Grinding: A grinding machine for metal surfaces is a power tool used to achieve a smooth or accurate finish on metal workpieces. It removes material using an abrasive wheel as the cutting tool. These machines are essential in metalworking for finishing operations, shaping, or sharpening.

Types of Grinding Machines for Metal Surfaces

- Surface Grinding Machine

- Used for flat surfaces.

- Features a rotating abrasive wheel and a work table that moves back and forth.

- Types:

- Horizontal-spindle (peripheral) grinders

- Vertical-spindle (rotary) grinders

- Cylindrical Grinding Machine

- Grinds the outer surfaces of cylindrical workpieces.

- Suitable for shafts, rods, and sleeves.

- Centerless Grinding Machine

- The workpiece is held between two wheels (a grinding wheel and a regulating wheel).

- Ideal for high-volume production of cylindrical parts without centers.

- Bench Grinder

- Small, manual machine with two grinding wheels.

- Used for sharpening tools and rough grinding.

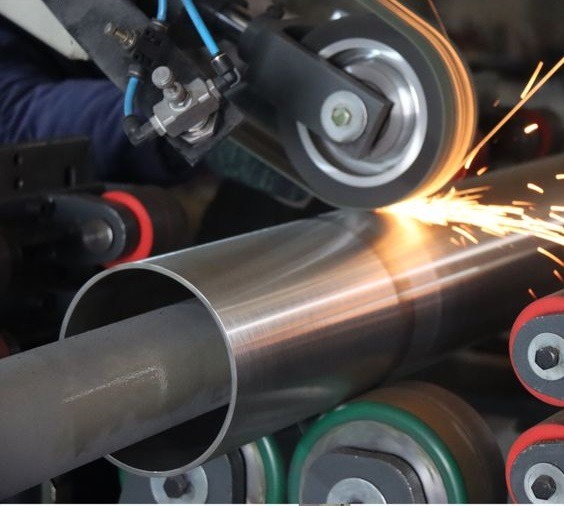

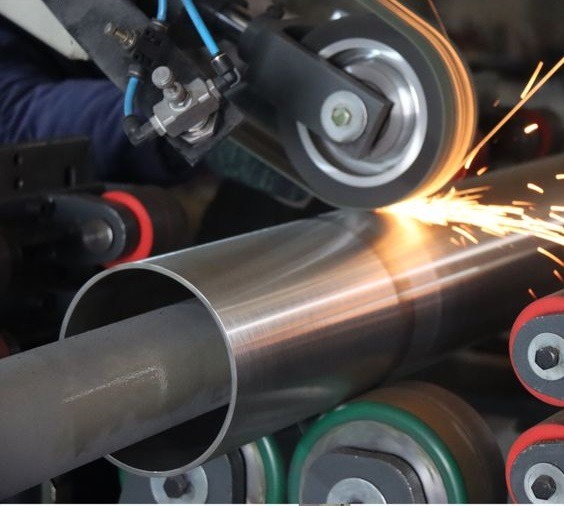

- Belt Grinder

- Uses a coated abrasive belt.

- Effective for deburring, polishing, and surface finishing.

- Tool and Cutter Grinder

- Specially designed for tool sharpening.

- Often CNC-controlled for precision.

- Rotary Surface Grinder

- Workpiece is mounted on a rotating table.

- Allows for high production rates on large flat surfaces.

Key Features to Consider

- Abrasive wheel type (aluminum oxide, silicon carbide, etc.)

- Machine power and speed

- Table size and travel range

- Coolant system to prevent overheating

- Automation level (manual, semi-automatic, or CNC)

Common Applications

- Surface finishing of metal plates or molds

- Grinding flat surfaces for precision machinery parts

- Deburring edges after machining or welding

- Sharpening cutting tools

A grinding machine for metal surfaces is a precision tool used to remove small amounts of material from metal workpieces to achieve a desired surface finish, shape, or dimension. It operates using an abrasive wheel that cuts or wears down the surface of the metal. These machines are commonly used in manufacturing, metal fabrication, and tool-making industries.

Surface grinding machines are widely used when a smooth, flat surface is required. They typically consist of a rotating abrasive wheel and a work table that moves either longitudinally or reciprocally beneath the wheel. The grinding wheel is usually made of abrasive materials like aluminum oxide or silicon carbide, depending on the hardness and type of metal being worked on.

There are also cylindrical grinding machines that handle round workpieces, typically rotating them against the grinding wheel to ensure even removal of material along their curved surface. In contrast, centerless grinders don’t require the workpiece to be mounted between centers but instead use a system of wheels to position and rotate the part, making them ideal for mass production of rods and pins.

Bench grinders are smaller, usually manually operated machines with two grinding wheels on either side. These are used for tool sharpening, deburring, and basic grinding tasks. For more aggressive or flexible grinding, belt grinders use abrasive belts to remove material quickly and are often employed in metal fabrication shops for finishing edges or smoothing welds.

Tool and cutter grinders are specialized machines used primarily for sharpening cutting tools like drill bits and milling cutters, often with complex geometry. Rotary surface grinders, with rotating work tables, allow for high-speed grinding of large flat surfaces and are common in mold making and die finishing.

Regardless of type, effective grinding requires appropriate wheel selection, proper work holding, and often a coolant system to control heat generated during the process. Automation and CNC capabilities are also integrated into many modern grinding machines, enabling higher precision, repeatability, and throughput in industrial settings.

In industrial environments, grinding machines play a critical role in achieving tight tolerances and fine surface finishes that are often beyond the capabilities of other machining methods. The abrasive action is not only effective in shaping and smoothing metal but also in removing surface imperfections such as scale, oxidation, or minor deformations caused by prior machining or welding processes.

The performance of a grinding machine depends heavily on the type and condition of the abrasive wheel. Wheel hardness, grain size, and bonding material influence both the cutting efficiency and the surface finish. For example, a coarser grit wheel removes material quickly but leaves a rougher surface, while a finer grit produces smoother finishes with slower material removal. The wheel must also be regularly dressed to maintain its cutting ability and profile, especially in high-precision applications.

Heat generation is another important consideration. Excessive heat can cause metal surfaces to warp, harden, or develop microscopic cracks. This is why many grinding machines include coolant systems that spray cutting fluid over the workpiece and wheel to reduce friction, carry away debris, and maintain dimensional stability. Coolants can be water-based or oil-based depending on the specific grinding application.

Workholding systems vary by machine type and application. Surface grinders may use magnetic chucks for holding ferrous workpieces, while non-magnetic parts require mechanical or vacuum clamping. Precision and repeatability in grinding operations are heavily influenced by the rigidity and accuracy of the setup.

Modern grinding machines, especially CNC-controlled models, are capable of complex tasks such as contour grinding, thread grinding, and multi-surface operations in a single setup. These capabilities have made grinding machines essential in fields like aerospace, automotive, mold and die production, and tool making, where both surface quality and dimensional precision are critical.

In maintenance and repair settings, grinding is often used to restore worn components to their original specifications, particularly when machining new parts is not feasible or economical. Additionally, grinding can be used as a final finishing step after processes like milling, turning, or welding to ensure the part meets precise engineering standards.

Centerless Grinding Machine

A centerless grinding machine is a specialized type of grinding tool used for machining the outer surface of cylindrical parts without the need for centers or chucks to hold the workpiece. Instead of being fixed in place, the workpiece is supported by a combination of a regulating wheel, a grinding wheel, and a workrest blade. This setup allows for continuous, high-speed, and high-precision grinding of round or slightly tapered components.

In centerless grinding, the workpiece is placed between two rotating wheels: the grinding wheel, which performs the cutting action, and the regulating wheel, which controls the rotational speed and axial movement of the workpiece. The workrest blade, located beneath the part, supports it at the correct height and angle. As the regulating wheel rotates at a slower speed and with an angled axis, it feeds the workpiece through the grinding wheel while spinning it. This arrangement allows for uninterrupted grinding of long bars or small parts in large quantities.

