Sheet Hydroforming Presses Manufacturers: Sheet hydroforming presses are specialized machines used in the metal forming industry to shape sheet metal into complex geometries by applying hydraulic pressure. Unlike traditional stamping or mechanical presses, which rely on matched male and female dies to form parts, sheet hydroforming presses use a single-sided tool (usually a punch) and a flexible diaphragm or bladder that applies uniform hydraulic pressure to mold the metal sheet into the desired shape. This process allows manufacturers to produce parts with greater precision, fewer defects, and enhanced material efficiency.

The technology has found widespread use in industries such as automotive, aerospace, appliance manufacturing, and medical device production. Its ability to form complex, lightweight, and high-precision components with fewer tooling requirements makes it a popular choice for high-performance applications.

This guide will explore the working principles, types, advantages, and applications of sheet hydroforming presses.

Working Principles of Sheet Hydroforming Presses

Sheet hydroforming presses use hydraulic fluid to apply pressure evenly over a metal sheet, pressing it against a die to create the desired shape. The process involves three main components: a rigid die, a hydraulic bladder or diaphragm, and hydraulic fluid. The die defines the final geometry of the part, while the hydraulic bladder (or diaphragm) transmits the fluid pressure to mold the sheet metal.

1.1 Basic Process Steps

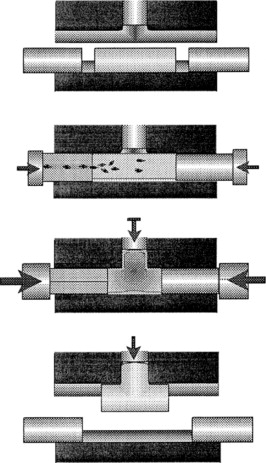

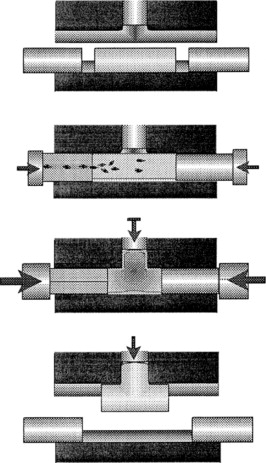

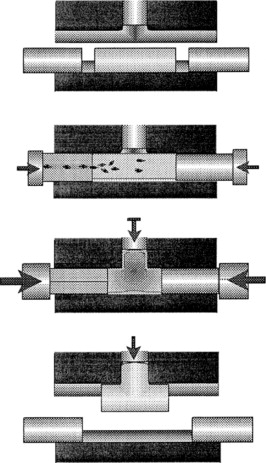

The sheet hydroforming process typically involves the following steps:

- Die Placement: A rigid die, representing the shape of the final part, is placed in the press. This die is a solid, fixed structure.

- Sheet Metal Placement: A flat metal sheet is positioned over the die. Common materials include aluminum, stainless steel, titanium, and mild steel.

- Hydraulic Bladder Engages: A flexible bladder, filled with hydraulic fluid, is placed over the metal sheet. This bladder replaces the traditional upper die used in conventional stamping.

- Pressurization: The hydraulic system applies controlled fluid pressure through the bladder, forcing the sheet metal to conform to the shape of the die below.

- Part Removal: After the pressure is released, the bladder retracts, and the formed metal part is removed from the die.

The uniform application of pressure over the entire sheet ensures smooth material flow, precise geometry, and reduced stress on the metal, resulting in parts with fewer defects like wrinkling or tearing.

1.2 Types of Sheet Hydroforming Presses

There are two main types of sheet hydroforming presses, based on how the hydraulic pressure is applied:

- Fluid Cell Hydroforming Presses: In this method, a flexible diaphragm filled with hydraulic fluid applies uniform pressure over the sheet metal. This press is well-suited for relatively shallow, simple shapes and works well for smaller production runs or prototypes.

- Deep Draw Sheet Hydroforming Presses: Designed for deep-draw applications, these presses use higher hydraulic pressures to form more complex and deeper parts. They can handle deep, intricate shapes and are commonly used in automotive and aerospace applications.

2. Advantages of Sheet Hydroforming Presses

Sheet hydroforming presses offer several advantages over traditional metal forming processes such as stamping and mechanical pressing. These benefits make sheet hydroforming presses an attractive option for high-performance and precision-driven industries.

2.1 Design Flexibility and Complex Geometries

One of the most significant advantages of sheet hydroforming presses is the ability to form complex geometries in a single operation. The flexible bladder evenly distributes pressure across the sheet, allowing for precise and uniform shaping even with intricate designs.

- Shallow and Deep Draws: Sheet hydroforming presses can be used to create both shallow and deep draws, expanding the range of possible geometries. This flexibility is particularly useful in industries like aerospace and automotive, where complex shapes are common.

- Variable Wall Thickness: The process allows for greater control over material thinning and deformation, making it possible to form parts with variable wall thicknesses. This improves the structural integrity and performance of the part.

2.2 Fewer Tooling Requirements

Sheet hydroforming only requires a single rigid die, eliminating the need for a second matching die as in traditional stamping. This reduces tooling costs, especially for low-volume production runs or parts with complex designs that would require intricate tooling.

- Cost Savings in Tooling: With fewer dies needed and no need for expensive matched sets, manufacturers can significantly reduce the upfront tooling costs. This makes sheet hydroforming an ideal choice for prototyping or custom parts where high-cost tooling isn’t justified.

- Reduced Tool Wear: Because the process applies less localized stress on the material and tooling, the life of the die is extended, and maintenance costs are lower.

2.3 Improved Part Quality and Surface Finish

The uniform application of pressure in hydroforming presses results in smoother surfaces and higher-quality finishes than traditional stamping. Since there is no direct contact between the punch and the sheet metal during most of the forming process, defects such as scratches, tool marks, and irregularities are minimized.

- Minimal Surface Defects: The flexible bladder’s uniform pressure prevents localized material stress, which reduces the likelihood of wrinkling, tearing, or surface imperfections. This is particularly important in industries such as aerospace or medical devices, where surface finish quality is critical.

- Consistent Dimensional Accuracy: Hydroforming allows for tight tolerances and high repeatability, ensuring that every part meets the required dimensional specifications. This precision is difficult to achieve with traditional methods, especially for complex shapes.

2.4 Material Efficiency

Because the material is evenly stretched and formed, material thinning is minimized, leading to better material utilization. This efficiency not only reduces material costs but also ensures that the final part is stronger and more durable.

- Reduced Material Waste: Traditional methods often result in high material waste due to excess trimming and discarded parts. In contrast, hydroforming presses form the part directly from the sheet, reducing the amount of scrap material generated.

3. Applications of Sheet Hydroforming Presses

The versatility and efficiency of sheet hydroforming presses make them well-suited for a variety of industries. Below are some of the most common applications:

3.1 Automotive Industry

In the automotive sector, sheet hydroforming presses are used to create lightweight, high-strength components that contribute to better fuel efficiency and safety. Common parts include:

- Body Panels: Hydroformed sheet metal is used for complex body panels, doors, and hoods. The ability to form complex shapes in a single operation reduces the number of welding seams, improving the structural integrity and appearance of the vehicle.

- Structural Components: Sheet hydroforming is used to produce reinforcements, frame parts, and crash structures that need to withstand impact forces while maintaining a lightweight design.

3.2 Aerospace Industry

Aerospace manufacturers rely on sheet hydroforming to produce high-performance components that require both precision and lightweight properties. The process is particularly valuable for creating complex, thin-walled parts that would be difficult or impossible to achieve using conventional methods.

- Fuselage Components: Sheet hydroforming is used to create lightweight structural components for aircraft fuselages, which are critical for reducing the aircraft’s overall weight and improving fuel efficiency.

- Engine Components: Complex parts such as aircraft engine covers and heat shields are often hydroformed due to the process’s ability to produce seamless, high-strength components that can withstand extreme temperatures and stresses.

