High Pressure Hydroform Press: We manufacture Hydroforming Press types. A Tee hydro forming press is used to manufacture T-formed parts from metal. High quality & Low Price & Free Consultation

A hydroforming press is a type of press used for shaping metal components through the application of hydraulic pressure. This process involves placing a sheet of metal over a die and then applying hydraulic pressure to form the metal into the desired shape.

The hydroforming press consists of a hydraulic system that supplies the pressure, a blank holder to hold the metal in place, and a die to shape the metal. The hydraulic system applies a force to a piston, which in turn applies the force to the blank holder. The pressure can be adjusted to control the speed and force of the forming process.

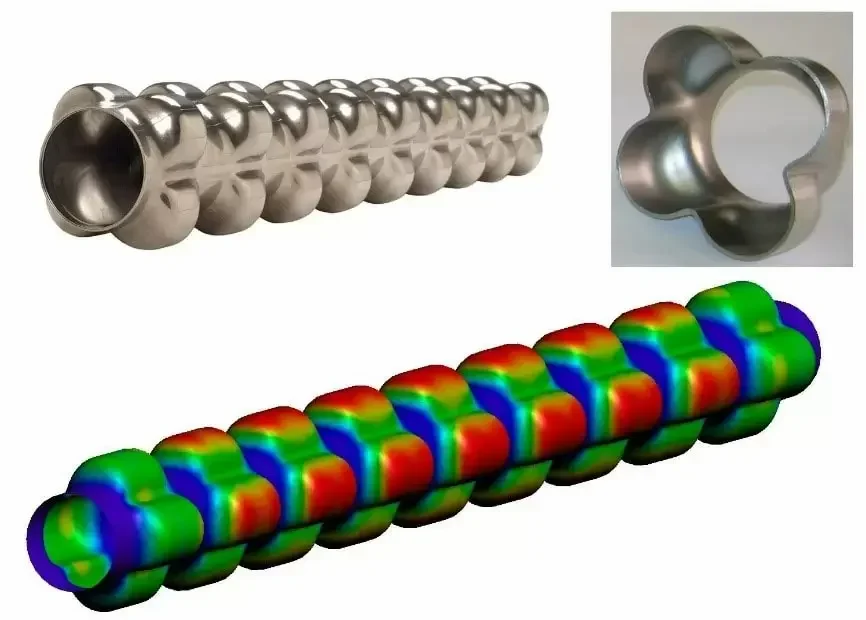

Hydroforming is commonly used in the production of complex shapes such as tubes, ducts, and other irregular shapes that cannot be easily formed using traditional stamping or forging methods. This process offers advantages such as improved part strength, reduced material waste, and increased design flexibility.

Hydroforming presses come in various sizes and capacities, and can be customized to meet the specific needs of different industries, including aerospace, automotive, and medical device manufacturing.

Hydroforming Press

A hydroforming press is a type of press that is used to shape ductile metals into complex shapes using a combination of fluid pressure and mechanical force. It is often used in the manufacturing of parts for the automotive and aerospace industries, where precision and strength are critical factors.

The hydroforming process begins with a blank piece of metal, typically made of aluminum or steel, that is placed into a die. The die is then closed and fluid is pumped into the chamber, which applies pressure to the metal from all directions. This pressure forces the metal to take on the shape of the die, resulting in a highly precise and complex part.

A hydroforming press is a specialized type of press that uses a high-pressure fluid to deform sheet metal into complex shapes. The process is similar to deep drawing, but it uses fluid pressure instead of mechanical force to form the material.

Advantages of Hydroforming

Hydroforming offers several advantages over traditional metal forming methods, including:

- Reduced material waste: Hydroforming can produce complex shapes with minimal material waste, compared to other forming methods that may require trimming or scrap.

- Improved surface finish: The fluid pressure used in hydroforming produces a smooth, even surface finish on the formed part, eliminating the need for secondary finishing operations.

- Increased part strength: Hydroforming can produce parts with higher strength and fatigue resistance compared to other forming methods.

- Versatility: Hydroforming can be used to form a wide range of shapes, including hollow and closed shapes that are difficult to produce with other methods.

Applications of Hydroforming

Hydroforming is commonly used in the automotive industry to produce a variety of components, such as:

- Frame rails: Hydroformed frame rails are lighter and stronger than traditional frame rails, and they can be produced with complex shapes that improve vehicle performance.

- Doors and body panels: Hydroformed doors and body panels are lighter and more dent-resistant than traditional panels, and they can be produced with intricate details.

- Exhaust systems: Hydroformed exhaust systems are more durable and have fewer welds than traditional exhaust systems, making them less prone to leaks and corrosion.

Components of a Hydroforming Press

A hydroforming press consists of several key components:

- Press frame: The press frame is a rigid structure that supports the other components of the press.

- Platens: The platens are the heated surfaces that come into contact with the material being formed. They are typically made of steel or aluminum and can be heated electrically or with steam.

- Hydraulic system: The hydraulic system generates the pressure that is used to deform the material. It consists of a pump, a reservoir, and a series of valves.

- Die: The die is the mold that gives the formed part its shape. It is typically made of tool steel or high-strength aluminum.

- Bladder: The bladder is a flexible membrane that is placed inside the die. It is filled with high-pressure fluid to deform the material against the die.

Hydroforming Process

The hydroforming process typically involves the following steps:

- Blank preparation: The material is cut to the desired size and shape.

- Preheating: The blank is preheated to a temperature that makes it more malleable.

- Die loading: The blank is placed inside the die.

- Bladder inflation: The bladder is inflated with high-pressure fluid, causing the blank to deform against the die.

- Hold and cooling: The pressure is held for a period of time to allow the material to cool and set in the desired shape.

- Unloading: The bladder is deflated, and the formed part is removed from the die.

Conclusion

Hydroforming is a powerful and versatile metal forming process that is used to produce a wide variety of components for a variety of industries. It offers several advantages over traditional metal forming methods, including reduced material waste, improved surface finish, increased part strength, and greater versatility.

How does a Hydroforming Press function?

The process of hydroforming can be broken down into several key steps:

- Material selection: The first step in the hydroforming process is to select the appropriate material for the part being produced. Typically, this will be a ductile metal such as aluminum or steel.

- Blank preparation: The blank, or sheet of metal, is then cut to the appropriate size and shape for the part being produced. It may also be pre-formed to a certain degree to make it easier to shape during the hydroforming process.

- Die preparation: The die, which will be used to shape the metal, is then prepared. This involves heating and lubricating the die to ensure that the metal can be shaped smoothly and accurately.

- Loading: The blank is loaded into the die and the press is closed. The fluid pressure is then applied to the metal, forcing it to take on the shape of the die.

- Forming: As the fluid pressure is applied, the metal is shaped into the desired form. The pressure is carefully controlled to ensure that the metal is not overstretched or damaged during the process.

- Unloading: Once the forming process is complete, the fluid pressure is released and the part is removed from the die. It may then be trimmed or finished as necessary.

Hydroforming presses come in a variety of sizes and configurations, ranging from small tabletop models to large, industrial-scale machines capable of shaping parts several feet in diameter. They can be used to produce a wide range of parts, from simple tubes and cylinders to highly complex shapes with multiple curves and bends.

Overall, the hydroforming process offers a number of advantages over traditional stamping and forming methods. It allows for greater precision and accuracy in shaping metal parts, while also reducing the amount of material waste and minimizing the need for secondary operations such as welding and machining.

In the last decades, advanced forming processes such as sheet hydroforming have an increasing interest, particularly in the automotive and aerospace industries. This process has many advantages such as reduction of tool costs, enhanced formability, capability to form complex parts, reduced die wear, higher dimensional accuracy, and surface quality compared to the conventional sheet metal forming processes.

Material selection for the hydroforming press

The selection of materials for the hydroforming press is crucial for ensuring its durability, performance, and cost-effectiveness. Various factors influence the choice of materials, including the desired properties of the press, the type of components being formed, and the operating conditions.

Key Considerations for Material Selection

- Strength and Durability: The materials used for the press frame, platens, and dies must be strong enough to withstand the high pressures and forces involved in the hydroforming process. They should also be durable and resistant to wear and tear.

- Heat Resistance: The platens and dies must be able to withstand the high temperatures required to preheat the material being formed. They should also be able to maintain their shape and dimensions under these conditions.

- Dimensional Accuracy: The dies must be made from materials that can maintain precise dimensions over time. This is essential for producing high-quality components with the desired tolerances.

