Complex Geometry Forming with Metal Spinning Machine: Metal spinning, also known as spin forming or metal turning, is a process used to produce axially symmetric components by rotating a flat metal disc or tube at high speeds while applying localized pressure. This technique forms the metal into a desired shape over a mandrel, often resulting in products such as cones, hemispheres, or cylindrical forms. Its use spans industries from aerospace to automotive, due to its cost-effectiveness and ability to handle both small and large production runs with high precision.

Historical Context The origins of metal spinning date back several centuries, where artisans manually shaped metals for decorative and practical purposes. Historically, the technique was applied to metals like silver and gold to create household items such as bowls, candlesticks, and vases. However, with the advent of industrialization in the 19th and 20th centuries, metal spinning transitioned from a craft-based process to a critical manufacturing technique. With the introduction of powered lathes and automated systems, the process evolved to handle various metals and alloys, enhancing its industrial relevance.

Importance in Modern Manufacturing Today, metal spinning plays a crucial role in modern manufacturing. Its versatility allows for the production of parts across a wide array of sectors, including aerospace, automotive, medical devices, lighting, and energy. Its capacity for producing seamless, strong, and lightweight components makes it particularly valuable in industries that require high-strength, lightweight parts, such as aerospace. The process is also environmentally sustainable, as it minimizes waste compared to other metal-forming methods like casting or stamping.

Metal spinning is not a new technique. The process dates back over 2,000 years, with early examples found in ancient civilizations. Traditional metal spinning involved manually spinning a metal blank on a lathe while applying pressure with a tool to shape it. The process was labor-intensive, requiring highly skilled artisans to produce consistent and precise results.

In the early industrial age, metal spinning evolved with the advent of steam-powered lathes. This reduced some of the manual labor, though the technique still relied heavily on the operator’s skill. Metal spinning was primarily used to create items such as bowls, lampshades, and other simple hollow forms.

1.2 Transition to CNC Metal Spinning

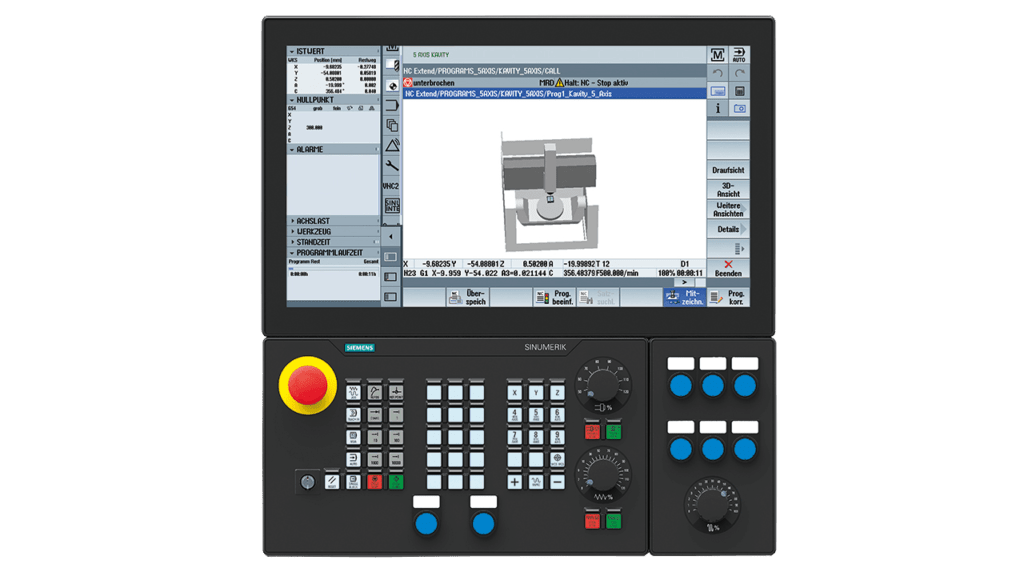

The introduction of CNC technology in the late 20th century revolutionized metal spinning. CNC metal spinning combines the traditional method with computerized controls, allowing for greater precision, consistency, and the ability to handle complex geometries. The need for highly skilled manual operators was reduced, and the automation of processes meant that manufacturers could produce higher volumes of products with minimal human intervention.

With CNC technology, the operator now programs the spinning machine using G-code (a type of numerical control programming language). The code directs the lathe to follow a precise path, manipulating the metal blank with incredible accuracy. As a result, CNC metal spinning opened new possibilities in industries like aerospace, medical devices, automotive, and heavy machinery.

