Dust Collection Buffing Machine: A Polishing and Buffing Combo Machine combines two surface-finishing functions—polishing (removing surface imperfections and achieving a smooth texture) and buffing (enhancing surface gloss and shine)—into a single machine.

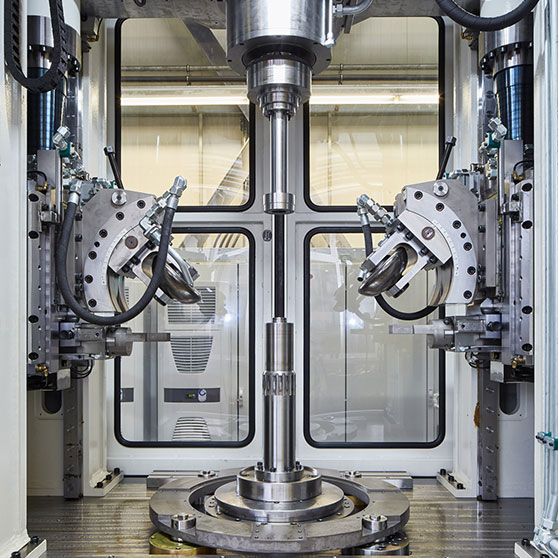

Key Components of Polishing and Buffing Machine

- Motor – Powers the rotating wheels, typically ranging from 0.5 to 2 HP depending on application.

- Polishing Wheel – Often made of abrasive materials like emery or silicon carbide, used for initial surface refinement.

- Buffing Wheel – Softer wheels made of cloth, felt, or other flexible materials, used with buffing compounds for shine.

- Work Rest/Support – Provides a platform to steady the workpiece.

- Speed Control (optional) – Allows for variable RPM to suit different materials and finishing stages.

- Dust Collector or Ports (optional) – Helps manage debris and metal dust during operation.

Applications

- Metalworking: Removing rust, smoothing welds, and bright finishing on stainless steel, brass, aluminum, etc.

- Woodworking: Polishing lacquered or painted wood surfaces.

- Jewelry Making: Precision polishing of fine metal items.

- Automotive: Chrome and aluminum trim restoration.

- Plastics and Composites: Edge polishing and surface refinishing.

Advantages

- Space Saving: One unit handles both polishing and buffing.

- Cost-Effective: Eliminates the need to purchase two separate machines.

- Increased Productivity: Enables quick change between operations.

A polishing and buffing combo machine is designed to handle both the initial surface smoothing (polishing) and the final high-gloss finishing (buffing) in a single unit. This type of machine typically features two spindles or shafts, each mounted with a different wheel—one abrasive polishing wheel and one softer buffing wheel made of cloth or felt. The machine is powered by an electric motor, often in the range of 0.5 to 2 horsepower, and may operate at fixed or variable speeds depending on the model. Operators use the polishing wheel to remove oxidation, scratches, or casting marks from metal, plastic, or wood surfaces. Once the desired smoothness is achieved, the workpiece is moved to the buffing wheel, often with an applied buffing compound, to bring out a mirror-like finish. These machines are commonly used in metal fabrication, automotive detailing, woodworking, jewelry making, and plastic finishing. Some models are equipped with safety features like spark guards, adjustable tool rests, and dust collection ports to enhance usability and maintain a clean workspace. Combo units are favored for their efficiency, cost-effectiveness, and the convenience of switching between two essential finishing operations without changing equipment.

Many polishing and buffing combo machines are bench-mounted, making them compact and suitable for workshops with limited space. Industrial-grade models may also be floor-mounted for handling larger or heavier workpieces. The choice of wheel materials and compounds plays a crucial role in achieving specific results—coarse abrasives for heavy material removal during polishing, and finer compounds like rouge or tripoli for delicate buffing tasks. Some machines allow quick wheel changes, which adds flexibility when working on different materials such as aluminum, stainless steel, brass, or even acrylics. Consistent maintenance, such as checking wheel wear and ensuring proper alignment, extends the machine’s life and ensures uniform surface finishes. Proper operator training is essential to avoid issues like over-polishing, which can deform soft metals, or under-buffing, which leaves dull surfaces. Overall, these combo machines provide a streamlined, dual-function approach to surface finishing that saves time and improves productivity across a variety of industries.

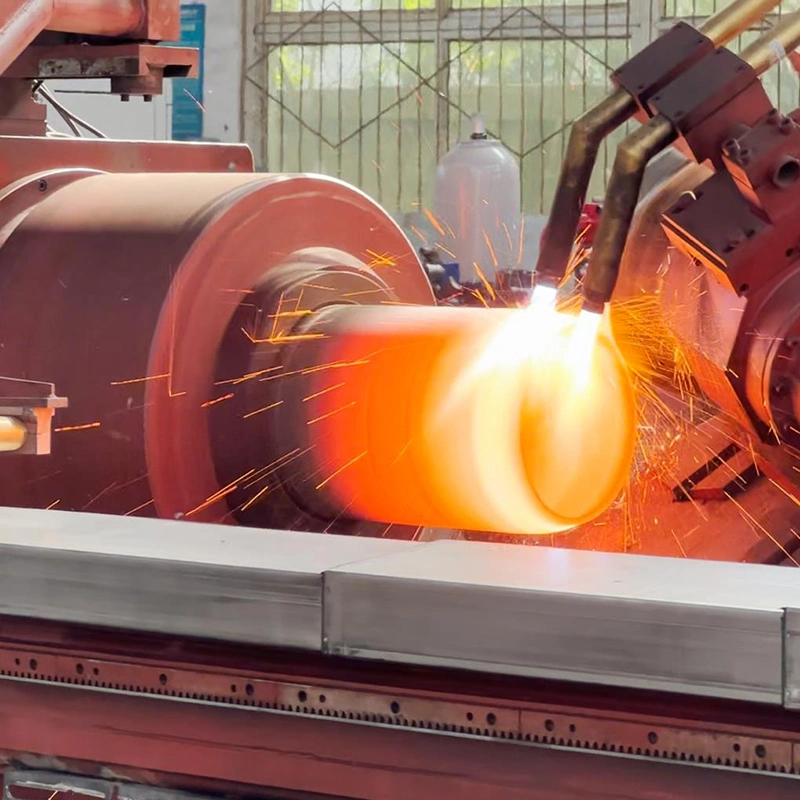

In practical use, the polishing and buffing combo machine becomes an integral part of any workshop that deals with surface refinement, whether in fabrication, restoration, or decorative finishing. When a raw or semi-finished part is introduced to the machine, it often carries imperfections such as tool marks, scale, oxidation, or general roughness from casting or machining. The first step is polishing—this is not just about aesthetics but also about preparing the surface for coating, plating, or further mechanical processing. The polishing wheel, usually embedded with abrasive particles or paired with an abrasive compound, cuts into the surface lightly to smooth out these defects. Depending on the material being worked on, wheels may vary from hard rubberized abrasives to cloth-based flaps loaded with cutting compounds.

Once the surface is polished to a uniform level of smoothness, the operator transitions to the buffing side of the machine. Buffing is a more delicate, finishing process aimed at producing a high-gloss, mirror-like shine. It uses soft, pliable wheels—often made from cotton, muslin, or felt—and relies on fine buffing compounds, which can range from brown tripoli for pre-polishing to white rouge or green chrome oxide for final finishing. The operator must be skilled in applying the right amount of pressure and compound to avoid burn marks, streaks, or surface inconsistencies. In many industries, this high-quality finish is not just for appearance—it reduces friction, enhances corrosion resistance, and in some cases, meets critical tolerance requirements for high-performance components.

The machine’s design often includes a solid base to minimize vibration, ensuring steady and safe operation. Some higher-end models come with variable speed controls, allowing the user to adjust the RPM to match the specific task. Lower speeds are ideal for buffing delicate materials, while higher speeds can be used during the polishing stage for quicker material removal. Safety considerations are also crucial—spark guards, eye shields, and even integrated vacuum ports for dust and particulate extraction are common in industrial setups. Metal polishing and buffing generate fine particles and heat, so proper ventilation and personal protective equipment (PPE) are essential for long-term use.

