Small Hydraulic Press Brake: A Press Brake Machine is a critical piece of equipment in the metalworking industry, primarily used for bending and shaping sheet metal into precise, predetermined forms. These machines are fundamental in manufacturing processes that require the formation of metal parts, ranging from simple brackets to complex components used in various industries, including automotive, aerospace, and construction.

At its core, a press brake operates by clamping a piece of sheet metal between a matching punch and die, which are tools specifically designed to create a particular bend. The machine applies a controlled force to the metal, deforming it along the desired bend line. The precision and accuracy of the bends produced by a press brake are essential, especially in industries where component tolerances are tight.

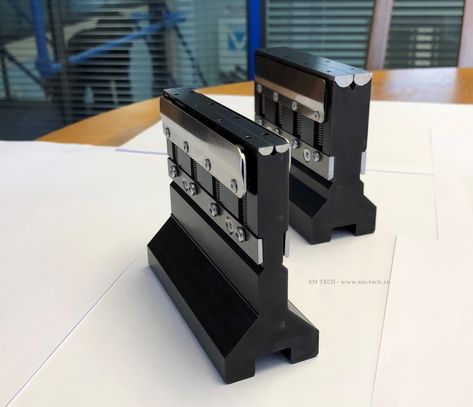

A Mini Press Brake is a compact, precision-based machine used for bending metal sheets or plates in metalworking processes. The term “press brake” generally refers to a machine tool that is used for bending sheet metal by pressing a workpiece between a punch and a die. The “mini” version of this machine offers the same functionalities but on a smaller scale, making it suitable for workshops, educational institutions, and other industries requiring precise, small-scale metal bending. The mini press brake provides all the essential characteristics of a traditional press brake but is designed for lighter loads and smaller projects.

The Evolution of Press Brakes

Press brakes have a long history, dating back to when blacksmiths used simple hammers to bend metal by hand. With industrialization, more efficient and powerful machines were developed to handle increasing demand for metal forming, especially in industries such as automotive, aerospace, and construction. Traditional press brakes are large, heavy-duty machines used for bending large sheets of metal into specific shapes. However, as technology advanced, the need for smaller, more precise bending machines led to the development of mini press brakes.

The mini press brake was born out of necessity for manufacturers who required precision but did not have the space or demand for a full-sized press brake. Small workshops, prototype developers, hobbyists, and educational institutions are now able to benefit from the high precision and efficiency of press brake technology without the large footprint and cost of larger machines.

A Mini Press Brake is a compact, precision-based machine used for bending metal sheets or plates in metalworking processes. The term “press brake” generally refers to a machine tool that is used for bending sheet metal by pressing a workpiece between a punch and a die. The “mini” version of this machine offers the same functionalities but on a smaller scale, making it suitable for workshops, educational institutions, and other industries requiring precise, small-scale metal bending. The mini press brake provides all the essential characteristics of a traditional press brake but is designed for lighter loads and smaller projects.

Press brakes have a long history, dating back to when blacksmiths used simple hammers to bend metal by hand. With industrialization, more efficient and powerful machines were developed to handle increasing demand for metal forming, especially in industries such as automotive, aerospace, and construction. Traditional press brakes are large, heavy-duty machines used for bending large sheets of metal into specific shapes. However, as technology advanced, the need for smaller, more precise bending machines led to the development of mini press brakes.

The mini press brake was born out of necessity for manufacturers who required precision but did not have the space or demand for a full-sized press brake. Small workshops, prototype developers, hobbyists, and educational institutions are now able to benefit from the high precision and efficiency of press brake technology without the large footprint and cost of larger machines.

Components of a Mini Press Brake

Although a mini press brake is smaller in scale, its essential components mirror those of a traditional press brake. Some of the key components include:

- Frame: The frame of the mini press brake is typically made of high-strength steel to withstand the forces applied during bending. Even though it’s smaller, the machine must still be robust enough to handle the pressure generated during the bending process.

- Ram: The ram is the moving component of the machine, which presses the punch into the die to shape the metal. In mini press brakes, the ram’s movement is often controlled by a manual or hydraulic mechanism.

- Punch and Die: These are the tools used to shape the metal. The punch is attached to the ram and presses the material into the die, which is mounted on the bed. The shape of the die determines the final bend angle and form of the metal.

- Back Gauge: The back gauge is a device that helps position the metal sheet accurately under the punch and die. This ensures consistent bending and repeatability across multiple pieces.

- Control System: Some mini press brakes are equipped with manual controls, while others may feature computerized numerical control (CNC) systems, which allow for highly accurate bending operations with digital precision.

Types of Mini Press Brakes

Mini press brakes can be categorized based on their mechanism of operation:

- Manual Mini Press Brake: In this version, the machine is operated manually, using a lever or handwheel to move the ram. These are commonly used for lighter materials and simpler projects that do not require high levels of precision or automation.

- Hydraulic Mini Press Brake: Hydraulic mini press brakes use hydraulic cylinders to move the ram. This allows for greater force and precision compared to manual machines. These are ideal for small to medium-sized workshops that require consistent and accurate bends.

- Pneumatic Mini Press Brake: This type of press brake uses air pressure to move the ram. Pneumatic systems are often preferred for their speed and energy efficiency, though they may not provide as much force as hydraulic systems.

- CNC Mini Press Brake: CNC (Computer Numerical Control) mini press brakes offer the highest level of precision and automation. The operator inputs the bending parameters into a computer, and the machine automatically adjusts the ram and back gauge to achieve the desired bends. CNC mini press brakes are used in industries where precision is paramount, such as in electronics, aerospace, and medical device manufacturing.

Applications of Mini Press Brakes

Mini press brakes are used in various industries due to their versatility and ability to produce precise bends on smaller pieces of metal. Some common applications include:

- Prototyping: Mini press brakes are ideal for developing prototypes of metal parts, especially when only a small quantity of components is required. Engineers and designers can use these machines to create custom parts quickly and with high precision.

- Sheet Metal Fabrication: Mini press brakes are commonly used in sheet metal fabrication for making brackets, enclosures, and other components. They can handle thin sheets of metal, bending them into a wide range of shapes and angles.

- Jewelry and Artisanal Work: Artists and jewelers often use mini press brakes to create intricate metal designs, such as rings, bracelets, or custom metal art pieces. The precise control offered by mini press brakes allows for detailed and intricate bends that are essential in the art world.

- Educational Use: Mini press brakes are frequently found in vocational schools and universities for training students in metalworking and manufacturing processes. Their small size and ease of use make them ideal teaching tools for learning the basics of metal bending.

- Repair Shops: In automotive and machine repair shops, mini press brakes are often used to repair or fabricate small metal parts. This includes custom brackets, mounts, and other components that need to be bent to specific angles.

Advantages of Mini Press Brakes

There are several advantages to using mini press brakes over their larger counterparts, particularly in settings where large-scale bending is not necessary:

- Compact Size: One of the most significant benefits of a mini press brake is its compact size. It requires less space than a full-sized machine, making it ideal for small workshops or garages.

- Cost-Effective: Mini press brakes are generally more affordable than larger machines, both in terms of initial cost and ongoing maintenance. This makes them accessible to small businesses, hobbyists, and educational institutions with limited budgets.

- Precision: Despite their small size, mini press brakes are capable of producing highly accurate bends. CNC-controlled models, in particular, offer exceptional precision, making them suitable for high-precision industries such as aerospace and electronics.

