Exhaust Pipe Polishing Line: A metal polishing machine is a mechanical device used to improve the surface finish of metallic components by reducing surface roughness, removing oxidation, and enhancing appearance. These machines are critical in industries where surface quality is essential, such as automotive, aerospace, medical devices, cookware, jewelry, and manufacturing of precision tools. The polishing process can also increase corrosion resistance and prepare metal parts for further coating or painting.

Metal Polishing Machine Working Principle

The working principle of a metal polishing machine involves the abrasion of the metal surface using a rotating wheel or belt embedded with abrasive materials. As the workpiece comes into contact with the abrasive surface, microscopic layers of the material are removed. This process smooths out irregularities, scratches, or other imperfections. Depending on the intended finish, the process may include several stages of polishing with abrasives of progressively finer grits.

2. Types of Metal Polishing Machines

There are several types of machines used for polishing metal, each suited to specific applications:

- Manual Polishing Machines: These are operated by hand and provide high flexibility. They are ideal for intricate or custom work, such as jewelry and small components, but are labor-intensive.

- Semi-Automatic Polishing Machines: These machines combine manual loading with automated polishing cycles. They offer better consistency than fully manual systems and are commonly used in small-scale industrial setups.

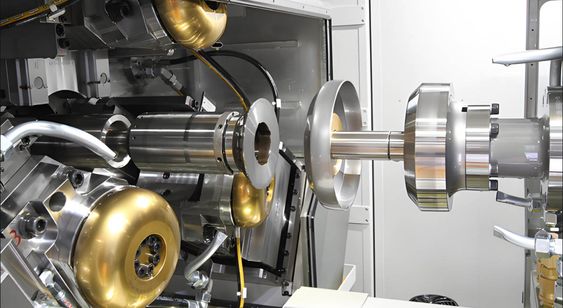

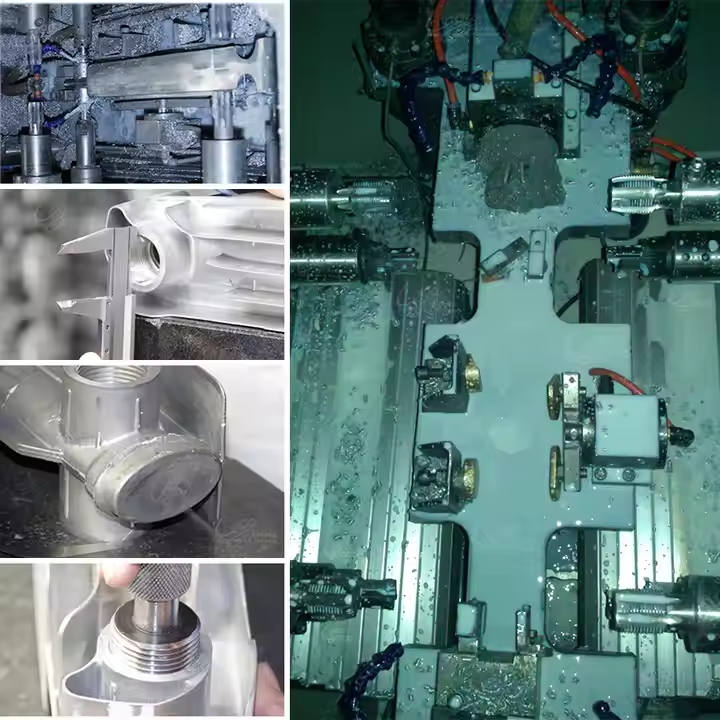

- Fully Automatic CNC Polishing Machines: Controlled by computer numerical control (CNC) systems, these machines offer high-speed, precision polishing for mass production. They are capable of working on complex geometries and ensure uniform surface finish across all parts.

- Belt Polishing Machines: These use abrasive belts and are suitable for flat or curved surfaces. They can remove heavy oxidation, weld seams, or surface defects quickly.

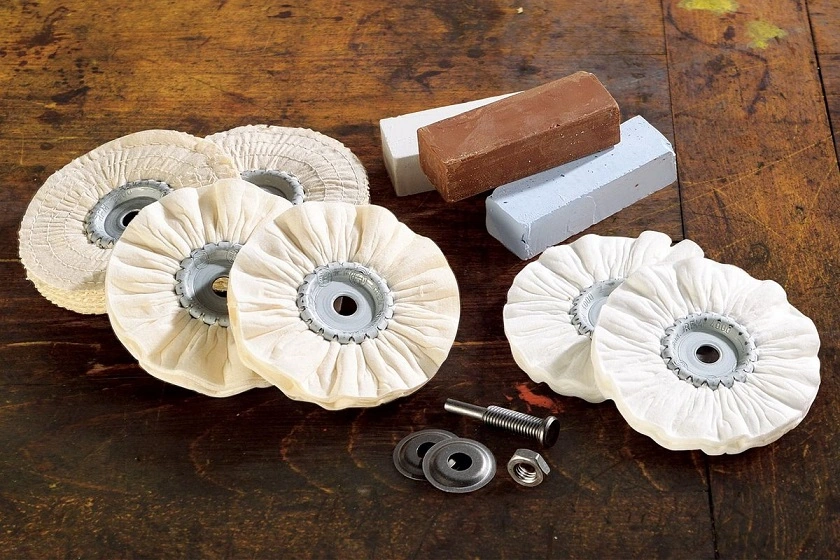

- Buffing Machines: These use soft cloth wheels with fine abrasives or polishing compounds. Buffing is often the final step in the polishing process to achieve a mirror-like finish.

3. Applications

Metal polishing machines are used in a wide range of industries:

- Automotive Industry: To polish engine parts, bumpers, and trims for aesthetic appeal and corrosion resistance.

- Aerospace: For improving surface integrity and fatigue resistance of critical components.

- Medical Equipment: Surgical tools and implants require ultra-smooth finishes for hygiene and performance.

- Cookware and Utensils: For achieving a clean, reflective surface that is easy to maintain.

- Architectural Hardware: Door handles, railings, and decorative fittings are polished for enhanced visual appeal.

4. Advantages of Metal Polishing

- Enhanced Appearance: Polishing produces a shiny, aesthetically pleasing finish.

- Improved Corrosion Resistance: A smoother surface reduces the accumulation of moisture and corrosive agents.

- Ease of Cleaning: Polished surfaces are easier to maintain and clean.

- Improved Functionality: In moving parts, polishing can reduce friction and wear.

- Pre-Coating Preparation: A smooth base ensures better adhesion of paints or coatings.

5. Challenges and Considerations

While metal polishing provides numerous benefits, there are also challenges:

- Heat Generation: Excessive heat during polishing can warp the metal or degrade its properties.

- Material Loss: Polishing removes material, which may be unacceptable in precision components.

- Health Hazards: Dust and fumes from polishing operations can pose health risks if proper ventilation and protective equipment are not used.

- Surface Contamination: If abrasive compounds are not properly cleaned off, they can contaminate subsequent manufacturing steps.

6. Environmental and Safety Aspects

Modern metal polishing machines are increasingly designed with environmental considerations. Features like dust collectors, noise dampening, and enclosed systems help to reduce emissions and improve workplace safety. Additionally, many industries now prefer water-based or eco-friendly polishing compounds to reduce chemical waste.

7. Future Trends

With the rise of automation and Industry 4.0, metal polishing machines are becoming more intelligent and adaptive. Integration with robotic arms, AI-powered defect detection, and real-time process monitoring are becoming standard in high-end polishing setups. Moreover, additive manufacturing and 3D printing have created demand for polishing machines capable of handling unconventional shapes and materials.

Conclusion

Metal polishing machines play a vital role in modern manufacturing and product finishing. Whether it is for aesthetics, performance, or protective purposes, the right polishing technique and machinery can significantly enhance the quality and value of metal components. As technology evolves, so too will the capabilities and applications of these versatile machines, making them indispensable tools in numerous industries.

A metal polishing machine is a specialized piece of equipment used to refine and smooth the surface of metal components through mechanical abrasion. Its primary function is to enhance the aesthetic appearance of the metal, improve its resistance to corrosion, and in some cases, prepare it for further processes such as coating or painting. These machines work by removing small amounts of surface material using abrasive wheels, belts, or compounds, which can vary in coarseness depending on the desired finish. Polishing can result in a matte, satin, or mirror-like reflective finish, depending on the technique and materials used.

The process involves placing the metal workpiece in contact with a rotating polishing medium under controlled pressure and speed. As the abrasive interacts with the surface, imperfections such as scratches, oxidation, and minor dents are removed. The smoother the desired finish, the finer the abrasive required, and the more time and precision needed in the polishing process. In many industries, a multi-stage polishing process is adopted, starting with a coarse abrasive to shape or clean the surface and ending with a fine polish to achieve a high-gloss result.

