Cookware, Kitchenware, Utensil Forming Machine: A kitchenware production line involves a series of machines and tools designed to manufacture items such as pots, pans, utensils, cutlery, and other cooking-related products. The type of equipment used depends heavily on the materials (e.g., stainless steel, aluminum, plastic, ceramic) and the specific product. Below is an overview of typical equipment used in a kitchenware production line, categorized by function:

Raw Material Handling

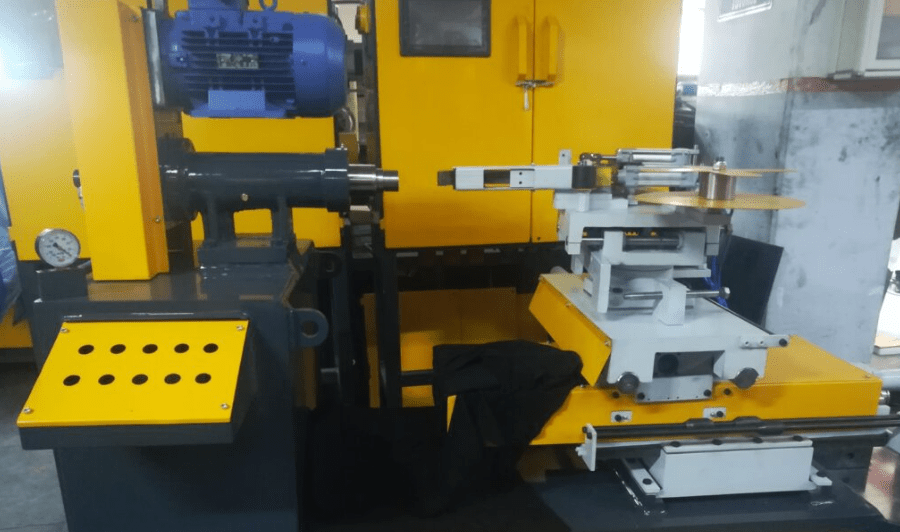

- Sheet Metal Decoiler & Straightener – For unwinding and leveling metal sheets.

- Plastic Pellet Loader & Hopper Dryer – For plastic-based kitchenware like spatulas, bowls, or measuring cups.

Forming & Shaping

- Hydraulic Press / Stamping Machine – Shapes metal sheets into forms (e.g., pan bodies, lids).

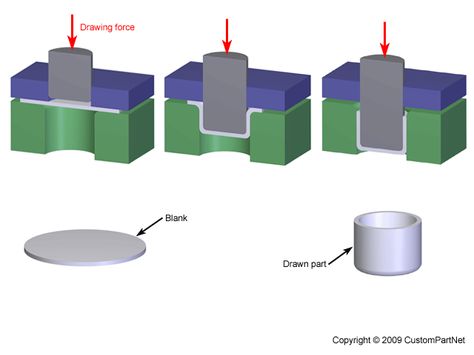

- Deep Drawing Machine – Used for forming deeper items like pots and pans.

- Injection Molding Machine – For plastic kitchenware or plastic handles for metal tools.

- Die Casting Machine – For cast aluminum cookware or parts like knobs and handles.

- Extrusion Machines – Used for producing profiles (e.g., plastic or silicone spatula handles).

Machining & Trimming

- Trimming Press – Removes excess material after forming.

- CNC Lathes & Milling Machines – Precision machining of parts such as knife blades or pan rims.

- Drilling/Tapping Machines – For holes in handles, fasteners, or assembly.

Surface Treatment

- Polishing Machines / Buffing Units – Give items a smooth, shiny finish.

- Sandblasting Machines – For matte finishes or texture.

- Electroplating Line – For chrome or nickel finishes (common in cutlery).

- Anodizing Equipment – For aluminum cookware.

- Powder Coating or Spray Painting Booths – For colorful or non-stick finishes.

Heat Treatment

- Annealing Furnace – For stress-relieving and improving metal toughness.

- Tempering Furnace – Used for knives and cutlery to harden blades.

Assembly

- Riveting Machines – To attach handles or knobs.

- Ultrasonic Welding Machine – For plastic parts.

- Screw/Drill Assembly Stations – Semi-automated or manual.

7. Quality Control

- Inspection Stations – Dimensional and surface quality checks.

- Leak Testing Machines – Especially for pressure cookers or kettles.

- Weighing Machines – To ensure consistency.

Packing & Labeling

- Automatic Packing Machines – Box packaging or blister sealing.

- Shrink Wrapping Machines – For protective film packaging.

- Labeling Machines – Apply product info, brand, and barcodes.

Optional Equipment

- Laser Engraving Machines – For branding/logos.

- Induction Bottom Welding Machines – For cookware compatible with induction stoves.

A kitchenware production line combines various machines to efficiently manufacture items such as pots, pans, utensils, and cutlery. The process starts with raw material handling, where sheet metal decoilers and straighteners prepare metal sheets, while plastic pellet loaders and dryers handle plastic materials. Forming and shaping follow, using hydraulic presses and deep drawing machines to shape metal into pots, lids, or trays, while injection molding machines are employed to form plastic items like spatulas or handles. Die casting machines are common for aluminum parts, and extrusion machines create long profiles for handles or support parts.

