Pipe Spinning Machine: EMS Metalworking Machinery offers a comprehensive range of advanced tube and fan processing machines designed for high-precision, high-performance industrial applications. Our portfolio includes Tube Spinning Machines, Tube Flanging Machines, Copper Tube Spinning Machines, Pipe Spinning Machines, Tube End Closing Machines, and Fan Flanging Machines. Each machine is engineered to deliver superior quality, efficiency, and reliability while supporting a wide range of materials, sizes, and production requirements. EMS machines are ideal for manufacturers seeking precision, productivity, and long-term operational performance in metal forming and spinning applications.

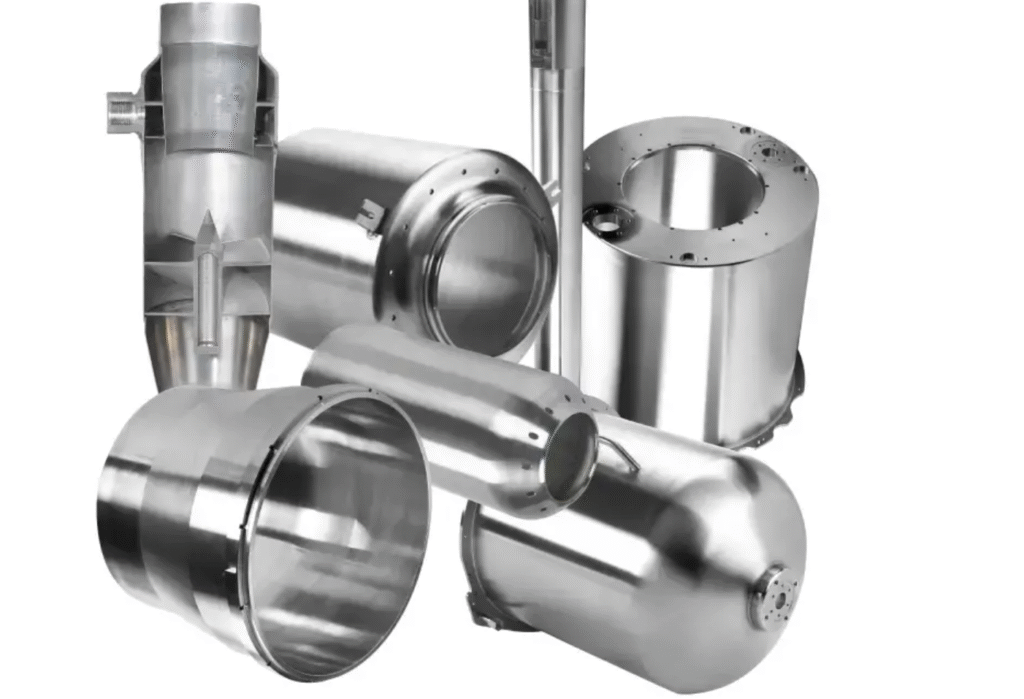

The Tube Spinning Machine is a versatile solution for shaping cylindrical tubes into precise profiles with consistent wall thickness and surface finish. It employs a combination of rotary motion and controlled forming pressure to manipulate metal tubes into desired geometries. EMS Tube Spinning Machines are capable of handling steel, aluminum, copper, and other alloys, producing high-quality spun tubes for automotive, HVAC, industrial, and custom applications. These machines provide repeatable results, excellent dimensional accuracy, and smooth surface finishes, making them ideal for both high-volume production and specialized custom orders.

Tube Flanging Machines are designed to create precise flanges on tube ends, enhancing connectivity, sealing, and structural strength. EMS Tube Flanging Machines offer flexibility to handle various tube diameters, wall thicknesses, and materials. Equipped with hydraulic, mechanical, or CNC-controlled actuators, these machines ensure uniform flange geometry, consistent wall thickness, and high-quality surface finish. Flanging is critical for applications such as pipelines, ventilation systems, and industrial assemblies, where reliable sealing and fit are essential. EMS Tube Flanging Machines enable efficient, repeatable, and precise flange production with minimal waste and downtime.

The Copper Tube Spinning Machine specializes in forming and shaping copper tubes, offering precise control over wall thickness and surface quality. Copper is widely used for plumbing, refrigeration, and electrical applications due to its conductivity, corrosion resistance, and malleability. EMS Copper Tube Spinning Machines employ controlled spinning processes that maintain material integrity while producing high-quality finished products. These machines ensure uniformity, smooth surfaces, and accurate dimensions, supporting manufacturers in producing reliable copper tubes for industrial, commercial, and residential applications.

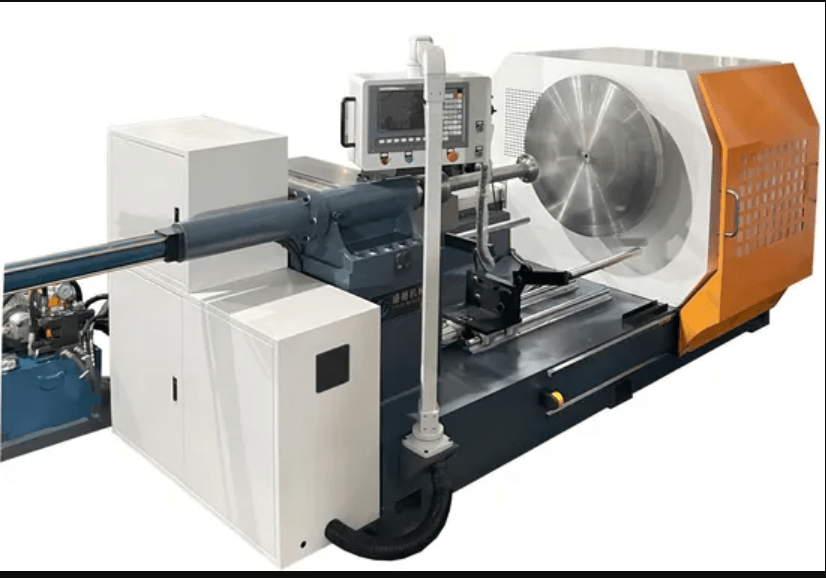

Pipe Spinning Machines are designed for shaping metal pipes into complex profiles or tapered geometries with consistent precision. EMS Pipe Spinning Machines utilize rotary forming, controlled force, and CNC guidance to produce high-quality spun pipes for automotive, aerospace, industrial, and energy sector applications. These machines can process steel, stainless steel, aluminum, and other alloys, offering versatility and precision for diverse manufacturing needs. By ensuring uniform wall thickness, smooth surfaces, and accurate diameters, EMS Pipe Spinning Machines enhance product quality, reduce scrap, and improve production efficiency.

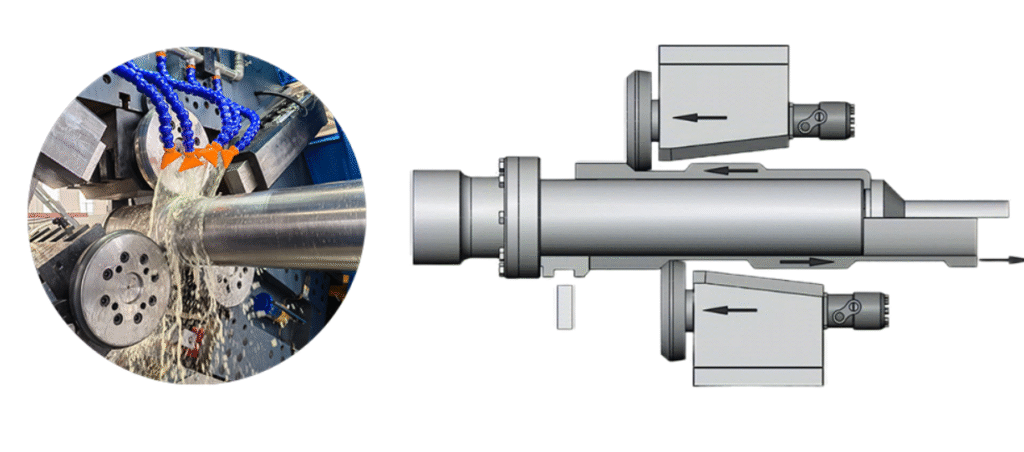

The Tube End Closing Machine is engineered for securely sealing, closing, or forming the ends of metal tubes. This process is essential for pressure vessels, gas cylinders, automotive components, and industrial piping systems. EMS Tube End Closing Machines provide controlled forming using hydraulic, mechanical, or CNC systems to produce precise end geometry while maintaining wall thickness and surface quality. Mandrels and internal supports ensure tube stability during forming, preventing wrinkling or collapse. These machines deliver consistent, high-quality results across various tube diameters, materials, and wall thicknesses, supporting both high-volume and specialized production requirements.