Metal polishing machines come in various forms. Some are designed for manual operation, allowing the user to guide the workpiece by hand and apply polishing compounds manually. These are often used for intricate or delicate components such as jewelry, custom metalwork, or restoration projects. On the industrial side, semi-automatic and fully automatic machines are common. Semi-automatic machines require manual loading but execute the polishing cycle automatically, improving efficiency and consistency. Fully automatic machines, particularly those integrated with CNC systems, can handle complex shapes and volumes with minimal human input. These systems are ideal for mass production in industries such as automotive, aerospace, and medical manufacturing, where precision and uniformity are paramount.

Among the different types of polishing machines, belt polishers are widely used for flat or slightly curved surfaces, offering rapid material removal and a consistent finish. Buffing machines, on the other hand, use softer wheels and polishing compounds to impart a high-shine finish and are usually the final step in a polishing process. Some systems incorporate robotic arms to handle and manipulate parts with complex geometries, enabling uniform polishing on surfaces that are difficult to reach manually.

The applications of metal polishing machines span a wide range of industries. In the automotive sector, parts like wheels, trims, and engine components are polished to enhance their visual appeal and durability. In aerospace, critical components are polished to exacting standards to ensure optimal performance and safety. In the medical field, instruments and implants must be polished to a high degree of cleanliness and smoothness to meet stringent regulatory standards. Similarly, consumer products such as kitchenware, door handles, and decorative fixtures are polished to improve their appearance and feel.

While metal polishing offers many benefits, it also presents several challenges. The process can generate significant heat, which, if not controlled, may distort the workpiece or affect its mechanical properties. Material removal, though often minimal, may be unacceptable in precision applications. Furthermore, dust and fumes generated during polishing pose health and safety risks, making protective equipment and ventilation systems essential. Proper handling of polishing compounds and waste materials is also important to minimize environmental impact.

Modern polishing machines are evolving to address these challenges. Many are now equipped with advanced safety features, dust extraction systems, and noise reduction technologies. The integration of automation and smart control systems allows for real-time monitoring and adjustments, enhancing efficiency and consistency. In line with environmental concerns, manufacturers are increasingly adopting water-based or biodegradable polishing compounds that reduce harmful emissions.

As industries continue to push for higher quality, sustainability, and efficiency, metal polishing machines are becoming more sophisticated and versatile. The demand for machines capable of handling unconventional shapes, exotic materials, and custom finishes is rising, particularly with the growth of technologies like additive manufacturing and 3D printing. Consequently, the role of metal polishing machines in shaping, refining, and finishing metal products remains crucial, and their importance in the production chain is only expected to grow in the future.

8. Key Components of a Metal Polishing Machine

A typical metal polishing machine consists of several core components, each playing a critical role in the operation:

- Motor/Drive System: This is the heart of the machine, providing the rotational force required for polishing wheels or belts. Motors vary in power depending on the type of work—high-torque motors are often needed for heavy-duty or high-volume applications.

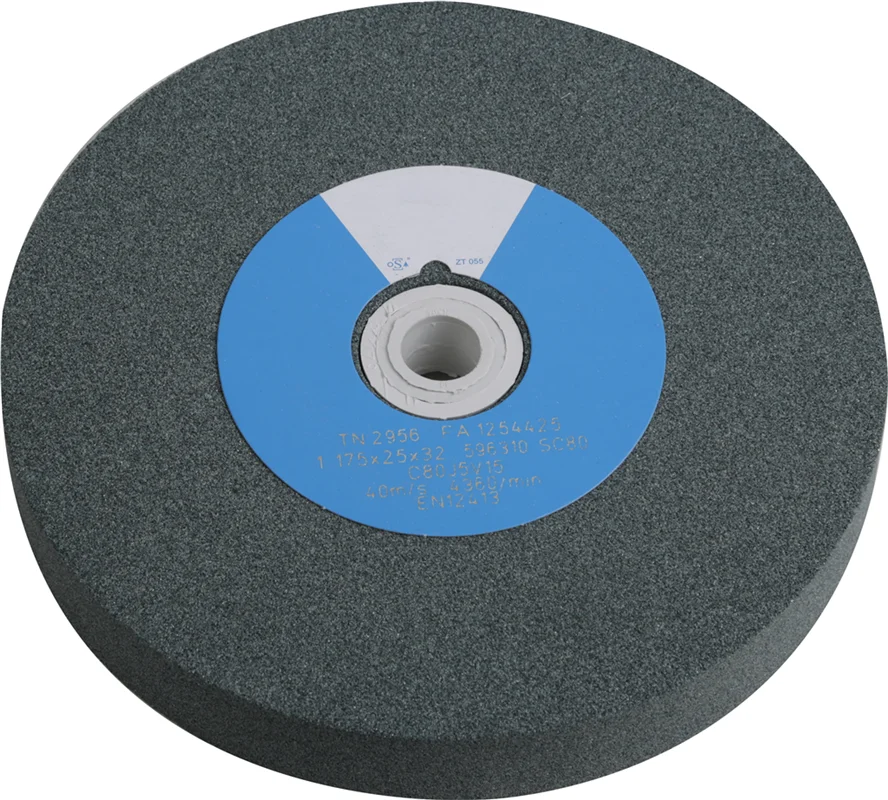

- Polishing Wheel or Belt: These are the abrasive components that come into contact with the metal surface. Polishing wheels can be made of cloth, felt, sisal, or other materials and are often used with polishing compounds. Abrasive belts, on the other hand, are commonly made from materials like aluminum oxide or silicon carbide.

- Workpiece Holder or Jig: In semi-automatic or fully automatic machines, the part to be polished is held in a fixture or jig to ensure stability and repeatability during the process. These can be customized to fit complex geometries.

- Control Panel/System Interface: Modern polishing machines come equipped with digital control panels or CNC interfaces. These allow operators to precisely control variables such as speed, pressure, polishing time, and compound application.

- Dust and Fume Extraction System: Since polishing can create fine particulate matter, many machines are equipped with dust extraction or vacuum systems to maintain a clean and safe environment.

- Coolant or Lubrication System (optional): In some applications, a cooling fluid or polishing slurry is used to prevent overheating, reduce friction, and improve surface finish.

9. Polishing Compounds and Abrasives

The success of a polishing process greatly depends on the type and quality of abrasive materials or polishing compounds used. These are generally categorized as:

- Cutting Compounds: Contain coarse abrasives for initial material removal. Common examples include emery and tripoli compounds.

- Polishing Compounds: These are finer and used to bring out a shine. Rouge compounds (such as red or white rouge) are popular for achieving mirror finishes.

- Dry vs. Wet Compounds: Some compounds are applied as dry powders or bars, while others are in liquid or paste form. Wet polishing often results in better control over heat and finish.

- Custom Slurries: In precision or high-tech industries, slurries with specific chemical and abrasive properties are used to meet strict surface quality requirements.

10. Process Control and Quality Assurance

To ensure consistent and high-quality polishing, modern machines employ various process control strategies:

- Variable Speed Control: Adjusting the speed of the polishing wheel or belt allows the machine to adapt to different materials and finish requirements.

- Pressure Monitoring: Sensors can measure the pressure applied to the workpiece, ensuring that it remains within safe and effective limits.

- Cycle Time Programming: In automated systems, polishing time is precisely controlled for repeatability across multiple parts.

- Surface Finish Inspection: Quality control may involve using tools like surface profilometers, gloss meters, or visual inspection stations to verify that the target finish is achieved.

- Feedback Systems: Advanced machines can include feedback loops with machine vision or force sensors to automatically adjust the process in real time.

11. Maintenance and Longevity

Proper maintenance is essential to keep a metal polishing machine operating efficiently and safely. Key maintenance practices include:

- Regular Cleaning: Dust and residue from abrasives can clog components and reduce efficiency. Routine cleaning is necessary, especially in machines with built-in extraction systems.

- Inspection of Wear Parts: Polishing wheels, belts, and motor brushes should be inspected regularly for wear and replaced as needed to maintain optimal performance.

- Lubrication of Moving Parts: Bearings, drive shafts, and other mechanical parts should be lubricated according to the manufacturer’s guidelines to avoid mechanical failure.

- Calibration: Machines with electronic sensors and control systems should be calibrated periodically to maintain accuracy.

- Software Updates: CNC and smart polishing machines may require firmware or software updates to incorporate new features or bug fixes.

12. Safety Considerations

Operating a metal polishing machine involves several safety risks. Employers and users must take the following precautions:

- Personal Protective Equipment (PPE): Operators should wear safety goggles, dust masks or respirators, gloves, and hearing protection.

- Training and Supervision: Only trained personnel should operate polishing equipment, especially automated or high-power systems.

- Emergency Stop Systems: Machines should have easily accessible emergency stop buttons to quickly shut down operations in case of malfunction.

- Guarding and Shields: All rotating parts should be adequately shielded to prevent accidental contact.

- Ventilation: Proper airflow is necessary to handle fumes and fine dust, particularly when polishing toxic metals or using chemical-based compounds.

13. Customization and Integration

Many manufacturers offer customized polishing solutions tailored to the needs of specific industries. These custom systems may feature:

- Multiple Polishing Heads: For simultaneous multi-surface treatment.

- Robotic Integration: For parts that require complex handling or rotation during polishing.

- Inline Conveyor Systems: For integration into continuous production lines.

