Four-Column Deep Drawing Press: An Automated Machining Line is a highly integrated manufacturing system designed to produce parts with minimal human intervention. It typically consists of a series of machine tools (e.g., CNC lathes, milling machines, drilling machines) that are connected by material handling systems and controlled by a central computer or PLC (Programmable Logic Controller).

Key Components of the Automated Machining Line

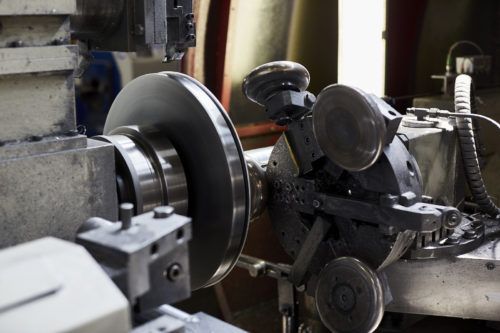

- CNC Machines – Perform operations like turning, milling, drilling, etc.

- Robotic Arms / Gantry Systems – Load and unload parts between stations.

- Conveyors / Transfer Lines – Move parts through the line.

- Inspection Stations – Use vision systems or sensors for quality control.

- Tool Management Systems – Monitor and change tools automatically.

- Centralized Control System – Coordinates all operations and collects data for monitoring and optimization.

Advantages:

- High Productivity: Continuous, 24/7 operation.

- Consistency & Precision: Reduced human error.

- Reduced Labor Costs: Fewer operators required.

- Better Data Collection: Enables predictive maintenance and real-time quality tracking.

Applications:

- Automotive components

- Aerospace parts

- Consumer electronics

- Industrial equipment

An automated machining line is a production system where multiple machine tools and handling devices are connected to perform sequential operations on workpieces with minimal human intervention. These lines are typically controlled by centralized computer systems or PLCs that coordinate each stage of the process, from raw material input to finished product output. The core of the system includes CNC machines such as lathes, milling machines, or grinders, which are programmed to carry out precise machining operations. Between these machines, automated material handling systems—such as robotic arms, gantry loaders, or conveyors—transport parts, ensuring smooth workflow and minimal downtime.

The system may also integrate inspection stations equipped with sensors, vision systems, or coordinate measuring machines (CMMs) that verify dimensional accuracy and surface quality during or after machining. This ensures defective parts are identified early and reduces waste. Automated tool changers and tool monitoring systems help keep the line running by switching out worn tools and maintaining machining precision.

Automated machining lines are especially beneficial in high-volume production environments where consistency, speed, and cost-efficiency are critical. Industries such as automotive, aerospace, and electronics rely heavily on such systems to produce complex parts at scale. While the initial investment is high, the long-term benefits include reduced labor costs, improved product quality, faster turnaround times, and better use of manufacturing data for process optimization and predictive maintenance.

In a typical real-world scenario, such as an automotive engine component production line, the automated machining process starts with raw forgings or castings being loaded into the system—often by robotic arms or palletized feeders. The first CNC station might perform rough turning to shape the basic geometry. After this, the part is transferred—usually via a conveyor or robotic gripper—to the next station, where more detailed operations like milling, drilling, or threading take place.

Each machine is pre-programmed with the exact machining instructions and tolerances, ensuring that every part meets the same specifications. Sensors on the machines track cutting forces, spindle speed, vibration, and tool wear. If any parameter deviates from its threshold, the system either compensates automatically or triggers a maintenance alert. Some lines include adaptive machining, where minor real-time adjustments are made based on part variability or tool conditions.

Inspection and quality control are often embedded into the line itself. For example, a vision system might scan the part for surface defects immediately after milling. Later, a contact probe or laser scanner might verify critical dimensions. If a defect is detected, the part can be ejected from the line automatically and logged in a database for traceability and root cause analysis.

Finished parts are either collected in bins, stacked on pallets, or automatically transferred to an assembly line or packing station. Throughout the entire cycle, the central control system logs data from every operation, enabling detailed reporting, traceability, and continuous process improvement through machine learning or statistical process control techniques.

This kind of integration enables not only high-volume output but also flexibility for batch-size variations and product changeovers. With Industry 4.0 and IoT technologies, modern automated machining lines can also be remotely monitored and adjusted, further reducing the need for on-site personnel and enabling centralized control over multiple production facilities.

In traditional automated machining lines without AI or modern digital technologies, the system still relies heavily on mechanical and electrical automation controlled by programmable logic controllers (PLCs), relay-based logic, or basic numerical control (NC) systems. These setups are robust and reliable, often built for longevity and consistent performance in high-volume production environments.

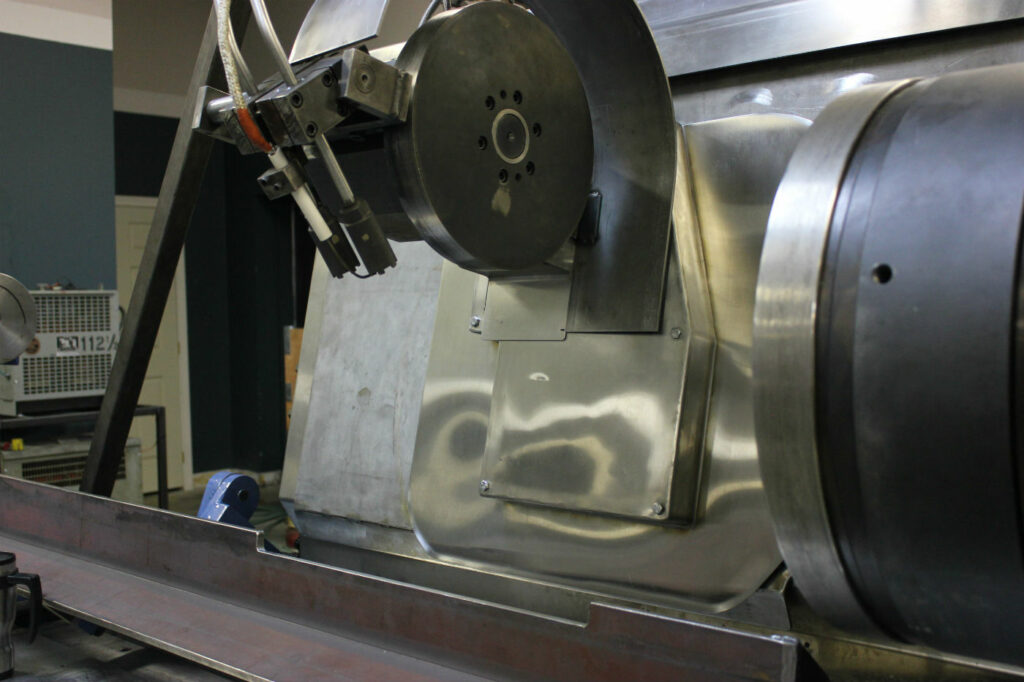

The process begins with manual or semi-automated loading of raw materials into the first machine tool. These machines—typically NC lathes, milling machines, or drills—perform specific operations based on preset programs stored in the machine’s memory. The workpiece is clamped in place, and machining proceeds according to fixed cycle parameters. Once the operation is complete, mechanical transfer systems such as linear tracks, pneumatic pushers, or rotary indexing tables move the part to the next station.

Tool changes are usually scheduled at regular intervals based on time or part count rather than real-time tool condition. Operators may be responsible for monitoring tool life and performing manual replacements when necessary. Likewise, quality checks are typically carried out at regular intervals by human inspectors using gauges, micrometers, or dedicated checking fixtures. In some systems, dial indicators or hard stops are used to maintain dimensional control.

Despite the absence of sensors or real-time feedback, such systems are remarkably effective in stable production conditions where the material and part design do not vary significantly. Maintenance is preventive or breakdown-based, relying on routine inspections, lubrication schedules, and experience-based troubleshooting.

These older automated lines are often found in long-established manufacturing plants, particularly in the automotive, heavy equipment, and appliance industries. They are less flexible than modern systems but are valued for their simplicity, mechanical reliability, and the skill-based approach of their operators and technicians.

In older automated machining lines, the transfer mechanisms are a critical part of the system and are designed for mechanical simplicity and reliability. Common types include chain conveyors, roller conveyors, overhead trolleys, rotary index tables, and linear shuttles. Each is chosen based on the type and size of the part, the required throughput, and the physical layout of the shop floor.

One widely used method is the rotary indexing table, especially in compact setups. It positions the workpiece at different machining stations arranged in a circular configuration. After each operation, the table indexes to the next position, allowing simultaneous machining at multiple stations. This results in high efficiency for parts that require several short, sequential operations.