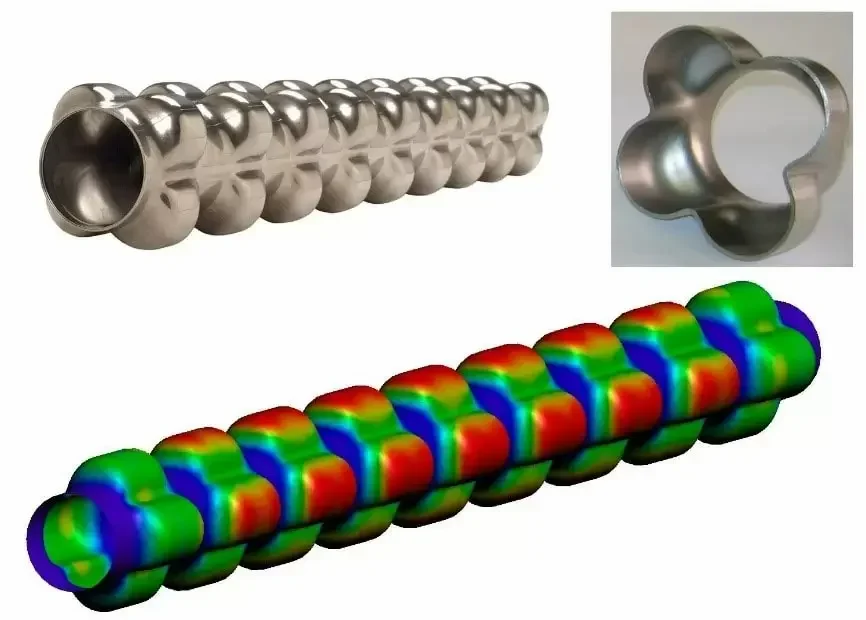

3.3 Medical Devices

In the medical field, precision, surface finish, and biocompatibility are essential. Sheet hydroforming presses are used to manufacture surgical instruments, implant components, and diagnostic equipment from materials like titanium and stainless steel.

- Surgical Instruments: The smooth, high-quality finishes produced by hydroforming are ideal for medical instruments, ensuring ease of cleaning and sterilization.

- Implant Components: Hydroforming is also used to create biocompatible implants that must conform to specific anatomical shapes and meet stringent regulatory standards.

3.4 Consumer Goods and Appliances

In consumer goods, sheet hydroforming presses are used to manufacture durable and aesthetically pleasing components for products like kitchen appliances, sporting goods, and furniture. The process allows for sleek, modern designs without compromising material strength.

- Appliance Panels: Sheet hydroforming is used to create appliance housings, control panels, and decorative elements for products like refrigerators, washing machines, and ovens.

4. Challenges and Limitations of Sheet Hydroforming

While sheet hydroforming presses offer many advantages, there are certain challenges and limitations to consider.

- Initial Investment: The hydraulic systems and presses required for sheet hydroforming can be more expensive than traditional stamping presses, especially for high-pressure applications.

- Cycle Time: Hydroforming processes, especially deep-draw applications, may have longer cycle times compared to traditional stamping, which could affect overall production speed in high-volume settings.

- Material Limitations: Not all materials are suitable for hydroforming. Low-ductility materials may experience cracking or other defects, limiting their use in this process.

Conclusion

Sheet hydroforming presses represent a powerful tool in modern manufacturing, enabling the production of complex, high-quality components with fewer tooling requirements, improved material efficiency, and greater design flexibility. The technology’s ability to create seamless, precise parts with excellent surface finishes makes it indispensable in industries such as automotive, aerospace, medical devices, and consumer goods.

While there are some limitations, such as higher initial costs and potential cycle time challenges, the benefits of sheet hydroforming make it an increasingly popular choice for manufacturers looking to produce lightweight, high-performance components with precision and cost efficiency.

Working Principles of Sheet Hydroforming Presses

Sheet hydroforming is a metal forming process that uses hydraulic pressure to shape sheet metal into complex geometries. Sheet hydroforming presses are specialized machines designed for this process, offering a flexible and precise method for forming parts with smooth surfaces, complex shapes, and minimal defects. Unlike traditional stamping, where matched male and female dies are used, sheet hydroforming employs a single-sided die and a flexible diaphragm or bladder, which presses the sheet metal into the desired shape under the influence of hydraulic pressure.

This guide will explore the working principles of sheet hydroforming presses, outlining the key steps in the process, the components involved, and the factors that contribute to the accuracy and quality of the final part.

1. Basic Operating Principle

At its core, sheet hydroforming relies on applying uniform hydraulic pressure to force a metal sheet against a die. The pressure is transmitted through a flexible diaphragm or bladder, which ensures that the sheet conforms precisely to the shape of the die. Unlike mechanical presses, which use rigid tooling to deform the metal, sheet hydroforming achieves the desired part geometry through the controlled application of fluid pressure, providing greater precision and fewer defects.

2. Key Components of a Sheet Hydroforming Press

The main components of a sheet hydroforming press include:

- Hydraulic System: The heart of the hydroforming press, responsible for generating the fluid pressure needed to shape the metal. The hydraulic system includes pumps, valves, accumulators, and control systems.

- Rigid Die: A fixed die that defines the shape of the final part. The die can be a solid, one-sided tool that the sheet metal is pressed against during the forming process.

- Flexible Diaphragm/Bladder: A flexible membrane that holds hydraulic fluid and transfers the pressure uniformly to the sheet metal. It replaces the upper die in traditional pressing methods.

- Sheet Metal Blank: A flat piece of metal placed between the die and the diaphragm. Common materials include aluminum, stainless steel, titanium, and other alloys depending on the application.

3. Step-by-Step Working Process

3.1 Die and Sheet Metal Placement

The process begins by placing a rigid die in the lower section of the hydroforming press. This die corresponds to the shape of the final part. A flat sheet of metal, also known as a blank, is positioned on top of the die.

- Material Selection: The metal sheet is typically made from materials with good formability, such as aluminum, steel, stainless steel, or titanium, depending on the application.

The single-sided die means that the sheet metal is pressed into shape by the hydraulic pressure, not by a second die. This is a key difference from traditional stamping methods, where both a male and female die are required.

3.2 Sealing and Clamping

Once the metal sheet is placed on the die, the hydroforming machine’s flexible diaphragm is lowered into position, and the sheet is sealed and clamped between the die and the diaphragm. This clamping ensures that the sheet remains in the correct position throughout the forming process and prevents any movement or misalignment.

- Clamping Force: Sufficient clamping force is applied to prevent the sheet from shifting during the process, which is crucial for achieving high precision and preventing defects.

3.3 Hydraulic Pressure Application

The core of the process involves applying hydraulic pressure through the flexible diaphragm. The hydraulic fluid, which is stored in the system’s accumulator, is pumped into the bladder or diaphragm, and this fluid pressure is transmitted evenly over the surface of the metal sheet.

- Pressure Control: The pressure is gradually increased, and the process is highly controlled to ensure that the metal deforms uniformly without causing defects such as tearing, wrinkling, or thinning.

The pressure forces the sheet metal to conform to the shape of the die. The flexible diaphragm plays a critical role in distributing the pressure evenly over the entire surface of the sheet, allowing for uniform deformation and the formation of complex shapes without localized stress points.

3.4 Metal Forming and Shaping

As the hydraulic pressure builds, the sheet metal flows and stretches to fit the contours of the die. The flexibility of the diaphragm allows the metal to be pressed into deep recesses or drawn into complex shapes that would be difficult to achieve with conventional stamping methods.

- Deep Drawing Capabilities: In deep-draw hydroforming, the press can form deep, complex shapes with minimal thinning or defects, unlike traditional methods that often result in excessive thinning or tearing at sharp corners.

The ability to control material flow during the forming process is one of the key advantages of hydroforming. The press can produce parts with variable wall thickness, enabling thicker sections where strength is required and thinner sections where weight savings are prioritized.

3.5 Pressure Hold and Release

Once the metal has fully conformed to the die and reached the desired shape, the hydraulic pressure is held for a brief period to ensure the part stabilizes and the material fully takes on the form of the die.

- Pressure Holding: This is particularly important for parts with intricate details, where maintaining pressure allows for complete material flow and prevents springback or dimensional inaccuracies.

