Sheet Metal Trimming Machine: A sheet metal forming machine is a type of manufacturing equipment used to shape or bend sheet metal into various forms or components. These machines are essential in industries like automotive, aerospace, construction, and home appliances. There are several types of sheet metal forming machines, each suited for different operations depending on the shape, thickness, and material of the sheet metal.

Common Types of Sheet Metal Forming Machines

- Press Brake (or Brake Press)

- Purpose: Bending sheet metal at various angles.

- Types: Mechanical, hydraulic, pneumatic, and servo-electric.

- Applications: Making boxes, enclosures, brackets, and other bent shapes.

- Power Press

- Purpose: Punching, blanking, deep drawing, or forming operations.

- Types: Mechanical or hydraulic.

- Applications: Mass production of components like washers, deep-drawn cups, etc.

- Roll Forming Machine

- Purpose: Continuous bending of long strips of sheet metal.

- Process: Metal passes through a series of rollers that progressively shape it.

- Applications: Roofing sheets, metal siding, gutters, etc.

- Hydraulic Press

- Purpose: Deep drawing, punching, and forming.

- Advantages: Can handle thicker metals and provide higher force.

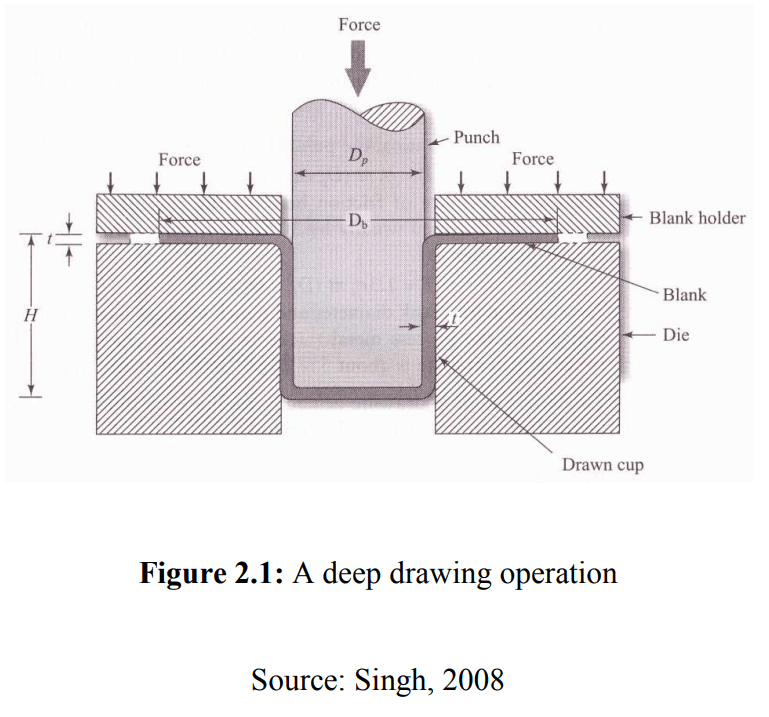

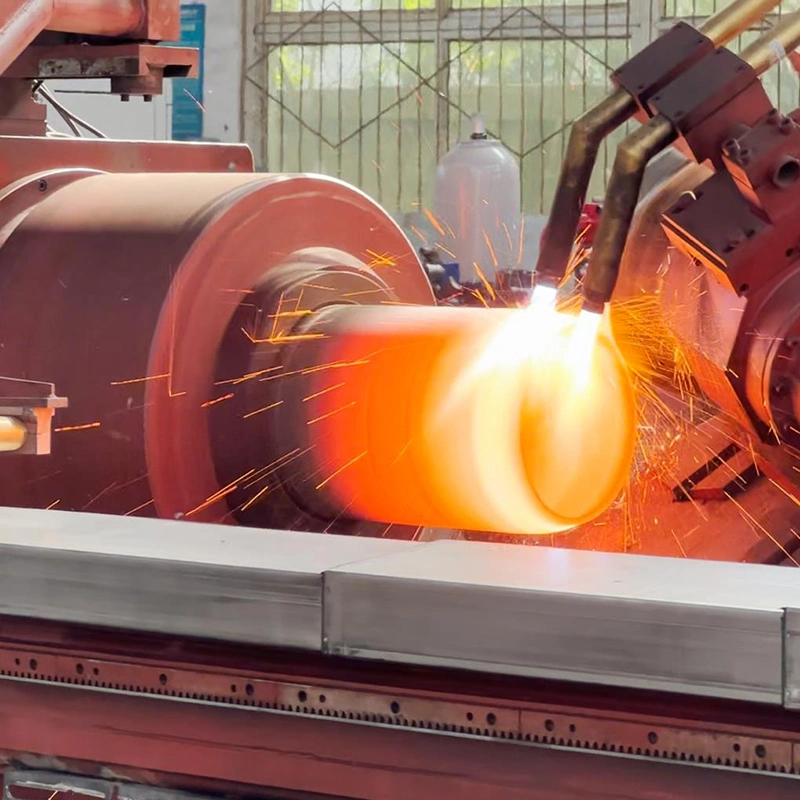

- Spinning Machine

- Purpose: Rotational forming to create round parts.

- Applications: Producing symmetrical objects like gas cylinders, cones, and hemispheres.

- Stretch Forming Machine

- Purpose: Stretching and bending sheet metal simultaneously.

- Applications: Aircraft skins, curved panels, and complex contours.

- Stamping Press

- Purpose: High-speed punching, blanking, embossing, and coining.

- Used With: Dies and tools specifically shaped for the desired output.

- Shearing Machine

- Purpose: Cutting sheet metal to size before forming.

- Types: Guillotine shear, bench shear, power shear.

Key Considerations When Choosing a Machine

- Material type and thickness

- Size and complexity of the part

- Production volume

- Required accuracy and repeatability

- Budget and space

A sheet metal forming machine is a manufacturing tool used to shape flat sheets of metal into specific forms or components without removing any material. These machines are essential in industries like automotive, aerospace, construction, and consumer electronics, where precise metal parts are required in high volume and consistent quality. The forming process relies on applying force to deform the sheet metal plastically, changing its shape without breaking or cutting it.

One of the most common types is the press brake, which bends sheet metal into desired angles using a punch and die setup. It is widely used for forming parts like brackets, panels, and chassis. Another widely used machine is the power press, capable of performing tasks like blanking, punching, and deep drawing. It’s particularly effective in high-speed production environments due to its ability to shape metal in a single stroke.

Roll forming machines are designed for continuous bending of long strips of metal by passing them through a series of rollers. These machines are ideal for producing uniform profiles such as roofing sheets, door frames, and channels. Hydraulic presses, with their ability to exert very high pressure, are used for deep drawing and forming operations on thicker sheets. They offer more control and are suitable for complex shapes.

Spinning machines are used when a symmetrical, round component is needed. A flat sheet or disc is rotated and pressed over a mold using a roller tool to form items like gas cylinders, cones, and domes. For large panels or parts with smooth contours, stretch forming machines apply tension and bend the sheet over a form, commonly used in aircraft manufacturing.

Stamping presses operate at high speeds and are suitable for tasks such as embossing, coining, and forming with high precision. They are typically used with custom-designed dies and punches for mass production. Before forming begins, shearing machines are often used to cut sheet metal to the required size. These can be manual or powered and are designed to provide clean, straight cuts.

Selecting the right sheet metal forming machine depends on factors such as material type and thickness, complexity of the part, production volume, and the level of precision required. Each machine type has its own advantages, and in many manufacturing setups, multiple machines are used together to complete the entire forming process efficiently.

In addition to machine types, the success of sheet metal forming also depends heavily on tooling and material behavior. The punch and die configuration in a press brake or stamping press must be precisely matched to the metal’s properties and desired shape. Factors like springback, which is the metal’s tendency to return to its original shape after bending, must be compensated for during the tool design phase. Advanced software tools are now often used for simulating forming operations to predict issues like tearing, wrinkling, or insufficient forming.

Materials used in sheet metal forming range from aluminum and stainless steel to copper and titanium, depending on the application. Each metal has different ductility and tensile strength, which influences how easily it can be formed and the amount of force required. For instance, aluminum is lightweight and relatively easy to form, making it a preferred choice in the automotive and aerospace sectors. On the other hand, high-strength steel is harder to form but offers superior durability and is often used in structural applications.

Automation is also playing an increasingly important role in modern sheet metal forming. CNC (Computer Numerical Control) systems allow for precise, repeatable movements of machine components, reducing manual labor and increasing accuracy. Robotic arms can feed sheets into machines, transfer parts between stations, or perform post-forming tasks like welding or assembly. This not only boosts productivity but also minimizes errors and improves safety in production environments.