For heavier parts or larger operations, linear transfer systems are more suitable. These include rigid rails or tracks along which pallets or fixtures holding the parts are mechanically advanced using cams, gears, or pneumatic cylinders. The indexing is precise and repeatable, ensuring each part is aligned correctly at each station. This system may include lifting and rotating units for reorienting parts as needed for subsequent machining.

Another key feature in these systems is dedicated tooling and fixturing. Each station typically has fixed-purpose jigs that precisely position and clamp the workpiece. These fixtures are often hard-mounted to the machine base and require manual adjustment during setup changes. For repeat production of a single part or family of parts, this system works efficiently and minimizes the need for frequent calibration.

Control is handled by relay logic or early PLCs with ladder diagrams programmed to execute sequences such as machine start/stop, indexing, tool changes, and coolant flow. These controls are robust, easy to troubleshoot with basic electrical knowledge, and designed for long-term operation. They don’t adapt in real-time but can reliably run for decades with minimal issues if maintained properly.

Coolant systems in traditional lines are also basic—usually centralized coolant tanks with pumps directing fluid to the tools. Filtration may be rudimentary, involving mesh filters or magnetic separators to remove chips and swarf.

Chip handling is mechanical too—often using screw conveyors or belt-driven systems to move chips away from the machining area to collection bins. Operators are typically responsible for emptying these bins and ensuring the system stays clear to prevent machine stoppage.

Overall, older automated machining lines are engineered for reliability and long production runs of identical parts. Changeovers are time-consuming, and flexibility is limited, but their mechanical simplicity, low software dependence, and proven durability make them well-suited for dedicated manufacturing tasks.

Automated Machining and Grinding Line

An Automated Machining and Grinding Line is a production system that combines cutting operations (like turning, milling, or drilling) with grinding processes in a continuous, integrated workflow. This setup is commonly used in industries that demand high precision and surface finish, such as automotive, aerospace, and heavy machinery manufacturing. Unlike purely machining lines, these systems can handle parts that require both dimensional accuracy and fine surface quality.

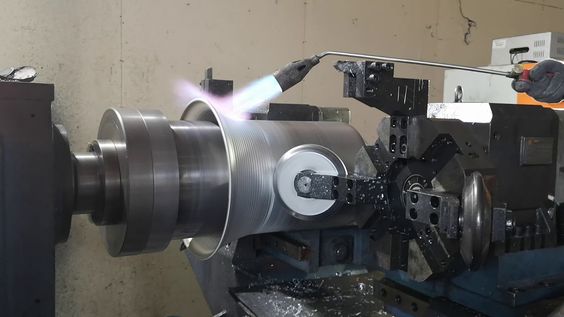

In traditional implementations without modern AI or smart sensors, these lines are built around a sequence of machine tools and grinders, connected via mechanical transfer systems such as conveyors, indexing tables, or robotic arms. Each station is dedicated to a specific operation. For example, a component may first be rough-machined in a CNC lathe, transferred to a milling machine for slots or holes, and finally moved to a grinding station for precision finishing. Grinding is typically done with cylindrical, surface, or centerless grinders, depending on the part geometry.

Parts are usually mounted on dedicated fixtures or pallets designed to maintain consistent orientation and minimize setup time at each station. Fixtures are clamped pneumatically or hydraulically, and the systems are aligned mechanically to ensure accurate positioning. Transfer between stations is timed and controlled by PLCs, which follow a strict logic sequence. These lines often incorporate automated tool changers in the machining stations and fixed grinding wheels in the grinding units.

Grinding stations are equipped with cooling systems and basic wheel dressing mechanisms. In older systems, dressing cycles are timed rather than sensor-driven, and operators rely on scheduled maintenance or visual inspection to identify wear or wheel damage. Coolant filtration may use magnetic separators, paper bed filters, or basic settling tanks to remove fine grinding debris.

Quality control is mostly manual or semi-automated. For high-tolerance parts, operators may use dial indicators, micrometers, or air gauges at designated inspection stations. Some lines include mechanical go/no-go gauges between stages to detect out-of-spec parts before they move to the next operation.

The major advantage of combining machining and grinding in one line is process integration: fewer setups, faster cycle times, and reduced handling between operations. This is particularly beneficial when producing hardened or high-strength materials where post-machining grinding is necessary for tolerance and finish. However, because of the heat, dust, and precision requirements of grinding, these stations are often physically isolated within the line and require more frequent maintenance.

Older automated machining and grinding lines are designed for long runs of standardized parts, with little flexibility for frequent part changes. Changeovers involve manual fixture replacement, program switching, and careful realignment, typically performed by skilled technicians. Despite their limitations, such systems remain in use where durability, consistency, and cost-per-part are more critical than flexibility.

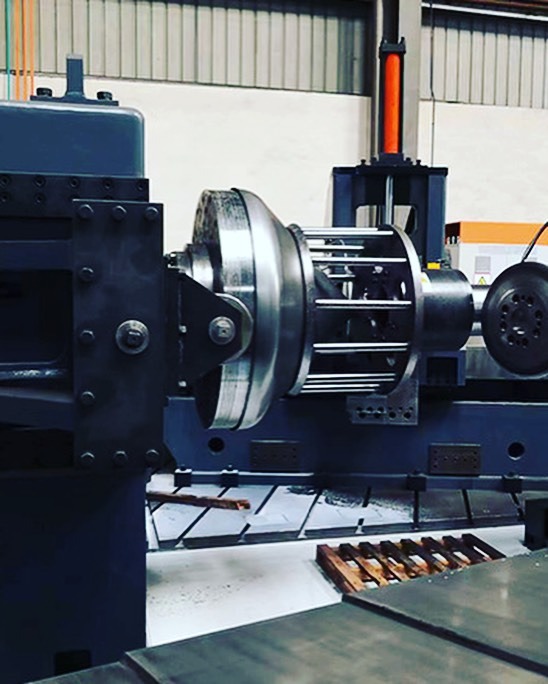

Let’s consider a typical crankshaft production line as an example of an automated machining and grinding line. Crankshafts are complex components that require a combination of heavy material removal and ultra-precise finishing. The line is usually designed for high-volume output, such as in automotive engine manufacturing.

The process begins with forged steel blanks being loaded—either manually or by robot—onto palletized fixtures. These fixtures travel through the line and maintain precise orientation of the crankshaft throughout each station. The first few machines perform rough machining using CNC lathes and milling machines to establish key features like journals, counterweights, and oil passages. Operations at this stage include turning, milling of flat faces, and drilling of oil holes.

Next, the part is transferred—usually by a chain conveyor or robotic arm—to semi-finish machining stations, where closer tolerances are achieved. Here, operations such as journal and pin turning to near-final dimensions are performed. The control is typically PLC-based, with set cycle times and limited part detection logic. Tool changes are pre-programmed based on part count, not real-time monitoring.

After semi-machining, the crankshaft undergoes heat treatment, often offline. It is then reintroduced to the line for hard machining or pre-grinding, depending on the material hardness and required tolerances. The hard surfaces—especially the main and pin journals—now require precise size and surface quality, which is where grinding becomes critical.

The part is now transferred to grinding stations, typically including:

- Cylindrical grinders for the main journals.

- Orbital or crankpin grinders for the offset crank pins.

- Face grinders for end faces and thrust surfaces.

These grinders are built for high rigidity and thermal stability, often with cast-iron beds and hydraulic or electric infeed systems. The grinding wheels are fixed and dressed periodically using diamond dressers. The dressing cycles are scheduled either by time or number of parts, depending on the line’s setup. The grinding process produces significant heat and fine particles, so coolant systems with filtration tanks and magnetic separators are essential.

To maintain accuracy, the line may include mechanical gauging stations after critical grinding operations. These use air gauges or contact probes to measure diameter, roundness, and taper. In some lines, go/no-go fixtures are positioned at intervals to catch out-of-spec parts. If a part fails, it is diverted off the line to a rework or scrap area.

At the end of the line, the crankshaft is washed in a cleaning station to remove residual grinding swarf and oil. It may then be subjected to manual final inspection, including magnetic particle inspection for cracks, followed by balancing and marking before packing.

Older systems like this are not designed for quick changeovers. A model change requires downtime to switch fixtures, adjust machine positions, update programs, and possibly modify transfer settings. But once running, these lines can produce thousands of identical crankshafts with minimal variation, making them ideal for large-scale manufacturing.