Fan Flanging Machines are designed to produce accurate flanges on fan blades, impellers, and other ventilation system components. Proper flanging ensures structural integrity, precise fit, and optimal performance in assembled fans. EMS Fan Flanging Machines combine hydraulic, mechanical, and CNC technologies to form consistent flanges with precise wall thickness and smooth surfaces. They accommodate a wide range of materials, including steel, aluminum, and copper, and can handle various diameters and blade thicknesses. These machines are suitable for high-volume industrial fan production as well as custom or specialized applications, providing repeatable, high-quality results.

All EMS machines are built with durability, precision, and efficiency in mind. Rigid frames, high-quality tooling, and advanced control systems ensure consistent performance and long-term reliability. Many of our machines integrate CNC control and automation capabilities, allowing operators to achieve complex geometries, reduce setup time, and enhance productivity. Modular tooling, quick-change dies, and accessible components simplify maintenance and allow rapid adaptation to different materials, sizes, and production requirements. EMS Metalworking Machinery combines advanced engineering with practical usability to support manufacturers in producing high-quality metal tubes, pipes, and fan components efficiently and reliably.

EMS Metalworking Machinery is committed to supporting modern manufacturing with machines that combine innovation, precision, and flexibility. Whether producing spun tubes, flanged ends, copper components, spun pipes, closed tube ends, or fan flanges, EMS machines deliver reliable, repeatable, and high-quality results. Our machines are designed to handle diverse materials and complex geometries while maintaining structural integrity, surface finish, and dimensional accuracy. With EMS solutions, manufacturers can optimize production efficiency, reduce waste, maintain consistent quality, and meet the rigorous demands of industrial, commercial, and custom applications.

Tube Flanging Machine – High-Precision End Forming for Pipes and Tubes

A Tube Flanging Machine is a specialized end-forming system designed to create precise, durable, and uniform flanged edges on metal tubes and pipes. These machines are essential in industries where leak-proof, mechanically reinforced, or assembly-ready tube ends are required. Typical applications include HVAC systems, automotive exhausts, heat exchangers, fluid transfer lines, fire-fighting piping, steel drum manufacturing, and countless metalworking operations that rely on strong, dimensionally accurate flange geometry.

Modern tube flanging technology offers a combination of speed, repeatability, automation, and forming power, making it an indispensable machine for companies seeking to increase productivity while maintaining strict quality standards.

Purpose and Functionality

Tube flanging involves folding, shaping, or expanding the tube edge outward or inward to create a flange. This flange can serve multiple purposes:

- Improved sealing surface

- Reinforcement of tube ends

- Preparation for assembly (bolting, welding, clamping)

- Structural stability

- Aesthetic finishing

A tube flanging machine applies axial forming force using hydraulic or servo-driven actuators while controlling the material flow with specially designed tooling. The result is a smooth, crack-free, and dimensionally precise flange, even on high-strength materials.

Machine Types

Depending on production volume, tube size range, and application, Tube Flanging Machines are available in several configurations:

• Hydraulic Tube Flanging Machines

Robust, versatile, and ideal for medium to heavy-duty industrial operations. They provide high forming force and work well with a wide range of materials and wall thicknesses.

• CNC Servo Tube Flanging Machines

Equipped with servo-driven positioning and programmable cycles. These models offer high repeatability, low noise, and energy efficiency while enabling complex flange shapes and multi-step programs.

• Automatic Loading & Unloading Flanging Lines

Designed for mass production, these lines integrate:

- Tube feeding systems

- Automatic clamping

- Flanging cycle

- Unloading conveyors or robotic pickers

Perfect for automotive or HVAC mass-production environments.

Materials and Tube Sizes

A Tube Flanging Machine can operate on:

- Stainless steel

- Carbon steel

- Aluminum

- Copper

- Brass

- Alloy steels

- Special materials used in heat exchangers or chemical applications

Typical tube diameter ranges from Ø10 mm to Ø600 mm, depending on the machine model. Custom-built heavy-duty models can handle even larger tubes used in industrial ducts, tanks, or vessel manufacturing.

Key Features and Capabilities

1. High Forming Accuracy

Precision sensors and rigid construction ensure that each flange maintains consistent thickness, angle, and height — crucial for sealing and assembly.

2. Programmable Working Cycles

Advanced models allow the operator to store hundreds of programs for different tube diameters, materials, and flange geometries.

3. Heavy-Duty Tooling Design

Tooling is engineered to minimize material stress and prevent cracking during the forming process.

4. Quick Changeover

Fast tool changes reduce downtime and increase production efficiency, especially in multi-size operations.

5. Safety and Ergonomics

Guarding systems, electronic safety modules, and simplified operator interfaces ensure safe and comfortable working conditions.

6. Energy Efficiency

Servo control and optimized hydraulic systems reduce energy consumption while maintaining constant forming force.

Applications of Tube Flanging Machines

Tube flanging is essential in multiple sectors:

- Automotive Industry

Exhaust pipes, turbo charger connections, fluid pipes, fuel systems, and HVAC tubing. - HVAC & Refrigeration

Air-conditioning lines, heat exchanger tubes, and copper/aluminum coil ends. - Fire Protection Systems

Fire sprinkler piping, flange prep for bolted connections. - Metal Drums and Containers

Rolling flanges on steel cable drums, barrels, or cylindrical housings. - Aerospace & Defense

Precision flanges for high-pressure systems. - General Fabrication and Metalworking

Any application requiring a reinforced or aesthetically clean tube end.

Advantages of Using a Tube Flanging Machine

- Consistent and repeatable quality with zero defects

- Fast cycle times for mass production

- Reduced manual labor compared to traditional spinning or hammering

- High structural integrity of the formed flange

- Lower risk of cracking or deformation

- Flexibility to create flanges of different sizes and shapes

- Ability to work with thin and thick wall tubes alike

These advantages make tube flanging machines a strategic investment for manufacturers seeking to improve efficiency and final product reliability.

Optional Integrations and Custom Features

Modern tube flanging machines can include:

- Automatic lubrication systems

- Laser diameter measurement

- Hydraulic or servo mandrel expansion

- Multi-stage forming (flange + bead + collar)

- Tube trimming & hole punching modules

- Robot-based handling units

- Complete production cells with Industry 4.0 connectivity

For special projects, machines can be custom-designed with non-standard stroke lengths, forming heads, or clamping systems.

Quality Control and Precision

A well-engineered flanging machine performs forming with:

- Smooth material flow

- Controlled axial pressure

- Zero waviness on flange edges

- Perfect concentricity and roundness

- No thinning or cracking at the form transition

These quality points ensure that the final tubes are suitable for high-pressure, high-temperature, or structural load applications.

Why Choose a Professional Tube Flanging System

Compared to improvisational manual methods or outdated machinery, a modern tube flanging system delivers:

- Better production consistency

- Safer operation

- Faster throughput

- Higher precision

- Lower scrap rate

- Less operator dependency

When combined with CNC control, manufacturers gain programmability, data monitoring, real-time diagnostics, and full repeatability.

Tube Flanging Machine – Complete Technical Description and Industrial Application Guide

A Tube Flanging Machine is a highly specialized metal-forming system designed to create reliable, uniform, and mechanically enhanced flanges on the ends of pipes and tubes. This process is fundamental in industries where tube joints must offer high structural strength, airtightness, pressure resistance, and compatibility with bolted, welded, or clamped connections. From HVAC and automotive lines to chemical installations, heat exchangers, and high-pressure piping systems, flanging ensures that tube assemblies are prepared for demanding working conditions.

Unlike manual flanging or improvised forming methods, modern Tube Flanging Machines deliver precision, speed, and repeatability, allowing manufacturers to maintain strict dimensional tolerances and consistent forming quality. These machines combine hydraulic or servo-driven forming forces with custom-engineered tooling to produce flanges without cracks, wrinkles, or excessive thinning. Below is an in-depth, expanded description of the technology, covering every aspect of machine design, operation, applications, and advantages.