- Automatic Compound Dispensers: To ensure even and consistent application of polishing materials.

Such customization allows for scalability and efficient integration into broader manufacturing or finishing workflows.

Rotary Table Polishing Machine: Detailed Overview

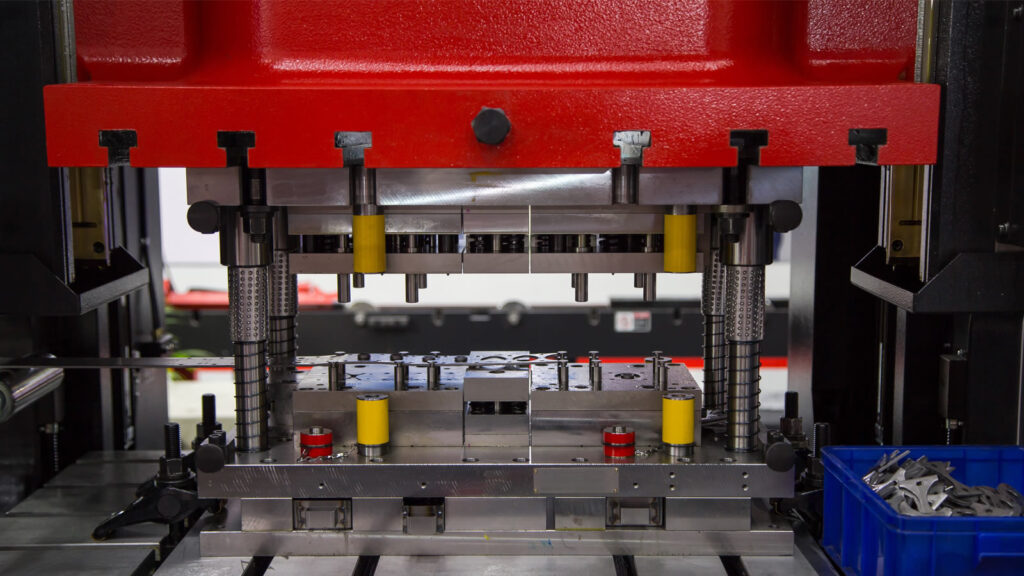

A Rotary Table Polishing Machine is a specialized type of surface finishing equipment designed for high-efficiency, consistent, and repeatable polishing of metal components. It is widely used in mass production environments where uniform surface quality, precise control, and high throughput are critical. The defining feature of this machine is its rotary table, which continuously indexes or rotates to bring workpieces into contact with polishing tools, making it suitable for both flat and contoured parts.

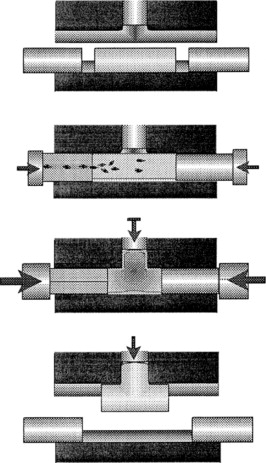

1. Working Principle

The Rotary Table Polishing Machine operates on the principle of mechanical abrasion combined with controlled automation. The machine features a circular rotary table that holds multiple workpieces, either on individual fixtures or mounted directly. As the table rotates—either continuously or in indexed steps—each workpiece is brought sequentially into contact with polishing stations arranged around the perimeter.

Each polishing station may consist of:

- Abrasive wheels

- Buffing mops

- Belts

- Brushes

- Compound applicators

The table can be configured to stop at each station for a fixed time (indexing mode) or rotate continuously at a slow speed for uninterrupted processing. The speed, pressure, and duration of contact are controlled through a central control system, often integrated with PLC or CNC automation.

2. Key Features and Components

A Rotary Table Polishing Machine is comprised of the following essential components:

- Rotary Indexing Table: A heavy-duty, precisely machined turntable that holds multiple fixtures or clamps for securing workpieces.

- Polishing Heads: These may include belt grinders, buffing wheels, or flap wheels. Each head is typically adjustable in multiple axes to suit complex geometries.

- Compound Dispensers: Automated systems for applying polishing or abrasive compounds consistently during operation.

- Pneumatic or Hydraulic Pressing Mechanisms: These apply consistent pressure between the polishing head and the workpiece, ensuring uniform results.

- Control System: Most modern systems include a programmable logic controller (PLC) or a CNC interface, allowing for exact parameter control, recipe saving, and error detection.

- Safety Guards and Dust Extraction: Enclosures and exhaust systems maintain operator safety and minimize environmental impact.

3. Applications

Rotary Table Polishing Machines are widely used across industries for polishing metal parts of various shapes and sizes. Common applications include:

- Automotive Parts: Brake levers, handles, alloy wheel components, and decorative trims.

- Hardware: Door handles, locks, knobs, and hinges.

- Cookware and Cutlery: Spoons, ladles, pots, and pans.

- Medical Instruments: Surgical tools, orthopedic implants, and dental instruments.

- Sanitary Fittings: Faucets, valves, and pipe fittings.

The machine is ideal for applications that demand uniform surface quality across high volumes of parts.

4. Advantages

Rotary Table Polishing Machines offer several key benefits:

- High Productivity: Multiple workpieces can be processed simultaneously, reducing cycle time.

- Consistent Quality: Automation ensures uniform polishing across all parts, minimizing human error.

- Versatility: Machines can be configured for different part sizes, shapes, and materials with interchangeable tooling and fixtures.

- Compact Design: Despite their capabilities, rotary systems are often more space-efficient than linear production lines.

- Reduced Labor: Once loaded, the machine performs tasks autonomously, reducing the need for skilled manual polishing.

5. Machine Variants and Customization

Depending on the application, rotary table polishing machines may be designed in different formats:

- Single-head vs. Multi-head Configuration: For sequential polishing steps like roughing, intermediate, and final buffing.

- Horizontal vs. Vertical Axis Table: Depending on the orientation and gravity requirements of the workpiece.

- Manual Loading vs. Robotic Integration: For either basic setups or high-throughput automated cells.

- Wet or Dry Polishing: Machines may include coolant systems to manage heat and dust.

Customization is common, with tailor-made jigs, tooling, and polishing programs developed to match the client’s part geometry and finish requirements.

6. Maintenance and Operational Considerations

Like any industrial machinery, rotary table polishers require regular maintenance to ensure long-term efficiency and product quality:

- Routine inspection of belts, wheels, and motors

- Lubrication of rotary and head drive components

- Calibration of pressure sensors and speed controls

- Cleaning and replacement of filters in the dust extraction system

Operators must also be trained to monitor noise, vibration, or any deviations in finish quality that could signal equipment wear or malfunction.

7. Safety and Compliance

Given the presence of rotating parts, abrasive materials, and dust generation, safety is critical:

- Fully enclosed stations protect operators from direct exposure.

- Emergency stop mechanisms and interlock switches prevent unintended access during operation.

- Integrated fire suppression systems may be required when polishing combustible metals like aluminum or titanium.

- Compliance with standards such as CE, ISO, or OSHA may be necessary depending on regional regulations.

8. Innovations and Industry 4.0 Integration

Advanced rotary polishing systems are now integrating Industry 4.0 technologies, such as:

- Real-time performance monitoring

- Predictive maintenance via sensors

- Automated defect detection using cameras

- Remote diagnostics and software updates

- Energy-efficient motors and drives

These innovations not only increase efficiency but also help reduce downtime and production costs.

Conclusion

The Rotary Table Polishing Machine is a high-performance solution for companies that require efficient, repeatable, and high-quality surface finishing. With its combination of automation, precision control, and adaptability, it plays a vital role in modern manufacturing processes. From high-end automotive parts to everyday consumer goods, these machines help deliver the polished surfaces that define quality and professionalism in metal products.

A rotary table polishing machine is an advanced type of surface finishing equipment used predominantly in industrial settings for polishing metal components with high precision and consistency. Unlike conventional polishing systems, which typically handle one part at a time, the rotary table configuration allows multiple parts to be processed in a continuous or indexed circular motion, improving throughput and ensuring uniform results across all workpieces. The central component of the machine is its rotating table, which holds jigs or fixtures that securely position the metal parts. As the table turns, either in continuous rotation or indexed steps, each part is sequentially presented to various polishing stations mounted around the machine’s perimeter.

Each polishing station may be outfitted with different types of abrasive or buffing heads, including belts, flap wheels, mops, or brushes, depending on the surface finish requirements. Some machines are designed with just one head for simple applications, while more advanced models can feature multiple heads for multi-step processes such as pre-polishing, intermediate finishing, and final buffing. These polishing heads can often be adjusted in several axes to accommodate varying part geometries, from flat surfaces to complex contours. Automation in rotary table machines plays a critical role. Most are equipped with PLC or CNC systems that control table rotation speed, polishing head pressure, contact time, and the application of polishing compounds. This precision ensures high repeatability and minimal variation between parts, which is essential in industries like automotive, sanitary hardware, kitchenware, and medical instruments, where surface finish quality directly affects both function and aesthetics.