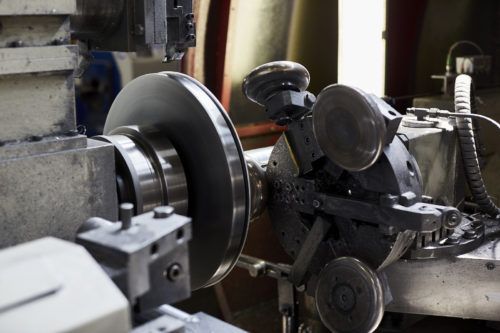

Let’s continue with a focus on bearing race production in an automated machining and grinding line. Bearing races require extremely tight tolerances and mirror-like surface finishes, especially on the inner and outer diameters that mate with rolling elements. This makes them ideal candidates for combined machining and grinding lines, particularly where large volumes are involved, such as in automotive wheel hubs or industrial motors.

The process starts with raw steel tubes or forged rings that are cut to approximate length and then loaded onto the line—often using a gravity chute, lift-and-place system, or vibratory bowl feeder for small races. The first station is usually a facing and centering lathe, which squares both ends and generates a center bore or reference surface. The part is then transferred via linear shuttle or rotary table to the next machine, typically a rough-turning lathe, which machines the basic internal and external diameters.

After this, the part might move to a groove turning machine, where the raceways are cut to near-net shape. These operations use fixed tooling and follow numerical control commands via early CNC or PLC systems. At this stage, tolerances are relatively loose, as the final precision will come from grinding.

Following turning, the rings go through a heat treatment process (carburizing or hardening) offline, and are then reintroduced to the line for grinding. This is the critical stage where the inner and outer raceways are ground to final dimension and finish. Here’s how grinding is typically handled in such a line:

- Centerless grinding is used for the external diameters of the outer races. It provides high throughput and good roundness, as the part is supported between a regulating wheel and a grinding wheel without chucks.

- Internal grinding machines are used for the inner diameters of inner races, requiring high spindle speed and careful coolant delivery due to heat buildup in confined spaces.

- Raceway grinding, which may use plunge grinding or oscillating (swiveling) methods depending on the bearing type and production strategy. These machines often have fixed grinding wheels mounted on precision spindles, dressed periodically by a mechanical dresser.

Coolant is heavily used at this stage, delivered through nozzles aimed directly at the contact zone. Coolant systems are relatively basic in older lines, using central tanks with gravity return lines and magnetic or paper bed filters. Since grinding creates very fine swarf and heat, keeping the coolant clean and the grinding wheels dressed is essential to avoid burning or dimensional deviation.

After grinding, the races move to inspection and superfinishing. This may include:

- Lapping or honing to achieve mirror finish and final geometry.

- Air gauging or mechanical comparators to check roundness, diameter, and taper.

- Crack detection using magnetic particle inspection or eddy current testing.

Some lines may also include marking stations where part numbers, batch codes, or hardness zones are engraved using dot-peen or laser systems. In older lines, this is sometimes done manually or semi-automatically.

The final steps involve cleaning, rust prevention coating, and packaging. Rings are passed through a washing tunnel with heated solution and then dried using air blowers. Anti-rust oil is applied via spray or dip tanks before packaging into trays or cartons.

This kind of line, though mechanically complex, operates with high reliability and repeatability over long periods. It’s engineered for mass production with minimal flexibility, but its robustness and mechanical design make it a strong choice where digital technologies are not required or available.

Automated Deep Drawing Production Line

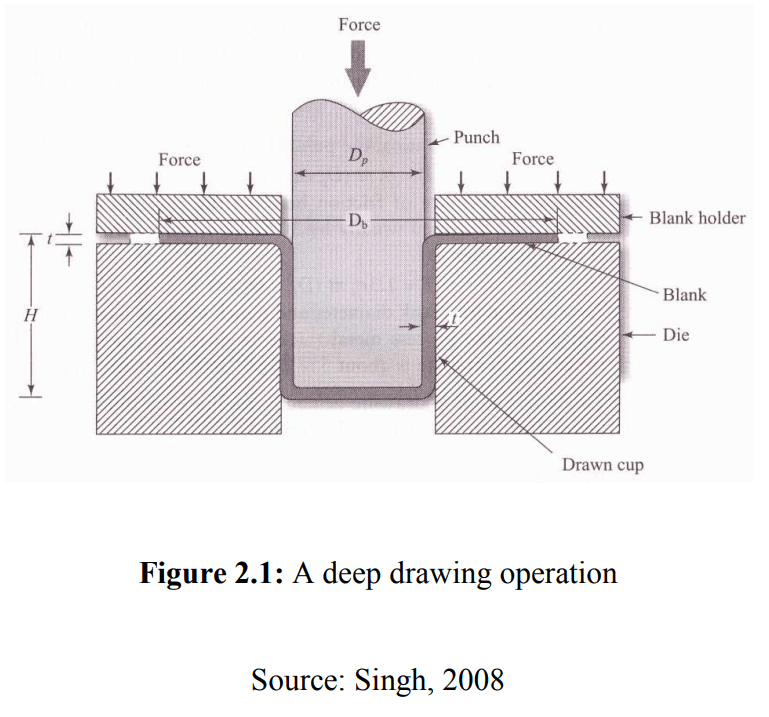

An Automated Deep Drawing Production Line is a high-precision manufacturing system designed for producing complex, hollow metal parts from flat sheets, typically using a process called deep drawing. Deep drawing involves forming a sheet metal blank into a three-dimensional shape, like automotive body panels, kitchen sinks, or pressure vessels, by pulling the sheet over a die with a punch.

In an automated deep drawing production line, the entire process is integrated, often with robotic arms, conveyors, and automated presses working together to form, inspect, and finish the parts with minimal human intervention. The key focus of these lines is to ensure high throughput, precision, and consistent part quality, while reducing labor costs and cycle time.

Key Stages of an Automated Deep Drawing Production Line:

- Blanking and Feeding:

- The process begins with blanking, where flat metal sheets (typically aluminum, steel, or brass) are cut into precise blanks of the required size and shape. In some automated lines, automated blank feeders are used to move the blanks from a material stack to the first forming station.

- A coil-fed system can also be used where a continuous strip of material is unspooled and fed into the line.

- For high-volume production, this stage may involve robotic arms or automatic conveyors to precisely position the blanks into the press.

- Pre-forming/Pre-heating (if necessary):

- Some materials, especially tougher metals, may require pre-heating to make them more malleable before deep drawing.

- A heated die or induction heating system may be employed to soften the metal blank, making it easier to form without cracking or wrinkling.

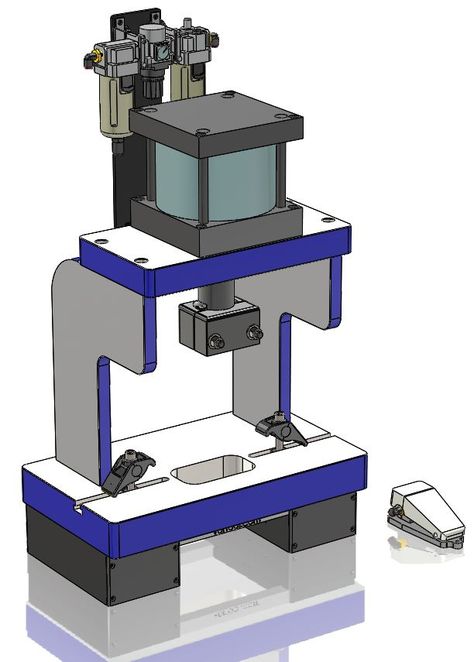

- Deep Drawing (Forming):

- The core operation of the line is deep drawing, where the metal blank is placed in a die and pressed into the desired shape using a punch.

- In the traditional process, the sheet metal is drawn through a die using a mechanical press, while the punch pulls the metal into the die cavity. The metal may go through several stages of drawing, especially for complex shapes.

- Automated presses are often used in these systems, typically hydraulic or mechanical presses, which provide consistent force and speed. The press may be equipped with automatic stroke adjustments, controlling the drawing depth and force depending on the material and part geometry.

- Multiple drawing stations can be used sequentially, with each one progressively drawing the part deeper and shaping it closer to the final form.

- Lubrication and Cooling:

- A key aspect of deep drawing is the lubrication of the metal blank to reduce friction between the punch and die, and to prevent the metal from sticking or cracking.

- Automated lubrication systems are used, which spray or flood the blank with a lubricant before it enters the die. This ensures consistent application and reduces the need for manual intervention.

- Cooling systems may also be integrated into the die to regulate temperature and prevent overheating of the metal during drawing.

- Ejection and Part Handling:

- Once the part is formed, it is ejected from the die. This is often done using automated ejectors, robotic arms, or mechanical pushers that remove the part from the die without damaging its shape.

- Conveyors are used to transport the ejected parts to the next station for quality inspection, trimming, or other finishing operations.

- If needed, parts may be automatically stacked or placed into containers for downstream processing or shipping.

- Inspection and Quality Control:

- After the drawing process, the parts are automatically inspected for defects such as wrinkles, cracks, or dimensional deviations.