Introduction to the Tube Flanging Process

Tube flanging is the process of expanding or shaping the end of a tube outward (or inward) to create a rim-like structure known as a flange. The flange serves multiple roles depending on the application:

- Reinforcing the tube end to avoid deformation

- Creating a broader sealing surface for gaskets

- Allowing bolting or clamping of tube ends

- Improving tube connection stability

- Preparing tubes for welding or brazing

- Enhancing structural rigidity

- Providing a cleaner, more aesthetic finish

In many industries, flanges are essential for ensuring mechanical safety, pressure handling, and high-quality assembly. A professional flanging machine guarantees that these flanges are produced with consistent dimensions and without material defects.

Machine Construction and Forming Principles

A Tube Flanging Machine typically consists of the following components:

• Frame / Body

A heavy-duty welded steel structure ensures rigidity, precision, and vibration-free operation during forming. Machine frames are engineered to withstand repeated high force cycles and maintain alignment over years of operation.

• Hydraulic or Servo Forming Unit

The forming unit provides axial force that pushes the tool into the tube end.

- Hydraulic systems offer extremely high tonnage and are suitable for thick-walled tubes.

- Servo-driven systems provide programmable force profiles, energy savings, quiet operation, and exceptional repeatability.

• Mandrel and Tooling

Tooling design is crucial for achieving crack-free flanges.

- Internal mandrel supports the tube from inside, preventing collapse.

- External forming tool gradually shapes the flange according to programmed movement.

Custom tooling can be produced for different materials, flange angles, flange heights, and wall thicknesses.

• Clamping System

The clamping mechanism holds the tube firmly during forming to prevent rotation or slippage. Clamps may be hydraulic, pneumatic, or servo-electric depending on the machine type.

• Control System (CNC / PLC)

The control system manages all machine parameters:

- Stroke length

- Speed and force control

- Multi-step forming sequences

- Tool positioning

- Automatic cycle management

CNC flanging machines allow the operator to save hundreds of programs for different tube sizes and materials.

Types of Tube Flanging Machines

3.1 Hydraulic Tube Flanging Machines

These machines use hydraulic pressure to generate forming force. They are ideal for:

- Thick-walled pipes

- Heavy-duty industrial applications

- Steel tubes, pressure vessels, oil and gas piping

Advantages include high forming capability and durability.

3.2 CNC Servo Tube Flanging Machines

Advanced machines equipped with servo motors allow precise control over movement and force. Ideal for:

- Automotive exhaust systems

- HVAC tubing

- Precision stainless steel applications

Servo-driven machines offer low noise, repeatability, energy efficiency, and advanced programmability.

3.3 Automatic Tube Flanging Lines

For mass production environments, fully automated lines integrate:

- Automatic tube loading

- Positioning and clamping

- Multi-stage flanging

- Unloading conveyors or robotic pickers

These lines minimize labor requirements and ensure extremely high production speeds.

Materials, Tube Sizes, and Geometries

Tube flanging machines can process a wide range of materials:

- Stainless steel AISI 304 / 316

- Carbon steel

- Aluminum and aluminum alloys

- Copper and brass tubes

- Titanium (in advanced models)

- High-pressure alloy steels

- Nickel and heat-resistant alloys

Typical tube diameters range from 10 mm to 600 mm, although custom machines can handle much larger tubes for ducting, industrial drums, or structural metal fabrication.

Flanges can be designed in various forms:

- Standard 90° outward flange

- Rounded or radius flanges

- Inward flanges

- Curling edges

- Step flanges

- Multi-stage flange + bead combinations

Each geometry requires dedicated tooling and forming profiles.

Advanced Features and Options

Modern Tube Flanging Machines may include:

• Servo-controlled forming axis

Allows precise multi-step shaping with variable speed and force.

• Laser or camera measurement systems

Used for real-time diameter or flange height verification.

• Quick-change tooling

Minimizes downtime between product changes.

• Automatic lubrication

Ensures smooth forming and prevents tool wear.

• Mandrel expansion modules

Support thin-walled tubes during aggressive forming.

• Integrated trimming units

To cut or smooth tube edges before or after flanging.

• Industry 4.0 connectivity

Machine connectivity for production monitoring, maintenance data, and remote diagnostics.

Industrial Applications in Depth

6.1 Automotive Industry

Flanged tubes are used in:

- Exhaust pipes

- Turbo systems

- Fuel and hydraulic lines

- Vibration dampening tubes

High repeatability is critical for high-volume automotive production.

6.2 HVAC and Heat Exchangers

Flanged copper and aluminum tubes are essential in:

- Air-conditioning units

- Heat exchanger coils

- Chillers and cooling systems

Flanged ends allow secure brazing and improved sealing.

6.3 Oil, Gas, and Chemical Industry

Flanging ensures safer, leak-proof connections in systems handling:

- High pressure

- High temperature

- Corrosive chemicals

Stainless steel flanges are preferred for chemical resistance.

6.4 Firefighting Piping

Sprinkler systems use flanged pipes to allow fast assembly and bolted connections.

6.5 Metal Drum and Cylinder Manufacturing

Flanging is used to reinforce the edges of:

- Steel drums

- Cable drums

- Gas cylinders

- Pressure containers

6.6 Aerospace Industry

Precision flanges for lightweight tubing systems require extremely tight tolerances.

Advantages of Tube Flanging Machines

7.1 Precision and Repeatability

Machines maintain strict tolerances even after thousands of cycles.

7.2 Increased Productivity

Fast forming cycles boost throughput significantly compared to manual or semi-manual processes.

7.3 Reduced Material Waste

Controlled forming prevents defects such as cracking and thinning.

7.4 Safety

Integrated safety systems and enclosed forming areas reduce operator risk.

7.5 Lower Labor Dependency

Automation minimizes the need for skilled manual flanging operators.

7.6 Flexible Production

Easily change between tube diameters, materials, and flange types.

7.7 Consistent Finish Quality

Smooth, clean flanges require minimal post-processing.

8. Tooling Engineering and Forming Quality

Tooling design dramatically impacts forming success. High-quality tooling ensures:

- Proper material flow

- No wrinkling or cracking

- Even wall thickness distribution

- Perfect roundness and symmetry

- Smooth flange surface

Tool materials typically include high-strength alloy steel or special wear-resistant coatings.

9. Automation and Production Integration

Tube flanging machines can be seamlessly integrated into automated production lines:

- Robotic loading/unloading

- Tubing feed conveyors

- Barcode/RFID part identification

- Automated quality inspection

- Communication with MES/ERP systems

These integrations enable lights-out production and maximize output.

10. Quality Control and Standards

Professional machines ensure compliance with industrial standards such as:

- EN / DIN flanging requirements

- ASTM tube material compatibility

- Automotive and HVAC industry tolerances

- Pressure vessel manufacturing codes

Machines can include built-in sensors to monitor forming force, displacement, and deformation.

11. Why Choose a Tube Flanging Machine?

In modern manufacturing, the demand for reliability and precision makes tube flanging machines indispensable. Benefits include:

- Lower production costs

- Faster order fulfillment

- Large-scale batch consistency

- Extended tube lifespan

- Compatibility with automated factories

A tube flanging system is not merely a machine but a critical component of a high-quality metal fabrication workflow.

Tube Flanging Machine | High-Precision Tube End Forming Solutions by EMS Metalworking Machinery

At EMS Metalworking Machinery, we design and manufacture advanced Tube Flanging Machines engineered for high-precision end forming, industrial durability, and continuous production efficiency. With decades of experience in metal forming technology, EMS provides robust flanging solutions used worldwide in automotive, HVAC, aerospace, fire-fighting piping, heat exchangers, and high-pressure fluid systems.

Our Tube Flanging Machines combine state-of-the-art CNC control, servo or hydraulic forming power, heavy-duty frames, and custom-engineered tooling to create perfectly formed flanges on metal tubes with unmatched consistency. Whether your production involves stainless steel, aluminum, copper, or thick-wall carbon steel pipes, EMS offers machines and custom tooling that ensure reliable, repeatable, and crack-free forming results.

Why Choose an EMS Tube Flanging Machine?

EMS machines are engineered for companies requiring:

- High-repeatability flanging for serial or mass production

- Zero-defect forming in demanding applications

- Long-lasting industrial machinery designed for 24/7 operation

- Flexible tooling solutions for various tube diameters and materials

- Seamless integration into automated production lines

Our commitment is simple: maximum forming precision, minimum production cost, and superior reliability.