There are two main types of centerless grinding:

- Through-feed grinding: The workpiece is fed continuously through the space between the wheels. This method is fast and ideal for grinding straight cylindrical parts like rods, pins, or tubes.

- In-feed (or plunge) grinding: The workpiece is fed in and ground in a fixed position without axial movement. This method is used for parts with complex shapes or features, such as shoulders or grooves.

Centerless grinding is widely used in automotive, aerospace, medical device manufacturing, and general metalworking. It’s known for its high production rate, tight tolerances, and excellent surface finish. The process is particularly well-suited for producing small, high-precision parts such as fuel injector components, valve pins, bearing races, and hydraulic pistons.

One of the key advantages of centerless grinding is that it eliminates the need for workholding fixtures, reducing setup time and enabling quick changeovers between different part sizes. However, the process does require precise setup of the wheels and blade, as even small misalignments can affect part quality.

Overall, centerless grinding is a highly efficient and repeatable process for producing cylindrical metal parts in large volumes with excellent dimensional accuracy and surface quality.

Centerless grinding machines operate on a fundamentally different principle compared to other grinding methods that use centers or chucks. In a centerless system, the absence of a fixed center allows for faster operation and easy automation, especially for high-volume production. The regulating wheel plays a crucial role by not only rotating the workpiece but also controlling its axial feed. Its speed, angle, and friction all influence the final dimensions and surface finish of the part. The grinding wheel, typically made of abrasive materials like aluminum oxide or cubic boron nitride, does the actual cutting by removing material from the surface of the rotating workpiece.

The workrest blade, often made from hardened tool steel or tungsten carbide, supports the workpiece during grinding. The blade height is critical—it must be set accurately to maintain the proper relationship between the workpiece centerline and the wheel centerlines. If this alignment is off, it can lead to tapering, poor roundness, or surface irregularities.

One of the unique advantages of centerless grinding is its ability to grind long or flexible parts that would be difficult to support using traditional chuck-based methods. Since the part is continuously supported along its length, centerless grinders can handle thin, delicate, or slender parts that would otherwise deflect under pressure. This makes it ideal for applications like medical guidewires, small shafts, or pump pins where maintaining straightness and concentricity is critical.

Centerless grinding is also favored for its efficiency. The continuous nature of through-feed grinding allows for non-stop processing of parts, significantly increasing throughput. Even complex geometries can be handled with in-feed setups, though they require more careful setup and sometimes custom tooling to hold tight tolerances or profile-specific shapes.

Despite its many advantages, centerless grinding requires a highly skilled setup. Wheel dressing must be done with precision to ensure the wheels maintain their shape and sharpness. Temperature control is another factor, as excessive heat during grinding can cause thermal expansion, leading to dimensional errors. Many modern machines incorporate advanced cooling systems and CNC control to adjust parameters dynamically and maintain process stability.

In terms of applications, centerless grinding is indispensable in industries that demand high-precision, high-volume production. Automotive manufacturers use it for lifter pins, camshafts, and piston rods. The bearing industry uses it for outer and inner races, while the aerospace and defense sectors rely on it for precision shafts and bushings. Because it produces superior roundness and surface finish with minimal handling, it’s also popular in industries that require tight dimensional control and consistent part quality.

Automation has further enhanced the capability of centerless grinding machines. Integrated loading and unloading systems, gauging systems for in-process measurement, and automatic wheel balancing make modern machines highly productive and consistent. As a result, centerless grinding continues to be a preferred solution for precision machining where reliability, speed, and repeatability are essential.

As centerless grinding continues to evolve, machine builders have introduced a range of enhancements that improve precision, adaptability, and efficiency. CNC control systems allow for programmable adjustments of wheel speeds, positioning, and dressing cycles, making it easier to switch between part designs with minimal downtime. This flexibility is especially valuable in job shops or operations where frequent changeovers are required. CNC systems also enhance repeatability by ensuring consistent setup and operation parameters across shifts and production runs.

Wheel dressing technology has also advanced. Automatic diamond dressers shape the grinding and regulating wheels in real time, maintaining optimal form and sharpness throughout the grinding process. Proper wheel dressing is critical not only for surface finish but also for maintaining dimensional consistency over large production runs. Dressing units are now programmable and can compensate for wear, which is crucial for long runs of small-tolerance components.

Materials processed through centerless grinding range from soft aluminum and brass to hardened tool steels and superalloys. Depending on the application, different wheel compositions and bonding agents are used to optimize performance and extend wheel life. For example, vitrified-bonded wheels offer excellent form-holding capabilities and are suitable for heavy-duty grinding, while resin-bonded wheels provide better surface finish on softer materials.

Another consideration is the use of coolant. Grinding generates significant heat, and without proper cooling, thermal expansion can alter part dimensions, degrade surface finish, or even cause metallurgical damage such as burns or microcracking. Modern centerless grinders often feature advanced coolant filtration and delivery systems, including high-pressure and directed nozzles that deliver coolant exactly where it is needed most—at the contact point between wheel and workpiece.

Noise, vibration, and environmental control have also seen improvements. Machines are now designed with better damping materials and acoustic enclosures to reduce operator fatigue and comply with stricter workplace standards. Dust extraction and mist collection systems ensure that grinding residues and coolant vapors are safely managed, protecting both workers and equipment.

In terms of tolerances, centerless grinding can achieve roundness within 0.001 mm and surface finishes down to Ra 0.05 µm, depending on the material and wheel choice. These capabilities make it suitable not just for rough stock removal but for finishing precision components. Automated inspection and in-process gauging systems are often integrated to continuously monitor part dimensions, enabling real-time feedback and adjustments that further enhance process reliability.

The future of centerless grinding is leaning towards greater digitization and process integration. Smart machines are increasingly capable of self-monitoring, alerting operators to issues like wheel wear, improper dressing, or coolant problems. These features minimize downtime and reduce the need for constant supervision. In high-end production environments, centerless grinding lines may be fully automated—from raw stock feeding to finished part ejection—operating around the clock with minimal human intervention.

Ultimately, centerless grinding stands out not just for its speed but for its ability to produce extremely accurate, consistent results at scale. Whether for high-volume automotive components, aerospace-grade shafts, or micro-sized medical pins, it remains a cornerstone of modern precision manufacturing.

Plunge Cut Centerless Grinding

Plunge cut centerless grinding (also known as in-feed centerless grinding) is a variation of the centerless grinding process where the grinding wheel is fed radially into a fixed-length workpiece rather than allowing it to pass continuously through the machine as in through-feed grinding. This method is ideal for producing complex or non-uniform cylindrical shapes that have shoulders, grooves, or varying diameters—features that cannot be made with a continuous feed.

In plunge grinding, the workpiece is positioned between the grinding wheel and the regulating wheel and supported on a fixed workrest blade. Unlike through-feed grinding, the regulating wheel does not move the part axially. Instead, the grinding wheel plunges directly into the part to remove material. Both the grinding wheel and the regulating wheel maintain rotational motion, allowing for efficient material removal while keeping the part stable.

This method is commonly used for parts like valve spools, gear blanks, piston pins, and fasteners where a specific section of the workpiece needs to be ground while leaving other sections untouched. It’s particularly effective when the workpiece has features that prevent axial movement, such as flanges or heads.

One key to effective plunge cut centerless grinding is precise setup. The wheel shapes must be dressed to match the desired profile of the part. For example, if the part has a shoulder or step, the grinding wheel must be dressed with a corresponding contour to create that geometry. Advanced machines often feature CNC wheel dressing systems that allow for intricate and highly accurate profiles.

Coolant application is critical in plunge grinding, since the entire grinding action is concentrated in a smaller area and generates more localized heat. Proper coolant flow helps control temperatures, prevent burning, and flush away grinding debris. Machines are typically equipped with high-precision flow nozzles and filtration systems to manage this.

Plunge cut centerless grinding also benefits from in-process gauging, which measures the part while it is being ground. This allows for real-time feedback and automatic compensation for wheel wear or thermal expansion, ensuring consistent part quality.