The design of rotary table polishing machines makes them particularly suitable for mass production. Multiple parts can be loaded onto the table and processed in one continuous cycle, dramatically reducing idle time and increasing productivity. Some systems incorporate robotic loading and unloading arms to further enhance automation, reducing labor costs and the potential for human error. Additionally, machines can be tailored for wet or dry polishing depending on the materials being processed and environmental safety standards. Safety and environmental considerations are integral to the design. The enclosed structure of many rotary systems not only protects operators from direct exposure to moving parts and flying debris but also facilitates effective dust and fume extraction. Many machines are also designed to handle combustible dust safely, especially when processing materials like aluminum or magnesium, which pose explosion risks if not properly managed.

The choice of abrasives and compounds is another critical aspect of performance. Coarse abrasives are used for initial surface leveling and defect removal, while finer compounds are employed in later stages to achieve high-gloss or mirror finishes. In some high-precision applications, such as polishing medical implants or optical components, special polishing slurries or chemical-mechanical processes may be used. Maintenance of rotary table polishing machines involves regular inspection of polishing heads, replacement of worn abrasives, lubrication of moving parts, and cleaning of dust filters and extraction ducts. Advanced models may include sensor-based monitoring systems that provide real-time feedback on wear and performance, enabling predictive maintenance and minimizing unplanned downtime.

Modern rotary polishing machines are increasingly equipped with smart features that support Industry 4.0 integration. These include data logging, remote diagnostics, and process optimization based on historical performance. They can also interface with factory-level MES (Manufacturing Execution Systems) or ERP (Enterprise Resource Planning) software, allowing seamless integration into broader production workflows. The flexibility, precision, and efficiency of rotary table polishing machines make them a vital asset in any manufacturing process where surface quality is paramount. Their ability to deliver consistent, repeatable results while minimizing operator involvement and maximizing output makes them one of the most preferred systems for large-scale and high-value production environments.

Beyond the mechanical and operational advantages, rotary table polishing machines contribute significantly to improving overall product quality and brand perception. A polished, uniform finish not only enhances the visual appeal of a component but can also increase its functional value by reducing friction, preventing corrosion, and improving cleanliness, especially in industries with stringent hygiene standards such as medical, food processing, and pharmaceuticals. The machine’s precision ensures that every part, whether it’s a surgical instrument or a decorative hardware fitting, meets the exact same specifications, supporting rigorous quality control systems like ISO 9001 and similar standards.

One of the key factors contributing to the widespread adoption of rotary table polishing machines is their adaptability. With interchangeable tooling and programmable settings, the same machine can be configured to process a wide variety of materials including stainless steel, brass, aluminum, titanium, and even non-metallic items like plastic or composite parts in specialized applications. This versatility is particularly valuable in industries with diverse product lines or in job-shop environments where flexibility is essential. Machine builders often offer customized solutions that include specific jigs and fixtures tailored to unique part geometries, ensuring maximum surface contact during the polishing process for optimal results.

Another major area where rotary table polishing machines shine is in labor efficiency. Traditional manual polishing is highly labor-intensive, requiring skilled technicians to maintain consistent pressure and angle, which is not only time-consuming but also physically demanding. Over time, this can lead to fatigue-related quality fluctuations and potential repetitive strain injuries. In contrast, a rotary table machine automates these repetitive motions, reducing the need for direct manual intervention and freeing up skilled labor for more value-added tasks like inspection, programming, or maintenance. This not only boosts overall productivity but also makes the polishing process more ergonomic and sustainable for manufacturers.

The environmental aspect of polishing operations has also come under increased scrutiny, especially with rising global emphasis on green manufacturing. Rotary table polishing machines help address these concerns by enabling more efficient use of materials and compounds, reducing wastage through controlled dispensing systems, and offering better containment of dust and emissions. With integrated filtration systems, manufacturers can ensure compliance with environmental regulations while maintaining a cleaner, safer working environment. Moreover, some modern machines are being designed with energy-efficient motors and components that contribute to lower overall power consumption and operational costs.

From a financial standpoint, while the initial investment in a rotary table polishing machine can be significant, the long-term return on investment (ROI) is often highly favorable. This is due to the combination of reduced labor costs, higher throughput, improved product quality, and fewer reworks or rejects. In highly competitive markets where visual appeal and durability can make or break a product, the ability to deliver flawless finishes reliably and at scale becomes a powerful differentiator. For OEMs and subcontractors alike, such machines can open doors to new contracts, premium product segments, and stricter industry sectors that demand consistent surface performance.

Looking forward, innovations continue to push the capabilities of rotary polishing systems. Developers are exploring the use of AI-based process optimization, where machine learning algorithms analyze polishing results and adjust machine parameters in real time for continuous improvement. Robotic integration is also evolving, allowing robots not just to load and unload parts but also to perform intelligent in-process repositioning of workpieces for optimal surface coverage. Some advanced models even feature automated vision systems to inspect polished parts before unloading, eliminating defective items from the line without operator involvement.

In summary, the rotary table polishing machine stands as a cornerstone of modern surface finishing technology. It blends mechanical precision, automation, and versatility in a compact, efficient system capable of handling high-volume production with minimal variation. As industries continue to demand higher standards of appearance, performance, and cleanliness, rotary table polishers will remain indispensable tools, continually evolving to meet the needs of advanced manufacturing environments.