Basics of CNC Metal Spinning

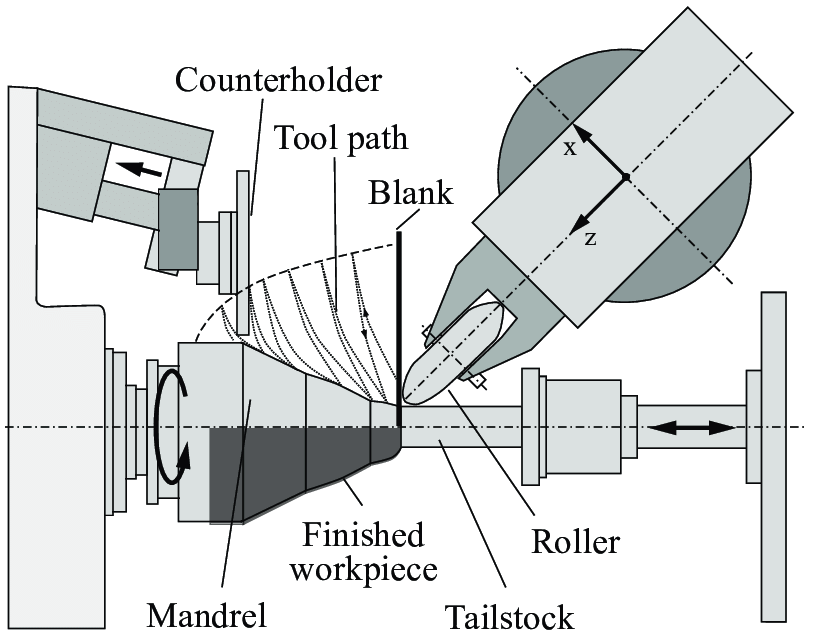

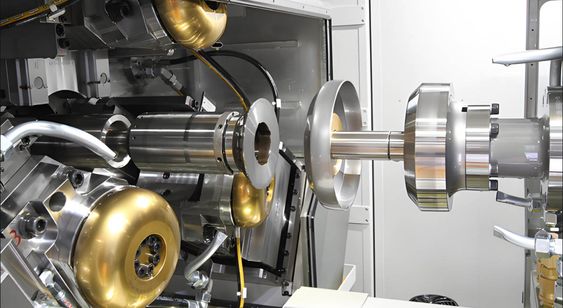

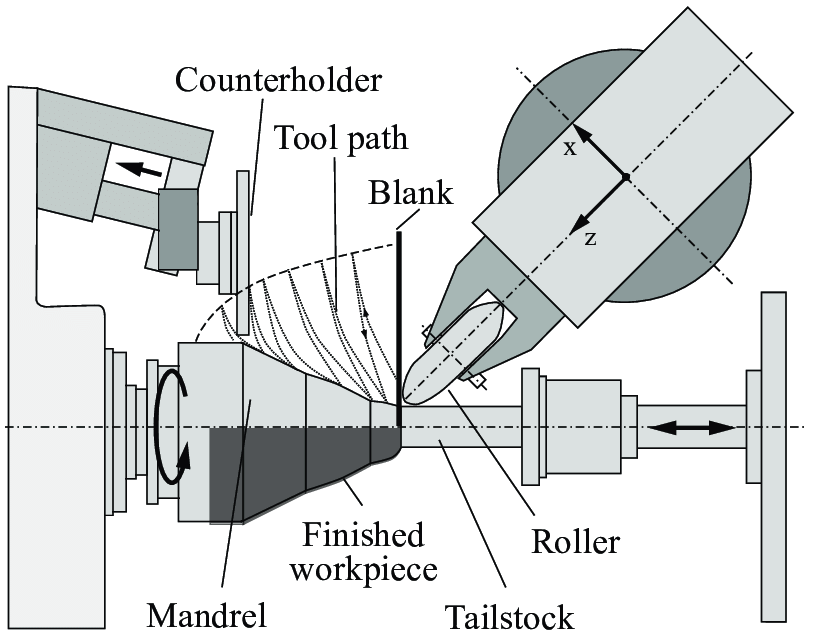

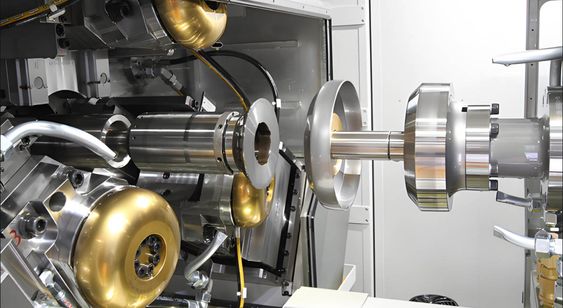

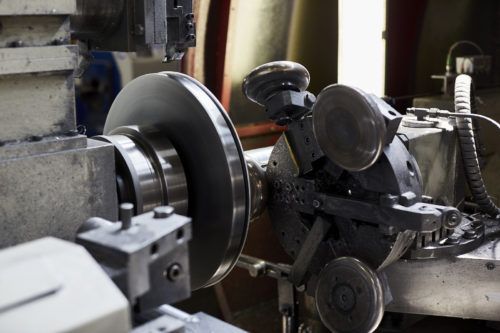

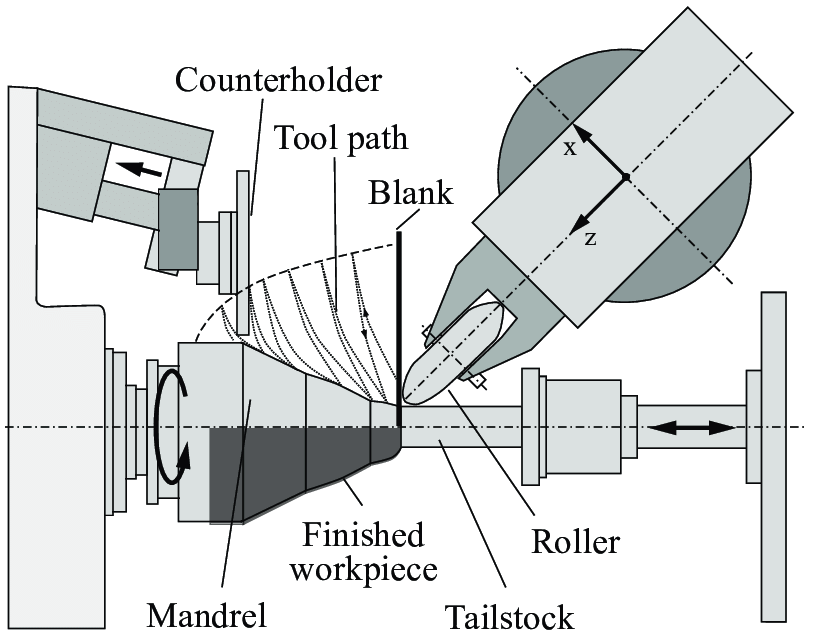

The CNC metal spinning process starts with a flat metal blank, typically circular, which is placed on a spinning lathe. Once the blank is set into motion, it rotates at high speeds. A roller tool, following a pre-programmed path, gradually forms the spinning blank into a desired shape. This transformation occurs through a series of passes, with the roller tool moving in increments to prevent tearing or warping of the material.

CNC metal spinning allows for the creation of symmetrical and asymmetrical shapes. With its ability to produce smooth, accurate, and high-quality finishes, CNC metal spinning is favored for components that require structural integrity and surface smoothness.

2.2 Key Equipment in CNC Metal Spinning

The primary equipment used in CNC metal spinning includes:

- CNC Lathe: The centerpiece of the operation, the lathe rotates the metal blank at controlled speeds.

- Roller Tool: This applies pressure to shape the blank during rotation. Different tools are used based on the material type and desired end shape.

- Clamping System: Holds the blank in place while it spins, ensuring it doesn’t move during the process.

- Computer System: Where the operator inputs the program or G-code that dictates the spinning process.

In a typical CNC metal spinning operation, the machine operator uses CAD (Computer-Aided Design) software to create a model of the component. This model is then converted into G-code, which the CNC machine reads to perform the spinning operation.

2.3 Precision and Quality Control

One of the most significant advantages of CNC metal spinning is the precision it offers. Unlike manual methods, CNC systems ensure that each piece produced is identical, meeting strict tolerances. Quality control is also improved through real-time monitoring systems, which track the machine’s performance and make automatic adjustments to prevent defects.

For industries like aerospace, medical devices, and automotive, where the reliability and precision of parts are critical, CNC metal spinning provides a superior manufacturing option.

Materials Used in CNC Metal Spinning

CNC metal spinning is compatible with a variety of metals, each offering unique properties. The most common materials used include:

- Aluminum: Light and highly malleable, aluminum is frequently used for applications requiring corrosion resistance and electrical conductivity, such as in aerospace and electronics.

- Stainless Steel: Known for its strength, durability, and corrosion resistance, stainless steel is used in applications like medical devices, food processing equipment, and chemical containers.

- Copper: Malleable and conductive, copper is commonly used in electrical components and heat exchangers.

- Brass: With its low friction and high resistance to corrosion, brass is ideal for mechanical components and decorative pieces.

- Titanium: Valued for its high strength-to-weight ratio and resistance to extreme temperatures, titanium is often used in aerospace and medical applications.

Each material responds differently to the metal spinning process. For example, harder metals like stainless steel require more force and precision during forming, while softer metals like aluminum can be shaped more easily but may need additional support to prevent wrinkling or distortion.

3.2 Specialty Alloys and Their Applications

Beyond traditional metals, CNC metal spinning can also accommodate a range of specialty alloys designed for specific purposes. These include:

- Inconel: A nickel-chromium alloy known for its heat and corrosion resistance, making it ideal for turbine blades and exhaust systems.

- Monel: Another nickel alloy, Monel is often used in marine and chemical processing applications due to its excellent resistance to saltwater corrosion.

- Hastelloy: Often found in chemical processing equipment, Hastelloy offers superior resistance to chemical corrosion, particularly in highly acidic environments.

The ability to work with these specialized materials has expanded the reach of CNC metal spinning, making it a versatile manufacturing method for industries requiring components with enhanced durability, heat resistance, or corrosion protection

CNC Metal Spinning Techniques and Variations

4.1 Shear Forming

Shear forming is a variation of metal spinning that changes the thickness of the metal during the spinning process. This technique is used when parts require specific thickness dimensions in different areas, such as aerospace components that need to be lightweight but strong in certain sections. Shear forming allows for the thinning of metal in some places without sacrificing overall strength.

4.2 Flow Forming

Flow forming is a more advanced variation of CNC metal spinning. It uses axial and radial forces to elongate the metal, producing cylindrical components with extremely thin walls. Flow forming is commonly used for manufacturing tubes, rocket shells, and pressure vessels. The precision offered by this method ensures that the walls of the formed part are uniformly thin, which is crucial in industries where weight reduction is key.

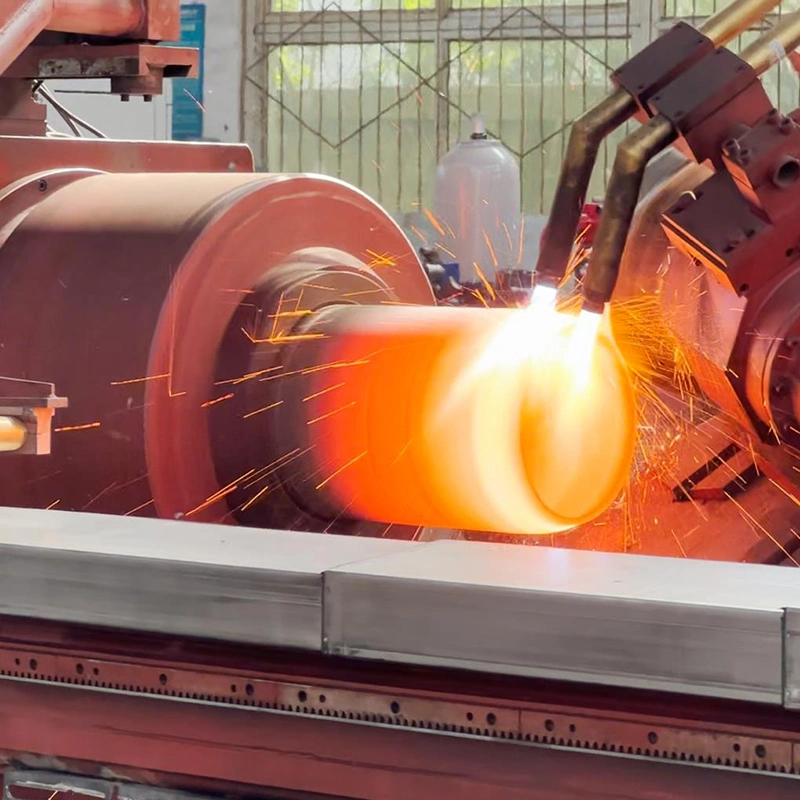

4.3 Hot Spinning vs. Cold Spinning

CNC metal spinning can be performed in either hot or cold conditions, depending on the material and the complexity of the shape being formed:

- Hot Spinning: The metal blank is heated before or during the spinning process. This makes it more malleable, reducing the likelihood of cracking or tearing when working with harder materials. Hot spinning is often used for metals like titanium and stainless steel.

- Cold Spinning: The metal is spun at room temperature. Cold spinning is ideal for softer metals like aluminum and copper, which don’t require the additional heat to be shaped efficiently. Cold spinning also helps to maintain the material’s mechanical properties without altering them through heating.

4.4 Multi-Pass vs. Single-Pass Spinning

CNC metal spinning can be performed using either single-pass or multi-pass techniques, depending on the desired end result. In single-pass spinning, the roller tool forms the entire shape in one continuous motion. This method is faster but less precise and is generally used for simple shapes.

In multi-pass spinning, the tool makes several passes over the blank, gradually shaping it into the final form. This method offers greater precision and is preferred for more complex shapes, where consistent thickness and structural integrity are critical.

Advantages and Limitations of CNC Metal Spinning

5.1 Advantages

CNC metal spinning offers several key advantages over other metal-forming techniques:

- Precision: With CNC control, manufacturers can achieve extremely tight tolerances and repeatable accuracy in production runs.

- Efficiency: CNC automation reduces the need for manual labor, speeding up production times and lowering costs.

- Versatility: The ability to work with a wide range of metals and create complex geometries makes CNC metal spinning suitable for numerous industries.

- Material Utilization: The spinning process produces very little waste, making it an environmentally friendly option.

