We manufacture equivalent for AFACAN machine B18 rebar bending machine 220V to bend sheet metal edges. Hydraulic Press Machines are used in metalworking industries

The AFACAN machine B18 rebar bending machine is a specific model of a rebar bending machine designed for bending reinforcing steel bars (rebars). Here are some key details about the AFACAN machine B18 rebar bending machine:

- Capacity: The B18 model is capable of bending rebar with a maximum diameter of 18mm (or equivalent).

- Power Supply: The machine operates on a 220V electrical power supply, making it suitable for standard voltage requirements.

- Bending Mechanism: The machine utilizes a bending mechanism to bend the rebars into the desired shape or angle. It typically incorporates a bending head or roller that applies the bending force to the rebar.

- Control System: The machine may have manual or semi-automatic controls for operating and controlling the bending process. This could involve adjusting the bending angle, setting the bending radius, and controlling the bending speed.

- Portability: The AFACAN machine B18 rebar bending machine is often designed to be compact and portable, allowing for ease of transportation and use in various job sites or workshop environments.

- Safety Features: Rebar bending machines generally have safety features in place to protect the operator during operation. These may include emergency stop buttons, safety guards, and safety interlocks to prevent accidents and ensure safe operation.

It’s important to note that specific features and specifications may vary depending on the manufacturer and model of the AFACAN machine B18 rebar bending machine. It’s recommended to refer to the machine’s documentation or contact the manufacturer for detailed information regarding its capabilities, operating procedures, and any additional accessories or features available.

Additionally, when working with rebar bending machines or any machinery, it’s essential to follow proper safety guidelines, wear appropriate personal protective equipment, and receive proper training to ensure safe and efficient operation.

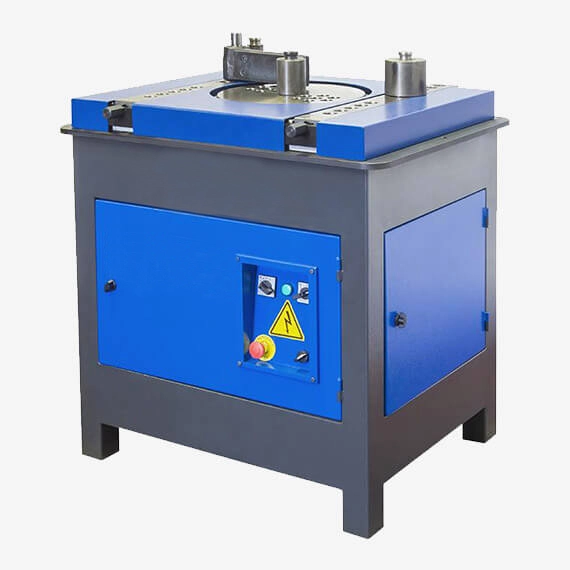

Rebar Bending Machine

The AFACAN B18 rebar bending machine is a portable, electric rebar bender that can bend rebar up to 18mm in diameter. It is a versatile and powerful machine that is ideal for a variety of applications, including residential, commercial, and industrial construction.

Here are some of the key features of the AFACAN B18 rebar bending machine:

- Portable and lightweight: The AFACAN B18 weighs only 70 kg, making it easy to transport and use on-site.

- Powerful motor: The 1.1 kW motor provides ample power to bend even the most stubborn rebar.

- Adjustable bending angle: The bending angle can be adjusted from 0 to 90 degrees, making it easy to bend rebar to the exact angle you need.

- Telescopic table: The telescopic table can be adjusted to accommodate different rebar lengths.

- Easy to use: The AFACAN B18 is easy to operate, even for novice users.

- Safe and durable: The AFACAN B18 is built with safety in mind and features a number of safety features, such as a voltage saving relay and a metal frame.

Here are some of the specifications of the AFACAN B18 rebar bending machine:

- Rebar diameter: 18mm

- Bending angle: 0-90 degrees

- Drive power: 1.1 kW

- Voltage: 220V

- Weight: 70 kg

- Dimensions (W/L/H): 450 x 550 x 750 mm

Overall, the AFACAN B18 rebar bending machine is a powerful, versatile, and easy-to-use machine that is ideal for a variety of applications. It is a great choice for contractors, builders, and DIY enthusiasts who need a reliable and affordable rebar bending machine.

EMS Metalworking Machinery

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

- Beading and ribbing

- Flanging

- Trimming

- Curling

- Lock-seaming

- Ribbing

- Flange-punching