While not as fast as through-feed grinding, plunge grinding offers the versatility and accuracy needed for parts with complex geometries and tight tolerances. It’s widely used in industries like automotive, aerospace, hydraulics, and medical devices, where precision and repeatability are critical.

Plunge cut centerless grinding continues to be a preferred method when parts require detailed profiling or multiple diameters ground in a single operation. Because the part remains stationary in the axial direction, the operator or machine programmer has much more control over where material is removed, allowing for complex profiles and tightly specified geometries to be achieved consistently. This makes it particularly effective for short-run, high-precision components or parts that would otherwise require multiple setups on other machines.

The setup for plunge grinding is more intricate than through-feed. The grinding wheel must be carefully dressed not just for sharpness but also to the exact contour required for the finished part profile. This is often done with diamond dressing tools that move in programmable paths, enabling even concave or compound shapes to be formed on the grinding wheel. These dressers are mounted on dedicated arms and can be controlled by the machine’s CNC system to ensure absolute precision.

The regulating wheel, while not feeding the part axially, still plays a key role in controlling rotation and stabilizing the part during grinding. Its surface texture, hardness, and inclination angle directly affect the surface finish and concentricity of the workpiece. The angle and pressure applied by the regulating wheel need to be balanced precisely to prevent slippage or chatter, which could degrade the surface or dimensional accuracy.

Another critical factor in plunge grinding is thermal management. Because the grinding action is concentrated in one area and often deeper, heat builds up more rapidly. Without sufficient cooling, this can lead to localized thermal expansion, which affects part tolerances, or even surface burns and metallurgical damage. Sophisticated coolant systems with variable pressure and multi-nozzle configurations are used to direct fluid precisely at the grinding zone, ensuring both lubrication and effective heat dissipation.

Cycle time in plunge grinding is typically longer than in through-feed because of the more localized grinding zone and the need to carefully control wheel feed rates to avoid overloading or damaging the part. However, the tradeoff is greater precision and the ability to finish parts that would otherwise require multiple machining steps. Some machines combine plunge grinding with secondary processes like polishing or deburring, reducing the need for downstream finishing and improving overall efficiency.

Automation can also be integrated into plunge cut centerless systems, particularly in high-volume production settings. Robotic loading and unloading systems, automatic part gauging, and tool wear compensation allow the process to run continuously with minimal operator intervention. These setups are often seen in production lines for fuel system components, transmission parts, bearing races, and surgical instruments, where uniformity and high output are essential.

As materials continue to evolve, from hardened steel to exotic alloys and even ceramics, plunge centerless grinding machines have adapted through more powerful spindles, improved wheel materials, and smarter control systems. Whether for producing identical parts in mass or handling specialty components in smaller batches, plunge cut centerless grinding remains one of the most effective and reliable methods for achieving high-precision cylindrical surfaces with complex geometries.

Small-Diameter Centerless Grinding Machine

A small-diameter centerless grinding machine is designed specifically for precision grinding of workpieces with very small outer diameters, typically ranging from under 1 mm up to around 20 mm, depending on the machine model and configuration. These machines are widely used in industries where miniature, high-precision components are required, such as medical device manufacturing, electronics, watchmaking, aerospace, and precision automotive applications.

These machines operate on the same basic principle as conventional centerless grinders: the workpiece is supported between a high-speed grinding wheel and a slower rotating regulating wheel, while resting on a workrest blade. The key difference in small-diameter machines lies in the extremely fine tolerances they must maintain and the specific mechanical adaptations required to handle tiny, delicate components. The smaller the diameter of the part, the more critical it becomes to control vibration, wheel pressure, thermal effects, and workpiece deflection.

To achieve the required accuracy and surface finish, small-diameter centerless grinders typically feature extremely precise spindles and slides, fine-resolution feed mechanisms, and advanced wheel dressing systems. The grinding and regulating wheels may be specially formulated with ultra-fine abrasives and tighter bonding characteristics to provide a sharp cutting action while minimizing part distortion. Additionally, workrest blades for small parts are often made from high-grade carbide or even diamond-coated materials, shaped and positioned with sub-micron accuracy.

Coolant delivery and filtration become especially important at these small sizes. Coolant needs to be delivered in a highly controlled, pinpoint stream to the grinding zone to avoid heat build-up, which can quickly distort tiny parts or degrade surface quality. High-performance filters are used to remove even microscopic grinding debris from the coolant to avoid scratches or wheel contamination.

Part handling in small-diameter grinding is typically automated due to the impracticality of manual loading. Vibratory bowl feeders, precision collet-based loaders, and air-blow transfer systems are commonly used. For extremely small or fragile parts, special fixtures or conveyors may be custom designed to support and transfer the parts without bending or scratching them.

These machines are also often equipped with in-process gauging systems that measure the part diameter in real time, allowing the machine to automatically compensate for tool wear or thermal drift. This capability is vital when grinding micro shafts, medical pins, hypodermic needles, or small gear blanks where tolerances may be in the range of ±1 micron or better.

Modern small-diameter centerless grinding machines are usually CNC-controlled, enabling flexible programming for plunge or through-feed operations, complex profiles, and automatic wheel dressing cycles. The precision of these machines allows them to produce parts with exceptional roundness, surface finishes down to Ra 0.02 µm, and excellent dimensional stability, even over long production runs.

In summary, small-diameter centerless grinding machines are highly specialized tools capable of producing miniature parts with extraordinary accuracy and finish. Their design emphasizes rigidity, vibration damping, fine control systems, and automation—all essential for working at such small scales.

As demand for miniaturized components continues to grow across industries like medical, aerospace, electronics, and precision engineering, small-diameter centerless grinding machines have become increasingly vital. These machines are specifically designed to address the unique challenges of grinding thin, lightweight, or flexible parts, where even the slightest deviation in force, temperature, or alignment can result in defects, bending, or rejection of parts. Because the mass of small components is minimal, they are especially sensitive to heat and mechanical stress, making thermal control, wheel sharpness, and mechanical rigidity critical elements in machine design.

One of the major challenges in small-diameter centerless grinding is workpiece stability. Long, slender parts such as medical guidewires or miniature shafts can easily deflect under pressure if not perfectly supported. To mitigate this, machines often incorporate specialized support systems, such as hydrostatic workrests or synchronized guiding bushings, which help maintain concentricity throughout the grinding cycle. The workrest blade geometry is another factor. Its height relative to the centerline of the grinding and regulating wheels determines whether the part will remain stable or deflect. In small-diameter machines, this blade is often finely adjustable to sub-millimeter increments and can be fabricated with a mirror finish to reduce friction and wear.

Because part loading and unloading cannot be done manually at high volumes or with delicate micro-components, these machines are nearly always equipped with automated part handling systems. Vibratory feeders are often used to orient and feed parts in the correct position, while robotic arms or air-jet systems transfer them into the grinding zone. For extremely small parts, vacuum pickup or capillary grip systems may be employed to prevent damage during handling. The integration of such automation allows these machines to run continuously with minimal human intervention, a key factor in achieving cost efficiency and process consistency.

Another important capability in small-diameter centerless grinding is the machine’s ability to maintain tight tolerances over long production runs. As grinding wheels wear or environmental temperatures fluctuate, machine accuracy can drift. To counteract this, modern machines often feature thermal compensation systems, linear motors for backlash-free motion, and in-process measurement probes that continually monitor part diameter and automatically adjust the grinding wheel position in real time. This level of control enables tolerances as tight as ±0.5 microns and surface finishes below Ra 0.02 µm.

Wheel selection for small-diameter grinding also requires careful consideration. The grinding wheel must be fine-grained and sharp enough to cut without loading or glazing, which could cause heat buildup. In many applications, superabrasive wheels made from cubic boron nitride (CBN) or diamond are used due to their ability to maintain sharpness and form over long periods. The regulating wheel, on the other hand, must provide sufficient friction to rotate the part without distorting it, which can be especially tricky with smooth or soft materials. Some systems use a low-friction guide to limit axial movement without damaging the part surface.