- Structural Integrity: Spinning produces parts with smooth surfaces and consistent wall thickness, resulting in components with superior strength and durability.

5.2 Limitations

Despite its many benefits, CNC metal spinning does have some limitations:

- Initial Costs: The investment in CNC equipment and tooling can be high, which may not be economical for small production runs.

- Material Limitations: While CNC spinning works well with malleable metals, harder materials may require additional processing steps like annealing.

- Complexity Constraints: Although CNC machines can handle complex geometries, there are limitations in creating parts with extreme undercuts or sharp internal corners.

- Thickness Variability: While spinning allows for gradual thickness changes, it may not be the best choice for components that require abrupt transitions in wall thickness.

Applications of CNC Metal Spinning

6.1 Aerospace

In the aerospace industry, where weight, precision, and durability are critical, CNC metal spinning is used to create parts such as turbine housings, nose cones, and fuel tanks. The ability to produce lightweight, thin-walled components with high structural integrity makes CNC metal spinning an ideal choice for aerospace manufacturers.

6.2 Automotive

The automotive industry benefits from CNC metal spinning in the production of components such as wheel rims, exhaust systems, and transmission parts. By utilizing spinning, manufacturers can produce high-strength parts with tight tolerances, which are essential for performance and safety in vehicles.

6.3 Medical Devices

CNC metal spinning is also prevalent in the medical field. Stainless steel and titanium, in particular, are commonly used to create surgical instruments, implantable devices, and other critical components. The precision and cleanliness of the spinning process ensure that these devices meet stringent medical standards.

6.4 Industrial and Heavy Machinery

In industrial settings, CNC metal spinning is used to create parts for heavy machinery, such as pressure vessels, pipes, and funnels. The durability and strength of spun metal components are essential in environments where high pressures and extreme temperatures are present.

CNC Metal Spinning vs. Other Metal Forming Methods

7.1 CNC Metal Spinning vs. Stamping

Stamping is another common metal-forming technique, but it differs significantly from CNC metal spinning. Stamping is ideal for high-volume production runs of small, simple parts, while CNC spinning excels in creating larger, more complex components. Stamping generally produces more waste, whereas spinning is more efficient in material usage.

7.2 CNC Metal Spinning vs. Deep Drawing

Deep drawing is a metal-forming process that stretches a metal blank into a die to create a hollow shape. While deep drawing is well-suited for high-volume production of small to medium-sized parts, CNC metal spinning offers greater flexibility in part size and geometry. Deep drawing can also result in thinning of the material, which may not be ideal for applications where uniform thickness is required.

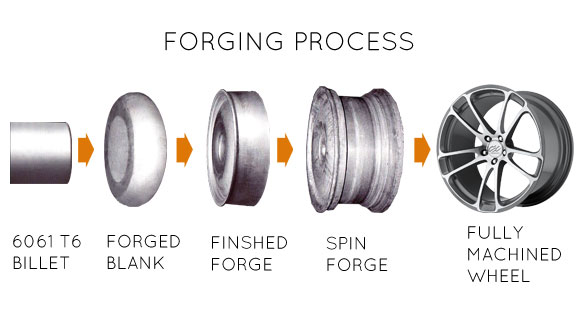

7.3 CNC Metal Spinning vs. Forging

Forging involves heating a metal blank and applying pressure to form a part. While forging is excellent for creating parts with high strength, it lacks the precision of CNC metal spinning. Spinning is also more efficient in producing parts with complex geometries and smoother surfaces.

Innovations in CNC Metal Spinning

8.1 Automation and Robotics

As CNC metal spinning continues to evolve, the integration of automation and robotics is becoming more common. Automated systems can load and unload blanks, change tools, and even perform quality checks. This reduces the need for human intervention, further increasing efficiency and consistency in production.

8.2 Advanced Materials

The development of new materials, such as superalloys and composites, has expanded the capabilities of CNC metal spinning. These materials offer enhanced properties, such as heat resistance, strength, and corrosion resistance, making them ideal for advanced applications in aerospace, defense, and energy sectors.

8.3 Hybrid Manufacturing Techniques

Some manufacturers are combining CNC metal spinning with other processes, such as additive manufacturing and CNC machining, to create hybrid solutions. These hybrid techniques allow for even greater complexity in part design, combining the strengths of different manufacturing methods.

Future Trends in CNC Metal Spinning

9.1 Increased Use of AI and Machine Learning

The future of CNC metal spinning is likely to see an increased integration of AI and machine learning. These technologies will allow machines to self-optimize, adjusting parameters in real-time based on sensor data and past performance. This will lead to even greater precision, faster production times, and lower defect rates.

9.2 Sustainable Manufacturing

As sustainability becomes a greater focus for manufacturers, CNC metal spinning is poised to play a role in reducing waste and energy consumption. The process already produces minimal waste, and advancements in energy-efficient machines and materials will further enhance its environmental benefits.

9.3 Expanding Applications

With continuous improvements in CNC technology and material science, new applications for CNC metal spinning are expected to emerge. The medical, renewable energy, and transportation sectors are all likely to see increased use of this versatile manufacturing process.

Conclusion

CNC metal spinning has come a long way since its manual beginnings. Today, it is a highly advanced, versatile, and efficient manufacturing process used across industries ranging from aerospace to medical devices. With ongoing advancements in technology, materials, and sustainability, CNC metal spinning is set to remain a cornerstone of modern manufacturing for years to come

The Origins and Evolution of Metal Spinning

1.3 Manual vs. Modern Techniques: A Detailed Comparison

One of the most notable shifts in metal spinning technology is the move from manual techniques to modern CNC-controlled processes. Manual spinning required years of apprenticeship, where artisans developed a keen understanding of the material’s behavior, using nothing more than their experience and a set of basic tools. While this craftsmanship is still respected today, it has largely been replaced by the more efficient and accurate CNC process.

- Manual Metal Spinning:

- Dependent on operator skill and experience.

- Ideal for custom, one-off pieces or low-volume production.

- Inconsistent precision due to human error.

- High labor costs and slower production times.

- Limited complexity in part design, as intricate forms are difficult to achieve consistently.

- CNC Metal Spinning:

- Automated, ensuring consistency and high precision in mass production.

- Capable of producing both low- and high-volume parts with identical accuracy.

- Lower labor costs due to reduced manual input.

- Can handle more complex geometries, including asymmetrical shapes, which are difficult to achieve manually.

- Integrated quality control features that ensure defects are minimized during the process.

The transition from manual to CNC-based techniques has had profound effects across the manufacturing industry, providing businesses with more flexibility in product design and enabling mass production of parts that meet exacting standards.

1.4 Economic Impact of CNC Metal Spinning

CNC metal spinning has not only revolutionized manufacturing from a technical standpoint but has also had a significant economic impact. The efficiency of CNC processes has reduced production costs for manufacturers, particularly in industries that require large quantities of precision parts. This has led to price reductions in end products, benefiting both manufacturers and consumers.

Additionally, CNC metal spinning supports shorter lead times, meaning that manufacturers can respond more quickly to market demands. This is especially important in sectors like automotive and aerospace, where rapid prototyping and quick production turnaround can offer a competitive edge.

The increasing affordability of CNC equipment has made it more accessible for smaller manufacturing businesses, democratizing the production of high-quality metal components and further boosting the industry’s economic impact

3.3 Surface Treatments and Coatings

While CNC metal spinning produces parts with excellent surface finishes, some applications require additional surface treatments or coatings to enhance the durability, corrosion resistance, or aesthetic appeal of the final product. Common surface treatments and coatings used in conjunction with CNC-spun parts include:

- Anodizing: A process mainly used for aluminum, anodizing increases corrosion resistance and surface hardness. It also allows for the addition of color, making it a popular choice for decorative or branding purposes.

- Powder Coating: Powder coating provides a durable, uniform finish that protects the metal from scratches, corrosion, and wear. It’s frequently used in the automotive and consumer goods industries.

- Electroplating: This involves depositing a thin layer of metal onto the surface of the part to improve appearance, corrosion resistance, or wear resistance. Common electroplated metals include chrome, zinc, and nickel.

- Passivation: Primarily used for stainless steel, passivation is a chemical process that removes contaminants from the metal surface, improving its resistance to corrosion.

- Heat Treatments: In some cases, heat treatments are applied to increase the hardness, strength, or malleability of a spun part. This is particularly useful for metals like titanium or steel, where post-spinning heat treatments can enhance the mechanical properties of the part.

The choice of surface treatment or coating depends on the material used, the environment in which the part will operate, and the desired lifespan of the component.

3.4 Selecting the Right Material for CNC Metal Spinning

Selecting the right material for CNC metal spinning is crucial and depends on various factors, including the application of the part, the required mechanical properties, and the manufacturing budget. For instance, aerospace components often need materials that can withstand high temperatures and stresses, which makes titanium or high-performance alloys like Inconel and Hastelloy suitable choices.

By contrast, applications that prioritize corrosion resistance without needing extreme strength, such as parts for food processing or marine equipment, typically use stainless steel or aluminum. The key factors in material selection include:

- Strength-to-Weight Ratio: For applications like aerospace, lightweight materials with high strength, such as titanium, are essential.

- Corrosion Resistance: For parts exposed to harsh environments or chemicals, materials like stainless steel or copper alloys are preferred.

- Thermal Conductivity: Copper or aluminum is used in applications where heat dissipation is critical, such as in electronics or heat exchangers.

- Cost: While specialty alloys offer enhanced performance, they are typically more expensive. Manufacturers need to balance material costs with performance requirements to choose the most cost-effective solution.