1. Overview of the Tube Flanging Process

Tube flanging is a critical forming operation where the tube end is expanded or shaped outward to create a mechanically reinforced flange. This flange serves functional and structural purposes:

- Provides a sealing surface for gaskets

- Enables bolted, clamped, or welded connections

- Reinforces the tube end against deformation

- Enhances structural stability

- Improves assembly speed and safety

- Ensures pressure and leak resistance

In modern manufacturing, precision flanging is essential for components that operate under vibration, high pressure, thermal expansion, or corrosive environments. EMS machines ensure that every formed flange meets strict dimensional standards and is free from cracks, thinning, or distortion.

2. EMS Machine Construction & Engineering Excellence

Heavy-Duty Machine Frame

All EMS Tube Flanging Machines are built on rigid, stress-relieved welded steel frames to ensure vibration-free operation and long-term structural integrity. This stability is essential for maintaining consistent flange geometry across thousands of forming cycles.

Hydraulic or Servo Forming System

EMS offers two high-performance forming technologies:

- Hydraulic Forming Machines – ideal for large diameters and thick-walled tubes requiring high forming tonnage.

- Servo-Driven CNC Flanging Machines – perfect for precision applications with superior repeatability, programmable force profiles, and energy efficiency.

Specialized Internal Mandrel + Forming Tools

Our tooling is engineered for maximum material flow without cracking. Internal mandrels support the tube during forming, while outer forming tools shape the flange precisely. EMS also produces custom tooling sets for complex geometries, unconventional materials, or multi-stage forming operations.

Precision Clamping System

Hydraulic or servo clamps hold the tube securely and ensure perfect alignment, preventing slippage, distortion, or eccentric forming.

Advanced CNC / PLC Control

EMS control systems offer:

- Multi-step forming cycles

- Adjustable speeds, pressures, and stroke lengths

- Storage of hundreds of flanging programs

- Operator-friendly touchscreen interface

- Diagnostic tools and smart alarms

3. Types of Tube Flanging Machines Offered by EMS

A. EMS Hydraulic Tube Flanging Machines

Designed for heavy-duty industrial applications, these machines provide high forming power and exceptional structural rigidity. They are ideal for:

- Large diameters

- Thick-walled carbon steel tubes

- Oil, gas, and pressure vessel industries

- Industrial ducting and structural tubing

B. EMS CNC Servo Tube Flanging Machines

Our CNC servo models offer superior precision, low noise, energy savings, and extremely fast cycle times. They are preferred in:

- Automotive tube production

- Stainless steel manufacturing

- Copper and aluminum HVAC production

- High-accuracy, thin-wall tube forming

C. EMS Fully Automated Flanging Lines

For mass production, EMS provides turnkey systems that can include:

- Automatic tube loading

- Positioning, clamping, and multi-stage forming

- Integrated trimming or beading

- Robotic unloading

- Quality inspection modules

Such lines drastically reduce labor costs and increase consistency in high-volume environments.

4. Supported Materials & Tube Sizes

EMS Tube Flanging Machines process:

- Stainless Steel (304, 316, Duplex, etc.)

- Carbon Steel & Mild Steel

- Aluminum & Aluminum Alloys

- Copper & Brass

- Titanium & High-Strength Alloys

- Nickel-Based & Heat-Resistant Materials

Tube diameters typically range from Ø10 mm to Ø600 mm, with custom solutions available for even larger industrial applications.

Flange forms available:

- 90° outward flange

- Curved or radius flanges

- Inward flanges

- Roll-formed curling edges

- Multi-step flanges

- Flange + bead combined forming

- Special geometries based on customer drawings

5. Key Features and Benefits of EMS Tube Flanging Machines

Precision & Repeatability

EMS machines guarantee consistent results with strict tolerances — essential for high-pressure systems and automotive standards.

High Production Efficiency

Fast forming cycles reduce production time and increase throughput.

Long Tool Life

Tooling designed by EMS ensures smooth forming, minimal friction, and maximum durability.

Zero-Defect Forming

Controlled force profiles and optimized tooling eliminate cracks, wrinkles, and deformation.

Industry 4.0 Compatibility

EMS machines can be equipped with:

- Data logging

- Production monitoring

- Remote diagnostics

- Preventive maintenance alerts

Flexible Operation

Fast tool change systems make EMS machines ideal for companies handling multiple tube sizes.

Operator Safety

Comprehensive safety modules (light curtains, emergency stops, safety PLCs) ensure a secure working environment.

6. Industrial Applications of EMS Tube Flanging Machines

Automotive Manufacturing

Flanged tubes for:

- Exhaust lines

- Turbocharger connections

- Fuel and hydraulic lines

- Engine cooling and HVAC tubes

EMS machines deliver the repeatability required for Tier-1 automotive suppliers.

HVAC & Refrigeration

Flanging is crucial for:

- Heat exchangers

- AC copper/aluminum lines

- Industrial chillers

- Cooling and refrigeration systems

Perfect flanges guarantee leak-free brazing and sealing.

Oil, Gas & Chemical Processing

Our machines produce flanges capable of resisting:

- High pressure

- High temperature

- Corrosive environments

Ideal for chemical plants, process lines, and stainless-steel piping systems.

Fire-Fighting & Sprinkler Pipe Systems

Flanged steel pipes allow fast installation, reduced welding, and reliable bolted connections.

Metal Drums & Cylinder Manufacturing

EMS flanging technology ensures reinforced, uniform edges on:

- Cable drums

- Oil / fuel drums

- Pressure-resistant cylinders

- Industrial storage tanks

Aerospace & Energy Industries

High-precision flanging for specialized lightweight alloy tubes used in demanding environments.

7. Tooling Engineering at EMS

Tooling quality is one of the core strengths of EMS Metalworking Machinery. Each tool is:

- Designed specifically for the customer’s application

- Manufactured from high-grade alloy steel

- Heat-treated for maximum wear resistance

- Polished to ensure smooth material flow

- Calibrated for long-term dimensional accuracy

Advanced tooling options include coatings, modular multi-step tools, mandrel expansion designs, and high-precision die sets for thin-walled tubes.

8. Automation & Integration Options

EMS provides full automation solutions such as:

- Robotic loading/unloading

- Tube conveyors

- Barcode/RFID reader integration

- In-line measuring & inspection

- Custom production cells

- Complete Industry 4.0 connectivity

These integrations transform the machine into a fully automatic production platform capable of 24/7 operation.

9. Quality Control & Standards

EMS machines are designed to comply with:

- DIN / EN flanging standards

- ASTM material and dimensional standards

- Automotive OEM specifications

- HVAC and refrigeration industry requirements

- Pressure vessel and industrial piping norms

We also offer in-machine sensors and calibrated forming force monitoring to ensure absolute consistency.

10. Why EMS Metalworking Machinery?

EMS offers a unique combination of:

- Engineering expertise in metal forming

- Fully customizable machines

- Robust industrial design

- Fast technical support and spare parts supply

- Global customer network and industry reputation

Our Tube Flanging Machines are built to last, engineered to perform, and designed to help manufacturers reduce costs while increasing production reliability.

Request a Quote or Technical Consultation

If you need a Tube Flanging Machine for your production line — whether standard, CNC, servo, or fully automated — EMS Metalworking Machinery can design the perfect solution tailored to your material, diameter range, and production volume.

A Tube Flanging Machine is one of the most essential and technically specialized systems in the world of modern metalworking, and at EMS Metalworking Machinery we have dedicated years of engineering expertise, manufacturing competence, and process-defined innovation to create machines that redefine what precision tube end forming can achieve. When manufacturers across automotive, HVAC, chemical processing, aerospace, energy, and industrial piping sectors require absolute repeatability, structural reliability, and long-term production consistency, they look for solutions that do not simply deform metal but transform it with control, intelligence, and a deep understanding of material behavior. This is where the Tube Flanging Machines produced by EMS Metalworking Machinery demonstrate their full value. By integrating meticulous mechanical design with high-level hydraulic or servo-driven forming technologies and advanced CNC control systems, EMS machines are engineered to deliver consistent, high-strength flanges across a wide spectrum of tube materials and geometries.