After the pressure hold phase, the hydraulic fluid is released from the diaphragm, and the press opens, allowing the flexible diaphragm to retract.

3.6 Part Removal

Once the hydraulic pressure is released, the formed part can be removed from the die. The result is a precise, high-quality part with smooth surfaces and minimal defects, ready for post-processing if needed.

- Minimal Finishing: Due to the smooth application of pressure and the absence of direct contact with hard tooling during forming, the final part typically requires minimal finishing. This reduces secondary processing costs and enhances production efficiency.

4. Pressure Control and Forming Accuracy

The success of sheet hydroforming relies heavily on pressure control. Pressure must be carefully managed to ensure that the metal deforms evenly and fills the die without over-stretching or wrinkling. Different parts and materials require varying pressure levels, depending on the complexity of the geometry and the material’s properties.

4.1 Gradual Pressure Increase

The pressure in a sheet hydroforming press is typically increased gradually to avoid sudden deformations that could cause defects. The system monitors and adjusts pressure in real-time, ensuring uniform deformation across the entire surface of the sheet metal.

- Pressure Ramping: Controlled ramp-up of pressure helps prevent localized thinning or tearing, especially when working with high-strength materials like steel or titanium.

4.2 Maximum Pressure

The maximum pressure applied during the process can vary depending on the material being formed and the complexity of the part. In some cases, pressures can exceed 10,000 psi, particularly for high-strength materials or deep-draw components.

5. Advantages of the Hydroforming Press Process

Sheet hydroforming offers several key advantages over traditional stamping or mechanical pressing methods:

- Complex Shapes: Sheet hydroforming presses excel at producing parts with complex geometries, including those with deep draws, sharp corners, and intricate contours.

- Uniform Material Thickness: The gradual application of pressure ensures that material thinning is minimized, resulting in stronger, more reliable parts.

- Fewer Tooling Requirements: Only a single-sided die is needed, reducing tooling costs and setup time compared to traditional stamping, which requires both a male and female die.

- High Surface Quality: The use of a flexible diaphragm means there is no direct contact between the metal and hard tooling, resulting in smooth surfaces with minimal defects, such as scratches or tool marks.

- Material Efficiency: The precise control of material flow leads to reduced waste, as the process uses the exact amount of material needed to form the part without excessive trimming.

Conclusion

Sheet hydroforming presses operate based on the principles of hydraulic pressure and uniform deformation, allowing manufacturers to create complex, high-precision parts with superior surface quality. By using a single-sided die and a flexible diaphragm, sheet hydroforming reduces tooling costs, minimizes material waste, and offers greater design flexibility than traditional metal forming processes. The ability to control pressure precisely ensures that parts are formed with high accuracy, making sheet hydroforming presses an ideal solution for industries that demand lightweight, durable, and intricately shaped components, such as automotive, aerospace, and medical devices.

Basic Process Steps of Sheet Hydroforming

Sheet hydroforming is an advanced metal forming process that utilizes hydraulic pressure to shape sheet metal into complex geometries. This method is widely used in industries such as automotive, aerospace, consumer goods, and medical devices due to its ability to create precise, lightweight, and strong components with minimal defects. The process offers several advantages over traditional stamping, such as reduced tooling requirements, improved material utilization, and better surface quality. However, to fully understand the benefits of sheet hydroforming, it’s important to explore the fundamental steps involved in the process.

This guide will take a comprehensive look at the basic process steps of sheet hydroforming, from material preparation and die setup to hydraulic pressure application and part removal. Each step is critical to ensuring a successful and defect-free final product, with precise control over pressure, material flow, and dimensional accuracy.

1. Material Preparation

The first step in the sheet hydroforming process is the preparation of the metal sheet, also referred to as the blank. The material selection and preparation are critical factors in determining the success of the process and the quality of the final part.

1.1 Material Selection

The choice of material is dictated by the application requirements, including the need for strength, ductility, corrosion resistance, and weight reduction. Common materials used in sheet hydroforming include:

- Aluminum: Lightweight and highly ductile, making it ideal for automotive and aerospace applications where weight savings are crucial.

- Steel: Particularly advanced high-strength steels (AHSS), which offer high strength and durability, often used in safety-critical automotive components.

- Stainless Steel: Known for its corrosion resistance and strength, stainless steel is often used in medical devices and consumer products.

- Titanium: Lightweight, strong, and corrosion-resistant, titanium is frequently used in aerospace and medical industries for high-performance parts.

The material must have sufficient ductility to undergo plastic deformation without cracking or tearing during the hydroforming process. Additionally, the material’s thickness is carefully selected based on the part design and application.

1.2 Sheet Cutting

Once the appropriate material is selected, the metal sheet is cut into the desired dimensions, referred to as the blank. Precision in cutting the blank is essential to ensure that it fits correctly within the die and forms evenly during the process.

- Laser Cutting: This method is often used for precision cutting, especially when dealing with complex geometries or small parts.

- Waterjet Cutting: An alternative for thicker or more heat-sensitive materials that may be affected by the heat generated in laser cutting.

- Shearing or Sawing: For simpler parts or thicker materials, shearing or sawing may be used to cut the sheet into the correct dimensions.

After cutting, the edges of the sheet may need to be deburring to remove any sharp edges or rough areas that could affect the forming process.

1.3 Cleaning and Lubrication

Before the sheet is placed into the hydroforming press, it is essential to clean it thoroughly to remove any contaminants, such as oils, dirt, or oxidation. Contaminants on the surface of the sheet metal can cause defects like scratches or material buildup during forming, compromising the final part’s quality.

- Surface Cleaning: Cleaning may involve washing the sheet in a degreasing solution or using a mechanical cleaning process, depending on the material and contaminants present.

Next, lubrication is applied to the sheet to reduce friction between the metal and the die. Lubrication helps ensure smooth material flow during forming and minimizes the risk of damage to the die or the sheet metal. The type of lubricant used depends on the material and the complexity of the part being formed.

2. Die Setup and Clamping

The second step in the hydroforming process involves preparing the hydroforming press and setting up the die. This step is critical to ensure that the metal sheet is formed correctly and that the final part meets the required specifications.

2.1 Die Placement

In sheet hydroforming, a rigid die is used to define the shape of the final part. Unlike traditional stamping, which requires both a male and female die, sheet hydroforming only requires a single-sided die, simplifying the tooling setup.

- Die Design: The die is typically made of hardened steel or another durable material that can withstand the hydraulic pressure used in the process. It is designed to match the exact geometry of the part being formed, with considerations for material flow and dimensional tolerances.

The die is placed into the lower portion of the hydroforming press. It must be properly aligned and securely mounted to ensure accurate part formation and prevent movement during the application of hydraulic pressure.

2.2 Sheet Placement

Once the die is positioned, the prepared metal sheet (or blank) is placed on top of the die. Careful alignment of the sheet over the die is crucial for achieving uniform material flow and avoiding defects such as wrinkles or uneven thickness.

- Sheet Centering: The blank is centered over the die using positioning guides or markers. This ensures that the metal is evenly distributed across the die, allowing for consistent deformation during the forming process.

2.3 Clamping and Sealing

After the sheet is placed over the die, the flexible diaphragm or bladder of the hydroforming press is lowered over the sheet. The diaphragm is a key component that holds the hydraulic fluid and applies pressure to the sheet during forming.

- Clamping: The sheet is clamped securely between the die and the diaphragm, ensuring that it does not move or shift during the forming process. Proper clamping prevents misalignment and ensures that the sheet conforms precisely to the die’s shape.

- Sealing: A tight seal is created between the sheet and the die, allowing for uniform application of hydraulic pressure. This seal is essential to prevent hydraulic fluid from leaking out during pressurization and to ensure that the metal is evenly deformed.

3. Hydraulic Pressure Application

The core of the sheet hydroforming process involves the application of hydraulic pressure to the metal sheet. This step is where the metal undergoes plastic deformation, taking on the shape of the die.

3.1 Pressurization

With the sheet securely clamped in place, the hydraulic system of the press begins to apply pressure to the sheet through the diaphragm. Hydraulic fluid, typically oil or another high-pressure fluid, is pumped into the diaphragm, which in turn applies even pressure across the surface of the metal sheet.