What truly sets the polishing and buffing combo machine apart from separate tools is its ability to streamline workflow. In production settings where throughput and finish quality must be balanced, having both functions integrated into a single station allows operators to move seamlessly from surface preparation to final finishing. This not only reduces equipment cost and space requirements but also cuts down on handling time, which in turn improves consistency and productivity. For small workshops, artisans, or businesses that work with metals, plastics, wood, or composite materials, this machine becomes a core asset—capable of delivering professional-grade finishes on everything from industrial parts to custom-crafted jewelry or automotive components.

Polishing and Buffing Combo Machine

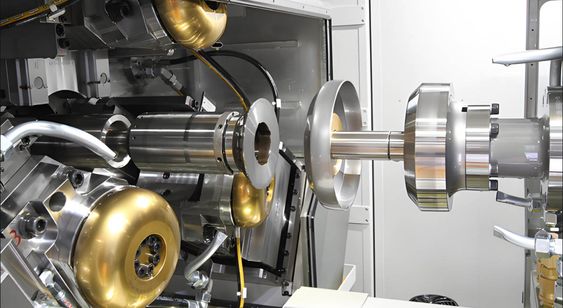

A Polishing and Buffing Combo Machine is a dual-purpose finishing tool designed to perform both polishing and buffing tasks using a single unit. It is widely used in workshops, manufacturing plants, fabrication facilities, automotive garages, and artisan studios where surface treatment is essential. The machine typically features two opposing spindles mounted on a shared motorized base—one side dedicated to polishing, and the other for buffing. This allows the user to transition quickly between the two processes without changing tools or workstations, significantly increasing efficiency and convenience.

In polishing, the goal is to remove surface imperfections such as scratches, oxidation, or tool marks by using an abrasive wheel or polishing compound. This process is aggressive compared to buffing and is usually the first step in surface preparation. Polishing wheels are typically made from harder materials like sisal, impregnated cloth, or synthetic abrasives. They can be combined with various grits of abrasive paste depending on the material being worked—whether it’s steel, aluminum, brass, plastic, or even wood.

Buffing follows polishing and serves as a finishing process. It’s more refined and aims to produce a high-gloss, reflective surface. Buffing wheels are softer, usually constructed from multiple layers of muslin, cotton, or felt. They’re used with buffing compounds—fine, wax-like substances that smooth and brighten the surface without removing significant material. Popular buffing compounds include white rouge (for light metals), green compound (for stainless steel), and red jeweler’s rouge (for soft, precious metals). Proper buffing not only enhances the visual appeal of a component but also improves surface characteristics such as corrosion resistance and cleanliness.

The motor driving the machine typically ranges from 0.5 HP to 2 HP depending on application requirements. Some models are single-speed, while more advanced machines offer variable speed control, which is crucial when switching between materials that require different surface treatments. High RPMs are ideal for aggressive polishing, while lower speeds are safer and more effective for delicate buffing operations.

Modern combo machines often include safety features such as spark guards, eye shields, and non-slip bases. Dust extraction ports or attachments for vacuum systems may also be present, especially in industrial models, as both polishing and buffing generate fine dust and debris that must be controlled to protect both the operator and nearby equipment. Additionally, adjustable tool rests are usually provided to support the workpiece during operation and reduce operator fatigue during extended use.

From a functional perspective, the polishing and buffing combo machine is a highly efficient solution for anyone needing to process metal, plastic, or wood components to a refined finish. It is valued not just for its space-saving design but for its ability to provide consistent and high-quality results. Industries that benefit from this machine include metal fabrication, automotive restoration, aerospace, woodworking, jewelry production, and even consumer electronics repair. Its versatility makes it one of the most practical finishing machines in any multi-material workshop.

The polishing and buffing combo machine continues to stand out in industrial and artisan settings due to its adaptability, ease of use, and the quality of surface finish it can provide. In a typical workflow, operators appreciate the seamless transition from polishing to buffing without the need to interrupt their process or reposition the workpiece between machines. This uninterrupted workflow not only saves time but also helps maintain uniformity in finish, especially on pieces that require consistent surface characteristics across multiple faces or parts. For example, in automotive restoration, chrome parts like bumpers or trim are often polished to remove pitting or discoloration before being buffed to a mirror-like shine. Similarly, in metal fabrication shops, welders and machinists use combo machines to clean up weld seams or machined surfaces before final finishing, enhancing both appearance and performance of the component.

The machine’s effectiveness depends heavily on the choice of wheel and compound combinations. For instance, a coarse polishing wheel combined with a heavy-cut compound is ideal for removing deep scratches or oxidation on hard metals like stainless steel, while a soft buffing wheel with a fine rouge compound is better suited for bringing out a reflective finish on softer materials such as aluminum or gold. Knowing how to match the right wheel, compound, and speed to the material is essential for achieving professional results. This level of control becomes especially valuable in fields like jewelry making or precision engineering, where surface quality has both aesthetic and functional importance.

Beyond its operational features, the polishing and buffing combo machine also contributes to workplace efficiency by consolidating two essential finishing functions into one compact footprint. This is particularly beneficial in smaller workshops where space and budget may not allow for multiple standalone machines. It reduces setup time, minimizes movement between tools, and simplifies maintenance routines, as the user only has to service one motor and one frame. In terms of durability, most commercial-grade combo machines are built with heavy-duty cast iron or steel housings, sealed bearings, and industrial-grade motors to withstand long hours of continuous use. These rugged designs are crucial in production environments where downtime can be costly.

Operator safety and ergonomics are also important considerations in the design and use of these machines. Since both polishing and buffing produce dust, heat, and sometimes sparks, machines are often equipped with shrouds or guards to contain debris, and many allow connection to external dust collection systems. Proper lighting, workpiece support, and non-slip bases also contribute to safer operation. Users are typically trained to wear protective gear, including safety glasses, gloves, and sometimes respirators, particularly when working with fine powders or toxic materials.

Overall, the polishing and buffing combo machine represents a balance of power, precision, and practicality. Whether used for industrial part finishing, fine metalwork, or decorative surface treatment, it provides a reliable and versatile solution that meets the needs of both high-volume operations and custom fabrication shops. Its dual-functionality not only enhances workflow and finish quality but also offers a smart investment for those seeking long-term value and consistent performance in surface finishing tasks.

In continuous operation, the polishing and buffing combo machine plays a critical role in quality assurance, especially where visual appeal and surface integrity are directly tied to product value. This is particularly evident in industries such as aerospace, medical device manufacturing, and high-end consumer goods, where even minor surface flaws can disqualify a part from being accepted. The machine allows for close control over the finishing process, which is vital in environments that demand tight tolerances and repeatable results. By adjusting variables like wheel hardness, compound abrasiveness, motor speed, and pressure applied, skilled operators can fine-tune the outcome to meet highly specific standards. The versatility of the machine extends further when additional accessories are introduced—such as tapered spindles for quick wheel changes, flexible shaft attachments for precision detailing, or specialized jigs for handling complex geometries and delicate parts.

From an economic standpoint, this machine offers both direct and indirect benefits. Directly, it reduces capital expenditure since a single unit performs two processes. Indirectly, it enhances labor productivity by reducing idle time between stages of surface preparation. A worker using a combo machine can complete more parts per hour compared to setups that require moving between separate stations or waiting for other machines to become available. Furthermore, as this tool becomes a central part of production flow, it can be easily incorporated into lean manufacturing systems or continuous improvement programs. The consistency it delivers allows for more accurate scheduling, fewer reworks, and higher customer satisfaction due to the improved finish quality of the end product.