- Ease of Use: Many mini press brakes are designed with simplicity in mind. Manual versions are straightforward to operate, while CNC versions often feature user-friendly interfaces that allow operators to input bending parameters easily.

- Versatility: Mini press brakes can be used on a wide variety of materials, including aluminum, stainless steel, and mild steel. They can handle thin sheets of metal and produce a wide range of bend angles and shapes.

- Energy Efficiency: Mini press brakes, especially pneumatic or hydraulic models, are often more energy-efficient than larger machines. This can lead to cost savings in the long run, particularly in shops that perform frequent bending operations.

Limitations of Mini Press Brakes

While mini press brakes offer several advantages, they also come with some limitations:

- Limited Capacity: Due to their smaller size, mini press brakes are not suitable for bending large or thick sheets of metal. Their capacity is typically limited to thin sheets, and they may struggle with heavier materials.

- Lower Force Output: Mini press brakes generate less force than full-sized machines, which limits the types of materials they can bend. For example, they may not be able to handle hardened or thick metals.

- Slower Production Speed: In comparison to larger, automated press brakes, mini press brakes may have slower production speeds. This is particularly true for manual versions, where the operator must manually adjust the machine for each bend.

- Manual Operation in Some Models: While CNC models are available, many mini press brakes are manually operated. This requires more skill and experience from the operator, as there is less automation involved in the bending process.

- Limited Bend Length: Mini press brakes have a shorter bending length compared to full-sized machines, which can be a limitation when working with longer sheets of metal.

The Future of Mini Press Brakes

As industries continue to evolve, the demand for small-scale, precision manufacturing tools like mini press brakes is expected to grow. Several trends are shaping the future of mini press brakes:

- Increased Automation: As CNC technology continues to improve, we can expect to see more mini press brakes with advanced automation features. This will make it easier for operators to produce complex bends with minimal manual intervention.

- Improved Materials: Advances in materials science are likely to result in mini press brakes that are lighter, stronger, and more durable. This could lead to machines that are capable of handling heavier loads without increasing their size.

- Integration with Other Technologies: Mini press brakes may become more integrated with other manufacturing technologies, such as laser cutting and 3D printing. This could lead to more efficient and streamlined production processes, especially in small-scale manufacturing.

- Sustainability: As energy efficiency becomes an increasingly important concern, manufacturers are likely to focus on creating mini press brakes that consume less energy while maintaining high performance. This could lead to the development of more eco-friendly machines that are ideal for small workshops and businesses.

- Customization: The growing demand for customized products is likely to drive innovation in mini press brakes. Manufacturers may develop machines that are highly flexible and capable of producing custom bends for a wide range of applications, from automotive parts to artistic creations.

Conclusion

Mini press brakes are invaluable tools for a wide range of industries and applications, offering precision bending capabilities on a smaller, more accessible scale. Their compact size, cost-effectiveness, and ease of use make them ideal for small businesses, workshops, educational institutions, and hobbyists. As technology continues to advance, mini press brakes are likely to become even more versatile and efficient, making them an essential tool in the world of metalworking and fabrication. Whether for prototyping, repair work, or precision manufacturing, the mini press brake continues to play a crucial role in shaping the future of metalworking.

Mini Press Brake in Industrial Sectors

Mini press brakes, although designed for small to medium-scale projects, have found their way into various industrial sectors due to their versatility and precision. Their compact nature, combined with modern technology, allows these machines to perform highly specialized tasks that larger machines might struggle with due to space or overcapacity issues. Below is a closer look at how mini press brakes are utilized across different industries:

1. Aerospace Industry

The aerospace industry demands precision and reliability, as the parts used in aircraft and space vehicles need to meet strict safety and performance standards. Mini press brakes are widely used to fabricate small components that must fit within tight tolerances. These include brackets, mounting components, and various sheet metal parts used in aircraft interiors and control systems.

Mini press brakes equipped with CNC technology allow aerospace manufacturers to produce repeatable bends with extreme precision. The smaller machine footprint also enables easier setup and faster transitions between different production tasks, which is essential in the highly competitive aerospace sector, where even minor inefficiencies can lead to significant delays or increased costs.

2. Automotive Sector

In the automotive industry, mini press brakes are used to manufacture smaller parts such as brackets, levers, and mounting systems. These components are crucial for vehicle assembly, contributing to safety, structural integrity, and functionality. While larger press brakes handle larger body panels, mini press brakes excel in bending smaller, detailed parts that require finesse.

In custom and aftermarket automotive applications, mini press brakes are ideal for fabricating custom parts like roll cages, chassis reinforcements, and bespoke interior components. They allow workshops to create these components in low volumes while maintaining high precision and quality.

3. Electronics and Electrical Enclosures

The mini press brake plays an essential role in the production of electrical enclosures, boxes, and housings for various electronic devices. These enclosures must not only protect the delicate components inside but also meet precise specifications for assembly and functionality.

Sheet metal used in electronics is often thin, lightweight, and requires intricate bends that only a mini press brake can achieve. In addition, CNC mini press brakes are frequently employed in the electronics sector due to their ability to produce detailed parts consistently, which is critical in high-tech applications where errors in dimensions can lead to equipment malfunctions.

4. Medical Devices

In the medical field, devices and equipment often contain custom-fabricated metal parts. These parts are critical for the functionality and safety of medical instruments, surgical tools, and diagnostic equipment. Mini press brakes are used to form these parts with the required precision, ensuring they meet strict medical industry standards.

Given the high safety and regulatory standards in the medical field, the precision of mini press brakes is essential. Stainless steel and other high-grade materials, often used in medical devices, require specific bending forces that mini hydraulic or CNC press brakes can provide. Moreover, the ability to prototype small quantities quickly using mini press brakes allows medical engineers to test new designs and innovations more efficiently.

5. HVAC Systems (Heating, Ventilation, and Air Conditioning)

Mini press brakes play a significant role in the HVAC industry for manufacturing air ducts, vents, and other sheet metal parts. The demand for custom HVAC solutions in both commercial and residential settings requires versatile bending machines that can create a variety of shapes and sizes quickly and efficiently.

The precision offered by mini press brakes ensures that air ducts and other components fit perfectly within HVAC systems, improving airflow and efficiency. HVAC companies benefit from the compact size of these machines, allowing them to work within confined spaces and produce the necessary components on-site or in small workshops.

6. Jewelry and Artisanal Metalwork

The small-scale, intricate bending required for jewelry and artistic metalwork makes mini press brakes an indispensable tool in this niche industry. Jewelers and artisans use these machines to shape metal sheets into beautiful and complex designs, such as rings, bracelets, pendants, and sculptures.

The control and precision offered by manual or CNC-operated mini press brakes allow for creativity without compromising on the quality or durability of the final product. Artists can create smooth curves, sharp angles, and intricate designs in metal, all of which are essential to high-quality jewelry and custom metal art pieces.

7. Prototyping and Research & Development (R&D)

Prototyping is an essential phase in product development, whether in automotive, aerospace, electronics, or consumer goods. Mini press brakes are frequently used in R&D settings to quickly produce and test prototypes of metal parts. Engineers and product designers use these machines to experiment with different materials, thicknesses, and bend angles to fine-tune their designs before moving to full-scale production.

The ability to produce small batches of parts on demand is a major advantage in R&D environments. The flexibility of CNC mini press brakes allows designers to modify their designs in real-time, adjusting parameters and re-bending parts until the desired outcome is achieved. This iterative process is crucial in industries where innovation drives success, and mini press brakes enable companies to accelerate their product development timelines.