- Cost-effectiveness: The materials used for the press should be cost-effective without compromising on quality or performance. The balance between initial cost and long-term durability is crucial.

Common Materials Used in Hydroforming Presses

- Steel: Steel is a common choice for the press frame, platens, and dies due to its strength, durability, and heat resistance. Various grades of steel are used depending on the specific requirements of the press.

- Aluminum: Aluminum is sometimes used for the platens due to its lighter weight and faster heating and cooling rates. However, aluminum is generally not as strong or durable as steel.

- Tool Steel: Tool steel is a high-strength material that is often used for dies, especially for forming complex shapes. It is known for its wear resistance and ability to maintain dimensional accuracy.

- High-Strength Aluminum: High-strength aluminum alloys are sometimes used for dies, particularly for forming lighter components. They offer a balance between strength and weight.

- Rubber or Plastic Membranes: Rubber or plastic membranes are used for the bladder, the flexible component that applies pressure to the material being formed. These materials must be able to withstand high pressure and maintain their flexibility under these conditions.

Factors Influencing Material Selection for Specific Components

- Press Frame: The press frame is subjected to the highest forces and pressures, so it requires strong and durable materials like high-grade steel.

- Platens: The platens must withstand high temperatures and maintain dimensional accuracy, so materials like steel or high-strength aluminum are often used.

- Dies: Dies must be strong, wear-resistant, and dimensionally accurate, so materials like tool steel or high-strength aluminum alloys are commonly used.

- Bladder: The bladder needs to be flexible and pressure-resistant, so rubber or plastic membranes are typically used.

- Other Components: Other components, such as hydraulic cylinders and valves, also require specific materials based on their function and operating conditions.

Conclusion

Careful material selection is essential for designing and manufacturing a high-performance hydroforming press that can operate efficiently and produce quality components. By considering the desired properties, operating conditions, and cost-effectiveness, engineers can choose appropriate materials for each component, ensuring the long-term durability and reliability of the press.

Blank preparation

Blank preparation is a crucial step in the hydroforming process, ensuring the material is properly shaped and conditioned for forming. It involves several key steps to achieve the desired dimensions, surface quality, and material properties for successful hydroforming.

- Cutting: The starting material, typically a sheet metal blank, is cut to the approximate size and shape required for the final formed part. Accurate cutting ensures minimal material waste and a good starting point for subsequent forming operations.

- Edge Preparation: The edges of the blank are trimmed and prepared to remove any imperfections, burrs, or sharp edges that could cause tears or disruptions during hydroforming. This ensures a smooth transition between the blank and the die, preventing material snagging or tearing.

- Cleaning: The blank is thoroughly cleaned to remove any surface contaminants, such as oils, greases, or dirt. These contaminants can interfere with the adhesion of the forming lubricant and affect the surface finish of the formed part.

- Degreasing: After cleaning, the blank may be degreased using a solvent or chemical solution to remove any remaining oils or residues that could hinder the forming process. Proper degreasing ensures a clean surface for lubricant application and prevents adhesion issues.

- Lubrication: A suitable lubricant is applied to the blank to reduce friction and prevent galling or tearing during the hydroforming process. The lubricant should be compatible with the material being formed and provide adequate protection against wear and tear.

- Preheating: Depending on the material and the complexity of the formed part, preheating may be necessary to increase the malleability of the material and facilitate the forming process. Preheating helps to reduce the forming force required and improves the flow characteristics of the material.

- Blank Inspection: The prepared blank is thoroughly inspected for any defects, imperfections, or inconsistencies in its dimensions, surface quality, or material properties. Detecting and correcting any issues at this stage prevents problems during the hydroforming process and ensures the production of high-quality formed parts.

In summary, blank preparation plays a critical role in the hydroforming process by ensuring the material is properly shaped, conditioned, and free from defects, enabling successful forming and achieving the desired part dimensions and surface finish.

Die preparation

Die preparation is an essential step in the hydroforming process, ensuring the proper configuration and condition of the die to produce high-quality formed parts. It involves several key steps to achieve the desired accuracy, surface finish, and wear resistance of the die.

- Die Design and Manufacturing: The die is designed and manufactured according to the specifications of the desired formed part. This includes precise dimensions, surface contours, and internal features to accommodate the material flow and forming process.

- Heat Treatment: Depending on the material and the complexity of the die, heat treatment may be necessary to enhance its strength, hardness, and wear resistance. Heat treatment ensures the die can withstand the high pressures and forces involved in hydroforming without deformation or wear.

- Surface Preparation: The surface of the die is carefully prepared to achieve a smooth, uniform finish. This may involve grinding, polishing, or other surface finishing techniques. A smooth surface helps to prevent material tearing or galling during hydroforming and contributes to a good surface finish on the formed part.

- Lubrication: A suitable lubricant is applied to the die to reduce friction and prevent sticking between the die and the material during hydroforming. The lubricant should be compatible with the material being formed and provide adequate protection against wear and tear.

- Die Inspection: The prepared die is thoroughly inspected for any defects, imperfections, or discrepancies in its dimensions, surface quality, or material properties. Detecting and correcting any issues at this stage ensures the die is in optimal condition for hydroforming and prevents problems that could affect the quality of the formed parts.

- Die Installation: The die is carefully installed into the hydroforming press, ensuring proper alignment and positioning with the platens and other components. Accurate installation is crucial for achieving the desired part dimensions and preventing off-center forming or other defects.

- Die Maintenance: Regular maintenance of the die is essential to maintain its performance and extend its lifespan. This includes cleaning, lubrication, and inspection to detect and address any wear, damage, or material degradation that could affect the forming process.

In summary, die preparation plays a critical role in the hydroforming process by ensuring the die is properly designed, manufactured, and maintained to produce high-quality formed parts. A well-prepared die contributes to accurate dimensions, smooth surface finish, and consistent part quality throughout the hydroforming process.

Loading

Loading in hydroforming refers to the process of introducing the preheated blank material into the hydroforming die and positioning it correctly for forming. The loading method and sequence are crucial for ensuring proper material flow, preventing defects, and achieving the desired part shape.

Types of Loading Methods in Hydroforming

- Axial Loading: Axial loading involves placing the blank directly into the die cavity and applying axial force to push it into the desired shape. This method is suitable for forming simple shapes with symmetrical geometry.

- Radial Loading: Radial loading involves placing the blank over the die cavity and applying radial force to deform it into the desired shape. This method is often used for forming more complex shapes with asymmetrical geometry.

- Combined Loading: Combined loading utilizes a combination of axial and radial forces to form the blank into the desired shape. This method is particularly useful for forming complex shapes with multiple contours and bends.

Factors Influencing Loading Method Selection

- Part Geometry: The complexity of the part geometry determines the most appropriate loading method. Axial loading is suitable for simple shapes, while radial or combined loading is better suited for complex shapes.

- Material Properties: The material properties, such as ductility and flow characteristics, influence the loading method. Ductile materials may require more radial force, while less ductile materials may benefit from combined loading.

- Press Capacity: The press capacity, including the available force and stroke, determines the feasibility of certain loading methods. Complex shapes may require higher forces, necessitating specific loading techniques.

Loading Sequence in Hydroforming

- Blank Positioning: The blank is carefully positioned within the die cavity, ensuring proper alignment and orientation. This step ensures the material flows correctly during forming.

- Holding Mechanisms: Holding mechanisms, such as clamps or pins, are engaged to secure the blank in place and prevent movement during forming. This prevents misalignment or defects.

- Bladder Inflation: The bladder, the flexible membrane inside the die, is inflated with high-pressure fluid. The pressure gradually increases, forcing the blank to conform to the die shape.

- Pressure Control: The pressure is controlled and monitored throughout the forming process to achieve the desired part shape and prevent over-forming or material defects.

- Pressure Release: Once the forming process is complete, the pressure is gradually released, allowing the blank to cool and set in the desired shape.

- Part Removal: The formed part is carefully removed from the die, ensuring no damage or deformation occurs.

Conclusion

Loading in hydroforming is a critical step that directly impacts the quality and accuracy of the formed part. By selecting the appropriate loading method, following a structured loading sequence, and implementing precise control over the loading process, manufacturers can achieve consistent and high-quality hydroformed parts.

Forming

Forming in hydroforming is the stage where the pre-heated blank material is subjected to high-pressure fluid to deform it into the desired shape. It is a critical step in the hydroforming process, as it determines the accuracy, dimensions, and surface finish of the formed part.