The machine’s relevance also extends into educational and training environments. In technical schools, vocational programs, and maker spaces, combo machines are often used to teach students the fundamentals of surface finishing. Because they combine two essential techniques, they allow learners to understand the complete process flow—from material preparation to final polish—without needing a suite of equipment. This helps build foundational skills while encouraging safe and efficient work habits. Students can experiment with different materials and finishes, gaining insight into how small adjustments in speed, pressure, or compound can lead to dramatically different results. These lessons are invaluable for future careers in machining, fabrication, restoration, and design.

In artisan and craft settings, particularly among metal sculptors, custom knife makers, or furniture builders, the polishing and buffing combo machine becomes a creative tool as much as a technical one. Here, surface finish is not just about function or standardization—it’s part of the product’s identity. Whether aiming for a soft satin sheen on a wooden edge, a deep reflective polish on a custom blade, or a subtly aged patina on a brass fixture, this machine supports a wide range of artistic expressions. The ability to switch quickly between aggressive material removal and delicate final touches allows artisans to bring their visions to life with both efficiency and craftsmanship.

Over time, the durability of the combo machine pays off. With proper maintenance—such as regular cleaning, lubrication of moving parts, replacement of worn wheels, and occasional motor servicing—it can last for decades, becoming a reliable fixture in the workshop. Many users even customize or upgrade their machines with aftermarket parts like extended shafts, upgraded motors, or precision rests to better suit their specific workflow. This adaptability, combined with its dual-purpose design, cements the polishing and buffing combo machine as an enduring staple in both industrial and creative environments.

Angle Buffing Machine

An Angle Buffing Machine is a specialized power tool designed for polishing and buffing surfaces using a rotating abrasive or soft wheel mounted at a right angle to the motor shaft. Unlike standard bench-top or straight-shaft polishing tools, the angle buffing machine features a compact, angled head that allows operators to work on vertical, contoured, or hard-to-reach surfaces with greater control and flexibility. It’s widely used in automotive detailing, metal fabrication, construction, shipbuilding, and maintenance work where surface refinement must be performed in tight or awkward spaces.

The tool resembles an angle grinder in form and function but is optimized for polishing and buffing rather than cutting or grinding. Most models are handheld and powered either electrically or pneumatically. The head, usually set at 90 degrees to the body, holds a spindle or arbor onto which various buffing pads, wool bonnets, foam discs, or abrasive flap wheels can be attached using quick-change systems or threaded mounts. The rotation of the head combined with the angled configuration allows the user to apply consistent pressure across uneven or vertical surfaces such as car panels, stainless steel tanks, pipes, weld seams, and even interior corners of fabricated structures.

The motor in an angle buffing machine typically operates between 1,000 and 3,000 RPM, and many models offer variable speed control to suit different materials and compounds. Lower speeds are essential when working with heat-sensitive surfaces like plastics or paint, while higher speeds may be used for tougher polishing jobs on metal. The tool is often equipped with ergonomic handles, trigger locks, and soft starts for safety and comfort during prolonged use.

Angle buffing machines can be paired with a variety of buffing compounds depending on the material and desired finish—coarse compounds for initial polishing, and finer rouges for high-gloss buffing. In automotive use, for example, detailers use these machines with foam pads and polishing compounds to remove swirl marks, oxidation, and light scratches from painted surfaces. In marine and industrial environments, they are essential for cleaning and restoring stainless steel, aluminum, or coated surfaces subjected to harsh weather and chemicals.

Their portability and versatility make angle buffing machines ideal for on-site work, touch-ups, or maintenance tasks where bench machines are impractical. With proper training and care, they deliver professional-level finishes and are a key tool for anyone working in surface restoration or finishing.

The angle buffing machine continues to be a crucial tool in both professional and hobbyist settings where precision surface finishing is required in challenging or confined spaces. Its right-angle head configuration makes it especially useful for working on irregular geometries, edges, vertical planes, and interiors of structural components where straight or bench-mounted machines cannot reach effectively. For instance, in automotive refinishing, the angle buffing machine is commonly used on contoured body panels, bumpers, and tight areas around mirrors or trim, providing smooth transitions and high-gloss finishes without risking damage to surrounding parts. The angled design also makes it easier to maintain a steady polishing line across vertical surfaces, which is difficult to achieve with flat tools or orbital polishers.

Because it is a handheld tool, operator skill plays a significant role in the final finish quality. Users must learn to apply consistent pressure and maintain the correct angle and movement pattern to avoid issues such as holograms, swirl marks, or overheating of the surface. Variable speed control is an important feature in this context, as it allows the operator to tailor the machine’s performance to the material and stage of the buffing process. Lower speeds may be used to spread compound evenly or to perform finishing passes, while higher speeds are more appropriate for cutting back oxidation or leveling minor scratches. The use of speed-adjustable machines also minimizes the risk of burning through paint or soft coatings, which is a common concern with fixed-speed tools.

The range of attachments available for angle buffing machines adds to their versatility. Depending on the application, users can switch between wool pads for aggressive compounding, foam pads for fine polishing, or microfiber heads for ultra-fine finishing. In metalwork, users might employ abrasive non-woven discs to clean welds or remove oxidation before switching to cloth buffing wheels for a polished shine. The ability to swap out heads quickly means that a single tool can handle multiple stages of finishing without interruption. This modularity makes it highly efficient for professionals who need to maintain productivity while achieving superior surface quality.

In industrial environments such as shipbuilding, railcar fabrication, or pipeline maintenance, angle buffing machines are used to prepare metal surfaces for coating or inspection. Surfaces like aluminum bulkheads, steel hulls, or stainless steel piping require a specific degree of smoothness and cleanliness to meet technical and safety standards. The portability of the angle buffing machine allows technicians to move easily across large structures and perform work directly on-site, reducing the need for disassembly or transport of heavy components. This mobility is also valuable in maintenance settings, where equipment may need to be refurbished or retouched in place, such as in HVAC systems, tanks, or heavy machinery frames.

In more delicate or artistic applications, like musical instrument restoration or architectural metalwork, the angle buffing machine enables highly controlled work on complex or ornamental surfaces. The operator can carefully maneuver the tool around curves, ridges, or recesses to remove tarnish, smooth seams, or enhance luster without flattening detail or causing damage. Artists, conservators, and custom fabricators often rely on the angle buffing machine for this level of tactile precision, as it bridges the gap between coarse grinding tools and fine hand polishing.

Durability and ergonomics are key to long-term use, especially in professional settings where the tool might run for hours at a time. High-quality angle buffing machines are built with reinforced gear housings, sealed bearings to resist dust and moisture, and insulated motors that can handle continuous duty without overheating. Ergonomic design features such as vibration-dampening handles, compact head profiles, and lightweight body construction contribute to reduced user fatigue and more stable handling. Safety features, including soft-start mechanisms, electronic overload protection, and adjustable guard systems, are becoming standard in modern models, enhancing both usability and operator protection.

Ultimately, the angle buffing machine is not just a convenience but a necessity for any work environment that demands consistent, high-quality finishes in complex or confined spaces. Its combination of power, portability, and precision makes it a go-to solution across industries—from car detailing and metalworking to marine maintenance and fine craftsmanship. With proper technique, maintenance, and selection of accessories, it delivers professional-level results that rival more stationary equipment, while offering unmatched flexibility and control. Would you like recommendations on specific models or guidance for selecting pads and compounds for a certain type of material or finish?

As the demand for surface perfection continues to rise across industries, the angle buffing machine is becoming increasingly refined in terms of technology, materials, and performance features. Manufacturers now offer machines with digital speed displays, programmable settings, and intelligent load sensors that adjust torque output based on the resistance encountered during use. These features enhance both the precision and safety of the tool, especially in environments where surface finish standards are tightly regulated, such as aerospace or medical manufacturing. Digital control also allows more consistent performance over extended polishing sessions, reducing the variability that can occur due to operator fatigue or changing surface conditions.