- Vision systems may be employed to inspect the parts for visual defects, while coordinate measuring machines (CMMs) or other contact sensors can check critical dimensions like wall thickness, depth, or diameter.

- Some lines incorporate automatic rejection systems, where defective parts are immediately removed from the line to avoid further processing.

- Trimming and Finishing:

- If the drawn part has excess material (such as a flange or edge), it is sent to a trimming station. This is typically done with automated cutting tools, which trim away the excess metal.

- Parts may then undergo additional processes such as deburred edges, punching, or flange forming as needed for the final design.

- Cleaning and Coating (if required):

- After trimming, the parts may need to be cleaned, either manually or automatically using ultrasonic cleaners or industrial washing systems, to remove oils, lubricants, or other residues from the drawing process.

- Some parts may also require surface coating, such as painting, galvanizing, or coating with protective films. This can be done automatically via spray booths or robotic systems for precise application.

- Packaging and Shipping:

- Finally, the formed and finished parts are ready for packaging and shipment. Automated systems can handle packaging, whether it’s wrapping parts individually, placing them in bulk containers, or preparing them for palletization.

Key Advantages of Automated Deep Drawing Lines:

- High Throughput: With minimal human intervention, the system can operate at high speeds, producing large volumes of parts quickly.

- Consistency and Quality: Automated systems ensure that each part meets the required specifications with minimal variation, reducing scrap and rework.

- Reduced Labor Costs: Many manual steps (such as blank handling, lubrication, and inspection) are automated, reducing the need for operators.

- Flexibility in Material Handling: While deep drawing typically involves metals, automated systems can adapt to different material types, thicknesses, and shapes.

- Process Integration: The entire production process, from blanking to shipping, can be seamlessly integrated into one automated system, reducing downtime and improving efficiency.

Applications:

- Automotive Industry: For parts like car body panels, fuel tanks, or engine components.

- Aerospace: For lightweight, high-strength parts like fuselage panels or wing skins.

- Household Goods: For items such as sinks, tubs, and other kitchen or bathroom products.

- Industrial Equipment: For parts like pressure vessels or enclosures for machinery.

In essence, automated deep drawing lines are highly efficient systems optimized for mass production, especially when complex parts with tight tolerances need to be formed quickly and consistently.

An automated deep drawing production line is designed to streamline the process of forming complex metal parts by transforming flat sheets of material into three-dimensional shapes. The process begins with blanking, where flat metal sheets are precisely cut into blanks, which are then fed into the first stage of the forming process. Depending on the system, blanks may be fed manually or automatically using robotic arms or conveyor belts. After this, the blanks are placed in a die, and a punch is used to draw the material into the die, shaping it into a desired part.

The deep drawing process often occurs in multiple stages, each progressively drawing the part deeper to create the final shape. As the material is drawn, it can be lubricated to reduce friction between the punch and die, helping prevent the material from cracking or sticking. Automated lubrication systems spray or flood the blanks with lubricant, ensuring consistent application and eliminating the need for manual intervention. The metal may also be pre-heated in certain cases to make it more malleable, especially when forming tougher metals that require additional care.

Once the part is formed, it’s ejected from the die using automated ejectors, robotic arms, or mechanical pushers. The parts are then transported via conveyors to the next stages of the process. Automated inspection systems, such as vision systems and coordinate measuring machines, check the parts for defects like cracks, wrinkles, or dimensional inconsistencies. Parts that don’t meet specifications are automatically rejected, ensuring that only quality parts proceed to the next step.

For parts with excess material, an automated trimming station removes the excess through cutting or punching, shaping the part further. Some parts may also go through additional finishing processes like deburring or edge rounding, all carried out by automated systems to maintain precision and reduce manual labor. After trimming, parts are often cleaned in ultrasonic cleaning systems or industrial washing stations to remove lubricants and other residues before any surface coatings are applied. The final step typically involves packaging the parts for shipment, which is often automated, ensuring that the finished products are packaged efficiently for delivery.

The key benefits of automated deep drawing production lines include high throughput, consistent quality, and reduced labor costs. With the entire process integrated, from blank feeding to packaging, these systems minimize downtime and improve efficiency. By automating the handling, lubrication, inspection, and finishing stages, manufacturers can maintain high-quality standards while reducing manual intervention, making the process ideal for high-volume production.

Continuing from where we left off, an automated deep drawing production line offers significant benefits in terms of efficiency, cost-effectiveness, and scalability. The integration of robotics and automated systems minimizes human error and improves consistency across large production runs. For example, robotic arms in these systems can handle the delicate task of positioning blanks into dies with high precision and speed, eliminating the risk of misalignment and improving cycle time.

In addition to handling blanks, robotic systems can be used for automated lubrication application, ensuring even coverage and reducing wastage of lubricant. The lubrication not only helps to reduce friction but also minimizes wear on the dies and punches, extending their lifespan and reducing downtime for maintenance. Some systems even have automatic lubrication management that adjusts based on the type of material being processed or the drawing process stage, optimizing both lubrication quality and cost.

The automation of part inspection through vision systems and sensor technology is another significant advancement in deep drawing lines. Automated inspection not only checks for visual defects such as cracks or scratches but also measures critical dimensions of the drawn parts. This includes evaluating wall thickness, roundness, and overall dimensional tolerance. If a part fails inspection, it is automatically diverted off the line for rejection, saving time and materials compared to manual inspection methods. In some advanced systems, in-line quality control using X-ray or ultrasonic testing can be implemented to detect internal defects that would be invisible to traditional inspection methods.

Once the part has passed inspection and trimming, finishing operations like deburring (removal of sharp edges or small metal fragments) and polishing are automated. Automated machines can perform these tasks at high speeds while maintaining tight tolerances, ensuring the parts are smooth and ready for final application or coating.

Surface coating, such as painting, galvanizing, or anodizing, is also a key part of the automated deep drawing production line, especially for parts that require additional protection or a finished appearance. These lines often integrate spray booths, robotic arms, or dipping tanks to apply coatings consistently. For example, if the parts are to be coated with a corrosion-resistant layer, an automated system can ensure even coating thickness and proper drying time, reducing the need for human labor and enhancing the quality of the final product.

The final stage of an automated deep drawing line involves packaging and shipping, where finished parts are automatically stacked, boxed, or palletized for shipment. Conveyor systems guide the parts to automated packaging stations, where the parts are grouped, labeled, and wrapped for shipping. These systems often include robotic pick-and-place units for precise placement into shipping containers, ensuring that the parts are well-protected during transportation.

By automating these stages, manufacturers can significantly reduce the labor required for each part of the production process, improve overall cycle time, and increase throughput. The use of integrated systems allows for quicker adjustments to production runs, meaning that the line can handle a range of products with minimal setup time. This is especially beneficial in industries that require both flexibility and high volume, such as the automotive, aerospace, and consumer goods sectors.

The integration of real-time data monitoring and predictive maintenance technologies can further enhance the efficiency of the production line. Sensors embedded in machines can track parameters like temperature, pressure, and vibration, alerting operators to potential issues before they cause significant downtime. This predictive maintenance reduces unexpected failures and extends the life of expensive equipment like presses and dies.

Building on the previous discussion, let’s dive into some of the more advanced technologies and systems that are commonly found in automated deep drawing production lines to ensure maximum efficiency, product quality, and reliability.

One of the key technologies that enhances the functionality of an automated deep drawing line is the use of advanced press technologies. These presses are typically hydraulic or mechanical presses that provide the high force necessary for deep drawing operations. Hydraulic presses are known for their versatility, as they offer variable speed and force control, making them ideal for different types of materials and drawing depths. On the other hand, mechanical presses are faster and more suitable for high-speed production lines, as they can deliver a consistent force with less variation.

In many modern systems, presses are coupled with servo-driven actuators for greater control over the stroke, speed, and force applied during the drawing process. Servo presses allow for real-time adjustments during the drawing operation, optimizing the forming process to reduce defects such as wrinkles, cracks, or tearing, which are common challenges in deep drawing. This precision leads to better material usage, minimizing waste, and ensuring parts meet stringent quality standards.

In-line sensors are another critical element of advanced automated deep drawing systems. These sensors monitor the entire process in real time and provide feedback to the system. For instance, force sensors installed on the punch and die can monitor the amount of force being applied during the deep drawing process. This feedback can be used to adjust the press’s force, preventing damage to the material and die. Additionally, thickness sensors help monitor wall thickness throughout the drawing process, ensuring that the part maintains uniformity and quality across its entire surface.

In material handling, vision systems are commonly used to automatically position blanks and ensure they are accurately aligned in the die before the press cycle begins. These systems can also detect misfeeds or any material defects that could lead to production delays or defective parts. If a problem is detected, the system can either reject the part automatically or alert operators to take corrective action.