A flange formed on a tube is far more than an outward-bent rim. It is a mechanical interface that determines whether a joint will hold under pressure, whether a connection will leak, whether an assembly will withstand vibration, thermal expansion, corrosive environments, or dynamic load cycles. A flange must be geometrically perfect, structurally robust, and formed in a way that preserves the integrity of the original tube wall. This demands not only forming force but also controlled material flow, precise alignment, and stability in machine tooling and structure. EMS Tube Flanging Machines are designed around these principles. Every component, from the heavy-duty frame to the mandrels, forming dies, control units, clamping systems, hydraulic circuits, and servo axes, is optimized to deliver predictable material behavior even when forming thin-wall stainless steel, high-strength titanium alloys, thick-wall carbon steel tubes, soft copper, aluminum, or nickel-based alloys. The ability to switch between different materials without compromising forming quality is one of the defining achievements of EMS engineering.

The process of tube flanging may appear simple at first glance—press the tube end between tooling until a flange is created—but the underlying mechanics are highly complex. Metal does not flow uniformly by default; it stretches, compresses, and experiences localized stress concentrations that can lead to cracking, wrinkling, thinning, or unwanted distortion. Engineers at EMS understand these material behaviors deeply, which is why each Tube Flanging Machine is paired with application-specific tooling, refined forming paths, and carefully tuned control algorithms. The inner mandrel supports the tube from inside, preventing collapse, while the outer forming tool gradually shapes the flange. The angle, radius, height, and thickness of the flange all depend on how the tooling interacts with the tube, and EMS designs these interactions with precision. For manufacturers dealing with high-pressure piping, turbocharger connections, heat exchangers, or critical fluid transfer assemblies, the difference between a perfect flange and a flawed one can decide product success, warranty risk, or compliance with industry standards.

In industries such as automotive exhaust manufacturing, where thousands of tubes must be formed with identical specifications every day, productivity and repeatability become as important as forming precision. EMS Tube Flanging Machines are built specifically for such environments. The clamping system holds the tube firmly in place, ensuring that each flange is produced without slippage or misalignment. The hydraulic or servo forming systems operate with controlled speed, variable force profiles, and programmable stroke lengths, allowing the machine to adapt to thin-wall stainless steel or thick carbon steel simply by changing the program and tooling. For companies that produce stainless steel tubes for heat exchangers, HVAC systems, or industrial cooling units, right-angle flanges, soft radius flanges, or multi-stage flanges can be formed with equal accuracy. EMS machines are able to create clean, crack-free flanges even on materials with challenging metallurgical properties because the machine’s movement is smooth, predictable, and coordinated through CNC or PLC controllers designed to optimize forming forces at each stage of the cycle.

What sets EMS Metalworking Machinery apart in the global market is not only the capability of the machines but the engineering philosophy that underpins their design. EMS believes that a Tube Flanging Machine must not only produce a flange but must integrate seamlessly into the broader realities of industrial manufacturing. This means adaptability to automation, compatibility with robotic systems, integration with production monitoring software, and the capability to support multiple product variations with minimal downtime. Machine operators benefit from intuitive interfaces that allow them to select programs, adjust parameters, monitor pressures, and receive diagnostic feedback. Maintenance technicians gain from accessible machine components, robust construction, and durable tooling that reduces wear and extends service intervals. EMS’s approach ensures that the machine is not merely a piece of equipment but a dependable partner in production, capable of delivering consistent performance for years under demanding industrial conditions.

The Tube Flanging Machines manufactured by EMS are frequently integrated into fully automated production lines where tubes are fed into the system through conveyors or robotic arms. The tube is automatically positioned, clamped, and formed in a multi-stage process. Some customers require a flange followed by trimming, beading, expanding, or calibration, and EMS machines can be configured to perform multiple operations within one integrated cell. For mass-production industries, this level of automation eliminates human error, shortens cycle times, and ensures that each finished part meets the same exact specifications. For smaller-scale manufacturers who operate with labor flexibility, EMS machines can also be configured as stand-alone units with manual loading, but still offer programmable precision and rapid setup changes for small-batch production or prototyping.

Material versatility is one of the strongest attributes of EMS Tube Flanging Machines. Stainless steel tubes used in chemical processing or food-grade applications have different forming characteristics compared to aluminum tubes used in air-conditioning systems or copper tubes used in refrigeration coils. Carbon steel tubes for industrial piping require high force and strong support from the mandrel, while titanium and nickel alloys demand finely controlled forming sequences to avoid cracks. EMS machines are capable of handling all of these materials, with tooling designed specifically for each application. The ability to support tube diameters ranging from small precision tubes of 10 mm up to large structural tubes of 600 mm or more makes EMS solutions suitable for industries as diverse as automotive exhaust manufacturing, HVAC coil production, metal drum fabrication, gas cylinder reinforcement, and heavy industrial ducting. Custom machines can be constructed for extra-large diameters or specialized flange geometries such as inward flanging, curling, step flanging, or combined flange-and-bead operations.

The reliability of a flange is dependent on the internal and external geometry produced during forming. If the wall thickness becomes too thin at the flange root, the tube may fail under pressure. If the angle is not uniform, sealing surfaces may not align. If cracks appear due to improper material flow, the assembly becomes unsafe. EMS Metalworking Machinery designs each Tube Flanging Machine with sensors and control systems that regulate forming force and monitor displacement. This feedback ensures that the forming operation remains within safe material limits. Additionally, EMS offers advanced tooling options that minimize friction, distribute stress evenly, and guide material into the desired shape without overstretching. The result is a flange that is dimensionally accurate, mechanically strong, and ready for subsequent manufacturing processes such as welding, brazing, bolting, gasket sealing, or assembly into larger equipment.

Customers who operate in industries governed by strict standards—such as fire suppression piping, where flanged steel tubes must meet strict pressure and leak requirements—benefit greatly from EMS’s ability to deliver machines that produce consistent results. Fire sprinkler systems rely on pipes that maintain integrity even during thermal expansion and vibration, and the flanges must hold gaskets securely under varying loads. HVAC manufacturers need flanges that enable quick brazing and guarantee airtight connections. Chemical and petrochemical industries require flanges that resist corrosion and high pressure. Automotive manufacturers need flanges that survive repetitive thermal cycling, road vibration, and exhaust gas exposure. EMS Metalworking Machinery ensures that the flanges produced by its Tube Flanging Machines meet the expectations of these industries by providing machines that maintain strict tolerances, reduce defect rates, and deliver long-term mechanical consistency.

In the aerospace and energy sectors, where the tubes often carry fluids under extreme temperatures or serve as part of structural components, the material behavior becomes even more critical. Flange dimensions must be accurate within narrow tolerances, and structural integrity must be guaranteed. EMS machines provide the precision and control necessary to form flanges on lightweight high-strength materials such as titanium, Inconel, or high-alloy steels. These materials require careful force ramping, precise tool positioning, and often multi-stage forming routines to avoid cracks. The CNC control systems used in EMS machines can store hundreds of forming programs, each optimized for a specific tube type, diameter, and material grade. Operators can switch between jobs quickly, making the machines highly suitable for manufacturers who produce a diverse range of tube components within a single facility.

The design philosophy at EMS Metalworking Machinery extends beyond the mechanical construction of the machine into the realm of production analytics and Industry 4.0 integration. Modern manufacturing increasingly demands real-time monitoring, data-driven decision-making, preventive maintenance algorithms, and connectivity with central production control systems. EMS Tube Flanging Machines can be equipped with sensors that record cycle times, forming pressures, material data, tool life status, and production statistics. Through network connectivity, this information can be transmitted to factory management systems, enabling operators and managers to analyze machine performance, predict maintenance needs, and optimize production flow. In high-volume operations, this creates significant cost savings, reduces downtime, and ensures that the machine continues to operate at peak efficiency.

The engineering and tooling teams at EMS bring decades of experience to each customer project. Tooling design is a particularly critical aspect of tube flanging because the shape, surface finish, hardness, and dimensional accuracy of the tooling directly influence the forming results. EMS uses advanced software to simulate forming operations, ensuring that the tooling will guide the material into the correct shape without excessive strain. The mandrels, forming dies, and clamping jaws are manufactured from hardened alloy steels and often coated for durability and reduced friction. Some applications require modular tooling, where multiple forming steps can be completed using a sequence of tools that interact with the tube progressively. Other applications require single-step forming with specialized geometries. EMS handles all of these variations and ensures that the machine and tooling work together as a unified system for optimal forming performance.