Safety is a major consideration in sheet metal forming operations, as the machines exert significant force and involve sharp edges and high-speed components. Safety features like light curtains, emergency stops, two-hand controls, and enclosed work areas are standard on modern machines. Operator training is equally important to ensure proper handling, maintenance, and emergency response.

In recent years, the industry has also seen growth in flexible forming technologies like hydroforming and incremental sheet forming. Hydroforming uses a high-pressure fluid to shape sheet metal against a die, allowing for complex and seamless shapes with high strength-to-weight ratios. Incremental forming, which uses a small tool to gradually shape a sheet through localized deformation, is suitable for prototyping and small-batch production due to its flexibility and low tooling cost.

Overall, sheet metal forming machines are a cornerstone of industrial manufacturing. With advancements in material science, digital control, and forming techniques, they continue to evolve—enabling faster production, better precision, and the ability to form increasingly complex geometries. Whether for mass production or custom components, these machines are essential for transforming raw sheet metal into the parts and products we rely on every day.

As industries demand more complex, lightweight, and durable components, the evolution of sheet metal forming machines is becoming increasingly centered around precision engineering, digital integration, and sustainability.

One of the most impactful advancements is the integration of smart manufacturing technologies, such as IoT (Internet of Things) sensors and real-time data analytics. Modern machines can monitor forming force, stroke cycles, temperature, and even vibration during operation. This data is fed into monitoring systems that can detect anomalies early, predict tool wear, and optimize maintenance schedules—minimizing downtime and extending machine life.

Laser-assisted forming is another emerging technique where localized heating with lasers reduces the force needed to form high-strength materials. This is especially useful in automotive applications, where ultra-high-strength steels are used for crash-resistant vehicle structures. By softening the metal in a controlled way, manufacturers can form more intricate shapes without cracking the material.

Meanwhile, additive manufacturing (3D printing) is starting to complement traditional sheet metal processes, especially for the creation of forming dies and custom tooling. Complex, lightweight die structures can be produced more quickly and with optimized internal features, such as cooling channels, which improve performance and reduce lead times.

In terms of energy efficiency, newer hydraulic and electric press systems are designed to consume less power and operate more quietly compared to traditional machines. Servo-electric presses, for example, use precise electric actuators instead of hydraulics, enabling extremely accurate control over speed and position while reducing oil usage and environmental impact.

Another area gaining traction is modular machine design, where sheet metal forming machines can be quickly adapted to different tasks or materials by changing modules or tooling. This flexibility is crucial for industries like aerospace or medical devices, where frequent design changes and small batch sizes are common.

From a sustainability perspective, the industry is also focused on minimizing material waste. This is done through better nesting algorithms (for cutting operations), scrap recycling systems, and more efficient forming techniques that reduce the number of rejected parts. Closed-loop feedback systems between CAD/CAM software and the forming machine can adjust tool paths or bending angles in real-time to ensure the part remains within tolerance throughout production.

In educational and prototyping environments, desktop-scale sheet metal forming machines are becoming more accessible. These machines allow students, designers, and small manufacturers to experiment with forming techniques at a smaller scale, encouraging innovation and hands-on learning without large capital investment.

Looking ahead, the future of sheet metal forming will likely include greater use of AI-driven optimization, where machine learning algorithms analyze vast amounts of production data to improve process parameters continuously. Combined with robotics, machine vision, and collaborative interfaces, these intelligent systems will enable autonomous forming lines capable of adjusting to new product designs with minimal human intervention.

The sheet metal forming machine, once a purely mechanical workhorse, has now become a high-tech, adaptive part of the modern manufacturing ecosystem—bridging traditional metalworking skills with the digital demands of Industry 4.0.

Sheet Metal Drawing Machine

A Sheet Metal Drawing Machine is a specific type of forming machine used in the deep drawing process, where a flat sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It transforms a flat sheet into a hollow or cup-shaped component without wrinkling, tearing, or excessive thinning. This process is widely used to manufacture parts like kitchen sinks, gas cylinders, automotive body panels, and various containers.

How It Works

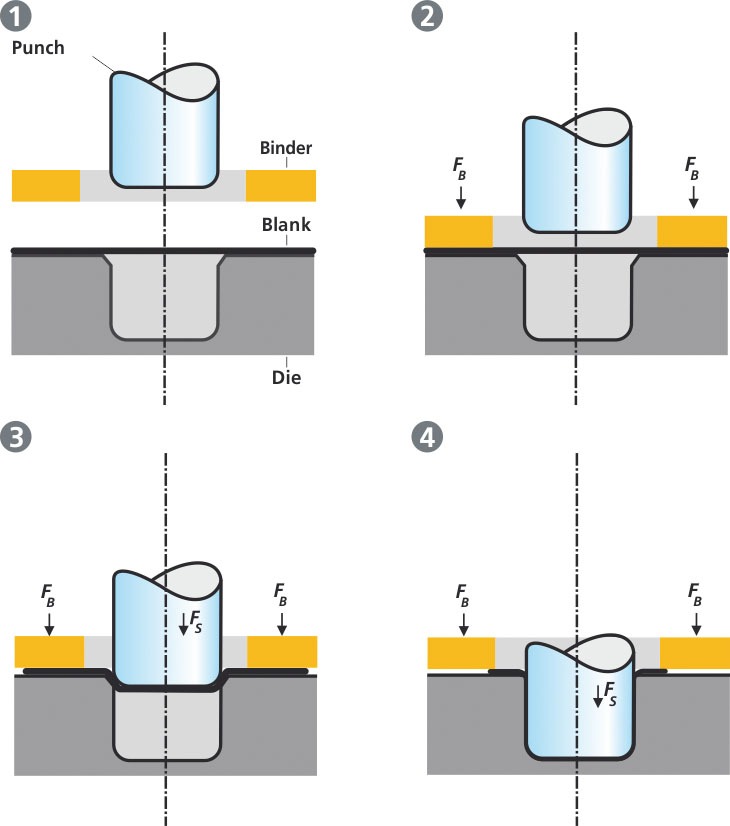

In a sheet metal drawing machine, the metal blank is placed over a die cavity, and a blank holder (also called a pressure pad) holds it in place to control material flow. A punch then pushes the metal into the die, stretching it into a new shape. The punch and die are usually precision-engineered to maintain tight tolerances and avoid surface defects.

Types of Sheet Metal Drawing Machines

- Hydraulic Drawing Press

- Offers precise force control, ideal for deep drawing high-strength or thick materials.

- Often used for complex or large parts.

- Smooth and adjustable speed and stroke.

- Mechanical Drawing Press

- Operates via crankshaft and flywheel mechanisms.

- Faster than hydraulic types, but less adaptable to complex geometries.

- Suitable for high-speed production of shallow drawn parts.

- Double Action Drawing Press

- Has two rams: one controls the blank holder, and the other moves the punch.

- Ensures better control over material flow during deep drawing.

- Common in automotive and appliance manufacturing.

- Pneumatic Drawing Press

- Uses compressed air to drive the punch.

- Simple and clean but limited in force capacity.

- More often used for light gauge metal and smaller parts.

Key Components

- Die: The cavity into which the sheet is drawn.

- Punch: The tool that presses the sheet into the die.

- Blank Holder: Holds the sheet and prevents wrinkling.

- Draw Beads: Control the metal flow into the die cavity.

Applications

- Automotive: Fuel tanks, body panels, wheel housings.

- Consumer goods: Kitchen sinks, cooking pots, metal containers.

- Aerospace: Engine housings, pressure vessels.

- Industrial: Electrical enclosures, filter housings.