Stages of Forming in Hydroforming

- Pressure Application: The bladder, a flexible membrane inside the die, is inflated with high-pressure fluid, gradually increasing the pressure to deform the blank into the desired shape.

- Material Flow: The high-pressure fluid forces the blank to conform to the shape of the die, causing the material to flow and stretch along the contours of the die cavity.

- Material Strengthening: As the material undergoes deformation, it experiences strain hardening, increasing its strength and resistance to further deformation.

- Shape Retention: Once the desired shape is achieved, the pressure is maintained for a period of time to allow the material to cool and set in the desired form.

Factors Influencing Forming Success

- Blank Preparation: Proper blank preparation, including trimming, cleaning, lubrication, and preheating, ensures optimal material flow and prevents defects.

- Die Design: The die design, including its dimensions, surface finish, and internal features, plays a crucial role in achieving the desired part shape and surface quality.

- Pressure Control: Precise control of the hydraulic pressure is essential to prevent over-forming, under-forming, and material tearing or rupture.

- Temperature Control: Maintaining the appropriate temperature throughout the forming process ensures the material has the necessary ductility and flow characteristics for proper deformation.

- Process Monitoring: Continuous monitoring of the forming process, including pressure, temperature, and material flow, allows for adjustments and interventions to prevent defects.

Conclusion

Forming in hydroforming is a complex and dynamic process that requires careful consideration of material properties, die design, pressure control, and temperature management. By optimizing these factors and implementing precise process control, manufacturers can achieve consistent and high-quality hydroformed parts.

Unloading

Unloading in hydroforming is the final step in the process, where the formed part is carefully removed from the die. This stage is crucial for preventing damage to the formed part and ensuring its smooth release from the die.

Steps in Unloading

- Pressure Release: The pressure in the bladder is gradually released, allowing the material to relax and the formed part to shrink slightly as it cools.

- Bladder Deflation: The bladder is completely deflated, allowing access to the formed part within the die cavity.

- Part Removal: The formed part is carefully removed from the die, using appropriate tools and techniques to prevent damage or deformation. This may involve using ejectors, lifting mechanisms, or manual extraction.

- Inspection: The formed part is thoroughly inspected for any defects, imperfections, or inconsistencies in its dimensions, surface finish, or material properties. Early detection of defects allows for corrective actions or part replacement.

Factors Influencing Unloading Success

- Die Design: The die design should incorporate features that facilitate easy part removal, such as draft angles, clearances, and release mechanisms.

- Surface Lubrication: Proper lubrication of the die and the formed part reduces friction and prevents sticking or tearing during unloading.

- Part Handling: Careful handling of the formed part during unloading prevents damage from scratching, dropping, or excessive force.

- Inspection Procedure: A structured inspection procedure ensures that any defects or inconsistencies are identified and addressed promptly.

Conclusion

Unloading in hydroforming is an essential step for ensuring the successful completion of the forming process and the production of high-quality parts. By following proper unloading procedures, manufacturers can prevent damage to the formed part, maintain die integrity, and achieve consistent production of high-quality hydroformed components.

Characteristics of a Hydroforming Press

We specified that there are many different types of sheet hydroforming such as hydrostatic deep drawing, hydrodynamic deep drawing, hydromechanical deep drawing, and deep drawing assisted by radial pressure the hydromechanical deep drawing (HDD) is a special drawing process in which pressurized fluid medium is used instead of one of the die compared to the conventional deep drawing process.

HDD process is a kind of soft tool technology which was originated from hydroforming. In HDD, a pressurized fluid is taken as the female die, and the punch is a rigid body. As the punch forms the sheet, pressurized fluid assists the sheet against the punch and wraps it on the punch.

In the HDD process firstly the sheet is compressed at a definite blank holder force in such a manner that there is not any fluid leakage and there is not any wrinkling on the sheet as the sheet deforms. Then the sheet is bulged by a given pre-bulging pressure towards the punch while the punch is fixed at a definite position below the sheet. Thereafter the punch progresses and forms the sheet at a given forming pressure.

Prebulging has two actions in the process. The first is building pressure at the beginning of the forming stage and the second is hardening the material near the punch radius and increasing its strength against fracture. The process parameters that can affect obtaining a successfully formed cup are fluid pressure, blank holder force, friction between the sheet and the punch; the sheet and the blank holder, the radius of the punch, the gap between the punch and the die, the pre-bulging pressure, and height.

Hydromechanical Deep Drawing with a Hydroforming Press

Since the HDD is a complicated process, it needs to use Finite Element Method (FEM) to determine the correct parameter values. Therefore, many failures in the sheet such as fracture, thinning, and wrinkling can be analyzed and predicted without any expensive experimental repetitions