Coolant and lubrication management is another area where automation plays a crucial role. In older systems, lubrication may have been a manual process or simply a routine spray, but in modern lines, lubrication is highly controlled through automated systems. This includes centralized lubrication systems, which deliver precise amounts of lubricant to different parts of the machine, especially in the punch-die interface. The correct application of lubricant reduces wear and tear on the tooling, extends the life of the press, and ensures a smoother forming process. Moreover, the lubrication system can be linked to real-time monitoring systems, which adjust lubrication based on the materials being processed and the specific needs of the drawing stage.

In terms of maintenance, predictive technologies are revolutionizing how downtime is managed. Condition-based monitoring systems equipped with sensors provide real-time data on the health of critical equipment like punches, dies, and presses. These systems can track parameters like temperature, vibration, and pressure, which are often the first indicators of potential failure. Using this data, the system can predict when a component is likely to fail, allowing operators to replace or service the equipment before a failure occurs. This approach, often called predictive maintenance, significantly reduces unplanned downtime and maintenance costs, ensuring the line remains in operation for longer periods.

Moreover, data collected from sensors throughout the process can be sent to a central Manufacturing Execution System (MES), which provides an overview of the entire production line. The MES collects data on machine performance, part quality, cycle times, and material usage, and provides operators with actionable insights. These insights can help optimize the workflow, reduce bottlenecks, and improve overall line efficiency.

One significant advantage of automated deep drawing production lines is their ability to easily accommodate small batch production runs or variations in part designs. While traditional deep drawing lines require substantial downtime and manual intervention to adjust for new part designs, automated systems allow for quick changeovers. This flexibility is achieved through the use of robotic part loading systems, quick-change tooling setups, and programmable presses that can automatically adjust stroke and force parameters depending on the new part being produced. In many cases, automated lines can even handle multiple different part sizes and designs within a single production run, making them highly adaptable.

Energy efficiency is also a focus in modern automated deep drawing systems. Hydraulic presses, while energy-intensive, have become more efficient thanks to variable displacement pumps and energy recovery systems that capture and reuse energy during the press cycle. Similarly, automated lubrication systems and cooling systems help ensure that energy consumption is kept in check by only operating when needed, further contributing to sustainability in manufacturing.

Finally, integrated robotics and AI-based control systems allow the deep drawing line to operate with minimal human oversight. These systems can autonomously adjust to changes in material properties, detect part defects, and even optimize the drawing process in real time. Artificial intelligence algorithms can analyze historical production data to predict the best settings for new material batches, optimizing each part of the process for efficiency and quality.

Overall, an automated deep drawing production line is designed to ensure that manufacturers can produce complex, high-quality parts at high volume with minimal human intervention. The integration of robotics, AI, advanced sensors, and predictive maintenance technologies ensures that the production process is more efficient, consistent, and adaptable, while also reducing costs and improving product quality.

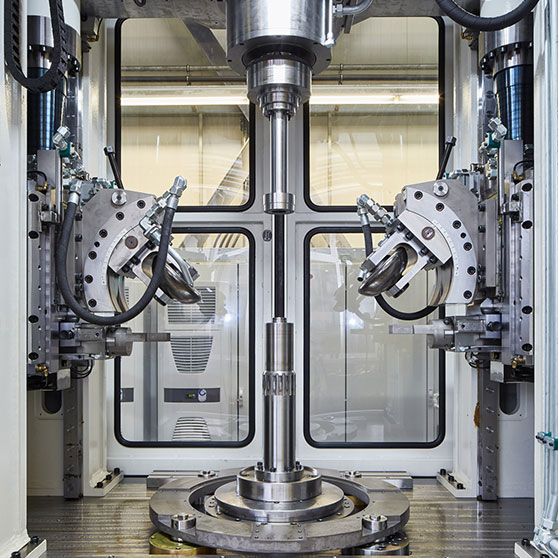

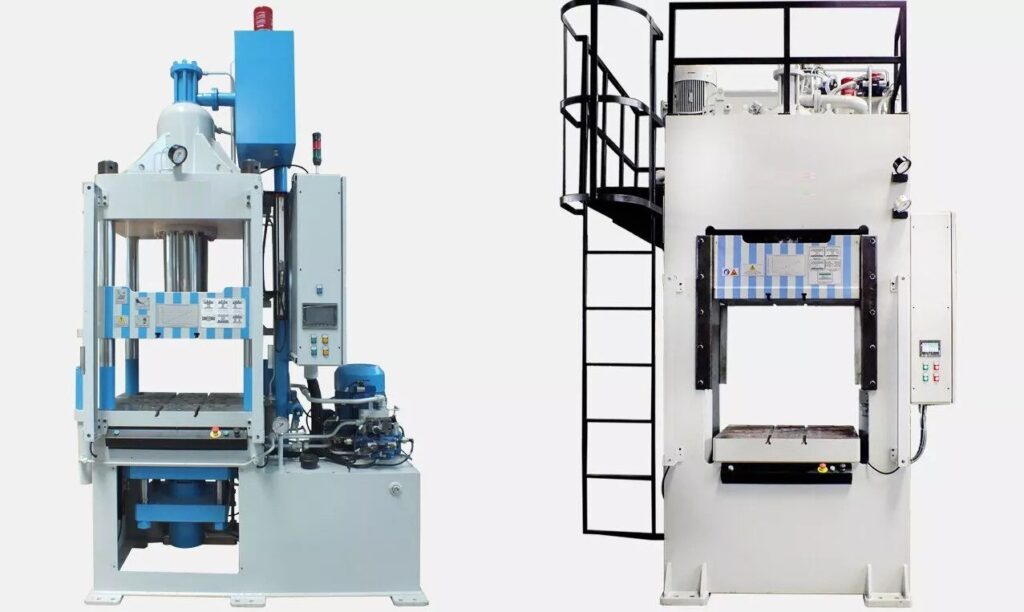

Four-Column Deep Drawing Press

A Four-Column Deep Drawing Press is a type of mechanical or hydraulic press specifically designed for deep drawing operations, where metal sheets are formed into deep, hollow shapes. This type of press gets its name from the four vertical columns that support the press structure, providing stability, strength, and precision during the deep drawing process.

Key Features and Components of a Four-Column Deep Drawing Press:

- Four-Column Frame Structure:

- The press’s four-column design provides a stable and rigid framework that supports the ram (punch), die, and other components. These columns help distribute the load evenly, making the press suitable for high-force applications, such as deep drawing.

- The structure ensures that the vertical movement of the ram is aligned and stable, minimizing any deviations in the part geometry.

- Pressing Mechanism (Hydraulic or Mechanical):

- The pressing action is typically provided by hydraulic cylinders or mechanical systems. In a hydraulic four-column press, hydraulic cylinders are used to apply force to the ram. The advantage of a hydraulic system is its ability to offer precise force control over the entire stroke, making it ideal for deep drawing, which requires varying force levels throughout the forming process.

- Mechanical presses, while faster and more rigid, are less flexible when it comes to force adjustments and are generally used in high-speed stamping rather than deep drawing.

- Die and Punch Setup:

- The die set is positioned on the lower portion of the press and forms the cavity into which the blank is drawn. The punch (ram) is mounted above the die and moves downward to pull the material into the die, forming the part.

- In four-column presses, both the die and punch are aligned vertically with precision, ensuring that the material is drawn consistently without warping or damage.

- Stroke and Force Control:

- The press allows for adjustable stroke length and force settings, which is essential for deep drawing processes that involve materials of varying thicknesses or hardness. By adjusting the stroke, the operator can control how deeply the material is drawn and how much force is applied during each step of the process.

- In hydraulic presses, the stroke can be finely controlled by adjusting hydraulic pressure. In mechanical presses, stroke control is usually limited to pre-set options, but force control can still be achieved by adjusting the ram speed and ram displacement.

- Guiding Mechanism:

- Guides are used to ensure the ram (punch) moves vertically along the four columns without lateral deviations. This precision is crucial, as even minor misalignment can result in defects like wrinkles, uneven thickness, or part failure during drawing.

- Linear guides or roller guides are often employed to reduce friction and ensure smooth, precise motion of the punch.

- Safety and Monitoring Systems:

- Four-column deep drawing presses are typically equipped with safety features such as light curtains, pressure sensors, and emergency stop buttons to protect operators and prevent accidents during operation.

- Force and position sensors can also be incorporated into the system to monitor the press’s operation, ensuring that the correct amount of force is applied at each stage of the forming process.

- Automation Integration:

- Four-column presses can be integrated with automation systems, including robotic arms for part loading and unloading, and conveyor systems for part handling throughout the production line. Automated blank feeders and die changers can also be used to improve efficiency and reduce manual intervention.