After forming, machining and trimming equipment like trimming presses, CNC lathes, and milling machines refine the shapes and add precision details. Drilling and tapping machines prepare holes for assembly components. Surface treatment is then performed, where polishing and buffing units give a glossy finish, sandblasting machines apply texture, and electroplating or anodizing units enhance appearance and corrosion resistance. Spray painting booths and powder coating systems add protective or decorative layers, especially for non-stick or colorful cookware.

Heat treatment furnaces are used to improve the durability and strength of metal parts, particularly for items like knives that require hardening and tempering. Once the parts are treated, assembly machines such as riveters and ultrasonic welders are used to attach handles, knobs, or multi-part assemblies. Manual or semi-automated stations with screwdrivers or drills are also common.

Quality control stations inspect the dimensions, surface finish, and integrity of each item, using visual checks, measuring tools, leak testers, and precision scales. Once the products pass inspection, they move to the packaging and labeling area. Automated packing machines place items into boxes or blister packs, while shrink-wrapping machines apply protective films. Labeling machines apply branding, barcodes, and instructions.

Optional systems include laser engravers for logos or markings, and induction base welding machines for producing cookware compatible with induction heating. The production line can be fully automated or semi-automated depending on the scale and investment level, with integration of conveyors and robotic arms for efficient handling between stages.

In a more advanced kitchenware production line, automation and integration play a key role in boosting productivity, consistency, and safety. Robotic arms may be deployed at critical points such as material loading, product transfer between machines, or packaging. These robots can be programmed for repetitive tasks with high precision, minimizing human error and reducing labor costs. Conveyor belts and automated guided vehicles (AGVs) further streamline internal logistics, transporting raw materials and finished goods efficiently throughout the production facility.

The entire line can be monitored and controlled via centralized production management systems. These systems track performance, machine status, quality control data, and production output in real time. Although full IoT integration is not always necessary, many modern setups include basic sensors for temperature, pressure, or dimensional feedback to ensure each process step stays within tolerance.

Maintenance and tool changeover are critical aspects of such a line. Quick-change die systems and modular fixtures reduce downtime when switching between different products or sizes. Preventive maintenance schedules, often aided by built-in diagnostic systems, help avoid unexpected breakdowns.

For environmentally conscious operations, waste management systems are included. Scrap metal from stamping or trimming can be collected and sent for recycling. In plastic production, off-spec or surplus parts are often ground and reused. Ventilation and fume extraction systems are essential in areas like surface treatment, heat treatment, or painting to maintain air quality and comply with environmental regulations.

The layout of the production line is also vital. It’s typically designed to follow a logical sequence from raw material input to finished product output, minimizing movement and ensuring smooth flow. A U-shaped or straight-line configuration is common, with workstations placed to maximize efficiency and safety.

In addition to the primary kitchenware production, some facilities include secondary processes such as decorative printing, silicone edge bonding, or the addition of temperature indicators on certain products. Final packaging may include accessories like manuals, warranty cards, or promotional inserts.

The degree of sophistication in a kitchenware production line depends on the product range, production volume, material types, and the quality standards required for the target market. For large-scale or export-focused manufacturers, high-capacity, precision-driven equipment is essential. In contrast, smaller or artisanal operations may prioritize flexibility, lower-cost equipment, and manual craftsmanship for niche or customized products.

Utensil Manufacturing System

A utensil manufacturing system refers to the coordinated setup of machinery, processes, and workflows used to produce kitchen utensils such as spoons, forks, knives, ladles, spatulas, tongs, and similar tools. These utensils can be made from materials like stainless steel, aluminum, plastic, wood, or silicone, and the system is designed based on the material type, production volume, and quality requirements.

The process typically begins with raw material preparation. For metal utensils, stainless steel sheets or coils are commonly used. These are uncoiled, flattened, and cut into blanks using sheet metal decoilers and shearing machines. For plastic or composite utensils, raw plastic pellets are fed into hoppers and dried to remove moisture before molding.

Shaping and forming is done next. Stamping presses or hydraulic presses punch out flat shapes from the metal sheets based on tool and die configurations. For example, a spoon is formed by blanking the shape and then deep drawing the bowl. Plastic utensils are formed using injection molding machines, which inject molten plastic into precision molds that shape the final product.

Machining follows for utensils that require finer shaping, especially forks, knives, and specialty tools. CNC milling or grinding machines may be used to refine edges or apply serrations. For products like tongs or spatulas that have multiple parts or moving joints, bending and welding machines help form the required shapes and join components.

Surface treatment is essential for both aesthetic and functional purposes. Polishing and buffing machines remove burrs and bring out a shiny or matte finish. Sandblasting or brushing machines can add texture or a satin look. For high-end utensils, electroplating or PVD (Physical Vapor Deposition) coatings can be applied for enhanced corrosion resistance and appearance. Plastic utensils may undergo surface printing, coloring, or overmolding with silicone for improved grip and heat resistance.

Heat treatment processes, particularly for knives and specialty tools, involve hardening and tempering in controlled furnaces to achieve desired hardness and edge retention. This is critical in ensuring performance and durability, especially in stainless steel blades.

Assembly stations are used where multiple parts must be connected, such as handles being attached to metal heads or silicone grips being added to plastic tools. This can involve riveting, screwing, ultrasonic welding, or adhesive bonding, depending on the material combination.

Quality control checks include visual inspections, dimensional accuracy testing with gauges or sensors, and edge sharpness or strength tests. Sophisticated setups may include automated inspection stations with cameras and sensors for real-time defect detection.