8. Custom Fabrication and Job Shops

In custom fabrication and job shops, mini press brakes are invaluable for producing one-off or small-batch orders. These shops often cater to clients who require custom metal parts for specific applications, ranging from machine components to architectural elements.

For job shops, the ability to quickly switch between different projects is essential, and the versatility of mini press brakes allows operators to handle a variety of materials and part designs without the need for extensive setup times. This flexibility makes mini press brakes an ideal solution for custom fabrication, where precision and speed are critical.

Key Features of Modern Mini Press Brakes

The evolution of press brake technology has brought several innovations to mini press brakes, enhancing their capabilities and ease of use. Here are some of the key features found in modern mini press brakes:

- CNC Control Systems: As mentioned earlier, many mini press brakes now come equipped with CNC systems. These computerized controls allow operators to program complex bending sequences, ensuring consistent results and reducing the need for manual adjustments. CNC systems also make it easier to handle repeat orders, as the machine can store bending programs for future use.

- Touchscreen Interfaces: Some modern mini press brakes feature touchscreen interfaces, making them user-friendly and easier to operate. These interfaces allow operators to input bending parameters, monitor the progress of the bending operation, and make adjustments as needed, all from a central control panel.

- Precision Sensors and Feedback Systems: Precision sensors and feedback systems are increasingly being integrated into mini press brakes to ensure accurate bending. These systems monitor the position of the ram and the material being bent, making real-time adjustments to maintain precision throughout the bending process.

- Automatic Tool Changes: In high-precision industries where multiple tools are required for different bends, mini press brakes with automatic tool change capabilities are becoming more common. This feature increases efficiency by reducing downtime between tool changes, making it easier to switch between different parts or bending operations.

- Safety Features: Modern mini press brakes are equipped with various safety features to protect operators. These include light curtains, safety interlocks, and emergency stop buttons that immediately halt the machine in case of an issue. With the rise in automation, these safety features are essential to ensure a safe working environment, especially in small workshops or educational settings.

Maintenance and Longevity of Mini Press Brakes

Like any machine tool, regular maintenance is critical to ensuring the longevity and optimal performance of a mini press brake. Proper maintenance not only extends the life of the machine but also ensures consistent, high-quality results.

Some basic maintenance tasks for mini press brakes include:

- Lubrication: Moving parts such as the ram, back gauge, and hydraulic cylinders (in hydraulic models) need regular lubrication to prevent wear and tear. Operators should follow the manufacturer’s recommendations for the type and frequency of lubrication.

- Tool Inspection and Replacement: The punch and die used in the bending process are subject to wear over time, especially if the machine is used frequently or for bending tougher materials. Regular inspection of these tools is necessary to ensure they are not damaged or worn, as this can lead to inaccurate bends or even machine damage.

- Hydraulic System Maintenance: For hydraulic mini press brakes, maintaining the hydraulic system is essential. This includes checking fluid levels, replacing hydraulic oil when necessary, and inspecting seals and hoses for leaks.

- Calibration: Regular calibration of the machine’s control systems and sensors is essential to maintain precision. This is particularly important for CNC mini press brakes, where even small deviations in alignment can lead to significant errors in the bending process.

- Electrical System Checks: The electrical systems, including control panels, motors, and sensors, should be checked regularly for any signs of wear, loose connections, or potential failures. Keeping the electrical components in good condition ensures the smooth operation of the mini press brake.

By following a regular maintenance schedule, operators can ensure that their mini press brake remains reliable, accurate, and safe to use for many years.

Conclusion: The Role of Mini Press Brakes in Modern Manufacturing

The mini press brake has become an essential tool in modern manufacturing, offering precision, versatility, and efficiency in a compact package. Whether used for small-scale production, custom fabrication, or educational purposes, these machines provide the flexibility needed to meet the demands of various industries.

As technology continues to evolve, mini press brakes are likely to become even more advanced, with greater automation, improved precision, and enhanced safety features. Their role in prototyping, repair work, and specialized manufacturing ensures that they will remain an indispensable tool for years to come, particularly as industries place increasing emphasis on customization, sustainability, and efficiency.

From aerospace to jewelry making, mini press brakes offer a unique combination of power and precision in a small footprint, making them a valuable asset in the world of metalworking and beyond.

Customization in Mini Press Brake Usage

One of the most significant advantages of mini press brakes is their ability to be customized for specific tasks. Customization, in this context, refers not only to the machine’s adaptability in terms of tooling and processes but also to the way these machines can be configured for particular industries or applications. The increasing demand for specialized and bespoke solutions across industries has made customization a key feature for manufacturers using mini press brakes.

Customizable Tooling

Tooling, the punch and die used in bending operations, is one of the most critical components in any press brake system, including mini press brakes. Different industries require various bend angles, shapes, and material thicknesses, making customized tooling essential. Mini press brakes often allow for interchangeable punches and dies, which can be tailored to the specific bending requirements of a project.

- Precision Tooling for Thin Materials: Industries like electronics and medical devices often use very thin materials that require high-precision tooling. These tools are designed to create specific bend radii that avoid damaging or warping the material, which can be as thin as a few millimeters.

- Complex Bends: For parts that require multiple bends, such as those used in HVAC systems or custom automotive applications, tooling can be designed to produce complex, multi-step bends. This eliminates the need for multiple setups and ensures consistency across the entire batch of parts.

- Material-Specific Tooling: The type of material being bent (aluminum, stainless steel, copper, etc.) also influences tooling customization. For example, stainless steel requires more force to bend compared to aluminum, so the tooling must be more robust. Similarly, copper’s malleability demands more delicate tooling to prevent damage to the material during bending.

Adjustable Bending Force and Speed

Mini press brakes, especially CNC or hydraulic models, often come with adjustable bending force settings. This feature allows operators to precisely control the pressure applied during the bending process, which is crucial when working with different materials. The ability to adjust force and speed can have several benefits:

- Material Versatility: Operators can bend materials of varying thicknesses and strengths by simply adjusting the force and speed settings. This makes mini press brakes adaptable to a wider range of projects, from thin metal sheets for electronics enclosures to thicker metal pieces for automotive components.

- Minimizing Material Fatigue: Certain materials, particularly metals like aluminum, can experience fatigue when exposed to excessive force or high-speed bending. Customizing the bending speed and force can reduce the risk of cracking, distortion, or other damage, resulting in a higher-quality final product.

- Energy Efficiency: Adjusting the force and speed based on the material and bend type can also help conserve energy. Slower, more controlled bending for delicate materials uses less power compared to high-speed operations on tougher materials. This contributes to cost savings, particularly in high-volume production environments.

Automated Customization in CNC Mini Press Brakes

CNC (Computer Numerical Control) technology has revolutionized the capabilities of mini press brakes by allowing for highly customizable and automated bending processes. CNC mini press brakes offer a wide range of programmable features that make them ideal for manufacturers who require consistent, repeatable precision.

- Programmable Back Gauge: The back gauge in a CNC mini press brake can be automatically adjusted based on the programmed settings, ensuring that each metal sheet is positioned correctly for each bend. This level of automation eliminates human error, particularly when multiple bends are required on a single piece.

- Repeatability: Once a bending sequence is programmed into a CNC mini press brake, it can be used repeatedly for large batches or future orders. This ensures that all parts in a production run are identical, which is essential in industries where precision and consistency are critical, such as aerospace or electronics.