Cordless versions of angle buffing machines have also emerged, thanks to advancements in lithium-ion battery technology. These portable units give users full freedom of movement without sacrificing much in terms of power or run time. In field maintenance, such as on wind turbines, large vehicles, or outdoor pipelines, this mobility can be crucial. While corded machines still dominate in terms of continuous heavy-duty use, cordless versions are gaining ground rapidly, especially in situations where convenience, accessibility, or safety (e.g., avoiding tripping hazards) are primary concerns.

The environmental and workplace health aspects of buffing and polishing are also gaining attention. Angle buffing machines often operate in environments where dust, metal particles, or compound residue are released into the air. These fine particulates pose both respiratory and cleanliness challenges. As a result, many industrial users now integrate dust shrouds, attach vacuum hoses, or work within ventilated booths. Proper personal protective equipment—including respirators, eye protection, gloves, and hearing protection—becomes essential, especially during extended use. Additionally, the compounds used with these machines have evolved to include water-based or low-residue formulas that are safer for the operator and easier to clean from the finished surface.

From a training perspective, the angle buffing machine is relatively easy to learn, but mastering it takes time. Novices often start with practice panels or scrap pieces to develop a feel for the right pressure and motion. Over time, skilled users learn to “read” the sound, vibration, and visual cues from the tool and the workpiece, adjusting their technique instinctively. For companies training multiple employees, this consistency in results becomes critical to maintaining product quality. Some manufacturers now offer training programs, demo units, and even simulator-based systems to accelerate the learning curve and improve safety.

Repair and maintenance of angle buffing machines are generally straightforward. Most models are designed with accessible brush housings, gearboxes, and motor components, making it possible to replace worn parts like carbon brushes, bearings, or power cords without sending the unit out for service. Keeping the machine clean—especially the spindle and venting system—is essential to maintaining its lifespan. If the machine becomes unbalanced due to uneven pad wear or misalignment, it can cause excessive vibration and reduced control, so regular inspection is a good practice. For industrial users, establishing a preventative maintenance routine helps ensure uptime and extends the life of both the machine and consumables.

In terms of innovation, some angle buffing machines are now incorporating orbital motion in addition to rotary action, blending the benefits of rotary and dual-action polishers. This hybrid movement reduces the risk of heat buildup and surface swirl, making the tool more forgiving for users and safer for delicate finishes like clear coats or polished plastics. These tools are especially popular in detailing and finishing work where surface perfection is critical but the risk of overworking an area must be minimized. They represent a natural evolution of the traditional angle buffing machine, pushing the limits of what’s possible with a handheld surface finishing tool.

The longevity and relevance of the angle buffing machine ultimately stem from its ability to adapt to new materials, new processes, and evolving user needs. Whether in the hands of a seasoned professional restoring a classic car, a technician polishing a turbine blade, or an artist finishing a hand-crafted sculpture, this tool continues to offer a blend of control, power, and versatility that few others can match. It remains a bridge between raw fabrication and final presentation, turning unfinished surfaces into polished, functional, and often beautiful results. Would you like to go into detail about compound selection for specific finishes or how to adapt the machine for curved or textured surfaces?

Polishing Cabinet Buffing Machine

A Polishing Cabinet Buffing Machine is a specialized equipment designed to facilitate safe, controlled, and efficient polishing and buffing operations within an enclosed space. These machines typically consist of a cabinet or booth where the polishing and buffing processes take place, often equipped with one or more buffing wheels, abrasive pads, or brushes, a motor, and integrated systems for dust collection. They are commonly used in industries that require precise surface finishing of small to medium-sized components, such as jewelry manufacturing, electronics, metalworking, and automotive detailing. The primary advantage of a polishing cabinet buffing machine lies in its enclosed design, which helps contain debris, reduces exposure to hazardous materials, and minimizes environmental contamination.

The cabinet typically features transparent viewing panels made from durable acrylic or tempered glass, allowing the operator to monitor the workpiece while maintaining a safe distance from the moving parts. The interior of the cabinet is equipped with buffing wheels or abrasive pads mounted on motor-driven spindles, which rotate at varying speeds depending on the model. These spindles can accommodate different sizes and types of buffing wheels, ranging from coarse to fine materials such as wool, cotton, or felt, which are ideal for different stages of the polishing process. In many cases, the user can switch between polishing and buffing wheels to progressively refine the surface finish, from initial material removal to high-gloss final polish.

A key feature of the polishing cabinet buffing machine is its integrated dust and fume extraction system. Polishing and buffing generate fine dust and debris, particularly when working with metals like aluminum or stainless steel, or with certain composites. These particles can pose health risks when inhaled or cause a mess in the workplace. To mitigate this, polishing cabinet machines are equipped with powerful suction fans or vacuum systems that remove airborne particles from the cabinet, funneling them into filters or external collection bins. This feature is essential for maintaining a clean, safe working environment, especially in compliance with workplace health and safety standards.

These machines are typically designed for ease of use, with access doors or glove ports allowing the operator to insert their hands into the cabinet without opening it, thus maintaining a sealed environment. Glove ports enable precise control over the workpiece, and the compact design of the machine helps in controlling the work area’s lighting and dust levels. The interior often includes adjustable shelves or tool supports, providing convenience for setting the workpiece at the ideal height and angle for the operator.

The buffing cabinet is typically made of sturdy metal, such as steel or aluminum, to provide durability and stability during operation. Some higher-end models also include advanced features like built-in lighting, vibration-dampening components, and optional accessories such as polishing compounds or sprays, which can be applied directly to the workpiece while it is being buffed. These compounds can further enhance the polishing process, especially when working with materials that require a high-gloss finish, such as precious metals, glass, or acrylics.

The polishing cabinet buffing machine is especially valuable in high-precision fields where surface finish quality is critical. In jewelry manufacturing, for example, these machines allow for a meticulous, controlled polishing process that produces a flawless shine on rings, necklaces, bracelets, and other pieces without damaging the delicate details. In automotive applications, such as buffing chrome trim or headlight lenses, the cabinet helps achieve an even, smooth finish that enhances the appearance of the part while also providing a layer of protection against oxidation.

Overall, a polishing cabinet buffing machine provides a controlled, efficient, and safe solution for precision polishing and buffing tasks. The enclosed design ensures both safety and cleanliness, while the versatility in buffing wheel and compound options allows the user to adapt the machine for different materials and finishes. Its application spans a wide range of industries, making it an essential tool for professionals seeking high-quality surface finishes in a secure, effective manner.

The polishing cabinet buffing machine remains an essential tool in environments where precise, high-quality finishes are required. Its enclosed nature offers distinct advantages, not only for the operator’s safety but also for maintaining consistency and cleanliness in the workspace. The ability to control the working environment inside the cabinet makes it easier to handle intricate parts and delicate materials without worrying about contaminants or exposure to harmful polishing compounds and dust. This makes it particularly beneficial in fields like jewelry design and restoration, where intricate detailing and high-shine finishes are a hallmark of quality. The dust and debris removal system ensures that any fine particles produced during the process are efficiently extracted, improving air quality and reducing the risk of cross-contamination or scratches on the workpiece. The machine’s ability to maintain a stable, clean environment also extends the life of polishing wheels and reduces the need for frequent tool changes, as the buildup of abrasive material is minimized.

Another key aspect of these machines is the ability to easily adjust the polishing parameters. Many models come with variable-speed motors, allowing users to tailor the speed of the buffing wheels to suit the material being worked on. Softer materials, like aluminum or plastics, require slower speeds to avoid overheating or gouging, while harder metals like stainless steel might benefit from faster rotation to remove oxidation or achieve a mirror-like finish. These adjustments allow for greater control over the polishing process, ensuring that the finish meets the required standards without risking damage to the workpiece. The variety of polishing pads and wheels that can be used in these machines also makes them versatile, catering to different stages of the polishing process, from coarse grinding to fine polishing and buffing.