Because EMS Metalworking Machinery works closely with customers from various industries, each machine is often tailored to the customer’s specific production goals. Some customers prioritize high-speed forming cycles, while others require the ability to handle a large variety of tube diameters within one machine. Some prefer servo-driven systems for precise control and energy efficiency, while others need hydraulic systems for maximum forming force. EMS offers both configurations, each engineered with the same level of durability and precision. The modular machine architecture allows EMS to incorporate additional functions such as tube trimming, deburring, expanding, end forming, or calibration within the same platform. This flexibility is particularly appreciated by manufacturers who want to reduce floor space, minimize part handling, and consolidate multiple operations into one machine.

Long-term reliability is a hallmark of EMS Metalworking Machinery products. The machines are built with reinforced structures, oversized linear guides, high-specification hydraulic components, and precise servo motors to ensure stability and accuracy over years of continuous operation. Maintenance access is designed into the machine layout to ensure that service routines such as lubrication, tool replacement, seal inspections, or hydraulic system checks can be performed quickly. Spare parts support and technical assistance are essential to maintaining customer operations, and EMS provides responsive after-sales service to ensure minimal downtime.

For manufacturers considering investment in tube flanging technology, the return on investment provided by an EMS Tube Flanging Machine is driven not only by the mechanical capability of the machine but also by its ability to reduce production errors, shorten cycle times, and deliver consistent quality. Poorly formed flanges can lead to assembly problems, leaks, cracks, or customer complaints. Reworking or scrapping these parts costs time and money, interrupts production flow, and may jeopardize delivery schedules. With an EMS machine, these risks are dramatically reduced. The machines are engineered to maintain dimensional accuracy even when switching between different batches of material or different tube suppliers. This ensures that customers can maintain smooth production regardless of variations in tube hardness or surface condition.

Another advantage of EMS Tube Flanging Machines is their adaptability to both small-scale custom fabrication shops and large-scale manufacturing plants. In smaller shops, the ability to quickly change tools and adjust parameters allows operators to produce prototypes, specialized components, or low-volume orders efficiently. In large plants, the machines can operate in a fully automated environment with minimal operator intervention. This scalability allows EMS customers to expand their production capabilities without having to replace their equipment entirely. Instead, they can build on the foundational strength of EMS machines and integrate additional modules, fixtures, or automation systems as their production needs grow.

For many customers across different industries, the quality of the flange determines the quality of their final product. An automotive exhaust manufacturer may require flanges that ensure airtight connections between pipes and mufflers. An HVAC coil manufacturer needs flanges that enable quick brazing without requiring excessive filler material. A fire suppression pipe manufacturer relies on flanged connections that will hold securely under high pressure during emergency situations. Each of these applications demands different flange shapes, thicknesses, tolerances, and forming characteristics, and EMS machines are designed to meet these demands through flexible programming, robust mechanical construction, and application-specific tooling.

The longevity of EMS machines is supported by rigorous testing and quality control during manufacturing. Each machine undergoes structural verification to ensure frame rigidity, hydraulic system pressure testing, alignment calibration of tooling, and verification of CNC or PLC control accuracy. Test tubes are formed to confirm that the flange geometry matches the programmed specifications. Customers receive detailed machine documentation, including hydraulic and electrical schematics, programming guidelines, setup procedures, and maintenance schedules. EMS also provides training for machine operators and technicians so that customers can maximize the utility of their equipment from the very first day.

Looking at the global metalworking industry, the demand for precision tube forming continues to rise, driven by the growth of industries such as electric vehicle manufacturing, renewable energy systems, and advanced heating/cooling technologies. These industries require lightweight materials, high-strength alloys, and tight-tolerance components. Tube flanging plays an increasingly important role as manufacturers transition to sophisticated system architectures where each component must work reliably within the broader assembly. EMS Metalworking Machinery positions itself as a trusted supplier to companies operating at the forefront of these industries, providing Tube Flanging Machines that are technically advanced, user-friendly, and suitable for both current and future production requirements.

The engineering team at EMS understands that a machine’s long-term performance depends not only on initial construction but also on continuous support. For this reason, EMS offers remote diagnostics capabilities, allowing service technicians to assist customers by reviewing machine parameters, analyzing forming cycles, and identifying potential issues before they lead to downtime. Preventive maintenance programs can be implemented to keep machines operating smoothly, and for customers with extremely demanding production environments, EMS can design custom maintenance intervals aligned with their operational schedules.

EMS Tube Flanging Machines reflect a combination of mechanical strength, precision engineering, software intelligence, and customer-focused adaptability. These machines are designed for manufacturers who need absolute control over their tube forming processes and who expect equipment that will perform reliably for many years. Whether used in high-volume automotive manufacturing, specialized aerospace applications, industrial piping, HVAC production, energy systems, metal drum and cylinder fabrication, or custom tube fabrication workshops, EMS machines deliver outstanding performance and consistent quality. With an understanding of material science, forming mechanics, automation technology, and industry-specific requirements, EMS continues to be a leader in Tube Flanging Machine manufacturing, helping customers around the world improve productivity, reduce costs, and maintain high standards of product integrity.

A Tube Flanging and Beading Machine manufactured by EMS Metalworking Machinery represents the culmination of decades of engineering knowledge, practical experience in the metal forming industry, and an ongoing commitment to delivering machines that exceed expectations in reliability, forming precision, and long-term durability. In industrial production environments where the quality of a flange or bead determines the integrity of an entire assembly, selecting a properly engineered machine is crucial, and EMS has established itself as a trusted global supplier of such technology. The Tube Flanging and Beading Machine is specifically designed to produce outward flanges, reinforced edges, rolled beads, or combined flange-and-bead geometries in a single continuous forming sequence, ensuring higher production efficiency and reduced labor dependency. The machine integrates a robust mechanical structure, advanced hydraulic or servo-driven forming systems, precision clamping mechanisms, and purpose-built tooling designed around each customer’s tube material, diameter, and production needs. As a result, the EMS Tube Flanging and Beading Machine has become a solution used in automotive exhaust fabrication, HVAC production, compressor tube manufacturing, pressure system assembly, fire suppression piping, stainless steel industrial systems, and many additional industries where tubes with reinforced ends provide safety, sealing, or structural performance advantages.

In modern manufacturing environments, the demand for consistent tube-end geometry is steadily increasing. Whether a production line requires a perfectly formed 90-degree flange, a rolled bead capable of resisting high internal pressure, or a combined flange-and-bead shape that allows for bolted or clamped assembly, a machine that can create both features in one cycle drastically increases efficiency. EMS understood this industrial requirement early and developed a machine platform that supports the combined forming of flanges and beads while avoiding the common problems of material cracking, thinning, wrinkling, and deformation. The engineering team at EMS places special emphasis on optimizing tool geometry, forming sequence timing, pressure application, and tube support during forming. This blend of mechanical stability and advanced forming control results in end products that meet strict tolerance requirements and satisfy the demands of global industries, including those governed by automotive standards, HVAC regulations, or pressure-system safety codes.

The machine’s primary goal is to ensure that every flange and bead formed on a tube meets the dimensional accuracy required for assembly, sealing, or long-term operation. To achieve this, the EMS Tube Flanging and Beading Machine is designed with a heavy-duty frame made of structural steel, stress-relieved to eliminate internal stress points that could otherwise cause vibration or mechanical drift during high-pressure forming. Vibrations or unstable forming motions are one of the leading causes of inconsistent flange thickness or uneven bead profiles. By eliminating these mechanical interferences, EMS ensures that forming results remain stable even during extended production shifts. The rigid frame also contributes to long-term machine life, which is an essential factor for factories looking to minimize downtime and maximize production throughput.

The forming system itself is engineered depending on the specific needs of each customer. EMS offers several configurations, including servo-electric, hydraulic, or hybrid forming systems. The hydraulic configuration is ideal for thick-walled steel tubes, heavy-duty industrial applications, or large-diameter pipes that require significant forming tonnage. The servo-electric configuration provides advanced repeatability, low noise levels, reduced energy consumption, and highly programmable forming cycles suitable for precision applications in automotive, stainless steel, or thin-wall material processing. Customers can select the forming method that best fits their production environment, ensuring optimal cycle times, forming force control, and repeatability.