- Multi-Axis Control: Advanced CNC mini press brakes can control multiple axes simultaneously, allowing for more complex bends and shapes. This is particularly useful in custom fabrication shops where intricate parts, such as enclosures or brackets with compound angles, are needed.

- Simulation Software: Many CNC mini press brakes come equipped with simulation software that allows operators to preview the bending process on a screen before performing the actual bend. This helps identify any potential issues, such as material interference or incorrect bend angles, reducing the likelihood of errors and wasted materials.

- Customization for Different Batches: CNC machines allow for quick setup changes between different jobs, making them ideal for manufacturers who handle small production runs or custom orders. Operators can easily switch between different programs, saving time and ensuring that each part is bent to the correct specifications without the need for manual recalibration.

Modularity and Expandability

One of the key selling points of mini press brakes is their modular design, which allows for easy expansion and customization. Manufacturers can start with a basic setup and then add components as their production needs grow or change.

- Expandable Tool Racks: Many mini press brakes come with modular tool racks, allowing operators to add or swap out tooling for different projects. This modularity is particularly useful in job shops where a wide variety of projects require different bending tools.

- Additional Gauges and Fixtures: Mini press brakes can also be customized with additional back gauges, fixtures, or clamping systems to accommodate larger or more complex projects. These add-ons can be purchased as needed, making it easier for shops to expand their capabilities without investing in a completely new machine.

- Enhanced Software: CNC mini press brakes often have upgradeable software, allowing manufacturers to add new features or improve existing ones. This is especially important in industries where technology is constantly evolving, such as electronics or medical devices.

Integration with Other Manufacturing Processes

As manufacturing technology becomes more interconnected, mini press brakes are increasingly being integrated with other manufacturing processes to streamline production and improve efficiency.

- Integration with Laser Cutting: Mini press brakes are often used alongside laser cutting machines, particularly in industries that require precision sheet metal fabrication. The laser cutting machine cuts the metal to the required size and shape, and the mini press brake then bends the cut pieces into their final form. By integrating these two processes, manufacturers can reduce handling time and improve production flow.

- 3D Printing and Metal Additive Manufacturing: As 3D printing and metal additive manufacturing gain popularity, mini press brakes are being used to bend metal components that are initially produced through these methods. This is particularly useful in industries that require rapid prototyping or custom parts, as it allows manufacturers to create complex shapes that would be difficult or impossible to achieve through traditional manufacturing methods alone.

- Automation and Robotics: In high-volume production environments, mini press brakes are increasingly being paired with robotic arms or automation systems that load and unload the metal sheets. This automation reduces the need for manual labor, increases production speed, and ensures consistent results.

Mini Press Brakes in Education and Training

Mini press brakes have also become essential tools in educational settings, particularly in vocational schools and training programs focused on metalworking and manufacturing. Their smaller size and user-friendly interfaces make them ideal for teaching students the fundamentals of metal bending without the need for large, industrial-scale equipment.

- Hands-On Learning: Mini press brakes allow students to gain hands-on experience in operating a press brake, learning about material properties, tooling, and bending processes in a controlled environment. This practical experience is invaluable in preparing them for careers in manufacturing, engineering, and fabrication.

- Introduction to CNC Technology: Many schools now use CNC mini press brakes to teach students about automated manufacturing processes. This introduces students to the principles of programming, machine operation, and precision engineering, giving them a head start in industries where CNC technology is the standard.

- Safety and Training: Safety is a crucial consideration in any manufacturing environment, and mini press brakes provide a safer alternative for beginners to learn the fundamentals of metal bending. These machines typically come with safety features like emergency stops, light curtains, and protective shields, ensuring that students can learn in a safe environment.

Emerging Trends and Innovations

As the manufacturing landscape continues to evolve, several emerging trends and innovations are likely to shape the future of mini press brakes.

- Smart Manufacturing: The rise of smart manufacturing and Industry 4.0 is driving innovation in mini press brakes. Manufacturers are developing machines that can communicate with other systems, monitor their own performance, and provide real-time data on production efficiency. These “smart” mini press brakes are equipped with sensors and IoT (Internet of Things) capabilities, allowing operators to track machine performance, schedule maintenance, and make data-driven decisions.

- Eco-Friendly Design: As sustainability becomes a growing concern, manufacturers are focusing on creating more energy-efficient mini press brakes. Hydraulic models, in particular, are being redesigned to reduce energy consumption, while pneumatic and electric models are gaining popularity for their lower environmental impact.

- Advanced Materials: As new materials are developed, mini press brakes will need to adapt to handle these advanced materials effectively. For example, lightweight composite materials used in aerospace and automotive applications may require specialized tooling or bending processes to avoid damage or deformation.

- Collaborative Robots (Cobots): Cobots are designed to work alongside human operators, enhancing productivity without replacing manual labor. In small workshops or custom fabrication environments, cobots can assist with material handling, positioning, and other tasks, allowing operators to focus on precision bending using the mini press brake.

- Augmented Reality (AR) and Virtual Reality (VR): Some manufacturers are exploring the use of AR and VR in press brake training and operation. These technologies could allow operators to visualize the bending process in a virtual environment before performing the actual bend, improving accuracy and reducing the risk of errors.

Conclusion: A Versatile Tool for Modern Manufacturing

The mini press brake has established itself as a versatile, efficient, and cost-effective tool in modern manufacturing. Its compact size, combined with advanced features like CNC control, customizable tooling, and integration with other manufacturing processes, makes it an essential piece of equipment for industries ranging from aerospace to jewelry making.

As technology continues to evolve, mini press brakes will likely play an even more significant role in small and medium-scale manufacturing. Their adaptability, precision, and expanding range of capabilities ensure that they will remain a valuable tool for businesses of all sizes, from large industrial operations to small custom fabrication shops.

Whether it’s used for producing high-precision parts in the aerospace sector, crafting custom jewelry, or teaching the next generation of metalworkers, the mini press brake is shaping the future of metalworking by providing manufacturers with the tools they need to innovate and succeed in a competitive global market.

Mini Press Brakes and Future Manufacturing Trends

The manufacturing industry is constantly evolving, with advancements in automation, materials, and processes driving new trends and innovations. Mini press brakes, while traditionally smaller in scale compared to their larger counterparts, are increasingly benefiting from these advancements. Their integration into the latest manufacturing trends not only enhances their capabilities but also positions them as vital tools for future-focused production environments.

1. Automation and Robotics in Mini Press Brakes

Automation is becoming an integral part of modern manufacturing, and mini press brakes are no exception. Incorporating robotic arms, automated feeding systems, and sensor-based technology, manufacturers can transform these machines into highly efficient automated systems that perform complex tasks with minimal human intervention. This trend, coupled with the rise of collaborative robots (cobots), allows mini press brakes to operate in environments where robots work alongside human operators safely.

- Robotic Arms for Material Handling: In automated systems, robotic arms handle tasks such as loading metal sheets onto the press brake and removing finished parts after the bending process. This minimizes manual labor and reduces the risk of human error, increasing the speed and efficiency of the production line. Automated handling is especially beneficial in high-volume production environments, where the same bending process is repeated on a large number of parts.

- Automated Quality Control: Modern mini press brakes equipped with advanced sensors and feedback systems can be integrated into a larger automated quality control system. These sensors ensure that every bend meets the required specifications, and if any deviation is detected, the machine can automatically adjust or stop the process. Automated quality control minimizes waste and improves overall production accuracy, ensuring that every part produced is of the highest quality.