Packaging is the final stage, involving automatic or manual systems for inserting utensils into blister packs, hanging cards, or box sets. Branding, labeling, and barcoding machines ensure products are retail-ready. For export or bulk distribution, carton sealing, palletizing, and strapping machines are used.

Throughout the system, material handling is optimized with conveyors, robotic arms, or manual carts to move items between stages. In more advanced operations, production data is monitored using manufacturing execution systems (MES) for real-time tracking, quality assurance, and performance analysis.

The utensil manufacturing system can be semi-automated or fully automated, scalable from small workshops to large industrial plants. The core aim is to ensure consistent quality, high efficiency, and cost-effective production of utensils that meet safety and durability standards.

In a utensil manufacturing system, the flow of production is carefully designed to minimize waste, optimize time, and maintain product consistency. After the initial forming and finishing processes, utensils that require additional functional features—like serrated edges for knives or slotted heads for spatulas—are passed through precision-cutting or laser-machining stations. These machines add detailed features with high accuracy and can be programmed for different product variants without the need for significant tooling changes.

As products move through the line, automated handling systems such as pick-and-place units or robotic arms may transfer pieces between machines. These systems reduce manual labor, improve speed, and protect the product from damage or contamination during transport. In operations dealing with plastic or silicone utensils, color additives or reinforcements such as fiberglass may be introduced during molding to enhance strength or achieve a particular aesthetic. Co-molding and dual-shot injection techniques are often employed when producing utensils with ergonomic or multi-material handles, allowing seamless bonding between hard and soft components.

Cleaning and degreasing steps are integrated into the line, especially after metalworking stages. These use ultrasonic washers or chemical baths to remove oils, dust, and residues before final surface finishing or coating. For utensils designed for food contact, all materials and coatings must comply with health and safety regulations like FDA or EU standards, which makes cleanliness and material traceability essential.

At the branding stage, laser engraving, pad printing, or embossing techniques are applied to imprint brand names, measurements, or design elements onto the utensils. This not only improves brand recognition but also supports regulatory compliance by adding batch codes or material identifiers. For utensils intended to be part of sets or themed collections, coordinated color schemes and packaging formats are handled at the final stages. Items may be bundled, arranged, and sealed using automated packaging lines that include tray formers, sleeve wrappers, or box loaders.

The control system behind the manufacturing process plays a vital role. Programmable logic controllers (PLCs) coordinate the sequence and timing of operations across the machines. In more advanced systems, touch-panel human-machine interfaces (HMIs) allow operators to monitor performance, adjust parameters, and troubleshoot issues in real time. Maintenance alerts, production statistics, and quality metrics can be logged and analyzed to ensure the entire system runs at optimal efficiency.

Energy use, waste management, and recycling processes are also considered within the system’s design. Scrap metal from trimming or punching is collected in bins and recycled, while excess plastic can be reground and reintroduced into the molding process. Ventilation and air filtration systems are installed in areas with heat, fumes, or fine particulates to maintain a safe working environment.

Ultimately, a utensil manufacturing system integrates forming, finishing, assembly, inspection, and packaging into a streamlined process. The level of automation and sophistication is tailored to the desired production scale, from high-output factories making tens of thousands of units per day to smaller operations producing artisanal or customized pieces. The goal is to consistently produce utensils that are durable, functional, aesthetically pleasing, and compliant with food safety standards—all while maintaining high throughput and operational efficiency.

As the utensil manufacturing system continues to evolve, flexibility becomes increasingly important. Modern systems are designed not just for mass production but also for quick changeovers to accommodate different designs, sizes, or materials with minimal downtime. This is especially valuable for manufacturers that serve diverse markets or offer customized products. Tooling systems are often modular, allowing quick replacement of dies, molds, or forming heads. In the case of CNC and robotic operations, programming changes can be made through software without physically adjusting the machinery, enabling seamless transitions between product batches.

In high-volume production environments, uptime and reliability are critical. Therefore, predictive maintenance is integrated into many systems using basic sensors and monitoring software. These systems track vibration, temperature, and machine cycle counts to forecast when parts like bearings, seals, or blades might wear out. By addressing these issues proactively, manufacturers avoid costly shutdowns and maintain consistent production flow.

Workforce integration also plays a role in system efficiency. While much of the operation can be automated, skilled technicians and operators are essential for setup, calibration, quality control, and oversight. Ergonomic design of workstations, tool access, and material flow ensures that human input remains safe and efficient. Training is provided to ensure that workers understand the operation of each component, from handling raw materials to troubleshooting robotic cells.

From a business standpoint, the manufacturing system is closely tied to supply chain and inventory management. Materials such as steel coils, plastic pellets, or silicone rubber must arrive just in time to avoid excess storage or delays. Finished goods are tracked using barcoding and integrated software systems that connect production output directly to warehouse management and distribution. This allows for real-time updates on order status, inventory levels, and delivery timelines.

Sustainability is an increasingly important consideration. Manufacturers are adopting environmentally friendly materials such as recycled stainless steel or biodegradable plastics where possible. Energy-efficient motors, low-emission furnaces, and closed-loop water systems are employed to reduce the ecological footprint of the plant. Packaging is optimized for material use and recyclability, often using cardboard inserts or plant-based plastics to align with global sustainability standards.