- Computer Numerical Control (CNC) or PLC-based control systems enable the press to follow precise part specifications, adjust parameters automatically based on material properties, and even adjust for different part designs without requiring manual retooling.

- Applications of Four-Column Deep Drawing Presses:

- These presses are often used in industries that require high-quality, precision-formed parts, such as automotive, aerospace, appliance manufacturing, and industrial equipment. Common parts include automotive body panels, metal cans, pressure vessels, kitchen sinks, and electrical enclosures.

- Four-column presses are particularly suitable for large, complex parts that require high forming force and precision. They excel in situations where parts have relatively deep profiles, requiring a press capable of applying a large, consistent force over the entire stroke.

Advantages of Four-Column Deep Drawing Presses:

- High Force Capability:

- The four-column structure provides enhanced strength and stability, allowing the press to apply the necessary high force required for deep drawing operations. This makes it suitable for thick materials and larger parts.

- Precision and Alignment:

- The four-column setup ensures precise alignment of the die and punch, leading to consistent quality and uniform part formation.

- Flexibility:

- The adjustable stroke length and force control make the four-column deep drawing press versatile for different materials and part designs. It can handle various thicknesses and hardness levels of materials without the need for retooling or major adjustments.

- Customization and Automation:

- The press can be easily integrated into automated production lines, which increases throughput, reduces human error, and improves overall efficiency. Automation systems can handle part feeding, lubrication, inspection, and part unloading, leading to faster cycle times and lower labor costs.

- Durability and Longevity:

- Due to their robust construction, four-column presses are designed for long-term use, even under the intense pressure of deep drawing. This durability reduces the need for frequent maintenance or replacement, providing a solid investment for high-volume manufacturers.

Potential Drawbacks:

- High Initial Investment:

- Four-column deep drawing presses can be costly to purchase and set up, especially when integrating advanced features like automation or hydraulic systems. However, this is often offset by the high throughput and reduced labor costs over time.

- Space Requirements:

- The four-column frame design requires a significant amount of space to accommodate the press, especially when used in larger configurations for producing big parts. This might require specialized facilities or larger production floors.

- Maintenance Complexity:

- The press’s intricate components, such as the hydraulic systems, guides, and sensors, require regular maintenance to ensure optimal performance. However, predictive maintenance systems can help mitigate unexpected downtime.

Conclusion:

The Four-Column Deep Drawing Press is an advanced, reliable machine that plays a vital role in the production of complex, high-quality formed metal parts. Its ability to provide consistent force, precision, and adaptability makes it a staple in high-performance manufacturing environments, particularly in industries that require intricate metal forming. The press’s ability to integrate with automation systems further enhances its efficiency and flexibility, making it an ideal choice for manufacturers looking to increase production speed and minimize human error.

A Four-Column Deep Drawing Press is built to handle the intense forces required to transform flat metal sheets into deep, intricate shapes, commonly used in industries like automotive, aerospace, and appliance manufacturing. The press operates by using four vertical columns to support and stabilize the press frame, ensuring precise alignment and minimal distortion during operation. This robust design allows for high-tonnage applications, ideal for forming thicker materials or producing larger parts. The frame supports a punch (ram) that applies force to a metal blank, pulling it into a die to form the desired part. The ability to adjust force and stroke length makes this press highly adaptable to different materials, thicknesses, and shapes.

One of the standout features of the Four-Column Deep Drawing Press is its versatility, as it can handle a wide range of part geometries, including deep and complex profiles. The system can be customized to accommodate varying part sizes, and hydraulic or mechanical systems provide the necessary force to ensure high-quality, consistent output. In addition, precise control over the drawing force is possible, which is essential for preventing material defects such as cracks or wrinkles. Furthermore, automation plays a significant role in enhancing efficiency, as robotic arms and conveyor systems can feed, transfer, and unload parts, reducing human labor and improving cycle times.

These presses are typically equipped with sensors and monitoring systems to ensure optimal operation. Force and position sensors monitor the punch’s movement, providing real-time data that helps prevent overloading or misalignment. This data can also be integrated with predictive maintenance systems, which alert operators to potential issues before they lead to unplanned downtime. Automated lubrication systems ensure that the die and punch are consistently lubricated, reducing friction and wear, which prolongs the life of the tooling and helps maintain part quality.

Although the Four-Column Deep Drawing Press offers significant advantages in terms of force, precision, and flexibility, there are some drawbacks to consider. The initial investment can be high, particularly if you incorporate advanced automation or hydraulic systems. The press also requires a considerable amount of space due to its large frame, making it less suitable for smaller production areas. Regular maintenance is crucial for maintaining performance, as components such as hydraulic systems, guides, and sensors need to be serviced to prevent breakdowns. However, these challenges can be mitigated with proper planning and investment in predictive maintenance technologies.

In summary, the Four-Column Deep Drawing Press is an essential piece of equipment for manufacturers who need to produce high-quality, complex metal parts at high volumes. Its combination of force, precision, and adaptability makes it ideal for industries where part integrity and consistency are critical. The integration of automation, monitoring systems, and predictive maintenance further enhances its efficiency, making it a valuable asset in modern manufacturing lines.

As the demand for more complex, high-quality metal parts continues to rise, the Four-Column Deep Drawing Press stands out as an essential tool for manufacturers aiming to keep up with production demands while maintaining high standards of precision and efficiency. The press’s ability to handle deep, intricate forming with uniform quality makes it an ideal choice for industries such as automotive, aerospace, and even the production of consumer goods.

While the Four-Column press excels at deep drawing, it also offers flexibility in terms of part design. It can handle a variety of materials, from soft metals like aluminum to harder materials like stainless steel. The press can be adjusted to accommodate different material properties, thicknesses, and hardness, making it versatile across a range of applications. This adaptability is particularly beneficial in industries where product designs constantly evolve, and flexibility is crucial to staying competitive.

One of the emerging trends in Four-Column Deep Drawing Presses is the integration of smart manufacturing technologies. These presses are increasingly equipped with real-time data analytics, allowing operators to monitor key performance indicators such as force application, stroke length, material flow, and even tool wear. These systems use sensors and cameras to collect data, which is then analyzed using AI and machine learning algorithms. By processing this data, the system can identify patterns, predict potential issues, and suggest adjustments to optimize the production process.

Machine learning algorithms can also help improve part quality by learning from previous drawing cycles. These algorithms can detect subtle changes in material properties and adjust the press parameters in real time to avoid defects, such as wrinkling or tearing. The incorporation of these AI-driven tools enhances the press’s ability to adapt to different conditions and materials, improving both efficiency and product quality. This level of automation and intelligence leads to fewer defects, reduced waste, and increased overall productivity.

Additionally, the trend of energy efficiency has become increasingly important in modern manufacturing. The energy consumption of a Four-Column Deep Drawing Press can be significant, especially when operating at full capacity. However, modern hydraulic systems and advanced control mechanisms have made significant strides in reducing energy usage. Many new systems are equipped with energy recovery features, such as regenerative drives, which capture and reuse energy during the press cycle. This not only helps reduce operational costs but also aligns with sustainability goals by lowering the environmental impact of manufacturing processes.

Another key consideration is the maintenance of the press. Predictive maintenance technologies, already embedded in many modern presses, continuously monitor the condition of the press and its components. By collecting data on things like vibration, temperature, and hydraulic pressure, these systems can predict when maintenance is required, preventing unscheduled downtime. This is a major advantage for manufacturers, as it allows them to plan maintenance around production schedules, reducing costly disruptions and ensuring the press operates at optimal efficiency.

Moreover, the safety features on Four-Column Deep Drawing Presses have evolved significantly over the years. In addition to traditional safety guards and emergency stop buttons, many presses now feature robotic safety systems such as light curtains and laser scanners. These systems can detect the presence of operators or obstacles within the press area, automatically stopping the press before any harm can occur. These innovations not only improve safety but also contribute to a more streamlined, automated production process by reducing human intervention.

In terms of flexibility, some Four-Column presses are now equipped with quick-change tooling systems, allowing manufacturers to switch between different part designs with minimal downtime. The tooling can be swapped automatically, and the press can adjust to the new design parameters, such as stroke length and force, with little to no manual input. This makes it easier to transition between different production runs, which is particularly beneficial in industries that produce a variety of parts in small to medium batches.

Lastly, the integration of robotic automation into the deep drawing process is helping improve both production efficiency and quality. Robotic arms are used to load and unload parts, position blanks accurately in the die, and remove finished parts from the press. These systems can also assist with secondary operations such as part cleaning or sorting. The use of robots minimizes human handling, reducing the risk of part contamination, misalignment, and injury, while also speeding up production cycles.