- Gradual Pressure Increase: The hydraulic pressure is increased gradually to avoid sudden deformation or tearing of the material. The controlled application of pressure ensures that the metal deforms uniformly without introducing defects like wrinkles, thinning, or cracking.

3.2 Metal Forming

As the hydraulic pressure builds, the sheet metal is pressed into the die, forcing it to take on the desired shape. The flexibility of the diaphragm allows the metal to flow into complex geometries, including deep recesses, sharp corners, and intricate contours.

- Material Flow: The pressure forces the material to flow smoothly over the die, conforming to its shape without excessive thinning or buckling. The uniform pressure distribution is key to achieving high-quality parts with minimal surface defects.

- Deep Drawing: In cases where deep draws are required, such as in the automotive or aerospace industry, the press can apply higher pressures to achieve deep forming without tearing or thinning the material excessively. Sheet hydroforming is particularly well-suited for deep-draw applications where traditional stamping might fail due to material limitations.

4. Pressure Holding and Release

Once the metal has been formed into the desired shape, the hydraulic pressure is maintained for a short period to allow the material to stabilize.

4.1 Pressure Holding

The pressure holding phase ensures that the material fully conforms to the die and that any residual stresses are relieved. This step is particularly important for parts with intricate details, where dimensional accuracy and surface quality are critical.

- Stress Relief: Maintaining pressure allows the material to “settle” into the die, reducing the risk of springback or other distortions once the pressure is released.

- Dimensional Accuracy: Holding the pressure helps ensure that the part maintains its exact shape and dimensions, preventing deviations that could compromise the part’s fit or function.

4.2 Pressure Release

Once the holding phase is complete, the hydraulic pressure is gradually released, allowing the diaphragm to retract. This step must be controlled carefully to avoid any springback or deformation of the part as the pressure is removed.

- Gradual Depressurization: The hydraulic fluid is released in a controlled manner, and the diaphragm lifts away from the formed part. Quick or uneven release of pressure can lead to warping or other defects.

5. Part Removal and Finishing

After the pressure has been released, the formed part is ready to be removed from the press.

5.1 Part Removal

The flexible diaphragm is lifted, and the formed part is removed from the die. Care must be taken during part removal to avoid damaging the newly formed part, especially if the geometry includes thin sections or complex contours.

- Ejection Systems: Some hydroforming presses are equipped with automated ejection systems that gently lift the part from the die, reducing the risk of damage.

5.2 Inspection and Finishing

Once the part is removed, it undergoes inspection to ensure that it meets the required specifications in terms of shape, dimensions, and surface quality.

- Visual Inspection: The part is checked for defects such as cracks, wrinkles, or surface irregularities that could affect its performance or appearance.

- Dimensional Inspection: Precision measuring tools or automated scanning systems may be used to verify that the part meets the required tolerances.

In some cases, the part may require post-processing, such as trimming or surface finishing, to meet final product specifications. However, because sheet hydroforming produces parts with smooth surfaces and minimal defects, finishing requirements are typically minimal compared to traditional forming processes.

6. Post-Processing and Quality Control

Once the part has passed inspection, it may undergo post-processing operations depending on the requirements of the application. These operations could include:

- Trimming: Any excess material or “flash” from the forming process is trimmed away to ensure the part meets dimensional tolerances.

- Surface Finishing: In some applications, the surface of the part may be polished, coated, or otherwise treated to improve aesthetics, corrosion resistance, or wear resistance.

- Heat Treatment: In certain cases, parts may undergo heat treatment to further strengthen the material or relieve internal stresses caused by the forming process.

Quality control procedures ensure that every part meets the required specifications before it is shipped to the customer or moved to the next stage of production.

Conclusion

The basic process steps of sheet hydroforming include material preparation, die setup, hydraulic pressure application, pressure holding, and part removal, followed by any necessary post-processing. Each of these steps is critical in ensuring that the final part meets the desired specifications for strength, precision, and surface quality. Sheet hydroforming offers several advantages over traditional forming methods, including greater design flexibility, reduced tooling requirements, and improved material efficiency. By understanding and controlling each step of the process, manufacturers can produce high-quality parts that meet the rigorous demands of industries such as automotive, aerospace, and medical devices.

Components of Sheet Hydroforming Presses

Sheet hydroforming presses are advanced machines designed for the metal forming process known as sheet hydroforming, where hydraulic pressure is used to form sheet metal into complex, high-precision parts. The press uses hydraulic fluid to force a sheet of metal against a rigid die, creating intricate shapes with fewer defects compared to traditional metal forming methods like stamping. The success of sheet hydroforming largely depends on the machine’s design and the individual components that make up the press.

This guide takes a detailed look at the key components of sheet hydroforming presses, explaining the function of each part and how it contributes to the overall performance and precision of the press. From the hydraulic system to the die and control units, each component plays a vital role in ensuring that the process runs smoothly, efficiently, and with the desired level of accuracy.

1. Hydraulic System

At the heart of any sheet hydroforming press is the hydraulic system, which generates the high pressures required to form metal sheets into the desired shapes. The hydraulic system consists of several subcomponents that work together to supply, regulate, and control the pressure applied to the sheet metal.

1.1 Hydraulic Pump

The hydraulic pump is the primary component that generates hydraulic pressure by moving fluid from a reservoir into the system. In sheet hydroforming presses, this pump needs to be powerful enough to generate pressures typically ranging from 10,000 to 20,000 psi (pounds per square inch), depending on the material and complexity of the part being formed.

- Types of Pumps: Hydraulic pumps in sheet hydroforming presses are often piston pumps or axial piston pumps, which are capable of delivering high pressures while maintaining efficiency.

- Flow Rate Control: The pump must be able to adjust its flow rate to match the requirements of the forming process. This ensures that the hydraulic fluid is supplied at the correct pressure and volume throughout the entire cycle.

1.2 Hydraulic Reservoir

The hydraulic reservoir is a large tank that stores the hydraulic fluid used in the system. This fluid is typically a type of oil that can withstand high pressures and temperatures without breaking down. The reservoir ensures that there is a constant supply of fluid available for the pump to draw from.

- Capacity: The reservoir must be sized appropriately to accommodate the fluid volume required for the press. In large presses, this may be several hundred liters or more.

- Cooling System: Since hydraulic systems generate heat during operation, many reservoirs are equipped with cooling systems that help maintain optimal fluid temperatures and prevent overheating.

1.3 Hydraulic Accumulator

The hydraulic accumulator is a critical component that stores pressurized fluid and releases it as needed to maintain consistent pressure during the forming process. Accumulators act as energy storage devices, allowing the system to maintain pressure even when the pump is not actively generating it.

- Pressure Stability: Accumulators smooth out pressure fluctuations, ensuring that the pressure applied to the metal sheet is consistent throughout the forming process. This is crucial for preventing defects such as thinning or wrinkling.

- Types of Accumulators: The most common types used in hydroforming presses are bladder accumulators, which use a bladder to separate the hydraulic fluid from a gas (usually nitrogen) that stores the pressure.

1.4 Hydraulic Valves

Hydraulic valves control the flow of fluid within the system, directing it to various parts of the press and regulating the pressure as needed. Several types of valves are used in hydroforming presses:

- Directional Control Valves: These valves control the direction in which hydraulic fluid flows, determining whether the press is building pressure, holding pressure, or releasing it.

- Pressure Relief Valves: These are safety devices that release excess fluid if the pressure in the system exceeds safe operating limits, preventing damage to the press.

- Flow Control Valves: These regulate the flow rate of hydraulic fluid to ensure that the correct amount of pressure is applied at each stage of the forming process.

1.5 Hydraulic Actuators and Cylinders

Hydraulic actuators convert the pressurized fluid energy into mechanical motion. In sheet hydroforming presses, hydraulic cylinders are the most common type of actuator. They apply force to the flexible diaphragm or bladder, compressing the fluid and pressing the sheet metal against the die.

- Single-Acting vs. Double-Acting Cylinders: Some presses use single-acting cylinders, which apply pressure in one direction, while others use double-acting cylinders, which apply pressure in both directions for greater control and precision.