Looking ahead, utensil manufacturing systems are likely to continue incorporating advanced features like AI-based vision systems for real-time defect detection, collaborative robots (cobots) that work safely alongside humans, and digital twins that simulate the entire production process to optimize layout and performance before physical changes are made. While not every facility requires these cutting-edge technologies, their selective adoption can significantly enhance productivity, quality, and adaptability.

In essence, a utensil manufacturing system is more than a collection of machines—it’s a synchronized ecosystem designed to turn raw materials into high-quality kitchen tools through efficient, reliable, and scalable processes. Whether producing basic utility utensils or premium-grade designer collections, the success of such a system lies in its ability to balance speed, precision, customization, and sustainability under one cohesive operational framework.

Household Cookware Processing Machine

A household cookware processing machine refers to a specialized piece of industrial equipment—or a series of integrated machines—used in the manufacturing of cookware items such as frying pans, saucepans, pressure cookers, woks, pots, and non-stick bakeware. These machines handle the transformation of raw materials like aluminum, stainless steel, or cast iron into finished, ready-for-sale cookware products. The configuration of the machine depends on the type of cookware, the base material, surface finish requirements, and production scale.

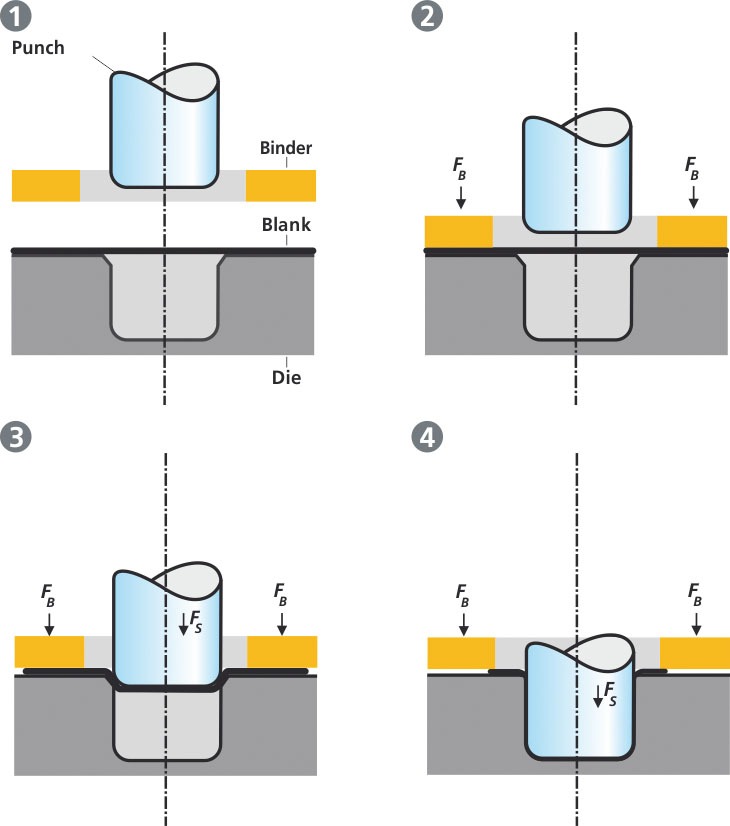

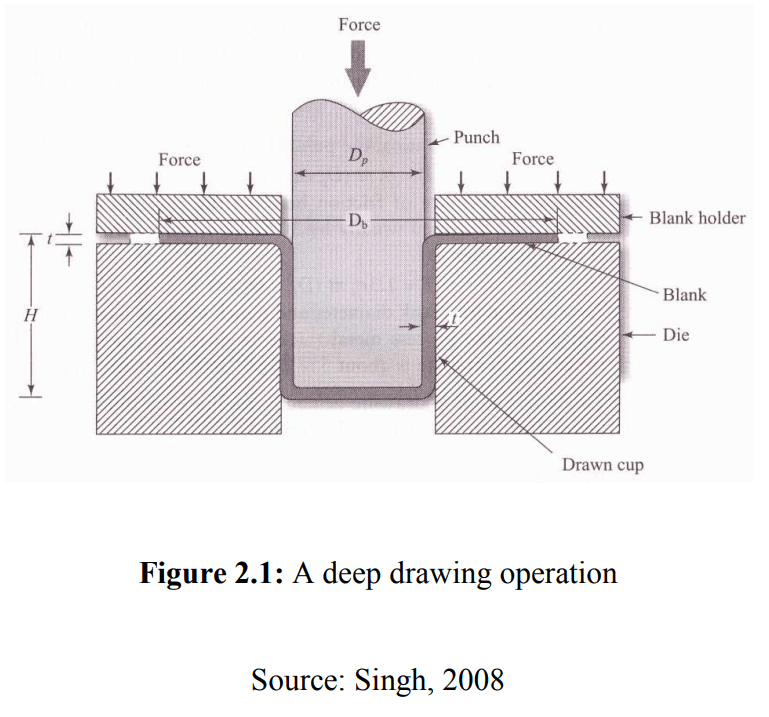

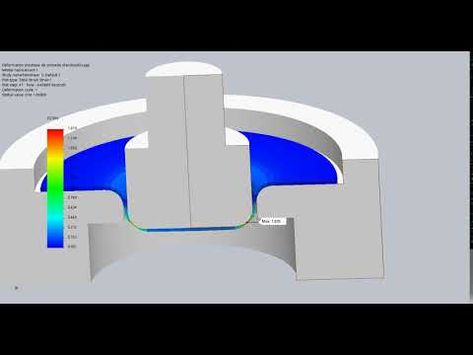

The process typically begins with metal blank preparation, where aluminum or stainless steel sheets are decoiled, straightened, and cut into circular or rectangular blanks using a hydraulic shear or punching press. These blanks are then fed into deep drawing machines, which use hydraulic or mechanical force to form the basic pot or pan shape by stretching the metal into a die. For multilayer or induction-compatible cookware, bottom disc welding machines fuse steel or copper plates to the base of the vessel using friction or resistance welding methods.

Once the basic shape is formed, edge trimming and flanging machines refine the rim and prepare it for rolling or curling. This is essential for forming clean edges and, in some cases, for allowing lid fitting. Spinning machines may be used to add contouring to the body or to form specific designs such as grooves or lips. At this stage, hole punching machines may also be used to create holes for rivets or fasteners if the cookware includes attached handles.

The cookware then undergoes surface preparation, which may include mechanical polishing, brushing, or blasting depending on the desired finish. For non-stick cookware, the inner surface is often roughened by sandblasting or acid etching to improve coating adhesion. Following this, PTFE or ceramic coating spray machines are used to apply the non-stick layer. This is typically done inside a controlled booth with electrostatic spray guns. The coated item is then sent through a curing oven where the coating is baked at high temperatures to harden and bond it to the metal surface.

If decorative exterior coatings or prints are required, powder coating systems or liquid paint booths are used, followed by additional curing stages. For stainless steel cookware, electropolishing or mirror polishing machines give the exterior a high-gloss finish, while anodizing lines may be used for aluminum cookware to improve durability and color retention.

Handle and accessory assembly is typically done using automatic riveting machines or screw-fastening systems. Some models include robotic arms for inserting and tightening components. Silicone or plastic handles are often molded separately using injection molding machines and then attached using ultrasonic welding or fastening tools. Pressure cooker lids and locking mechanisms require more intricate assembly and may involve custom mechanical fitting stations.

The completed cookware is then passed through quality inspection units, which check for coating uniformity, shape consistency, handle stability, and leak-proof seals. Automated vision systems or human inspectors may be used depending on the setup. Final steps include cleaning machines (ultrasonic or steam-based) to remove any residue, followed by packaging machines that insert items into cartons, wrap them in protective film, and apply labels and barcodes.

Cookware processing machines are often arranged in a production line that allows continuous flow from raw material to finished product. Advanced systems may include data tracking for each item, allowing traceability for quality control and warranty purposes. Depending on the plant size, the machinery may be standalone for batch production or fully integrated for continuous high-speed operation. The main goal is to ensure durability, thermal performance, food safety compliance, and an appealing finish in the final cookware product.

In a fully optimized cookware manufacturing environment, the household cookware processing machines are not only designed for performance and precision but also for flexibility and integration. Most machines are operated through programmable logic controllers (PLCs), allowing manufacturers to switch between different cookware sizes or models with minimal adjustment. Touchscreen interfaces provide real-time monitoring of cycle times, pressure levels, temperature control in ovens, and coating thickness, which ensures uniform quality across batches.

When it comes to induction cookware, an additional process involves the welding or bonding of a ferromagnetic disc, typically stainless steel, to the base of an aluminum or copper vessel. This is carried out using induction base welding machines or high-frequency welding systems that ensure strong adhesion without warping the base. These machines are critical in producing cookware compatible with modern induction cooktops, which require magnetic responsiveness.

For cast cookware like cast iron or cast aluminum pots, the processing machine setup is different. These start with die casting or sand casting machines that form the cookware body in a mold. After cooling, robotic arms or conveyors move the items to finishing stations, where excess flash is removed using grinders or sanders. The interior is then smoothed using tumbling or abrasive blasting systems before the application of protective oils or enamel coatings. Enamel-coated cookware undergoes a specialized glazing and curing process in high-temperature kilns to vitrify the surface and create a smooth, glossy finish.

Cookware processing machines also support multi-functional cookware production, such as steamer sets or pressure cookers, which involve multiple components. The lid manufacturing unit often includes precision forming and spinning machines for shaping the dome, while pressure release valves, gaskets, and safety locks are assembled using dedicated subassembly stations. These components are tested with pneumatic or hydraulic systems to ensure they can withstand high pressures and comply with international safety standards.

In advanced factories, robotic arms equipped with sensors and vision systems pick and place components, perform inspection, and even operate CNC stations. This reduces the need for manual handling and lowers the risk of contamination or defects. Automated guided vehicles (AGVs) may be used to transport bins of semi-finished or finished goods between workstations or to and from storage areas, reducing labor and improving logistical efficiency.

Data analytics and quality tracking are embedded within the system. Each cookware item may carry a production code that logs its entire manufacturing history—from the batch of raw material to each machine it passed through. This level of traceability is vital not just for quality assurance, but also for responding to product recalls or certification audits.

Environmental control is another key component. Machines involved in surface coating, painting, or curing are equipped with exhaust treatment systems, such as activated carbon filters or thermal oxidizers, to reduce emissions. Water used in cooling or cleaning is filtered and often recirculated. Manufacturing plants are increasingly expected to meet green standards, so machines are designed for low energy consumption, minimal waste, and recyclability of byproducts like trimmed aluminum or used coating powder.

All these elements make up a modern household cookware processing system that can produce a wide range of products—non-stick pans, enamel pots, stainless steel pressure cookers, induction-compatible woks, and more—with high repeatability and efficiency. Whether producing thousands of identical units per day or a small series of high-end cookware for premium markets, the performance of these machines directly impacts cost, quality, and brand reputation.

As the cookware industry evolves, the processing machines continue to adapt to meet increasing demands for performance, aesthetic appeal, and sustainability. One important area is the growing consumer preference for PFOA-free and environmentally safe non-stick coatings. In response, cookware processing systems now include dedicated spray booths and curing ovens that are compatible with newer generations of ceramic or water-based coatings. These setups must maintain strict control over spray pattern, coating thickness, and oven temperature to ensure the performance and safety of the final product.

Another important development is the push toward modular machine configurations. Instead of a fixed, linear production line, modern systems are often built around reconfigurable stations. This allows manufacturers to add or remove modules depending on current product demand—such as inserting an additional coating booth for a line of double-layered pans or bypassing a polishing unit for brushed-surface cookware. This modularity increases adaptability and shortens the time required to launch new product lines.

Precision continues to be a priority, particularly for high-performance cookware intended for professional or export markets. Machines used for forming and shaping must maintain extremely tight tolerances to ensure proper heat distribution and structural integrity. In many facilities, 3D scanning and laser measuring systems are integrated into the line to verify dimensional accuracy in real time. If a pan’s base is not perfectly flat or evenly thick, it can lead to hot spots or warping during use—defects that can result in consumer dissatisfaction or returns.

Automation plays a major role in increasing speed and consistency. Robots are not only handling materials but also performing repetitive processes such as spraying, buffing, screwing, or stacking. In high-output plants, vision systems guide robots in real-time, adjusting their movements based on exact product position and orientation. Even the packaging process is automated in many cases, with machines forming boxes, inserting cookware with protective liners, sealing cartons, and labeling them based on regional shipping requirements.

Digital integration extends beyond individual machines. Many modern plants utilize manufacturing execution systems (MES) or enterprise resource planning (ERP) platforms to connect machinery with logistics, inventory, and sales. This enables predictive planning based on incoming orders, materials in stock, or machine availability. Maintenance scheduling, energy usage, and workforce assignments are coordinated through this digital backbone, leading to smarter, more efficient operations.

Operator safety is also a major design consideration. Machines now come with more advanced enclosures, interlock systems, and emergency stops. Sensors detect abnormal movements, overheating, or misfeeds, and either pause the operation or alert operators immediately. Noise reduction, heat insulation, and better dust and fume extraction contribute to a safer and more comfortable working environment, which is especially important in coating or polishing areas.

For cookware items with special features—like detachable handles, tempered glass lids, or integrated strainers—customized tooling or specialty stations are developed. These are often built in-house or sourced from specialized machine tool vendors, allowing manufacturers to differentiate their product offerings while keeping production in-house. The tooling and changeover systems are designed for speed and precision to keep productivity high even when switching between standard and feature-rich products.

Overall, the household cookware processing machine is no longer a single-purpose tool but part of a comprehensive, adaptive system that balances automation, customization, and compliance. From the moment raw materials enter the facility to the time a fully finished and packaged pan leaves the line, the machinery ensures consistency, reliability, and competitiveness in an increasingly demanding market. As trends shift toward healthier cooking, smart kitchen integration, and sustainability, cookware manufacturing systems are being continuously updated to stay ahead, without compromising on traditional values of durability and user-friendly design.

Kitchen Cookware Fabrication Machines

Kitchen cookware fabrication machines refer to the full range of industrial equipment used to manufacture items such as frying pans, saucepans, stockpots, pressure cookers, woks, and griddles from raw materials like aluminum, stainless steel, or cast iron. These machines form the backbone of cookware production, shaping metal, applying coatings, assembling parts, and preparing finished products for market. The setup and level of automation in these machines vary depending on the material, type of cookware, production volume, and target quality.

The fabrication process typically starts with sheet or coil metal feeding into decoiling and blanking machines, which straighten the material and cut it into round or rectangular blanks. These blanks are then moved to deep drawing or hydraulic press machines, which stretch the metal into the shape of a pan or pot using matched dies and controlled force. This step forms the core body of most cookware. For multilayer or induction cookware, bottom impact bonding or disc welding machines are used to attach additional metallic layers, such as a magnetic stainless steel disc to an aluminum base.

Next, trimming and flanging machines clean the edges, roll the rim, and prepare it for lid compatibility or further assembly. In cases where more complex contours or thickness adjustments are needed, spinning machines are used to form rounded profiles and adjust wall dimensions through controlled pressure and rotation. Annealing furnaces may be included in the line to soften metal between forming stages and relieve internal stress, improving dimensional stability.

Once shaping is complete, cookware moves to surface preparation. Grinding and polishing machines remove any imperfections and create a smooth finish. For stainless steel products, mirror polishing systems give a glossy appearance, while brushing machines can apply a matte or satin finish. In aluminum cookware production, sandblasting or acid etching machines are used on the interior surface to create micro-roughness that helps non-stick coatings adhere effectively.

Application of coatings is done with automatic spray coating booths that apply PTFE, ceramic, or other food-safe non-stick layers. These are precisely sprayed onto the inner surface and then passed through high-temperature curing ovens, where the coatings are polymerized and hardened. For the exterior, powder coating or liquid paint systems can be used to color and protect the cookware surface. These systems often include electrostatic application and baking units to ensure even coverage and durability.

The next step is handle and component assembly. Riveting machines, robotic screwdrivers, or ultrasonic welding machines attach handles, knobs, and helper grips. Silicone or plastic handles are typically produced in injection molding machines and then fitted either manually or automatically. For cookware with glass lids or complex locking mechanisms, specialized lid fabrication machines form domes, drill holes for steam vents, and assemble metal rims or knobs.

Throughout the process, quality control machines and sensors check for roundness, coating thickness, leakage, and handle integrity. Vision systems and laser scanners often perform inline inspection, detecting surface defects, alignment issues, or incomplete coatings without interrupting the flow. Failed items are automatically rejected or marked for rework.

After passing all inspections, the cookware moves to final cleaning machines, often ultrasonic or high-pressure washers, to remove any dust or residues. From there, automatic packing lines insert cookware into boxes, apply protective materials, seal packages, and label them with barcodes or product details. The entire flow is coordinated by centralized control systems, often connected to production management software that handles order tracking, inventory, and maintenance alerts.

In advanced operations, these machines are supported by robotic material handling, predictive maintenance analytics, and modular layouts that allow rapid changeover between product types. Whether the plant is producing thousands of standardized items per day or smaller batches of high-end designer cookware, these fabrication machines are engineered for precision, efficiency, and reliability. They ensure that each piece of cookware meets performance, safety, and aesthetic standards required in the modern kitchen market.

Kitchen cookware fabrication machines operate in a tightly coordinated sequence to transform raw materials into durable, functional, and visually appealing kitchenware. The process begins with raw metal stock being fed automatically into decoilers and straightening units that prepare flat sheets or coils for cutting. These sheets are then blanked into the initial shapes, typically circular discs, by heavy-duty hydraulic or mechanical presses. The blanked pieces are immediately transferred to deep drawing presses, which use dies and punches to shape the metal into pots, pans, or lids. The deep drawing process often requires multiple stages of forming and annealing to prevent cracking or distortion, especially when working with harder metals or thicker gauges.

Once the rough shapes are formed, trimming machines precisely cut and clean up the edges, ensuring smooth rims that are safe to handle and compatible with lids or other components. Flanging and curling machines then shape the rim to provide strength, aesthetic finish, and functional compatibility for sealing or stacking. For cookware bases, impact bonding machines join layers of different metals to create clad structures optimized for heat distribution and compatibility with induction cooktops. The bonding process involves applying high pressure and heat to fuse materials like aluminum and stainless steel, producing a multilayer base that is both durable and thermally efficient.

The next critical step involves surface preparation, where grinding and polishing machines remove any imperfections and prepare the metal for finishing. Polishing ranges from rough buffing to mirror-like finishes, depending on the cookware style. Specialized sanding or blasting machines are used to texture surfaces where non-stick coatings will be applied, improving adhesion and durability. Coating application is performed in controlled spray booths, often using electrostatic spray guns for even distribution of non-stick materials like PTFE or ceramic-based coatings. These coatings are baked in high-temperature curing ovens that polymerize the coating layers, ensuring resilience under cooking conditions.

Exterior finishing machines add aesthetic and protective layers, using powder coating or wet paint systems tailored for cookware. These finishing systems are integrated with curing ovens and color management controls to produce consistent, vibrant, and scratch-resistant surfaces. Assembly stations equipped with riveting machines, robotic screwdrivers, or ultrasonic welders attach handles, knobs, and helper grips. Injection molding machines produce ergonomic handles, which may be combined with metal cores or heat-resistant materials, and these are assembled automatically or semi-automatically to ensure strong bonds and proper alignment.

Quality assurance is an integral part of the fabrication line, with inline inspection stations using vision cameras, laser scanners, and coating thickness gauges. These machines detect defects such as dents, coating inconsistencies, handle misalignment, or leaks, enabling immediate rejection or corrective action. Ultrasonic testing may also be employed for welded or bonded components to verify joint integrity without damaging the product.

Once the cookware passes inspection, it is cleaned in ultrasonic or high-pressure washing units to remove residues or contaminants from manufacturing. Drying ovens or air blowers prepare the product for packaging. Automated packaging machines then take over, inserting cookware into custom trays, wrapping with protective films, sealing boxes, and labeling for shipment. These packaging lines are often flexible enough to handle a variety of product sizes and bundle configurations, supporting both retail and bulk orders.

The entire manufacturing process is orchestrated by advanced control systems, where programmable logic controllers (PLCs) synchronize machine operations, monitor cycle times, and maintain safety protocols. Data from sensors and inspection machines feed into manufacturing execution systems (MES), which provide real-time dashboards and production analytics. Predictive maintenance modules analyze equipment condition data to schedule upkeep before breakdowns occur, reducing downtime and maintaining throughput.

Environmental considerations are increasingly integrated into cookware fabrication machinery. Systems incorporate waste collection for metal scraps and coating powders, water recycling for cleaning stations, and air filtration for spray booths and ovens. Energy-efficient motors, heat recovery systems, and eco-friendly coating materials help reduce the environmental impact of the manufacturing process.

Modern kitchen cookware fabrication machines thus represent a combination of mechanical precision, advanced automation, and digital integration. Their purpose is to deliver high-quality cookware that meets rigorous standards for safety, durability, and performance, while enabling manufacturers to respond quickly to market trends and consumer preferences. This balance of speed, flexibility, and quality ensures that cookware made on these machines remains competitive in a dynamic global market.