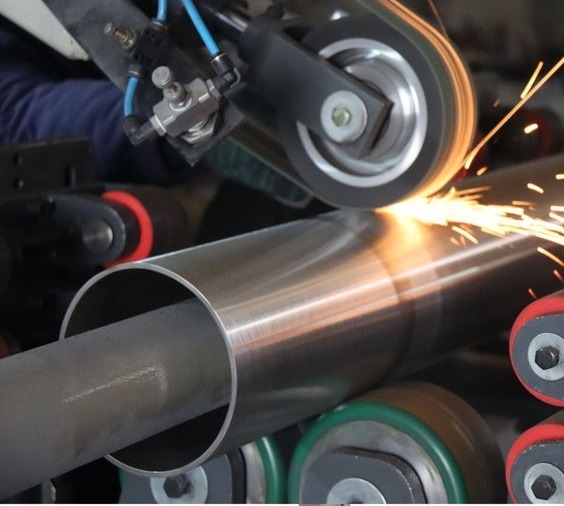

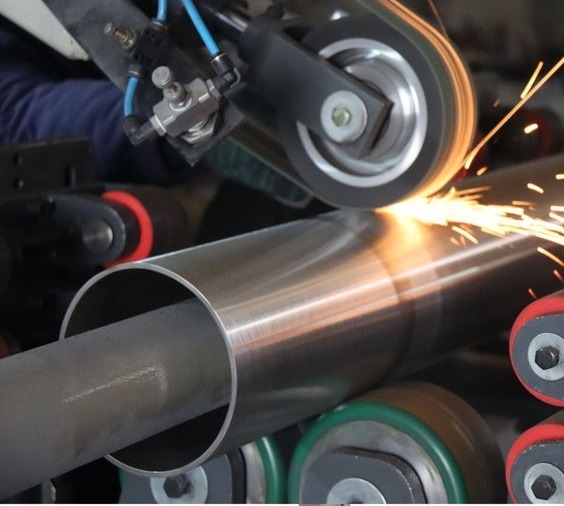

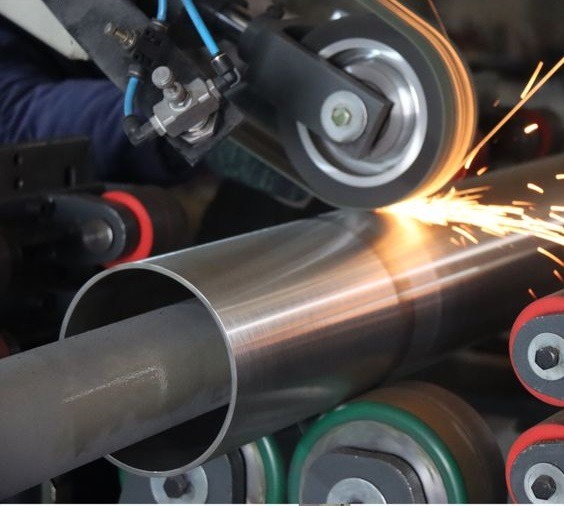

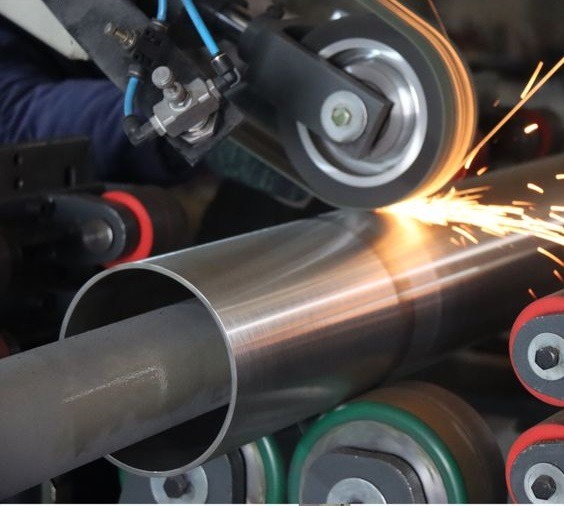

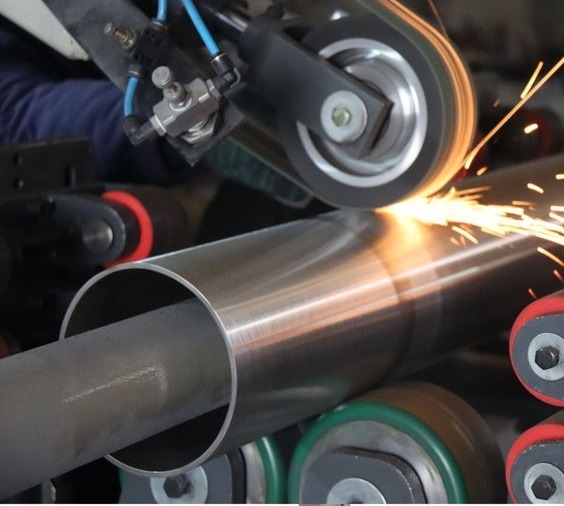

Belt Polishing Machine

A Belt Polishing Machine is a widely used surface finishing system designed to polish, grind, or finish metal and non-metal components using an abrasive belt. Unlike rotary or wheel-based polishers, belt polishing machines use a continuous abrasive loop (belt) that moves over rollers or a platen, allowing for high-speed, linear polishing. These machines are valued for their versatility, efficiency, and ability to produce uniform surface finishes across flat, curved, and complex surfaces. They are especially useful in both manual and automated industrial applications where speed and precision are required.

The basic structure of a belt polishing machine consists of a motor-driven belt assembly mounted on a rigid frame. The belt is tensioned between two rollers—one driven by a motor and the other acting as an idler. In many cases, additional contact wheels or platens are incorporated beneath the belt to provide consistent backing and pressure during polishing. Depending on the application, the belt can be positioned horizontally, vertically, or at an angle. Belt speeds and pressure can be adjusted to suit different materials and polishing requirements. In more advanced systems, variable frequency drives (VFDs) allow fine-tuning of speed for better control over the finish quality.

One of the defining features of belt polishing machines is the choice of abrasive belts. These belts come in a wide range of grit sizes and materials, including aluminum oxide, zirconia alumina, silicon carbide, and ceramic abrasives. Coarse belts are used for heavy stock removal or descaling, while fine belts are used for surface refinement and pre-polishing. For ultra-fine finishing or mirror effects, polishing compounds can be applied alongside non-woven or cloth-backed belts. The ability to swap belts quickly and easily makes the machine adaptable for multi-stage processes without requiring different tools.

Belt polishing machines come in many formats. Bench-top models are used for smaller parts and manual operations, while standalone floor models offer higher power and throughput. Backstand belt grinders are a popular variant in workshops for deburring, shaping, and polishing parts of various sizes. Wide belt polishers, used in sheet metal processing, can handle large flat panels with excellent uniformity. In automated production lines, belt polishing heads may be mounted on robotic arms or integrated into conveyor systems to handle repetitive, high-volume polishing tasks.

In terms of application, belt polishing machines are found across numerous industries. In metal fabrication, they’re used to remove mill scale, weld seams, and scratches from steel, stainless steel, and aluminum parts. In the automotive sector, they polish body components, bumpers, and engine parts. The aerospace industry uses them to prepare surfaces for coatings and ensure fatigue resistance. Cutlery, cookware, hand tools, and decorative hardware are also polished using belt systems for that final aesthetic finish. Even wood, plastic, and composite parts can be polished using belt systems with the right belt type and speed control.

The machines are appreciated for their uniform surface coverage, which reduces the risk of over-polishing or inconsistent finish—a common challenge in manual buffing. The linear motion of the belt makes it ideal for removing lines and creating directional grain finishes like satin or brushed textures. Additionally, the belt’s continuous motion helps dissipate heat more effectively than a wheel, reducing the risk of overheating or warping the workpiece.

Maintenance is relatively straightforward but important to preserve machine performance. Belts should be checked regularly for wear or clogging and replaced as needed. Rollers, bearings, and tension systems need to be cleaned and lubricated periodically. Dust collection is essential, as the belt action generates fine metal particles; most industrial models come with built-in or attachable dust extraction systems to keep the workspace safe and clean. Proper guarding and safety features—like emergency stops and overload protection—are standard and must be maintained to meet safety regulations.

Modern belt polishing machines may include automation features, such as digital control panels, touchscreens, programmable settings, and even integration with robotic or CNC systems. These improvements help reduce setup times, improve repeatability, and ensure high-quality finishes in complex production environments. For companies looking to modernize, there are options to retrofit older belt polishers with digital drives or sensors for process control and feedback.

In summary, the belt polishing machine remains one of the most versatile and indispensable tools in surface finishing. Its ability to combine high material removal rates with precision and surface refinement makes it ideal for a wide range of industries. Whether used manually by a skilled operator or integrated into an automated line, this machine delivers fast, reliable, and consistent finishes, making it a key asset in modern manufacturing and fabrication operations.

A belt polishing machine is a highly efficient and adaptable surface finishing tool designed to polish, smooth, or grind a wide variety of materials, most commonly metals. The core of the system is a continuously looping abrasive belt that moves at high speed over a series of rollers, allowing for linear contact with the workpiece. This setup enables the machine to deliver uniform surface finishes across both flat and contoured surfaces, making it especially useful in industries that demand precision, speed, and repeatability. The belt’s abrasive action can be used for both aggressive material removal and delicate surface refinement, depending on the grit of the belt and the pressure applied.

These machines come in a range of configurations, from compact bench-mounted units to large industrial systems integrated into production lines. At the heart of every machine is a motorized drive roller that propels the abrasive belt, an idler roller for tensioning, and often a contact wheel or platen behind the belt to provide support during polishing. The belts themselves are available in various grit sizes and abrasive materials such as aluminum oxide, silicon carbide, zirconia, and ceramic, each chosen based on the specific material and finish requirements of the part being processed. This variety gives operators significant control over the finishing outcome, whether it’s for heavy deburring, satin finishing, or mirror polishing.

Belt polishing machines are extremely versatile and can be adapted to different working positions—horizontal, vertical, or angled—to suit a range of part shapes and sizes. In many systems, adjustable arms or tilting heads provide access to hard-to-reach surfaces and edges. For manual applications, operators hold the workpiece against the moving belt, while in automated systems, the workpiece may be guided beneath the belt by conveyors, robots, or pneumatic actuators. The simplicity and reliability of the belt mechanism, combined with the ease of changing belts for different tasks, make these machines a staple in both custom workshops and high-volume industrial facilities.

Their applications are extensive and span multiple industries. In metal fabrication, they are used for deburring, descaling, and surface preparation of steel and aluminum parts. In the automotive sector, belt polishers are employed for finishing components like bumpers, exhaust parts, and trim. The kitchenware industry relies on them to polish stainless steel pots, pans, and utensils. In aerospace and defense manufacturing, the machines prepare surfaces to meet exacting specifications for coatings and fatigue resistance. Even wood, composites, and plastic parts can be processed with specialized belts designed for non-metallic materials, further highlighting the machine’s adaptability.

One of the most notable advantages of the belt polishing machine is its ability to produce consistent, directional finishes such as satin or brushed textures. The linear motion of the belt naturally imparts a uniform grain pattern, which is difficult to achieve using rotating wheels. Additionally, the belt’s continuous movement helps to dissipate heat, reducing the risk of thermal damage or distortion to sensitive workpieces. This thermal efficiency, combined with adjustable speed controls, allows the machine to work effectively across a range of materials and thicknesses without sacrificing surface integrity.

From a safety and maintenance perspective, belt polishing machines are generally easy to manage. Most models come with integrated guards, spark containment features, and dust extraction ports to control airborne particles. Routine maintenance includes checking the condition of the belts, inspecting bearings and rollers, and ensuring proper belt tracking and tension. In high-volume production environments, machines may be equipped with monitoring systems that track belt wear and alert operators when a change is needed, minimizing downtime and preventing damage to parts or equipment.

Technological advancements have enhanced the performance and functionality of belt polishing machines. Today, many industrial units feature programmable logic controllers (PLC), digital touch interfaces, and even integration with robotic systems for automatic loading, positioning, and unloading. These smart machines can store multiple polishing recipes, adapt in real time to different part geometries, and maintain consistent quality with minimal operator intervention. Additionally, energy-efficient motors and regenerative braking systems help reduce the environmental footprint and operational costs of these machines.

The economic benefits of belt polishing machines are significant. Their ability to perform fast, consistent finishing reduces manual labor, increases throughput, and minimizes material waste. They help manufacturers meet tight tolerances and aesthetic standards with minimal rework, which is essential in competitive markets. Whether used in batch production or as part of a continuous finishing line, belt polishing machines offer the kind of performance, flexibility, and reliability that modern manufacturers demand.

