shape. These machines are typically used for sheet metal bending and can accommodate various thicknesses and lengths of material.

- Roll Bending Machine: Used for bending metal plates or bars into curves, these machines have rollers that gradually shape the steel by passing it through the machine. Roll bending is commonly used for producing cylindrical shapes or large-radius bends.

- Pipe Bender: These machines are specialized for bending pipes and tubes, making them ideal for applications like plumbing, HVAC systems, and automotive exhaust systems. They use either rotary or rotary draw bending methods to shape the pipe into the required angles without kinking.

- Section Bender: Section benders are designed for bending structural steel sections, such as I-beams, H-beams, and channels. They are commonly used in the fabrication of frames and other structural components.

In addition to their versatility, steel bending machines are designed to be efficient, reducing the amount of time required for each bend and minimizing waste. Automation features in some advanced models also enable faster setups, higher production rates, and improved accuracy.

Overall, steel bending machines are crucial for the production of metal components that require precise, consistent bends. They are widely used in industries ranging from construction and infrastructure to automotive and aerospace, where structural integrity and precision are key.

Steel bending machines are essential tools in various industries that require the bending of steel and other metal materials into specific shapes and angles. These machines are designed to provide precise control over the bending process, ensuring that steel components maintain their structural integrity and meet required specifications. The bending process typically involves applying force to the material using either mechanical or hydraulic systems, allowing the metal to be shaped around a die or mandrel. This technique is widely used in construction, manufacturing, and fabrication, where steel needs to be bent for structural components, pipes, frames, and other applications.

These machines are capable of handling a range of steel types and thicknesses, allowing for versatility in the types of products they can produce. The ability to produce accurate bends without causing deformation is a key feature of steel bending machines. This ensures that the steel retains its strength and appearance after the bending process. Whether creating steel frames for buildings, bending pipes for plumbing, or forming metal components for machinery, the precision provided by these machines is crucial for the quality and safety of the final product.

Steel bending machines can perform various bending operations, depending on the type of machine and the complexity of the task. Some machines use press brakes to apply force to steel sheets, shaping them into the desired angle or form. Others, such as roll bending machines, can gradually bend metal plates or bars into curves or circular shapes. For specialized bending of pipes and tubes, pipe benders are used to create smooth, consistent bends without compromising the integrity of the material. In addition, section benders are designed to bend larger structural steel components, such as beams and channels, which are often needed for larger-scale construction projects.

The versatility of steel bending machines is enhanced by the range of automation features available on modern models. Automated controls allow for faster setups and higher production rates, making them ideal for high-volume production or complex, custom fabrication tasks. With the ability to bend a variety of materials and achieve precise results, these machines reduce waste and improve efficiency, ensuring that the steel is used effectively.

In industries like automotive, construction, and aerospace, where strength, durability, and accuracy are essential, steel bending machines play a vital role in the production of metal components. They are fundamental tools in ensuring that steel parts meet exacting standards while maintaining cost efficiency and reducing production time.

Cutting Machine for Sheet Metal

A cutting machine for sheet metal is a vital tool in industries where metal sheets need to be cut into specific shapes and sizes for various applications. These machines are designed to efficiently and accurately cut through different types of metal sheets, including steel, aluminum, and other alloys, with minimal waste and high precision. The process involves applying mechanical force, heat, or a combination of both to separate or shape the metal sheets according to the desired specifications.

Cutting machines for sheet metal can come in various types, each suited for different cutting needs and materials. Some of the most common types of cutting machines include shears, laser cutters, plasma cutters, and water jet cutters. Shearing machines, for example, are widely used for straight-line cutting of thin metal sheets, while more advanced technologies like laser cutting offer the ability to create intricate designs with high precision, especially for thinner materials. Plasma cutting, on the other hand, is often used for thicker materials, offering high-speed cuts with a high degree of accuracy.