Applications for small-diameter centerless grinding span a wide range. In the medical industry, it is used for grinding hypodermic needles, guidewires, bone pins, and surgical drills. In electronics, the process is used to grind contact pins, motor shafts, and spindle rods. In watchmaking and precision instrumentation, centerless grinding is used to produce micro gear shafts and balance wheels. In all these cases, the demand for uniformity, burr-free finishes, and extreme dimensional control makes centerless grinding the most viable process.

As technology continues to advance, small-diameter centerless grinding machines are incorporating more intelligent features like adaptive control, real-time analytics, remote diagnostics, and machine learning algorithms to fine-tune parameters dynamically. These innovations help maintain uptime, reduce scrap rates, and improve overall process control, especially important when working with difficult-to-grind materials like titanium, stainless steel, or superalloys. Ultimately, these machines have become indispensable in any environment where miniaturization, precision, and efficiency converge.

Large-Diameter Centerless Grinding Machine

A large-diameter centerless grinding machine is designed to handle cylindrical workpieces with relatively large outer diameters—often ranging from 50 mm up to several hundred millimeters or more. These machines are built to provide high-precision grinding of bigger components that are too large or heavy for conventional chuck-based grinders or that require the unique advantages of centerless grinding, such as continuous production and excellent roundness.

The fundamental operating principle remains the same: the workpiece is supported between a high-speed grinding wheel and a slower rotating regulating wheel, resting on a workrest blade. However, machines built for large-diameter parts must have a much more robust and rigid construction to accommodate the increased mass and size of the workpieces. Components such as the machine bed, wheelheads, and spindles are heavily reinforced and often made of high-grade cast iron or steel to minimize vibrations and ensure stability during grinding.

The grinding wheels used in large-diameter centerless grinders are correspondingly larger and more powerful, sometimes reaching diameters of 600 mm or more. These wheels are typically mounted on heavy-duty spindles with powerful motors capable of maintaining high rotational speeds under heavy load. The regulating wheels are also larger and engineered to exert the appropriate friction and feed control to move heavy workpieces steadily and precisely.

Workrest blades on large-diameter machines are generally thicker and wider to provide the necessary support for heavier parts, preventing deflection and ensuring concentricity. The setup and adjustment of these blades become more critical with increasing size, as even small misalignments can cause tapering or poor roundness in the finished parts.

Cooling and lubrication systems are enhanced on large-diameter machines to handle the greater heat generated during grinding. Coolant flow rates are higher, and delivery systems are engineered to ensure effective cooling around the entire contact zone. This prevents thermal expansion or burning, which could lead to dimensional inaccuracies or surface damage on large components.

Large-diameter centerless grinding is used across multiple heavy industries. It’s common in manufacturing large shafts, hydraulic cylinders, bearing races, gears, rollers, and heavy-duty pins. The process is favored when the production volume is moderate to high, and parts require excellent roundness, fine surface finish, and consistent dimensional accuracy.

Automation and process control technologies are increasingly integrated into these machines to optimize throughput and quality. Features like CNC-controlled wheel dressing, automatic workrest adjustment, in-process gauging, and adaptive grinding control allow for precise machining and reduced downtime. For extremely large or heavy parts, loading and unloading systems such as overhead cranes or robotic arms are often employed to facilitate safe and efficient handling.

One of the advantages of large-diameter centerless grinding over traditional cylindrical grinding is the ability to grind long lengths or multiple diameters with minimal setups. The process can accommodate complex profiles or stepped shafts by using specially dressed wheels and multi-stage grinding cycles. However, due to the scale of the workpieces, cycle times tend to be longer, requiring careful balancing between speed and accuracy.

Despite their size, modern large-diameter centerless grinding machines are designed with vibration damping, thermal stability, and ergonomic operation in mind. Some machines include enclosed grinding areas for safety and dust control, as well as advanced filtration systems to manage coolant and particulate waste.

In summary, large-diameter centerless grinding machines provide a robust, precise, and efficient solution for machining oversized cylindrical parts in heavy industries. Their design focuses on strength, stability, and control to handle large workpieces with high accuracy, making them essential in sectors such as automotive, aerospace, heavy machinery, and energy production.

Large-diameter centerless grinding machines face unique challenges compared to their smaller counterparts, primarily due to the increased mass and inertia of the parts being processed. Managing vibrations is critical because any oscillations can cause surface irregularities or dimensional inconsistencies. To combat this, machine designers incorporate heavy, ribbed cast iron beds and robust spindle assemblies with precision bearings to provide maximum rigidity. Some machines use hydrostatic or air bearings in key areas to reduce friction and enhance stability during grinding.

Thermal expansion is another concern. Large parts generate more heat, and uneven temperature distribution can cause warping or dimensional shifts. To address this, many large-diameter machines have integrated temperature monitoring systems and advanced cooling circuits. These may include segmented coolant nozzles that deliver fluid precisely where needed, and some setups use temperature-controlled coolant to keep the part and machine components stable.

Due to the size and weight of large parts, manual handling is often impractical or unsafe. Automated loading and unloading systems, such as overhead cranes, conveyor rollers, or robotic arms, are commonly integrated. These systems not only improve safety but also contribute to higher productivity by reducing cycle times and minimizing the risk of part damage during transfer.

Setup and calibration on large-diameter centerless grinders demand experienced operators or engineers. Wheel dressing must be done with diamond tools that can shape large wheels accurately, often using CNC-controlled dressers for consistent profiles. Because of the large contact areas, wheel wear patterns and balancing require careful monitoring to maintain surface finish and roundness throughout production runs.

The regulating wheel’s friction surface must be carefully selected and maintained. For heavy parts, wheels with rubber or resin bonds that provide appropriate grip without excessive pressure are common, reducing the risk of part slip or deformation. Adjusting the angle and pressure of the regulating wheel is vital to controlling the workpiece rotation speed and feed rate accurately.

Large-diameter centerless grinding machines also offer flexibility for different grinding styles. Through-feed grinding is used when parts have uniform diameter over their length and can pass continuously through the machine. For stepped shafts or parts with complex geometries, plunge grinding or in-feed grinding methods are employed, requiring precise wheel profile dressing and machine programming.

Because these machines are often part of production lines for critical components, data connectivity and process monitoring are increasingly integrated. Real-time analytics, predictive maintenance alerts, and automated quality control measures help maintain high uptime and consistent output quality. This integration aligns with Industry 4.0 trends, allowing manufacturers to optimize machine utilization and reduce scrap rates.

Applications for large-diameter centerless grinding span industries where reliability and precision at scale are paramount. These include automotive crankshafts and camshafts, large bearing rings, hydraulic cylinder rods, aerospace engine components, and heavy machinery shafts. The ability to grind large parts efficiently while maintaining tight tolerances and fine finishes makes centerless grinding machines an indispensable tool in these sectors.

Ultimately, large-diameter centerless grinding machines combine heavy-duty construction with advanced control technologies to deliver precise, repeatable, and efficient grinding of oversized cylindrical parts. Their robust design ensures they can withstand the demanding conditions of grinding large workpieces, while automation and smart controls improve consistency and throughput, meeting the evolving needs of modern manufacturing.

High-Precision Centerless Grinding Machine

A high-precision centerless grinding machine is engineered to deliver exceptionally tight tolerances and superior surface finishes, often required in industries like aerospace, medical devices, precision instruments, and micro-mechanics. These machines emphasize accuracy, repeatability, and process stability, enabling the production of components with dimensional tolerances often in the sub-micron range and surface finishes reaching Ra values as low as 0.01 µm or better.

The design of high-precision centerless grinders focuses on minimizing every potential source of error. The machine structure is built from high-grade, stress-relieved cast iron or composite materials that offer excellent vibration damping and thermal stability. Critical components like spindles and slides use precision ground surfaces combined with advanced linear motor or hydrostatic bearing technology to ensure smooth, backlash-free motion with micron-level positioning accuracy.