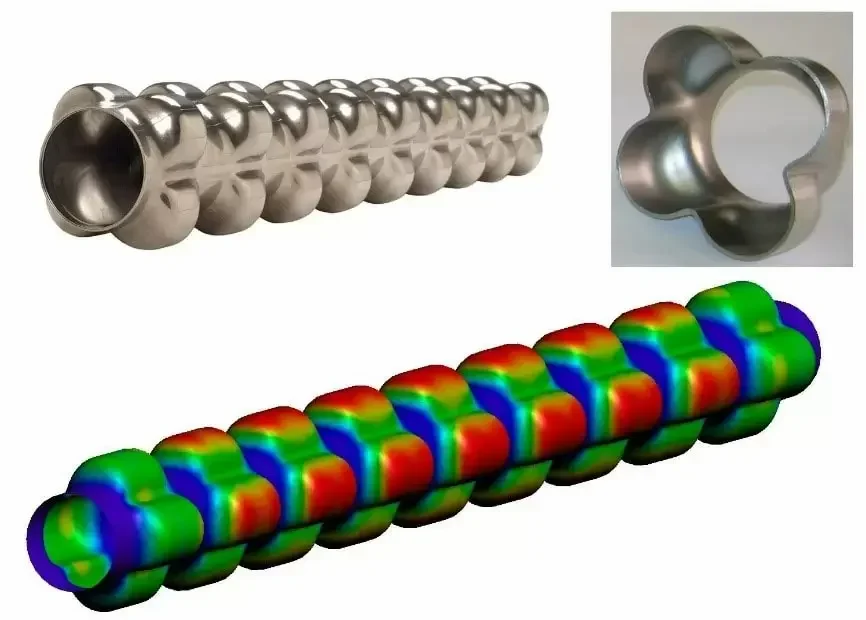

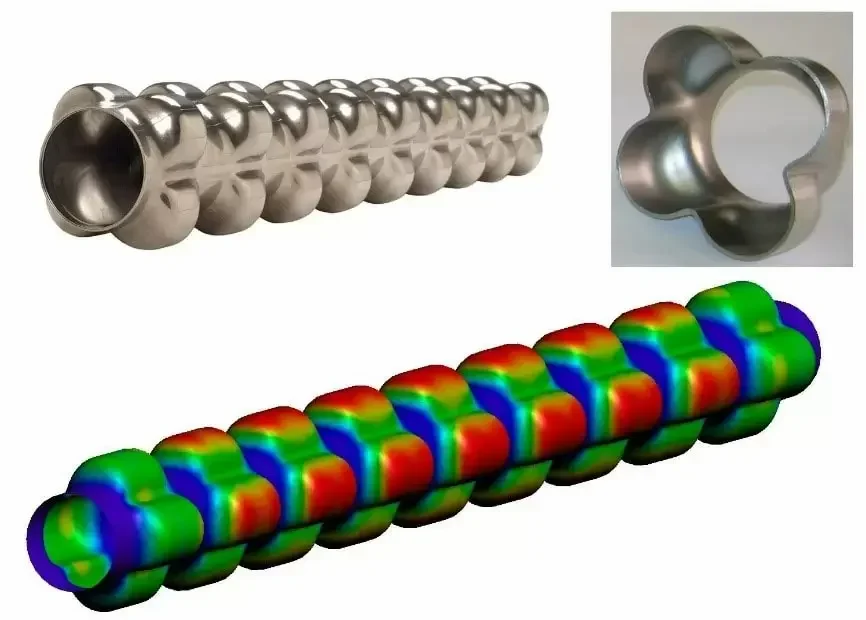

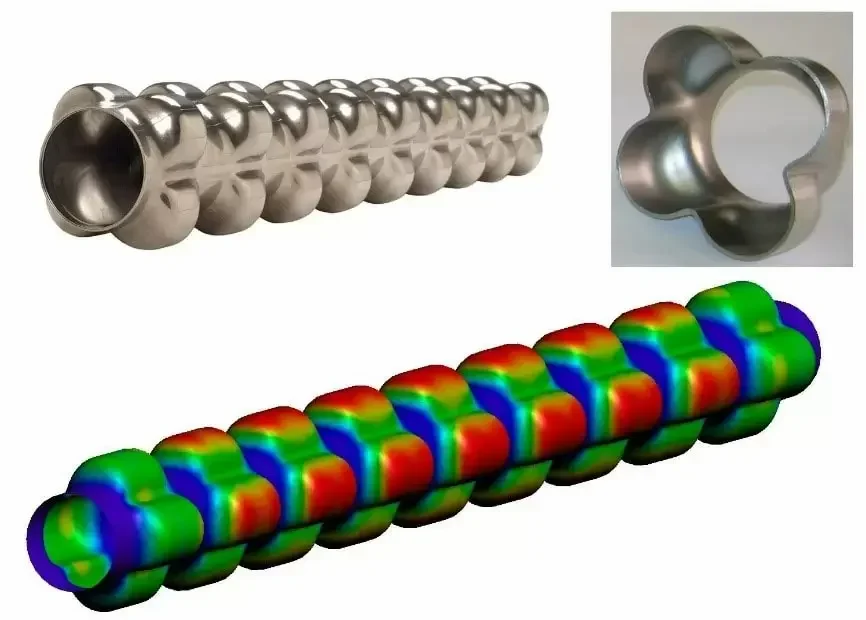

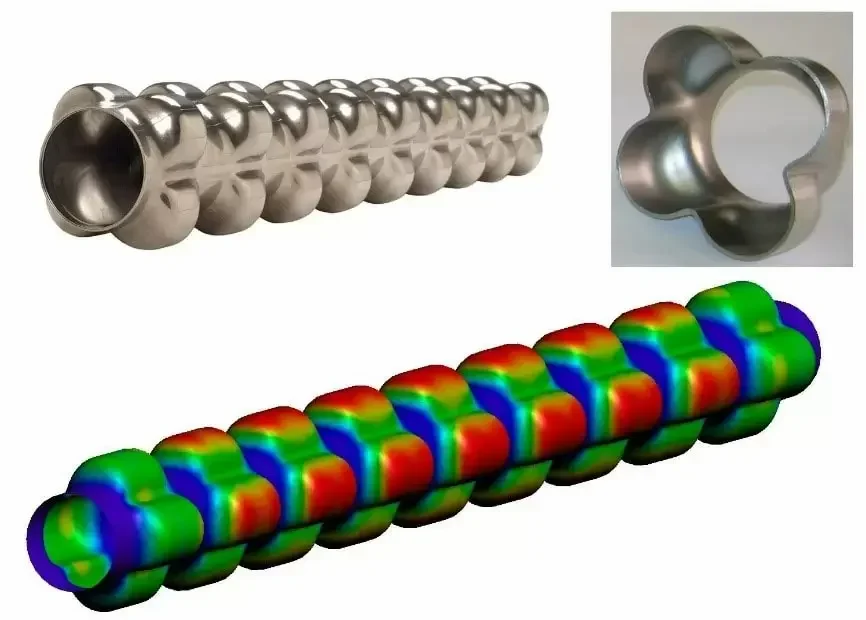

In this study, a hydromechanical deep drawing press, which is necessary for the production of the industrial teapot product, was designed. First, the dimensions of the body of the press were determined according to the specifications of the industrial product group to be produced. The press is designed to be axially symmetrical and able to use dies approximately 400 mm in diameter, which is necessary for the production of the teapot.

It was found from the preliminary analyses that at least a fluid pressure of 1150 bar and a blank holder force of 1100 tons were required for the production of the desired teapot. As a result of the required fluid pressure, the maximum force that the punch should have was obtained as 2310 kN (23 tons) from the finite element analyses (FEA) as can be seen in Fig. 2.

Consequently, the capacity of the press was determined as:

- 1200 bar for the fluid pressure

- 1250 tons for the blank holder force

- 300 tons for the punch force

Dimensions

The minimum table dimensions were determined as 1100 x 1600 mm considering the connection of the main and auxiliary hydraulic cylinders that will apply the closing force of 1250 tons. To facilitate the analysis, parts of the solid model that will not affect the simulation are excluded from the analysis. In the analysis first, St 37 was assigned to the body materials. The loads on the press elements were defined as in Fig. 3.

Sectional views were given to show the forces exerted on the press body. On account of the punch, 300 tons of force will be exerted on the flange of the punch cylinder (blue arrows) and the blank holder; on account of the blank holder, 1250 tons of force will be exerted on the flange of the blank holder cylinder and blank holder.

Therefore, a total force of 1250 tons (yellow arrows) will be exerted upwards on the top of the press body, 1250 + 300 = 1550 tons of force (red arrows) will be exerted downwards on the bottom of the press body, and a total force of 1250 + 300 = 1550 tons of force (green arrows) will be exerted both downwards and upwards on the blank holder.

After defining the forces and the areas on which the forces were exerted, the material and the necessary boundary conditions were identified and the mesh structure of the model was constructed and then analyzed. Since the blank holder was not rigidly attached to the body and the forces acting on the top and bottom of the blank holder were equal, the modeling was done both with and without the blank holder To test the suitability of the designed and manufactured press body, the closing force and the deformation tests on the press body were applied.

In order to test the suitability of the designed and manufactured press body, the closing force test was applied to the press body. The pressing process could be carried out with the full capacity of the blank holder with a closing force of 1200 tons. As a result, it was observed that there was no compression or backlash in the slides. According to the results of the analyzes carried out later, strain gauges were bonded to the four critical regions of the press body (Fig. 4).

After bonding the strain gauges, data were collected from the four different regions of the press by using data acquisition software for specific pressure values between 50 bar and 230 bar, which is the capacity of the press. The measurements were made at 50, 100, 150, 200, and 230 bar by sets of increasing and decreasing pressures with five repetitions.

Hydroforming is an advanced manufacturing process that utilizes a high-pressure hydraulic fluid to shape metal into desired forms. A Hydroforming Press is the specialized equipment used to perform this process, which is particularly valued for its ability to produce complex, lightweight, and structurally strong components. This technology is widely used in industries that demand precision and high-quality products, such as automotive, aerospace, and consumer goods manufacturing.

The hydroforming process stands out because it allows for the creation of intricate shapes that would be difficult, if not impossible, to achieve using traditional metal forming methods. By using a pressurized fluid instead of a solid die, hydroforming can evenly distribute force across the entire surface of the metal, resulting in more consistent and uniform products. This method not only enhances the strength and durability of the final component but also reduces material waste, making it an economically and environmentally efficient process.

Historical Background

The origins of hydroforming date back to the early 20th century, although it began gaining significant traction in industrial applications during the 1950s. Initially developed to address the limitations of traditional stamping and forging processes, hydroforming offered a solution to the challenges of forming complex shapes without compromising the material’s structural integrity. Over the decades, advancements in hydraulic technology and materials science have allowed hydroforming to evolve, becoming a cornerstone of modern manufacturing processes.

In the automotive industry, for example, hydroforming played a crucial role in the development of lighter and stronger vehicle components. This was particularly important as manufacturers sought to improve fuel efficiency and safety standards. Similarly, in the aerospace sector, hydroforming enabled the production of high-strength, lightweight parts that are essential for the performance and reliability of aircraft. The versatility and efficiency of hydroforming presses have made them indispensable in various other sectors as well, from producing consumer electronics to shaping high-end architectural elements.

Importance in Modern Manufacturing

In today’s manufacturing landscape, the demand for products that are both high in quality and cost-effective is higher than ever. The hydroforming press meets these demands by offering a process that can produce complex shapes with high precision and minimal material waste. This is especially critical in industries where the performance, weight, and durability of components are non-negotiable.

Moreover, as industries increasingly shift towards sustainable practices, the role of hydroforming presses becomes even more significant. The process’s inherent efficiency reduces the amount of raw material required, while its precision minimizes the need for post-processing and finishing. These factors not only contribute to lower production costs but also align with global efforts to reduce the environmental impact of manufacturing activities.