- Predictive Maintenance: A major advantage of automation in mini press brakes is the potential for predictive maintenance. By monitoring the machine’s performance in real-time, smart sensors can detect when components are showing signs of wear or if the machine is operating outside of optimal parameters. Predictive maintenance systems alert operators before a breakdown occurs, minimizing downtime and preventing costly repairs. This is particularly valuable in industries where consistent uptime is crucial, such as automotive and aerospace manufacturing.

2. Industry 4.0 and IoT Integration

The rise of Industry 4.0 and the Internet of Things (IoT) has introduced a new level of connectivity to manufacturing environments. Mini press brakes can be integrated into smart factories, where machines are connected to centralized systems that monitor and control every aspect of production. This integration allows for enhanced communication between machines, more efficient production planning, and real-time data analysis.

- Real-Time Monitoring: In a smart factory, mini press brakes can be connected to a network that monitors their performance in real-time. Operators can view machine status, production progress, and diagnostic information from a central dashboard, whether they are on-site or working remotely. This capability allows manufacturers to quickly identify and resolve issues, ensuring continuous production and minimizing downtime.

- Data-Driven Decision Making: IoT-enabled mini press brakes can provide valuable data on production performance, such as the number of parts produced, machine efficiency, and material usage. This data can be analyzed to optimize production processes, reduce waste, and improve overall efficiency. In addition, historical data can be used to identify trends and forecast future production needs, helping manufacturers make informed decisions about machine usage and capacity planning.

- Remote Diagnostics and Troubleshooting: One of the key benefits of IoT integration is the ability to perform remote diagnostics and troubleshooting. If a mini press brake experiences an issue, technicians can remotely access the machine’s data and control systems to diagnose and, in some cases, resolve the problem without needing to be physically present. This capability is particularly useful for manufacturers operating in multiple locations or those using automated production lines that require minimal human supervision.

3. Sustainability and Eco-Friendly Manufacturing

As sustainability becomes an increasingly important factor in manufacturing, mini press brakes are evolving to meet the demands of eco-friendly production practices. Reducing energy consumption, minimizing waste, and using environmentally friendly materials are all trends that are influencing the design and operation of these machines.

- Energy-Efficient Models: Manufacturers are designing mini press brakes with energy efficiency in mind. For instance, servo-electric press brakes use electric motors instead of hydraulic systems, which can significantly reduce energy consumption. These machines only use power when the bending process is in operation, unlike hydraulic systems that require continuous power to maintain pressure. This makes them more energy-efficient, particularly in environments where machines are not in constant use.

- Material Efficiency: With the rise of sustainable practices, mini press brakes are also contributing to material efficiency. The precision offered by modern mini press brakes ensures that material waste is minimized, reducing the amount of scrap produced during the bending process. Additionally, advanced programming allows for optimal use of materials, ensuring that sheet metal is used efficiently without excess waste.

- Recyclable and Sustainable Materials: As manufacturers shift toward using more sustainable materials, mini press brakes are becoming essential in working with these new materials. For example, many companies are now using recycled metals or composites that require specialized handling during the bending process. Mini press brakes can be customized to accommodate these materials, ensuring that they are bent without causing damage or degradation.

4. Advanced Materials and Mini Press Brake Applications

With the development of new materials in industries such as aerospace, automotive, and electronics, mini press brakes are being tasked with handling more advanced and specialized materials. The ability to work with these materials, which can range from high-strength alloys to lightweight composites, is becoming an increasingly important factor in the design and operation of mini press brakes.

- High-Strength Alloys: Industries like aerospace and automotive often require parts made from high-strength alloys such as titanium or hardened steel. These materials are more challenging to bend due to their increased resistance to deformation. Mini press brakes designed for these applications are equipped with more powerful hydraulic or servo-electric systems that provide the necessary force to bend these tough materials without causing cracks or fractures.

- Lightweight Composites: As the demand for lightweight materials grows, particularly in industries focused on fuel efficiency, mini press brakes are being used to form parts from composite materials. These materials require careful handling, as they can be more brittle than traditional metals. Advanced tooling and precise control systems are essential to ensure that composites are bent without damaging their structural integrity.

- Corrosion-Resistant Materials: In sectors like marine, medical, and chemical processing, corrosion-resistant materials such as stainless steel and certain alloys are often used. Mini press brakes equipped with specialized tooling can handle these materials, ensuring that bends are performed cleanly without compromising the material’s resistance to corrosion.

5. Prototyping and Rapid Manufacturing

Mini press brakes are increasingly being used in rapid prototyping and small-batch production, where speed and flexibility are crucial. This trend is particularly evident in industries that require quick turnaround times for custom parts or prototypes, such as automotive, electronics, and consumer products.

- Prototyping Flexibility: Mini press brakes offer manufacturers the ability to quickly produce prototypes without the need for large-scale production equipment. By using CNC technology, operators can quickly program and adjust settings to accommodate different part designs, materials, and bend angles. This flexibility is essential in prototyping, where designs are often modified multiple times before final production.

- Small-Batch Production: Many industries, particularly those focused on custom products, rely on small-batch production. Mini press brakes are ideally suited for this type of manufacturing, as they can be set up quickly and efficiently for short runs without the need for extensive tooling changes. This capability allows manufacturers to meet the demands of clients who require custom metal parts in limited quantities.

- On-Demand Manufacturing: With the rise of on-demand manufacturing, mini press brakes are being used to produce parts as needed, rather than relying on large inventories of pre-made parts. This approach reduces storage costs and waste, as parts are only made when they are required. Mini press brakes are particularly well-suited for on-demand production due to their quick setup times and adaptability to different projects.

6. Globalization and Distributed Manufacturing

As manufacturing becomes more globalized, the need for distributed manufacturing—where parts are produced closer to where they are needed—has grown. Mini press brakes are playing a crucial role in this trend, enabling smaller, localized factories to produce high-quality parts without the need for large, centralized production facilities.

- Localized Production: Mini press brakes allow smaller manufacturing facilities to produce parts that were traditionally made in larger factories. This trend supports distributed manufacturing models, where companies set up smaller, regional production centers closer to their customers. This reduces shipping costs and lead times, allowing for faster delivery of finished products.

- Custom Manufacturing: As customers demand more personalized products, mini press brakes enable manufacturers to produce custom metal parts in smaller batches. This is particularly valuable in industries like automotive, where customers may request unique features or designs that require specialized metalwork.

- Global Supply Chain Flexibility: The agility provided by mini press brakes allows manufacturers to adapt more quickly to changes in the global supply chain. Whether it’s responding to disruptions in material availability or shifting production to different locations, the flexibility of mini press brakes ensures that companies can maintain production efficiency, even in challenging conditions.

Conclusion: Shaping the Future of Manufacturing

Mini press brakes are not just smaller versions of their larger counterparts—they are versatile, powerful machines that are integral to the future of manufacturing. As industries evolve and embrace new technologies, mini press brakes are adapting to meet the needs of modern production environments. From automation and robotics to sustainable manufacturing practices and the integration of advanced materials, mini press brakes are at the forefront of these changes.

Their ability to handle small to medium-sized parts, combined with the precision and flexibility offered by modern technology, makes them indispensable in a variety of industries. Whether used for rapid prototyping, custom fabrication, or high-precision production, mini press brakes offer manufacturers a powerful tool to stay competitive in a fast-paced, ever-changing global market. As the world of manufacturing continues to evolve, mini press brakes will remain a critical component, shaping the future of metalworking and beyond.