The grinding wheel spindles are designed to run with minimal runout and high rigidity, using precision angular contact or ceramic hybrid bearings. Some high-end machines incorporate air or magnetic bearings to further reduce friction and vibration, contributing to ultra-fine surface finishes. The regulating wheel and workrest blade systems are also engineered for fine adjustment and stability, often with automated and programmable controls to maintain optimal part rotation and support throughout the grinding cycle.

Wheel dressing technology plays a crucial role in achieving the required precision. CNC-controlled diamond dressing systems enable the grinding wheels to be shaped with micron accuracy, maintaining consistent wheel profiles and sharpness for long production runs. In-process dressing can be integrated, allowing the machine to automatically refresh the grinding wheel surface without manual intervention, minimizing downtime and enhancing consistency.

Thermal management is meticulously addressed to prevent heat-related distortions. Machines may include temperature-controlled enclosures, coolant systems with highly filtered fluids, and sensors that monitor temperature fluctuations in real time. By maintaining stable thermal conditions, the machine preserves dimensional integrity and reduces the risk of thermal expansion affecting the workpiece or machine components.

In-process gauging and feedback systems are standard in high-precision centerless grinders. Laser or probe-based measurement devices continuously monitor the diameter and roundness of the workpiece during grinding. The data collected feeds back into the control system, which adjusts wheel positioning and feed rates dynamically to compensate for tool wear, thermal drift, or material inconsistencies. This closed-loop control enables consistent production of parts within extremely narrow tolerances.

Automation and integration capabilities are also key features. High-precision machines often come with automated loading/unloading systems, robotic handling, and sophisticated process monitoring software. These features reduce human error, increase throughput, and enable complex grinding sequences such as plunge cuts, multiple diameter zones, and tapered profiles—all programmable via CNC interfaces.

Materials processed on high-precision centerless grinders range from soft metals like aluminum to hardened steels, superalloys, ceramics, and composites. The machine’s rigidity, spindle power, and wheel selection can be tailored to the specific material, ensuring optimal cutting action and minimal surface damage. The flexibility and precision of these machines make them indispensable for manufacturing critical components such as fuel injector nozzles, surgical instruments, precision shafts, and micro-sized connectors.

Overall, high-precision centerless grinding machines represent the pinnacle of grinding technology, combining advanced mechanical design, intelligent control systems, and automation to produce parts with unparalleled accuracy and surface quality. Their capabilities support industries where even the smallest deviations can lead to failure, making them essential tools for precision manufacturing and quality-critical applications.

High-precision centerless grinding machines continue to evolve with advancements in sensor technology, control algorithms, and machine design, pushing the boundaries of what’s achievable in terms of accuracy and surface finish. Modern machines often incorporate real-time condition monitoring, using vibration analysis and acoustic emission sensors to detect tool wear, wheel loading, or abnormal cutting conditions before they impact part quality. This predictive capability helps reduce unplanned downtime and scrap rates by allowing maintenance or adjustments to be scheduled proactively.

Thermal compensation systems have become more sophisticated, using multiple temperature sensors strategically placed on the grinding wheels, workrest blade, machine frame, and even the workpiece itself. The control software dynamically adjusts machine parameters based on these inputs, counteracting thermal expansion or contraction in real time. Some machines use closed-loop cooling systems to maintain a constant temperature environment, further enhancing dimensional stability during long grinding cycles.

In terms of automation, integration with factory-wide Manufacturing Execution Systems (MES) and Industry 4.0 platforms allows for seamless data exchange, remote monitoring, and advanced analytics. Operators can track machine performance, quality trends, and production efficiency from a centralized dashboard. Machine learning algorithms analyze historical grinding data to optimize process parameters continuously, reducing cycle times while maintaining or improving part quality.

The versatility of high-precision centerless grinders is another notable feature. Through-feed, plunge-cut, and in-feed grinding techniques can be combined in a single setup to produce complex profiles or multi-diameter components without repositioning. This reduces setup time, minimizes handling errors, and increases throughput. Additionally, some machines are capable of grinding extremely thin-walled or flexible parts by carefully controlling grinding forces and feed rates, something traditionally difficult to achieve without deforming the workpiece.

Material adaptability has expanded as well. Advanced wheel materials such as vitrified CBN or synthetic diamond combined with optimized bonding agents allow these machines to effectively grind super-hard materials like ceramics, tungsten carbide, and titanium alloys with minimal wheel wear and high surface integrity. This capability is critical in sectors such as aerospace and medical where exotic materials are standard.

Furthermore, the precision workrest blade technology has seen innovations such as actively controlled blades that can adjust position and angle during grinding cycles based on sensor feedback, maintaining optimal support and minimizing deflection for every part geometry. These dynamic supports enhance the machine’s ability to handle challenging part geometries without compromising precision or surface finish.

Operator ergonomics and safety have also been enhanced in high-precision centerless grinding machines. Enclosed work areas with automated door interlocks, dust and coolant mist extraction systems, and user-friendly touch-screen interfaces contribute to safer, cleaner, and more intuitive operation environments. Remote diagnostics and maintenance support further reduce the need for on-site intervention, speeding up troubleshooting and repairs.

In summary, high-precision centerless grinding machines represent the cutting edge of grinding technology, integrating mechanical excellence with intelligent automation and connectivity. Their ability to deliver ultra-precise, consistent, and high-quality cylindrical components meets the demanding requirements of advanced manufacturing sectors. Continuous innovation in this field ensures these machines remain indispensable for producing parts where performance, reliability, and longevity depend on microscopic levels of accuracy and flawless surface finishes.

Twin-Grip Centerless Grinding Machine

A twin-grip centerless grinding machine is a specialized type of centerless grinder designed to securely hold and grind workpieces that are difficult to machine using conventional centerless methods. Unlike standard centerless grinding, where the workpiece is supported only between the regulating wheel, grinding wheel, and workrest blade, the twin-grip design incorporates an additional gripping mechanism that firmly clamps the workpiece during the grinding process. This ensures higher stability, reduces vibration, and allows for grinding parts with irregular shapes, stepped diameters, or thin-walled sections that might otherwise deflect or deform.

The twin-grip mechanism typically involves two clamping points positioned on opposite sides of the workpiece. One grip is usually integrated with the regulating wheel assembly, while the other is part of a movable clamping device that holds the workpiece against the grinding wheel and workrest blade. This dual clamping arrangement minimizes axial and radial movement, enabling the grinding of parts that require higher precision or have complex geometries.

Because the workpiece is firmly held, twin-grip centerless grinding machines are particularly useful for components such as stepped shafts, thin-walled tubes, or parts with multiple diameter zones. The increased rigidity allows for more aggressive grinding parameters without risking part distortion or chatter, leading to improved surface finishes and tighter dimensional tolerances.

Setup on twin-grip machines is more complex compared to standard centerless grinders, as the clamping mechanisms must be carefully adjusted to match the workpiece geometry and material properties. The machine often includes fine adjustment controls for grip pressure, positioning, and synchronization with the grinding and regulating wheels to ensure smooth, consistent part rotation and feed.

Wheel dressing and machine control technologies are usually CNC-enabled, allowing for precise programming of grinding profiles, wheel feed rates, and clamping sequences. This automation facilitates quick changeovers between different part types and reduces setup times, enhancing productivity in batch production or mixed-model manufacturing environments.

Thermal management remains critical due to the increased contact area and grinding forces. Advanced coolant delivery systems are implemented to provide effective cooling and lubrication, reducing heat-related part distortions or surface damage.

Applications of twin-grip centerless grinding machines are found in automotive, aerospace, medical, and precision engineering industries. Typical parts include stepped shafts, fuel injector components, small-diameter tubes, and other precision cylindrical parts that demand tight tolerances and high-quality finishes but pose challenges for conventional centerless grinding.