Working Principle of Hydroforming Press

Basic Concept of Hydroforming

At its core, hydroforming is a metal forming process that uses a pressurized hydraulic fluid to mold metal sheets or tubes into complex shapes. The process is distinguished by its ability to form intricate and lightweight components with uniform wall thicknesses, which are difficult to achieve using conventional stamping or forging methods. The key to hydroforming’s effectiveness lies in its use of fluid pressure rather than solid dies, allowing for even distribution of force across the metal surface.

In a typical hydroforming operation, a metal blank (either a sheet or tube) is placed into the hydroforming press. The press then closes, and the hydraulic fluid is introduced at high pressure, forcing the metal to conform to the shape of the mold. The pressure is carefully controlled to ensure that the metal flows uniformly and fills the mold completely without tearing or thinning excessively.

Key Components of a Hydroforming Press

A hydroforming press is a sophisticated piece of equipment comprising several critical components that work together to achieve precise metal forming:

- Hydraulic Pump: This is the powerhouse of the hydroforming press, generating the necessary pressure to force the fluid into the system. Hydraulic pumps in these presses are typically capable of producing pressures of up to several thousand bar, depending on the specific application.

- Die/Mold: The die or mold is the tool that shapes the metal. It is typically made of high-strength steel or other durable materials that can withstand the immense pressures involved in the hydroforming process. The die’s shape determines the final form of the metal part.

- Hydraulic Fluid: A specialized fluid, often water or oil-based, is used to transmit pressure from the pump to the metal. The fluid must be carefully selected to ensure it can operate effectively under high pressure and temperature conditions without degrading.

- Press Frame: The press frame is the structural support that holds the die and other components in place. It must be robust enough to handle the significant forces generated during the hydroforming process.

- Control System: Modern hydroforming presses are equipped with advanced control systems that monitor and regulate the pressure, temperature, and other variables throughout the process. These systems ensure precision and repeatability in the production of complex parts.

The Hydroforming Process: Step-by-Step

The hydroforming process can be broken down into several key steps, each crucial to achieving a high-quality finished product:

- Preparation: The metal blank or tube is first prepared by cleaning and cutting it to the desired size. This ensures that the metal is free of contaminants that could affect the quality of the final product.

- Placement: The prepared metal blank is placed into the die within the hydroforming press. For sheet hydroforming, the blank is placed over a lower die; for tube hydroforming, the tube is placed inside a cavity.

- Pressurization: Once the metal is securely positioned, the press closes, and the hydraulic pump begins to pressurize the fluid. The fluid pressure forces the metal to conform to the shape of the die. In sheet hydroforming, the fluid pushes the sheet against the die; in tube hydroforming, the fluid expands the tube against the mold walls.

- Forming: As the pressure increases, the metal continues to flow into the mold, taking on its final shape. The process is carefully controlled to avoid defects such as wrinkles, tears, or uneven wall thickness.

- Release: After the metal has fully conformed to the die, the pressure is gradually released, and the formed part is removed from the press. The part is then inspected for quality and any necessary post-processing steps, such as trimming or heat treatment, are performed.

Types of Hydroforming Presses

There are several types of hydroforming presses, each designed for specific applications:

- Sheet Hydroforming Presses: These presses are used to form metal sheets into complex shapes. They are commonly used in the automotive and aerospace industries to produce lightweight and structurally sound components.

- Tube Hydroforming Presses: These are designed specifically for forming tubes into intricate shapes, such as automotive exhaust systems or bicycle frames. Tube hydroforming allows for the creation of components with varying diameters and wall thicknesses along their length.

- High-Pressure Hydroforming Presses: These presses operate at extremely high pressures and are used for forming particularly strong or complex components. They are often employed in the aerospace industry for forming high-strength alloys.

- Low-Pressure Hydroforming Presses: Used for less demanding applications, these presses operate at lower pressures and are suitable for forming less complex parts or softer metals.

Applications of Hydroforming Press

Automotive Industry

The automotive industry is one of the largest users of hydroforming technology, particularly in the production of vehicle components that require a combination of strength, lightness, and precision. Hydroforming presses are employed to create complex parts such as engine cradles, suspension components, exhaust systems, and structural body panels.

One of the main advantages of using hydroforming in the automotive sector is the ability to produce components with superior strength-to-weight ratios. This is particularly important as the industry strives to meet stringent fuel efficiency and emissions standards. By reducing the weight of critical components without compromising their structural integrity, hydroforming contributes to the overall reduction of vehicle weight, leading to better fuel efficiency and lower emissions.

Additionally, hydroforming allows for the integration of multiple parts into a single, seamless component. This reduces the need for welding and assembly, which not only cuts production costs but also enhances the durability and safety of the final product. For example, hydroformed frames and chassis components are more resistant to impact and deformation, improving vehicle safety.

Aerospace Industry

In the aerospace industry, the demand for lightweight, high-strength components is even more critical. Hydroforming presses are used to produce various aircraft parts, including structural components, engine housings, and intricate shapes for the fuselage. The precision and repeatability of hydroforming make it ideal for producing aerospace parts that must adhere to strict quality and performance standards.

One of the key benefits of hydroforming in aerospace is its ability to work with high-strength alloys, such as titanium and aluminum, which are commonly used in aircraft construction. These materials, while challenging to form using traditional methods, can be precisely shaped using hydroforming techniques. This capability is essential for creating parts that can withstand the extreme conditions of flight, including high temperatures, pressure, and mechanical stress.

Moreover, hydroforming enables the production of parts with complex geometries that would be difficult or impossible to achieve with other forming methods. This is particularly important in the aerospace industry, where space and weight constraints demand the most efficient use of materials. The ability to create lightweight, aerodynamically optimized components contributes to the overall performance and fuel efficiency of modern aircraft.

Consumer Goods Manufacturing

Hydroforming presses are also widely used in the production of consumer goods, particularly in industries where design and aesthetics are paramount. For example, hydroforming is used to create high-end kitchenware, such as stainless steel sinks and cookware, as well as components for consumer electronics like enclosures and frames.

In the consumer goods sector, hydroforming is valued for its ability to produce parts with smooth, seamless surfaces and complex shapes. This capability is essential for products that must combine both form and function. For instance, in the production of stainless steel sinks, hydroforming allows for the creation of deep, complex shapes without seams or welds, resulting in a product that is both aesthetically pleasing and highly durable.

Additionally, the precision and repeatability of hydroforming ensure consistent quality across large production runs, which is crucial in consumer goods manufacturing. This consistency helps maintain brand reputation and customer satisfaction, as each product meets the same high standards of quality and finish.

Specialized Applications

Beyond the automotive, aerospace, and consumer goods industries, hydroforming presses find applications in a wide range of specialized fields. One notable example is the production of components for the energy sector, including parts for oil and gas pipelines, power generation equipment, and renewable energy systems.

In the oil and gas industry, hydroforming is used to produce strong, durable pipes and fittings that can withstand the harsh environments and high pressures encountered in drilling and extraction operations. The ability to create seamless, high-integrity components is critical in preventing leaks and ensuring the safety and efficiency of these systems.

Hydroforming is also increasingly being used in the production of components for renewable energy systems, such as wind turbine blades and solar panel frames. The need for lightweight, strong, and precisely formed parts is essential in these applications, where material efficiency and performance are key to the viability of renewable energy solutions.

Furthermore, hydroforming technology is employed in the medical device industry for producing complex, high-precision components used in surgical instruments, implants, and other medical equipment. The process’s ability to work with biocompatible materials and create intricate shapes makes it ideal for these critical applications.

Advantages of Hydroforming Press

Material Efficiency

One of the most significant advantages of hydroforming is its exceptional material efficiency. Traditional metal forming processes often result in a substantial amount of waste material due to the need for trimming, cutting, and reshaping. In contrast, hydroforming allows for the precise shaping of metal with minimal waste, as the material is evenly distributed under pressure to form the desired shape.

This efficiency not only reduces material costs but also aligns with modern manufacturing’s push towards sustainability. By minimizing waste, hydroforming contributes to a more environmentally friendly production process. Additionally, the ability to create complex parts from a single piece of metal reduces the need for multiple components and joints, further lowering material usage and potential points of failure.

Precision and Complexity of Shapes

Hydroforming is renowned for its ability to produce complex and intricate shapes with high precision. Unlike traditional stamping or forging, which may struggle with intricate designs, hydroforming presses can create parts with varying thicknesses, detailed contours, and smooth curves in a single operation. This capability is particularly beneficial in industries where precision is critical, such as automotive and aerospace manufacturing.