2. Flexible Diaphragm

One of the most distinctive components of a sheet hydroforming press is the flexible diaphragm or bladder. This component replaces the upper die used in traditional stamping, creating a uniform, even pressure across the entire surface of the sheet metal.

2.1 Material and Construction

The diaphragm or bladder is typically made from rubber or urethane, materials chosen for their flexibility, durability, and ability to withstand high pressures. These materials can deform without tearing, making them ideal for applying pressure evenly across the sheet metal as it conforms to the die.

- Diaphragm Design: The diaphragm must be thick enough to resist bursting under pressure while maintaining enough flexibility to conform to complex geometries in the die.

2.2 Function of the Diaphragm

During the hydroforming process, the diaphragm is filled with hydraulic fluid, which then applies pressure to the sheet metal. The flexible nature of the diaphragm ensures that pressure is distributed uniformly across the metal surface, allowing the sheet to deform without localized stress concentrations.

- Uniform Pressure Application: The diaphragm’s flexibility ensures that pressure is applied evenly, which is critical for forming complex shapes without defects like wrinkling or tearing.

3. Die (Tooling)

The die is the mold that defines the final shape of the part being formed. In sheet hydroforming presses, only a single-sided die is required, unlike in traditional stamping, where both a male and female die are needed. The die is placed in the lower part of the press, and the sheet metal is pressed against it by the diaphragm.

3.1 Die Materials

Dies in sheet hydroforming presses are typically made from hardened steel, aluminum, or cast iron. The material choice depends on factors such as the material being formed, the complexity of the part, and the number of parts being produced.

- Hardened Steel: Often used for high-volume production runs where durability is essential. Steel dies can withstand the repeated high pressures of hydroforming without wearing down.

- Aluminum or Cast Iron: These materials are commonly used for low-volume production runs or for prototypes, where the cost of steel dies may not be justified.

3.2 Die Design

The die is custom-designed to match the geometry of the final part. This involves precise machining to create the necessary contours, bends, and depths that the sheet metal will be pressed into.

- Single-Sided Die: Unlike in traditional stamping, where both male and female dies are used, sheet hydroforming requires only one rigid die. The hydraulic pressure applied by the diaphragm forces the metal into the shape defined by this single die.

3.3 Tooling Costs

One of the major advantages of sheet hydroforming is the reduced tooling costs. Since only one die is required, and no matching upper die is needed, the tooling costs are significantly lower compared to traditional forming methods.

4. Clamping and Sealing Systems

Clamping and sealing systems are essential for ensuring that the sheet metal remains securely positioned over the die during the hydroforming process. Proper clamping prevents the sheet from shifting, while sealing ensures that the hydraulic pressure is applied uniformly across the sheet.

4.1 Clamping Mechanisms

The clamping system holds the metal sheet in place over the die. It ensures that the sheet does not move or deform improperly during the forming process.

- Hydraulic Clamping: Most hydroforming presses use hydraulic clamps that apply uniform force around the edges of the metal sheet to hold it securely in place.

- Mechanical Clamps: In some cases, mechanical clamps are used, particularly for smaller presses or simpler parts. These are generally less flexible than hydraulic clamps but can be sufficient for straightforward applications.

4.2 Sealing Systems

The sealing system ensures that the pressurization process is fully contained, preventing hydraulic fluid from leaking out of the diaphragm and ensuring that the entire surface of the sheet metal is evenly pressurized.

- Rubber Seals: High-pressure rubber seals are commonly used to create a tight seal between the sheet, the die, and the diaphragm, ensuring no loss of pressure during forming.

5. Control Systems

Modern sheet hydroforming presses are equipped with sophisticated control systems that manage the hydraulic pressure, regulate the forming process, and monitor the performance of the press. These control systems are critical for achieving the precision and repeatability required in industries such as aerospace and automotive.

5.1 CNC (Computer Numerical Control) Systems

Many sheet hydroforming presses use CNC control systems, which automate key aspects of the forming process, such as pressure regulation, cycle timing, and die movement. These systems allow for precise control over each stage of the process, ensuring that parts are formed to exact specifications.

- Multi-Axis Control: In presses with multi-axis movement, CNC systems control the movement of the die or diaphragm along multiple axes, enabling the production of more complex geometries.

5.2 Programmable Logic Controllers (PLCs)

PLCs are used to automate the operation of the press, controlling the timing of hydraulic pressure application, clamping, and part removal. PLCs are essential for ensuring that each part is formed consistently and that the press operates efficiently.

- Process Automation: PLCs automate repetitive tasks, such as cycling the press, maintaining hydraulic pressure, and controlling fluid flow. This reduces the need for manual intervention and increases productivity.

5.3 Sensors and Monitoring

Modern sheet hydroforming presses are equipped with various sensors that monitor critical parameters such as pressure, temperature, fluid levels, and die alignment. These sensors feed data back to the control system, allowing real-time adjustments to be made during the forming process.

- Pressure Sensors: These sensors monitor the hydraulic pressure applied to the sheet metal, ensuring that it remains within the desired range for the specific material and part.

- Temperature Sensors: In cases where temperature control is important, sensors monitor the temperature of the hydraulic fluid and the metal sheet to prevent overheating or damage.

6. Ejection Systems

Once the part has been formed and the pressure released, the final component must be safely removed from the die. Ejection systems in sheet hydroforming presses help lift the part out of the die without damaging it.

6.1 Hydraulic Ejectors

Many hydroforming presses use hydraulic ejectors that push the formed part out of the die after the pressure has been released. These ejectors ensure that the part is removed without damage, especially in cases where the geometry of the part makes it difficult to lift manually.

6.2 Robotic Ejection Systems

In automated production lines, robotic ejection systems may be used to remove the part from the press and transport it to the next stage of production. These systems can be programmed to handle parts with precision, reducing the risk of damage and improving overall efficiency.

7. Safety Systems

Given the high pressures involved in sheet hydroforming, safety is a top priority. Modern hydroforming presses are equipped with a variety of safety features to protect operators and prevent damage to the machine.

7.1 Safety Guards and Enclosures

Physical barriers such as safety guards and machine enclosures are used to protect operators from the high-pressure systems and moving parts of the press. These guards are typically equipped with interlocks that prevent the press from operating if they are open.

7.2 Pressure Relief Systems

In the event of a pressure spike or system failure, pressure relief valves automatically release excess fluid to prevent the system from exceeding safe pressure limits. This helps protect both the machine and the operator from potential hazards.

Conclusion

The components of a sheet hydroforming press work together to create a highly efficient and precise metal forming machine capable of producing complex, high-quality parts. From the hydraulic system and flexible diaphragm to the die and control systems, each element plays a critical role in ensuring the success of the hydroforming process. By understanding how these components function and interact, manufacturers can optimize their operations, reduce costs, and improve part quality across a wide range of industries, including automotive, aerospace, and medical devices. As technology continues to advance, sheet hydroforming presses are likely to become even more versatile and capable, enabling the production of increasingly complex and lightweight components.

Applications of Sheet Hydroforming Presses

Sheet hydroforming is an advanced metal forming process that leverages hydraulic pressure to shape sheet metal into complex, high-precision components. This method is widely used across a variety of industries, including automotive, aerospace, medical devices, consumer electronics, and more. The main advantage of sheet hydroforming is its ability to create lightweight, durable, and intricately shaped components with minimal tooling and surface defects compared to traditional metal forming processes such as stamping or mechanical pressing.

Sheet hydroforming presses, which are designed specifically for this process, enable the efficient and cost-effective production of parts that require high dimensional accuracy, complex geometries, and excellent surface finishes. This article explores the key applications of sheet hydroforming presses, focusing on how they are used across different industries, the benefits they offer, and specific examples of their use in creating high-performance components.

1. Automotive Industry

The automotive industry is one of the largest adopters of sheet hydroforming technology. As the demand for lightweight, fuel-efficient, and crash-resistant vehicles grows, sheet hydroforming has become a critical process in the production of automotive components. By using hydraulic pressure to shape metal sheets, manufacturers can create parts that are both lightweight and structurally strong, improving vehicle performance and safety.