The Role of Mini Press Brakes in Small and Medium Enterprises

One of the significant areas where mini press brakes are making a substantial impact is in small and medium-sized enterprises (SMEs). These businesses often operate with limited resources but require high precision and flexibility in their manufacturing processes. Mini press brakes offer these companies the ability to perform complex bending operations without the need for large, expensive equipment, providing an entry point into advanced manufacturing technologies.

1. Affordability and Accessibility for SMEs

For SMEs, capital investment in machinery can be a critical decision that influences their competitive advantage and long-term sustainability. Mini press brakes, due to their compact size and lower cost compared to full-sized machines, are highly accessible for smaller companies.

- Lower Initial Investment: Mini press brakes are typically less expensive than larger press brake systems, which makes them a feasible option for SMEs. This lower investment cost allows smaller businesses to acquire essential bending technology without straining their budgets.

- Cost-Efficient Production: SMEs benefit from the cost efficiency of mini press brakes when it comes to production. The precision and repeatability of these machines minimize material waste and reduce the need for post-production adjustments, ultimately lowering the overall cost per part produced.

- Scalability: As SMEs grow, they can add more mini press brakes to their operations, allowing them to scale production gradually. This is a cost-effective way to expand manufacturing capabilities without the need to purchase large, complex equipment all at once. The modular nature of many mini press brake systems also means that additional components can be added as needed.

2. Flexibility in Custom Fabrication

SMEs often specialize in custom fabrication, where they produce small batches of highly customized parts for specific clients. Mini press brakes are particularly well-suited for this kind of work due to their adaptability and quick setup times.

- Quick Tool Changes: Mini press brakes are designed for fast tool changes, which is critical in custom fabrication environments where different projects may require unique tooling. This flexibility allows SMEs to switch between projects quickly, improving turnaround times and customer satisfaction.

- Prototyping and Short-Run Production: For custom fabrication, mini press brakes excel in producing prototypes and short production runs. Their programmable controls and ease of use make it possible to create prototypes that meet precise specifications. SMEs can also take advantage of short-run production capabilities, making them competitive in industries that require small quantities of high-quality, bespoke parts.

- Customizable Software for Specific Needs: Many mini press brakes come equipped with software that can be customized for specific applications. SMEs that serve niche markets can benefit from this by tailoring the machine’s programming to meet the exact needs of their clients, whether it’s a particular bend angle, complex shapes, or specialized materials.

3. Reducing Lead Times for SMEs

In today’s fast-paced business environment, reducing lead times is a critical factor in maintaining a competitive edge. Mini press brakes contribute significantly to shorter production cycles, allowing SMEs to respond to customer demands more quickly.

- Efficient Setup and Operation: The compact design and user-friendly controls of mini press brakes make them quick to set up and easy to operate. This efficiency in setup time is crucial for SMEs, where delays in production can have a more pronounced impact on profitability and customer satisfaction.

- In-House Production Capabilities: By incorporating mini press brakes into their operations, SMEs can bring metal bending processes in-house rather than outsourcing them to larger fabrication shops. This not only reduces lead times but also gives SMEs greater control over the quality and timelines of their production processes. This control can be a major differentiator in industries that value quick turnarounds, such as custom automotive or electronic enclosure manufacturing.

- On-Demand Manufacturing: Mini press brakes allow SMEs to adopt an on-demand manufacturing model. Instead of maintaining large inventories of pre-bent parts, businesses can produce items as needed, reducing the costs associated with storage and unsold inventory. This approach is particularly beneficial for SMEs that work with perishable or customized components.

4. Enhanced Competitiveness for Niche Markets

SMEs that operate in niche markets, such as custom furniture design, high-end automotive parts, or artisanal metalwork, can leverage mini press brakes to differentiate themselves from competitors. These machines provide the precision and customization capabilities needed to meet the unique demands of these specialized markets.

- Precision Bending for Artistic and Functional Pieces: Niche markets often require high levels of precision, not only for functional purposes but also for aesthetic reasons. Mini press brakes can create intricate and complex bends that are essential in the production of both decorative and functional metal pieces. This precision enables SMEs to meet the exacting standards of niche customers, who often require custom solutions.

- Unique Material Capabilities: Many niche markets require the use of specific or non-standard materials. Mini press brakes are versatile enough to handle a wide range of materials, from stainless steel to soft metals like copper, making them ideal for SMEs serving industries such as bespoke jewelry or high-end appliance design.

- Short Production Runs: Many niche markets do not require large quantities of parts, making mini press brakes ideal for small-batch production. SMEs can efficiently produce limited runs of highly customized parts without the overhead associated with large-scale production. This capability gives smaller businesses a competitive edge, as they can offer unique products without needing to invest in expensive, large-scale equipment.

5. Mini Press Brakes and Skilled Labor in SMEs

The availability of skilled labor is a challenge for many SMEs, especially in sectors like metal fabrication, where expertise is often required to operate complex machinery. Mini press brakes, particularly CNC-controlled models, are designed to simplify the bending process, making them easier to operate for workers with varying skill levels.

- User-Friendly CNC Interfaces: Modern mini press brakes come equipped with CNC controls that are intuitive and easy to learn. This means that SMEs do not need to invest heavily in extensive training programs to get their employees up to speed. Workers with minimal experience can quickly become proficient in operating the press brake, reducing labor costs and enhancing productivity.

- Safety Features for Entry-Level Operators: Many mini press brakes are equipped with advanced safety features such as automatic stops, light curtains, and emergency shut-off systems. These features help to prevent accidents and ensure a safer working environment, which is particularly important for SMEs that may have less-experienced operators.

- Cross-Training Opportunities: Mini press brakes, due to their ease of use and versatility, allow SMEs to cross-train their employees on multiple machines and processes. This flexibility in the workforce is crucial for small businesses, as it enables them to respond to changing production demands without the need to hire additional specialized staff.

6. Global Supply Chains and Localization in SMEs

As globalization reshapes manufacturing, many SMEs are looking for ways to localize their production processes and reduce dependency on international supply chains. Mini press brakes are playing a role in this shift by enabling smaller businesses to bring production in-house and manufacture parts locally.

- Localized Manufacturing: By using mini press brakes, SMEs can produce components locally, reducing the need to import pre-bent parts from overseas suppliers. This not only cuts down on shipping costs and lead times but also reduces exposure to global supply chain disruptions, which have become increasingly common in recent years due to events like the COVID-19 pandemic.

- Customization for Local Markets: Localizing production allows SMEs to respond more effectively to the specific needs of their local markets. Mini press brakes give businesses the flexibility to produce custom parts that cater to regional preferences or regulations, allowing them to gain a competitive advantage in their local markets.

- Sustainability through Localization: SMEs that focus on local production can market themselves as more sustainable and environmentally friendly, as localized manufacturing reduces the carbon footprint associated with long-distance shipping. Mini press brakes, with their energy-efficient models and ability to minimize waste, contribute to this sustainability by making localized, eco-friendly production possible.

7. Supporting Innovation in SMEs

Innovation is critical for the success of SMEs, particularly in competitive industries where staying ahead of technological advancements can mean the difference between thriving and struggling. Mini press brakes, with their ability to handle complex bending operations, support innovation by giving SMEs the tools they need to experiment with new designs, materials, and production methods.