The belt polishing machine also stands out in terms of its adaptability to various polishing and finishing needs. While some systems are designed for specific tasks like heavy deburring or coarse grinding, others are equipped to handle fine polishing or even mirror finishes, depending on the type of abrasive belt used. For example, a coarse grit belt might be employed for removing heavy oxidation or rust from metal surfaces, while a fine grit belt can be used for achieving a smooth, even surface ideal for decorative purposes. In industries where aesthetic quality is paramount, such as in the production of kitchenware, bathroom fittings, or automotive parts, belt polishing machines can create uniform, high-gloss finishes that enhance the appearance and durability of the product.

The efficiency of the belt mechanism makes it an attractive choice for mass production as well as for custom or low-volume jobs. In high-volume manufacturing, the ability to continuously feed parts into the system or use automated conveyors for part handling means that manufacturers can significantly reduce cycle times. This increased throughput is crucial in industries where tight production schedules and high output are essential for meeting market demands. Automated belt polishing systems, integrated into conveyor lines or robotic cells, can polish large numbers of parts with consistent quality, which is especially important for products that require a flawless finish across thousands of identical units.

In job shops or environments where parts vary greatly in size or complexity, a belt polishing machine offers exceptional flexibility. With the ability to change belts easily and adjust operational parameters such as speed, pressure, and angle, manufacturers can quickly switch between different tasks. For instance, one machine might be used to polish decorative trim one day, then switch to deburring complex aerospace components the next. This flexibility helps reduce the need for multiple machines, ultimately saving on equipment costs, floor space, and training time for operators.

Furthermore, belt polishing machines are highly customizable to meet specific production needs. Manufacturers can opt for specialized accessories like vacuum systems to enhance dust extraction, coolant delivery systems for wet polishing, and specially designed contact wheels for unique finishes. For example, a contact wheel with a soft rubber coating may be used in delicate applications to prevent damage to the workpiece, while harder contact wheels might be used for high-pressure grinding or finishing tasks. This level of customization makes the belt polishing machine a valuable tool across industries like aerospace, medical device manufacturing, electronics, and automotive where precision, surface quality, and material integrity are key.

In terms of material versatility, belt polishing machines are highly effective on a wide range of materials. While they are most commonly used for metals such as steel, stainless steel, aluminum, and brass, they are also effective on plastics, composites, and wood when paired with the appropriate abrasives. For example, in the wood industry, belt polishing is used to smooth surfaces and create an attractive finish for furniture, cabinetry, and flooring materials. Similarly, plastic and composite parts can be polished to remove marks, smooth edges, and enhance visual appeal without compromising the material’s integrity.

Despite all the advantages, operators must be aware of some challenges associated with belt polishing machines. Over time, abrasive belts wear out, and their performance can degrade if not regularly replaced or maintained. Belt tracking and tensioning also need to be carefully managed to prevent issues such as misalignment or premature wear. A poorly tensioned belt can cause uneven polishing, while a misaligned belt can damage both the machine and the workpieces. Regular maintenance of the tensioning system, the rollers, and the drive mechanisms ensures the machine operates smoothly and efficiently over time.

In addition to maintenance, it’s essential to consider operator safety when working with belt polishing machines. While most machines come with built-in safety features like emergency stop buttons and protective guards, the high-speed operation and the dust generated by abrasive belts require caution. Proper training for operators is essential to ensure they understand how to use the machine safely, as well as how to perform routine maintenance and change belts. Furthermore, implementing dust collection systems is critical not only to maintain a clean work environment but also to comply with health and safety regulations, especially when polishing metals that generate harmful dust.

Finally, sustainability has become an important consideration for modern manufacturing equipment. Belt polishing machines are no exception, as manufacturers are increasingly looking for ways to reduce energy consumption and waste. Many newer models feature energy-efficient motors and advanced dust extraction systems that minimize power usage and reduce the environmental impact of operations. Additionally, the ability to reuse or recycle certain types of abrasives, combined with innovations in cleaner compound dispensing, is helping to make the polishing process more eco-friendly.

In conclusion, the belt polishing machine is a versatile, reliable, and highly efficient tool for achieving superior surface finishes across a wide variety of materials. Whether in high-volume manufacturing, specialized custom work, or automated production lines, its flexibility and adaptability make it an essential part of many industries. The ability to achieve fine finishes consistently, coupled with the ease of maintenance and integration with other automated systems, ensures that the belt polishing machine will continue to be a key asset in modern manufacturing environments. As technologies evolve, further improvements in automation, energy efficiency, and sustainability will likely expand the capabilities and application of these machines, making them even more indispensable in the future of surface finishing.

Disc Polishing Machine

A Disc Polishing Machine is a versatile surface finishing tool used to polish, smooth, and refine the surfaces of various materials, typically metals, but also plastics, ceramics, and composites. It operates through the use of a rotary disc mounted on a motorized spindle, which rotates at high speeds while the workpiece is pressed against it or moved across its surface. The machine’s primary function is to achieve high-quality finishes, such as mirror-like surfaces or fine, satin textures, with minimal effort compared to manual polishing.

The core component of a disc polishing machine is the rotating disc, which can be made from various materials, depending on the application. For example, cloth-backed discs are commonly used for final polishing stages, while non-woven abrasive discs might be used for finer smoothing, or resin-bonded abrasive discs for more aggressive grinding tasks. The disc can be treated with specialized polishing compounds to achieve the desired finish. As the disc spins, the abrasive action removes material from the workpiece, smoothing out imperfections and scratches to create a refined surface.

A disc polishing machine generally consists of a few key parts: the rotating disc or wheel, the motor or drive mechanism that powers the disc, and the support structure or frame. The workpiece is either manually placed against the rotating disc or automated systems are used to feed and position parts precisely in industrial settings. Pressure and speed settings can be adjusted based on the material being worked on and the type of finish desired. Higher speeds are generally used for rough polishing and material removal, while lower speeds are ideal for final finishing and achieving a high-gloss surface.

These machines are often equipped with dust collection systems to handle the debris produced during the polishing process. The polishing action creates a significant amount of dust, particularly when working with metals like aluminum or steel. Effective dust extraction systems are essential for maintaining a clean working environment, reducing the risk of respiratory issues, and complying with health and safety standards.

Disc polishing machines come in different configurations, such as bench-mounted models for smaller parts and tasks, and floor-standing models designed for larger, heavier components. In industrial applications, dual-disc or multi-disc machines are used to achieve higher throughput, as they can polish multiple parts simultaneously, improving efficiency and reducing cycle times. Some models also feature adjustable heads or tilting mechanisms, which allow operators to adjust the angle at which the workpiece meets the polishing disc, providing greater flexibility for different part shapes.

The most common applications of disc polishing machines are found in industries like metalworking, where they are used for deburring, polishing, and finishing stainless steel, aluminum, and brass parts. They are also widely used in the automotive industry to polish automotive trim, wheels, and engine components. Jewelry manufacturing, electronics, and aerospace industries rely on disc polishing for fine-tuning finishes on parts and components where precision and appearance are critical. Disc polishers are also essential in the manufacture of kitchenware, where items like cookware and cutlery are polished to a high shine.

The benefits of using disc polishing machines are numerous. One of the primary advantages is the consistent, repeatable finishes they provide. Because the machine is designed to apply uniform pressure and speed, it delivers consistent results across multiple parts, which is crucial in high-volume production environments. The use of specific polishing compounds allows for a wide range of surface finishes, from a dull matte to a high-gloss shine, depending on the desired end result. Additionally, the efficiency of disc polishing machines makes them ideal for both small-scale workshops and large-scale manufacturing operations, reducing labor costs and improving throughput.

Maintenance of a disc polishing machine is relatively simple but essential to ensure long-lasting performance. Regular checks should be made to ensure that the disc is free from any damage, cracks, or excessive wear. Over time, polishing discs can become clogged with polishing compounds or particles, so cleaning them regularly is important. The motor and other moving parts should also be lubricated as per the manufacturer’s guidelines to prevent excessive wear and ensure smooth operation.

Safety is an important consideration when using disc polishing machines, particularly because the high-speed rotating discs can be hazardous. Operators should be properly trained in handling the machine, and personal protective equipment (PPE) such as gloves, safety glasses, and dust masks should always be worn. Furthermore, ensuring that the machine is equipped with safety guards and emergency shut-off switches is crucial to prevent accidents.

In addition to basic polishing functions, many modern disc polishing machines come with advanced features like programmable settings for automated control over speed, pressure, and polishing time. Some systems even integrate with robotic arms or conveyors, making them ideal for fully automated production lines where high precision and repeatability are necessary. Integration with CNC controls or PLC systems can further enhance the machine’s versatility, allowing it to adapt quickly to different part sizes and specifications without requiring manual intervention.

Overall, the disc polishing machine is an invaluable tool in the manufacturing and surface finishing world. It combines efficiency, precision, and flexibility to produce high-quality, aesthetically pleasing finishes on a wide range of materials. Whether used in small-scale workshops or large industrial settings, disc polishing machines help manufacturers meet the rigorous demands of modern production, reducing labor costs, minimizing defects, and ensuring consistent quality across parts.