The compact and efficient nature of the polishing cabinet buffing machine also makes it ideal for shops or operations with limited space. Instead of needing multiple stations for different polishing tasks, a single polishing cabinet can handle a variety of materials and finishes, making it both a space-saver and a cost-effective solution. Operators can easily switch between tasks without needing to move the workpiece to different machines or setups. This efficiency is particularly valuable in high-volume production environments, where time and workflow are critical.

In addition to its functionality, the ergonomic design of the cabinet makes it easier for operators to perform long hours of buffing and polishing without experiencing undue strain. The ability to perform tasks through glove ports or from an upright position, with the workpiece secured at an optimal height, minimizes operator fatigue and increases overall comfort. This is an important consideration for environments where the operator’s well-being is a priority, such as in workshops with heavy or continuous polishing work.

From a safety perspective, the polishing cabinet buffing machine reduces the risk of accidents that can occur when using traditional open-bench polishing tools. With the operator enclosed within the cabinet, the likelihood of contact with moving parts is minimized. Additionally, the design often includes built-in safety features such as automatic shutoff mechanisms in case of overloads or unexpected malfunctions.

With regular maintenance, a polishing cabinet buffing machine can provide years of reliable service. Routine tasks like cleaning dust filters, inspecting buffing wheels for wear, and ensuring proper lubrication of moving parts keep the machine running smoothly. Many models also allow for easy replacement of worn-out components, such as brushes or wheels, helping to keep downtime to a minimum. This focus on durability and longevity is a significant benefit for businesses that rely on these machines for high-quality finishes on a daily basis.

In terms of application, polishing cabinet buffing machines are not limited to just one sector. Whether it’s polishing automotive parts, fine metal products, glassware, or even medical devices, these machines can adapt to a variety of materials and finishes. The precision offered by the enclosed, controlled environment allows for fine adjustments to the polishing process, ensuring that every part that leaves the machine meets the high standards required by the industry.

As industries continue to prioritize safety, efficiency, and quality, the polishing cabinet buffing machine remains a cornerstone tool for achieving professional finishes. Its ability to handle multiple polishing and buffing tasks while ensuring a safe, clean, and ergonomic workspace makes it a valuable asset in both small workshops and large-scale production facilities. Would you like more insights into choosing the right cabinet buffing machine for specific tasks or comparing models with unique features?

The versatility of polishing cabinet buffing machines extends to various industries, each benefiting from the machine’s ability to handle complex finishing tasks with precision and control. In industries such as aerospace, automotive manufacturing, and metalworking, where component appearance, durability, and surface integrity are paramount, polishing cabinet machines provide consistent, high-quality results. For example, in aerospace, precision-polished metal parts must meet stringent quality standards for both aesthetic and functional reasons, such as ensuring resistance to corrosion or minimizing drag. Polishing cabinet buffing machines allow technicians to fine-tune their processes to meet these exacting specifications, ensuring that even the smallest components, such as turbine blades or fuel fittings, are polished to perfection.

In automotive production, these machines are invaluable for detailing car parts, especially chrome and metal trim, which often require an immaculate finish to meet customer expectations and industry standards. The ability to maintain a controlled environment while polishing intricate surfaces, like grills, rims, or emblems, allows for a high-gloss finish without the risk of contamination from dust or compound residues. Polishing cabinet buffing machines help achieve the signature gleam that’s so important in vehicle aesthetics, from luxury cars to motorcycles.

In the field of medical devices, the quality of the finish on surgical instruments, implants, and prosthetics is crucial not only for the appearance but also for hygiene and functionality. Polishing cabinet buffing machines ensure that these parts are free from imperfections that could harbor bacteria or cause mechanical failure. For example, the smooth, polished finish on stainless steel surgical tools is not just about looks; it’s also essential for reducing the risk of infection and facilitating easier cleaning and sterilization. The precision of these machines makes them ideal for achieving such results.

Another major benefit of polishing cabinet buffing machines is their ability to handle delicate or highly specialized materials, such as gemstones, ceramics, and glass. In industries like jewelry design or glass manufacturing, where the material is often fragile or prone to scratching, the controlled environment inside a polishing cabinet helps prevent unintended damage. The ability to apply a controlled, even buffing action to such materials is essential for creating stunning finishes without compromising their integrity. In jewelry making, for instance, polishing cabinets are used to bring out the brilliance in metals like gold, platinum, and silver, as well as to perfect the clarity and shine of diamonds or other gemstones.

The adoption of polishing cabinet buffing machines in small-scale and artisan settings is also on the rise. Artists and small manufacturers who focus on custom or high-end products often rely on these machines for their precise control and ability to produce professional-grade finishes. Whether creating custom furniture, restoring antiques, or designing bespoke jewelry, the cabinet buffing machine offers a way to ensure consistent, high-quality results. It’s particularly useful in small shops where a single machine can handle multiple materials and finishes, providing versatility without requiring an array of separate machines.

As technology advances, polishing cabinet buffing machines are becoming more integrated with digital systems that allow for greater automation and efficiency. Some high-end models are now equipped with programmable controls, allowing users to input specific parameters such as speed, pressure, and compound type, creating a more automated process that can be repeated consistently. This reduces the potential for human error and ensures that each workpiece receives the exact same level of attention, making the polishing process both more reliable and efficient. This shift towards automation is especially beneficial in high-volume production settings, where consistency is crucial and reducing manual labor can lead to significant time and cost savings.

The environmental impact of polishing operations is another important consideration, and polishing cabinet buffing machines are increasingly designed with eco-friendly features. Many modern models incorporate filtration systems that reduce the amount of waste and pollutants released into the environment. For instance, some units use water-based or biodegradable compounds instead of traditional petrochemical-based polishing pastes, reducing the environmental footprint of the polishing process. Additionally, advancements in energy efficiency are helping to minimize power consumption, making these machines more sustainable for long-term use.

For businesses looking to optimize their operations, integrating polishing cabinet buffing machines with existing workflows is relatively straightforward. These machines can often be incorporated into automated production lines, where multiple parts need to be polished in a consistent and repeatable manner. The compact, enclosed design of the polishing cabinet makes it easy to fit into tight spaces or alongside other finishing equipment. Integration with dust extraction and filtration systems ensures that the entire polishing process remains clean and compliant with workplace health and safety regulations.

In terms of future trends, polishing cabinet buffing machines will continue to evolve, incorporating even more advanced technology such as touch-screen interfaces, real-time monitoring systems, and the ability to work with an even broader range of materials. These machines will continue to support industries that require precision and high-quality finishing, all while enhancing the overall safety, ergonomics, and environmental sustainability of the polishing process.

Whether for industrial, commercial, or artisanal use, polishing cabinet buffing machines represent a perfect balance of safety, efficiency, and high-performance. They provide a secure and controlled environment for achieving flawless finishes, protecting both the operator and the environment. With the right model, maintenance practices, and polishing compounds, businesses can ensure that they achieve the best possible surface finishes on a variety of materials, from metals to plastics and ceramics.

Would you like to explore more about specific polishing compounds or materials suitable for these machines, or perhaps recommendations on optimizing a polishing cabinet for your particular needs?

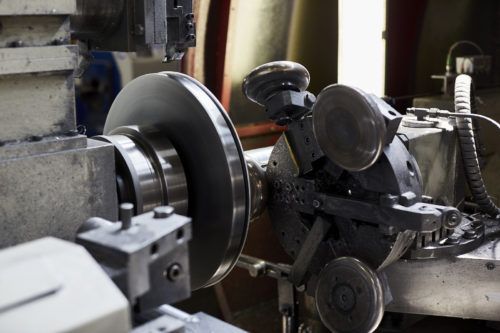

Industrial Buffing Machine

An industrial buffing machine is a high-powered tool used in commercial and industrial settings for polishing and finishing surfaces of various materials, such as metal, wood, plastic, and stone. These machines are designed to perform heavy-duty buffing tasks that require consistent, high-quality results across large quantities of parts or products. Industrial buffing machines are essential in sectors such as metalworking, automotive manufacturing, aerospace, and woodworking, where surface finishing is a critical step in ensuring the quality and appearance of the final product.