Each material used in CNC metal spinning has its advantages and trade-offs, and the choice of material often dictates the complexity and cost of the manufacturing process.

CNC Metal Spinning Techniques and Variations

4.5 Hybrid Spinning Techniques

Hybrid techniques combine CNC metal spinning with other metal-forming processes to achieve unique results that would be difficult or impossible to attain with a single technique. These methods enhance flexibility in part design and provide additional material properties that are beneficial for specific applications.

- CNC Spinning with Deep Drawing: This hybrid method combines the precision of CNC spinning with the depth-forming capability of deep drawing. This is particularly useful for creating large, deep parts with uniform wall thicknesses and smooth transitions.

- CNC Spinning with Welding: In some cases, manufacturers combine spinning with welding techniques to produce parts that have both complex shapes and assemblies. For example, after spinning a component, a secondary welding process can be used to attach additional parts or to reinforce specific areas.

- Additive Manufacturing and CNC Spinning: Additive manufacturing (3D printing) is increasingly being combined with traditional metal-forming techniques like CNC spinning. In this hybrid approach, complex structures are first created using additive techniques, and then CNC spinning is used to refine the part, providing a high-quality finish and enhanced mechanical properties.

Hybrid techniques offer expanded possibilities for part design and material manipulation, making them ideal for cutting-edge industries like aerospace and medical device manufacturing.

4.6 Tooling Innovations

Tooling in CNC metal spinning has undergone significant advancements over the years. Traditionally, the roller tools used in the spinning process were limited in terms of shape and material. However, modern advancements in tooling materials and design have led to more versatile and durable options.

- Carbide and Diamond-Coated Tools: Tools made from carbide or coated with diamond offer increased durability and longer tool life, especially when working with hard metals like titanium or Inconel. These tools maintain their cutting edges for longer, reducing the need for frequent replacements and ensuring consistency in part quality.

- Modular Tooling: Modular tooling systems allow for quick changes between different tool heads, which enhances the flexibility of the CNC metal spinning process. This is particularly useful in high-mix, low-volume production environments where part designs may vary significantly between production runs.

- Smart Tooling Systems: New developments in “smart” tooling involve integrating sensors directly into the tooling components. These sensors monitor parameters like force, temperature, and vibration in real time, allowing for immediate adjustments to the process. This results in higher precision and reduced material waste.

Tooling innovations are key to expanding the capabilities of CNC metal spinning, enabling the production of more complex parts while reducing costs and lead times.

Advantages and Limitations of CNC Metal Spinning

5.3 Addressing the Limitations of CNC Metal Spinning

While CNC metal spinning is a highly effective and versatile process, manufacturers have developed methods to address some of its limitations.

- Initial Costs and Small Runs: To mitigate the high initial costs of CNC equipment, many companies offer metal spinning as a service. This allows smaller manufacturers to produce spun components without investing in expensive equipment. In addition, advances in CNC technology have made smaller, more affordable machines available, increasing access to the technology.

- Material Hardness: To address the challenge of spinning harder materials, manufacturers often use a combination of pre-heating (for hot spinning) and advanced tooling materials like carbide and ceramics. These techniques reduce wear on the tooling and allow for smoother, more precise forming of difficult materials.

- Thickness Transitions: In cases where abrupt thickness changes are needed, CNC metal spinning can be combined with machining processes to fine-tune the thickness after spinning. This hybrid approach allows for the creation of parts with variable thicknesses while maintaining the structural benefits of spun metal.

By addressing these limitations through technological innovations and hybrid techniques, CNC metal spinning continues to expand its applications across industries.

5.4 Case Studies of CNC Metal Spinning Advantages

A deeper look into the real-world application of CNC metal spinning highlights the process’s advantages.

- Aerospace: A major aerospace manufacturer needed lightweight, high-strength nose cones for its aircraft. By using CNC metal spinning, they were able to produce these parts with precise wall thickness and smooth surfaces. The spun nose cones were lighter and more aerodynamic than those made using traditional forging techniques.

- Medical Devices: A medical device company required biocompatible, durable titanium parts for implantable devices. CNC metal spinning allowed them to produce these components with tight tolerances and smooth finishes, meeting the strict standards required for medical devices.

- Automotive: In the automotive sector, CNC metal spinning has been used to create lightweight exhaust systems. By reducing the thickness of certain areas without sacrificing strength, manufacturers were able to lower the overall weight of the exhaust systems, improving fuel efficiency.

These case studies demonstrate the versatility and practicality of CNC metal spinning in producing components that meet stringent requirements for performance and quality.

Applications of CNC Metal Spinning

6.5 Renewable Energy

The renewable energy sector is another area where CNC metal spinning is playing a pivotal role. Components for wind turbines, solar energy collectors, and even energy storage systems can be manufactured using this process. For instance:

- Wind Turbines: The nacelles (the housing for the turbine components) and certain parts of the rotor blades can be manufactured using CNC metal spinning. This provides the necessary strength and durability to withstand extreme environmental conditions while reducing weight to improve efficiency.

- Solar Energy: Reflective dishes used in solar power generation systems often require precise geometric shapes to maximize the concentration of sunlight. CNC metal spinning is ideal for producing these components, as it ensures uniformity and surface smoothness, which are critical for optimal performance.

- Energy Storage: CNC metal spinning is also used to create pressure vessels for energy storage systems, such as compressed air energy storage (CAES) systems, where strong, lightweight materials are essential for efficient operation.

6.6 Defense and Military

CNC metal spinning is also used extensively in the defense industry to produce critical components that require high precision and durability. This includes:

- Rocket Casings: Flow-formed rocket casings are produced using CNC metal spinning techniques. These components need to be lightweight, yet strong enough to withstand the extreme forces and temperatures during launch and flight.

- Armor Components: In some cases, CNC metal spinning is used to create armor components, including protective plates for military vehicles or personnel. The process ensures that the metal is dense and strong while remaining relatively lightweight.

Future Trends in CNC Metal Spinning

9.4 Customization and On-Demand Manufacturing

As industries continue to push toward customization and on-demand manufacturing, CNC metal spinning is expected to play a key role. With CNC technology, manufacturers can quickly switch between designs, allowing for the efficient production of custom parts without the need for extensive retooling. This is especially valuable in industries where personalization is becoming a norm, such as:

- Automotive: Customized car parts, from exhaust systems to wheels, are becoming more popular among consumers. CNC metal spinning allows manufacturers to meet this demand with high precision.

- Consumer Goods: For items like cookware, lighting fixtures, or even furniture, CNC metal spinning offers a way to produce unique, high-quality designs with minimal lead time.

- Medical Devices: The ability to create custom implants and instruments tailored to individual patients is a significant advancement in the medical field. CNC metal spinning, combined with other manufacturing techniques, will continue to support personalized healthcare solutions.

The trend toward customization is driving innovation in CNC metal spinning, as manufacturers seek to meet the growing demand for tailored, on-demand products.

CNC Metal Spinning vs. Other Metal Forming Methods

7.4 CNC Metal Spinning vs. Hydroforming

Hydroforming is another method used to shape metals into complex geometries, especially in industries that require high precision and structural integrity. However, there are key differences between CNC metal spinning and hydroforming:

- Process Differences: Hydroforming uses high-pressure hydraulic fluid to press metal blanks into a die, forming the desired shape. In contrast, CNC metal spinning applies mechanical force via rollers to shape the metal on a rotating lathe.

- Tooling Costs: Hydroforming typically requires expensive dies, making it less cost-effective for small runs or custom projects. CNC metal spinning, on the other hand, requires simpler tooling setups, which reduces upfront costs and makes it more economical for lower production volumes or prototyping.

- Material Thickness: While both processes can handle a range of material thicknesses, hydroforming is often more suitable for very thin materials, as the high-pressure fluid evenly distributes force across the metal surface. CNC metal spinning can produce thinner walls but might require multiple passes or more advanced techniques, such as shear forming, to achieve similar results.

- Flexibility in Design: CNC metal spinning offers greater flexibility in terms of part design. With spinning, parts can be adjusted or reprogrammed quickly using the CNC system, which is ideal for applications requiring frequent design changes or customization. Hydroforming is generally more suited for high-volume production with stable designs due to the high cost of creating dies for each specific shape.

7.5 CNC Metal Spinning vs. Casting

Casting is a widely used metal-forming process where molten metal is poured into a mold and allowed to cool, taking the shape of the mold. While both casting and CNC metal spinning are used for producing parts, they differ significantly in several key areas:

- Complexity of Shape: Casting is excellent for creating highly intricate shapes with internal geometries, undercuts, and fine details that would be difficult to achieve with CNC spinning. However, casting can result in rougher surfaces and may require post-processing to smooth out the part.

- Surface Finish: CNC metal spinning, on the other hand, typically produces smoother surface finishes right out of the process, with little to no need for secondary machining or finishing operations. This makes it ideal for applications that require high-quality surface finishes, such as reflective components in lighting or aesthetic pieces in consumer products.

- Strength and Durability: While cast parts can have complex geometries, they are often more brittle due to the nature of the cooling process, which can introduce internal stresses and microfractures. CNC-spun parts, in contrast, maintain the inherent strength of the metal due to the mechanical deformation process, which can actually improve the grain structure of the metal, resulting in stronger, more durable components.

- Lead Times: Casting involves longer lead times, especially if custom molds are required. CNC metal spinning, with its flexible tooling and faster setup times, is more suited for projects where quick turnaround is needed.