These machines offer significant advantages, such as high cutting speed, minimal distortion of the material, and the ability to handle complex geometries. For example, laser cutting machines use a high-powered laser to focus energy onto the metal, vaporizing it along the cutting path. Plasma cutters utilize a high-temperature plasma stream to melt and blow away the metal, while water jet cutters use a high-pressure stream of water mixed with abrasives to cut through the material without generating heat, which helps to maintain the material’s integrity.

The choice of cutting machine depends on several factors, including the type of metal, thickness, complexity of the cut, and production volume. For large production runs, automated cutting machines may be employed to increase efficiency and reduce labor costs, while custom or small-batch production may rely on more manual or semi-automated machines for greater flexibility.

In industries like automotive, construction, aerospace, and metal fabrication, sheet metal cutting machines are essential for creating a wide range of components such as car panels, structural beams, ducts, and enclosures. Their ability to deliver precise cuts quickly and consistently makes them indispensable tools in modern manufacturing.

A cutting machine for sheet metal is an essential piece of equipment used in various industries to precisely cut metal sheets into specific shapes and sizes. These machines are designed to handle a wide range of materials like steel, aluminum, and other metals, making them versatile tools in metalworking and manufacturing processes. The cutting process can be accomplished through different methods, each suited to different types of metal, thicknesses, and desired results.

Machines like shears are commonly used for straight-line cutting of thinner sheets, providing quick and clean cuts. These machines apply a mechanical force to the metal, making them ideal for mass production of simple, straight cuts. For more intricate or detailed designs, technologies like laser cutting are often used. Laser cutters employ a focused laser beam to melt or vaporize the metal along the cutting path, offering extremely high precision. This method is particularly useful for thin materials or parts that require intricate patterns and detailed shapes.

Plasma cutting is another popular technique, particularly when dealing with thicker materials. Plasma cutters use an ionized gas stream, which reaches temperatures high enough to melt the metal, allowing it to be blown away along the cutting path. This method is known for its speed and ability to cut through metals with varying thicknesses, but it may generate more heat, which can sometimes affect the surrounding material.

Water jet cutting is a process that uses a high-pressure stream of water, often mixed with abrasives, to cut through metal sheets. This method has the advantage of not generating heat, which can prevent the material from warping or losing its mechanical properties. Water jet cutting is especially effective for materials that are sensitive to heat, like aluminum and copper.

The choice of cutting machine depends on several factors such as the material to be cut, the thickness of the metal, the complexity of the cuts required, and the scale of production. Some machines are designed for high-volume, automated cutting, while others are more suitable for custom or smaller production runs, offering flexibility and adaptability for different jobs.

Cutting machines for sheet metal are crucial in industries like automotive, aerospace, construction, and general metal fabrication. They are used to create components ranging from car body panels to structural supports and ducts. The ability of these machines to produce precise, consistent cuts quickly is key to ensuring the quality and efficiency of the manufacturing process. These machines also help to reduce material waste and labor costs, making them valuable tools for improving productivity in metalworking operations.

The continued development and refinement of cutting machines for sheet metal have further enhanced their capabilities, making them more efficient, accurate, and cost-effective. With advancements in automation, modern cutting machines can integrate with computer numerical control (CNC) systems, allowing for precise control over the cutting process and reducing the need for manual intervention. CNC machines are particularly beneficial for applications that require repeated, high-precision cuts, ensuring that every part produced meets the same exacting standards.

Automation has also increased the speed of cutting operations, significantly reducing production time. This is particularly valuable in industries where time is critical, such as automotive manufacturing, where large quantities of parts must be produced quickly and with high consistency. Automated material handling systems can further optimize the process by automatically loading and unloading materials, improving throughput, and minimizing the risk of human error.

Another major advantage of modern cutting machines is their ability to minimize material waste. Laser cutting, for example, is known for its efficiency in material usage, as the narrow width of the laser beam allows for cuts that are almost as narrow as the material thickness, reducing scrap. Additionally, advanced software used in these machines can optimize the layout of the cuts to make the most of the available sheet material, further minimizing waste and maximizing material yield.