Materials Typically Used

- Mild steel

- Stainless steel

- Aluminum

- Copper and brass

- Titanium (for aerospace and medical)

Advantages

- High dimensional accuracy

- Smooth surface finish

- Stronger parts due to work hardening

- Efficient material usage for hollow parts

Challenges

- Requires precise control to avoid tearing or wrinkling

- Tooling is expensive and needs regular maintenance

- Material selection is critical for successful drawing

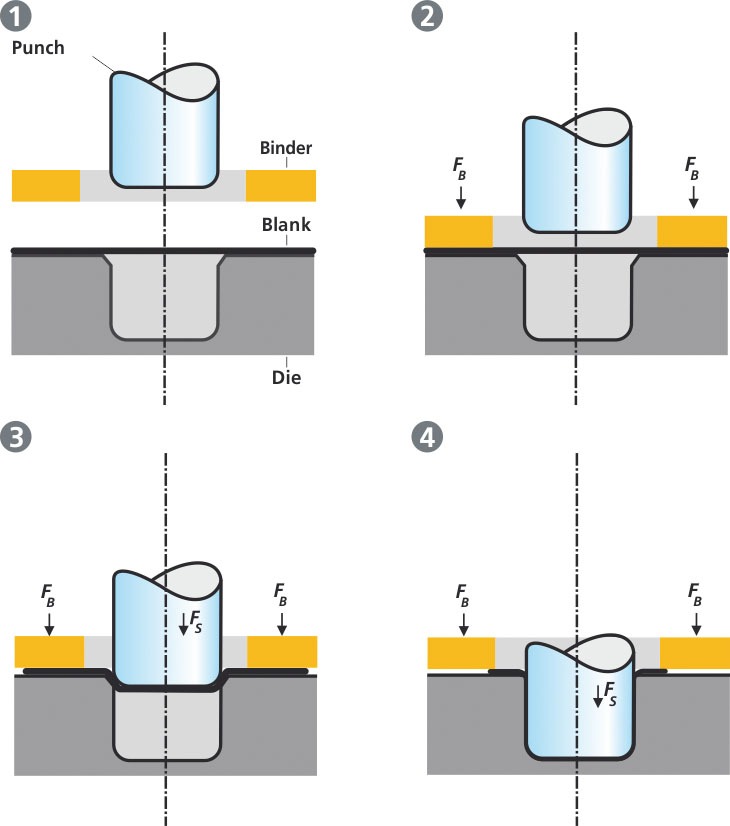

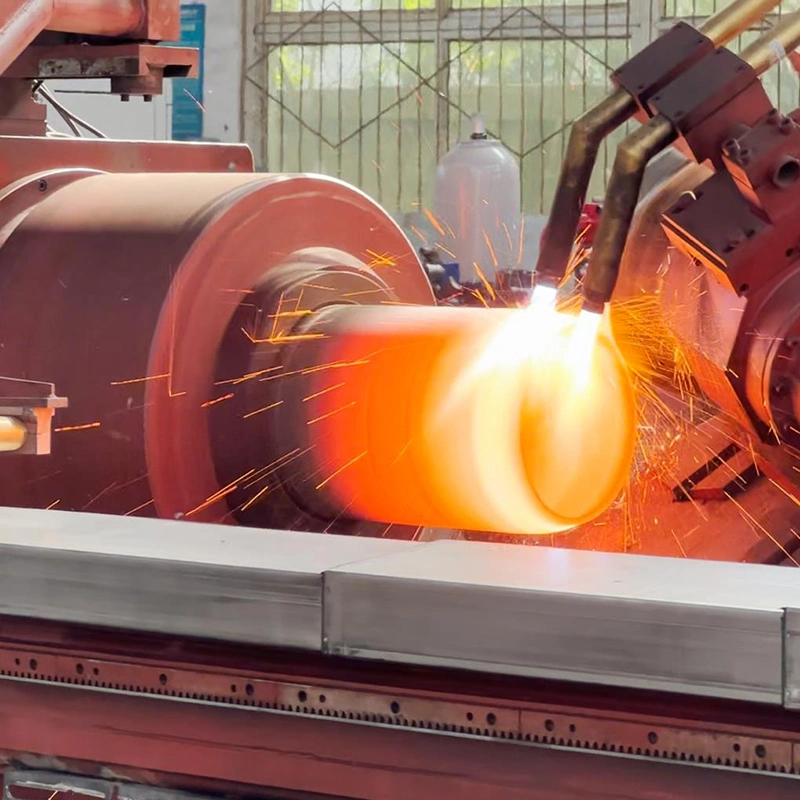

A sheet metal drawing machine is designed to perform one of the most critical processes in metal forming—deep drawing. This operation transforms flat metal blanks into hollow, cup-like or box-like shapes using a combination of pressure, controlled force, and precision tooling. Unlike bending or rolling, drawing involves significant plastic deformation, where the material is pulled radially inward and forced into a die cavity by a punch. The machine must ensure that the material flows correctly without wrinkling at the flange or tearing near the punch radius, both of which are common defects if the process isn’t carefully controlled.

The machine typically operates in a sequence starting with the placement of a flat metal blank over a die opening. A blank holder then clamps down on the edges of the blank to control how the metal flows during the punch stroke. As the punch descends, it pushes the material into the die, forming it into the desired shape. The challenge here lies in maintaining a balance between holding force and punch force. If the blank holder force is too high, it may restrict the material flow and cause tearing; if too low, it may lead to wrinkling or uncontrolled flow. This delicate balance is why deep drawing machines often feature sophisticated hydraulic systems or servo-controlled actuators to finely tune these forces in real time.

The performance of a drawing machine also depends on the geometry of the punch and die, the lubrication conditions, and the properties of the sheet material. Smooth die surfaces and proper lubrication are critical because they reduce friction and prevent galling, which can damage both the part and the tooling. Additionally, the material’s ductility, thickness, and grain direction play a big role in determining how deep or complex a shape can be drawn in a single stroke. For more difficult parts or stronger metals, multi-step drawing processes may be used, involving redrawing, ironing, or annealing between steps to relieve stresses and allow further shaping.

In mass production environments, especially in automotive and appliance manufacturing, drawing machines are often automated and integrated into press lines with robotic handling systems. This automation not only improves speed and consistency but also reduces the physical strain on operators and minimizes human error. These systems can produce thousands of identical parts per shift with very tight tolerances and surface finish requirements. Sensors and real-time monitoring systems track each stroke, ensuring every part meets quality standards, and stopping the process if any anomaly is detected.

Modern sheet metal drawing machines are also increasingly equipped with digital controls and feedback systems that allow for adaptive forming. With the integration of Industry 4.0 technologies, these machines can learn from each production cycle, adjusting parameters like punch speed, dwell time, or holding pressure dynamically to optimize part quality. This is especially useful when forming high-performance alloys or working with recycled materials, where variability in sheet quality can affect outcomes.

In research and prototyping applications, smaller-scale or lab-grade drawing machines are used to test material formability, study lubrication effects, and develop new forming strategies. These experimental setups help manufacturers design better tooling and predict formability limits using techniques like finite element analysis, which can simulate the drawing process before any physical part is made.

As manufacturers continue to push for lighter, stronger, and more complex components—particularly in electric vehicles, aerospace, and medical devices—sheet metal drawing machines will remain a foundational technology. Their evolution will likely focus on even greater precision, faster cycle times, improved material compatibility, and deeper integration with smart manufacturing ecosystems.

In advanced manufacturing settings, the role of sheet metal drawing machines goes beyond simply forming shapes—it’s about achieving consistently high quality at high speed while adapting to ever-changing design requirements and materials. As product development cycles become shorter, drawing machines are expected to handle a wider range of geometries and materials without the need for extensive retooling. This flexibility is being enabled by modular tooling systems and programmable control interfaces that allow rapid setup changes and fine-tuning of forming parameters.

Tooling in a drawing machine, particularly the die and punch, must be designed with not only the final shape in mind but also the mechanical properties of the material during deformation. For example, sharper corners on a die might result in stress concentration and tearing if the material doesn’t have sufficient ductility. To prevent this, the edges are usually radiused, and in critical applications, simulations are performed before tooling is ever manufactured. Finite Element Method (FEM) simulations are now commonly used to predict material flow, thinning, stress distribution, and potential failure zones. These simulations save both time and money by identifying and correcting issues early in the design stage.

Another important aspect is lubrication. The drawing process involves significant contact between the tool and the sheet metal, and without proper lubrication, there’s a high risk of surface defects and tool wear. Lubricants must be carefully chosen based on the material type, the complexity of the draw, and environmental considerations. For example, deep drawing aluminum requires different lubricants than stainless steel due to differences in surface adhesion and friction characteristics. In high-speed automated lines, lubrication systems are integrated directly into the machine to apply the right amount at the right locations on each blank.

The evolution of materials also presents new challenges and opportunities for sheet metal drawing. With the rise of lightweight alloys like aluminum-magnesium blends, ultra-high-strength steels (UHSS), and even titanium in aerospace and medical fields, drawing machines must be capable of applying higher forces with greater control. These materials often require a combination of deep drawing and additional processes like ironing, where the wall thickness is reduced and the surface is smoothed, or reverse drawing, where the part is drawn in the opposite direction to refine geometry and strength.