Overall, the twin-grip centerless grinding machine offers a powerful solution for grinding complex or delicate cylindrical parts by combining the speed and efficiency of centerless grinding with enhanced workpiece stability and control. This results in superior accuracy, surface integrity, and process reliability for demanding manufacturing applications.

The twin-grip centerless grinding machine’s enhanced holding capability also improves process consistency and reduces scrap rates. By securely clamping the workpiece, it minimizes deflection, vibration, and potential runout that can occur in traditional centerless grinding setups, especially when dealing with slender or uneven parts. This stability allows the machine to maintain tighter dimensional tolerances and achieve better roundness and surface finishes, which is critical for high-precision components.

Because the twin-grip design accommodates complex part geometries, it expands the range of parts that can be efficiently centerless ground, reducing the need for secondary operations or multiple setups. For example, stepped shafts with different diameters along their length can be ground in a single pass without repositioning, which improves throughput and reduces handling errors.

Automation and CNC integration play a significant role in maximizing the capabilities of twin-grip centerless grinders. These machines often include programmable clamping sequences synchronized with wheel movement and feed rates, allowing precise control over the grinding cycle. Automated wheel dressing, in-process measurement, and feedback systems help maintain wheel sharpness and part quality over long production runs, reducing operator intervention and enhancing repeatability.

In terms of tooling, the grinding wheels and regulating wheels are selected and dressed to complement the clamping forces, ensuring the workpiece rotates steadily without slippage. The workrest blades are also optimized to provide the proper support angle and surface finish to reduce friction and wear. Coolant systems are carefully designed to deliver high-volume, directed cooling at the grinding interface, which prevents heat buildup that could lead to thermal distortion or surface burns.

Twin-grip centerless grinding machines are particularly advantageous when processing delicate materials such as thin-walled stainless steel tubes, titanium components, or composite shafts, where conventional centerless grinding might induce deformation. The secure clamping reduces part movement, allowing for gentler grinding forces and improving the quality of thin or flexible parts.

Industries such as aerospace and medical device manufacturing benefit from these machines by achieving the stringent dimensional and surface quality standards required for critical parts. The automotive sector uses them for high-volume grinding of complex shafts and fuel system components, where cycle time and precision are equally important.

Ultimately, the twin-grip centerless grinding machine represents a hybrid approach that combines the speed and efficiency of centerless grinding with enhanced workpiece control typically associated with chucking methods. This combination allows manufacturers to tackle challenging geometries and materials while maintaining high productivity and quality standards. As a result, twin-grip grinders have become an essential tool in advanced manufacturing environments where both precision and throughput are demanded.

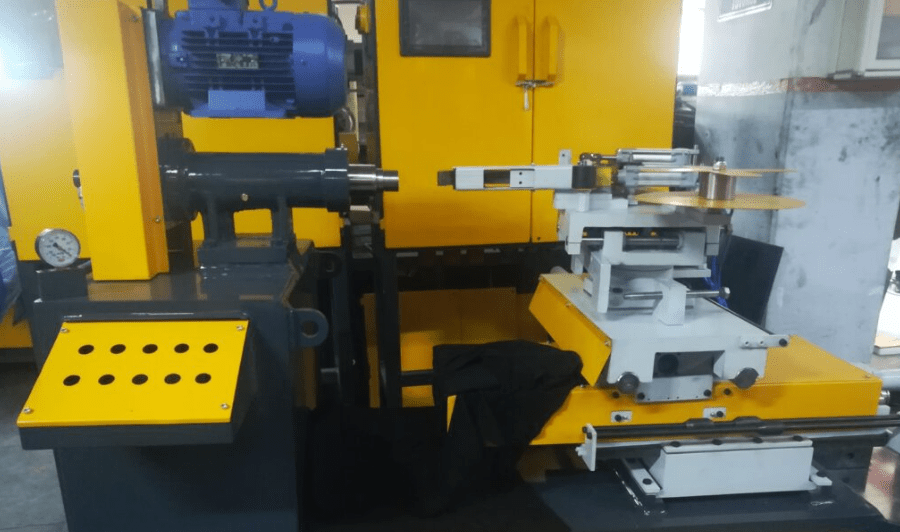

Automatic Centerless Grinding Machine

An automatic centerless grinding machine is a highly automated version of the conventional centerless grinder, designed to perform continuous, unattended grinding operations with minimal human intervention. These machines integrate advanced automation technologies—such as robotic loading and unloading systems, programmable controls, automatic wheel dressing, and in-process gauging—to optimize productivity, consistency, and quality, especially in high-volume manufacturing environments.

The key advantage of automatic centerless grinders lies in their ability to handle large production runs efficiently, reducing cycle times and labor costs while maintaining tight dimensional tolerances and excellent surface finishes. Automation eliminates much of the manual setup, loading, and monitoring traditionally required, allowing the machine to operate continuously with consistent parameters, which minimizes variability and scrap.

These machines often feature sophisticated CNC or PLC control systems that manage all aspects of the grinding process, including wheel speeds, feed rates, regulating wheel pressure, workrest blade position, and clamping forces if applicable. The control software can store multiple grinding programs, enabling quick changeovers between different parts and grinding profiles. Advanced interfaces provide operators with real-time feedback on machine status, cycle counts, and quality metrics, facilitating proactive maintenance and process adjustments.

Automated part handling is a critical component of these machines. Vibratory or rotary feeders orient and deliver raw workpieces to the grinding zone, while robotic arms, pneumatic pushers, or air jets position parts precisely between the grinding and regulating wheels. After grinding, finished parts are automatically removed, sorted, and transferred to inspection stations or downstream processes. This seamless integration reduces manual handling errors and protects delicate or small components from damage.

Automatic centerless grinders are also equipped with in-process gauging and measurement systems, such as laser micrometers or contact probes, which continuously monitor part dimensions during grinding. These systems feed data back to the control unit to automatically adjust wheel positioning or feed rates, compensating for wheel wear, thermal variations, or material inconsistencies in real time. This closed-loop control helps maintain tight tolerances over long production runs without operator intervention.

Wheel maintenance is similarly automated. CNC-controlled diamond dressing tools reshape and refresh grinding wheels at programmed intervals or based on measurement feedback, ensuring consistent cutting performance and surface quality. This reduces downtime and extends wheel life, improving overall equipment effectiveness.

Thermal management systems are integrated to maintain stable grinding conditions. Coolant delivery is precisely controlled to optimize lubrication and cooling at the grinding interface, preventing thermal expansion or burns that could compromise part accuracy and finish.

Automatic centerless grinding machines find applications in industries requiring mass production of precision cylindrical components, such as automotive, electronics, medical devices, aerospace, and general engineering. Common parts include shafts, pins, rollers, valves, needles, and small tubes. The combination of automation, precision control, and process repeatability makes these machines indispensable for meeting demanding production schedules and quality standards.

In summary, automatic centerless grinding machines transform the traditional grinding process into a highly efficient, reliable, and quality-focused operation by leveraging automation and intelligent control systems. They enable manufacturers to achieve high throughput, consistent precision, and reduced labor costs, supporting the needs of modern industrial production.

Automatic centerless grinding machines continue to evolve with advancements in sensor technology, artificial intelligence, and Industry 4.0 connectivity. Modern systems can incorporate predictive maintenance features, where sensors monitor machine health indicators such as vibration, temperature, and spindle load to predict potential failures before they occur. This capability reduces unexpected downtime and helps maintain steady production flow.

The integration of machine learning algorithms allows the grinding process to be optimized continuously. By analyzing historical data and real-time feedback, the system can adjust grinding parameters like wheel speed, feed rate, and regulating wheel pressure to improve part quality and extend tool life. This adaptive control reduces waste and enhances consistency, even when raw material properties vary.

Flexibility is another hallmark of contemporary automatic centerless grinders. Multi-function machines can switch between different grinding modes—through-feed, plunge, or in-feed grinding—automatically, accommodating a wide range of part geometries without manual intervention. Quick-change tooling and programmable wheel dressing further speed up production changeovers, making these machines suitable for both high-volume and batch production.