One of the defining features of the EMS Tube Flanging and Beading Machine is the engineered tooling design, which is fully customized for each diameter and material combination. Tube materials behave differently under compression, expansion, and bending forces. Stainless steel, for example, tends to harden quickly during forming, while copper and aluminum require more delicate force application to prevent thinning. Carbon steel may tolerate high forming pressure but can wrinkle if unsupported. EMS engineers analyze each application by examining tube thickness, tensile strength, yield strength, hardness, weld seam conditions, and customer-required flange or bead dimensions. Based on this analysis, EMS designs an internal mandrel, external forming dies, clamping segments, and bead-forming rollers that create the desired shape through controlled material flow. Tool surfaces are polished to ensure smooth forming, reduce friction, and extend tool life. Heat-treated tool steels, carbide coatings, and modular tool sets are used to provide long operational life and easy maintenance. Tool life is an essential cost factor in tube manufacturing, and EMS prioritizes durability to reduce downtime and lower operating costs for its customers.

In flanging operations, the internal mandrel plays a key role in supporting the tube during expansion. Without proper internal support, the material can deform unevenly, causing tears or thinning. EMS designs mandrels that match the tube’s internal dimensions with precise tolerances, ensuring that the tube maintains its circular shape during the flange-forming stage. Once the flange is fully formed, the machine transitions into the beading stage, in which a bead is rolled onto the tube end. This bead may serve several functions: it may reinforce the tube end, provide a mechanical stop for hose attachments, create a sealing groove for clamps, or offer structural rigidity to resist internal or external pressure. The ability to form both flange and bead in a single cycle provides significant efficiency improvements compared to running tubes through two separate machines.

During the beading phase, the machine uses specially shaped forming dies or rolling tools to create the bead profile. The bead shape must be consistent across all pieces to ensure compatibility with hose clamps, seals, or assembly fixtures. EMS machines closely control forming force, speed, and progression to achieve uniform bead height, width, and radius. The transition between flanging and beading must be smooth, preventing deformation of the newly formed flange during bead creation. EMS developed a forming sequence logic that protects the integrity of the flange while the bead is created. This sequencing ensures that both features meet customer specifications and that no additional correction operations are required.

Clamping stability is another essential aspect of combined flanging and beading operations. If the tube shifts even slightly during forming, the flange may become eccentric or the bead may have inconsistent shape. EMS designs clamping jaws and holding fixtures that grip the tube firmly but gently, avoiding surface damage while preventing movement. Hydraulic or servo-driven clamping systems ensure strong holding forces and controlled release. The alignment between the tube, mandrel, and forming dies is maintained through precision machining and alignment systems built into the machine. These engineering considerations ensure repeatability, reduce scrap rates, and enhance overall production efficiency.

In addition to mechanical engineering, EMS emphasizes a user-friendly control system. The machine is equipped with a PLC or CNC-based control panel that allows operators to adjust forming speed, stroke length, forming force, beading progression, and return cycles. Operators can store hundreds of forming programs, making it simple to switch between different tube sizes or flange-bead combinations. In mass production environments, the ability to change tools and programs quickly is essential to maintaining productivity. EMS control systems include intuitive touchscreen interfaces, language options, smart error reporting, maintenance reminders, and real-time production monitoring. When integrated into a fully automated production line, the control system can communicate with robotic loaders, tube feeders, inspection systems, and conveyor systems.

The EMS Tube Flanging and Beading Machine is used in a wide range of industries. In automotive manufacturing, it is used to create reinforced tube ends for exhaust systems, turbocharger lines, cooling system tubes, and structural components requiring attachment points. Automotive production requires extremely tight tolerances and high repeatability, both of which the EMS machine delivers. In HVAC and refrigeration industries, flanged and beaded tubes ensure leak-free connections in air conditioning units, condensers, chillers, and heat exchangers. These tubes must withstand pressure fluctuations, temperature variations, and environmental exposure. The forming consistency delivered by EMS machines ensures long-term reliability and compatibility with fittings, seals, and brazing processes.

The machine is also widely used in industrial piping systems, especially in stainless steel tube fabrication for factories, chemical lines, process plants, and food industry installations. Stainless steel tubes must maintain precise geometry to ensure proper assembly, seal integrity, and compliance with pressure standards. The ability to form flanges and beads without material damage is essential. EMS machines are engineered to prevent cracking, a common problem when forming stainless steel or similar hard materials. The combination of controlled force application, optimized tool geometry, and reliable tube support ensures that every tube meets industry requirements.

In fire suppression and sprinkler systems, flanging and beading enable fast assembly with mechanical couplings. High-pressure water systems require reinforced tube ends capable of withstanding sudden surges or mechanical stress. EMS machines ensure that each forming step produces a strong, uniform geometry. This reliability helps reduce installation time and ensures system safety. Similar reliability is needed in pressure tank manufacturing, cylinder production, agricultural machine tubing, and industrial drum manufacturing, where reinforced edges provide structural stability and impact resistance.

The Tube Flanging and Beading Machine can also be supplied as part of a fully automated production line. EMS offers systems that include tube loading modules, length-checking stations, automatic tool change mechanisms, robotic unloading, and in-line inspection systems. Automation reduces labor costs, eliminates operator error, and increases production speed. Each automated installation is customized according to customer layout, production volume, and workflow. EMS engineers collaborate with customers to analyze plant requirements, design optimal machine placement, and program automated sequences that increase efficiency. This flexibility allows customers to scale production without purchasing separate machines for different forming tasks.

Quality control is integrated into the EMS Tube Flanging and Beading Machine. Sensors monitor forming pressure, cycle completion, and tool alignment. Advanced CNC models can log production data, detect abnormalities, and alert operators to maintenance needs. This predictive maintenance capability significantly reduces downtime and ensures consistent performance. EMS designs machines to comply with global standards such as automotive OEM tolerances, HVAC manufacturing regulations, and industrial piping requirements. Customers operating in regions with strict certification demands can rely on EMS to deliver machines that support compliance.

The long-term durability of the EMS Tube Flanging and Beading Machine is ensured through the use of high-quality components, precision machining, and robust engineering. Hydraulic systems are equipped with high-grade valves, pumps, and cylinders selected from reputable global brands. Servo systems use advanced motors and drives capable of maintaining precise control even after years of operation. Safety systems including emergency stops, light curtains, and protective guards are integrated into the machine. Electrical panels are built with industrial-grade components and designed for easy access during maintenance. The overall design reflects EMS’s dedication to producing machines that remain operational under demanding industrial conditions.

Customer support is another strength of EMS. Each machine is delivered with detailed documentation, user manuals, lubrication instructions, and troubleshooting guides. EMS technical teams provide remote support, spare parts, on-site installation assistance, and operator training. For customers with unique production needs, EMS offers consultation services to help optimize forming sequences, design new tooling, or upgrade existing machines. This level of technical collaboration helps customers improve output quality, reduce scrap, and achieve higher efficiency.

As industries worldwide continue to adopt advanced manufacturing technologies, the need for reliable and precise tube-end forming machines is growing. EMS remains committed to researching new forming techniques, improving machine software, and developing innovative tooling solutions. Ongoing investment in R&D ensures that EMS machines remain competitive and capable of meeting new industrial demands, such as lightweight material forming, higher precision tolerances, and faster production cycles.

In summary, the EMS Tube Flanging and Beading Machine is a comprehensive solution designed to meet the challenges of modern tube-end forming. With its robust structure, advanced forming systems, precision tooling, user-friendly controls, and automation compatibility, it provides a long-term production advantage to manufacturers in numerous industries. Its ability to produce both flanges and beads in a single cycle increases productivity, reduces equipment needs, and ensures consistent forming quality. EMS Metalworking Machinery continues to build its reputation as a leading manufacturer in the metal forming sector by designing machines that achieve exceptional results, maintain high reliability, and deliver measurable benefits to production environments. For any company seeking a high-quality solution for tube-end reinforcement, sealing preparation, or assembly readiness, the EMS Tube Flanging and Beading Machine stands out as a dependable and highly engineered choice that is designed to meet the needs of both today’s industries and future manufacturing developments.

EMS Tube Flanging + Trimming Machine

The Tube Flanging and Trimming Machine manufactured by EMS Metalworking Machinery is the result of a long engineering tradition centered around precision metal forming, production efficiency, and reliable industrial automation. In tube processing environments where accuracy of the tube end determines the quality and integrity of the final assembly, a machine that combines both flanging and trimming in one continuous sequence offers tremendous value. EMS designed this machine to eliminate the need for separate trimming and flanging stations, reduce manual handling, minimize cycle time, and ensure that every tube end meets strict dimensional standards. This combination of operations is especially important in industries such as automotive, HVAC, domestic appliances, fire suppression systems, stainless-steel piping assemblies, pressure equipment, and various industrial installations where tube ends must be both perfectly cut and mechanically shaped to allow sealing, welding, clamping, or assembly.