In some advanced processes, sheet metal drawing is combined with hydroforming, where a pressurized fluid supports the material during forming, allowing for more complex and delicate shapes without cracking. Similarly, warm forming involves heating the sheet metal before drawing to improve ductility, especially for high-strength alloys. Drawing machines that incorporate such hybrid techniques expand the range of parts that can be manufactured, offering designers more freedom and enabling the creation of optimized lightweight structures.

The growing emphasis on sustainability in manufacturing also affects drawing operations. Manufacturers are looking for ways to reduce scrap, reuse lubricants, and lower energy consumption. Energy-efficient motors, regenerative braking in hydraulic systems, and advanced monitoring help meet environmental standards while maintaining productivity. Some manufacturers are also exploring forming recycled sheet metal, which introduces variability in the input material and requires highly responsive drawing machines to compensate in real time.

As these machines become more digitally connected, operators and engineers can access real-time dashboards showing cycle times, press loads, lubricant flow rates, part dimensions, and even predictive maintenance alerts. The machine effectively becomes part of a smart factory ecosystem where every stroke contributes data to improve the process continuously. AI and machine learning algorithms analyze this data to recommend settings, adjust machine behavior on the fly, or suggest when to replace tooling before defects occur.

Ultimately, the modern sheet metal drawing machine is not just a tool for shaping metal—it’s a high-precision, intelligent platform that supports innovation in design and efficiency in production. It sits at the intersection of mechanical engineering, material science, data analytics, and automation, enabling manufacturers to create stronger, lighter, and more complex components with incredible reliability.

Sheet Metal Bulging Machine

A Sheet Metal Bulging Machine is a specialized forming machine used to expand or “bulge” a portion of a hollow or tubular metal workpiece outward, creating a controlled protrusion or dome-like feature. This process is commonly applied in the manufacturing of components like pressure vessels, fire extinguishers, bellows, plumbing fittings, automotive exhaust parts, and containers requiring reinforced or functional geometric changes.

Unlike deep drawing, which pulls flat sheet metal into a cavity, bulging pushes part of a closed or partially closed metal surface outward—either by applying internal pressure (hydraulic, pneumatic, or explosive) or by mechanical pressing with shaped dies. The result is a localized increase in diameter or outward expansion of the material in a defined area without tearing or thinning beyond acceptable limits.

The typical working principle involves placing a tubular or closed-end cylindrical workpiece between two die halves. Then, internal pressure is applied, usually with a hydraulic medium or a rubber bladder, which forces the metal to expand outward into the die cavity. Some bulging machines use a punch-and-die mechanism where external force is applied radially or axially to bulge a specific section. The dies define the final external shape of the bulged region, and the process must be carefully controlled to avoid splitting, wrinkling, or material thinning.

Modern bulging machines come in several variations:

- Hydraulic Bulging Machines: Use fluid pressure to expand the metal. Precise and commonly used for medium to large-sized components.

- Rubber Bulging Machines: Employ a rubber pad or diaphragm to apply uniform pressure, often used for complex or delicate shapes.

- Mechanical Bulging Machines: Utilize cam-driven or servo-controlled punches to mechanically expand the material into a bulged shape.

- Explosive Bulging (used in R&D or special aerospace cases): Relies on a controlled detonation to create extreme internal pressure and form complex shapes—rare and highly specialized.

Bulging is especially effective for creating necks, flanges, ribs, and bosses on metal parts without welding or joining separate components. It improves structural rigidity and often reduces part count and weight in assembled products. The success of the bulging process depends on the material’s ductility, wall thickness, initial diameter, and pressure control. Thicker and more ductile materials like stainless steel, aluminum, copper, and mild steel perform well under bulging operations.

Tooling must be robust and designed to match the expected deformation profile. In automated systems, bulging machines can be integrated into production lines with feeding mechanisms, positioning sensors, and post-forming quality checks using vision systems or ultrasonic thickness gauges.

As with other metal forming technologies, bulging machines are increasingly equipped with digital control systems, load monitoring, and CNC/PLC programming to improve repeatability and minimize defect rates. By precisely controlling the expansion process, manufacturers can produce high-integrity parts with smooth surfaces and consistent mechanical properties.

A sheet metal bulging machine operates on the principle of internal or external force application to create a controlled expansion in a localized area of a metal workpiece, typically cylindrical or tubular in shape. The main objective is to form features such as bulges, necks, or domes without cutting or welding, preserving the material’s continuity and structural strength. This makes the bulging process ideal for industries that require pressure-tight, seamless components such as in fire extinguishers, air tanks, automotive exhaust parts, and HVAC systems.

The bulging process begins by securely positioning the metal tube or preformed part within the machine’s die cavity. The die cavity is shaped to define the final form of the bulged area. In most hydraulic or hydro-mechanical bulging machines, a fluid medium—either hydraulic oil or water—is introduced into the interior of the workpiece under very high pressure. As the internal pressure increases, the material is forced outward into the contours of the die, forming a precise and uniform bulge. Rubber-based bulging machines replace the fluid with an elastic membrane or pad that distributes pressure more evenly, which is particularly beneficial when dealing with irregular shapes or complex profiles.

Control of the bulging pressure is critical. Too much force can cause the material to thin excessively or rupture, while too little may result in incomplete forming or wrinkling. Advanced machines use real-time pressure feedback systems and programmable logic controllers (PLCs) to ensure that the pressure curve matches the specific requirements of the material and shape. The material’s yield strength, ductility, and wall thickness directly influence the maximum safe pressure that can be applied. To increase formability, sometimes the material is heated before or during the process, allowing more complex or deeper bulges to be achieved without failure.

In mechanical bulging, instead of internal pressure, force is applied externally through tools or punches that press against a segment of the metal from the outside, often aided by a mandrel inside the tube for support. This is particularly useful for forming beads or reinforcing rings in exhaust pipes or structural frames. These machines are often cam- or servo-driven and provide a fast, repeatable method of producing bulged shapes where high-volume, lower-complexity production is required.

One key advantage of bulging is that it enhances part functionality and aesthetics without the need for joints or weld seams, which can be weak points in pressure vessels or fatigue-sensitive parts. The process also lends itself well to material saving, since the bulged form is achieved through plastic deformation rather than assembly from multiple parts. Additionally, the elimination of joining processes reduces the chances of leaks, corrosion, and manufacturing errors.

Post-forming operations such as trimming, piercing, or calibration are often integrated with the bulging machine or handled in downstream processes. In automated production environments, robots or material handling systems may move the part through several stations—bulging, trimming, cleaning, and inspection—all within a single integrated cell. Non-destructive testing methods such as ultrasonic thickness gauging or eddy current inspection are used to verify that the bulged regions meet safety and dimensional standards, especially in applications involving pressure containment.

Modern bulging machines continue to evolve with the integration of CNC controls, servo-hydraulics, and simulation-driven design. Computer modeling of the bulging process using finite element analysis allows engineers to predict material behavior, identify potential weak points, and optimize die shapes before physical trials begin. This significantly reduces development time and tooling costs, especially when dealing with new materials or complex geometries.

As lightweighting becomes increasingly important in automotive, aerospace, and industrial design, bulging offers a viable method to reduce part weight while maintaining strength and stiffness. It enables designers to create innovative structural features that are both functional and aesthetically clean, and it aligns well with modern goals of material efficiency, automation, and product integrity.

The continued development of sheet metal bulging machines is deeply tied to advances in materials science, automation, and digital manufacturing. As new materials like high-strength steels, aluminum alloys, and even titanium become more common in industrial applications, bulging machines must adapt to handle their unique behaviors under pressure. High-strength steels, for instance, resist deformation and require carefully calculated pressure profiles to bulge effectively without cracking. Aluminum, while more ductile, is prone to thinning and wrinkling, making pressure modulation and die surface finish critically important.

To address these challenges, modern machines often include real-time thickness monitoring and adaptive pressure systems that respond to feedback from sensors during the forming process. These sensors can detect minute changes in material flow or pressure resistance and instantly adjust internal parameters—slowing down the stroke, increasing support pressure, or holding at a particular stage of deformation. This dynamic feedback loop enhances process reliability and significantly reduces scrap rates, which is crucial in industries like aerospace and medical devices where part precision is non-negotiable.

Digital twins are increasingly being used in the development and refinement of bulging processes. A digital twin is a virtual replica of the bulging machine and the forming process, constantly updated with data from sensors, control systems, and simulations. Engineers can use this digital model to simulate countless scenarios—trying different die shapes, material types, or pressure cycles—to optimize production before physically forming even a single part. This integration between physical and virtual systems marks a shift toward smarter, more predictive manufacturing.