User interfaces on these machines have become highly intuitive, often featuring touchscreen controls, graphical process visualization, and remote monitoring capabilities. Operators can oversee multiple machines simultaneously, receive alerts, and make parameter adjustments from centralized control rooms or mobile devices. This level of control supports lean manufacturing practices and reduces the need for specialized grinding expertise on the shop floor.

Safety and ergonomics are also enhanced in automatic centerless grinding machines. Enclosed grinding zones with interlocked doors protect operators from flying debris and coolant spray. Automated part handling minimizes manual loading, reducing the risk of injury and improving workplace conditions.

In industries such as automotive and medical device manufacturing, where precision and traceability are paramount, automatic centerless grinders can be integrated with barcode scanners or RFID systems to track each part through the grinding process. This traceability ensures compliance with quality standards and facilitates root-cause analysis if defects arise.

Overall, automatic centerless grinding machines represent a convergence of mechanical precision, automation, and intelligent control. They enable manufacturers to achieve higher productivity, consistent part quality, and operational efficiency, meeting the demands of modern competitive markets while reducing costs and manual labor. This makes them a critical asset in advanced manufacturing environments focused on precision and volume.

Regulating Wheel Controlled Centerless Grinding

Regulating wheel controlled centerless grinding is a method where the speed, feed, and rotation of the workpiece are primarily governed by the regulating wheel, making it a critical component in the grinding process. Unlike the grinding wheel, which performs the material removal, the regulating wheel controls the workpiece’s rotational speed and axial feed rate by applying frictional force. This control is essential for maintaining accurate part dimensions, surface finish, and overall process stability.

In this grinding setup, the workpiece is positioned between the grinding wheel and the regulating wheel, resting on a workrest blade. The grinding wheel rotates at high speed to remove material, while the regulating wheel rotates slower and can be angled to control the axial movement of the part through the machine. By adjusting the regulating wheel’s speed and tilt angle, the operator controls the feed rate of the workpiece, determining how quickly it moves through the grinding zone.

The friction between the regulating wheel and the workpiece generates the rotational motion of the part. This frictional grip must be sufficient to rotate the workpiece steadily without slipping but not so high as to deform or damage it. The regulating wheel is usually made of a rubber or resin-bonded abrasive material, providing the necessary friction and some compliance to accommodate slight variations in part diameter or surface.

Regulating wheel control allows for different grinding methods: through-feed grinding, plunge grinding, and in-feed grinding. In through-feed grinding, the regulating wheel is set at an angle to feed straight parts continuously through the machine. In plunge grinding, the regulating wheel’s speed and angle remain fixed while the grinding wheel feeds radially into the workpiece, suitable for stepped or tapered parts. In in-feed grinding, the regulating wheel controls the rotation while the grinding wheel feeds the workpiece axially in discrete steps, allowing complex profiles to be ground.

Maintaining the proper speed ratio and angle of the regulating wheel is essential for achieving dimensional accuracy and consistent surface quality. Too much friction or an incorrect speed ratio can cause part slip, burn marks, or chatter, while too little friction leads to poor rotation control and inaccurate grinding.

Regulating wheels require regular dressing to maintain their shape, friction properties, and surface condition. CNC-controlled diamond dressing ensures the wheel profile and surface texture are kept consistent for reliable part feeding and rotation. The material and hardness of the regulating wheel must be chosen based on the workpiece material and grinding application to optimize grip without damaging the part.

In addition to controlling speed and feed, the regulating wheel also contributes to the stability of the workpiece during grinding. Proper setup and alignment of the regulating wheel, grinding wheel, and workrest blade are critical for minimizing vibration and ensuring smooth operation.

Applications of regulating wheel controlled centerless grinding are widespread across manufacturing sectors. It is commonly used for producing precision cylindrical parts such as shafts, pins, tubes, and rollers where high throughput and consistent quality are required. The method’s flexibility in handling different part shapes and sizes makes it valuable for both mass production and specialized machining tasks.

Overall, the regulating wheel controlled centerless grinding technique is central to the process, providing precise control over the workpiece’s motion and feed rate, enabling efficient and accurate grinding operations for a wide variety of cylindrical components.

The effectiveness of regulating wheel controlled centerless grinding depends heavily on the correct selection and maintenance of the regulating wheel itself. Factors such as the wheel’s hardness, grit size, bonding material, and diameter influence the grip and feed characteristics. Softer wheels provide better compliance and grip for delicate or irregular parts, while harder wheels are suited for stable, consistent feeding of tougher materials. The wheel’s surface texture and dressing profile also play crucial roles in maintaining steady friction and minimizing slippage during grinding.

Adjustments to the regulating wheel’s speed ratio relative to the grinding wheel are fundamental for controlling the workpiece’s rotational speed and axial feed rate. Typically, the regulating wheel runs at a slower speed than the grinding wheel, and this ratio can be finely tuned to optimize throughput and surface finish. If the speed is too low, the workpiece may slip or stall; if too high, it may cause excessive heating or chatter, affecting part quality.

The angle or tilt of the regulating wheel is another important parameter. By inclining the regulating wheel relative to the axis of the grinding wheel, operators control the axial feed of the workpiece. Small changes in this angle can significantly impact the feed rate, allowing for precise control over the grinding process and enabling the machine to handle parts with various lengths and profiles efficiently.

The interaction between the regulating wheel and the workpiece also affects the grinding forces applied. Proper balance is required to ensure that the regulating wheel applies enough force to drive the workpiece without causing deformation or inducing vibrations. This balance enhances the machine’s capability to grind thin-walled or flexible parts that would otherwise be prone to distortion.

In advanced machines, regulating wheel control is integrated into CNC or PLC systems, allowing automated adjustments of speed, angle, and pressure based on in-process measurements. Feedback from sensors such as laser micrometers or acoustic emission detectors enables real-time corrections, optimizing grinding conditions and ensuring consistent part quality throughout production runs.

Regulating wheel controlled centerless grinding is particularly advantageous in applications requiring high throughput and repeatability. Its ability to feed parts continuously without the need for individual clamping or centering reduces cycle times and simplifies handling. This efficiency makes it ideal for industries like automotive, electronics, and medical device manufacturing, where large volumes of precision cylindrical components are produced.

Additionally, this method supports various grinding techniques within the same setup, offering flexibility. Through-feed grinding is efficient for simple cylindrical parts, while plunge and in-feed grinding accommodate more complex geometries without requiring extensive repositioning or multiple setups.

Regular maintenance and monitoring of the regulating wheel and its control parameters are essential for sustaining optimal performance. Worn or improperly dressed wheels can lead to slippage, inconsistent feed rates, and degraded surface finishes, resulting in higher scrap rates and downtime. Therefore, integrating automated dressing cycles and condition monitoring can greatly enhance process stability and machine uptime.

In summary, regulating wheel controlled centerless grinding forms the backbone of the centerless grinding process, providing precise and adjustable control over the workpiece’s rotation and feed. This control ensures efficient, accurate, and high-quality grinding operations across a wide range of industrial applications, making it a fundamental technique in modern manufacturing.

Internal Grinding Machine with Automatic Dressing System

An internal grinding machine with an automatic dressing system is a specialized grinding machine designed to accurately grind the inner surfaces of cylindrical or tapered holes, bores, or internal features with minimal manual intervention. The machine combines precise internal grinding capabilities with an integrated automatic dressing mechanism that maintains the grinding wheel’s sharpness, shape, and surface condition during operation, ensuring consistent quality and reducing downtime.

Internal grinding involves rotating a small-diameter grinding wheel inside the workpiece to remove material from internal surfaces. This process requires high precision because of limited access, tight tolerances, and often complex geometries. The grinding wheel must be periodically dressed—reshaped and cleaned—to maintain its cutting efficiency, remove glazing or loading, and preserve its dimensional accuracy.