- Rapid Prototyping for Product Development: SMEs can use mini press brakes to produce prototypes quickly and cost-effectively. This is especially important in industries such as automotive or electronics, where product development cycles are fast-paced, and the ability to iterate designs quickly is crucial for staying ahead of competitors.

- Testing New Materials: Mini press brakes allow SMEs to experiment with new materials, such as lightweight composites or advanced alloys, without the need for significant retooling. This flexibility in material handling enables smaller businesses to innovate in areas like product durability, weight reduction, and material sustainability.

- Customization and Bespoke Solutions: One of the key ways SMEs can differentiate themselves in the marketplace is through customization and offering bespoke solutions to their customers. Mini press brakes are perfectly suited for producing custom parts with unique designs, allowing SMEs to cater to specific client needs and explore new markets.

Conclusion: Empowering Small and Medium Enterprises with Mini Press Brakes

Mini press brakes are proving to be a game-changer for small and medium enterprises by providing them with access to advanced metalworking capabilities without the high cost and complexity of larger machinery. These compact, versatile machines enable SMEs to produce high-quality parts efficiently, scale production as needed, and innovate in their respective industries.

The combination of affordability, precision, flexibility, and ease of use makes mini press brakes a perfect fit for the diverse needs of SMEs. From rapid prototyping to custom fabrication and localized production, mini press brakes empower small businesses to remain competitive in an increasingly complex and globalized manufacturing environment. As manufacturing continues to evolve, mini press brakes will continue to play a crucial role in supporting the growth and success of SMEs worldwide.

The Educational and Training Potential of Mini Press Brakes

As industries evolve and new technologies emerge, the need for a skilled workforce in metal fabrication has never been greater. Mini press brakes not only serve as valuable tools in manufacturing but also offer significant potential for education and training programs aimed at developing the next generation of metalworkers.

1. Hands-On Learning Opportunities

Mini press brakes provide an excellent platform for hands-on training, allowing students and new employees to gain practical experience in metal bending and fabrication. This experiential learning is crucial in developing the skills needed in a manufacturing environment.

- User-Friendly Design: The compact size and intuitive controls of mini press brakes make them suitable for educational settings. Students can easily operate these machines, gaining confidence and hands-on experience without the intimidation that larger, more complex machinery may present.

- Real-World Applications: Training programs that incorporate mini press brakes allow students to work on real-world projects, bridging the gap between theoretical knowledge and practical skills. This experience is invaluable when transitioning into the workforce, as students learn to tackle actual manufacturing challenges.

- Integration with CAD/CAM Software: Many modern mini press brakes are equipped with software that integrates seamlessly with CAD/CAM systems. This integration allows students to learn how to design parts using CAD software and then translate those designs into real-world products through programming the press brake. This skill set is highly relevant in today’s manufacturing landscape, where digital design and fabrication go hand in hand.

2. Curriculum Development for Metalworking Programs

Educational institutions can develop comprehensive curricula focused on metalworking that include mini press brakes as a core component. This approach prepares students for various career paths in manufacturing, engineering, and design.

- Comprehensive Metal Fabrication Training: By incorporating mini press brakes into their programs, educational institutions can offer students training in various aspects of metal fabrication, including bending, cutting, and welding. This comprehensive training prepares graduates for diverse roles in the manufacturing sector.

- Focus on Innovation and Design: Educational programs can emphasize the importance of innovation in metalworking. By allowing students to experiment with custom designs and materials using mini press brakes, schools can encourage creative thinking and problem-solving skills that are crucial in today’s fast-paced manufacturing environment.

- Collaboration with Local Industries: Educational institutions can partner with local businesses that utilize mini press brakes in their operations. These collaborations can provide students with internship opportunities, real-world projects, and job placements after graduation, further enhancing the educational experience.

3. Promoting STEM Education

The use of mini press brakes in educational settings aligns with efforts to promote STEM (Science, Technology, Engineering, and Mathematics) education. By introducing students to advanced manufacturing technologies, educators can inspire interest in these fields and encourage future careers in engineering and manufacturing.

- Interdisciplinary Learning: Mini press brakes can be used to teach concepts in physics, engineering, and design. Students can learn about force, material properties, and mechanical systems while gaining practical experience in metal fabrication. This interdisciplinary approach helps students see the real-world applications of STEM principles.

- Encouraging Diversity in Manufacturing: By incorporating mini press brakes into educational programs, schools can attract a more diverse group of students to metalworking. Encouraging underrepresented groups, including women and minorities, to pursue careers in manufacturing is essential for creating a more inclusive workforce. Exposure to modern tools like mini press brakes can help dispel stereotypes about the industry and inspire a broader range of students to consider careers in metalworking.

- Developing Problem-Solving Skills: Working with mini press brakes encourages students to develop critical thinking and problem-solving skills. As they encounter challenges in design and production, they learn to analyze problems, make adjustments, and optimize their processes—skills that are valuable in any career path.

4. Remote Learning and Training Solutions

The COVID-19 pandemic accelerated the adoption of remote learning and training solutions in many fields, including manufacturing. Mini press brakes can play a role in hybrid training models that combine online education with hands-on experience.

- Virtual Training Platforms: Educators can develop virtual training platforms that allow students to learn about mini press brake operations and programming through interactive simulations. These platforms can provide theoretical knowledge and even offer virtual hands-on experiences, preparing students for real-world applications.

- Blended Learning Approaches: By combining online coursework with scheduled hands-on sessions in a physical classroom, educators can offer a flexible learning model. This approach allows students to learn at their own pace while still gaining the essential hands-on experience needed for proficiency in metalworking.

- Remote Troubleshooting and Support: With the integration of IoT technology into mini press brakes, educators can offer remote troubleshooting and support to students and trainees. This capability can enhance learning by allowing instructors to monitor student progress, provide feedback, and assist with challenges in real-time.

Economic Impact of Mini Press Brakes

The adoption of mini press brakes has broader economic implications, particularly in terms of job creation, local manufacturing, and overall economic growth.

1. Job Creation in Manufacturing

The increased use of mini press brakes in manufacturing contributes to job creation, particularly in small and medium enterprises (SMEs). As these businesses invest in mini press brakes, they often expand their operations, leading to new job opportunities.

- Expanding Workforce: As SMEs grow, they typically hire additional workers to meet production demands. The need for skilled operators who can efficiently run mini press brakes creates job opportunities in local communities.

- Technical Training Positions: The demand for training programs related to mini press brakes leads to the creation of positions for instructors, trainers, and mentors. This can bolster local economies by providing jobs focused on skill development in manufacturing.

- Support Industries: The growth of businesses that utilize mini press brakes can stimulate demand for ancillary industries, including suppliers of materials, components, and services related to metalworking. This ripple effect further enhances job creation and economic activity in the region.

2. Revitalizing Local Manufacturing Economies

Mini press brakes play a role in revitalizing local manufacturing economies by promoting on-site production and reducing reliance on overseas suppliers. This trend can have significant economic benefits for communities.

- Encouraging Local Production: By enabling local businesses to produce parts in-house, mini press brakes reduce the need for outsourcing and long-distance shipping. This not only supports local economies but also encourages innovation and customization tailored to local markets.

- Sustainability Initiatives: Localized production facilitated by mini press brakes can contribute to sustainability efforts, as businesses reduce their carbon footprint by minimizing transportation needs. This focus on sustainability can attract environmentally conscious consumers and businesses to the area, further boosting economic growth.