Bulging machines are also evolving in terms of structural design and energy efficiency. Servo-hydraulic systems, which replace traditional hydraulic valves with servo-driven actuators, allow for much finer control over pressure and movement while using less energy and generating less heat. These systems also run quieter, require less maintenance, and offer more environmentally friendly operations, aligning with green manufacturing trends. In some cases, fully electric bulging machines are being developed for smaller applications, eliminating the need for hydraulic oil altogether.

Safety is another area where improvements are ongoing. Because bulging involves high internal pressures—sometimes reaching thousands of psi—it presents risks that must be carefully managed. Modern machines feature multi-layer containment systems, emergency release mechanisms, and interlock systems to prevent operation if the part or tooling is misaligned. Operators are protected by transparent shields, pressure-rated enclosures, and software safeguards that halt the process if any parameter moves out of the safe operating range.

From a production standpoint, bulging machines are increasingly modular, allowing quick changeovers between different product types. This is especially useful for manufacturers that produce multiple variants of a part with only slight differences in bulge size or position. Tooling systems can be swapped out quickly, and pre-programmed forming recipes can be loaded through the control interface to switch jobs in minutes rather than hours. This flexibility reduces downtime and supports lean manufacturing practices.

In educational and prototyping environments, scaled-down versions of bulging machines are used to teach metal forming fundamentals and explore new design concepts. These smaller machines allow students and engineers to experiment with different forming strategies, materials, and die geometries in a hands-on way. In research labs, they’re used to explore cutting-edge ideas like multi-step bulging, controlled wrinkling for textured surfaces, or integration with additive manufacturing for hybrid parts.

Ultimately, the sheet metal bulging machine represents a key capability in advanced manufacturing—one that enables designers and engineers to push the boundaries of what can be made from a single piece of metal. Whether it’s a simple flare on a pipe end or a complex, load-bearing dome on a pressure vessel, bulging adds both form and function without compromise. As the technology continues to evolve, its role will only grow in importance across industries that demand strength, reliability, and innovation from every part they produce.

Sheet Metal Deep Draw Stamping Machine

A Sheet Metal Deep Draw Stamping Machine is a specialized piece of equipment used in the process of deep drawing, which is a forming technique that transforms a flat metal sheet into a three-dimensional part. The process typically involves stretching the material into a die cavity using a punch to form shapes such as cups, cylinders, and other complex geometries. Deep drawing is essential in industries like automotive, aerospace, appliances, and consumer electronics, where parts require precise, complex shapes with minimal material waste.

In a deep draw stamping machine, the sheet metal is fed into a die cavity. The die cavity determines the final shape of the part, while a punch presses down on the metal, pushing it into the die. The challenge with deep drawing, compared to other metal forming processes like bending, is that the material must stretch without tearing or excessively thinning, and this requires carefully controlled pressure, speed, and material handling. Deep draw stamping machines are designed to apply the necessary force while controlling the material flow, ensuring that the final part meets dimensional accuracy and surface finish requirements.

The core components of a deep draw stamping machine include the punch, die, blank holder, and sometimes, draw beads. The punch applies downward force on the sheet metal, while the die creates the cavity into which the metal is drawn. The blank holder holds the sheet in place to prevent wrinkling as the punch descends. Draw beads are used to control the material flow into the die and prevent wrinkles in the material during the forming process.

One of the key considerations when designing a deep draw stamping machine is ensuring that the material is evenly distributed and flows properly. If the material is drawn too quickly, it could tear; if it’s drawn too slowly, it may wrinkle. To prevent this, machines are equipped with features like variable stroke control and adjustable blank holding pressure. Additionally, the machine may incorporate lubrication systems to reduce friction between the punch, die, and sheet metal, which helps to prevent wear and tear on the tooling and ensures a smoother finish on the part.

The deep draw stamping process is typically done in stages. For more complex parts, multiple drawing stages might be required. The part is drawn incrementally, with each stage reducing the thickness of the material while increasing its depth. After the final drawing stage, the part may be subjected to further operations like trimming, punching, or flanging to complete its final shape.

These machines can be mechanical presses, which operate via a crank mechanism, or hydraulic presses, which use hydraulic fluid to generate the necessary force. Hydraulic presses are often favored for deep drawing due to their ability to provide precise control over the force, which is essential for creating deep, complex shapes. Mechanical presses, on the other hand, are faster and are typically used for high-volume production of simpler parts.

In modern deep draw stamping machines, automation plays a significant role. Automatic feeders and part handling systems can load sheets, remove finished parts, and handle materials with minimal human intervention, which increases throughput and reduces labor costs. For highly automated operations, robots or conveyors are used to transport parts to the next stage of production, ensuring continuous and efficient processing.

Furthermore, advanced sensors and monitoring systems are now integrated into many machines to ensure process consistency and quality. These systems monitor parameters like pressure, temperature, and material thickness throughout the stamping process. By collecting real-time data, manufacturers can immediately detect deviations in part quality, allowing them to make adjustments to the machine settings on the fly, minimizing the risk of defects and reducing scrap.

Deep draw stamping is used for a wide variety of applications. In automotive manufacturing, it’s used to create parts like body panels, fuel tanks, and wheel rims. In the appliance industry, deep draw stamping is used to create items such as washing machine tubs and sinks. Medical device manufacturers also rely on deep drawing to create components like surgical trays and housings for electronic equipment.

The process itself is highly energy-efficient compared to some other forming techniques, especially when combined with modern hydraulic and automation technologies. It’s also highly scalable, meaning manufacturers can produce large quantities of parts quickly and with minimal waste, which is ideal for industries requiring high-volume production.

To summarize, sheet metal deep draw stamping machines represent a critical technology for producing complex, high-quality metal parts with a smooth, precise finish. By carefully controlling material flow, pressure, and tooling, these machines can create intricate shapes from a single sheet of metal, reducing the need for additional fabrication steps like welding or joining. As demand for lightweight, durable, and complex parts continues to grow in industries ranging from automotive to electronics, deep draw stamping remains a key manufacturing process.

Sheet metal deep draw stamping machines are essential in shaping a wide range of products with complex geometries. These machines excel in creating deep, seamless parts by drawing a flat metal sheet into a cavity using a punch. Unlike other stamping techniques, deep drawing significantly stretches the material, transforming it into hollow or cup-like shapes. This process is crucial in industries like automotive, aerospace, and consumer electronics, where precision, part strength, and material efficiency are critical.

The challenge of deep drawing lies in managing material flow and preventing issues like tearing, thinning, or wrinkling during the forming process. Proper management of force, speed, and material positioning is essential to achieve high-quality parts. This is why deep draw stamping machines often have features that allow for adjustable blank holding pressure, variable stroke control, and precise lubrication systems. These components work in tandem to control the material’s behavior and ensure the part’s integrity, reducing scrap and defects.

Deep drawing machines may be equipped with different types of presses depending on the application. Hydraulic presses are commonly used for deep drawing because they offer precise control over the applied force, which is essential for creating parts with greater depth and complexity. Mechanical presses, on the other hand, are often used for higher-volume production of simpler shapes due to their speed and efficiency. The choice between hydraulic and mechanical presses depends on the complexity of the parts being produced and the required production speed.

To enhance efficiency and reduce downtime, modern deep draw stamping machines are increasingly automated. Automated systems for feeding material, handling finished parts, and positioning components improve throughput and minimize the need for manual labor. These systems often include robotic arms or conveyors to streamline operations and maintain a continuous production flow. This automation not only boosts productivity but also reduces human error, ensuring more consistent part quality.

In addition to the basic components of punch, die, and blank holder, advanced deep draw machines incorporate sensors and real-time monitoring systems to enhance process control. These sensors track key parameters, such as pressure, temperature, and material thickness, throughout the stamping process. By analyzing this data, manufacturers can detect issues early, allowing for timely adjustments to ensure consistent part quality and minimize waste.

The deep draw stamping process is often used in the production of parts with specific requirements such as strength, shape, and material properties. In automotive manufacturing, for example, deep draw stamping is used to create components like body panels, fuel tanks, and other structural elements. The ability to form complex shapes from a single sheet of metal reduces the need for additional processes like welding or assembly, which contributes to lower production costs and higher part strength.

The method also offers significant advantages in terms of material efficiency. Since the process uses a single metal sheet to create a finished part, the material waste is typically minimal, making it more environmentally friendly than other manufacturing processes. For manufacturers focused on reducing costs and improving sustainability, deep drawing offers an attractive solution for producing high-strength, lightweight parts without excessive scrap.