The disc polishing machine is one of the most effective tools for achieving consistent and high-quality surface finishes across various materials. Its basic design—comprising a rotating disc and a motor that drives it—allows for efficient polishing, smoothing, and even light grinding. The rotating disc can be made from a variety of materials such as cloth, paper, rubber, or resin-bonded abrasives, depending on the required finish and material of the workpiece. When polishing, the abrasive surface of the disc removes material from the surface of the workpiece, reducing imperfections, scratches, and other surface defects. The pressure applied to the workpiece, the speed of the disc, and the type of abrasive used all influence the quality of the finish, which can range from matte to high-gloss.

The disc polishing machine offers flexibility in terms of the types of finishes it can produce. For instance, in metalworking applications, it is commonly used for removing oxidation, rust, or scale from metals like stainless steel, aluminum, and brass. The machine’s ability to create smooth, even finishes makes it particularly valuable for industries where the appearance and surface integrity of the final product are critical, such as in the automotive, aerospace, electronics, and jewelry industries. Whether the goal is to create a brushed finish on automotive trim or a shiny surface on jewelry, the disc polishing machine can adapt to various polishing requirements, providing consistent, repeatable results with minimal effort.

In mass production environments, the disc polishing machine stands out due to its speed and efficiency. For example, in the production of cutlery or cookware, a disc polishing machine can significantly reduce the time and labor required for polishing large quantities of parts. The ability to adjust parameters such as speed and pressure means operators can easily tailor the polishing process to suit the material being worked on, whether it’s for light deburring or high-gloss finishing. This efficiency helps manufacturers meet tight production schedules and maintain high throughput while ensuring consistent quality. In automated systems, the disc polishing machine can be integrated into conveyor lines or robotic arms, further enhancing productivity by reducing manual intervention.

Cleaning and maintenance of the machine are important to ensure long-term performance. Over time, polishing discs may become clogged with compounds or particles, requiring regular cleaning to maintain their effectiveness. The machine’s motor, drive system, and other moving parts should also be maintained according to the manufacturer’s instructions to avoid wear and tear. Regular checks of the disc alignment, belt tension, and abrasive wear can prevent defects from affecting the surface finish and ensure smooth operation.

Safety is another critical factor when using a disc polishing machine. The high-speed rotating discs can pose risks to operators, especially if safety precautions are not followed. Wearing appropriate PPE (personal protective equipment) such as gloves, safety glasses, and dust masks is essential. Machines should be equipped with safety guards to prevent accidental contact with the rotating disc, and emergency shut-off switches should be readily accessible in case of malfunction. For systems with automated or robotic components, ensuring that these features are properly safeguarded is critical to preventing accidents.

In recent years, technological advancements have made disc polishing machines even more capable and efficient. Many models now include digital controls, allowing operators to set precise polishing parameters such as speed, pressure, and time. These machines may also come with automated feedback systems, ensuring that the polishing process is continuously adjusted for optimal performance. Some models incorporate CNC or PLC controls, enabling highly automated operations where the machine can be programmed to handle different parts and finishes with minimal human intervention.

Another exciting development is the integration of disc polishing machines with robotic systems. This automation reduces the need for manual labor and improves the consistency of the finish. Robotic arms equipped with specialized grippers can load and unload parts, while sensors and vision systems ensure that parts are positioned correctly for consistent polishing. This level of automation is especially useful in industries like aerospace and automotive, where precision and repeatability are vital.

The environmental impact of disc polishing machines is also a growing concern in modern manufacturing. Dust created during polishing can be hazardous to operators’ health, as well as to the environment. As a result, many newer machines are equipped with advanced dust collection systems to capture and contain airborne particles. Additionally, energy-efficient motors and controls are being incorporated into newer models to reduce energy consumption. The use of eco-friendly polishing compounds and reusable abrasives is also on the rise, further reducing the machine’s environmental footprint.

The versatility, efficiency, and precision of disc polishing machines make them an essential tool for many industries. Whether used for light polishing in custom workshops or as part of high-speed automated production lines, these machines offer a flexible and reliable solution for creating polished, smooth, and aesthetically pleasing finishes. Their ability to produce high-quality results consistently, combined with their adaptability to different materials and finishes, makes them a go-to choice for both small-scale and large-scale manufacturing environments. As new technologies emerge, these machines are expected to become even more efficient, user-friendly, and environmentally sustainable, solidifying their position as an indispensable tool in surface finishing applications.

As disc polishing machines continue to evolve, their capabilities expand in response to growing demands for precision, speed, and sustainability. Manufacturers are increasingly looking for ways to optimize production and reduce operational costs while maintaining high-quality finishes. This has led to the development of advanced automation and smart technologies that enhance the efficiency of disc polishing machines even further.

One area of improvement is the integration of adaptive control systems, which enable the machine to automatically adjust parameters like speed, pressure, and polishing time in real-time. These systems use sensors and feedback loops to monitor the polishing process, ensuring that the finish remains consistent across all parts, even as variables like material hardness or part geometry change. For example, in situations where the workpiece has an uneven surface or varies in thickness, the machine can automatically modify the polishing action to maintain an even finish, reducing the need for manual intervention and improving overall throughput.

Another trend in the evolution of disc polishing machines is the use of robotic arms for part handling and precision placement. Automated systems equipped with robotic arms can perform precise loading and unloading of workpieces, as well as fine-tune the positioning of each part during polishing. This integration helps eliminate human error and ensures that parts are polished uniformly, even in high-volume, continuous production environments. The ability to program these systems with specific polishing routines makes it easier to switch between different tasks, such as polishing different types of materials or creating various surface finishes, without having to reset or recalibrate the entire system.

In multi-disc systems, where several polishing discs are used simultaneously, automation plays a critical role in optimizing efficiency. These systems allow for the polishing of multiple parts at once, increasing throughput and reducing cycle times. When combined with automated part handling systems, multi-disc polishing machines can operate with minimal downtime, processing large batches of components with precision and consistency.

Moreover, data analytics and predictive maintenance are making their way into the disc polishing process. Manufacturers can now track machine performance and collect data on key operational parameters such as belt wear, motor efficiency, and polishing time. Using this data, machine operators can anticipate maintenance needs, reducing unexpected downtime and avoiding costly repairs. Predictive maintenance systems can send alerts when parts are nearing the end of their useful life, enabling operators to replace worn components before they cause issues. This proactive approach helps maintain optimal performance while reducing maintenance costs and increasing machine longevity.

The growing emphasis on sustainability has also spurred innovations in the disc polishing machine market. To address environmental concerns, manufacturers are designing machines that are more energy-efficient, using less power while still maintaining high performance. Some newer models incorporate energy-saving features, such as variable-speed drives and more efficient motors, which reduce electricity consumption. Additionally, the integration of eco-friendly abrasives and polishing compounds that are less harmful to the environment is becoming more common, aligning with the broader industry trend of reducing the carbon footprint of manufacturing processes.

Dust control systems have also seen significant improvements. Older models often relied on simple filters or basic collection mechanisms, which could be inefficient and ineffective in fully capturing harmful particles. Modern disc polishing machines are equipped with high-efficiency dust extraction systems that trap fine particles at the source, preventing them from becoming airborne and contaminating the workspace. These systems often include advanced HEPA filters, which can capture even the smallest particles, ensuring a safer and cleaner working environment for operators.

For industries that require specialized polishing finishes, such as in the aerospace and medical device sectors, disc polishing machines are now designed with greater flexibility. For example, some machines feature adjustable polishing heads that can tilt or rotate to accommodate different part geometries, ensuring that all surfaces—whether flat, curved, or intricate—receive an even finish. These machines can also handle delicate materials like titanium, which is commonly used in the medical field, or exotic alloys used in aerospace applications, without compromising the integrity of the material.

In the jewelry industry, where achieving a flawless surface finish is crucial for both aesthetic and functional reasons, the need for high precision has led to the development of fine polishing machines with extremely high-speed disc rotation. These machines can polish even the most intricate designs, ensuring that no part of the jewelry is overlooked. Additionally, they can achieve mirror-like finishes with minimal effort, making them ideal for processing fine metals like gold, silver, and platinum.

The automotive industry, particularly in the manufacture of exterior trim, wheels, and engine parts, has also benefited from advancements in disc polishing machines. These machines can handle both large and small components with ease, providing an impeccable finish that not only enhances the appearance of the vehicle but also improves corrosion resistance by creating smoother surfaces that are less prone to collecting dirt and moisture. Advanced disc polishing systems can also work with painted or coated surfaces, ensuring that the final finish matches the manufacturer’s high standards.

In research and development, disc polishing machines are used for a variety of applications, including the preparation of specimens for analysis. These machines can be used to polish materials for microscopic examination, ensuring that the surface is free of scratches and imperfections that might interfere with the study of microstructures.

The future of disc polishing machines looks promising, with advancements in automation, data-driven optimization, and sustainability paving the way for more efficient and eco-friendly manufacturing. As the demand for precision and quality continues to grow, these machines will evolve to meet the needs of increasingly diverse industries, helping manufacturers stay competitive in a global market.