Maintenance and operational costs have also improved with newer models, thanks to advances in machine design, durability, and automation. Many cutting machines now include monitoring systems that track performance and alert operators to any issues before they lead to downtime. These systems help ensure that machines operate at peak efficiency, reducing unexpected repairs and maintenance costs.

The versatility of sheet metal cutting machines also allows them to be used in a wide range of industries beyond automotive and aerospace. For instance, in architecture and construction, they are used to cut metal panels for building facades, roofing systems, and structural reinforcements. In electronics, cutting machines help produce components like enclosures, connectors, and heat sinks, where precision is critical to the function of the final product. Even in the energy sector, these machines play a role in manufacturing components for wind turbines, solar panels, and oil rigs.

With their ability to adapt to different materials, thicknesses, and cut complexities, sheet metal cutting machines remain indispensable in modern manufacturing. As technology continues to evolve, the machines will likely become even more precise, faster, and more energy-efficient, making them even more essential to industries that rely on the creation of high-quality metal components.

Joggle Machine

A joggle machine is a specialized piece of equipment used in metalworking to create a joggle, which is a small, controlled offset or step in a metal sheet or part. This offset is typically used to align parts, create a more secure fit between metal pieces, or prepare components for welding. The joggle process is especially important in industries like aerospace, automotive, and construction, where precise alignment and the ability to fit components together smoothly are crucial.

The joggle machine works by applying force to a metal sheet or part, bending it in a specific way to create the desired offset or step. The process can be used to form joggles in various materials, including aluminum, steel, and other alloys, with different thicknesses. These machines are designed to provide accurate and consistent results, ensuring that the joggle is uniform and fits perfectly with the corresponding part.

In applications like sheet metal fabrication, the joggle is often used to create flanges or joining points where two metal parts need to be connected. By adding a small offset, a joggle ensures that the parts align correctly and create a tight, secure fit for welding, bolting, or riveting. This can improve the strength and stability of the joint and can also help with the assembly process, reducing the potential for misalignment or gaps.

Joggle machines are typically equipped with adjustable dies or tools that allow the operator to control the size and angle of the joggle, depending on the specific requirements of the part. These machines are often integrated into automated production lines to facilitate the mass production of metal components with joggles. In some cases, CNC-controlled joggle machines offer high precision and repeatability, ensuring that each part is consistently formed to the required specifications.

The ability to create precise joggles using a joggle machine is essential for industries that require high-quality, durable metal parts. Whether for aerospace applications, where the integrity of joints is critical, or for automotive and construction projects, the joggle machine plays a vital role in ensuring the successful assembly of metal components.

A joggle machine is an essential tool in metalworking used to create a joggle, which is a controlled offset or step in metal sheets or parts. The joggle process helps ensure precise alignment between metal components, especially in applications that require tight fits for welding, bolting, or riveting. The offset created by the joggle machine allows for smoother assembly and a more secure connection between parts, which is critical in industries such as aerospace, automotive, and construction.

These machines work by applying force to a metal piece to form a specific offset at a precise angle or distance. The result is an evenly shaped step or bend in the metal, which helps components fit together with minimal gaps or misalignment. This can be particularly important in industries where components need to fit together perfectly to maintain strength and structural integrity, such as in aircraft fuselages, automotive frames, or building structural supports.

Joggle machines are designed for accuracy and repeatability, ensuring that every joggle is made to the exact specifications required for a particular application. The process allows manufacturers to produce parts that can be easily joined together, providing both mechanical stability and ease of assembly. The machine typically uses adjustable dies or tooling to control the size and shape of the joggle, allowing operators to tailor the process to different materials, thicknesses, and part configurations.