Another notable advantage is the scalability of the deep draw stamping process. Once the tooling is set up and the machine is calibrated, it can produce large quantities of identical parts quickly. This is especially useful in industries that require high-volume production, such as automotive or appliance manufacturing. The efficiency of the deep draw stamping machine ensures that manufacturers can meet high demand while maintaining consistent quality.

Moreover, innovations in machine design continue to improve the capabilities of deep draw stamping machines. Advances in die design, material technology, and automation are making it possible to create even more complex parts with greater precision. Additionally, the integration of smart technologies like artificial intelligence and machine learning into deep draw stamping machines allows for predictive maintenance and real-time optimization of the forming process.

As industries demand lighter, stronger, and more intricately shaped parts, the deep draw stamping machine continues to be a key technology. By adapting to the evolving needs of modern manufacturing, these machines help produce components that meet the highest standards for performance and durability. Whether used for automotive parts, aerospace components, or household appliances, deep draw stamping is a versatile and efficient technique that remains indispensable in high-precision metal forming.

As manufacturing industries continue to demand higher levels of efficiency and precision, deep draw stamping machines are evolving to meet these needs. Innovations in materials, tooling, and machine controls are enhancing the capabilities of deep drawing processes, allowing manufacturers to push the limits of what can be produced from a single sheet of metal.

One significant area of development is the use of advanced materials that push the boundaries of deep drawing capabilities. Manufacturers are increasingly working with high-strength alloys, lightweight metals like aluminum and titanium, and even new composite materials that present unique challenges in forming. These materials often require more delicate handling to ensure they do not fail during the deep drawing process, and this has led to more sophisticated machine controls that can adjust parameters such as pressure, speed, and stroke length on the fly. The ability to form high-strength, lightweight materials efficiently makes deep draw stamping increasingly attractive in sectors like automotive manufacturing, where reducing weight while maintaining strength is crucial.

In addition to material advancements, tooling technology is also improving. Modern deep draw stamping dies are designed with greater precision and longevity. Die materials have become stronger and more durable, reducing wear and tear over time, which can otherwise lead to defects or inconsistent quality. Advanced die coatings and surface treatments further increase the lifespan of tooling, making it more cost-effective and allowing for higher production volumes before the need for maintenance or replacement.

One particularly promising area in deep draw stamping technology is the integration of advanced simulation and digital twins into the design and operation of machines. Digital twins create a virtual model of the machine and the forming process, allowing manufacturers to simulate the entire deep drawing operation before it is executed in real life. This allows for early detection of potential problems, such as wrinkles, thinning, or material failure, and enables engineers to make adjustments to tooling or material choices before physical trials. By leveraging these technologies, manufacturers can optimize tooling designs, material choices, and process parameters to ensure the highest quality and efficiency in production.

Automation and digital control systems have also greatly enhanced deep draw stamping machines’ capabilities. Industry 4.0 technologies are making deep draw presses smarter, with the ability to collect data in real-time, analyze it, and adjust machine settings autonomously. These “smart” presses can monitor a variety of factors, such as punch load, die wear, and material properties, adjusting the process to optimize part quality and prevent defects. The use of predictive maintenance is another key benefit of these digital systems, where machine components are monitored for signs of wear or failure, and maintenance can be performed proactively to avoid downtime and reduce repair costs.

Energy efficiency is another consideration as the demand for sustainable manufacturing increases. Hydraulic deep draw stamping machines are being designed with more energy-efficient systems, and innovations in hydraulic systems, such as regenerative energy recovery, are being incorporated to recover and reuse energy during the press cycle. Some presses are moving toward fully electric solutions, which offer even greater energy savings and more precise control, while also reducing the carbon footprint of the manufacturing process.

In terms of product quality, deep draw stamping machines are now capable of producing parts with extremely tight tolerances and excellent surface finishes. This is especially critical in industries such as aerospace and medical device manufacturing, where part precision is paramount for safety and functionality. Surface finish improvements are achieved through better lubrication, improved die designs, and optimized machine settings that reduce friction between the metal and tooling. This leads to smoother parts with fewer defects and reduces the need for secondary finishing processes.

The future of deep draw stamping is also intertwined with the evolution of hybrid manufacturing processes. For example, combining deep drawing with additive manufacturing (3D printing) could lead to more complex parts that integrate different materials or feature internal structures that are difficult or impossible to achieve with traditional manufacturing methods. This hybrid approach allows manufacturers to take advantage of the strengths of both processes—precision deep drawing for shaping and 3D printing for adding intricate details or supporting structures.

In some industries, multi-material deep drawing has emerged as a technique where different types of metal or composite materials are formed together in a single part. For example, combining a steel exterior with an aluminum core, or using a composite material for weight reduction, is made possible with specialized deep drawing techniques. This could offer even further potential for lightweighting, energy efficiency, and cost reduction, especially in automotive and aerospace sectors where multi-material design is increasingly popular.

Finally, the growing focus on sustainability is driving the development of closed-loop production systems for sheet metal forming. By designing deep draw stamping processes that produce minimal waste and ensure that scrap metal can be fully recycled into the production cycle, manufacturers are contributing to more sustainable industrial practices. In fact, deep drawing is often chosen for its ability to minimize material waste compared to other forming processes like casting or welding, as the process starts with a single sheet and typically results in fewer offcuts.

In summary, sheet metal deep draw stamping machines are evolving at the intersection of material science, digital technology, and automation. These machines are becoming more efficient, precise, and capable of handling an increasing range of materials and complexities. As industries continue to demand stronger, lighter, and more intricate parts, deep draw stamping machines will remain a cornerstone of modern manufacturing, driving innovation and meeting the needs of high-performance applications across multiple sectors.

Sheet Metal Shear Spinning Machine

A Sheet Metal Shear Spinning Machine is a specialized machine used for the process of shear spinning, a metal forming technique where a flat sheet of metal is transformed into a hollow, thin-walled part, such as a cone, cylinder, or other rotationally symmetric shapes. This process combines the principles of spinning and shear deformation to shape the metal into the desired form while maintaining material integrity and minimizing waste.

Shear spinning differs from traditional spinning in that it involves a combination of both radial and tangential forces. The metal sheet is clamped on a spinning mandrel, which is then rotated at high speeds. A forming tool, typically a roller or a set of rollers, applies pressure to the metal sheet while it is being rotated. As the sheet is deformed, it stretches and flows over the mandrel, taking on the shape of the die or tooling. The process is often used for creating thin-walled parts, especially in aerospace, automotive, and other industries that require lightweight and high-strength components.

The core components of a shear spinning machine include:

- Spinning Mandrel: The central rotating part of the machine onto which the sheet metal is placed. The mandrel can be a fixed or adjustable diameter, depending on the shape of the final part.

- Forming Tool: A tool (usually a set of rollers or a spinning tool) that applies pressure to the metal sheet as it rotates. The tool shapes the metal by stretching and compressing it to form the desired part.

- Tooling and Dies: Custom-designed dies or forms help control the final shape and dimensions of the part. The tooling design is crucial for achieving the required geometry and surface finish.

- Rotational Speed Control: The rotational speed of the mandrel is carefully controlled to ensure that the material flows evenly and does not become overstretched, which could lead to thinning or cracking.

- Blank Holder: In some shear spinning machines, a blank holder is used to prevent the metal from shifting or wrinkling as it is formed, ensuring that the metal remains in place during the spinning process.

The process begins with a flat sheet of metal, called the “blank,” which is clamped to the mandrel. As the mandrel rotates at high speed, the forming tool is gradually brought into contact with the edges of the sheet. The tool applies radial force, causing the metal to stretch and conform to the shape of the mandrel. The machine may use several stages of deformation, with the tool moving progressively down the length of the mandrel to gradually form the part.

Shear spinning is ideal for producing parts that are both lightweight and strong, such as aerospace components like aircraft fuselage sections, turbine casings, and heat exchangers. The process is also used for parts in automotive industries, such as wheels, housings, and other structural components. One of the main advantages of shear spinning is its ability to produce parts with a uniform thickness, even in complex shapes. The process also allows for tight control over the part’s geometry and surface finish, often eliminating the need for further machining or finishing operations.

Another key benefit of shear spinning is its material efficiency. Because the process stretches and shapes the metal sheet without cutting or removing material, it minimizes waste, making it a cost-effective method for producing parts, especially in high-volume production. Additionally, shear spinning is a relatively quick process compared to other methods like casting or forging, making it ideal for producing large quantities of parts in a short amount of time.