The uniform application of hydraulic pressure ensures that the metal conforms precisely to the die, resulting in parts with consistent thickness and structural integrity. This precision reduces the need for secondary finishing processes, such as machining or polishing, which can add time and cost to production. The ability to achieve complex geometries also allows designers more freedom to innovate, leading to the development of more efficient and effective products.

Cost-effectiveness

While the initial investment in hydroforming equipment can be significant, the long-term cost savings make it a highly cost-effective solution for many manufacturers. The material efficiency and precision of hydroforming reduce the overall production costs by minimizing waste and reducing the need for additional processing steps. Moreover, the ability to integrate multiple parts into a single hydroformed component eliminates the need for costly assembly and welding processes.

In high-volume production, hydroforming becomes even more economical, as the process is highly repeatable and can produce consistent, high-quality parts with minimal variation. This consistency is crucial in industries where quality control is paramount, as it reduces the likelihood of defects and the associated costs of rework or scrap.

Furthermore, the durability and longevity of hydroformed parts can lead to cost savings over the product’s lifecycle. Components made using hydroforming are often stronger and more resistant to wear and tear, reducing the need for repairs or replacements. This durability is especially important in applications where reliability and performance are critical, such as in automotive and aerospace components.

Environmental Impact

Hydroforming is considered a more environmentally friendly alternative to traditional metal forming techniques. The process’s material efficiency directly contributes to reduced resource consumption and waste generation, both of which are key factors in sustainable manufacturing practices. By using less material to achieve the same or superior results, hydroforming helps manufacturers lower their carbon footprint and reduce their environmental impact.

Additionally, the reduced need for secondary operations, such as welding, grinding, or finishing, further minimizes energy consumption and emissions. Hydroforming’s ability to create lighter components also plays a role in the overall environmental impact of the end products. For instance, lighter vehicles and aircraft contribute to lower fuel consumption and reduced greenhouse gas emissions, aligning with global efforts to combat climate change.

Moreover, as industries increasingly adopt green manufacturing practices, the ability of hydroforming to work with environmentally friendly materials, such as recycled metals or sustainable alloys, becomes an important advantage. This adaptability allows manufacturers to meet regulatory requirements and consumer demands for more sustainable products without compromising on quality or performance.

Enhanced Structural Integrity

Another critical advantage of hydroforming is the enhanced structural integrity of the parts it produces. The process creates components with uniform wall thickness and material properties, resulting in stronger, more durable parts that can withstand higher loads and stresses. This is particularly important in applications where safety and performance are paramount, such as in automotive crash structures or aerospace components.

Hydroforming also allows for the creation of parts with fewer seams or joints, which are typically weak points in a structure. By producing seamless components, hydroforming reduces the risk of failure due to fatigue or stress concentration, leading to longer-lasting and more reliable products. This is especially valuable in industries where component failure can have severe consequences, such as in transportation or medical devices.

Limitations and Challenges

Material Constraints

While hydroforming offers many advantages, it also has some limitations, particularly regarding the types of materials that can be effectively used. Hydroforming is best suited for malleable metals that can withstand significant deformation without cracking or losing structural integrity. Common materials include aluminum, copper, and certain steel alloys. However, materials with low ductility, such as cast iron or high-strength steels, can be challenging to hydroform, as they are prone to cracking under the high pressures involved in the process.

Additionally, some materials may require special treatment, such as annealing, to enhance their ductility before hydroforming. This adds complexity and cost to the process, which can be a drawback for manufacturers looking to use these materials. The limitations on material choice can also restrict the application of hydroforming in certain industries where specific material properties are required, such as extreme hardness or temperature resistance.

Equipment Costs

The initial investment in hydroforming equipment can be a significant barrier for some manufacturers, especially small to medium-sized enterprises. Hydroforming presses, particularly those capable of handling high pressures and complex shapes, are expensive to purchase and maintain. The cost of the hydraulic systems, control units, and precision dies can add up, making it a considerable upfront expenditure.

Moreover, the specialized nature of hydroforming presses means that the costs associated with maintenance, repairs, and operator training can also be high. Skilled technicians are often required to operate and maintain the equipment, adding to the overall cost of production. For manufacturers with limited resources, these factors can make it difficult to justify the investment in hydroforming technology, especially if production volumes are low.

Process Limitations

Despite its ability to produce complex shapes, hydroforming does have certain process limitations that can affect its applicability. For example, the process is generally slower than other metal forming techniques, such as stamping, because of the time required to apply and release hydraulic pressure. This can be a disadvantage in high-volume production environments where speed is a critical factor.

Another limitation is the thickness of the metal that can be hydroformed. While hydroforming is excellent for creating parts with uniform wall thickness, it is less effective when dealing with very thick or very thin materials. Extremely thick metals may not deform as easily under pressure, leading to incomplete or inaccurate forming. On the other hand, very thin metals can be prone to tearing or wrinkling during the process, resulting in defective parts.

Additionally, the complexity of the hydroforming process itself can lead to challenges in quality control. The high pressures involved require precise control and monitoring, and even small deviations can result in defects. This necessitates stringent quality assurance measures, which can increase production costs and time.

Maintenance and Operational Challenges

Maintaining a hydroforming press in optimal working condition presents several challenges. The hydraulic systems, in particular, are subject to wear and tear due to the high pressures and fluid dynamics involved. Regular maintenance is required to prevent leaks, ensure consistent pressure application, and maintain the integrity of the hydraulic fluid. Failure to properly maintain these systems can lead to costly downtime and repairs.

Operational challenges also arise from the need for precise control over the hydroforming process. The equipment must be carefully calibrated to ensure that the pressure is applied evenly and consistently across the metal blank. Any variation in pressure can result in defects, such as uneven thickness or incomplete forming. This level of precision requires skilled operators and sophisticated control systems, both of which add to the operational complexity.

Moreover, the dies used in hydroforming presses must be carefully designed and maintained to ensure they can withstand the high pressures without deforming. This is particularly challenging when producing parts with intricate shapes or sharp details, as the dies must be able to replicate these features accurately without wearing out too quickly. The cost and time involved in producing and maintaining these dies can be a significant challenge, especially for custom or low-volume production runs.

Technological Innovations in Hydroforming

Recent Developments in Equipment and Techniques

The field of hydroforming has seen significant technological advancements in recent years, driven by the need for greater precision, efficiency, and versatility in manufacturing. One notable innovation is the development of multi-stage hydroforming presses, which allow for the sequential forming of complex components in multiple stages. This approach reduces the risk of defects such as thinning or tearing by gradually shaping the material, making it possible to create even more intricate and precise parts.

Another key development is the advancement of high-pressure hydroforming technology. Modern presses can now achieve pressures exceeding 10,000 bar, enabling the forming of ultra-high-strength materials that were previously difficult to process. This is particularly beneficial in the automotive and aerospace industries, where lightweight, high-strength components are essential for performance and safety. The ability to work with these advanced materials opens up new possibilities for product design and functionality.

In addition, servo-hydraulic systems have been introduced to improve the efficiency and control of hydroforming presses. These systems use servo motors to precisely control the flow and pressure of the hydraulic fluid, resulting in more accurate and repeatable forming processes. The enhanced control provided by servo-hydraulic systems also allows for the fine-tuning of the process parameters, enabling the production of parts with tighter tolerances and improved surface finishes.

Integration of Automation and AI

The integration of automation and artificial intelligence (AI) into hydroforming processes represents a significant leap forward in manufacturing capabilities. Automated hydroforming presses are equipped with robotic systems that handle material loading, unloading, and die changes, significantly reducing the time and labor required for these tasks. This not only increases production efficiency but also reduces the risk of human error, leading to more consistent and reliable outcomes.

AI-driven control systems are also being implemented to optimize the hydroforming process in real-time. These systems use machine learning algorithms to analyze data from sensors embedded in the press, such as pressure, temperature, and material flow rates. By continuously monitoring these parameters, AI can adjust the process on the fly to prevent defects and ensure that each part meets the required specifications. This capability is particularly valuable in high-precision industries like aerospace, where even minor deviations can have significant consequences.

Furthermore, AI and machine learning are being used to improve the design of hydroforming dies. By simulating the forming process and analyzing the results, AI can optimize die geometry and material selection to minimize wear and extend the lifespan of the dies. This not only reduces the cost and time associated with die maintenance but also enhances the overall efficiency of the hydroforming process.

Advancements in Materials Used

Material science has also played a crucial role in the evolution of hydroforming technology. The development of new alloys and composite materials that are specifically designed for hydroforming has expanded the range of applications for this process. These materials offer improved formability, strength, and resistance to environmental factors such as corrosion or high temperatures, making them ideal for use in demanding industries.

For instance, aluminum-lithium alloys are increasingly being used in aerospace applications due to their high strength-to-weight ratio and excellent fatigue resistance. These alloys can be hydroformed into complex shapes with high precision, contributing to the overall performance and fuel efficiency of aircraft. Similarly, the automotive industry is exploring the use of advanced high-strength steels (AHSS) and magnesium alloys in hydroforming processes to create lighter, safer, and more fuel-efficient vehicles.

In addition to metals, hydroforming is now being applied to composite materials, which consist of a combination of fibers and resins. These materials offer exceptional strength and stiffness while being lightweight, making them ideal for applications where weight reduction is critical. The ability to hydroform composite materials opens up new possibilities for innovative product designs that were previously unattainable with traditional metals.

Comparison with Other Forming Technologies

Stamping is a widely used metal forming process in which a metal sheet is placed between a die and a punch, and force is applied to shape the metal. While stamping is highly efficient and suitable for high-volume production, it has limitations when compared to hydroforming.

- Complexity of Shapes: Stamping is generally limited to simpler shapes due to the way force is applied directly to the metal. In contrast, hydroforming can produce more complex and intricate geometries, including parts with variable thicknesses, smooth curves, and complex contours. This makes hydroforming the preferred choice for applications where precision and complexity are crucial.

- Material Utilization: Stamping often results in significant material waste, especially when producing complex parts that require multiple stamping operations or trimming. Hydroforming, on the other hand, minimizes material waste by evenly distributing pressure across the entire metal surface, resulting in more efficient material usage.

- Structural Integrity: Hydroformed parts tend to have superior structural integrity due to the uniform pressure applied during the process, which reduces the likelihood of defects such as wrinkles or tears. Stamping can create stress concentrations at the edges or corners of the stamped part, which may weaken the component and require additional finishing operations.

Hydroforming vs. Forging

Forging involves shaping metal by applying compressive forces through hammering or pressing. It is known for producing extremely strong parts but has its own set of limitations when compared to hydroforming.

- Strength vs. Precision: Forging is ideal for producing parts that require high strength and durability, such as automotive and aerospace components. However, it is less effective at creating precise and intricate shapes. Hydroforming excels in precision, making it better suited for applications where detailed geometries and fine tolerances are required.

- Material Choice: Forging is typically limited to metals that can withstand the intense compressive forces involved, such as steel and titanium. Hydroforming, while also capable of working with high-strength materials, is more versatile in terms of the range of materials it can handle, including softer metals like aluminum and copper.

- Production Efficiency: Hydroforming is generally more efficient for producing complex parts in one step, while forging may require multiple stages or secondary processes to achieve the desired shape. This makes hydroforming a faster and potentially more cost-effective option for certain applications, especially in high-volume production.

Hydroforming vs. Deep Drawing

Deep drawing is a metal forming process where a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is commonly used to produce cylindrical or box-shaped parts, such as cans or automotive body panels.

- Forming Capability: Deep drawing is highly effective for producing simple, deep-drawn parts, but it has limitations when it comes to forming more complex geometries. Hydroforming, on the other hand, can create parts with varying cross-sections, multiple curves, and more intricate designs, making it a more versatile forming method.

- Thickness Uniformity: One of the challenges of deep drawing is maintaining uniform wall thickness, especially in deep or complex shapes. Hydroforming addresses this issue by applying fluid pressure uniformly, ensuring consistent thickness throughout the part. This results in parts that are not only aesthetically pleasing but also structurally sound.

- Tooling and Costs: Deep drawing requires highly specialized tooling and is most cost-effective for large production runs. While hydroforming also requires specific tooling, its ability to produce complex shapes in fewer steps can lead to cost savings in both tooling and production time, particularly for medium to large production volumes.

Comparative Analysis Based on Cost, Efficiency, and Applications

- Cost: While hydroforming presses can be more expensive to purchase and maintain than the equipment used for stamping, forging, or deep drawing, the overall cost-effectiveness of hydroforming comes from its material efficiency, precision, and ability to integrate multiple parts into a single component. This reduces assembly costs and the need for secondary operations, potentially lowering overall production costs.

- Efficiency: Hydroforming is particularly efficient for producing parts with complex shapes and uniform thicknesses. Its ability to reduce the number of steps in the manufacturing process and minimize material waste makes it an attractive option for industries that prioritize both quality and efficiency. However, for very high-volume production of simpler shapes, traditional stamping or deep drawing may still be more efficient due to the faster cycle times of these processes.

- Applications: Hydroforming is widely used in industries that demand high precision and complexity, such as automotive, aerospace, and consumer goods. In contrast, stamping is often used for producing large quantities of simpler parts, forging for parts that require exceptional strength, and deep drawing for cylindrical or box-shaped components. The choice of process depends on the specific requirements of the application, including the desired shape, material, and production volume.

Future Trends in Hydroforming

The future of hydroforming is poised for exciting developments, driven by ongoing advancements in materials science, automation, and digital technologies. One key area of innovation is the development of smarter and more adaptive hydroforming presses. These next-generation presses will likely incorporate more advanced sensors and AI-driven control systems that can monitor and adjust the forming process in real-time. This will enhance precision, reduce defects, and enable the forming of even more complex geometries.

Another expected advancement is the integration of additive manufacturing (3D printing) with hydroforming processes. Combining these technologies could allow manufacturers to create hybrid components with both additive and formed elements, opening up new possibilities for design and functionality. This hybrid approach could be particularly valuable in industries like aerospace, where components need to meet stringent performance criteria while being as lightweight as possible.

Additionally, advances in simulation and modeling software are expected to play a significant role in the future of hydroforming. Improved software tools will allow for more accurate and detailed simulations of the hydroforming process, enabling engineers to optimize die design, material selection, and process parameters before physical production begins. This not only reduces development time and costs but also minimizes the risk of errors during production.

Emerging Applications

As hydroforming technology continues to evolve, its applications are expected to expand into new and emerging fields. One such area is the production of components for electric vehicles (EVs). The shift towards electrification in the automotive industry is creating a demand for lightweight, high-strength components that can improve the efficiency and range of EVs. Hydroforming is ideally suited to meet these needs, as it can produce complex, integrated structures that reduce vehicle weight without compromising safety or performance.

Another promising application is in the renewable energy sector, particularly in the production of parts for wind turbines and solar panels. As the world moves towards more sustainable energy sources, the demand for efficient and durable components in these systems will grow. Hydroforming’s ability to create large, complex shapes with high structural integrity makes it an attractive option for manufacturing these critical components.

The medical device industry is also expected to see increased use of hydroforming, particularly in the production of implants and surgical instruments. The precision and biocompatibility of hydroformed components make them well-suited for use in medical applications, where safety and performance are paramount. As medical technology advances, the demand for customized, patient-specific implants and tools is likely to drive further innovation in hydroforming techniques.

Industry Growth Projections

The hydroforming industry is expected to experience steady growth in the coming years, fueled by increasing demand from key sectors such as automotive, aerospace, and consumer electronics. The global push towards lightweighting in automotive and aerospace manufacturing is a significant driver, as hydroforming offers an effective solution for producing lightweight yet strong components.

In the automotive industry, the continued focus on improving fuel efficiency and reducing emissions will likely lead to greater adoption of hydroforming technology, particularly for electric vehicles and hybrid systems. The aerospace industry is also expected to see increased demand for hydroforming as new aircraft designs require components that are both lightweight and capable of withstanding extreme conditions.

In addition to traditional markets, emerging economies are expected to contribute to the growth of the hydroforming industry. As manufacturing capabilities in countries like China and India continue to expand, so too will the adoption of advanced forming technologies like hydroforming. This global expansion will likely lead to increased competition and innovation within the industry, driving further advancements in hydroforming techniques and equipment.

Furthermore, the trend towards greater sustainability in manufacturing is expected to boost the demand for hydroforming. The process’s inherent efficiency, reduced material waste, and ability to work with environmentally friendly materials make it an attractive option for companies looking to reduce their environmental footprint. As sustainability becomes a more significant factor in manufacturing decisions, hydroforming is well-positioned to become an even more critical technology in the global manufacturing landscape.