In conclusion, the Four-Column Deep Drawing Press is a critical piece of equipment in modern manufacturing, offering precision, adaptability, and high force capabilities for forming complex metal parts. As technology advances, these presses continue to evolve, integrating smart technologies, automation, and energy-saving features that optimize production processes. With the added benefits of predictive maintenance and enhanced safety systems, Four-Column presses are now more efficient, reliable, and capable than ever before, making them an indispensable asset for high-volume, high-precision manufacturing operations.

H-Frame Deep Drawing Press

An H-Frame Deep Drawing Press is another type of press used in metal forming, specifically for deep drawing operations, where flat metal sheets are transformed into deep, hollow shapes. The primary difference between the H-Frame press and the more commonly used Four-Column press lies in the frame structure. As the name suggests, the H-Frame press features a frame shaped like the letter “H,” where two vertical columns are connected by horizontal cross members. This design provides the press with a strong and stable frame capable of withstanding high forces during the drawing process.

Key Characteristics of an H-Frame Deep Drawing Press:

- H-Frame Design:

- The H-Frame design consists of two vertical columns connected by a crossbeam or bridge, forming an “H” shape. This configuration provides a robust, rigid structure that distributes the load evenly during the drawing operation.

- The H-Frame press tends to have a more open design compared to the Four-Column press, which can offer better accessibility to the tooling area and facilitate easier maintenance and part handling.

- Hydraulic or Mechanical Drive:

- Similar to the Four-Column press, H-Frame presses are usually powered by either hydraulic systems or mechanical drives.

- Hydraulic systems offer flexibility by providing adjustable force and stroke length, which is essential for handling varying material types, thicknesses, and drawing depths.

- Mechanical systems, typically used for high-speed operations, deliver constant force and are more efficient for quicker, repetitive drawing cycles.

- The hydraulic version, in particular, provides the versatility needed for deep drawing processes where varying force levels are necessary throughout the cycle.

- Similar to the Four-Column press, H-Frame presses are usually powered by either hydraulic systems or mechanical drives.

- Force Application:

- The press uses a ram (punch) that moves vertically, pushing the material into the die to form the desired part. The H-Frame design ensures that the punch remains aligned and that force is applied uniformly to prevent material defects such as cracking or tearing.

- Force control in an H-Frame press can be adjusted to suit the specific material being processed. Some advanced systems include variable displacement pumps or servo-controlled hydraulics to provide precise control of the force, which is vital for the consistency and quality of the formed parts.

- Open Frame Design:

- The H-Frame’s open structure makes it particularly well-suited for large and heavy parts. Its design allows for easier loading and unloading of parts, especially for applications requiring large metal blanks. The open structure also facilitates tool changeover and maintenance access, allowing operators to reach the die and punch areas more easily.

- The lower part of the frame provides additional space for handling equipment or auxiliary machinery such as automatic blank feeders or part stacking systems, enhancing the press’s ability to integrate into a fully automated production line.

- Precision and Alignment:

- H-Frame presses are equipped with guides and alignment mechanisms that ensure the punch and die remain aligned during operation. This helps prevent defects like misformed parts, uneven wall thickness, and material wrinkling.

- In some models, linear guides or roller guides are used to reduce friction and ensure smooth, precise movement of the punch. The rigidity of the frame ensures that the punch applies force in a straight, uniform motion, contributing to the consistent quality of the drawn parts.

- Customization and Flexibility:

- One of the major advantages of the H-Frame design is its customizability. The press can be tailored to accommodate different die sizes, material thicknesses, and part geometries. Adjustments to stroke length, force, and speed can be made quickly to adapt to different production runs, making H-Frame presses suitable for both high-volume and small-batch production.

- The ability to quickly swap tooling and adjust press settings makes H-Frame presses well-suited for industries where part designs frequently change or where there is a need for flexible manufacturing.

- Automation and Integration:

- H-Frame presses can be easily integrated into automated production lines with robotic arms, conveyor systems, and automatic die changers. This integration improves production efficiency, reduces human error, and minimizes downtime between different production runs.

- The press can be equipped with vision systems for automatic part inspection, ensuring that only quality parts move through the production process. Additionally, automated part handling systems can load and unload parts, reducing manual labor and increasing throughput.

- Energy Efficiency and Cost Considerations:

- The energy efficiency of an H-Frame press depends on the hydraulic or mechanical system in use. Hydraulic presses can be optimized for energy use with features like energy recovery systems, which capture and reuse energy during the pressing cycle.

- Servo-driven hydraulic systems are becoming increasingly common in modern H-Frame presses. These systems offer energy savings by using only the energy required for each specific operation, adjusting the force and stroke length dynamically based on the material being processed.

Advantages of an H-Frame Deep Drawing Press:

- Strong Structural Design: The H-Frame press provides excellent support and load distribution during deep drawing, ensuring uniform force application and preventing deflection that could lead to defects.

- Ease of Maintenance and Tooling Changeover: The open frame structure provides easy access to tooling, reducing downtime and maintenance costs. The large space underneath the frame also allows for the addition of auxiliary systems, like automated part handling equipment.

- Customizability and Flexibility: H-Frame presses can handle a wide range of material types and part designs, making them adaptable to different production needs. The quick changeover of tools and settings allows for efficient switching between different jobs or products.

- Higher Production Speed: With the integration of automation systems and fast cycle times in mechanical models, H-Frame presses can produce high volumes of parts at a faster pace, reducing overall production costs and increasing throughput.

Disadvantages:

- Space Requirements: Like other large presses, the H-Frame design requires considerable floor space. The open frame structure, while beneficial for maintenance and part handling, can be cumbersome in smaller production environments.

- Initial Investment: The cost of purchasing and setting up an H-Frame press can be substantial, especially if the press is equipped with advanced features like automated systems, servo-driven hydraulics, and smart monitoring systems. However, this is often offset by the long-term efficiency gains and lower operational costs.

- Energy Consumption in Hydraulic Models: While energy-saving features can be added, traditional hydraulic presses tend to be more energy-intensive compared to mechanical systems, especially when running high-force operations.

Applications of H-Frame Deep Drawing Presses:

H-Frame Deep Drawing Presses are widely used in industries where large, complex metal parts are required. These include:

- Automotive Manufacturing: For producing parts like car body panels, chassis components, and engine parts that require precise forming under high force.

- Aerospace Industry: For parts such as fuel tanks, aircraft panels, and structural components, where precision and material strength are critical.

- Consumer Goods: For the production of kitchenware, metal cans, and appliances, which require deep drawing of thin-gauge metals into precise, uniform shapes.

- Heavy Equipment Manufacturing: For forming large parts like hydraulic cylinders and pressure vessels, where high forces are needed.

Conclusion:

The H-Frame Deep Drawing Press is a versatile and robust piece of equipment well-suited for deep drawing operations that require high force and precision. Its open, customizable design, ease of maintenance, and ability to integrate with automated systems make it a valuable tool in industries producing large, complex metal parts. While there are some drawbacks, such as space requirements and initial investment costs, the benefits of improved flexibility, efficiency, and production speed make the H-Frame press a strong choice for manufacturers looking to optimize their deep drawing processes.

The H-Frame Deep Drawing Press stands out for its versatility in metal forming, particularly in deep drawing applications where large, complex parts need to be created. The “H” frame design, characterized by two vertical columns connected by horizontal cross members, provides a stable and rigid structure capable of handling high forces during the drawing process. This makes it ideal for industries requiring precision in forming thick materials or parts with intricate shapes, such as automotive, aerospace, and appliance manufacturing.

The press operates by using a ram (punch) that moves vertically, pushing the material into a die. The H-Frame’s design ensures that the punch stays aligned, and the force applied to the material is evenly distributed, preventing issues such as wrinkles or material tearing. Its ability to accommodate high-tonnage applications allows it to handle tough, thick materials or parts that demand substantial forming forces. The hydraulic system, in particular, offers great flexibility, as the force and stroke length can be adjusted depending on the material and the specific part requirements. This ensures that the press can adapt to different part geometries and material properties, making it suitable for both high-volume production and smaller batch runs.

One of the major advantages of the H-Frame press is its open structure. Unlike the Four-Column press, which may have a more enclosed design, the H-Frame press offers easier access to tooling, making maintenance and tool changes more efficient. The ability to swap tools quickly is a significant benefit, especially for operations that require frequent adjustments between different part designs. This open frame also facilitates the integration of automated systems, such as robotic arms or conveyor belts, which can improve overall production efficiency by reducing manual labor, enhancing speed, and reducing the chances of human error.