1.1 Body Panels and Exterior Components

Sheet hydroforming presses are widely used to produce automotive body panels and other exterior components. These parts require high levels of precision and smooth surface finishes, making hydroforming an ideal process for their production. Hydroformed body panels are often used in luxury and high-performance vehicles where weight reduction and aerodynamics are critical.

- Hoods, Doors, and Trunk Lids: Hydroforming is commonly used to manufacture car hoods, doors, and trunk lids. The ability to form complex, curved surfaces with minimal tooling reduces production costs and ensures a high-quality surface finish, reducing the need for additional surface treatments or polishing.

- Fenders and Bumpers: Fenders and bumpers are often hydroformed to create sleek, aerodynamic shapes that improve the overall aesthetics and performance of the vehicle. These components are also designed to absorb impact in the event of a collision, contributing to vehicle safety.

1.2 Chassis and Structural Components

In addition to body panels, sheet hydroforming presses are used to create chassis components and other structural parts that contribute to the overall strength and rigidity of the vehicle. These components must be lightweight yet capable of withstanding the stresses and forces experienced during vehicle operation, particularly in high-performance or off-road applications.

- Subframes and Crossmembers: Hydroforming is used to create subframes and crossmembers, which form the backbone of the vehicle’s structure. These components must be strong enough to support the vehicle’s weight while providing flexibility and impact resistance. Hydroforming allows for the production of lightweight, high-strength parts that meet these requirements.

- Crash Structures and Crumple Zones: Crash structures and crumple zones are critical safety components that absorb energy during a collision, protecting the occupants of the vehicle. Hydroformed parts in these areas are designed to deform in a controlled manner, dissipating energy and reducing the impact force on passengers.

1.3 Lightweighting for Electric Vehicles (EVs)

With the rise of electric vehicles (EVs), manufacturers are increasingly focused on reducing vehicle weight to improve battery efficiency and extend driving range. Sheet hydroforming plays a key role in the lightweighting of EVs, allowing manufacturers to create lightweight structural components that meet performance and safety standards without compromising strength.

- Battery Enclosures: Hydroforming is used to create lightweight, structurally sound battery enclosures that protect the vehicle’s battery pack while minimizing weight. The ability to form intricate shapes with high precision ensures that the enclosure fits tightly around the battery, optimizing space and efficiency.

- Suspension Components: EVs require lightweight suspension components to offset the weight of the battery pack. Hydroformed suspension arms, control arms, and other components are used to reduce weight and improve vehicle handling.

2. Aerospace Industry

The aerospace industry is another major user of sheet hydroforming presses, as the process enables the production of lightweight, high-strength components that are essential for aircraft performance and fuel efficiency. Aircraft must be designed with both strength and lightweight properties to maximize fuel efficiency, range, and payload capacity, making hydroforming an ideal solution for manufacturing structural and non-structural aerospace components.

2.1 Fuselage and Structural Components

One of the most common applications of sheet hydroforming in aerospace is the production of fuselage components and other structural elements that contribute to the aircraft’s overall frame and stability. These parts must withstand extreme loads and stresses during flight, and hydroforming allows manufacturers to create highly complex shapes that are both lightweight and strong.

- Fuselage Frames: Hydroformed fuselage frames provide the structural support for the aircraft’s outer skin. The precision and strength offered by hydroforming make these components crucial for maintaining the integrity of the aircraft during flight.

- Stringers and Longerons: Stringers and longerons, which are used to reinforce the fuselage and wings, are often hydroformed to ensure they meet the aircraft’s weight and strength requirements. These components need to be lightweight while offering the necessary rigidity to maintain the aircraft’s aerodynamic shape and structural integrity.

2.2 Wing Components

Wing components are another area where sheet hydroforming is commonly used. The wing structure must support the weight of the aircraft and handle various aerodynamic forces during flight, making it essential that these components are both lightweight and durable.

- Wing Ribs: Hydroforming is used to create wing ribs, which support the overall structure of the wing and distribute the loads experienced during flight. Hydroforming ensures that these components are lightweight while providing the necessary strength to support the aircraft.

- Spars and Struts: Spars and struts are critical structural elements that reinforce the wings and help distribute the forces experienced during takeoff, landing, and flight. Hydroforming is ideal for producing these parts due to its ability to form complex, strong, and lightweight components.

2.3 Engine Components

In addition to structural components, sheet hydroforming is used in the production of aircraft engine components. These parts must be able to withstand extreme temperatures and pressures, making material strength and precision critical.

- Turbine Housings and Ducts: Hydroformed components are used in turbine housings and air ducts, where precise shapes are required to ensure efficient airflow and optimal engine performance. The ability to create seamless parts with uniform wall thicknesses ensures that these components perform reliably under demanding conditions.

2.4 Fuel and Hydraulic Systems

Fuel lines, hydraulic tubes, and other fluid handling components are often hydroformed to create lightweight, seamless parts that can withstand the high pressures and temperatures found in aerospace applications. Hydroforming allows for the production of complex, thin-walled tubes that offer high precision and leak resistance, ensuring the safe and efficient operation of fuel and hydraulic systems.

3. Medical Devices

In the medical field, precision, surface finish, and material quality are critical factors in the design and manufacture of medical devices. Sheet hydroforming presses are commonly used to create high-precision components for surgical instruments, diagnostic equipment, and implants, ensuring that these devices meet stringent regulatory requirements for performance, safety, and biocompatibility.

3.1 Surgical Instruments

One of the primary applications of sheet hydroforming in the medical field is the production of surgical instruments. These instruments must be lightweight, strong, and easy to clean, making hydroforming an ideal process for their manufacture. Hydroformed instruments often have smooth, seamless surfaces, reducing the risk of contamination and making them easier to sterilize.

- Forceps, Scalpels, and Retractors: Hydroforming is used to create precision surgical tools such as forceps, scalpels, and retractors. The ability to form thin, strong, and lightweight components ensures that these tools meet the necessary performance and hygiene standards required in the operating room.

3.2 Medical Implants

Medical implants such as orthopedic devices, dental implants, and joint replacements require materials that are both biocompatible and strong enough to withstand the forces and stresses they will experience inside the human body. Hydroforming allows for the production of implants with customized shapes and tight tolerances, ensuring that they fit perfectly within the patient’s anatomy.

- Hip and Knee Replacements: Hydroformed components are used in joint replacement devices, where the precision of the forming process ensures a custom fit for each patient, improving the performance and longevity of the implant.

- Spinal Implants: Hydroforming is also used to produce spinal implants, which require highly intricate geometries and exacting tolerances to ensure proper alignment and function.

3.3 Diagnostic Equipment

In addition to surgical instruments and implants, sheet hydroforming is used to produce components for diagnostic equipment such as MRI machines, X-ray equipment, and other medical devices. These devices require parts with precise dimensions and smooth surfaces to ensure accurate readings and long-term durability.

- Casing and Housings: Hydroforming is often used to create the outer casings and housings of diagnostic equipment, where the smooth, seamless surfaces produced by the process help maintain the cleanliness and sterility of the device.

- Electromagnetic Shields: For devices like MRI machines, hydroformed components are used to create electromagnetic shields that protect sensitive electronics from interference, ensuring accurate diagnostic readings.

4. Consumer Electronics and Appliances

Sheet hydroforming presses are also widely used in the production of consumer electronics and appliances, where the ability to create lightweight, aesthetically pleasing, and durable components is essential. The process is especially useful for creating the sleek, modern designs that are popular in today’s consumer products.

4.1 Consumer Electronics

In the world of consumer electronics, sheet hydroforming is used to manufacture the housings, frames, and structural components of devices like smartphones, laptops, and tablets. These products require thin, lightweight parts with precise geometries, making hydroforming an ideal solution.

- Smartphone Housings: Hydroformed aluminum and stainless steel housings are commonly used in high-end smartphones, where a combination of strength, durability, and design aesthetics is required. The smooth surface finish and seamless construction provided by hydroforming ensure that the device has a premium look and feel.