Industrial buffing machines come in a wide variety of configurations, from standalone bench-mounted models to larger, more complex systems that integrate multiple stages of polishing or are part of automated production lines. The main components typically include buffing wheels or pads, a powerful motor that drives the rotation of these wheels, and often an adjustable stand or frame to hold the workpiece at the correct angle for polishing. Many models are also equipped with speed controls, allowing operators to adjust the machine’s rotation speed based on the material being worked on and the stage of the buffing process.

The design of industrial buffing machines varies depending on the specific requirements of the task. For example, machines used for polishing large metal parts might feature larger buffing wheels, while those for finer detailing or finishing work might use smaller, more precise wheels. Some models are designed for specific applications, such as polishing automotive parts like chrome trim or buffing metal molds used in manufacturing, while others are more versatile and can handle a range of materials and finishes.

One of the key features of an industrial buffing machine is its motor, which is typically much more powerful than that found in smaller, consumer-grade polishers. These motors can be variable-speed to allow greater control over the polishing process. High RPMs (revolutions per minute) are ideal for quickly removing material or for aggressive polishing, while lower RPMs allow for finer finishing and a smoother, more reflective finish. For example, in metalworking, high speeds are used to cut back oxidation or remove rust, while slower speeds are ideal for fine polishing or creating a mirror-like finish.

Buffing wheels or pads are the heart of the industrial buffing process. These wheels come in a variety of materials such as cotton, felt, wool, and synthetic fibers, and are often treated with polishing compounds or abrasives to enhance their performance. For heavy-duty work, a stiff wheel might be used to remove oxidation or scratches, while softer, more delicate wheels are employed for final finishing. In some cases, the type of buffing compound used will depend on the material being polished. For example, a metal polish or abrasive compound might be used for polishing steel, while a gentler compound might be employed for polishing plastics or softer metals like aluminum or brass.

Industrial buffing machines also tend to feature built-in dust collection systems to manage the debris created during the buffing process. These systems help maintain a cleaner workspace and improve air quality by collecting the dust, metal filings, and polishing compound particles that are generated. This is particularly important in industries where worker health and cleanliness are a priority. In addition, the dust collection systems can improve the longevity of the buffing wheels and other components, as excessive dust buildup can lead to overheating or clogging of parts.

In larger-scale industrial operations, buffing machines may be integrated into automated production lines. These systems allow for consistent and repeatable polishing of high volumes of parts. In these setups, the buffing machine may be programmed to work with robotic arms or conveyors that feed parts into the polishing station, minimizing the need for manual handling and significantly improving efficiency. Such systems can be customized for specific products, enabling companies to meet high throughput requirements without sacrificing quality.

Safety is a major consideration with industrial buffing machines due to their high-speed rotation and potential hazards associated with polishing compounds and airborne debris. Machines are often equipped with safety guards or covers to prevent accidental contact with the buffing wheels. Operators are usually required to wear personal protective equipment (PPE), such as safety goggles, gloves, ear protection, and respiratory masks, especially in environments where fine dust or fumes may be present. Many machines also have emergency stop features and automatic shut-off mechanisms in case of overloads or malfunctions.

In terms of maintenance, industrial buffing machines require regular care to ensure that they continue to operate efficiently and effectively. This includes checking the motor and electrical components for wear, ensuring the buffing wheels are properly balanced, and cleaning or replacing the dust collection filters. Buffing wheels should be inspected for damage or wear, as a worn-out wheel can lead to uneven polishing or potential damage to the workpiece.

Given their durability, power, and ability to handle large-scale tasks, industrial buffing machines are a fundamental tool in many sectors. They ensure that products are finished to a high standard, improving both their appearance and functionality. In industries such as automotive, aerospace, metalworking, and manufacturing, these machines are vital for achieving the precision and surface finishes required for both aesthetic and practical purposes

Industrial buffing machines are designed to tackle demanding polishing tasks that require both power and precision. They are ideal for finishing large quantities of parts or high-volume production environments, where consistency and quality are essential. These machines can be used on a variety of materials, including metals, plastics, ceramics, glass, and composites, making them highly versatile in industries ranging from automotive and aerospace to metalworking, electronics, and manufacturing. The ability to perform both heavy-duty polishing and fine detailing allows these machines to meet the needs of a wide array of applications, such as restoring the shine to automotive parts, polishing turbine blades, buffing metal fixtures, or refining jewelry components.

What sets industrial buffing machines apart from consumer-grade tools is their robustness and ability to handle continuous operation without compromising on performance. High-speed motors, ranging from 1 horsepower (HP) to upwards of 10 HP or more, provide the necessary power for large-scale polishing tasks. This ensures that operators can maintain optimal production speeds while achieving a high-quality surface finish on parts of various sizes and shapes. In some cases, the motor’s power is supplemented by advanced speed control systems, allowing operators to dial in the perfect RPM for each task.

A key component of an industrial buffing machine is its buffing wheel, which can be tailored to specific applications based on the type of material and the level of finish required. Buffing wheels are available in different materials, such as cotton, wool, felt, or synthetic fibers, and they can be impregnated with various polishing compounds to enhance their cutting or finishing ability. For example, a wool wheel might be used for aggressive polishing tasks that involve removing oxidation or rust from metal parts, while a cotton wheel might be used for finer finishing or creating a mirror-like finish on softer metals or plastics.

Many industrial buffing machines come equipped with additional features such as oscillating or dual-action buffing motions. These motions are designed to reduce the risk of swirl marks or uneven finishes, especially when working with delicate or highly reflective surfaces. The oscillating motion helps to distribute the polishing compound more evenly and ensures that the surface being worked on receives consistent attention, which is especially important in industries that require a flawless finish, such as the luxury automotive or jewelry sectors.

Dust extraction and fume control systems are integral to industrial buffing machines, especially in environments where harmful particles or fumes might be released during the buffing process. These systems help capture and remove the fine dust, metal shavings, or polishing compound residues generated, which could otherwise contaminate the work area or pose a health risk to operators. Many machines feature integrated vacuum ports or separate dust collection units that help keep the workspace clean and safe. These systems are particularly important in industrial settings where maintaining air quality is essential for compliance with safety regulations.

Given the heavy-duty nature of these machines, maintenance is crucial to ensure their long-term reliability and performance. Regular inspection and replacement of buffing wheels, motor brushes, and polishing compounds are necessary to keep the machine running smoothly. Additionally, ensuring that the dust collection system is functioning properly, and that no debris or particles are clogging the system, helps prevent overheating and ensures efficient operation.

The integration of industrial buffing machines into production lines can further optimize efficiency in large-scale manufacturing environments. These machines can be automated to feed parts through buffing stations via conveyor belts or robotic arms, reducing manual labor and increasing throughput. In automated setups, buffing machines can be programmed to execute precise polishing sequences, ensuring consistency across large batches of parts. This level of automation not only speeds up production but also enhances product quality by reducing the risk of human error during the polishing process.

As industries continue to prioritize automation, sustainability, and efficiency, industrial buffing machines are also evolving to meet these needs. Many modern machines are designed to be energy-efficient, reducing power consumption and operational costs. Furthermore, advancements in buffing compounds, such as the development of water-based or eco-friendly formulas, help minimize the environmental impact of polishing tasks.

In conclusion, industrial buffing machines are indispensable in industries where high-quality, consistent surface finishes are a must. They are powerful, versatile, and designed for continuous operation, making them an essential part of many manufacturing and finishing processes. With the right maintenance, proper use of buffing compounds, and regular inspection, these machines can deliver exceptional results for a wide range of applications, from metal polishing to automotive detailing and beyond. Whether used in high-volume production environments or for specialized tasks, industrial buffing machines ensure that every part is finished to the highest standards. Would you like to explore specific manufacturers or features of these machines?