The automatic dressing system is typically equipped with a diamond dressing tool that can be positioned and controlled by CNC or PLC systems. This tool reshapes the grinding wheel according to programmed profiles without manual intervention. The dressing process can be scheduled based on time intervals, wheel wear measurements, or in-process monitoring, ensuring the wheel is always in optimal condition throughout production runs.

Automation of the dressing cycle minimizes machine downtime and reduces the reliance on skilled operators for wheel maintenance. It also improves repeatability by applying consistent dressing parameters and profiles every time. The system often includes sensors that monitor wheel condition, dressing tool position, and grinding forces, feeding data back to the control system for adaptive process adjustments.

The internal grinding machine itself usually features a high-precision spindle with low runout, capable of operating at variable speeds tailored to the workpiece material and grinding wheel specification. The workpiece is held rigidly in a chuck, collet, or fixture, often supported by steady rests or centers to prevent deflection during grinding.

Coolant delivery systems are integrated to supply lubrication and cooling directly to the grinding zone, minimizing thermal distortion and improving surface finish. Some machines include vibration dampening features and thermal compensation to further enhance grinding accuracy.

Programming the internal grinding machine with automatic dressing allows for complex grinding cycles, including different wheel profiles, variable depths of cut, and multiple passes with varying feed rates. This flexibility supports a wide range of internal geometries such as straight bores, tapered holes, stepped diameters, and intricate contours.

Applications for internal grinding machines with automatic dressing span many industries, including automotive (for engine cylinder bores, valve guides), aerospace (precision bushings, bearing seats), hydraulic systems (cylinders, valves), and tool manufacturing. The ability to maintain wheel condition automatically is especially valuable in high-volume production where consistent quality and minimal downtime are critical.

In summary, internal grinding machines equipped with automatic dressing systems provide a highly efficient, precise, and reliable solution for grinding internal surfaces. By combining advanced wheel maintenance automation with precision grinding technology, these machines ensure superior surface finishes, dimensional accuracy, and enhanced productivity in demanding manufacturing environments.

Internal grinding machines with automatic dressing systems also benefit from enhanced process stability and repeatability. Because the grinding wheel is constantly maintained in optimal condition, variations caused by wheel wear, glazing, or loading are minimized, resulting in consistent surface finishes and dimensional accuracy throughout long production runs. This is particularly important for parts with tight tolerances or those requiring fine surface textures, where even minor deviations can lead to functional or assembly issues.

The integration of automatic dressing reduces the dependency on skilled operators for manual wheel maintenance, lowering labor costs and the risk of human error. It also shortens machine downtime associated with wheel dressing, allowing for higher machine utilization and improved overall productivity. Some advanced systems enable in-process dressing, where the wheel is dressed incrementally during pauses in the grinding cycle without fully stopping the machine, further boosting efficiency.

Adaptive control features often accompany the automatic dressing system, using feedback from sensors that monitor grinding forces, acoustic emissions, or vibration. These inputs allow the machine to adjust dressing parameters or grinding conditions dynamically, optimizing the grinding process for different materials or varying workpiece conditions. Such smart control helps prevent wheel damage, part overheating, or surface defects, enhancing both quality and tool life.

In addition to wheel dressing, the machine’s control system can coordinate the entire grinding cycle, including workpiece positioning, spindle speed, feed rates, and coolant flow. This level of automation supports complex internal geometries by enabling multi-pass grinding with varying wheel profiles and depths, all managed through programmable logic controllers or CNC interfaces.

Maintenance features may include automated coolant filtration and delivery systems, lubrication for spindle and moving parts, and diagnostic tools that alert operators to wear or faults in machine components before they cause breakdowns. These systems contribute to longer machine life and stable grinding performance over time.

Applications for such machines are broad and critical in industries requiring precision internal features, such as engine manufacturing, hydraulic cylinder production, aerospace components, and precision tooling. The ability to achieve tight roundness, cylindricity, and surface finish specifications with minimal manual intervention makes these machines highly valuable in quality-sensitive and high-volume production environments.

Overall, internal grinding machines equipped with automatic dressing systems represent a fusion of precision mechanical engineering and advanced automation technology. They deliver reliable, consistent, and efficient internal grinding performance, reduce operational costs, and support the production of complex, high-quality components essential to modern manufacturing.

Angular Internal Grinding Machine

An angular internal grinding machine is a specialized type of internal grinder designed to grind internal surfaces at specific angles or tapers inside a workpiece rather than just straight cylindrical bores. This machine is engineered to handle complex internal geometries where the grinding wheel needs to approach the workpiece at an angle, allowing for the precise finishing of tapered holes, angled bores, or conical surfaces.

The angular internal grinding machine typically features a grinding spindle capable of tilting or swiveling to various preset angles. This flexibility enables the grinding wheel to access and machine internal surfaces that are not parallel to the workpiece axis. The machine often incorporates a rotary table or an adjustable workhead that can orient the workpiece accordingly to match the desired grinding angle.

Precision and rigidity are crucial in angular internal grinding because the wheel must maintain consistent contact with the angled internal surface while compensating for complex tool paths. The machine’s spindle is designed to provide low runout and smooth rotational motion, ensuring fine surface finishes and accurate dimensional control even at oblique angles.

Coolant delivery systems are adapted to supply coolant effectively to the grinding zone, which is especially important when grinding at angles to prevent overheating, maintain surface integrity, and remove grinding debris from tight spaces.

Control systems on angular internal grinders are often CNC-based, allowing for programmable grinding cycles with precise control over spindle tilt angles, feed rates, wheel speeds, and multiple passes. This automation enables the machining of complex profiles and ensures repeatability across batches.

Applications for angular internal grinding machines include aerospace component manufacturing (such as turbine blade roots and engine parts with angled internal features), hydraulic valve bodies, precision toolmaking, and other industries where internal tapered or angled surfaces require high precision and excellent surface finish.

In summary, the angular internal grinding machine expands the capability of traditional internal grinders by enabling the precise machining of angled internal surfaces. Its specialized spindle articulation, rigid construction, and advanced control make it ideal for producing complex internal geometries with high accuracy and quality.

Angular internal grinding machines often incorporate multi-axis movement capabilities to achieve the necessary positioning flexibility for complex internal geometries. These machines can combine spindle tilt with longitudinal and radial feeds, allowing the grinding wheel to follow intricate tool paths inside the workpiece. This multi-axis coordination is typically managed by CNC controls, enabling highly precise and repeatable grinding operations on angled or tapered internal surfaces.

The grinding wheels used in angular internal grinding are usually small-diameter, high-precision wheels made from abrasive materials tailored to the workpiece material. The wheel profile can be custom-shaped through dressing processes to match the angular features being ground, ensuring accurate material removal and surface conformity. Automatic or programmable wheel dressing systems are often integrated to maintain the wheel’s profile and cutting efficiency throughout the production cycle.

Because angular internal grinding involves grinding at various angles, machine stability and vibration control are critical to prevent chatter, which can degrade surface finish and dimensional accuracy. To address this, angular internal grinders are built with rigid frames, high-quality bearings, and damping systems. In some designs, active vibration control or spindle balancing technologies are implemented to enhance machining stability further.

The coolant delivery system is carefully engineered to provide targeted cooling and flushing, especially since angled grinding zones can create challenging fluid dynamics. Proper coolant flow helps dissipate heat, remove debris, and prevent thermal damage or burn marks on the workpiece, which is particularly important when grinding heat-sensitive materials or complex profiles.

Angular internal grinding machines find significant use in industries requiring high-precision, complex internal features. Aerospace components, such as turbine blade attachments, require tapered and angled internal surfaces with extremely tight tolerances. Hydraulic and pneumatic valve bodies often feature angled ports and bores that must be ground accurately for optimal sealing and function. Precision tooling and mold components also benefit from this technology, where angled internal profiles are common.

The flexibility of angular internal grinders reduces the need for multiple setups or specialized fixtures, improving production efficiency. By enabling complex profiles to be ground in a single setup, these machines minimize handling errors and reduce cycle times, which is particularly valuable in high-mix, low-volume manufacturing environments.