Each of these metal-forming processes has its own set of advantages and limitations, and the choice between them depends largely on the specific requirements of the part being manufactured, such as the complexity of the shape, the mechanical properties needed, and the budget for tooling and production.

7.6 CNC Metal Spinning vs. Roll Forming

Roll forming is a continuous process used to shape long strips of metal into desired cross-sectional profiles. Here’s how it compares to CNC metal spinning:

- Material Usage: Roll forming is typically used for large volumes of long, uniform sections like beams, rails, or structural supports. It excels in producing parts with constant profiles over long lengths. In contrast, CNC metal spinning is used to create axially symmetric shapes, such as cones, hemispheres, and cylindrical components, making it ideal for hollow parts.

- Production Speed: Roll forming is generally faster than CNC metal spinning, especially for high-volume runs of simple, repetitive shapes. However, the setup costs for roll forming are higher due to the complex tooling required, whereas CNC metal spinning allows for quick retooling and can accommodate more custom shapes without significant setup changes.

- Precision: CNC metal spinning provides tighter tolerances for complex geometries, especially when creating parts with varying wall thicknesses. Roll forming is better suited for parts that require consistent cross-sectional shapes over long lengths but may not provide the same level of precision for complex designs.

- Versatility: CNC metal spinning offers greater versatility in terms of design, material options, and production runs. While roll forming is limited to continuous shapes, CNC metal spinning can create diverse, hollow, and varying designs from a single blank, making it more adaptable for custom manufacturing projects or specialized industries like aerospace and medical devices.

Innovations in CNC Metal Spinning

8.4 Integration of CAD/CAM Software

One of the key innovations driving CNC metal spinning technology is the integration of advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. These systems allow engineers and designers to create highly detailed models of the parts they need, which can then be translated directly into CNC programming code for the spinning machines. The integration of CAD/CAM software into CNC metal spinning has several benefits:

- Enhanced Precision: Designers can create highly complex geometries in 3D CAD software, ensuring that the final part meets exact specifications. CAM software then translates these designs into G-code that the CNC machine uses to accurately form the metal part.

- Reduced Prototyping Time: With CAD/CAM, engineers can simulate the entire spinning process before the part is produced, identifying potential issues or inefficiencies in the design. This virtual prototyping significantly reduces the time and cost associated with physical prototyping and helps ensure that the first production run is successful.

- Customization Capabilities: For industries like automotive or consumer goods, where customized parts are increasingly in demand, CAD/CAM integration allows for easy adjustments to design files, enabling rapid reprogramming of the CNC machine for different part configurations.

- Data-Driven Manufacturing: The integration of CAD/CAM systems with CNC metal spinning opens up new possibilities for data-driven manufacturing. Engineers can analyze production data in real-time, fine-tuning processes to optimize material usage, minimize waste, and ensure consistency across production runs.

8.5 AI-Powered Optimization

The integration of artificial intelligence (AI) and machine learning into CNC metal spinning is another cutting-edge development that is set to revolutionize the industry. AI algorithms can analyze vast amounts of data collected from CNC machines during the spinning process, allowing the system to make real-time adjustments to the speed, force, and path of the spinning tool. This leads to several benefits:

- Predictive Maintenance: AI systems can predict when a machine is likely to experience wear or breakdown based on historical data. This allows manufacturers to perform maintenance before issues arise, reducing downtime and avoiding costly repairs.

- Process Optimization: AI-powered systems can optimize the spinning process by continuously learning from previous production runs. The AI adjusts parameters to improve efficiency, reduce material waste, and ensure higher-quality parts with fewer defects.

- Customizable Tolerances: AI can help fine-tune tolerances on complex parts, dynamically adjusting the process as needed. This is particularly useful in industries like aerospace and medical devices, where precision is critical and tolerances are extremely tight.

As AI continues to evolve, its integration with CNC metal spinning will only deepen, further enhancing the precision, speed, and efficiency of the manufacturing process.

8.6 Green Manufacturing and Sustainability

Sustainability is becoming an increasingly important consideration in manufacturing, and CNC metal spinning is no exception. Several innovations are helping to make the process more environmentally friendly:

- Material Efficiency: One of the inherent advantages of CNC metal spinning is its minimal waste. Unlike machining, which often involves cutting away material, metal spinning transforms a flat blank into a finished part with very little excess material. New advances in simulation software allow manufacturers to further optimize material usage, reducing waste even more.

- Energy-Efficient Machinery: Modern CNC machines are being designed with energy efficiency in mind. Innovations in motor technology, lubrication systems, and automation have resulted in machines that consume less energy while maintaining high levels of productivity.

- Recycling and Circular Economy: Many manufacturers are now incorporating recycled metals into their production processes. CNC metal spinning can easily accommodate recycled materials, which helps reduce the environmental impact of mining and processing new metals. Additionally, the end products created through CNC spinning can be recycled at the end of their life cycle, contributing to a circular economy.

These innovations are positioning CNC metal spinning as a leader in sustainable manufacturing, ensuring that the process remains competitive in a world where environmental responsibility is increasingly important.

Future Trends in CNC Metal Spinning

9.5 Advanced Materials and Their Potential

The future of CNC metal spinning is closely tied to advancements in material science. As new alloys and composites are developed, CNC metal spinning machines will need to adapt to handle these advanced materials, offering new possibilities for performance and application:

- Superalloys: The development of superalloys, such as Inconel, Hastelloy, and Waspaloy, is allowing for the creation of parts that can withstand extreme temperatures and corrosive environments. These materials are critical in industries such as aerospace, nuclear power, and chemical processing. CNC metal spinning is well-positioned to form these superalloys into complex shapes with precision, making it a valuable tool for manufacturers in these sectors.

- Metal Matrix Composites (MMCs): Metal matrix composites combine metals with other materials (such as ceramics or carbon fibers) to create parts that are both lightweight and incredibly strong. CNC metal spinning is being adapted to handle these materials, which are particularly useful in aerospace, automotive, and defense applications where weight reduction without compromising strength is a priority.

- Biodegradable Metals: In the medical field, researchers are developing biodegradable metals, such as magnesium alloys, for use in implants that dissolve in the body after they have fulfilled their purpose. CNC metal spinning can help shape these materials into precise medical devices, opening new possibilities for temporary implants that do not require surgical removal.

These material advancements will drive the future of CNC metal spinning, as manufacturers look for ways to combine strength, durability, and lightweight properties with sustainability and performance in extreme conditions.

9.6 Industry 4.0 and the Smart Factory

CNC metal spinning is set to be a critical part of the “Industry 4.0” revolution, where smart factories use interconnected systems, real-time data, and automation to enhance production capabilities:

- IoT Integration: In the smart factory, CNC machines are connected to the Internet of Things (IoT), enabling real-time communication between machines, sensors, and software. This allows for automated adjustments to the spinning process based on live data, reducing errors and ensuring optimal performance at all times.

- Digital Twins: One emerging concept in Industry 4.0 is the use of digital twins—virtual replicas of physical machines. Manufacturers can simulate the CNC spinning process in a digital environment, allowing them to predict outcomes, troubleshoot potential issues, and optimize processes before they are implemented on the shop floor.

- Full Automation: With advancements in robotics and AI, the future CNC metal spinning factory will likely see full automation, where machines handle everything from material loading to quality inspection without human intervention. This will further reduce production times and improve accuracy, especially for high-volume, precision-demanding industries.

The integration of CNC metal spinning into smart manufacturing environments will enhance productivity, reduce costs, and position the industry for the future of advanced manufacturing.

Fundamentals of Metal Spinning

Metal spinning, also known as spin forming or metal turning, is a manufacturing process used to produce axially symmetric parts by rotating a metal workpiece around a central axis and shaping it with a tool. This technique has been used for centuries, dating back to ancient civilizations where manual spinning techniques were employed to form basic metal components. Over time, metal spinning has evolved significantly, from being a craft-based manual process to a highly automated and precision-controlled operation, incorporating computer numerical control (CNC) machines for complex and accurate shaping.

The basic concept of metal spinning remains simple: a flat metal disc, referred to as a blank, is clamped onto a rotating mandrel that mirrors the desired shape. Using rollers or other tools, the metal is incrementally formed around the mandrel as it spins at high speed, resulting in components that are typically round or conical. The process is highly adaptable, suitable for producing parts in a wide range of sizes, thicknesses, and materials.

Traditional vs. Modern Metal Spinning

Historically, metal spinning was a labor-intensive process, requiring highly skilled craftsmen to shape the workpiece by hand. The artisan would rely on their experience to apply force uniformly across the workpiece to achieve a smooth finish. While the basic tools were simple (rollers, levers, and mandrels), the skill needed to maintain consistency made traditional spinning a respected craft.

In contrast, modern metal spinning employs advanced machinery, including CNC systems, which allow for precision forming without the need for direct human intervention. CNC metal spinning machines can produce intricate and consistent parts with tight tolerances, revolutionizing the industry and enabling the production of complex components in large quantities.

Industrial Applications

Metal spinning is extensively used in various industries, where it delivers components with superior strength, excellent surface finish, and minimal material waste. Here are some key industrial sectors where metal spinning plays a crucial role:

- Aerospace Industry: The aerospace sector relies heavily on metal spinning for creating lightweight, durable components such as rocket nose cones, turbine housings, and air intake parts. The high precision and strength-to-weight ratio of spun metal components make them ideal for aircraft and spacecraft applications.

- Automotive Industry: In automotive manufacturing, metal spinning is utilized to produce various parts, including wheel rims, brake discs, and exhaust systems. The process provides cost-effective manufacturing solutions for both mass production and custom-designed components.