In modern manufacturing, many joggle machines are automated or CNC-controlled, which adds a level of precision and efficiency. Automation makes it easier to produce large batches of components with consistent results, reducing the chance of errors and ensuring that each part is identical. This is particularly useful in mass production settings where high precision and high throughput are crucial.

Joggle machines are crucial in industries where parts must meet strict tolerances and fit together perfectly, whether for structural strength, ease of assembly, or both. The machine’s ability to create precise joggles ensures that components will align correctly during the assembly process, reducing the risk of defects and improving overall product quality. As technology evolves, the joggle machine continues to be an important part of the manufacturing process, especially in industries that require durable, high-quality metal parts.

As joggle machines evolve, advancements in technology have led to more sophisticated models capable of handling a wider range of materials and offering greater flexibility in production. Modern joggle machines, especially those with CNC (Computer Numerical Control) capabilities, can be programmed to perform complex joggle patterns with high precision, enabling manufacturers to meet increasingly stringent design specifications. This automation has significantly reduced the amount of manual labor required, improving both the efficiency and consistency of the production process.

The ability to create multiple joggles on a single part is another feature that modern machines offer, making them even more versatile. This capability allows for the creation of intricate, multi-step designs that would have been difficult or time-consuming to produce manually. The machines can handle various types of metal, including aluminum, steel, stainless steel, and other alloys, and are capable of producing joggles on metal sheets of different thicknesses. This broad capability makes them useful in a variety of applications, from complex aerospace parts to more routine automotive and construction components.

Furthermore, joggle machines are often integrated with other machines in a fully automated production line, which can significantly speed up the entire fabrication process. By linking the joggle machine with cutting, bending, and welding systems, manufacturers can streamline the creation of parts, reducing handling times and improving the overall flow of production. This integration helps reduce costs, minimize errors, and shorten lead times, allowing businesses to meet demand more effectively.

In industries where quality control is critical, the precision offered by modern joggle machines is invaluable. Automated systems often come with built-in inspection capabilities, ensuring that each part meets required specifications before it moves to the next stage of production. This ensures that defective or misaligned components are caught early, preventing costly mistakes further down the production line.

Joggle machines also contribute to sustainability efforts in manufacturing by minimizing material waste. The precise nature of the joggle, along with automated layout optimization, allows manufacturers to make the best use of available material, reducing scrap and enhancing overall material efficiency. This is particularly important in industries where high-cost materials like titanium or high-strength alloys are used, making the efficient use of resources a priority.

As manufacturing processes continue to advance, joggle machines will likely become even more automated, precise, and versatile, ensuring their place as essential tools for producing high-quality, reliable components in a wide range of industries. Their role in creating secure, well-aligned joints between metal parts will remain crucial for building products that meet the exacting standards of sectors like aerospace, automotive, and construction, where safety and performance are of the utmost importance.

Sheet Metal Machinery

Sheet metal machinery encompasses a range of equipment used to shape, cut, form, and finish metal sheets into specific shapes or components. These machines are crucial in industries such as automotive, aerospace, construction, and general manufacturing, where precision and efficiency are essential for producing metal parts and assemblies.

One of the most common machines in sheet metal fabrication is the shearing machine, used to cut metal sheets into straight lines. Shears can handle different materials and thicknesses, providing clean and precise cuts. Laser cutting machines are another widely used tool, which utilize a high-powered laser to cut through sheet metal with exceptional precision. Laser cutters are particularly beneficial for intricate patterns and fine details, making them suitable for applications that require detailed work.

Press brakes are used to bend sheet metal into various angles and shapes. They work by applying force through a punch and die mechanism, allowing manufacturers to create parts like metal brackets, frames, and enclosures. These machines can handle both simple and complex bends, and more advanced models use CNC controls to ensure high precision and repeatability in production.

Roll forming machines are used for producing continuous profiles from metal sheets. By passing the metal through a series of rollers, roll forming machines gradually shape the metal into specific profiles, such as channels, beams, and roofing panels. This process is often used for high-volume production of long, uniform shapes.