- Attracting Investment: The presence of a robust local manufacturing sector supported by technologies like mini press brakes can attract investment from larger companies looking to partner with local businesses or establish a presence in the area. This investment can lead to job creation and economic growth.

3. Driving Innovation and Competitiveness

The use of mini press brakes in various industries fosters innovation and competitiveness, which are crucial for economic growth in a globalized marketplace.

- Encouraging R&D: The flexibility and precision offered by mini press brakes can encourage businesses to invest in research and development (R&D) for new products and processes. This focus on innovation can lead to the development of cutting-edge solutions that enhance a company’s competitive edge.

- Fostering Collaboration: As SMEs adopt mini press brakes and invest in advanced manufacturing technologies, they are often prompted to collaborate with other businesses, educational institutions, and research organizations. These partnerships can lead to the sharing of knowledge, resources, and best practices, ultimately driving further innovation and economic growth.

- Competitive Positioning: Businesses that utilize mini press brakes can offer unique, high-quality products that differentiate them from competitors. This competitive positioning can lead to increased market share and profitability, which can be reinvested in the company and the local economy.

Conclusion: The Multifaceted Impact of Mini Press Brakes

Mini press brakes have established themselves as essential tools in the modern manufacturing landscape, providing a range of benefits that extend beyond simple metal bending. Their affordability, precision, and versatility make them invaluable for small and medium-sized enterprises (SMEs), while their role in education, job creation, and local manufacturing revitalization adds further economic and societal value.

As industries continue to embrace automation, sustainability, and localized production, mini press brakes will play an increasingly significant role in shaping the future of manufacturing. Their adaptability to emerging trends, combined with their potential to foster innovation and collaboration, positions them as key drivers of growth in both local and global markets.

In summary, mini press brakes represent a convergence of advanced technology and practical application, making them indispensable tools for metalworking. As manufacturing evolves, these machines will continue to empower businesses, support education and training initiatives, and drive economic growth, ensuring their place at the forefront of the industry for years to come.

Innovations and Future Trends in Mini Press Brakes

As the landscape of manufacturing continues to evolve, mini press brakes are also adapting to new technologies and methodologies. Emerging trends and innovations promise to enhance the capabilities of these machines, making them even more valuable for businesses in various sectors.

1. Integration of Industry 4.0 Technologies

The advent of Industry 4.0 is transforming manufacturing, and mini press brakes are no exception. The integration of advanced technologies can significantly improve efficiency, connectivity, and data management.

- IoT Connectivity: Mini press brakes are increasingly being equipped with Internet of Things (IoT) capabilities. This allows machines to connect to the internet, enabling real-time monitoring of production processes. Operators can receive alerts regarding machine performance, maintenance needs, and production metrics, allowing for proactive adjustments to minimize downtime.

- Data Analytics: The data collected from IoT-enabled mini press brakes can be analyzed to improve efficiency and productivity. Businesses can use this data to identify bottlenecks in production, optimize workflow, and make data-driven decisions regarding resource allocation and operational

Components of a Mini Press Brake

Although a mini press brake is smaller in scale, its essential components mirror those of a traditional press brake. Some of the key components include:

- Frame: The frame of the mini press brake is typically made of high-strength steel to withstand the forces applied during bending. Even though it’s smaller, the machine must still be robust enough to handle the pressure generated during the bending process.

- Ram: The ram is the moving component of the machine, which presses the punch into the die to shape the metal. In mini press brakes, the ram’s movement is often controlled by a manual or hydraulic mechanism.

- Punch and Die: These are the tools used to shape the metal. The punch is attached to the ram and presses the material into the die, which is mounted on the bed. The shape of the die determines the final bend angle and form of the metal.

- Back Gauge: The back gauge is a device that helps position the metal sheet accurately under the punch and die. This ensures consistent bending and repeatability across multiple pieces.

- Control System: Some mini press brakes are equipped with manual controls, while others may feature computerized numerical control (CNC) systems, which allow for highly accurate bending operations with digital precision.

Types of Mini Press Brakes

Mini press brakes can be categorized based on their mechanism of operation:

- Manual Mini Press Brake: In this version, the machine is operated manually, using a lever or handwheel to move the ram. These are commonly used for lighter materials and simpler projects that do not require high levels of precision or automation.

- Hydraulic Mini Press Brake: Hydraulic mini press brakes use hydraulic cylinders to move the ram. This allows for greater force and precision compared to manual machines. These are ideal for small to medium-sized workshops that require consistent and accurate bends.

- Pneumatic Mini Press Brake: This type of press brake uses air pressure to move the ram. Pneumatic systems are often preferred for their speed and energy efficiency, though they may not provide as much force as hydraulic systems.

- CNC Mini Press Brake: CNC (Computer Numerical Control) mini press brakes offer the highest level of precision and automation. The operator inputs the bending parameters into a computer, and the machine automatically adjusts the ram and back gauge to achieve the desired bends. CNC mini press brakes are used in industries where precision is paramount, such as in electronics, aerospace, and medical device manufacturing.

Applications of Mini Press Brakes

Mini press brakes are used in various industries due to their versatility and ability to produce precise bends on smaller pieces of metal. Some common applications include:

- Prototyping: Mini press brakes are ideal for developing prototypes of metal parts, especially when only a small quantity of components is required. Engineers and designers can use these machines to create custom parts quickly and with high precision.

- Sheet Metal Fabrication: Mini press brakes are commonly used in sheet metal fabrication for making brackets, enclosures, and other components. They can handle thin sheets of metal, bending them into a wide range of shapes and angles.

- Jewelry and Artisanal Work: Artists and jewelers often use mini press brakes to create intricate metal designs, such as rings, bracelets, or custom metal art pieces. The precise control offered by mini press brakes allows for detailed and intricate bends that are essential in the art world.

- Educational Use: Mini press brakes are frequently found in vocational schools and universities for training students in metalworking and manufacturing processes. Their small size and ease of use make them ideal teaching tools for learning the basics of metal bending.

- Repair Shops: In automotive and machine repair shops, mini press brakes are often used to repair or fabricate small metal parts. This includes custom brackets, mounts, and other components that need to be bent to specific angles.

Advantages of Mini Press Brakes

There are several advantages to using mini press brakes over their larger counterparts, particularly in settings where large-scale bending is not necessary:

- Compact Size: One of the most significant benefits of a mini press brake is its compact size. It requires less space than a full-sized machine, making it ideal for small workshops or garages.

- Cost-Effective: Mini press brakes are generally more affordable than larger machines, both in terms of initial cost and ongoing maintenance. This makes them accessible to small businesses, hobbyists, and educational institutions with limited budgets.

- Precision: Despite their small size, mini press brakes are capable of producing highly accurate bends. CNC-controlled models, in particular, offer exceptional precision, making them suitable for high-precision industries such as aerospace and electronics.

- Ease of Use: Many mini press brakes are designed with simplicity in mind. Manual versions are straightforward to operate, while CNC versions often feature user-friendly interfaces that allow operators to input bending parameters easily.

- Versatility: Mini press brakes can be used on a wide variety of materials, including aluminum, stainless steel, and mild steel. They can handle thin sheets of metal and produce a wide range of bend angles and shapes.

- Energy Efficiency: Mini press brakes, especially pneumatic or hydraulic models, are often more energy-efficient than larger machines. This can lead to cost savings in the long run, particularly in shops that perform frequent bending operations.

Limitations of Mini Press Brakes

While mini press brakes offer several advantages, they also come with some limitations: