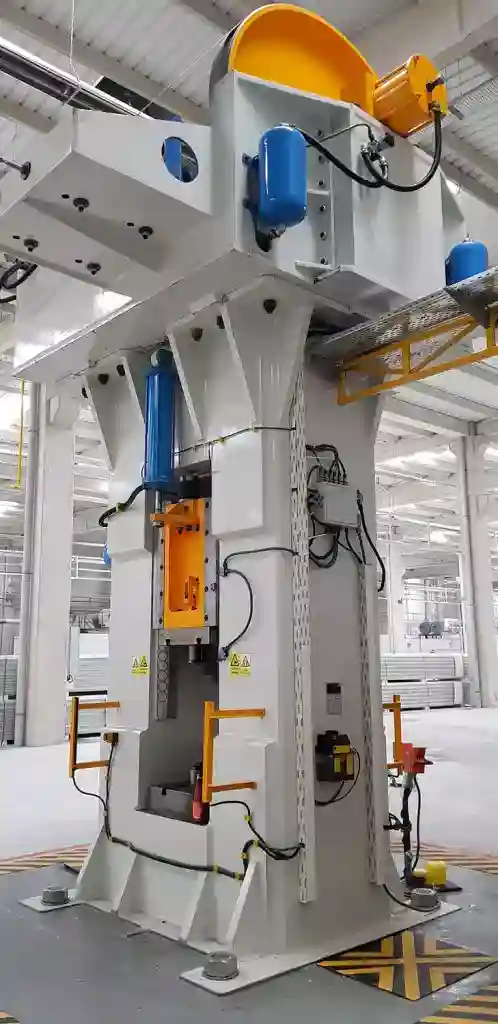

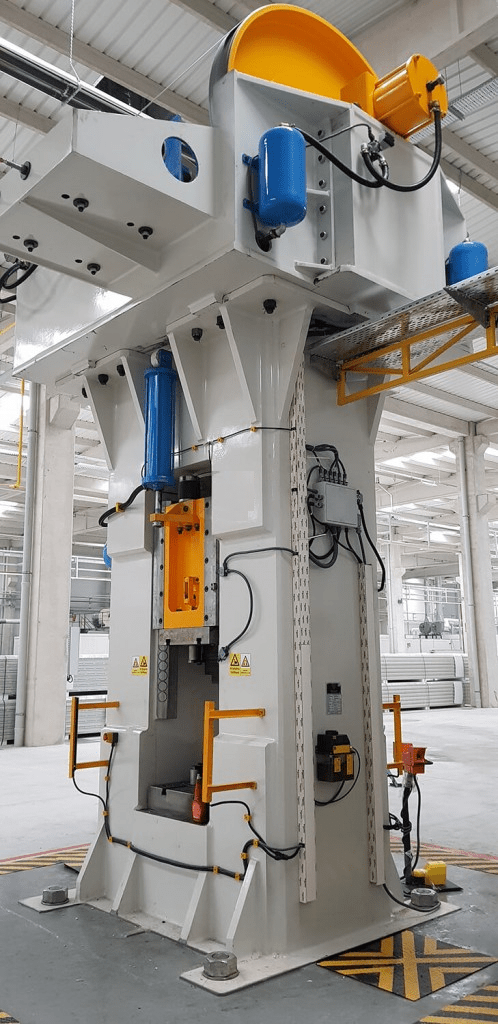

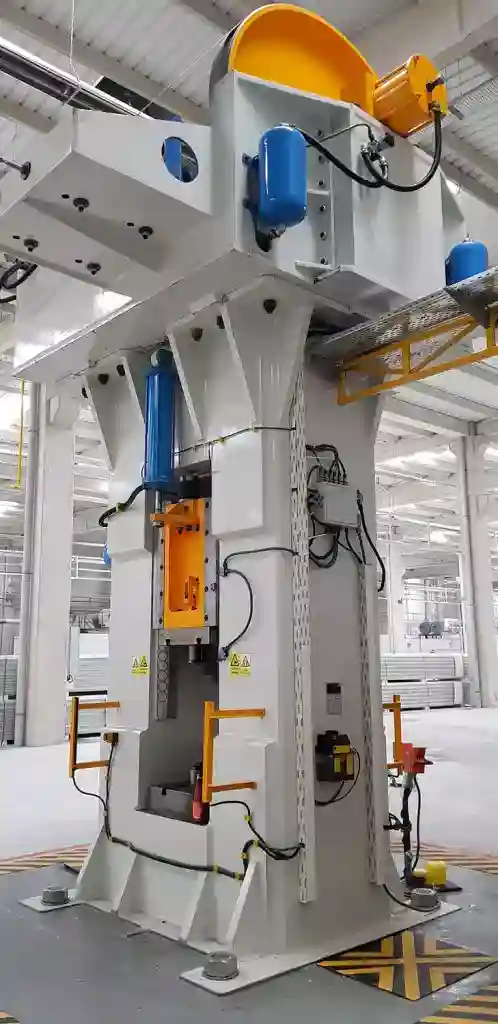

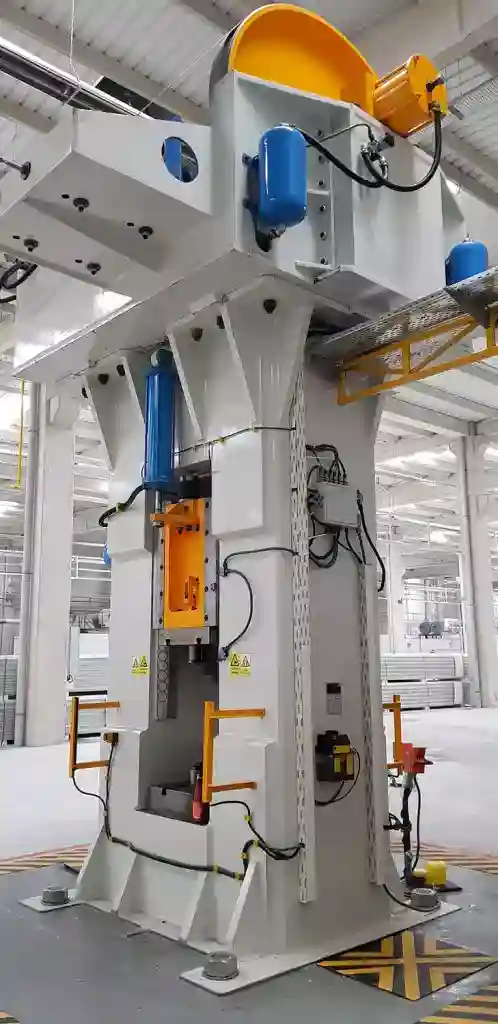

A friction screw press with a capacity of 1000 tonnes is an industrial-grade mechanical press designed to exert a maximum forging force of 1000 metric tonnes (approximately 2,204,623 pounds) during its operation. These presses are among the largest and most powerful forging machines available, and they are used in heavy-duty industrial applications where immense forging forces are required to shape and deform large metal materials effectively. Here are some key details and applications related to a 1000-tonne friction screw press:

- Forging Capacity: A 1000-tonne friction screw press can exert a maximum forging force of 1000 metric tonnes. This force is generated through the frictional resistance between the rotating screw and the fixed nut within the press.

- Working Principle: The operation of a 1000-tonne friction screw press is based on the same fundamental principles as other friction screw presses. It involves the use of a rotating screw that threads into a fixed nut. As the screw rotates, it moves vertically, pushing the ram (slide) downward. The ram carries the forging dies, which shape and deform the heated metal workpiece placed between them.

- Applications:

- Heavy-Duty Forging: These presses are primarily used for heavy-duty forging processes where metal workpieces are heated to high temperatures (usually above their recrystallization temperature) before being formed and shaped. Common applications include the production of large and massive components used in industries such as heavy machinery manufacturing, shipbuilding, aerospace, and energy generation.

- Die Forging: A 1000-tonne friction screw press is capable of performing die forging operations, where metal blanks are pressed into precision dies to create complex shapes and large-sized components.

- Upsetting: These presses can perform upsetting operations, which are essential for creating large, high-strength components like axles, anchor chains, and heavy bolts.

- Control and Precision: Modern friction screw presses, including 1000-tonne models, are equipped with advanced control systems that allow precise control over the forging process. This ensures that the desired dimensions and quality of the forged components are consistently achieved.

- Energy Efficiency: Despite their immense power, friction screw presses are known for their energy efficiency compared to other types of forging equipment, which is particularly important in large-scale heavy forging applications where energy consumption can be substantial.

- Safety Considerations: Safety precautions are of utmost importance when operating a 1000-tonne friction screw press due to the immense forces involved. Comprehensive safety measures, operator training, and adherence to safety protocols are essential to prevent accidents and ensure the well-being of personnel working with the press.

In summary, a 1000-tonne friction screw press is an industrial workhorse used for heavy-duty forging applications where extremely high forging forces are required to shape and form large metal components. These presses are commonly found in industries that manufacture large machinery, infrastructure components, and other critical industrial equipment.

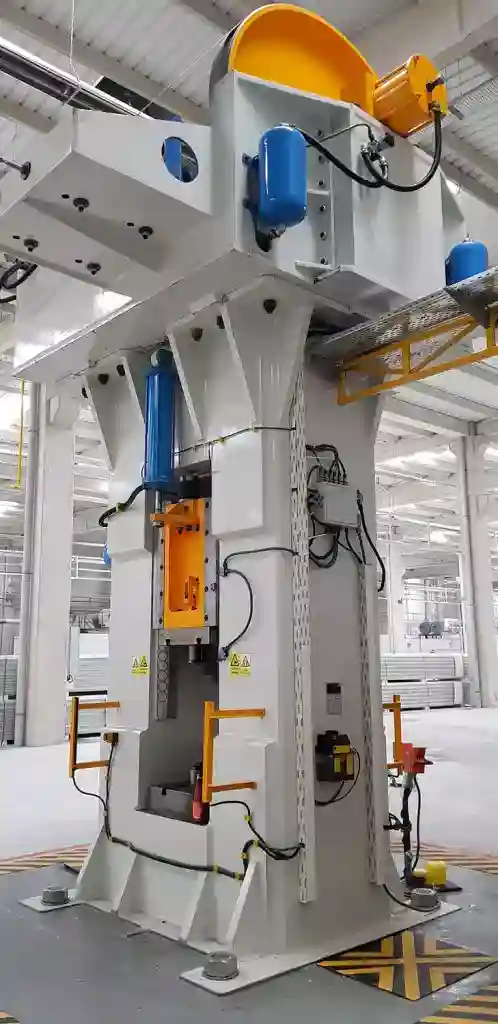

Friction Screw Press 1000 Tonnes

A friction screw press with a capacity of 1000 tonnes is an industrial-grade mechanical press designed to exert a maximum forging force of 1000 metric tonnes (approximately 2,204,623 pounds) during its operation. These massive machines are used for a variety of demanding heavy-duty forging applications where extremely high forging forces are required to shape and form very large metal components.

Key Features of 1000-Ton Friction Screw Presses

- High Forging Force: Capable of generating 1000 tonnes of forging force, enabling the shaping of large and intricate metal components.

- Stable Operation: Employ a friction-clutch mechanism that ensures smooth and stable operation during forging processes.

- Versatility: Can handle a wide range of forging tasks, including upsetting, drawing, and coining.

- Precision Control: Equipped with advanced control systems for precise and consistent forging results.

- Robust Construction: Built with durable materials and robust designs to withstand the demanding forging environment.

Applications of 1000-Ton Friction Screw Presses

- Heavy-Duty Forgings: Production of large and complex metal parts for various industries, including automotive, aerospace, and construction.

- Shaping and Forming: Forming and shaping of metal components into desired shapes and dimensions.

- Upsetting: Shortening and increasing the diameter of metal blanks.

- Drawing: Elongating and reducing the diameter of metal blanks.

- Coining: Impressing patterns or designs onto metal surfaces.

Examples of Components Forged Using 1000-Ton Friction Screw Presses

- Crankshafts

- Connecting Rods

- Gear Blanks

- Flywheels

- Pressure Vessels

- Large Tooling Components

1000-ton friction screw presses are an essential part of modern industrial manufacturing, enabling the production of large and complex metal components for a wide range of applications. Their high forging force, stability, versatility, and precision control make them indispensable tools for heavy-duty forging operations.

Key Specifications with More Details

Sure, here is a more detailed list of the key specifications of a 1000-ton friction screw press:

Forging Capacity:

- Maximum forging force: 1000 metric tonnes (2,204,623 pounds)

- Forging speed: Adjustable from 0 to 4 strokes per minute

- Stroke length: Typically 300 to 500 millimeters (11.8 inches to 19.7 inches)

- Bed opening: Typically 400 to 500 millimeters (15.7 inches to 19.7 inches)

- Die area: Typically 600 by 600 millimeters (23.6 inches by 23.6 inches)

Mechanical Structure:

- Rigid and robust frame construction to withstand the high forging forces

- Friction screw mechanism for generating the forging force

- Hydraulic system for controlling the movement of the screw and slide

- Pneumatic system for operating the clutch and brake mechanisms

Control System:

- Advanced PLC (Programmable Logic Controller) for precise and consistent operation

- Touchscreen interface for user-friendly operation

- Real-time monitoring of forging parameters, such as force, stroke, and speed

- Data logging for process analysis and quality control

Additional Specifications:

- Motor power: Typically 30 to 50 kilowatts (40 to 67 horsepower)

- Machine weight: Typically 15 to 25 metric tonnes (33,069 to 55,116 pounds)

- Machine dimensions: Typically 2 meters by 1.5 meters by 1.5 meters (6.5 feet by 4.9 feet by 4.9 feet)

Please note that these are general specifications and may vary depending on the specific manufacturer and model.

Friction Screw Press

A friction screw press, also known as a screw press or screw press machine, is a mechanical device used for various industrial processes, including forging, forming, and pressing operations. It operates on the principle of converting rotary motion into linear force through the use of a screw mechanism. Friction screw presses are widely used in metalworking, automotive, aerospace, and other manufacturing industries.

Our Friction Screw Press Types

- Friction Screw Press 150 Tonnes

- Friction Screw Press 300 Tonnes

- Friction Screw Press 1000 Tonnes

- Friction Screw Press 1300 Tonnes

- Friction Screw Press 1500 Tonnes

- Friction Screw Press 2000 Tonnes

- Friction Screw Press 2500 Tonnes

Here’s an overview of how a friction screw press works and its key characteristics:

How a Friction Screw Press Works:

- Screw Mechanism: The core component of a friction screw press is a large screw or spindle that runs vertically through the press. This screw is often called the “flywheel screw” because it stores and transfers energy during the operation.

- Motor or Power Source: A motor or power source is used to rotate the screw. The screw is threaded, and as it rotates, it moves either up or down, depending on the direction of rotation.

- Flywheel: The screw is connected to a heavy flywheel or a clutch mechanism. The flywheel stores kinetic energy, and this energy is transferred to the screw when the press is activated.

- Material Placement: The material to be processed, such as a metal workpiece or a forging blank, is placed on the press’s lower die or anvil.

- Pressing Operation: To perform a pressing operation, the operator activates the press by engaging the motor or power source. The screw rotates rapidly, causing it to move downward, applying a compressive force to the material placed on the lower die.

- Compression and Forming: The downward movement of the screw results in the material being compressed, shaped, or formed between the upper die (attached to the screw) and the lower die (the anvil). The force applied can be controlled and adjusted based on the application’s requirements.

- Energy Release: During the pressing operation, energy is transferred from the flywheel to the screw, and this energy is released as mechanical force, creating the pressing action.

- Repetition: The pressing operation can be repeated as needed, with adjustments made to the force, speed, and other parameters to achieve the desired results.

Key Characteristics of Friction Screw Presses:

- Adjustability: Friction screw presses allow for precise control of pressing force and speed, making them suitable for a wide range of applications.

- Energy Efficiency: These presses are known for their energy efficiency because the kinetic energy stored in the flywheel can be reused for subsequent press cycles.

- Versatility: Friction screw presses are versatile machines used for tasks such as forging, extrusion, blanking, bending, and other forming operations.

- High Force Capacity: They are capable of exerting high compressive forces, making them suitable for heavy-duty applications in the metalworking industry.

- Reliability: Friction screw presses are robust and reliable machines, often used in continuous production processes.

- Safety: Modern friction screw presses are equipped with safety features to protect operators and prevent accidents.

- Ease of Maintenance: Routine maintenance is generally straightforward, making them cost-effective to operate.

In summary, friction screw presses are essential machines in metalworking and manufacturing industries, offering the ability to perform various forming and pressing operations with precision, efficiency, and versatility.

Friction Screw Press

A friction screw press is a type of mechanical press widely used in industrial forging, metal forming, and various manufacturing processes. Unlike other mechanical presses that rely on hydraulic or pneumatic systems, a friction screw press utilizes the principle of friction to drive the motion of the press’s screw and ram. The energy required to deform materials is generated by the friction between rotating discs and the flywheel, which in turn, propels the screw and applies force onto the workpiece.

Importance in Industry

Friction screw presses play a critical role in industries where precise control over force application is essential. These presses are known for their ability to provide high force over short strokes, making them highly effective for various metal forming operations such as stamping, coining, embossing, and hot forging. Additionally, friction screw presses are commonly used in non-metallic applications, such as ceramics, where precise force control is also needed. The versatility of the friction screw press is one of the reasons it remains relevant across a range of industrial sectors.

Historical Development

The origins of the friction screw press date back to the late 19th and early 20th centuries, coinciding with the rise of industrialization and the demand for more efficient manufacturing methods. Early mechanical presses were driven by human or animal power, but the development of friction-based systems revolutionized the way industrial presses operated. With the introduction of the flywheel and friction drive mechanisms, presses could generate greater force while allowing more precise control over the process. The advent of friction screw presses significantly increased production speeds and the ability to form more complex shapes, laying the foundation for modern forging and metalworking industries.

Over time, friction screw presses have undergone continuous development, integrating modern technologies and materials. Today’s presses are designed to be more energy-efficient and feature improved control systems for greater precision. Despite the introduction of hydraulic and pneumatic presses, friction screw presses continue to be favored in many sectors due to their cost-efficiency, durability, and ability to perform well in high-volume production environments.

Principles of Operation

The operation of a friction screw press is based on the fundamental principles of mechanical energy, friction, and screw-driven motion. Understanding these principles helps in appreciating how the machine functions and why it is so effective in its various applications.

Mechanical Energy and Friction

At the heart of the friction screw press is the flywheel, which stores rotational energy. This energy is transferred to the screw mechanism via friction discs. The friction discs are typically connected to a motor, and they rotate when the motor is engaged. As the operator activates the press, the flywheel spins and generates the necessary energy. The friction discs then engage with the flywheel, converting this rotational energy into linear motion by turning the screw.

- Friction as a Driving Force: Friction plays a central role in the operation. By controlling the friction between the flywheel and the discs, operators can control the amount of energy transferred to the screw, thereby controlling the press’s force. The frictional engagement can be modulated depending on the requirements of the pressing operation, whether it’s a light embossing or a heavy forging.

The Screw and Ram Mechanism

The screw is the primary component that converts the rotational motion of the flywheel into linear motion. As the screw rotates, it moves the ram (a heavy component at the bottom of the press) up and down. The downstroke of the ram exerts the necessary pressure to deform or shape the workpiece positioned in the die below.

- The Role of the Ram: The ram is a key component because it applies the actual force required to compress or shape the material. The pressure exerted by the ram is proportional to the rotational speed of the flywheel and the force generated by the friction between the flywheel and friction discs. This provides the press with its characteristic advantage of delivering high force within a short stroke, making it especially useful for metal forming tasks that require significant force over a small area.

Step-by-Step Operation

- Initial Setup: Before operation, the workpiece is placed in the die, which is attached to the lower part of the press.

- Motor Activation: The press operator engages the motor, causing the flywheel to rotate.

- Friction Engagement: Once the flywheel reaches the desired rotational speed, the friction discs engage, transferring the rotational energy to the screw.

- Ram Movement: The screw converts this energy into linear motion, causing the ram to move downward and apply pressure to the workpiece.

- Material Deformation: Under the force of the ram, the material is compressed or shaped according to the design of the die.

- Ram Return: After the pressing operation is complete, the motor is reversed, or the flywheel is decelerated, causing the ram to retract, and the process can be repeated for the next workpiece.

Efficiency and Force Control

The friction screw press excels in applications where force control is essential. Unlike hydraulic presses, where force is generated through fluid pressure, friction screw presses allow for more immediate control of the applied force by adjusting the friction between the flywheel and discs. This level of control is especially useful for operations that require both light touches and high-impact force within the same workflow. Additionally, the short-stroke nature of the press allows it to operate with fewer cycles than other types of presses, resulting in higher production efficiency.

Advantages of the Friction Mechanism

- Precision: The friction mechanism offers exceptional control over the force applied, ensuring precise results in processes like coining or precision forging.

- Energy Conservation: The flywheel stores energy and allows the machine to use it as needed, making the system more energy-efficient than presses that require constant power input, such as hydraulic systems.

- Quick Setup: The operation of a friction screw press is relatively straightforward, and once the correct die and settings are in place, operators can quickly set up the press for mass production.

In summary, the operational principles of a friction screw press revolve around the efficient conversion of mechanical energy into pressing force through the use of friction. This system provides excellent control over force application, making it ideal for industries requiring precision and power in their production processes.

Key Components and Parts

The friction screw press consists of several essential components that work together to deliver the pressing force required in various industrial applications. Each part is carefully designed to withstand high levels of stress, friction, and heat, ensuring the machine’s durability and effectiveness. Below is a detailed look at the key components of a friction screw press:

1. Flywheel

The flywheel is one of the most important components of the friction screw press. It stores rotational energy that is later transferred to the screw mechanism to power the pressing operation. Flywheels in friction screw presses are typically heavy, solid discs designed to minimize energy loss and provide a consistent source of power throughout the press cycle.

- Energy Storage: The primary function of the flywheel is to store kinetic energy. This energy is accumulated when the flywheel spins at high speeds, driven by the motor. Once the friction discs engage, the energy is transferred from the flywheel to the screw and ram system.

- Inertia: Flywheels provide mechanical advantage by maintaining momentum. This is particularly beneficial in operations that require high-impact force over short periods. The larger and heavier the flywheel, the more energy it can store and transfer, contributing to the press’s efficiency.

2. Friction Discs

The friction discs are responsible for engaging and transferring the rotational energy from the flywheel to the screw. These discs are typically made of materials that can withstand high levels of friction and heat, such as composite ceramics or specialized steel alloys.

- Energy Transfer: When the operator initiates the press, the friction discs engage with the flywheel, transferring the stored energy to the screw mechanism. The amount of friction applied determines how much energy is transferred and, consequently, how much force is exerted by the press.

- Durability: Given that the discs are subject to continuous wear due to friction, they are made from materials that resist heat and mechanical stress. Periodic maintenance and replacement of the friction discs are crucial for the longevity of the machine.

3. Screw Mechanism

The screw is the central driving component of the press, responsible for converting the rotational motion from the flywheel into linear force. The screw, typically made of hardened steel, operates in a threaded mechanism that drives the ram downwards.

- Conversion of Motion: The rotational energy from the flywheel is converted into linear motion by the screw. As the screw rotates, it drives the ram downward, applying force to the workpiece. The precise threading of the screw allows for controlled and accurate force application, which is crucial in precision forging and forming tasks.

- Load Capacity: The screw is designed to withstand significant loads and stresses during operation. Proper lubrication of the screw is necessary to reduce wear and tear and ensure smooth operation.

4. Ram

The ram is the component that directly applies force onto the workpiece. Positioned at the bottom of the screw mechanism, the ram transfers the energy from the screw into the material being pressed.

- Force Application: The ram exerts the actual pressing force, deforming the material within the die. The size and design of the ram depend on the specific application of the press, ranging from small, precise rams for light operations to larger rams for heavy-duty forging.

- Precision: The ram’s movement is guided by the threaded screw mechanism, allowing for controlled force application. The accuracy of the ram’s downward stroke is essential in applications such as coin minting or precision metal stamping.

5. Frame

The frame of the friction screw press provides structural support for all the moving parts and components. It needs to be robust enough to withstand the enormous forces generated during the pressing operation. Frames are typically made of cast iron or steel, ensuring both strength and durability.

- Structural Integrity: The frame holds the entire machine together and absorbs the shock generated during pressing. A well-designed frame minimizes vibration and maintains the alignment of the screw, ram, and die during operation.

- Durability: Since the frame bears the brunt of mechanical stress during operation, it is constructed from materials with high tensile strength, such as steel or cast iron, and often reinforced with additional supports.

6. Motor

The motor powers the flywheel, initiating the energy transfer process. Motors in friction screw presses are typically electric and are designed to handle varying loads and speeds, depending on the press’s size and application.

- Power Generation: The motor provides the initial rotational force required to spin the flywheel. The size and power of the motor directly influence the amount of energy the press can store and use during operation.

- Variable Speed Control: In modern friction screw presses, the motor may feature variable speed control, allowing operators to adjust the flywheel’s speed based on the required pressing force. This feature enhances the versatility of the machine for different applications.

7. Die and Workpiece Holder

The die is a critical component that shapes the material during the pressing operation. The workpiece is placed within the die, and the force applied by the ram deforms it into the desired shape. Dies can be customized based on the specific product being manufactured, whether it’s a forged metal part, a stamped component, or a ceramic piece.

- Customization: Dies are typically custom-made for specific applications and can range from simple, flat surfaces to complex, multi-part shapes.

- Precision Manufacturing: The accuracy of the die is crucial for the quality of the finished product. Precision machining and engineering are required to ensure the die can withstand repeated high-pressure operations.

8. Clutch and Brake System

The clutch and brake system provides control over the press’s operation. The clutch engages the flywheel, transferring energy to the screw, while the brake system halts the operation when necessary.

- Clutch Engagement: The clutch allows the operator to control when the flywheel’s energy is transferred to the screw mechanism. This ensures that the press only operates when required, conserving energy and reducing wear on the machine.

- Braking for Safety: The brake system stops the ram and screw from continuing their downward motion, ensuring that the press can be safely halted in the event of an emergency or when the cycle is complete.

Types of Friction Screw Presses

Friction screw presses come in various designs and configurations, each suited to specific industrial applications. The differences between these presses are often based on their mechanical configurations, size, and intended use. The two most common types of friction screw presses are single-disc and double-disc models, though variations exist within these broad categories.

1. Single-Disc Friction Screw Press

A single-disc friction screw press features one friction disc that engages with the flywheel. This design is simpler and more compact, making it suitable for smaller operations or applications where force requirements are moderate.

- Advantages: Single-disc presses are generally easier to maintain and operate due to their simpler design. They are ideal for light forging, stamping, and other medium-duty applications.

- Limitations: While simpler, single-disc presses have limitations in terms of the maximum force they can generate, making them less suitable for heavy forging operations.

2. Double-Disc Friction Screw Press

Double-disc presses feature two friction discs that engage with the flywheel, allowing for greater energy transfer and, consequently, more force generation. These presses are typically larger and used in heavy-duty industrial applications.

- Advantages: The double-disc design allows for a more even distribution of force, which is beneficial in high-pressure operations like forging large metal parts. The additional friction surface enables the press to handle higher loads and provide more consistent force.

- Limitations: Due to their complexity and larger size, double-disc presses require more maintenance and are more expensive to operate and maintain compared to single-disc models.

3. Hydraulic vs. Mechanical Friction Screw Presses

While friction screw presses are mechanical, it is essential to understand how they differ from hydraulic presses.

- Mechanical (Friction Screw): As discussed, friction screw presses rely on mechanical energy stored in the flywheel. These presses provide quick energy release, making them suitable for rapid forging or stamping operations.

- Hydraulic Presses: These presses use fluid power to generate force. While they provide more consistent force over a more extended period, hydraulic presses are slower and often less energy-efficient compared to friction screw presses.

Applications of Friction Screw Presses

Friction screw presses have wide-ranging applications across multiple industries due to their ability to provide precise control over force, energy efficiency, and versatility in material forming processes. Their usage spans from heavy-duty metal forging to delicate precision tasks like coin minting or ceramic molding. Below are some of the most prominent industrial applications where friction screw presses are frequently used:

1. Metal Forging

One of the primary applications of friction screw presses is in metal forging, a manufacturing process that involves shaping metal using localized compressive forces. The energy-efficient operation and ability to deliver high force in a controlled manner make these presses ideal for forging tasks that require precision and strength.

- Hot Forging: Friction screw presses are commonly used in hot forging operations, where metal is heated until it becomes malleable and then pressed into desired shapes. The high energy storage in the flywheel allows the press to apply enough force to deform the heated metal, creating complex shapes with minimal wastage. This process is widely used in industries such as automotive, aerospace, and heavy machinery, where components like gears, crankshafts, and connecting rods are forged.

- Cold Forging: Although less common, friction screw presses can also be used in cold forging, where metals are shaped at room temperature. Cold forging requires more precise force control, as the material’s resistance is higher. Friction screw presses excel in this application due to their ability to generate high, consistent pressure, ensuring uniformity in the finished parts.

2. Ceramics and Powder Metallurgy

Friction screw presses are extensively used in industries that manufacture ceramics and powder metallurgy components. The precision force control provided by these presses makes them ideal for molding fine ceramic powders or metal particles into complex shapes before sintering.

- Ceramic Forming: In ceramic industries, friction screw presses are utilized to mold materials like clay or porcelain into specific shapes. The short, high-impact strokes of the press enable efficient compaction of the material, ensuring it fills the mold accurately and uniformly. Applications range from decorative ceramic items to industrial components such as insulators and tiles.

- Powder Metallurgy: In powder metallurgy, metal powders are compacted into shapes using friction screw presses. This process is often used to manufacture parts that would be difficult or costly to produce using traditional casting methods. The precise control over the pressing force allows manufacturers to achieve high density and uniformity in the compacted parts, which is essential for high-quality, durable components.

3. Coin Minting and Jewelry Production

The coin minting and jewelry production industries rely heavily on friction screw presses for their precision and ability to imprint fine details. In these applications, the press needs to apply controlled, consistent force to engrave intricate patterns or designs into the metal without damaging the material.

- Coin Minting: The high precision offered by friction screw presses makes them perfect for coin minting. The dies used in coin minting have intricate designs, and even minor inconsistencies in the force applied can result in defective coins. With friction screw presses, operators can control the force down to the smallest detail, ensuring the minting process is flawless. These presses can also be adjusted to mint coins of various sizes and materials, from standard currency coins to collectible medallions.

- Jewelry: Similarly, in the jewelry industry, friction screw presses are used to stamp designs onto metals like gold, silver, and platinum. The ability to finely control the pressure prevents damage to delicate metals while ensuring that the designs are embossed or engraved clearly.

4. Stamping and Embossing

Friction screw presses are frequently used in stamping and embossing processes, where high precision and speed are essential. These operations involve pressing a workpiece into a die to create a specific shape or pattern, often used in the production of metal parts, packaging, or artistic designs.

- Metal Stamping: In the metalworking industry, friction screw presses are used to create a variety of stamped products, including automotive parts, electronic components, and industrial fasteners. The high force generated by these presses allows for deep stamping in hard materials, making them ideal for heavy-duty operations.

- Embossing: Embossing involves creating raised or recessed designs on the surface of materials, often for decorative or functional purposes. Friction screw presses are capable of producing highly detailed embossing on materials like metal sheets, leather, and even certain plastics. This makes them popular in industries like packaging, signage, and decorative arts.

5. Refractory Materials

Another key application of friction screw presses is in the production of refractory materials, which are used in industries like steelmaking, glass production, and cement manufacturing. Refractory bricks and shapes must withstand extreme temperatures, and their production often involves compressing powders and materials into specific forms before they are fired in a kiln.

- Shaping Refractory Bricks: Friction screw presses are widely used to compress raw refractory materials into dense bricks or blocks. The precision control and high-pressure capabilities ensure that the materials are compacted thoroughly, which is essential for creating durable, heat-resistant products.

- Customization: The ability to customize the press settings allows manufacturers to produce a wide range of shapes and sizes, from standard bricks to complex, specialized components used in industrial furnaces and kilns.

6. Other Industrial Applications

Friction screw presses are also utilized in several other industries, showcasing their versatility and effectiveness in a wide range of applications.

- Agriculture: In the agricultural sector, friction screw presses are used to manufacture farming tools and equipment. The press’s ability to handle high-strength materials like steel makes it useful for forming parts for tractors, plows, and harvesting machinery.

- Textile Industry: In some instances, friction screw presses are employed in the production of textiles and related equipment. For example, they are used to shape and press components for textile machinery, ensuring durability and longevity under heavy use.

- Military and Defense: The military and defense sectors utilize friction screw presses for the production of equipment, ammunition casings, and other components that require high precision and durability. The press’s ability to shape metals with intricate detail and strong force is valuable for manufacturing parts for military vehicles, weaponry, and infrastructure.

Advantages of Friction Screw Presses in These Applications

The widespread application of friction screw presses in such a diverse range of industries highlights several inherent advantages of the technology:

- High Precision: Many applications, such as coin minting, jewelry making, and powder metallurgy, require extreme precision. Friction screw presses offer fine control over the force applied, ensuring that intricate details are perfectly replicated in each pressing operation.

- Energy Efficiency: The energy stored in the flywheel allows for high-impact force with minimal energy consumption compared to other press technologies. This makes friction screw presses more cost-effective in the long run, particularly in industries that require continuous, high-volume production.

- Versatility: From shaping ceramics to metal forging, friction screw presses can handle a wide range of materials and applications. Their ability to adjust pressure and force makes them adaptable to both heavy-duty operations and delicate, high-precision tasks.

- Durability and Longevity: Friction screw presses are designed to withstand the rigors of industrial use. Their robust construction and mechanical simplicity (compared to hydraulic systems) make them reliable and durable, which is especially important in industries where equipment downtime can lead to significant financial losses.

Advantages of Friction Screw Presses

Friction screw presses are known for several advantages that make them the preferred choice in various industries, despite the availability of other pressing technologies like hydraulic or pneumatic presses. Below are some key benefits:

1. Energy Efficiency

One of the most significant advantages of friction screw presses is their energy efficiency. The flywheel in these presses stores energy during idle times, which is then released during the pressing cycle. This system reduces the need for continuous energy input, making the press more economical in the long run.

- Lower Operational Costs: The efficient use of stored energy means that friction screw presses consume less power than hydraulic presses, which require constant energy to maintain pressure. This translates to lower electricity bills and operational costs, especially for companies running high-volume production.

2. Precision in Force Application

Friction screw presses offer excellent control over the force applied to the workpiece, making them ideal for industries requiring precision, such as coin minting and jewelry production. Operators can fine-tune the amount of friction applied between the flywheel and discs, ensuring the exact amount of force is transferred to the screw.

- Consistency: This precision also leads to consistent results across multiple operations. For example, in stamping or forging, each workpiece receives the same amount of pressure, reducing defects and waste.

3. Durability and Longevity

The simple, mechanical nature of friction screw presses makes them incredibly durable. Unlike hydraulic presses that rely on complex systems of pumps and fluid control, friction screw presses have fewer moving parts that are prone to wear and tear.

- Low Maintenance Requirements: The robust construction of friction screw presses reduces the need for frequent repairs or maintenance, allowing companies to maintain high production rates without significant downtime. This is especially important in industries that operate around the clock, where downtime can be costly.

4. Flexibility

Friction screw presses can handle a variety of materials and operations, from heavy metal forging to delicate ceramic shaping. The ability to control the force applied also makes them suitable for a range of applications, allowing manufacturers to use the same press for different production tasks.

- Multiple Industries: This flexibility is why friction screw presses are found in so many industries, from automotive manufacturing to pottery. Their versatility helps companies save on equipment costs by using a single machine for different operations.

Limitations and Challenges

While friction screw presses offer many advantages, they also come with certain limitations and challenges. Understanding these drawbacks is essential for industries that rely on these presses to ensure that they are used appropriately and efficiently. Below are some of the common limitations and challenges faced when working with friction screw presses:

1. Mechanical Wear and Tear

One of the primary challenges associated with friction screw presses is mechanical wear. Since the operation of the press relies on friction between the flywheel and friction discs, the repetitive engagement and disengagement create significant wear on these components over time. The constant exposure to high friction forces and heat leads to:

- Wear of Friction Discs: The friction discs in the press are particularly susceptible to wear. As they degrade, their ability to transfer energy efficiently is reduced, potentially leading to inconsistent force application and a drop in the press’s performance.

- Lubrication Needs: The screw mechanism itself requires regular lubrication to reduce wear between the moving parts. Insufficient lubrication can result in increased friction, causing overheating, more rapid deterioration of parts, and even mechanical failure.

Frequent maintenance is required to monitor and replace worn components. While friction screw presses have fewer parts than hydraulic presses, this wear and tear still results in downtime and increased operational costs for maintenance and part replacement.

2. Limited Stroke Length

Friction screw presses are known for their short stroke length compared to other types of presses, such as hydraulic presses. This limited stroke length can restrict the types of operations that friction screw presses can perform. The following challenges arise due to this limitation:

- High-Force, Short-Stroke Operations: While friction screw presses excel at applying high force in short bursts, they are not ideal for operations that require a longer, controlled stroke. For example, deep drawing processes, which involve pulling material into a die to create deep, hollow shapes, are better suited to hydraulic presses that can apply continuous pressure over a longer stroke.

- Difficulty with Large Components: Pressing large components or materials that require gradual deformation can be difficult with friction screw presses. Industries that need to process large workpieces often opt for hydraulic presses due to their ability to apply sustained pressure.

3. Challenges in High-Load Operations

Although friction screw presses can generate significant force, they may struggle in extremely high-load operations or environments where extremely large forces are consistently required. This limitation stems from their reliance on mechanical friction for energy transfer. For very large loads, hydraulic systems may be more suitable due to their superior force generation capabilities over prolonged strokes.

- Force Fluctuations: Because friction screw presses rely on the friction between the flywheel and discs, slight variations in friction can result in fluctuations in the applied force. In operations where extreme consistency is required, such as in precision forging of aerospace parts, these force variations may lead to quality control issues.

4. Energy Consumption at High Speeds

While friction screw presses are generally energy-efficient for many operations, they can consume a considerable amount of energy when operating at high speeds or when used for repetitive tasks over extended periods. This can result in:

- Flywheel Inertia Management: The flywheel must be kept at high rotational speeds to store energy, and maintaining this speed can require significant energy input, particularly for presses handling heavy-duty operations. As the press engages and disengages, energy is lost in the form of heat, leading to inefficiencies.

- Overheating and Heat Dissipation: Continuous use at high speeds can lead to overheating in the friction discs and the screw mechanism. Overheating reduces efficiency and can also lead to safety issues if not properly managed. Operators need to ensure that the press is not pushed beyond its thermal limits, as excessive heat can degrade materials, cause warping, or even result in part failure.

5. Maintenance and Downtime

The need for frequent maintenance is another limitation. While friction screw presses are more durable than their hydraulic counterparts, their reliance on friction and mechanical movement means that key components like the friction discs, screw, and ram are subject to regular wear. Without routine inspection and maintenance, performance can decline, leading to:

- Increased Downtime: As parts wear down, operators must halt production to replace or repair components. For industries that rely on continuous, high-volume production, this can lead to significant downtime, which can affect overall productivity and increase operational costs.

- Part Availability: Depending on the age and model of the press, finding replacement parts for older friction screw presses can be difficult, adding to potential delays in production.

6. Environmental Factors

Friction screw presses may face challenges in environments where extreme temperatures or corrosive conditions are present. The performance of the press can be affected by these external factors in several ways:

- Extreme Heat: In extremely high-temperature environments, the heat generated by the friction discs may combine with the external temperature to push the press components beyond their operational thresholds. This can lead to faster degradation of parts and increased wear.

- Corrosive Environments: In environments where the press is exposed to corrosive materials or humidity, key components such as the screw, ram, and friction discs may be subject to rust or corrosion, reducing their lifespan and efficiency. Special protective coatings or more frequent maintenance may be required to counteract these effects.

Conclusion

In summary, while friction screw presses offer numerous benefits, they do have some inherent limitations and challenges. Mechanical wear and tear, short stroke lengths, energy consumption at high speeds, and maintenance needs are all factors that industries must consider when deciding whether to use friction screw presses for their production processes. However, when used appropriately and maintained properly, these presses can provide long-lasting, reliable service in a variety of applications.

Materials and Construction

The materials and construction of friction screw presses play a critical role in their overall performance, durability, and efficiency. Given the extreme forces and friction involved in the operation of these presses, the materials used must be able to withstand mechanical stress, high temperatures, and wear over time. Advances in material science have also contributed to the development of more robust and efficient friction screw presses. Below is an overview of the materials commonly used in the construction of friction screw presses and how they contribute to the press’s functionality.

1. Frame and Structural Components

The frame and structural components of a friction screw press are typically made from materials that offer high strength and durability. The frame must be able to absorb and withstand the immense forces generated during the pressing operation without deforming or vibrating.

- Cast Iron: One of the most commonly used materials for the press frame is cast iron. It offers excellent strength, durability, and vibration-damping properties, making it ideal for large, heavy-duty presses. Cast iron is also relatively cost-effective, making it a popular choice for the construction of industrial machinery.

- Steel: In some cases, high-grade steel is used for the press frame and other structural components. Steel offers greater tensile strength compared to cast iron, allowing for thinner yet stronger frames. However, steel is generally more expensive than cast iron, so it is often used selectively in high-stress areas of the press.

2. Friction Discs

The friction discs are a critical component of the friction screw press, responsible for transferring energy from the flywheel to the screw mechanism. As the name suggests, these discs rely on friction to operate, so the materials used in their construction must be able to withstand high levels of heat and wear.

- Composite Ceramics: Modern friction discs are often made from composite ceramics, which offer excellent heat resistance and wear durability. Composite ceramics are designed to maintain their structural integrity even under high temperatures generated by friction, making them ideal for industrial applications where the press is used continuously.

- Hardened Steel Alloys: In some presses, hardened steel alloys are used for the friction discs. These alloys are treated to enhance their wear resistance and thermal conductivity, ensuring they can handle the stress of repeated engagement with the flywheel.

3. Screw Mechanism

The screw is the central component that translates the rotational energy from the flywheel into linear motion, driving the ram down to apply force on the workpiece. The screw must be made from materials that can withstand the high loads and stresses generated during operation.

- Hardened Steel: The screw is typically made from hardened steel, a material chosen for its high strength, toughness, and resistance to wear. Hardened steel undergoes heat treatment processes that enhance its durability, allowing the screw to perform consistently under heavy loads without deforming.

- High-Strength Alloys: In advanced friction screw presses, high-strength alloys may be used for the screw mechanism. These alloys are specifically designed to offer superior mechanical properties, including increased tensile strength, better resistance to fatigue, and improved durability under extreme pressures.

4. Ram

The ram is the component that directly applies pressure to the workpiece, and it must be able to transfer the full force generated by the screw mechanism. The material used for the ram needs to be both strong and wear-resistant, especially in applications where the press is used for heavy-duty forging or stamping.

- Tool Steel: Tool steel is commonly used for the ram because of its hardness and wear resistance. This type of steel is designed to withstand repeated impacts and pressure without losing its shape or structural integrity. Tool steel rams are particularly useful in applications where the press is used for forging hard metals like steel or titanium.

- Forged Steel: In some applications, the ram may be made from forged steel, which offers excellent toughness and fatigue resistance. Forging the steel ensures that the material has a uniform grain structure, increasing its strength and ability to withstand repeated cycles of high-pressure operations.

5. Flywheel

The flywheel is responsible for storing energy and transferring it to the friction discs and screw. The material used for the flywheel must have high inertia, strength, and the ability to withstand repeated rotational forces.

- Cast Iron or Steel: Flywheels are typically made from cast iron or steel due to the high density and strength of these materials. Cast iron is commonly used for its cost-effectiveness and vibration-damping properties, while steel is preferred for its greater tensile strength, which allows for more energy storage in a smaller, lighter flywheel.

6. Bearings and Bushings

The bearings and bushings in a friction screw press support the moving parts, ensuring smooth operation while reducing friction and wear. These components are crucial for the longevity of the press, as they help to minimize wear on the screw and ram mechanisms.

- Bronze: Bronze is a common material for bushings and bearings because of its low friction coefficient and excellent wear resistance. Bronze bearings are self-lubricating, reducing the need for frequent maintenance and ensuring smooth operation.

- Hardened Steel: Hardened steel bearings are also used in heavy-duty applications where the press is subjected to extreme forces. These bearings are heat-treated to enhance their hardness and durability, making them ideal for industrial presses that operate under high loads.

Modern Innovations and Technological Developments

The evolution of friction screw presses has been marked by significant technological advancements and innovations, especially in recent decades. As industries continue to demand higher precision, efficiency, and automation, manufacturers have developed new technologies that enhance the performance, durability, and versatility of these presses. Below, we explore some of the modern innovations and developments that have improved friction screw presses:

1. Computerized Control Systems

One of the most impactful innovations in friction screw presses is the integration of computerized control systems. These systems allow for the automation of many press operations, improving accuracy, consistency, and efficiency.

- Precision Force Control: Modern presses are equipped with computer-based controls that allow operators to precisely control the force applied during pressing operations. This level of control ensures that the press delivers consistent results, which is especially important in applications like coin minting, jewelry production, and precision forging. Computer systems can also monitor the force applied in real-time, ensuring that it matches the required specifications for each workpiece.

- Automated Adjustments: With computerized controls, friction screw presses can automatically adjust their settings for different tasks. For instance, the amount of energy transferred from the flywheel to the screw can be adjusted for different materials or processes, allowing the press to handle a wide range of applications without manual intervention. This level of automation significantly improves the efficiency of production lines and reduces human error.

2. Integration of Sensors and Monitoring Systems

Modern friction screw presses are often equipped with sensors and monitoring systems that track various operational parameters in real-time. These sensors provide critical feedback on the condition of the press, helping to prevent mechanical issues and improve safety.

- Force and Pressure Sensors: These sensors monitor the force applied by the press and provide feedback to ensure that it matches the desired specifications. This is particularly useful in precision applications where slight deviations in force could lead to defective parts or suboptimal performance. The sensors also help prevent overloading, which could damage the machine or compromise the quality of the workpiece.

- Temperature Sensors: Since friction screw presses generate significant heat during operation, temperature sensors are often installed to monitor the condition of the friction discs, screw, and bearings. By detecting excessive heat, the system can alert operators to potential issues before they cause serious damage or downtime. In some cases, the press will automatically reduce its operational speed or pause if temperatures exceed safe limits.

- Vibration Monitoring: Modern presses use vibration sensors to monitor the machine’s structural integrity. Excessive vibrations can indicate problems with the press’s components, such as misalignment or wear. Vibration monitoring helps maintain the longevity of the machine by alerting operators to issues early on, allowing for preventive maintenance before major failures occur.

3. Industry 4.0 and Smart Manufacturing

As part of the broader trend toward Industry 4.0, friction screw presses are becoming more connected and integrated into smart manufacturing systems. Industry 4.0 refers to the digital transformation of manufacturing, where machines, systems, and processes are connected through data exchange and automation.

- Internet of Things (IoT) Integration: IoT technologies allow friction screw presses to be connected to a network where they can communicate with other machines and systems in real time. This connectivity enables remote monitoring, diagnostics, and control, allowing operators to manage press operations from centralized control centers or even offsite locations.

- Predictive Maintenance: With the integration of sensors and IoT technologies, predictive maintenance is becoming a reality for friction screw presses. Data collected from the press during operation, such as temperature, force, and vibration metrics, can be analyzed to predict when maintenance is needed. This approach helps prevent unexpected machine failures and reduces downtime by allowing operators to schedule maintenance during periods of low production activity.

- Data Analytics for Optimization: Data from friction screw presses can be analyzed to optimize production processes. By understanding how the press performs under different conditions and materials, manufacturers can fine-tune their processes for maximum efficiency and output quality. This data-driven approach allows for continuous improvement in manufacturing operations.

4. Advanced Materials and Coatings

The development of advanced materials and coatings has significantly improved the durability and performance of friction screw presses. Innovations in material science have led to the creation of components that can withstand higher forces, temperatures, and wear, extending the lifespan of the machine and reducing maintenance costs.

- Ceramic Coatings: Many modern friction discs are coated with advanced ceramic materials that provide excellent resistance to heat and wear. These coatings improve the longevity of the discs and ensure consistent performance even in high-friction, high-temperature environments. Ceramic-coated components also require less frequent replacement, reducing the overall maintenance requirements of the press.

- Superalloys and Composites: The use of superalloys and composite materials in the construction of key press components, such as the screw and ram, has increased their ability to withstand extreme pressures and temperatures. Superalloys are engineered to maintain their strength and resistance to deformation even under the most demanding conditions, making them ideal for high-force pressing applications.

5. Improved Lubrication and Cooling Systems

Another key area of innovation is the development of enhanced lubrication and cooling systems for friction screw presses. These systems help manage the heat generated during operation and reduce friction between moving parts, leading to smoother operation and longer component life.

- Automatic Lubrication Systems: Many modern presses are equipped with automatic lubrication systems that apply lubricant to key components such as the screw and bearings at regular intervals. This ensures that the press operates smoothly and reduces the risk of component wear due to friction. Automatic lubrication also reduces the need for manual maintenance, increasing overall productivity.

- Enhanced Cooling Mechanisms: In addition to lubrication, modern friction screw presses often incorporate advanced cooling mechanisms to dissipate heat generated during pressing operations. Water-cooled or air-cooled systems are used to maintain optimal operating temperatures, especially in high-volume production environments. These cooling systems help prevent overheating, improving the press’s efficiency and safety.

6. Environmental Considerations and Sustainability

Sustainability has become a significant focus in modern manufacturing, and friction screw presses have benefited from innovations that reduce their environmental impact. The adoption of more efficient designs, materials, and processes helps industries meet their sustainability goals while maintaining high productivity.

- Energy Efficiency Improvements: Recent innovations in friction screw presses have focused on reducing energy consumption by improving the efficiency of the flywheel and friction disc systems. By optimizing the transfer of energy, modern presses can deliver the same level of force with less energy input, leading to lower operational costs and reduced environmental impact.

- Recycling and Waste Reduction: Advanced materials used in the construction of modern presses are often designed to be recyclable, contributing to a circular economy. Additionally, precise control over pressing operations helps reduce material waste by minimizing the number of defective parts produced.

Conclusion

Modern innovations in friction screw presses have dramatically improved their performance, efficiency, and sustainability. The integration of computerized controls, sensors, IoT technologies, advanced materials, and improved lubrication systems has made friction screw presses more reliable and versatile than ever before. These developments ensure that friction screw presses will continue to play a critical role in manufacturing processes across a wide range of industries, from automotive to precision metalworking.

Maintenance and Care of Friction Screw Presses

Proper maintenance is crucial to ensure that friction screw presses operate efficiently and have a long service life. Regular upkeep helps prevent breakdowns, reduces downtime, and ensures consistent performance across various applications. Below, we outline essential maintenance practices and care tips for friction screw presses:

1. Routine Lubrication

One of the most critical aspects of maintaining a friction screw press is routine lubrication of moving parts, such as the screw, bearings, and friction discs.

- Screw Lubrication: The screw mechanism should be regularly lubricated to reduce friction and wear. Without adequate lubrication, the screw can become difficult to operate, leading to mechanical strain and faster wear.

- Friction Discs: Although friction discs are designed to generate friction, they also need proper lubrication to ensure smooth engagement with the flywheel. Care should be taken to use the correct type of lubricant, as some materials are sensitive to certain oils or greases.

- Automated Lubrication Systems: Many modern presses are equipped with automated lubrication systems, which apply lubricant at preset intervals. These systems ensure consistent lubrication and can be monitored for proper operation.

2. Regular Inspection of Key Components

Frequent inspections of the press’s critical components are necessary to identify potential issues before they lead to mechanical failure.

- Friction Discs and Flywheel: Regularly inspect the friction discs for wear and tear. Any visible signs of degradation, such as thinning or heat damage, should prompt immediate replacement. The flywheel should also be checked for balance and alignment to prevent uneven force distribution.

- Screw and Ram: The screw and ram must be inspected for signs of wear, such as scoring or misalignment. Minor issues can often be resolved with proper lubrication or realignment, but major wear may require part replacement to prevent operational failure.

3. Cleaning and Debris Removal

Friction screw presses should be kept clean to avoid the accumulation of debris, dust, or foreign materials, which can interfere with the machine’s operation.

- Clean Press Surfaces: Keeping the press clean, especially around the friction discs and flywheel, ensures that no foreign particles interfere with the engagement of these parts. Cleaning also prevents contaminants from entering critical areas like bearings or the screw.

- Preventive Measures: In high-dust environments, it’s beneficial to use protective covers or enclosures to shield the press from contamination.

Safety Standards and Best Practices

Operating a friction screw press involves significant force and energy, making it essential to adhere to stringent safety standards and implement best practices to protect operators and ensure safe, efficient operations. Proper safety measures not only prevent accidents but also enhance productivity by minimizing machine downtime and reducing the risk of equipment damage. Below, we outline the critical safety standards and best practices for operating friction screw presses.

1. Adhering to Regulatory Safety Standards

Friction screw presses are subject to occupational health and safety regulations, which vary by region but often include similar guidelines for ensuring safe operation in an industrial setting. Compliance with these regulations is mandatory to avoid fines, legal liability, and, more importantly, to safeguard the health and safety of workers.

- OSHA (Occupational Safety and Health Administration) in the United States sets forth guidelines for the operation of mechanical presses, including friction screw presses. These guidelines mandate regular inspections, operator training, and the use of safety features such as emergency stop buttons and guards.

- CE Marking (Conformité Européenne) in Europe certifies that machinery complies with the essential health and safety requirements of the EU. Friction screw presses must meet the standards set out in directives such as the Machinery Directive (2006/42/EC), which governs mechanical safety and operator protection.

2. Operator Training and Certification

Proper training is a critical component of safe press operation. Operators must be trained not only in how to use the friction screw press but also in identifying potential hazards and using the machine’s safety features.

- Comprehensive Training Programs: Operators should undergo comprehensive training programs that cover all aspects of the machine’s operation, including how to start, operate, and shut down the press safely. Training should also address troubleshooting common issues, such as identifying signs of component wear or malfunction.

- Operator Certification: In some jurisdictions and industries, it is mandatory for operators to be certified before they are allowed to operate a friction screw press. Certification ensures that operators have a thorough understanding of safety protocols, which helps to reduce workplace accidents.

3. Use of Safety Guards and Barriers

Friction screw presses must be equipped with safety guards and barriers to protect operators from accidental contact with moving parts, such as the ram, screw, and flywheel. These safety features are essential in preventing injuries during operation.

- Physical Guards: Physical barriers or guards are installed around moving parts to prevent accidental contact. For example, guards around the ram or screw mechanism help to protect the operator from crushing or entanglement injuries.

- Light Curtains and Sensors: In modern presses, light curtains or safety sensors can be used to detect the presence of an operator’s hand or body near dangerous parts of the machine. If the sensor detects an object in its path, the press is automatically stopped to prevent injury.

4. Emergency Stop and Shutoff Systems

Friction screw presses should be equipped with emergency stop systems that allow operators to halt the machine instantly in the event of a malfunction or emergency. These systems are critical for preventing accidents and minimizing the damage to the machine or workpiece.

- Emergency Stop Buttons: The press should have clearly labeled, easily accessible emergency stop buttons that immediately cut power to the machine and disengage the friction discs. Operators must be trained to use these buttons in case of emergencies.

- Brake Systems: Many friction screw presses are equipped with brake systems that engage automatically when the press is stopped. These brakes ensure that the ram does not continue to descend after the machine is powered down, reducing the risk of unintended operations.

5. Regular Maintenance for Safety

Routine maintenance is not only essential for ensuring the longevity and performance of a friction screw press but also for maintaining safety. Worn or damaged components can lead to accidents if not addressed promptly, making regular inspections a crucial part of press operation.

- Scheduled Inspections: Regular inspections of the machine’s key components, such as the friction discs, screw, ram, and bearings, help identify potential issues before they escalate. Operators should look for signs of wear, such as thinning discs or unusual vibrations, and schedule maintenance as necessary.

- Replacing Worn Parts: Worn components must be replaced as soon as they are identified. For example, worn friction discs can reduce the efficiency of energy transfer, leading to erratic press performance. Similarly, worn bearings or bushings can increase friction and heat, potentially causing parts to seize or fail.

6. Personal Protective Equipment (PPE)

Operators of friction screw presses must always wear appropriate personal protective equipment (PPE) to minimize the risk of injury from machine operation or material handling. Depending on the specific application, the following PPE may be required:

- Gloves: Heat-resistant gloves should be worn when handling hot materials during forging operations. Gloves also protect the hands from cuts and abrasions when handling sharp or rough materials.

- Safety Goggles: Eye protection is essential to shield the operator from flying debris, sparks, or fragments of the workpiece that may be ejected during pressing.

- Hearing Protection: Press operations can generate significant noise, especially in metal forging or stamping applications. Hearing protection, such as earplugs or noise-canceling earmuffs, should be worn to protect against hearing damage.

7. Ergonomics and Operator Fatigue Management

While much of the safety focus is on mechanical hazards, ergonomic considerations are also important to ensure that operators can work comfortably and without strain. Poor ergonomic practices can lead to long-term injuries, such as musculoskeletal disorders.

- Adjustable Workstations: Press workstations should be adjustable to accommodate the height and reach of individual operators. This reduces the risk of back strain, repetitive motion injuries, and fatigue.

- Rest Breaks and Rotation: Operators should be encouraged to take regular breaks and rotate tasks to avoid fatigue, which can lead to mistakes or accidents. Fatigue is a significant factor in workplace accidents, particularly in industries that require repetitive manual tasks.

Conclusion

Ensuring the safe operation of a friction screw press requires a combination of adherence to regulatory standards, proper training, and the use of protective measures. From physical guards and emergency stop systems to the consistent use of PPE and ergonomic practices, every aspect of press operation must prioritize the safety and well-being of operators. By implementing these best practices, companies can not only protect their workforce but also improve efficiency and maintain compliance with safety regulations.

Environmental Impact and Sustainability

With the growing emphasis on sustainability and reducing the environmental footprint of industrial processes, friction screw presses have undergone various changes to align with more environmentally friendly practices. While traditionally associated with high energy consumption due to their mechanical nature, modern friction screw presses have been optimized to minimize energy use and promote sustainability in several ways. Below, we explore the environmental impact of friction screw presses and the steps being taken to enhance their sustainability.

1. Energy Consumption

One of the most significant environmental concerns for any industrial press, including friction screw presses, is energy consumption. Historically, mechanical presses have been energy-intensive, but modern innovations have helped reduce their environmental impact by improving energy efficiency.

- Flywheel Optimization: In friction screw presses, the flywheel stores rotational energy, which is then released as needed during pressing. By optimizing the size and material of the flywheel, modern presses can store energy more efficiently, reducing the amount of energy lost as heat. This leads to lower overall power consumption during operation.

- Variable Speed Drives: Some modern friction screw presses are equipped with variable speed drives that allow operators to adjust the speed of the motor based on the specific needs of the application. By only using the necessary amount of energy for each pressing operation, these systems can reduce energy waste and improve overall efficiency.

2. Sustainable Materials

Another key area of focus for reducing the environmental impact of friction screw presses is the use of sustainable materials in their construction. Advanced materials not only improve the durability and performance of the press but also contribute to a more sustainable manufacturing process.

- Recyclable Components: Many modern friction screw presses are designed with components made from recyclable materials, such as steel and aluminum. When parts wear out or are replaced, these materials can be recycled and reused, reducing waste and the need for new raw materials.

- Advanced Coatings: The use of advanced, eco-friendly coatings on key components, such as the screw and friction discs, helps to extend the life of these parts and reduce the frequency of replacements. Coatings made from non-toxic, environmentally safe materials also contribute to a more sustainable production process.

3. Waste Reduction and Resource Efficiency

Friction screw presses have also been optimized to minimize material waste during production, particularly in industries like metal forging and ceramics, where raw materials can be expensive and resource-intensive to produce.

- Precision Forging: The high level of precision offered by modern friction screw presses ensures that raw materials are used efficiently. By reducing the number of defective parts or excessive material deformation, less waste is produced, leading to more sustainable manufacturing operations.

- Reuse of Scrap Materials: Many industries that use friction screw presses have implemented scrap recycling systems, where leftover or scrap materials from forging or stamping operations are collected and melted down for reuse. This practice reduces the overall demand for new raw materials and minimizes waste sent to landfills.

4. Lower Emissions

While friction screw presses are primarily mechanical and do not directly produce emissions during operation, their overall environmental impact can still be influenced by the energy sources used to power them. Reducing emissions is a critical aspect of making these machines more sustainable.

- Renewable Energy Integration: Some manufacturing facilities that use friction screw presses are incorporating renewable energy sources like solar or wind power to reduce their reliance on fossil fuels. By using cleaner energy to power their presses, companies can significantly lower their carbon footprint.

- Energy Recovery Systems: In certain applications, energy recovery systems can be integrated into the press’s operation, capturing excess heat or mechanical energy and converting it back into usable power. This helps reduce overall energy consumption and lowers the environmental impact of the press.

5. Sustainability Certifications

As part of the broader movement toward sustainability in manufacturing, many companies that use friction screw presses are seeking sustainability certifications such as ISO 14001, which is the international standard for environmental management systems.

- ISO 14001 Compliance: Achieving ISO 14001 certification demonstrates that a company is committed to minimizing its environmental impact. This certification requires companies to implement systems that reduce waste, lower emissions, and conserve resources, which are all relevant for operations that rely on energy-intensive equipment like friction screw presses.

- Lifecycle Assessments (LCAs): Some manufacturers are conducting lifecycle assessments of their friction screw presses to evaluate the environmental impact of the machines from production to disposal. These assessments help identify opportunities to make the press more sustainable throughout its lifecycle, from the materials used in its construction to its energy consumption during operation.

Conclusion

The environmental impact of friction screw presses has been significantly reduced in recent years due to technological innovations and a growing focus on sustainability. By improving energy efficiency, using sustainable materials, and reducing waste, modern friction screw presses align with the broader goals of eco-friendly manufacturing. As industries continue to prioritize sustainability, friction screw presses will play a key role in minimizing the environmental footprint of production processes.

Selecting the Right Friction Screw Press for Your Business

Choosing the right friction screw press for your business involves considering various factors, including the type of materials you will be processing, the production capacity needed, and the specific applications for which the press will be used. Below is a guide to help you select the best friction screw press based on your requirements.

1. Determine Your Production Requirements

The first step in selecting the right friction screw press is to clearly define your production requirements. Understanding the scale of your operations, the materials you work with, and the types of products you produce will guide your decision.

- Material Type: Different materials require different levels of force and precision. For example, heavy metals like steel require higher force presses, whereas softer materials, such as aluminum or ceramics, may need a press with more precise control over force application.

- Production Volume: If your business operates in a high-volume production environment, you will need a press that can handle continuous operation without frequent downtime for maintenance. Presses designed for heavy-duty use tend to have larger flywheels, stronger frames, and more durable components.

- Product Complexity: For complex parts that require intricate designs or multiple stages of pressing, a friction screw press with advanced control systems and precise force application may be necessary.

2. Evaluate Press Capacity

The capacity of the friction screw press refers to the maximum force it can exert during operation. This is a crucial factor to consider, as choosing a press with insufficient capacity can lead to poor product quality or equipment damage.

- Force Rating: Friction screw presses are typically rated by the maximum force they can apply, measured in tons. The size of the flywheel and the strength of the screw mechanism determine this force. Selecting a press with the appropriate tonnage is essential for ensuring that the press can handle the material thickness and workpiece dimensions.

- Stroke Length: The stroke length refers to how far the ram travels during operation. If you are working with deep-drawing processes or large components, a longer stroke length may be required to complete the pressing cycle effectively.

3. Consider Operational Efficiency

Efficiency is an important consideration when selecting a friction screw press, especially in high-volume production environments. Factors such as cycle time, energy consumption, and ease of maintenance can significantly impact overall operational costs.

- Cycle Time: For businesses that rely on quick turnaround times, the speed of the press’s cycle is a critical factor. Presses with optimized friction disc engagement systems and automated controls can achieve faster cycle times, improving throughput and efficiency.

- Energy Consumption: Energy-efficient presses, especially those with advanced flywheel designs and variable speed drives, can lower operational costs by reducing power consumption. Evaluating the energy requirements of a press is especially important if your business is focused on sustainability and reducing its environmental impact.

4. Review Maintenance Requirements

Maintenance plays a key role in the longevity and performance of friction screw presses. Some models are designed with low-maintenance features, such as automatic lubrication systems and durable, wear-resistant components, which can minimize the need for frequent maintenance.