Punch presses are used to create holes, slots, or other forms in metal sheets by using a punch and die system. These machines can be automated to perform multiple operations in one cycle, making them ideal for mass production of components like electrical panels, ventilation ducts, and other sheet metal products that require holes or complex shapes.

CNC machines, like CNC punching machines or CNC laser cutters, offer advanced automation and control, allowing for highly precise and efficient production of complex sheet metal parts. These machines are typically controlled by computer programs, which makes them ideal for mass production or jobs requiring consistent quality across large volumes.

Flanging machines and joggle machines are also used in sheet metal fabrication. A flanging machine is designed to create a flange or lip on the edge of a sheet metal piece, which can then be used for joining or securing other parts. Joggle machines, as previously mentioned, are used to create controlled offsets or steps in the metal, ensuring perfect alignment for welding or other assembly processes.

Finally, welding machines, such as spot welders and TIG/MIG welders, play a critical role in sheet metal fabrication, allowing metal sheets to be permanently joined together. These machines are crucial for the final assembly of metal parts and ensure that components remain securely fastened, providing the necessary strength and durability.

Overall, sheet metal machinery is a diverse and essential aspect of modern manufacturing, enabling the efficient production of high-quality metal components used in a wide range of industries. Whether cutting, bending, forming, or joining, these machines offer the precision, speed, and reliability required for producing durable and accurate metal parts.

Sheet metal machinery is a vital part of modern manufacturing, enabling the production of a wide variety of metal components used in different industries. These machines handle different processes such as cutting, bending, forming, punching, and welding, allowing manufacturers to produce precise and durable parts that meet specific design requirements. The versatility of sheet metal machinery is evident in the different types of machines available, each designed for specific tasks but often capable of performing a variety of operations depending on the setup and tooling used.

Machines like shearing machines are fundamental for cutting sheet metal into manageable sizes. They provide straight cuts with high precision, ensuring that the material is ready for further processing. Laser cutting machines, on the other hand, offer higher precision and can handle intricate designs, allowing manufacturers to create complex patterns and shapes in thin to medium-thickness metals. Their ability to focus a laser beam on a precise area makes them perfect for tasks requiring fine details and clean cuts, reducing the need for post-processing.

Press brakes are integral for bending sheet metal into the desired angles or shapes. The press brake’s ability to apply force through a punch and die mechanism makes it possible to create everything from simple bends to more complex geometries, all with high repeatability. Modern press brakes, especially those with CNC controls, provide manufacturers with more flexibility and accuracy, ensuring parts are consistently bent to exact specifications across large production runs.

Roll forming machines are essential for continuous production of profiles from metal sheets. This process is especially useful for high-volume manufacturing, such as in the production of roofing materials or metal channels used in construction. The process involves passing metal through a series of rollers to shape it into the desired profile, ensuring that the final product is uniform and consistent.

Punch presses are another critical piece of sheet metal machinery. These machines create holes, slots, or other complex shapes in sheet metal by applying a punching force. With the ability to carry out multiple operations within a single cycle, punch presses are ideal for high-speed production of parts like electrical enclosures, ventilation ducts, or automotive components. The automation available in modern punch presses allows for faster production times and ensures precision even in high-volume runs.

CNC sheet metal machinery, such as CNC laser cutters or CNC punching machines, brings advanced automation and control to the process. These machines are controlled by computer programs, which means parts can be produced with a high level of accuracy and consistency. The ability to input detailed designs and quickly make adjustments via software gives manufacturers the flexibility to adapt to different orders, ensuring that even complex parts are produced efficiently.

Welding machines also play a crucial role in sheet metal fabrication, providing the means to join parts together securely. Spot welders, MIG (Metal Inert Gas) welders, and TIG (Tungsten Inert Gas) welders are commonly used for joining sheet metal parts, with each method offering specific advantages depending on the materials and joint requirements. These machines ensure that the final assembled parts are durable and capable of withstanding the forces and conditions they will face in their respective applications.