The process also allows for flexibility in material selection. While commonly used with metals like aluminum, copper, steel, and titanium, shear spinning can also be adapted for use with some plastic materials or composite sheets, depending on the part requirements.

One challenge in shear spinning is managing the material flow during the deformation process. If the process is not carefully controlled, there is a risk of uneven thinning or excessive wrinkling, particularly in the areas of the part that experience the greatest deformation. To mitigate this, many shear spinning machines are equipped with sophisticated control systems that monitor and adjust the speed, force, and path of the forming tool in real-time to ensure uniform material distribution and to prevent defects. In high-precision applications, the entire process may be monitored using computer numerical control (CNC) systems, which allow for more intricate, detailed, and repeatable part production.

Additionally, shear spinning machines are often designed to be flexible, allowing for quick changeovers between different part sizes and geometries. Adjustable mandrels and tooling can be swapped out easily, and the machine’s settings can be modified to accommodate different materials and thicknesses. This makes shear spinning machines suitable for both small batch production and large-scale manufacturing.

The shear spinning machine’s role in industries that require both precision and strength is becoming more critical as design requirements become more complex. Aerospace manufacturers, for instance, rely on shear spinning to produce lightweight, high-strength parts for aircraft. In automotive production, shear spinning is increasingly being used to create structural components that need to withstand high stress while reducing weight to improve fuel efficiency.

In conclusion, a sheet metal shear spinning machine is an advanced piece of manufacturing equipment that allows for the production of high-quality, lightweight, and precise metal parts. Its ability to form thin-walled parts from a single sheet of material while maintaining strength and minimizing waste makes it indispensable in industries like aerospace, automotive, and more. With continuous advancements in technology, shear spinning is expected to play an even greater role in meeting the demand for complex, high-performance parts.

Shear spinning machines continue to advance, especially as industries demand even higher precision, material efficiency, and flexibility. The growing use of automation and digital control systems is making these machines more adaptable and capable of handling a wider range of materials and part geometries. One significant trend is the integration of Industry 4.0 technologies, which allows manufacturers to optimize production through real-time data collection, predictive analytics, and automated adjustments. This can greatly improve the speed and accuracy of the process, reducing scrap and ensuring consistent part quality.

In addition, advanced materials like high-strength alloys, composites, and lightweight metals like titanium and aluminum are increasingly being used in shear spinning. These materials require careful management during the forming process to avoid defects like cracking or excessive thinning. With newer machines that incorporate adaptive control systems and sophisticated sensors, the machine can detect material behavior during the process and adjust the parameters dynamically to ensure a flawless result.

The ability of shear spinning machines to handle multiple materials and complex shapes means they are highly versatile. Many modern machines allow for quick tool changes and adjustments to accommodate different material thicknesses and part configurations. This makes them ideal for industries that require flexibility, such as automotive and aerospace, where designs frequently change and parts must be produced in both small batches and large volumes.

The tooling used in shear spinning machines has also evolved. Newer tooling systems are designed for better wear resistance, reducing maintenance downtime and increasing production efficiency. The design of tooling and dies has become more sophisticated, allowing for greater precision in the final part shape and surface finish. In some cases, tooling systems are designed to reduce or eliminate the need for secondary operations, such as trimming or finishing, by improving the accuracy of the part right off the machine.

The role of sustainability in manufacturing is also shaping the future of shear spinning. As companies focus more on reducing their environmental impact, processes that minimize material waste and energy consumption are highly valued. Shear spinning, by its nature, is material-efficient because it uses a single sheet of metal and stretches it to form the part, rather than cutting away excess material as in traditional machining. This makes it a preferred choice for producing complex parts without excessive scrap, which is especially important in industries that deal with expensive or rare materials.

Furthermore, composite materials are starting to be explored in shear spinning for applications where metal alone may not suffice. In these cases, the machine can be adapted to handle not just traditional metals but also some types of plastics and composites, opening up new opportunities for the production of lightweight yet strong parts in industries like electronics, medical devices, and renewable energy sectors.

As the demand for lightweight and high-performance components grows, especially in industries like aerospace and automotive, shear spinning continues to be a valuable technology. It allows for the production of parts that are both strong and lightweight, meeting the increasing requirements for fuel efficiency, structural integrity, and performance. By offering a fast, cost-effective way to produce parts with uniform thickness and minimal waste, shear spinning remains an integral process in modern manufacturing, particularly in the production of parts with rotational symmetry.

Looking ahead, the future of shear spinning will likely see more integration with additive manufacturing (3D printing) for hybrid processes, which could enable even more complex and customized part designs. For example, parts could be partially produced using additive techniques, with areas of the part that require specific material properties or geometries then completed using shear spinning. This hybrid approach could bring together the strengths of both technologies, enabling the creation of parts with even more intricate features, optimized material distribution, and reduced weight.

In conclusion, sheet metal shear spinning machines are becoming increasingly sophisticated, offering greater versatility, precision, and efficiency. As technology continues to advance, these machines will play an even more significant role in producing high-quality, lightweight, and durable parts across a wide range of industries, from aerospace to automotive and beyond. The integration of automation, digital control, and adaptive technologies will make shear spinning more efficient and adaptable to the ever-changing demands of modern manufacturing.

As the manufacturing landscape evolves, the capabilities of sheet metal shear spinning machines are expanding, particularly with the integration of artificial intelligence (AI) and machine learning. These technologies allow machines to not only monitor the forming process in real time but also to predict potential failures or deviations in material behavior before they occur. For example, AI algorithms can analyze historical data from the machine to identify patterns and predict when maintenance might be required, helping to minimize downtime and reduce operational costs. This level of predictive maintenance ensures that parts are produced with high precision and quality, while also extending the lifespan of the machine itself.

The data-driven manufacturing trend is also gaining traction, with shear spinning machines becoming more connected to larger smart factories. By linking to central systems that collect and analyze data from multiple machines across a facility, manufacturers can better optimize their processes for efficiency and consistency. This connected approach helps manufacturers identify areas of improvement, streamline production workflows, and achieve higher levels of automation, which is especially beneficial in high-volume production environments.

The demand for customization in parts is another area where shear spinning machines are increasingly being used. As industries like aerospace and automotive require more bespoke components to meet specific performance standards, shear spinning offers the flexibility to produce complex parts with tight tolerances and unique geometries. The ability to make rapid adjustments to tooling and machine settings allows for quick reconfiguration and production of one-off or small-batch parts without significant downtime or cost.

Additionally, there is an ongoing push toward process integration, where shear spinning is combined with other forming techniques such as hydroforming or deep drawing. These integrated processes enable the creation of even more intricate parts that require multiple forming stages. For instance, a part may be partially formed using shear spinning to create a thin-walled section, then further processed with hydroforming to achieve more complex internal geometries or increased strength. The combination of processes provides a high level of flexibility and enables manufacturers to meet the increasing demands for lightweight, high-strength parts with advanced material properties.

Another emerging trend is the use of sustainable materials in shear spinning. As industries focus on reducing their environmental impact, there is a growing interest in using renewable and eco-friendly materials in production. This can include recycled metals or biocomposites, which can be formed using shear spinning machines. While these materials may require special handling or adjustments to process parameters, the potential benefits in terms of sustainability and cost reduction make them a promising choice for the future of manufacturing.

The versatility of shear spinning machines also makes them suitable for applications outside traditional metalworking industries. For example, medical device manufacturing has begun to leverage shear spinning for creating complex parts like implants, surgical instruments, and prosthetics. The ability to form thin, precisely shaped parts is essential in the medical field, where part strength, durability, and biocompatibility are critical. As medical technologies advance, shear spinning may play a greater role in producing the next generation of cutting-edge medical devices.

Customization and precision are also crucial in electronics manufacturing, where parts must meet specific performance requirements in compact, lightweight, and thermally efficient designs. Shear spinning enables the creation of thin-walled casings or housings for electronic components, ensuring that they are both lightweight and strong while minimizing material waste. This process, combined with other advanced techniques like laser welding and additive manufacturing, allows for the production of parts with complex internal geometries that would be difficult or impossible to achieve with traditional methods.

Furthermore, shear spinning continues to make strides in improving energy efficiency in manufacturing processes. As energy costs rise and sustainability becomes an even greater priority for manufacturers, the ability to produce parts with minimal material waste and lower energy consumption is becoming increasingly important. The inherent efficiency of shear spinning, which uses a single sheet of material and minimizes scrap, aligns well with these goals. Moreover, the ongoing development of more energy-efficient machines—whether through advancements in drive systems, better lubrication techniques, or optimized cycle times—will contribute to further reductions in energy usage.