The industrial buffing machine’s ability to deliver consistent results in high-demand environments is one of the key reasons it remains indispensable across various sectors. As industries continue to evolve and the need for precision and efficiency grows, the role of buffing machines will likely expand, with advanced technologies integrating seamlessly into automated processes. One area of development is the incorporation of smart technology and sensors into buffing machines. These features can monitor the condition of the buffing wheels, track the pressure applied to the surface, or even detect anomalies in the polishing process. Real-time feedback allows operators to adjust settings or perform maintenance before issues arise, improving uptime and reducing the risk of defects in the final product.

For example, certain modern industrial buffing machines are now equipped with vibration sensors or load monitoring capabilities that can detect when a buffing wheel is out of balance or when the motor is under strain. This early detection can help prevent damage to the machine and the workpieces, ensuring that any issues are addressed before they result in costly downtime or quality control problems. Such advancements in machine diagnostics not only improve the efficiency of polishing operations but also help with predictive maintenance, which can be crucial for operations with high output demands.

Moreover, the flexibility of industrial buffing machines in accommodating a range of materials continues to make them invaluable. From polishing steel and aluminum to working on more delicate materials like plastics, ceramics, or glass, these machines can be tailored with various buffing compounds, pads, and wheels designed to suit the specific requirements of each material. This adaptability allows businesses to handle a wide array of products, from heavy machinery parts to intricate jewelry pieces, all while maintaining the high standards of finish that are expected in industries like automotive, aerospace, medical device manufacturing, and even art restoration.

With advancements in automation, the integration of buffing machines into larger manufacturing lines becomes increasingly seamless. Automated systems allow for continuous, high-speed polishing of parts, reducing manual labor and increasing throughput. This integration often includes conveyor belts or robotic arms that move parts into position for polishing, and some machines can even be programmed to apply specific pressure and speed settings to different parts of the product, ensuring a customized finish for each piece. Such systems are essential for industries like automotive manufacturing, where large quantities of parts need to be polished to the same high standard, or in industries where precision is paramount, such as the aerospace sector.

Environmental concerns and sustainability continue to be important factors in industrial manufacturing, and the development of more eco-friendly buffing systems is becoming increasingly relevant. For instance, using biodegradable or water-based polishing compounds helps reduce the environmental impact of the buffing process. Additionally, dust extraction and air filtration systems are being improved to capture even finer particles, further minimizing environmental exposure to harmful chemicals or metal dust. Some companies are also developing machines that use less energy and produce less noise, addressing both environmental and workplace safety concerns.

Another factor that makes industrial buffing machines essential is their role in quality control. In industries like metalworking, where the aesthetics and functionality of the parts are critical, the buffing process plays a key role in eliminating imperfections such as scratches, rust, or oxidation. Buffing ensures that the finished products have a smooth, even surface, free from defects that could compromise their performance or appearance. High-quality surface finishes can also improve the durability and longevity of products, particularly in industries that require resistance to corrosion or wear, such as the marine or oil and gas sectors.

In woodworking, where polishing and buffing are often done to enhance the natural appearance of the wood and provide a protective finish, industrial buffing machines play an essential role in producing furniture, cabinetry, or decorative items. The buffing process ensures that the wood surfaces are smooth and polished, free from marks or imperfections, and properly sealed. Similarly, in the electronics industry, where components need to have smooth, contaminant-free surfaces for optimal performance, buffing machines are used to polish parts like circuit boards, casings, and connectors, ensuring they meet industry standards for both function and appearance.

As industries move towards more precision-driven and technology-enhanced manufacturing, the role of industrial buffing machines will likely become even more integral. Machines with integrated software and advanced control systems could further reduce human error and improve efficiency, allowing for more complex and intricate finishes. In addition, the incorporation of artificial intelligence and machine learning could help optimize polishing processes by learning from past operations and adjusting settings automatically for the best results.

In summary, industrial buffing machines are continually evolving to meet the increasing demands for precision, efficiency, and sustainability. These machines are critical in industries where surface finish plays an important role in both aesthetics and functionality. From high-volume production settings to specialized craftsmanship, industrial buffing machines ensure that products meet the highest standards of quality and finish. As technology advances, these machines will only become more sophisticated, offering even more benefits in terms of automation, customization, and eco-friendliness. Would you like further details on any specific models or recommendations based on particular industrial needs?

Dust Collection Buffing Machine

A dust collection buffing machine is a specialized tool designed for polishing and buffing tasks that includes an integrated dust extraction system to capture the debris generated during the buffing process. These machines are widely used in industrial settings, particularly in woodworking, metalworking, automotive manufacturing, and other industries where the polishing process can produce a significant amount of dust, shavings, or particulate matter.

The primary function of a dust collection buffing machine is to ensure a cleaner, safer work environment by capturing and removing harmful dust, polishing compounds, and metal shavings as they are created. This is especially important in environments where dust particles can pose health hazards to workers, create safety risks (e.g., explosions from flammable dust), or interfere with the quality of the finished product.

In a typical dust collection buffing machine setup, the machine is equipped with a high-efficiency dust collection system that either integrates directly with the buffing tool or operates as a standalone component. The dust extraction system usually consists of several key elements:

- Dust Hood or Shroud: A collection hood or shroud is positioned around the buffing wheel to capture the dust and particles generated during the polishing process. These hoods are strategically designed to enclose the work area around the wheel, minimizing the release of dust into the surrounding workspace.

- Vacuum System: The dust captured by the hood is then directed through a vacuum system. This system can be built into the buffing machine itself or connected to an external dust collector via flexible hoses. The vacuum system pulls the dust from the work area and transports it to a filtration unit, where it is safely contained.

- Filtration System: After the dust and debris are sucked into the vacuum system, they are passed through a filtration unit. Depending on the machine’s design, this filtration unit can include multi-stage filters to remove even fine particles. Common filter types include HEPA filters (high-efficiency particulate air filters), carbon filters for capturing fumes, or cyclone separators that remove larger debris before the air enters finer filters.

- Dust Collector or Hopper: The cleaned air is released back into the room, and the dust and debris are collected in a dust collector or hopper. The hopper or dust bin needs to be emptied regularly to prevent it from becoming clogged, and it may be equipped with a system to alert operators when it’s full.

- Workpiece Area or Booth: In some machines, especially those used in high-precision or sensitive applications, the dust collection system is integrated into an enclosed booth or workpiece area. This setup isolates the polishing process from the surrounding environment, providing an even cleaner working atmosphere and better control over the dust.

The inclusion of a dust collection system in a buffing machine offers several benefits:

- Improved Air Quality: By removing harmful dust particles from the air, these machines help maintain a healthier work environment. In industries like woodworking, metalworking, and automotive, where the polishing process can release fine particulate matter, keeping the air clean is crucial for protecting workers’ respiratory health.

- Enhanced Workplace Safety: Dust accumulation can create fire hazards, particularly when flammable polishing compounds or metals are involved. A dust collection buffing machine minimizes this risk by preventing the buildup of dust, which can otherwise become a source of ignition.

- Better Product Quality: Dust and debris in the environment can contaminate the polishing process and lead to imperfections in the finished surface. A dust collection system helps prevent these contaminants from interfering with the finish, ensuring that parts and products are polished to a high standard without the risk of dust marks or scratches.

- Cleaner Workspace: A cleaner work environment not only improves health and safety but also boosts productivity. Operators can work in a more organized and less cluttered environment, which reduces the time spent cleaning up after each task and keeps the workspace more efficient.

- Compliance with Regulations: In many industries, dust collection is not just a best practice; it’s often a legal requirement. For example, in the woodworking industry, dust is considered a significant health hazard, and businesses must comply with OSHA (Occupational Safety and Health Administration) standards or similar regulations. Using a dust collection buffing machine ensures compliance with these regulations and minimizes the risk of penalties.

In industries like metalworking and automotive production, buffing machines with integrated dust collection systems help to keep surfaces free of contaminants that could affect the quality of polished parts. In metalworking, buffing processes often involve the use of abrasives, which can create fine metal dust. This dust, if not controlled, can result in contamination or affect the surface quality of the finished product. Similarly, in automotive production, using a dust collection system ensures that polishing compounds and fine particles are safely contained, preventing damage to delicate components like mirrors, trim, and bodywork.

In woodworking, dust collection is crucial because the fine dust from sanding, buffing, and polishing wooden surfaces can contain wood fibers that are harmful when inhaled. A dust collection buffing machine helps mitigate the health risks associated with these fine particulates, ensuring that the workspace remains clean and the air quality is improved.

Moreover, the integration of eco-friendly features into modern dust collection systems is becoming more prevalent. Newer systems are designed to be more energy-efficient, reducing the overall environmental impact of polishing operations. This can include optimized vacuum motors that consume less electricity or using sustainable materials for filters that are both effective and biodegradable.

The incorporation of smart technology into dust collection buffing machines is also on the rise. Some machines now feature real-time monitoring and diagnostics, where sensors can detect the level of dust buildup in the filtration system, alerting operators when maintenance is needed or when the filters need to be changed. This ensures that the dust collection system operates at peak efficiency, reducing the chances of downtime and maintaining the cleanliness of the work environment.

In conclusion, a dust collection buffing machine offers a comprehensive solution for industries that require high-quality surface finishes while ensuring that the work environment remains safe, clean, and efficient. The integration of powerful vacuum systems, efficient filtration, and dust collection technologies not only helps protect workers’ health but also ensures the smooth and flawless results that are expected in precision industries. Would you like more details on specific models or features of dust collection systems for buffing machines?

Dust collection buffing machines are a critical advancement in industrial polishing, combining the functions of polishing and dust management into a single, cohesive system. These machines are engineered to perform high-quality buffing while effectively capturing the dust and debris generated during the process, which is essential for maintaining both the quality of the finished product and the safety of the workspace. In industries where dust and particulate matter can negatively impact both product quality and worker health, having an integrated dust collection system helps to address these concerns while boosting operational efficiency.

The dust collection system works by drawing in the airborne particles that are created as the buffing wheel makes contact with the workpiece. This debris can range from polishing compounds to metal shavings, wood dust, or plastic particles, depending on the material being worked on. Without a dust collection system, these particles can scatter into the air and the surrounding environment, potentially contaminating the work area, affecting air quality, and increasing the risk of fire or health issues. In industries like woodworking, metalworking, and automotive, these particles are not only an inconvenience but also a serious safety hazard.

A properly designed dust collection system in a buffing machine includes a powerful suction system that pulls in dust from the immediate work area. This is often achieved by using a combination of collection hoods or shrouds that surround the buffing wheels and vacuum suction hoses that connect to a central dust collector. The dust is pulled through the system, where it passes through various filters designed to trap fine particles, ensuring that only clean air is returned to the workspace. In addition to improving air quality, this system reduces the need for manual cleaning, making the workspace less cluttered and more productive. Moreover, the collection of dust is especially important in environments with high-speed buffing operations, where large amounts of dust are generated quickly.

These machines are also crucial for maintaining the quality of the finish on the workpieces. When dust and other debris are allowed to remain in the environment, they can settle back onto the workpieces and cause imperfections in the final polished surface. Even small particles can lead to scratches, streaks, or uneven finishes. By collecting dust at the source, a dust collection buffing machine helps to preserve the integrity of the surface finish, ensuring that parts remain free from contaminants. This is particularly important in industries such as automotive manufacturing, where high-quality finishes are essential for both aesthetic appeal and functional performance.

Beyond improving air quality and product finishes, dust collection systems in buffing machines also play a significant role in ensuring workplace safety. In industries like woodworking, where wood dust is produced, the dust can be highly combustible, posing a fire risk. Similarly, metal dust, especially from materials like aluminum or steel, can present an explosion hazard if not properly controlled. A dust collection buffing machine helps mitigate these risks by capturing potentially hazardous dust and preventing it from accumulating in the workspace. In doing so, it also helps businesses comply with safety regulations and health standards, which may require the installation of dust extraction systems in certain industries to prevent harmful exposure.

Maintenance of dust collection buffing machines is an essential aspect of keeping them functioning efficiently. Over time, dust can build up in the system, especially in the filters and collection hoppers, so routine cleaning and maintenance are required to keep the system running at peak performance. Regularly checking and replacing filters, ensuring that the vacuum system is not clogged, and keeping the buffing wheels in good condition are all part of maintaining the machine and ensuring optimal dust collection. Many modern dust collection systems are equipped with sensors and monitoring systems that notify operators when the system is nearing full capacity or when the filters need to be replaced, making maintenance easier and reducing downtime.

Another advantage of these machines is their ability to help businesses reduce their environmental footprint. By capturing and containing dust, companies can reduce the amount of airborne particulate matter that is released into the environment. This is particularly relevant in industries where regulations surrounding air quality are stringent, such as woodworking or metalworking. Dust collection buffing machines contribute to a cleaner and more sustainable manufacturing process by preventing the release of harmful pollutants and minimizing waste.

The design and technology of dust collection systems are also evolving to be more energy-efficient and user-friendly. Modern machines often feature adjustable suction power, allowing operators to fine-tune the level of dust extraction based on the material and type of buffing work being done. This helps optimize energy consumption and ensure that the dust collection system is working as efficiently as possible. Additionally, quieter models are available, reducing the noise level in the workspace, which can improve the working conditions for operators and comply with noise reduction regulations.

The incorporation of smart technologies in dust collection buffing machines is also an emerging trend. Some machines now include digital controls, allowing for more precise operation and real-time monitoring of the dust collection process. These systems can track the efficiency of the dust extraction, alerting operators to any potential issues such as blockages or system malfunctions. This real-time data helps ensure that the dust collection system is always functioning optimally, improving both the quality of the work and the safety of the environment.

Overall, a dust collection buffing machine is an essential piece of equipment for many industries that rely on polishing and buffing processes. Whether it is a standalone unit or part of a larger automated production system, the inclusion of a dust collection system enhances safety, improves air quality, and ensures that finished products meet the highest standards of quality. By reducing the environmental impact, increasing workplace safety, and ensuring that the buffing process is efficient and precise, these machines provide a comprehensive solution for a wide range of industrial applications.

The continued development of dust collection buffing machines is driven by the increasing demand for higher productivity, enhanced worker safety, and improved environmental standards. As industries strive to streamline operations, reduce costs, and meet sustainability goals, the role of these machines has evolved beyond simple dust extraction. Modern dust collection buffing machines are now integrating sophisticated features that increase their effectiveness in a variety of applications.

For instance, advancements in filter technology have significantly improved the efficiency of dust extraction. High-efficiency particulate air (HEPA) filters, commonly used in these machines, can capture even the finest dust particles, which are often invisible to the naked eye but can still cause serious health risks if inhaled over time. Additionally, multi-stage filtration systems are now commonly used to enhance dust collection by first removing larger particles and then capturing the finer, more hazardous dust. This progression has made dust collection systems more reliable and effective, ensuring a cleaner and healthier work environment for operators.

The automation of dust collection systems is another notable trend. Many modern machines are designed to integrate seamlessly with automated production lines. For example, buffing machines with dust collection systems are increasingly being equipped with sensors that automatically adjust the suction power depending on the type of material being polished or the volume of dust being generated. This smart functionality helps to ensure optimal dust removal without wasting energy or resources. Automated monitoring systems can also track the condition of the filters, alerting operators when maintenance is needed or when filters should be replaced, thus reducing manual intervention and preventing system failures.