In the production of sheet metal parts, other specialized machines, such as flanging machines, which create flanges or lips for joining metal pieces, and joggle machines, which create precise offsets in metal sheets, are also essential. These machines ensure that metal components can be joined seamlessly during assembly, whether for structural applications, electrical enclosures, or automotive parts.

The development of automated and CNC-controlled sheet metal machinery has revolutionized the manufacturing process, reducing human error, increasing speed, and improving precision. This has allowed for faster turnaround times, reduced material waste, and higher-quality products. As industries demand higher levels of customization and faster production times, sheet metal machinery continues to evolve, offering greater capabilities and versatility to meet the needs of modern manufacturing.

As the demand for faster, more accurate, and cost-effective production continues to grow, sheet metal machinery is becoming more advanced and automated. Technological innovations are enhancing the performance of these machines, making them more efficient, versatile, and capable of producing increasingly complex parts with minimal waste. The integration of robotics and artificial intelligence (AI) in sheet metal fabrication is one example of how automation is transforming the industry. Automated systems can now handle material handling, loading, and unloading tasks, reducing labor costs and improving overall efficiency in production lines.

For instance, automated material handling systems are often integrated with CNC punch presses, laser cutting machines, and press brakes, allowing for seamless operation without manual intervention. These systems can automatically load metal sheets onto the machine, manage inventory, and remove finished parts from the production line. The automation of these processes ensures a continuous workflow, reducing downtime between operations and improving throughput, which is especially beneficial in high-volume production environments.

Moreover, the software used in modern sheet metal machinery has advanced significantly. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are now commonly used to design parts and generate machine instructions. These software systems help optimize the cutting and bending process, reducing material waste and ensuring that parts are made with minimal scrap. Software also allows manufacturers to easily make changes to designs and adapt to new production requirements, providing greater flexibility and efficiency in production schedules.

In addition to enhancing production efficiency, the evolution of sheet metal machinery has also focused on improving sustainability. As manufacturers seek to reduce their environmental impact, newer machines are being designed to use less energy and generate less waste. Laser cutting machines, for example, are highly efficient in terms of material usage, producing precise cuts that minimize waste. Similarly, advancements in press brake technology have resulted in machines that can work with thinner materials, reducing energy consumption and waste generated during bending.

The flexibility of modern sheet metal machinery also allows manufacturers to produce parts with more complex geometries, enabling the creation of custom metal components for industries like aerospace, automotive, and medical device manufacturing. In aerospace, for example, sheet metal machinery is used to create lightweight and durable parts for aircraft structures, while in automotive manufacturing, it is used for precision parts like body panels and frames. The ability to produce parts with intricate designs and exact specifications is key to meeting the stringent requirements of these industries.

Maintenance and support for sheet metal machinery have also improved, with remote monitoring and diagnostic tools being increasingly integrated into machines. These tools allow manufacturers to monitor the performance of their equipment in real-time, identifying potential issues before they result in costly downtime. Predictive maintenance technology can analyze machine data and provide alerts for scheduled maintenance, helping to extend the life of the machinery and reduce the likelihood of unexpected failures.

Overall, the future of sheet metal machinery is moving toward even greater automation, precision, and sustainability. With the continuous improvement of technology, manufacturers are better equipped to meet the growing demand for high-quality, cost-effective, and customized metal parts across various industries. The integration of advanced software, automation, and energy-efficient technologies is setting the stage for a new era of sheet metal fabrication that will help drive innovation and productivity in manufacturing.

Steel Bending Machine

A steel bending machine is a type of industrial equipment used to bend steel and other metals into various shapes and angles. These machines are essential in industries like construction, automotive, aerospace, and metal fabrication, where precise bending of steel is required to create parts such as beams, brackets, frames, and other structural components. Steel bending machines apply force to metal to deform it, creating a bend at a desired angle or radius, which is critical in producing parts that fit specific design requirements.

There are different types of steel bending machines, each suited for specific tasks and types of bending. Press brakes are the most commonly used steel bending machines in industrial settings. They work by using a punch and die system to bend steel sheets or plates. The machine applies controlled force to the metal, bending it at a specific angle. Press brakes can handle a range of steel thicknesses, and modern versions are often CNC (Computer Numerical Control) machines, which allows for highly accurate and repeatable bends.

Angle bending machines are another type of machine used specifically for bending angle steel or structural steel sections. These machines are designed to handle the bending of angles, flats, and square bars into specific shapes or curves. They are widely used in the production of metal frames, columns, and other structural components that require precise bends in specific directions.

Roll bending machines are used to create curves or arcs in steel plates or sheets. These machines feature a set of rollers that gradually bend the metal as it passes through them. Roll bending is often used to create cylindrical shapes or large, curved structures, such as pipes or tanks. The machine applies pressure evenly across the steel sheet to form the desired curve, making it an ideal choice for creating round shapes or large-radius bends.

For more complex and precise bending tasks, CNC bending machines are increasingly common in steel bending operations. These machines offer advanced control, allowing for multiple bends to be performed in a single cycle. With CNC technology, operators can input specific parameters and designs, and the machine will automatically adjust to produce parts with high precision. CNC bending machines also improve efficiency by reducing human error and speeding up production times, making them ideal for high-volume manufacturing.

The process of bending steel is highly dependent on the type of steel being used, as different grades and thicknesses of steel may require varying amounts of force or different bending techniques. Some steel bending machines are equipped with adjustable settings to accommodate these variables, allowing for more flexibility in production.

Steel bending machines are crucial for the construction of metal frames, vehicle parts, industrial machinery, and structural supports. They help manufacturers create high-quality, durable metal parts with the exact specifications needed for assembly. Modern machines are designed for high efficiency, precision, and ease of use, making them essential tools in industries where metalworking is a key component of production. Additionally, the integration of advanced technologies such as automation and CNC systems has made steel bending machines faster, more accurate, and more cost-effective, improving overall productivity in metal fabrication.

Steel bending machines play a pivotal role in the metalworking industry by ensuring the precise bending of steel into various shapes and forms. These machines are designed to work with different grades and thicknesses of steel, making them highly versatile and essential for producing a wide range of parts and components. Whether it’s bending metal sheets, creating curved shapes, or forming angles and structural elements, steel bending machines provide the accuracy and control needed for these tasks.

In addition to press brakes and angle bending machines, there are hydraulic steel bending machines, which offer greater control over the bending process. Hydraulic systems use fluid pressure to apply force, providing smooth and precise bends. These machines are especially useful for handling large or heavy materials, as the hydraulic system can generate significant bending force with minimal physical effort. They are commonly used in construction and heavy industries where large steel components need to be bent to precise specifications.

The mandrel bending machine is another type of steel bending equipment, which is used for creating tight-radius bends without compromising the integrity of the material. Mandrel bending prevents the steel from collapsing or wrinkling during the bend, making it ideal for applications that require a smooth, consistent bend without any deformation. This method is particularly useful in industries like aerospace and automotive, where the aesthetic and structural quality of the bends is critical.

Automation and digital control technologies have significantly enhanced the capabilities of steel bending machines. With CNC systems, operators can input specific bending parameters, and the machine will automatically adjust to meet the required specifications. This has not only improved the accuracy of bends but also reduced human error and increased the speed of production. CNC bending machines also allow for complex, multi-bend components to be produced in a single cycle, improving efficiency and consistency in the manufacturing process.

Steel bending machines are also designed to be highly adaptable, allowing for adjustments in parameters such as bending radius, angle, and force to suit different types of steel and desired outcomes. With the ability to bend steel at a range of angles or to create specific curves and profiles, these machines are widely used in industries where custom metal parts are required. For example, in the automotive industry, steel bending machines are used to create frames, chassis, and other structural components that must meet precise tolerances. Similarly, in construction, these machines are used to bend steel rods and bars for reinforcing concrete structures.