The flexibility in the H-Frame design also extends to energy efficiency. Although hydraulic presses typically consume more energy than mechanical presses, modern H-Frame presses can incorporate energy-saving features like regenerative drives. These systems recover and reuse energy during the pressing cycle, helping to lower operational costs and make the press more environmentally friendly. The integration of servo-driven hydraulic systems further boosts energy efficiency by adjusting the amount of energy used depending on the specific operation, which reduces unnecessary energy consumption.

The automation potential of the H-Frame press can significantly increase throughput. Automated material handling systems, such as robotic feeders and stackers, can load blanks into the die, unload finished parts, and even perform secondary operations such as cleaning or inspection. This reduces the need for human intervention and speeds up the production cycle. Additionally, advanced monitoring and diagnostic tools can be integrated into the system, offering real-time feedback on the press’s performance. This allows operators to make adjustments on the fly, improving both product quality and machine efficiency.

However, the H-Frame press does come with some considerations. Due to its larger frame, it requires significant space, which may not be ideal for smaller production facilities. The cost of acquiring and setting up the press can also be considerable, particularly when equipped with advanced automation or servo-controlled systems. Despite these challenges, the long-term benefits of higher production speeds, reduced downtime, and improved part quality make the H-Frame press a worthwhile investment for manufacturers.

In terms of applications, the H-Frame press excels in sectors like automotive and aerospace, where parts need to be formed with high precision and strength. Components such as automotive body panels, fuel tanks, and structural parts are commonly produced using H-Frame presses. The open design of the press also makes it suitable for larger components, such as pressure vessels and industrial enclosures, where accessibility and tool changeover are critical for maintaining efficiency.

The continued evolution of H-Frame Deep Drawing Press technology, with smart features, energy-saving systems, and integration with automation, further enhances their role in modern manufacturing. Manufacturers are increasingly looking for ways to maximize productivity while maintaining high quality and minimizing environmental impact, and the H-Frame press delivers on all these fronts. The press offers the strength, adaptability, and efficiency required to keep pace with the ever-evolving demands of high-volume, precision manufacturing, making it a crucial asset in industries that rely on deep drawing processes.

The H-Frame Deep Drawing Press continues to be an essential tool in the production of high-quality metal components, particularly in industries that require precision and large-scale production. Its design, offering both robustness and flexibility, ensures it remains a reliable choice for complex, high-tolerance parts. The ability to handle large sheets of metal and apply substantial force while maintaining precise control over the drawing process makes it indispensable for creating parts with deep, intricate shapes.

Moreover, the integration of advanced sensors and monitoring systems is increasingly enhancing the capabilities of the H-Frame press. These systems provide real-time feedback on critical parameters such as force, stroke, material flow, and die condition. This continuous monitoring ensures that the press is running at peak efficiency, helps detect any anomalies in the drawing process, and can prevent part defects before they occur. It also allows for quicker adjustments in force and stroke, which can reduce scrap and improve overall quality. This predictive capability also leads to better quality control, ensuring that each part meets the exact specifications required.

The increased use of robotics in H-Frame presses further increases their efficiency. In addition to loading and unloading parts, robotic systems can now be used for more advanced tasks such as real-time inspection, sorting, and even post-forming operations like trimming or cleaning. The reduced reliance on human operators minimizes the risk of errors or injuries and speeds up the overall production process. The ability to automate these tasks also ensures consistency and repeatability, crucial for high-volume operations.

Furthermore, customization remains a key benefit of the H-Frame press. Different industries often require unique configurations of the press based on the specific materials they are working with or the types of parts they need to produce. The open design of the H-Frame allows for easy modifications and adjustments, such as varying the stroke length, force, or die configuration. These modifications can often be made quickly, improving flexibility and reducing downtime when switching between production runs.

As manufacturers strive for sustainability, the H-Frame press’s energy efficiency becomes increasingly important. The integration of energy-saving technologies, such as servo-driven systems and regenerative drives, ensures that the press operates more efficiently, consuming only the power required for each specific operation. This not only reduces the energy footprint but also lowers operational costs, making the press more cost-effective over time. Additionally, energy recovery systems can be used to harness and reuse energy during the operation, which further reduces waste and maximizes efficiency.

Safety is also a growing concern in modern manufacturing, and the H-Frame press incorporates a variety of safety features to protect operators and prevent accidents. In addition to traditional safety guards and emergency stop buttons, the press may include laser sensors, light curtains, and safety mats that detect the presence of operators or objects in the danger zone. If an obstruction is detected, the press can automatically stop or slow down, preventing injury or damage to the press itself. This high level of safety enhances both productivity and worker confidence in the production environment.

Another important consideration is maintenance. As with any large machine, the H-Frame press requires regular upkeep to ensure it continues to perform optimally. Predictive maintenance systems, which use real-time data to predict when a component might fail, are becoming increasingly common. By analyzing data from sensors monitoring vibration, temperature, pressure, and other metrics, these systems can forecast potential issues and notify operators in advance. This allows for proactive maintenance, reducing downtime and extending the life of the press.

With the ongoing demand for more efficient, sustainable, and customizable manufacturing processes, the H-Frame Deep Drawing Press continues to be an important solution for manufacturers. The combination of strength, precision, and flexibility, coupled with the integration of smart technologies, automation, and energy-saving features, ensures that this press will remain a key asset for years to come. It is particularly effective in industries like automotive, aerospace, and heavy machinery, where high-quality metal parts are critical and where production volumes require both speed and consistency.

In summary, the H-Frame Deep Drawing Press represents a robust, flexible, and efficient solution for the forming of deep-drawn metal parts. Its design ensures it can handle large, complex parts while maintaining precision, and its adaptability to automation, energy efficiency, and predictive maintenance technologies allows manufacturers to stay competitive in an increasingly demanding marketplace.

As industries continue to push for higher production rates, improved quality, and greater sustainability, the H-Frame Deep Drawing Press remains a crucial tool in the evolution of manufacturing. One area where the H-Frame press is particularly making an impact is in smart manufacturing. The shift toward digitalization and Industry 4.0 has led to the integration of advanced data analytics, machine learning, and the Internet of Things (IoT) into production processes. In the context of H-Frame presses, this means real-time monitoring and control over every aspect of the operation.

By utilizing IoT sensors, manufacturers can collect valuable data from the press’s various components. These sensors can monitor the condition of the hydraulic system, detect irregularities in pressure or temperature, and track the wear on dies or punches. This constant flow of data is fed into a central control system where it can be analyzed. If any issues are detected—such as excessive wear on a die or an anomaly in the material flow—the system can automatically adjust parameters to correct the problem or notify the operator of the need for maintenance. This level of real-time feedback enhances not only the efficiency of the press but also the overall quality of the parts being produced, reducing scrap and rework.

Additionally, machine learning algorithms can be applied to the collected data to identify trends and patterns. For example, an algorithm might learn the optimal settings for a given material type, thickness, or geometry based on previous production runs. Over time, the system can refine these settings to achieve even better outcomes, automatically adjusting the press’s parameters without the need for human intervention. This can lead to more consistent part quality and a reduction in defects, as the press continuously adapts to changing production conditions.

The predictive maintenance capabilities of modern H-Frame presses are another critical aspect of their efficiency. As the press operates, it generates wear and tear on components like hydraulic valves, seals, and dies. Traditional maintenance schedules often rely on fixed intervals, which can lead to unnecessary maintenance or unplanned downtime. With predictive maintenance, however, the press can monitor its own condition and alert operators to potential issues before they cause a failure. For example, if the vibration level of a hydraulic pump exceeds a certain threshold, the system can flag this as a potential problem and recommend maintenance before the pump fails completely. This approach minimizes downtime and maximizes the lifespan of critical components, leading to a more reliable and cost-effective operation.

In addition to predictive maintenance, remote monitoring has become an essential feature of modern H-Frame presses. Operators and managers can access data on the press’s performance from virtually anywhere, using cloud-based systems or mobile apps. This enables real-time performance tracking and troubleshooting from remote locations, allowing for quick intervention if necessary. This also facilitates centralized control for manufacturers with multiple facilities, allowing them to monitor the status of presses across different plants from a single location. With this level of connectivity, manufacturers can optimize their operations even more effectively and respond quickly to any issues that arise, improving both uptime and productivity.

The integration of robotic automation continues to complement the performance of the H-Frame press. As robotic systems evolve, they are increasingly capable of performing complex tasks such as precise material placement, post-forming operations, and quality inspection. These robots work alongside the press, enhancing its capabilities and reducing the need for human involvement in repetitive or dangerous tasks. For example, after a part is drawn, a robotic system might inspect the part for defects using high-resolution cameras and AI-driven vision systems. If defects are detected, the part can be automatically sorted out for rework, ensuring only the highest-quality products move through the production line.