In conclusion, disc polishing machines are an integral part of many industries, offering versatility, efficiency, and precision in the surface finishing process. Their ability to adapt to a wide range of materials and applications, coupled with advancements in automation, predictive maintenance, and environmental sustainability, ensures their continued relevance and importance in modern manufacturing. Whether for small-scale production or high-volume industrial operations, the disc polishing machine remains a cornerstone in the pursuit of perfect finishes.

Brush Polishing Machine

A Brush Polishing Machine is a specialized surface finishing tool primarily used to polish, deburr, and clean parts made from metals, plastics, and other materials. Unlike other polishing machines that use abrasive discs or belts, brush polishing machines utilize rotating brushes that can be made of different materials, including nylon, steel, or synthetic fibers, depending on the task at hand. These brushes are designed to produce a smooth and uniform finish on various surfaces, making them especially suitable for tasks like removing rust, smoothing rough edges, or achieving specific textures on workpieces.

The machine generally consists of one or more rotating brush heads, a motor that drives the brushes, and a mechanism to hold or move the workpiece. The brushes rotate at high speeds, and the workpiece is either fed manually or automatically to the brushes. The pressure applied by the brush to the workpiece, combined with the speed and type of brush used, determines the level of polishing or cleaning achieved. Brush polishing machines are often used for fine surface finishing, where an abrasive disc might be too aggressive or too coarse for the desired result.

One of the key advantages of using a brush polishing machine is its ability to achieve specific textures and finishes. For instance, circular or linear brushing can be used to produce specific grain patterns on metal surfaces, often seen in industries like architectural metalwork and automotive manufacturing. The use of wire brushes, in particular, is common for heavy-duty tasks like removing corrosion, rust, or oxide layers from metal parts. Wire brush polishing is also effective for cleaning parts like pipes or engine components, ensuring that they are ready for further processing, such as coating, painting, or welding.

In the metalworking industry, brush polishing machines are commonly used to clean or finish stainless steel, aluminum, and other metals that require a uniform appearance. Stainless steel is particularly popular in industries such as kitchenware, medical devices, and aerospace, where the surface finish is crucial not only for aesthetics but also for corrosion resistance and hygienic properties. The brush polishing process can help maintain a smooth, matte, or satin finish without the risk of over-polishing that might occur with traditional abrasive tools. Additionally, because the brushes can be softer than abrasive belts or discs, delicate surfaces are less likely to be damaged during the polishing process.

Brush polishing machines are available in various configurations, from bench-top models for small parts or low-volume tasks to large, automated systems that can polish numerous pieces simultaneously in high-volume production settings. These machines can be designed with multiple brush heads, each capable of different types of polishing, allowing for simultaneous multi-stage finishing. For example, one set of brushes might be used for rough cleaning and deburring, while another set could provide the final polish. This multi-stage process reduces cycle times and enhances efficiency, particularly in environments where speed is crucial.

The machine can also be equipped with features like adjustable speeds to accommodate different materials and desired finishes. For example, when working with softer metals like aluminum, slower speeds may be used to ensure a smooth, uniform finish without causing gouging or scratches. On the other hand, harder materials may require higher speeds or more aggressive brushes for effective polishing. Variable pressure settings allow the operator to control the amount of force applied to the workpiece, further enhancing the machine’s versatility.

A notable benefit of brush polishing machines is their ability to remove burrs, oxidation, and other surface contaminants from parts that are difficult to process with other polishing methods. This feature makes them an essential tool in industries such as automotive, where engine components or chassis parts must be deburred or smoothed to remove any sharp edges or imperfections that could affect performance or safety. The ability to effectively remove oxidation is also valuable in the electronic and aerospace sectors, where the integrity of parts must be preserved, and any contamination could affect the quality of the final product.

Brush polishing machines are also highly adaptable to different materials and shapes. For example, they can be used for polishing flat surfaces, curved components, or even intricate parts with detailed geometries, such as in jewelry or medical device manufacturing. This flexibility makes them suitable for a broad range of applications, from fine polishing to more aggressive deburring or cleaning tasks. In many cases, they are used in combination with other polishing methods, such as belt or disc polishing, to achieve a higher level of surface quality.

Dust control is an important consideration when using brush polishing machines, especially in industrial settings where large quantities of material are processed. The polishing process generates a significant amount of dust, particularly when working with metals. To address this, many brush polishing machines are equipped with integrated dust collection systems that capture airborne particles and direct them into a containment unit. These systems help maintain a clean working environment, improve air quality, and protect operators from harmful exposure to fine dust particles.

Safety is another important aspect of using brush polishing machines. While they are generally safer than machines that use more aggressive abrasive methods, operators should still follow safety guidelines. Protective guards around the brush heads are essential to prevent accidents caused by flying debris or accidental contact with the rotating brushes. Operators should also wear personal protective equipment (PPE), including gloves, safety glasses, and dust masks, to minimize the risk of injury and exposure to harmful dust.

In addition to their application in metalworking, brush polishing machines are also used for surface finishing in plastic and woodworking industries. For plastics, these machines can help remove marks, scratches, and imperfections that occur during the molding or fabrication processes, while in woodworking, they are used to create smooth, even finishes on furniture, cabinetry, and flooring. The versatility of brush polishing machines across different industries is a testament to their reliability and effectiveness as finishing tools.

In terms of maintenance, brush polishing machines are relatively easy to maintain compared to other types of polishing equipment. Brushes themselves will wear out over time and need to be replaced periodically, especially if they are used for heavy-duty tasks or on abrasive materials. Regular checks of the motor, brush heads, and dust extraction system are also essential to ensure that the machine operates at peak efficiency. Maintenance schedules and recommendations can vary based on the manufacturer and the specific model of the machine.

The future of brush polishing machines is likely to be shaped by further advancements in automation and intelligent controls. As industries continue to push for higher productivity and more consistent quality, the incorporation of smart sensors, data analytics, and machine learning will allow these machines to monitor and adjust the polishing process in real-time. These innovations will improve efficiency, reduce waste, and allow for greater precision in polishing a wide variety of materials.

In conclusion, brush polishing machines are an essential tool for achieving high-quality surface finishes in a variety of industries. Whether used for deburring, rust removal, or fine polishing, these machines provide a flexible, efficient, and safe solution for polishing a wide range of materials. With the ability to handle delicate surfaces, achieve specific textures, and remove contaminants, brush polishing machines continue to play a key role in both high-volume manufacturing and custom work environments.

Brush polishing machines are highly versatile tools that are designed to handle a wide range of surface finishing tasks across different industries. They are particularly useful for achieving smooth, uniform finishes on a variety of materials, including metals, plastics, and wood. By using rotating brushes made from materials like nylon, steel, or synthetic fibers, these machines can polish, deburr, clean, and texture parts to meet specific requirements.

One of the significant benefits of brush polishing machines is their ability to create specific textures on a workpiece’s surface. This is especially useful in industries where appearance and finish are crucial, such as in architectural metalwork or automotive manufacturing. The brushes can create distinctive grain patterns that are often desired in high-end metal products, from brushed finishes on stainless steel to satin or matte finishes. This method is especially favored for polishing materials like stainless steel, aluminum, and brass, which require a polished look that is resistant to rust and corrosion.

In metalworking, brush polishing is particularly advantageous because it is gentler than other abrasive methods. While abrasive discs or belt polishing machines may sometimes cause damage to delicate surfaces, brush polishing allows for more controlled abrasion, reducing the risk of scratches and gouges. This is particularly important in industries like aerospace, where metal components need to maintain their structural integrity while also having a smooth surface finish. The use of nylon or synthetic brushes makes this technique ideal for creating finishes on parts that need to undergo further processing, such as coating or welding, without compromising the quality of the material.

In addition to polishing, brush polishing machines are effective for cleaning and deburring. These machines are commonly used to remove oxidation, rust, paint, and other contaminants from surfaces. For instance, in the automotive industry, brush polishing is used to clean engine components, exhaust parts, and other metal components, ensuring they are free of rust or debris before they are further processed or painted. The abrasive nature of wire brushes allows them to remove tough contaminants like rust and grime without damaging the underlying material, making them essential tools for maintenance and repair work.

For applications in plastics and woodworking, brush polishing machines provide the same level of versatility. In plastics, they are used to smooth out surfaces that have become rough due to molding or fabrication processes. This ensures that the finished parts are ready for painting or coating without imperfections. Similarly, in woodworking, brush polishing machines are used to create smooth finishes on furniture, cabinetry, and flooring. These machines are also helpful in achieving specific effects, such as a rustic, weathered look in wood products.

The adaptability of brush polishing machines extends to different shapes and sizes of parts. They can be used to polish flat surfaces, curved components, or even intricate designs, such as those seen in jewelry or medical devices. This makes them a critical tool in custom work environments where precision and attention to detail are required. Multi-head polishing machines allow for simultaneous processing of multiple parts, improving productivity and reducing the time spent on individual polishing tasks.