The ability to work with different shapes, sizes, and types of steel is what makes steel bending machines such versatile tools. Whether it’s bending flat steel sheets, hollow sections, round bars, or square bars, these machines provide manufacturers with the tools to create high-quality metal parts that are durable, functional, and fit within the required design parameters. Moreover, the machines’ ability to integrate with other equipment in automated production lines ensures that the bending process is just one part of a seamless and efficient manufacturing workflow.

As technological advancements continue, steel bending machines are becoming faster, more efficient, and more accurate. The integration of AI, machine learning, and predictive maintenance technologies ensures that the machines run at optimal performance levels, minimizing downtime and improving the overall productivity of manufacturing operations. As the demand for customized and high-quality steel components continues to grow across various industries, steel bending machines will remain an integral part of the metal fabrication process.

The continued evolution of steel bending machines is pushing the boundaries of efficiency and precision in metal fabrication. With the integration of advanced technologies such as robotics and IoT (Internet of Things), these machines are becoming more autonomous and intelligent. Robotic arms, for example, are being used to automate the loading, unloading, and handling of steel pieces, reducing labor costs and enhancing production speed. This automation allows for 24/7 operation without the need for constant manual oversight, leading to significant increases in throughput and efficiency.

IoT-enabled steel bending machines can now collect real-time data from the manufacturing process, such as the machine’s operational status, performance metrics, and maintenance needs. This data can be analyzed to optimize the bending process, detect issues early, and predict when maintenance is needed. Predictive maintenance is a particularly important development, as it helps reduce unplanned downtime and extends the lifespan of the machines. By addressing potential issues before they result in breakdowns, manufacturers can avoid costly interruptions and maintain continuous production.

Furthermore, energy efficiency is becoming an increasingly important consideration in the design of steel bending machines. Manufacturers are focusing on creating machines that consume less energy while still providing the high levels of performance required in industrial settings. Energy-efficient designs help companies reduce operating costs and meet environmental sustainability goals. For example, hydraulic systems in steel bending machines are being optimized to use less power while maintaining their bending capabilities. This is particularly important in large-scale operations, where energy consumption can significantly impact overall costs.

Another key trend is the development of flexible bending solutions that can accommodate a broader range of materials, including not just steel but also aluminum, copper, and other metals. As industries increasingly require multi-material solutions, bending machines are being designed to handle a wider variety of materials with different properties and thicknesses. This capability allows manufacturers to produce parts that meet a diverse set of specifications without needing to invest in multiple machines for each material.

In addition, advancements in software are making it easier for operators to design, program, and manage the bending process. Software solutions are becoming more intuitive, with user-friendly interfaces that allow operators to input bending specifications, simulate the bending process, and optimize machine settings for maximum efficiency and minimal waste. These software tools can also integrate with other aspects of the production line, such as cutting and welding machines, providing a seamless workflow and improving overall production planning.

One of the most significant impacts of these advancements is in customization. Steel bending machines are becoming more capable of producing complex, one-off designs with the same efficiency as large-volume production. This opens up new possibilities for industries like architecture, where bespoke, intricately bent steel components are often needed for unique designs. The ability to quickly adapt to custom designs while maintaining precision and consistency is a game-changer for industries that rely on specialized steel components.

As the manufacturing landscape continues to evolve, the role of steel bending machines will remain critical in shaping the future of metalworking. Their ability to produce high-quality, precisely bent steel parts efficiently and at scale ensures their continued importance in industries that rely on metal components. With ongoing advancements in automation, energy efficiency, and software integration, steel bending machines will continue to provide manufacturers with the tools needed to meet the growing demands for precision, customization, and sustainability in modern production processes.

EMS Metalworking Machines

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press