- Laptop Frames: Hydroforming is also used to create the frames and chassis of laptops, providing the necessary structural support while maintaining a slim, lightweight design.

4.2 Home Appliances

The appliance industry benefits from sheet hydroforming presses for the production of kitchen appliances, laundry machines, and other home goods. The ability to form large, complex parts with smooth surfaces and minimal defects makes hydroforming ideal for creating both functional and aesthetically pleasing components.

- Refrigerator Doors and Panels: Hydroforming is used to create the outer panels and doors of refrigerators, where the process ensures a smooth, high-quality surface finish that is resistant to corrosion and easy to clean.

- Oven Liners and Control Panels: In ovens and other kitchen appliances, hydroformed components are used to create control panels and interior liners that can withstand high temperatures while maintaining their shape and finish.

5. Sporting Goods and Bicycles

In the world of sporting goods and bicycles, weight, performance, and durability are critical factors in product design. Sheet hydroforming presses are used to manufacture components that enhance the performance of sports equipment and bicycles by reducing weight without sacrificing strength.

5.1 Bicycle Frames

One of the most common applications of sheet hydroforming in the sporting goods industry is the production of bicycle frames. Hydroforming allows manufacturers to create lightweight, strong frames with complex geometries that improve the aerodynamics and performance of the bike.

- Mountain Bikes and Road Bikes: Hydroformed aluminum and titanium frames are used in both mountain bikes and road bikes, where the ability to create tapered tubes and customized shapes enhances both the strength and comfort of the bike.

- Electric Bicycles (e-Bikes): With the rise of e-bikes, hydroforming has become even more important, allowing manufacturers to integrate battery compartments and electrical components into the frame without adding unnecessary weight.

5.2 Golf Clubs and Other Sporting Goods

In addition to bicycles, hydroforming is used in the production of golf clubs, hockey sticks, tennis rackets, and other sports equipment where lightweight, high-strength materials are essential for performance.

- Golf Club Shafts: Hydroforming allows for the creation of precision-engineered golf club shafts, where the weight distribution and stiffness can be tailored to improve the player’s swing and overall performance.

- Tennis Rackets and Hockey Sticks: The ability to create lightweight, durable frames with minimal material wastage makes hydroforming ideal for producing high-performance tennis rackets and hockey sticks.

6. Energy and Power Generation

The energy and power generation industry also benefits from the use of sheet hydroforming presses, particularly in the production of components for wind turbines, solar energy systems, and oil and gas infrastructure. The process allows for the creation of large, complex parts that can withstand harsh environmental conditions and demanding operational requirements.

6.1 Wind Turbine Components

In wind energy systems, sheet hydroforming is used to produce structural components for wind turbines, including the hub, nacelle, and blades. These components must be both lightweight and durable to maximize energy output and withstand the elements.

- Nacelle Housings: Hydroformed nacelle housings provide the necessary protection for the sensitive electrical components inside the turbine, while maintaining a streamlined design that reduces wind resistance.

- Blade Root Fittings: Hydroforming is used to create the root fittings that connect the wind turbine blades to the hub, ensuring a secure, durable connection that can withstand the forces generated by the spinning blades.

6.2 Solar Energy Components

In solar energy systems, hydroforming is used to create mounting brackets and frames for solar panels, ensuring that they are lightweight, durable, and able to withstand harsh weather conditions.

- Solar Panel Frames: Hydroformed frames provide the necessary support for solar panels, while maintaining a lightweight design that reduces installation costs and improves energy efficiency.

Conclusion

Sheet hydroforming presses are highly versatile machines that are used in a wide range of industries to produce lightweight, high-precision components with complex geometries. From automotive and aerospace applications to medical devices, consumer electronics, and sporting goods, the ability to form intricate shapes with minimal defects and high material efficiency makes sheet hydroforming an invaluable tool for modern manufacturing. As industries continue to demand more efficient, sustainable, and high-performance components, sheet hydroforming will likely play an even greater role in shaping the future of product design and production.

Deep Draw Sheet Hydroforming Press: Overview, Process, and Applications

A deep draw sheet hydroforming press is a specialized machine used for forming complex, high-precision parts from metal sheets by applying hydraulic pressure. Unlike conventional stamping or drawing processes that use mechanical forces and matching male-female dies, deep draw hydroforming presses use a single die and hydraulic fluid pressure to shape the material. This advanced process is particularly effective for deep drawing operations, where the sheet metal is stretched into deep and complex shapes, often with minimal thinning or material waste.

Deep draw sheet hydroforming presses offer several advantages, such as reduced tooling costs, improved part quality, and the ability to create complex shapes with fewer defects. These benefits make the technology highly valuable in industries such as automotive, aerospace, medical devices, and consumer electronics.

1. What Is Deep Drawing?

Deep drawing is a manufacturing process in which a sheet metal blank is radially drawn into a forming die by a mechanical punch, typically resulting in a part with a greater depth than diameter. Commonly used to form hollow, cylindrical shapes like cups, cans, and tanks, deep drawing is widely used across various industries to manufacture parts that require significant depth.

In a conventional deep drawing process, the metal is mechanically drawn into the die using a punch, often resulting in defects like thinning, wrinkling, or tearing due to uneven material flow. However, deep draw hydroforming addresses these issues by replacing mechanical force with hydraulic pressure, offering better control over the material during the forming process.

2. Working Principles of Deep Draw Sheet Hydroforming Presses

The core principle of a deep draw sheet hydroforming press lies in the controlled application of hydraulic pressure, which shapes the metal sheet into the desired form by forcing it against a die. The press uses a flexible diaphragm or bladder filled with hydraulic fluid to apply pressure uniformly across the sheet metal.

2.1 Basic Process Steps

- Material Placement: A flat metal sheet (blank) is placed over the die. The material may vary based on the application but commonly includes aluminum, steel, stainless steel, or titanium.

- Clamping and Sealing: The blank is securely clamped to prevent movement during the forming process. The upper section of the press, containing the flexible diaphragm, is then lowered over the metal sheet, sealing the blank in place.

- Hydraulic Pressure Application: Hydraulic fluid is pumped into the diaphragm, which expands and applies uniform pressure across the surface of the metal sheet. This pressure forces the sheet to stretch into the die cavity, forming the desired deep shape.

- Material Flow and Stretching: As pressure builds, the material is drawn into the die, conforming to its shape without the need for a matching upper die. The hydraulic pressure ensures that the material flows smoothly, minimizing defects such as wrinkling or tearing.

- Pressure Holding and Release: Once the part has taken its final shape, the pressure is maintained briefly to allow the material to stabilize. Afterward, the hydraulic pressure is gradually released, and the diaphragm retracts.

- Part Removal: The clamping system is opened, and the deep-drawn part is removed from the die. The part is now ready for post-processing or further inspection.

2.2 Hydraulic Pressure Control

One of the key features of deep draw hydroforming presses is the ability to precisely control the hydraulic pressure applied during forming. The gradual increase in pressure allows the material to stretch uniformly, reducing the likelihood of defects such as material thinning or excessive wrinkling.

- Uniform Pressure Distribution: The hydraulic fluid ensures that pressure is applied evenly across the entire surface of the blank, allowing for uniform material deformation.

- Multi-Stage Pressure Application: In some cases, the pressure may be applied in multiple stages to ensure better control over material flow, especially for complex shapes or parts with variable wall thicknesses.

3. Key Components of Deep Draw Sheet Hydroforming Presses

Deep draw sheet hydroforming presses consist of several key components that work together to ensure the precise and efficient forming of metal parts. Each of these components plays a crucial role in maintaining the press’s performance and accuracy.

3.1 Hydraulic System

The hydraulic system is the core of the deep draw hydroforming press, generating the pressure needed to form the sheet metal into complex shapes. It typically includes the following components:

- Hydraulic Pumps: High-pressure hydraulic pumps provide the force required to move the hydraulic fluid into the diaphragm and exert pressure on the metal sheet.

- Accumulators: These store pressurized fluid and release it as needed, maintaining a consistent pressure throughout the forming process.

- Valves: Hydraulic control valves regulate the flow of fluid, ensuring precise control over the pressure levels at each stage of the process.