Conclusion

Hydroforming has established itself as a vital technology in modern manufacturing, offering a unique combination of precision, material efficiency, and versatility. Its ability to produce complex, lightweight, and structurally robust components makes it an invaluable process across various industries, including automotive, aerospace, consumer goods, and beyond. As manufacturing continues to evolve, the role of hydroforming is expected to grow, driven by advancements in technology and the increasing demand for high-quality, cost-effective, and sustainable production methods.

One of the most significant advantages of hydroforming is its material efficiency. By utilizing hydraulic pressure to form metal into precise shapes, hydroforming minimizes waste and reduces the need for additional processing steps. This not only lowers production costs but also supports the global shift towards more sustainable manufacturing practices. Additionally, the superior structural integrity of hydroformed parts enhances product performance and durability, which is particularly important in industries where safety and reliability are paramount.

The ongoing technological innovations in hydroforming, including the integration of automation, AI, and advanced materials, are pushing the boundaries of what this process can achieve. These developments are opening up new possibilities for design and functionality, allowing manufacturers to create increasingly sophisticated and high-performance products. As these technologies continue to mature, hydroforming is likely to play an even more critical role in meeting the challenges of modern manufacturing.

Moreover, as industries such as automotive and aerospace strive to meet ever-stricter environmental and performance standards, hydroforming offers a solution that aligns with these goals. The process’s ability to produce lightweight components contributes to improved fuel efficiency and reduced emissions, while its precision ensures that parts meet the highest quality standards. This makes hydroforming not just a valuable tool for today’s manufacturers, but a strategic technology for the future.

In conclusion, hydroforming represents a powerful and versatile solution for modern manufacturing challenges. Its ability to deliver complex, high-quality components with efficiency and sustainability makes it a key technology in the pursuit of innovation and excellence. As industries continue to evolve and demand more from their manufacturing processes, hydroforming is poised to remain at the forefront, driving progress and shaping the future of production.

Hydroforming Press

A hydroforming press is a type of press that is used to shape ductile metals into complex shapes using a combination of fluid pressure and mechanical force. It is often used in the manufacturing of parts for the automotive and aerospace industries, where precision and strength are critical factors.

The hydroforming process begins with a blank piece of metal, typically made of aluminum or steel, that is placed into a die. The die is then closed and fluid is pumped into the chamber, which applies pressure to the metal from all directions. This pressure forces the metal to take on the shape of the die, resulting in a highly precise and complex part.

A hydroforming press is a specialized type of press that uses a high-pressure fluid to deform sheet metal into complex shapes. The process is similar to deep drawing, but it uses fluid pressure instead of mechanical force to form the material.

Advantages of Hydroforming

Hydroforming offers several advantages over traditional metal forming methods, including:

- Reduced material waste: Hydroforming can produce complex shapes with minimal material waste, compared to other forming methods that may require trimming or scrap.

- Improved surface finish: The fluid pressure used in hydroforming produces a smooth, even surface finish on the formed part, eliminating the need for secondary finishing operations.

- Increased part strength: Hydroforming can produce parts with higher strength and fatigue resistance compared to other forming methods.

- Versatility: Hydroforming can be used to form a wide range of shapes, including hollow and closed shapes that are difficult to produce with other methods.

Applications of Hydroforming

Hydroforming is commonly used in the automotive industry to produce a variety of components, such as:

- Frame rails: Hydroformed frame rails are lighter and stronger than traditional frame rails, and they can be produced with complex shapes that improve vehicle performance.

- Doors and body panels: Hydroformed doors and body panels are lighter and more dent-resistant than traditional panels, and they can be produced with intricate details.

- Exhaust systems: Hydroformed exhaust systems are more durable and have fewer welds than traditional exhaust systems, making them less prone to leaks and corrosion.

Components of a Hydroforming Press

A hydroforming press consists of several key components:

- Press frame: The press frame is a rigid structure that supports the other components of the press.

- Platens: The platens are the heated surfaces that come into contact with the material being formed. They are typically made of steel or aluminum and can be heated electrically or with steam.

- Hydraulic system: The hydraulic system generates the pressure that is used to deform the material. It consists of a pump, a reservoir, and a series of valves.

- Die: The die is the mold that gives the formed part its shape. It is typically made of tool steel or high-strength aluminum.

- Bladder: The bladder is a flexible membrane that is placed inside the die. It is filled with high-pressure fluid to deform the material against the die.

Hydroforming Process

The hydroforming process typically involves the following steps:

- Blank preparation: The material is cut to the desired size and shape.

- Preheating: The blank is preheated to a temperature that makes it more malleable.

- Die loading: The blank is placed inside the die.

- Bladder inflation: The bladder is inflated with high-pressure fluid, causing the blank to deform against the die.

- Hold and cooling: The pressure is held for a period of time to allow the material to cool and set in the desired shape.

- Unloading: The bladder is deflated, and the formed part is removed from the die.

Conclusion

Hydroforming is a powerful and versatile metal forming process that is used to produce a wide variety of components for a variety of industries. It offers several advantages over traditional metal forming methods, including reduced material waste, improved surface finish, increased part strength, and greater versatility.

How does a Hydroforming Press function?

The process of hydroforming can be broken down into several key steps:

- Material selection: The first step in the hydroforming process is to select the appropriate material for the part being produced. Typically, this will be a ductile metal such as aluminum or steel.

- Blank preparation: The blank, or sheet of metal, is then cut to the appropriate size and shape for the part being produced. It may also be pre-formed to a certain degree to make it easier to shape during the hydroforming process.

- Die preparation: The die, which will be used to shape the metal, is then prepared. This involves heating and lubricating the die to ensure that the metal can be shaped smoothly and accurately.

- Loading: The blank is loaded into the die and the press is closed. The fluid pressure is then applied to the metal, forcing it to take on the shape of the die.

- Forming: As the fluid pressure is applied, the metal is shaped into the desired form. The pressure is carefully controlled to ensure that the metal is not overstretched or damaged during the process.

- Unloading: Once the forming process is complete, the fluid pressure is released and the part is removed from the die. It may then be trimmed or finished as necessary.

Hydroforming presses come in a variety of sizes and configurations, ranging from small tabletop models to large, industrial-scale machines capable of shaping parts several feet in diameter. They can be used to produce a wide range of parts, from simple tubes and cylinders to highly complex shapes with multiple curves and bends.

Overall, the hydroforming process offers a number of advantages over traditional stamping and forming methods. It allows for greater precision and accuracy in shaping metal parts, while also reducing the amount of material waste and minimizing the need for secondary operations such as welding and machining.

In the last decades, advanced forming processes such as sheet hydroforming have an increasing interest, particularly in the automotive and aerospace industries. This process has many advantages such as reduction of tool costs, enhanced formability, capability to form complex parts, reduced die wear, higher dimensional accuracy, and surface quality compared to the conventional sheet metal forming processes.

Material selection for the hydroforming press

The selection of materials for the hydroforming press is crucial for ensuring its durability, performance, and cost-effectiveness. Various factors influence the choice of materials, including the desired properties of the press, the type of components being formed, and the operating conditions.

Key Considerations for Material Selection

- Strength and Durability: The materials used for the press frame, platens, and dies must be strong enough to withstand the high pressures and forces involved in the hydroforming process. They should also be durable and resistant to wear and tear.

- Heat Resistance: The platens and dies must be able to withstand the high temperatures required to preheat the material being formed. They should also be able to maintain their shape and dimensions under these conditions.

- Dimensional Accuracy: The dies must be made from materials that can maintain precise dimensions over time. This is essential for producing high-quality components with the desired tolerances.

- Cost-effectiveness: The materials used for the press should be cost-effective without compromising on quality or performance. The balance between initial cost and long-term durability is crucial.

Common Materials Used in Hydroforming Presses

- Steel: Steel is a common choice for the press frame, platens, and dies due to its strength, durability, and heat resistance. Various grades of steel are used depending on the specific requirements of the press.

- Aluminum: Aluminum is sometimes used for the platens due to its lighter weight and faster heating and cooling rates. However, aluminum is generally not as strong or durable as steel.

- Tool Steel: Tool steel is a high-strength material that is often used for dies, especially for forming complex shapes. It is known for its wear resistance and ability to maintain dimensional accuracy.