- Lighting and Architecture: Metal spinning is frequently used to create light fixtures, decorative architectural elements, and reflectors. Its ability to produce seamless, symmetrical shapes lends itself well to aesthetic and functional applications in buildings and industrial lighting systems.

- HVAC (Heating, Ventilation, and Air Conditioning): HVAC systems often utilize metal spinning to manufacture parts such as fan housings, ductwork components, and blower wheels, where air-tight seals and durability are essential.

Advantages of Metal Spinning

Metal spinning offers several key benefits, which have contributed to its continued use and advancement in modern manufacturing processes:

- Material Efficiency and Waste Reduction: One of the most significant advantages of metal spinning is its efficiency in material usage. Unlike other manufacturing processes like stamping or milling, which often result in significant material wastage, metal spinning works by deforming a metal blank into the desired shape without removing excess material. This leads to higher material utilization rates and cost savings, particularly in large-scale production runs.

- Versatility and Production Flexibility: Metal spinning is highly versatile, capable of producing a wide range of shapes and sizes, from small parts like bells and vases to large components such as satellite dishes and tank ends. Furthermore, the process can accommodate different materials, including aluminum, stainless steel, copper, and brass. Whether for prototype production or large-scale manufacturing, metal spinning can adapt to varying production requirements.

- Enhanced Strength and Durability: During the spinning process, the material is subjected to significant compressive forces, which improve the mechanical properties of the final component. This results in a finished product with higher tensile strength, greater resistance to fatigue, and improved durability, making it suitable for applications where structural integrity is critical.

- Reduced Tooling Costs: Compared to other metal forming processes like deep drawing or forging, metal spinning requires relatively low-cost tooling. The process generally requires only a mandrel and simple rollers, reducing the need for expensive dies and molds. This makes it an economical choice, especially for low- to medium-volume production.

The Metal Spinning Process

The metal spinning process involves shaping a metal blank into a cylindrical or conical form by applying pressure while rotating the material on a lathe or specialized spinning machine. Though the equipment used today is highly sophisticated, the core principles remain the same as those employed centuries ago. The process can be broken down into several key stages:

- Preparation:

- The first step in metal spinning is selecting the appropriate metal blank. The material is chosen based on the final component’s design requirements, including factors such as strength, ductility, and corrosion resistance. The blank, typically circular and flat, is clamped onto a mandrel that reflects the desired final shape.

- Prior to spinning, the blank may undergo surface treatments such as cleaning, annealing, or coating, depending on the material type and intended use. These treatments ensure that the material can be spun efficiently and with minimal defects.

- Spinning:

- The actual spinning begins once the blank is secured on the mandrel. The mandrel rotates at high speed, and the operator (or CNC machine) applies pressure to the blank using a forming tool, usually a roller. The force causes the metal to flow and conform to the mandrel’s shape, gradually forming the component’s desired geometry.

- Several passes are often required, starting with rough passes to approximate the final shape, followed by finer passes to achieve the desired precision. The process is typically done in a lubricated environment to reduce friction and heat generation, improving surface finish and tool life.

- Finishing:

- After the spinning process is complete, the component may require secondary operations such as trimming, cutting, polishing, or heat treatment. Trimming removes excess material from the edges, while polishing enhances the surface finish. For some applications, further treatments such as anodizing, painting, or powder coating may be applied to improve corrosion resistance or aesthetic appeal.

- Finally, quality checks are performed to ensure that the part meets the required tolerances for size, thickness, and surface quality.

Types of Metal Spinning

There are various metal spinning techniques, each tailored to produce specific types of components and meet particular manufacturing requirements. The key types are as follows:

- Conventional Spinning:

- Conventional spinning, also known as hand spinning, is the most basic form of the process. In this method, the metal blank is spun and formed over a mandrel using rollers or forming tools. The process typically does not involve thinning of the material but instead maintains its original thickness throughout the forming process. This technique is ideal for producing symmetrical parts with simple geometries, such as cones, cylinders, and hemispheres.

- Applications include decorative items, lighting fixtures, and certain automotive components.

- Shear Spinning:

- Shear spinning, also known as power spinning, is an advanced form of metal spinning where the material is deliberately thinned as it is formed. Unlike conventional spinning, where the material retains its original thickness, shear spinning involves a reduction in wall thickness while maintaining the diameter of the blank. This is achieved by applying additional pressure during the spinning process.

- Shear spinning is commonly used for producing components such as missile cones, rocket casings, and other high-strength, lightweight structures.

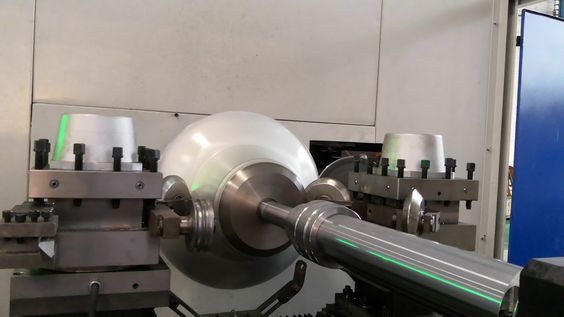

- Flow Forming:

- Flow forming is a specialized spinning technique used to produce long, thin-walled cylindrical parts, such as tubes and pressure vessels. This method involves pressing a preformed tube or blank against a mandrel while it rotates, progressively reducing its wall thickness while extending its length.

- Flow forming allows for precise control over material thickness and results in a stronger, more uniform structure than conventional processes. It is frequently used in aerospace, defense, and automotive industries for parts such as hydraulic cylinders, drive shafts, and pressure vessels.

- Tube Spinning:

- Tube spinning is a subset of flow forming where tubular blanks are spun and elongated to produce thin-walled cylinders. This process is highly efficient for manufacturing high-strength, lightweight tubular components.

- Applications include automotive parts such as drive shafts and transmission components, as well as specialized pipes for the oil and gas industry.

Materials Used in Metal Spinning

The metal spinning process is highly adaptable to a variety of metals and alloys. The material chosen for a specific application depends on factors such as required strength, corrosion resistance, and thermal properties. Some commonly used materials include:

- Aluminum:

- Aluminum is one of the most commonly spun metals due to its high strength-to-weight ratio, corrosion resistance, and ease of formability. It is used in aerospace, automotive, and decorative applications where lightweight and durability are key considerations.

- Stainless Steel:

- Stainless steel is valued for its corrosion resistance and mechanical strength. It is often used in industries where components must withstand harsh environmental conditions, such as in chemical processing, food and beverage, and marine applications. Due to its toughness, spinning stainless steel requires more force and specialized equipment.

- Copper:

- Copper offers excellent thermal and electrical conductivity, making it ideal for applications in the electronics and energy sectors. It is also highly formable and often used for decorative and architectural components due to its aesthetic appeal.

- Brass:

- Brass is frequently used in decorative and architectural applications because of its bright appearance and formability. Its resistance to corrosion also makes it suitable for use in marine environments.

- Titanium:

- Titanium is favored in aerospace and medical industries due to its exceptional strength, light weight, and biocompatibility. However, spinning titanium can be more challenging due to its high strength and low formability, requiring specialized equipment and processes.

Quality Control and Precision

In metal spinning, achieving dimensional accuracy and maintaining surface quality are critical, particularly for industries such as aerospace and medical manufacturing, where tight tolerances and high precision are necessary.

- Dimensional Tolerance:

- The metal spinning process can achieve high precision in component dimensions, but maintaining tight tolerances depends on various factors, including tool design, machine calibration, and operator skill (in manual spinning). CNC metal spinning machines are particularly useful for producing parts with consistent accuracy across large production runs.

- Surface Finish:

- A good surface finish is vital in applications where the part’s appearance or functionality (such as fluid dynamics) is essential. Surface defects like roughness, scratches, or marks can arise during the spinning process due to tool wear or improper lubrication. Post-processing operations such as polishing and surface coating are used to improve the finish where necessary.

- Non-Destructive Testing (NDT):

- For critical components, such as those used in aerospace or medical applications, non-destructive testing methods like ultrasonic inspection or X-ray imaging are employed to detect internal flaws without damaging the component. These tests ensure that the finished product meets the required structural and performance standards.

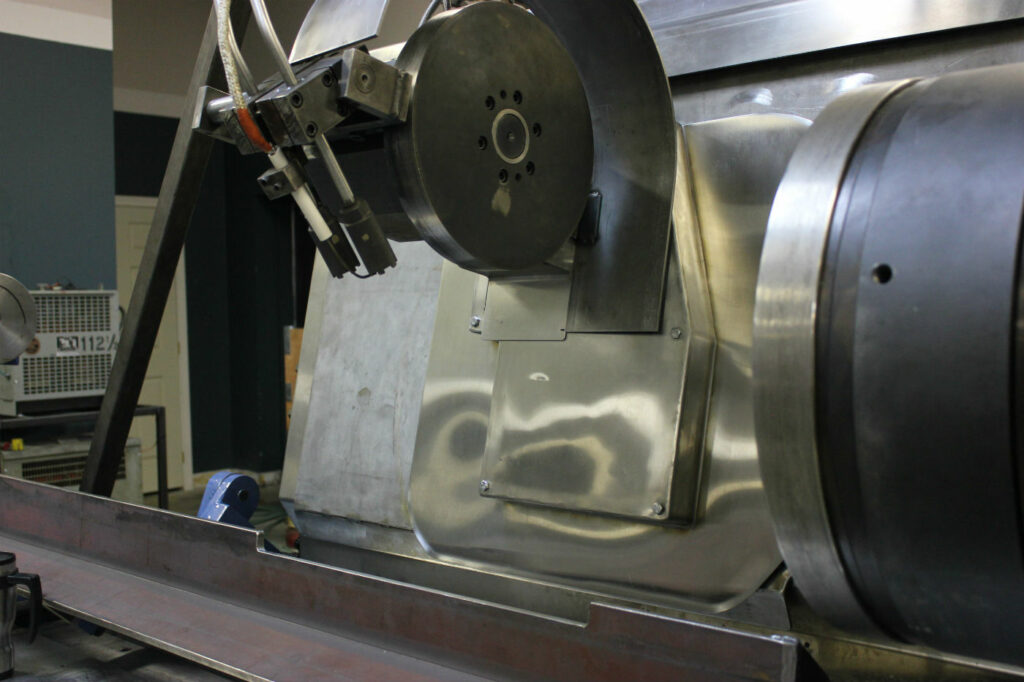

Metal Spinning Machines: An Overview

Metal spinning machines play a critical role in transforming flat metal blanks into symmetrical, three-dimensional shapes. The machinery used in metal spinning ranges from simple manual lathes to highly advanced CNC-controlled systems that allow for precision manufacturing at scale. Depending on the complexity of the part being produced, the type of machine used can vary significantly in terms of size, speed, and capability.

At the most basic level, a metal spinning machine consists of a rotating spindle or mandrel, where the metal blank is clamped, and a tool or roller that shapes the material. The mandrel spins at high speed while the tool presses the material onto the mandrel to form the desired shape. Machines are typically categorized based on their degree of automation, configuration (manual or CNC), and specific applications (conventional, shear, or flow spinning).

- Manual vs. Automated (CNC-Controlled) Machines:

- Manual metal spinning machines are the traditional equipment used in small-scale production or for prototyping. They rely on the skill of the operator to control the pressure and speed during the spinning process, making them highly flexible but labor-intensive.

- CNC metal spinning machines, on the other hand, are fully automated and computer-controlled, offering enhanced precision, repeatability, and efficiency. CNC machines are programmed using CAD/CAM software, allowing operators to create complex part geometries with minimal manual intervention. These machines are essential in modern manufacturing, particularly in industries requiring high precision and large production volumes, such as aerospace and automotive.

Key Components of Metal Spinning Machines

While there are various configurations of metal spinning machines, they all share a set of fundamental components that make the spinning process possible. Understanding these key components is essential for optimizing machine performance, ensuring quality output, and conducting routine maintenance.

- Headstock and Tailstock:

- The headstock houses the spindle, which holds the mandrel and rotates at high speed during the spinning process. The headstock must be rigid and stable to ensure precise spinning without vibrations, which can cause surface defects.

- The tailstock supports the other end of the workpiece, keeping the blank or preform in place during spinning. The tailstock can move along the bed to accommodate different lengths and sizes of workpieces, ensuring proper alignment throughout the process.

- Tooling Systems (Roller and Mandrel):

- The mandrel is one of the most critical components of the machine. It serves as the mold or template that the metal blank conforms to during spinning. Mandrels are typically made from durable materials such as hardened steel or aluminum, depending on the specific metal being spun and the complexity of the part.

- Rollers or other forming tools apply pressure to the blank, causing it to flow and take the shape of the mandrel. The rollers are mounted on a tool post, which can be manually or automatically controlled, depending on the machine type. Rollers must be designed to reduce friction and prevent marking on the metal surface.

- Bed and Frame:

- The bed is the foundation of the metal spinning machine, providing support for the headstock, tailstock, and tooling systems. It must be sturdy and well-aligned to ensure smooth operation. Some machines feature adjustable beds that can accommodate different part sizes and configurations.

- The frame of the machine must be rigid to minimize vibrations during the spinning process, as even slight movement can compromise part quality. High-performance machines use heavy-duty steel frames to maximize stability.

- Drive Systems:

- The drive system powers the rotation of the spindle and is typically controlled by an electric motor. CNC machines utilize servo motors for precise control over spindle speed and acceleration, while manual machines may rely on more basic motor setups.

- Advanced CNC systems allow for variable speed control, which is essential for spinning different materials and achieving the desired surface finish and dimensional accuracy.

Machine Configurations and Capabilities

Metal spinning machines come in various configurations, each suited for specific production needs. Understanding these configurations helps manufacturers choose the right machine for their application, whether for prototyping, mass production, or working with specialized materials.

- Vertical vs. Horizontal Configurations:

- Horizontal spinning machines are the most common type, where the workpiece is mounted on a horizontal spindle. These machines are versatile and can handle a wide range of part sizes and shapes, making them the go-to option for general metal spinning applications.

- Vertical spinning machines, while less common, are used for specific applications where gravity assists in the shaping process or where vertical clamping is more efficient for the workpiece geometry. These machines are often used for spinning large, heavy components such as pressure vessels.

- Load Capacities and Maximum Spindle Speeds:

- The capacity of a metal spinning machine is determined by its maximum spindle speed and the size of the workpiece it can accommodate. Machines designed for thin-walled, lightweight components require higher spindle speeds, sometimes exceeding 3,000 RPM. In contrast, machines used for thick-walled parts or heavy materials operate at lower speeds but with higher torque.

- Load capacity also refers to the maximum force that the machine can exert on the blank during spinning. Machines designed for shear spinning or flow forming often feature hydraulic or servo-driven systems that can apply significant pressure without damaging the material.

- Machine Adaptability for Different Materials:

- Different metals require different machine setups due to variations in material properties such as ductility, strength, and hardness. Machines designed for spinning aluminum, for instance, operate at higher speeds and require less force compared to machines that spin stainless steel or titanium, which require more robust motors and stronger frames to handle the increased stress.

- Advanced machines can be customized with interchangeable mandrels, rollers, and tailstock assemblies to accommodate a variety of materials and part sizes. CNC machines are particularly adaptable, with software-controlled settings that adjust tool paths and spinning parameters based on the material being processed.

Advantages of Modern Metal Spinning Machines

The advancements in metal spinning machine technology have brought numerous advantages to modern manufacturing. These benefits make metal spinning a competitive and cost-effective choice for many industries:

- Precision and Repeatability:

- CNC-controlled metal spinning machines offer unparalleled precision, capable of producing parts with tight tolerances and consistent dimensions across large production runs. By eliminating human error, these machines ensure repeatability, making them ideal for industries such as aerospace, automotive, and medical manufacturing, where accuracy is critical.

- Efficiency and Speed:

- Automated machines, especially those integrated with CNC systems, drastically reduce production times. Once programmed, the machine can execute the spinning process with minimal operator intervention, allowing for faster cycle times and higher throughput.

- In addition, modern machines are equipped with multiple tooling stations and automatic tool changers, further enhancing efficiency by reducing setup times between production runs.

- Versatility:

- Modern metal spinning machines are highly versatile, capable of producing parts with a wide range of sizes, shapes, and materials. The ability to spin everything from small, intricate components to large, heavy-duty parts makes these machines adaptable to diverse applications.

- Furthermore, the integration of hybrid technologies, such as combining spinning with other forming processes (e.g., stamping or deep drawing), has expanded the scope of what can be achieved with metal spinning machines.

- Cost Savings:

- Although the initial investment in CNC metal spinning machines can be high, the long-term cost savings are significant due to increased efficiency, reduced labor costs, and lower material waste. In particular, the ability to produce parts with minimal material waste makes metal spinning an eco-friendly and economical manufacturing process, particularly for high-strength alloys and expensive metals.

Types of Metal Spinning Machines

Metal spinning machines come in various types, each tailored to specific manufacturing needs, material properties, and production scales. The diversity of machine types ensures that the metal spinning process can meet the demands of various industries, from custom, low-volume production to high-precision, mass-manufactured components. Below are the main categories of metal spinning machines:

Manual Spinning Machines

Manual metal spinning machines represent the traditional approach to spin forming, requiring an experienced operator to manually guide the forming tools as the blank spins. These machines are relatively simple in design but demand a high level of craftsmanship and expertise to produce consistent, quality parts.

- Operation:

- The operator manually applies pressure using a hand-held forming tool or lever. The workpiece is spun on a lathe, while the operator progressively shapes the metal against a mandrel.

- Manual machines often have limited automation and rely heavily on the operator’s ability to maintain uniform pressure and speed throughout the spinning process.

- Applications:

- Manual spinning machines are typically used for small-scale production, custom parts, or prototyping. They are ideal for creating simple shapes such as bowls, cones, and hemispheres, often for decorative, artistic, or bespoke industrial applications.

- Advantages:

- Flexibility: Manual machines can quickly be set up for small production runs or one-off parts.

- Cost-Effective for Low Volume: Without the need for expensive CNC programming or tooling, manual machines are more affordable for low-volume or customized jobs.

- Limitations:

- Operator Skill Dependent: Achieving consistent quality requires a highly skilled operator, as variations in force application or speed can lead to defects.

- Limited Complexity: Manual spinning is best suited for simpler geometries, as complex shapes and tight tolerances are challenging to achieve without automation.

CNC Metal Spinning Machines

CNC (Computer Numerical Control) metal spinning machines have revolutionized the industry by providing high levels of precision, repeatability, and efficiency. These machines are fully automated and capable of producing intricate parts with minimal human intervention, making them the industry standard for large-scale manufacturing and complex geometries.

- Operation:

- CNC machines are controlled by software, which directs the motion of the spinning tool and the spindle. The operator programs the machine using CAD/CAM software, which generates the necessary G-code for the machine to follow.

- The CNC system controls factors such as spindle speed, tool position, and the amount of force applied during the spinning process. This precision allows for the production of parts with tight tolerances and consistent quality across multiple production runs.

- Applications:

- CNC metal spinning machines are used in industries that require high-precision components, such as aerospace, automotive, medical devices, and defense. Typical applications include aircraft nose cones, satellite dishes, automotive wheels, and high-performance exhaust systems.

- Advantages:

- Precision and Accuracy: CNC machines can produce parts with extremely tight tolerances and smooth surface finishes. The automated nature of these machines reduces the risk of human error, ensuring high-quality output.

- Repeatability: Once programmed, CNC machines can produce identical parts consistently, making them ideal for high-volume production.

- Complex Geometries: CNC systems are capable of producing intricate and complex shapes that would be difficult or impossible to achieve manually.

- Limitations:

- Initial Investment: CNC metal spinning machines are expensive, both in terms of the equipment itself and the programming required. However, this cost is offset by the efficiency and precision offered by the machines, especially in high-volume production.

- Programming Expertise: While the machine performs the spinning automatically, creating and optimizing the CNC program requires technical expertise in CAD/CAM and knowledge of the material being spun.

Hydraulic Metal Spinning Machines

Hydraulic metal spinning machines utilize hydraulic pressure to control the forming tool and apply force to the spinning workpiece. These machines are especially useful for spinning materials that are difficult to shape, such as high-strength alloys, where greater force is required. The hydraulic system allows for precise control over the pressure applied to the workpiece, ensuring uniform material deformation and consistency.

- Operation:

- Hydraulic spinning machines rely on hydraulic cylinders to drive the spinning tools. These machines often feature both manual and automatic controls, allowing operators to fine-tune the process as needed.

- The hydraulic system can be programmed to apply variable pressure during the spinning process, which is particularly useful for materials that exhibit work hardening or require gradual forming.

- Applications:

- Hydraulic spinning machines are used in the production of parts that require significant forming forces, such as large pressure vessels, gas cylinders, and heavy-duty automotive or aerospace components.

- These machines are also suitable for spinning high-strength materials like titanium, stainless steel, and high-strength alloys.

- Advantages:

- High Force Capacity: Hydraulic systems allow for greater control over the amount of force applied, making them ideal for spinning thicker, harder materials.

- Precision Pressure Control: The ability to precisely adjust the forming pressure improves material consistency and reduces the risk of cracking or warping.

- Limitations:

- Slower Cycle Times: Hydraulic systems typically operate more slowly than CNC or manual machines due to the time required to apply and adjust pressure.

- Cost: Hydraulic spinning machines are more expensive than manual machines but generally more affordable than high-end CNC systems.

Single-Head vs. Double-Head Machines

The configuration of metal spinning machines can be classified into single-head and double-head designs, depending on how the tooling is arranged. This configuration impacts the machine’s ability to handle certain types of parts and materials.

- Single-Head Spinning Machines:

- In single-head machines, there is only one set of tools and a single spindle that rotates the workpiece. These machines are commonly used for conventional spinning processes and are suitable for parts with simpler geometries.

- Applications: Single-head machines are typically used for producing items such as bowls, cones, and cylindrical parts that do not require complex forming or intricate detailing.

- Advantages:

- Cost-Effective: Single-head machines are generally more affordable and simpler to operate, making them ideal for low-volume production.

- Simplicity: Their straightforward design means fewer components and less maintenance.

- Limitations:

- Limited to Simple Shapes: Single-head machines struggle with more complex geometries and may require multiple passes or additional tooling to achieve intricate shapes.

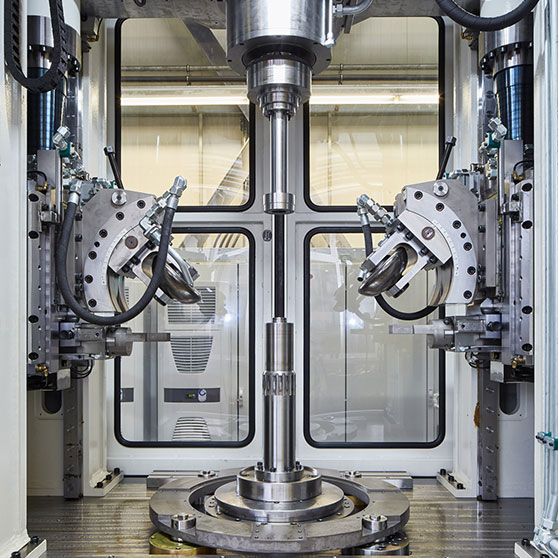

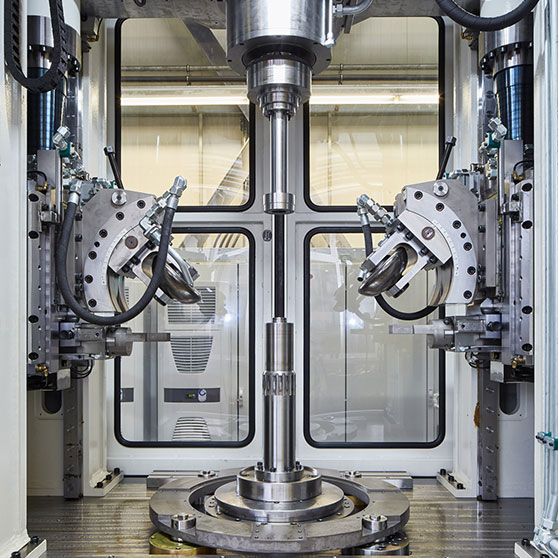

- Double-Head Spinning Machines:

- Double-head spinning machines are equipped with two sets of tools that work simultaneously, allowing for more complex shaping and forming. These machines are used for producing parts with detailed geometries or requiring precision on both sides of the workpiece.

- Applications: Double-head machines are ideal for applications where symmetrical or highly detailed parts are required, such as certain aerospace or automotive components.

- Advantages:

- Increased Precision: With two heads working in unison, double-head machines can form more complex parts in fewer passes, improving production efficiency.

- Enhanced Versatility: Double-head machines can handle more intricate parts, making them suitable for advanced applications where complex shapes and high precision are required.

- Limitations:

- Higher Cost: Double-head machines are more expensive due to their advanced tooling and dual-head configuration.

- More Complex Setup: These machines require careful calibration and setup, particularly for complex parts.

Specialized Spinning Machines

In addition to the general-purpose machines outlined above, there are specialized metal spinning machines designed for specific processes or industry requirements. These machines are typically customized for tasks such as shear spinning, flow forming, or spinning specific materials.

- Shear Spinning Machines:

- These machines are designed to perform shear spinning, a process that reduces the thickness of the workpiece while maintaining its diameter. Shear spinning is commonly used for producing lightweight, high-strength parts with reduced wall thickness, such as rocket cones or pressure vessels.

- Advantages: Shear spinning machines are ideal for applications where weight reduction is critical without compromising structural integrity.

- Flow Forming Machines:

- Flow forming is a specialized spinning process that produces thin-walled cylindrical parts by elongating the workpiece. Flow forming machines are used for manufacturing parts such as tubular structures, pressure vessels, and automotive drive shafts.

- Advantages: These machines are highly efficient at producing cylindrical parts with uniform wall thickness, offering high precision and material strength.

- Tube Spinning Machines:

- Tube spinning machines are used for forming tubular components with thin walls and precise dimensions. These machines are essential for applications such as exhaust systems, hydraulic cylinders, and structural tubing.

- Advantages: Tube spinning machines excel at producing components with consistent wall thickness, high strength, and excellent surface finish.

CNC Metal Spinning Technology

The advent of Computer Numerical Control (CNC) technology has brought significant advancements to the field of metal spinning. CNC metal spinning machines are at the forefront of modern manufacturing, providing precision, efficiency, and automation that traditional manual methods cannot match. This section delves into the architecture, functionality, and benefits of CNC metal spinning technology, along with the challenges it presents.

CNC Machine Architecture and Functionality

CNC metal spinning machines are automated systems driven by digital instructions that dictate the movements and actions of the spinning tools. The architecture of CNC metal spinning machines integrates multiple components designed to work in synchronization for precise shaping of metal parts.

- Spindle Motors:

- The spindle motor is a crucial component of the CNC metal spinning machine, responsible for driving the rotation of the mandrel and the workpiece. High-performance CNC machines often use servo motors to provide variable speed control and maintain consistent torque throughout the spinning process.

- Servo motors offer precise control over the spindle speed, allowing operators to adjust the speed based on the material being spun and the complexity of the part’s geometry.

- Servo Systems:

- In CNC machines, the servo system controls the positioning and movement of the forming tools. Servo motors enable precise, real-time adjustments to tool position, pressure, and speed, ensuring that the spinning process adheres to the programmed specifications.

- Servo-driven systems also allow for greater flexibility in shaping complex geometries, which would be difficult to achieve using manual methods.

- Tooling Mechanism:

- The CNC machine’s tooling mechanism includes rollers, forming tools, and the tool post. These components are controlled via the CNC program to apply the correct force and motion during the spinning process.

- In advanced CNC machines, multiple tools can be used simultaneously, with automatic tool changers to reduce downtime between operations. This multi-tool functionality enables more efficient production and minimizes the need for manual intervention during part forming.

- Drive Systems:

- CNC metal spinning machines typically employ a combination of electric and hydraulic drive systems to power the spindle and control the forming tools. The drive system must be robust enough to handle the forces generated during spinning, particularly for hard materials like stainless steel or titanium.