At the core of the EMS Tube Flanging and Trimming Machine is the principle that precision begins with the tube’s cut quality. If the tube end is not perfectly trimmed, the subsequent flange formation will be inconsistent, and the assembly may not fit correctly or may fail during operation. EMS engineers developed a robust trimming system capable of producing extremely smooth, perpendicular cuts regardless of material hardness, wall thickness, or tube diameter. Whether the tube is made from stainless steel, carbon steel, copper, aluminum, brass, or high-strength alloys, the trimming blades and holding system ensure a perfect cut every time. Unlike saw-cut or laser-cut tubes, which may have burrs, heat-affected zones, or slight irregularities, the trimming operation on the EMS machine provides a cold, chip-free, precision cut that prepares the material for an ideal flanging process. This consistency is what differentiates EMS machines from many other systems on the market and allows customers to achieve high production reliability and reduce rework or scrap.

Once trimming is completed, the tube transitions directly into the flanging sequence without requiring removal or repositioning. This continuous workflow eliminates alignment errors, reduces operator dependency, and ensures that the flange is always formed on a perfectly cut surface. The flanging system is engineered to apply uniform axial forming pressure and controlled material flow so the flange emerges with the required height, angle, roundness, and thickness distribution. The transition from trimming to flanging is carefully timed and mechanically synchronized to avoid vibrations, misalignment, or unwanted material stress. This integration between the two forming stages is one of the greatest strengths of the EMS machine, especially for companies that produce large volumes of tubes per shift and cannot afford inconsistent results or frequent adjustments.

The structural foundation of the EMS Tube Flanging and Trimming Machine is a heavy-duty, stress-relieved steel frame designed to withstand continuous industrial operation. Tube forming requires precise control of force, speed, and positioning; therefore the machine must be built with exceptional rigidity to prevent deflection or instability. EMS employs advanced welding techniques, CNC machining, and thermal stress-relief processes to ensure that the frame maintains perfect geometry over years of operation. The machine’s rigidity directly contributes to the precision of both trimming and flanging because each stage demands consistent tool alignment and controlled motion. Even minor frame distortions can lead to flange inconsistencies, uneven trimming, premature tool wear, and higher scrap rates. EMS’s commitment to structural stability reflects its focus on long-term operational reliability and customer satisfaction.

Tooling design is another essential component of the machine’s performance. For trimming operations, EMS uses specially developed carbide or high-speed steel blades depending on the material being processed. The blades are mounted in precision holders that ensure stable cutting pressure and eliminate chatter or vibration. The blade geometry is optimized according to tube thickness and material to reduce cutting forces, extend tool life, and maintain consistent results. Customers benefit from lower tooling costs and increased uptime because the EMS trimming system is engineered for longevity and easy maintenance. When a blade reaches the end of its usable life, it can be replaced within minutes, minimizing production interruption.

The flanging tooling is fully customized for each application. EMS engineers work with customer specifications to design internal mandrels, external forming dies, and clamping tools that match the required flange geometry. A proper flange requires controlled material expansion without cracking, thinning, or wrinkling. Stainless steel, for example, requires a gradual forming motion with carefully distributed pressure, whereas aluminum or copper allow more aggressive forming due to their ductility. High-strength steels or welded tubes require special mandrel designs that support the internal seam and prevent deformation. EMS considers all these factors during tooling development to ensure flawless forming results. The quality of the tooling directly affects the repeatability of the flange, so EMS invests heavily in high-precision machining, polishing, heat treatment, and surface finishing to guarantee long-lasting and consistent performance.

The machine’s clamping system ensures that the tube remains perfectly stationary during trimming and flanging. Any movement or vibration can cause uneven trimming or eccentric flanges. EMS employs hydraulic or servo-driven clamping units with adjustable pressure, allowing the machine to adapt to different tube materials without causing external surface damage. The clamping jaws are manufactured from hardened steel or coated materials to prevent marking while providing maximum gripping force. For customers producing tubes with decorative or polished surfaces, EMS offers specialized soft-contact clamping solutions that grip without scratching. This level of customization demonstrates EMS’s attention to practical production challenges and its ability to provide tailored solutions based on customer needs.

In many production environments, tube-end consistency is essential for sealing performance. For example, in HVAC systems, a flange that is even slightly asymmetrical may cause leaks or misalignment during assembly. In automotive components, flange geometry must meet strict standards to ensure compatibility with exhaust systems, turbo housings, coolant lines, or structural fittings. In fire suppression systems, flanged tubes must maintain pressure integrity during emergency situations. The EMS Tube Flanging and Trimming Machine is capable of meeting these high standards because it is designed to eliminate the variables that typically cause dimensional defects. By combining trimming and flanging in one continuous setup, the machine significantly reduces the risk of human error and ensures that the tube’s cut and flange complement one another perfectly.

The control system of the EMS machine plays a vital role in maintaining process consistency and ease of use. Operators interact with the machine through a modern PLC or CNC-based interface that allows them to adjust trimming depth, flanging force, forming speed, cycle progression, and return motion. The interface is intuitive, allowing quick setup changes and easy troubleshooting. It includes multi-language support, production counters, diagnostic tools, and maintenance reminders. Customers can program multiple tube specifications into the system and switch between them without needing to manually recalibrate the machine. This is especially useful in facilities that handle different product families or frequent diameter changes. EMS also offers the option to integrate the machine into automated production lines, complete with tube feeders, length detection systems, robotic handling, and outfeed conveyors. With these capabilities, the EMS Tube Flanging and Trimming Machine can function as a standalone workstation or as part of a fully automated manufacturing cell.

In environments where tube finishing quality must meet tight tolerances, EMS machines are highly valued for their accuracy. The trimming operation ensures that the tube end has no burrs, chips, or irregularities. This is especially important for welding processes, where the quality of the tube edge influences weld penetration, fusion consistency, and overall joint strength. Welders often struggle with tubes cut by saws or abrasive wheels because heat distortion or surface contamination affects welding results. The EMS trimming system resolves these issues by creating a cold-processed cut that is clean, perpendicular, and free from thermal effects. This results in improved weld preparation, reduced post-processing, and lower probability of weld defects. Combined with a precise flange, the resulting tube end becomes a high-quality component suitable for demanding applications.

The combined flanging and trimming process also improves production efficiency. Instead of processing tubes through a cutting station and then feeding them into a separate flanging machine, customers can complete both operations in one cycle. This reduces handling time, workforce requirements, equipment footprint, and overall cycle time. Factories often struggle with bottlenecks in tube forming operations due to sequential processing steps that require manual intervention. EMS solves this issue by integrating both functions into a single robust platform. The resulting workflow improvement provides measurable productivity gains and reduces the total cost of production.

The machine’s durability is another key advantage. EMS builds its machines for long-term industrial use, operating across multiple shifts per day without loss of accuracy. All mechanical components, including bearings, slides, guide rods, forming cylinders, and cutting spindles, are selected for heavy-duty performance. Lubrication systems ensure that moving components remain properly lubricated, reducing wear and extending service life. Electrical systems are built using high-quality components from global brands to ensure reliable operation in various environmental conditions. The machine is designed for easy maintenance, with accessible service points, clean routing of cables and hoses, and clear documentation provided with each machine.

The EMS Tube Flanging and Trimming Machine also excels in handling a wide range of tube diameters and material types. Tube diameters ranging from small precision tubes of 10 millimeters up to large industrial tubes exceeding 600 millimeters can be accommodated with appropriate mandrel and die tooling. Material versatility includes stainless steel, carbon steel, aluminum, copper, brass, titanium, and various high-strength alloys. Each material behaves differently during trimming and flanging, requiring tailored cutting blades, mandrel design, forming die geometry, and clamping pressure. EMS’s engineering team carefully analyzes these factors to create machines that can produce consistent, defect-free results across multiple material types, minimizing scrap, and ensuring that production goals are met regardless of material properties. This flexibility makes EMS machines ideal for multi-product facilities or manufacturers who frequently switch between tube sizes or material grades.