3.2 Diaphragm (Flexible Bladder)

The flexible diaphragm or bladder is a critical component in the hydroforming process. Made from durable materials such as urethane or rubber, the diaphragm holds the hydraulic fluid and transmits the pressure uniformly across the sheet metal.

- Durability: The diaphragm must be able to withstand repeated cycles of high pressure without rupturing or losing its flexibility.

- Uniform Pressure Application: Its primary function is to ensure even pressure distribution across the blank, preventing localized stress that could lead to defects.

3.3 Die (Tooling)

The die is the mold that defines the final shape of the deep-drawn part. In deep draw hydroforming, a single-sided die is used to form the part, which reduces tooling costs compared to traditional methods that require both a male and female die.

- Die Material: Dies are typically made from hardened steel, aluminum, or cast iron, depending on the production volume and material being formed.

- Custom Die Design: Each die is custom-designed to match the geometry of the part, ensuring accurate and repeatable results.

3.4 Clamping System

The clamping system holds the sheet metal blank in place over the die during the hydroforming process. Proper clamping ensures that the material does not shift or wrinkle during forming.

- Hydraulic or Mechanical Clamps: Clamping systems may be hydraulic or mechanical, depending on the press design. Hydraulic clamps provide more even pressure distribution and are commonly used in high-precision applications.

3.5 Control System

Modern deep draw hydroforming presses are equipped with computerized control systems that allow operators to manage every aspect of the process, from pressure levels to cycle timing.

- CNC (Computer Numerical Control): Many presses use CNC systems to control the pressure application and movement of the press components, ensuring repeatable and accurate part production.

- Real-Time Monitoring: Sensors monitor critical parameters, such as pressure, temperature, and material deformation, allowing real-time adjustments to prevent defects and ensure quality.

4. Applications of Deep Draw Sheet Hydroforming Presses

Deep draw sheet hydroforming presses are used across various industries, offering unique advantages in producing lightweight, high-strength components with complex geometries. Below are some of the most common applications.

4.1 Automotive Industry

The automotive industry is one of the largest users of deep draw hydroforming technology. As manufacturers strive to reduce vehicle weight while maintaining safety and performance standards, deep draw hydroforming plays a critical role in producing lightweight yet strong components.

- Fuel Tanks and Fluid Reservoirs: Deep-drawn fuel tanks and fluid reservoirs benefit from the process’s ability to create seamless, leak-resistant parts with complex shapes.

- Heat Shields and Engine Covers: Hydroforming allows for the precise shaping of heat shields and engine covers, which require tight tolerances and smooth surfaces to ensure optimal performance.

- Structural Components: Chassis parts, crossmembers, and other structural components are often deep-drawn using hydroforming presses, as the process allows for reduced material thickness while maintaining strength.

4.2 Aerospace Industry

In the aerospace industry, reducing weight is essential for improving fuel efficiency and performance. Deep draw hydroforming is used to create high-precision parts that meet stringent performance and safety standards.

- Aircraft Skin Panels: Hydroforming is used to produce lightweight, seamless skin panels that provide aerodynamic surfaces while reducing material wastage.

- Landing Gear Components: Deep-drawn hydroformed parts are used in landing gear, where they must withstand high stress and repeated impact during landing.

- Engine Components: The process is also used to manufacture parts for aircraft engines, such as turbine housings and exhaust components, where high-strength materials and precise shapes are required.

4.3 Medical Devices

In the medical industry, deep draw hydroforming is used to produce components that require high levels of precision, biocompatibility, and surface quality.

- Surgical Instruments: The process is used to create lightweight, durable surgical tools such as forceps, scalpels, and retractor blades, where precision and smooth finishes are critical.

- Implants: Custom-designed implants, such as joint replacements and spinal devices, benefit from the process’s ability to form intricate, biocompatible shapes with minimal defects.

4.4 Consumer Goods

In the consumer goods sector, deep draw hydroforming is used to create components for household appliances, electronics, and other consumer products.

- Appliance Housings: Seamless, lightweight housings for appliances such as washing machines, dryers, and refrigerators are often hydroformed to provide both structural strength and aesthetic appeal.

- Electronics: In the electronics industry, deep draw hydroforming is used to create lightweight, durable enclosures for devices such as smartphones, laptops, and tablets.

5. Advantages of Deep Draw Sheet Hydroforming Presses

Deep draw hydroforming presses offer numerous advantages over traditional mechanical forming methods. These include:

5.1 Reduced Tooling Costs

Because deep draw hydroforming requires only a single-sided die, tooling costs are significantly lower than in conventional methods that use both a male and female die. This makes hydroforming a cost-effective option, especially for low to medium production runs.

5.2 Improved Part Quality

The uniform pressure distribution in hydroforming results in parts with smoother surfaces and better dimensional accuracy than those produced through mechanical stamping or drawing. The process also minimizes the risk of defects such as wrinkling, tearing, and thinning, ensuring high-quality final products.

5.3 Greater Design Flexibility

Hydroforming offers greater design flexibility, allowing manufacturers to produce parts with complex geometries, deep draws, and intricate contours. This is particularly beneficial in industries like automotive and aerospace, where lightweight, high-performance components are essential.

5.4 Material Efficiency

Hydroforming allows for efficient material usage by minimizing waste and ensuring uniform wall thickness across the entire part. This reduces the overall material cost and improves the structural integrity of the part.

Conclusion

Deep draw sheet hydroforming presses are an essential tool for modern manufacturing, providing a cost-effective, precise, and versatile method for producing complex, high-strength components. Whether used in the automotive, aerospace, medical, or consumer goods industries, deep draw hydroforming enables manufacturers to create lightweight, high-performance parts with minimal defects and reduced material waste. The ability to control hydraulic pressure precisely and form intricate geometries makes deep draw hydroforming a preferred choice for producing parts that require a combination of strength, durability, and precision. As industries continue to demand more efficient and lightweight components, the use of deep draw sheet hydroforming presses will likely continue to grow, driving innovation in both machine design and production capabilities.

What Is Deep Drawing?

Deep drawing is a metal forming process used to manufacture hollow, cylindrical, or complex-shaped parts from flat sheet metal. The process involves radially drawing a sheet metal blank into a forming die using a punch, causing the material to stretch and deform into the shape of the die cavity. Deep drawing is commonly used in various industries to produce parts such as cans, cups, automotive components, appliance parts, and medical devices. The term “deep” refers to the fact that the depth of the part produced is greater than its diameter.

The deep drawing process is distinguished by its ability to create seamless, high-precision, and lightweight parts in a single operation or through multiple drawing stages. It is favored over other metal forming techniques when manufacturers need parts that require significant depth, smooth surfaces, and high strength-to-weight ratios.

1. The Deep Drawing Process: Step-by-Step

The deep drawing process transforms flat sheet metal into a hollow, three-dimensional shape by stretching the material. Below are the basic steps involved in the deep drawing process:

1.1 Blank Preparation

- Sheet Metal Selection: The process begins with a flat sheet of metal, commonly called a blank. The blank is typically cut into a circular shape and must be of a material with good formability, such as aluminum, steel, stainless steel, or copper.

- Blank Size: The size of the blank depends on the dimensions of the desired part. The blank needs to be large enough to stretch and fill the die cavity during the deep drawing process.

1.2 Die and Punch Setup

- Punch and Die: The primary tools in the deep drawing process are the punch and the die. The die defines the outer shape of the part, while the punch pushes the metal blank into the die cavity, forming the internal shape of the part.

- Blank Holder (or Binder): A blank holder is used to clamp the blank in place over the die. The blank holder prevents the sheet metal from wrinkling as it is drawn into the die cavity. The force applied by the blank holder is critical to achieving a smooth part without defects.

1.3 Drawing Stage

- Punch Movement: During the drawing stage, the punch moves downward, applying force to the center of the blank. As the punch pushes the blank into the die, the material is forced to stretch and flow around the punch, taking the shape of the die cavity.

- Metal Flow: The metal sheet experiences a combination of tension and compression as it is drawn. The material flows from the edges toward the center, and any excess material is absorbed by the blank holder to prevent wrinkling.