As global competition in industries like automotive and aerospace intensifies, manufacturers are seeking every opportunity to reduce costs while improving product quality. Shear spinning offers an ideal solution by producing parts with minimal waste, reducing the need for extensive post-processing, and allowing for rapid prototyping and low-volume production. The ability to easily adjust machine settings and tooling configurations also makes shear spinning an attractive option for manufacturers who need to quickly adapt to changing market demands or customer specifications.

The integration of robotics into shear spinning processes is another area of growth. Robotics can be used for material handling, tool changes, and even inspection tasks, ensuring that parts are formed and processed with minimal human intervention. This improves not only the speed of production but also the consistency and precision of the parts being produced. Automated quality control systems, often integrated with vision systems or AI-based monitoring, further ensure that parts meet strict tolerance and surface finish requirements.

In the long term, additive manufacturing techniques like 3D printing may play an increasingly significant role in combination with shear spinning. For example, 3D printing could be used to create intricate internal structures or features that are difficult to achieve with traditional forming methods. The combination of additive and shear spinning could lead to more innovative and efficient manufacturing techniques, offering designers and engineers greater flexibility in part design and production.

Ultimately, the future of sheet metal shear spinning machines is tied to the ongoing demands for innovation, sustainability, and efficiency in manufacturing. As industries evolve, shear spinning will continue to be a key technology in producing high-performance parts, particularly in industries where weight reduction, material strength, and precision are critical. The integration of digital control, automation, and advanced materials will only further enhance the capabilities of shear spinning, positioning it as an even more integral part of the modern manufacturing landscape.

Sheet Metal Transfer Die Forming Machine

A Sheet Metal Transfer Die Forming Machine is a type of metal forming equipment used to shape and form metal sheets into parts with complex geometries. It is often used in high-volume manufacturing processes, especially in industries like automotive, aerospace, and electronics, where precision and consistency are crucial. The machine is designed to carry out the entire forming process using a transfer die system, where the workpiece is transferred between multiple stations in the die set to perform various stages of forming, blanking, punching, bending, and drawing.

The transfer die forming process involves several distinct stations or steps that are integrated into one machine, allowing for the production of multi-step parts in a continuous, automated fashion. Here’s a breakdown of how the process works and the key features of a transfer die forming machine:

- Blanking and Feeding: The process starts with the feeding of a flat metal sheet, or blank, into the machine. The blank is positioned in the first station, where it is punched or cut to shape. The machine uses a feeder mechanism to transfer the blank through the various stations of the die, which is necessary for performing subsequent operations like bending, drawing, or punching.

- Multiple Stations: The machine is equipped with a series of die stations that perform different forming operations on the sheet metal. These stations are typically arranged in a sequence, each one contributing a specific function such as blanking, stamping, bending, piercing, drawing, or trimming. The workpiece is transferred from one station to the next using a system of transfer fingers or conveyors.

- Transfer Mechanism: The key feature of a transfer die forming machine is its transfer mechanism, which moves the sheet metal from one station to another. This mechanism can include mechanical, pneumatic, or hydraulic actuators that ensure accurate positioning of the workpiece at each station. The transfer system also allows for precise control over the timing and positioning of the blank, which is critical for producing high-quality parts with tight tolerances.

- Tooling and Dies: The dies used in transfer die forming machines are specifically designed to perform multiple functions in a single operation. These tools are often made from high-strength steel and are designed to withstand the pressures of metal forming. Custom tooling is often used to ensure the part is formed to the required shape, size, and finish, with minimal waste or distortion.

- Pressing and Forming: The press used in the transfer die forming process provides the force required to shape the material. It applies pressure to the metal sheet through the dies, causing it to conform to the desired shape. Depending on the part design and material, different types of presses, such as hydraulic presses or mechanical presses, can be used to provide the necessary force.

- Automation and Precision: Transfer die forming machines are often fully automated, with computer numerical control (CNC) systems controlling each station’s operations. Automation ensures high production rates, minimal human intervention, and greater consistency in part quality. The precision of the machine also reduces the risk of defects and increases part accuracy, which is especially important in industries that require tight tolerances, such as automotive and aerospace.

- Part Transfer and Handling: Once the part has been formed through the various stages of the die, it is transferred to the next phase of production. This could involve a final trimming step, assembly, or quality inspection. Depending on the part complexity, a robotic system or conveyor belts might be used to transfer the finished parts to the next stage of production.

The main advantage of sheet metal transfer die forming machines is their ability to produce complex parts in a continuous, automated process with high efficiency. This system is especially useful in high-volume production runs, where it can quickly produce large quantities of parts without sacrificing quality or precision. The high automation also reduces labor costs and ensures consistent output.

Some of the key benefits of this technology include:

- High Productivity: Due to its automated nature, a transfer die forming machine can handle large volumes of parts with minimal downtime, making it ideal for industries that require mass production.

- Complex Part Geometries: The use of multiple die stations allows for the production of intricate and multi-step parts that would be difficult or impossible to create using traditional stamping methods.

- Minimal Waste: The precision of the machine and the ability to transfer the blank between stations reduces material waste, making the process more efficient and cost-effective.

- Consistency and Precision: The automation and precision of the machine ensure that each part is formed with consistent quality, reducing variation and ensuring that parts meet the required specifications.

- Cost Efficiency for Large Batches: While the initial investment in a transfer die forming machine may be high, the machine’s ability to handle large batches at high speeds makes it cost-effective over time for high-volume production runs.

Transfer die forming is commonly used in industries such as:

- Automotive Industry: For producing parts like body panels, brackets, and structural components.

- Aerospace Industry: For creating parts like panels, brackets, and complex enclosures.

- Electronics: For manufacturing housings, brackets, and other intricate components.

- Consumer Goods: For producing various parts in appliances, hardware, and other products.

However, one of the challenges of transfer die forming is the initial setup cost. The creation of custom tooling and dies can be expensive, and the machine itself requires a significant capital investment. Despite these costs, the ability to produce parts with high precision and at high speeds makes the investment worthwhile for many manufacturers, especially in industries where production volumes are high.

Another consideration is the complexity of the part design. If the part has highly intricate geometries or requires multiple stages of forming, the die set may need to be specially designed, which can increase lead time and costs. Additionally, any changes to part design may require modifications to the tooling or die set, which can also impact production schedules.

Overall, a sheet metal transfer die forming machine is a highly efficient, versatile, and precise tool used in manufacturing to produce complex metal parts at high volumes. With its automated processes, minimal waste, and ability to handle intricate designs, it is an essential piece of equipment in many industries where precision, speed, and cost-effectiveness are paramount.

Sheet metal transfer die forming machines are becoming increasingly important in industries where precision and high-volume production are critical. The automated nature of these machines allows for rapid production of parts, reducing labor costs while ensuring that parts are formed with tight tolerances and minimal defects. The use of advanced control systems, such as CNC (Computer Numerical Control), has further enhanced the machine’s ability to perform complex operations with minimal manual intervention, allowing for greater consistency across large production runs.

The machine’s ability to transfer workpieces between multiple die stations allows for the creation of parts that would be impossible to produce in a single stamping operation. This is particularly useful when dealing with complex parts that require multiple forming steps, such as bending, punching, and drawing. With each stage of the forming process happening in a different station, the part can gradually take shape without the need for multiple passes through separate machines.

Transfer die forming machines are also known for their ability to handle a wide range of materials, from standard metals like steel, aluminum, and copper to advanced alloys and composite materials. This versatility is important in industries like automotive and aerospace, where the materials used in components often need to meet specific strength, weight, and performance criteria. The machines can be adjusted to accommodate different material thicknesses, ensuring that even delicate or high-strength materials are formed without damage or distortion.

One of the main challenges when working with a transfer die forming machine is ensuring that the transfer mechanism is reliable and precise. If the sheet metal is not properly aligned as it moves through the various stages of the die, it can lead to defects such as warping, dimensional inaccuracies, or part misalignment. As a result, it is crucial to maintain and calibrate the transfer system regularly to ensure it remains accurate and efficient. The integration of robotic systems or automated handling mechanisms further ensures that parts are consistently positioned as they move through each station.

Despite the initial cost of tooling and die creation, the long-term benefits of using transfer die forming machines become apparent when considering the high-speed production rates and minimal material waste. The precision with which these machines operate reduces scrap and rework, which helps keep costs low and production timelines tight. In industries where large volumes of parts are required, such as automotive manufacturing, the ability to produce high-quality parts quickly and efficiently can give manufacturers a significant competitive advantage.