As technology advances, kitchen cookware fabrication machines continue to integrate cutting-edge innovations to enhance productivity and product quality. One key trend is the adoption of Industry 4.0 principles, where interconnected machines communicate seamlessly through IoT (Internet of Things) sensors and cloud-based platforms. This connectivity allows real-time monitoring of every stage—from metal blanking and forming to coating and assembly—providing manufacturers with detailed insights on process parameters, machine health, and product quality.

Robotics plays an increasingly prominent role, especially in repetitive or ergonomically challenging tasks such as material handling, coating application, and component assembly. Collaborative robots (cobots) work safely alongside human operators, assisting with precision tasks like riveting handles or inserting lids, increasing throughput while maintaining flexibility for small batch sizes or custom orders.

Advanced vision systems coupled with AI-powered defect detection enable more consistent quality control. These systems analyze surface textures, coating uniformity, and dimensional accuracy with far greater speed and accuracy than manual inspection. They can detect even subtle defects that could impact cookware performance or aesthetics, allowing immediate rejection or rework, reducing waste and recalls.

Flexible tooling and modular machine design support rapid changeovers between different cookware models or materials. Quick-release dies, adjustable press parameters, and software-configured robotic sequences mean manufacturers can respond swiftly to shifting market demands without long downtime. This flexibility is vital for companies offering both standard product lines and bespoke, limited-edition cookware collections.

Sustainability also drives machine development. Fabrication systems now incorporate energy-efficient motors, regenerative braking in presses, and optimized airflow in ovens to reduce energy consumption. Waste management features recycle metal scraps and reclaim coating overspray, while water used in washing or cooling processes is filtered and reused. Eco-friendly coating materials that minimize volatile organic compounds (VOCs) are becoming standard, reflecting consumer demand for greener products.

Some manufacturers are exploring additive manufacturing (3D printing) to create complex tooling components or prototypes for new cookware designs, shortening development cycles and allowing for more innovative shapes or features that traditional methods struggle to produce. This hybrid approach complements conventional fabrication machinery rather than replacing it, enhancing overall flexibility.

Moreover, the data generated by fabrication machines feeds into enterprise resource planning (ERP) systems, enabling end-to-end supply chain optimization—from raw material procurement through production scheduling to inventory management and shipping logistics. Predictive analytics can forecast maintenance needs or production bottlenecks, helping factories achieve higher uptime and better cost control.

Ultimately, kitchen cookware fabrication machines today are sophisticated, interconnected systems designed to maximize efficiency, quality, and adaptability while minimizing environmental impact. They form the essential foundation upon which manufacturers build their capacity to meet diverse consumer needs, from everyday non-stick frying pans to high-performance professional-grade cookware. As technology continues to evolve, these machines will become even smarter, more versatile, and more sustainable, shaping the future of cookware production worldwide.

Cookware Production & Assembly Machines and Lines

Cookware production and assembly machines and lines encompass the full suite of equipment and integrated systems used to manufacture, finish, and assemble kitchen cookware—from raw material processing to final packaging. These lines combine specialized fabrication machinery, coating stations, inspection units, and assembly robots into a streamlined workflow designed for high efficiency, precision, and consistent quality.

The production phase typically begins with metal sheet feeding systems that straighten and cut raw material into blanks, followed by deep drawing or stamping presses that shape the cookware bodies and lids. Presses often operate in multiple stages with annealing ovens placed in between to reduce metal stress and improve formability. Trimming and flanging machines then refine edges and rims to exact specifications, preparing cookware components for assembly or additional processing.

For cookware requiring multilayer bases, bonding machines fuse dissimilar metals like aluminum and stainless steel through impact welding or high-frequency induction bonding, producing optimized heat-distribution bases compatible with induction cooktops. These machines ensure precise layer alignment and strong, durable bonds without warping.

Once shaped, the cookware moves to surface finishing lines. Grinding and polishing machines prepare surfaces by smoothing, brushing, or creating a specific texture. Coating stations, which may include automated spray booths or powder coating systems, apply non-stick or decorative finishes. High-temperature curing ovens bake these coatings, forming durable, heat-resistant layers.

Assembly lines bring together cookware bodies with handles, lids, and other accessories. Automated riveting machines and robotic screwdrivers attach handles securely, while ultrasonic welding or robotic arms handle the placement of silicone grips or knobs. For pressure cookers or specialized cookware, dedicated stations assemble sealing gaskets, locking mechanisms, and valves, often including pressure testing units to ensure safety compliance.

Integrated quality inspection stations use vision systems, laser scanners, and thickness gauges to detect surface defects, coating inconsistencies, dimensional variances, or assembly faults. Inline rejection systems remove defective units automatically, maintaining high-quality output without slowing production.

After inspection, cleaning machines—such as ultrasonic washers—remove residual oils, dust, or contaminants, preparing cookware for packaging. Automated packing machines then place items into protective trays or boxes, seal cartons, and apply labels and barcodes, readying products for distribution.

Modern cookware production and assembly lines are controlled through centralized programmable logic controllers (PLCs) linked to manufacturing execution systems (MES). This allows real-time monitoring, data collection, and process optimization. Predictive maintenance tools analyze machine data to minimize downtime and maintain smooth operation.

These lines can be configured for high-volume continuous production or modular batch manufacturing, depending on product variety and market demand. Flexible tooling, quick-changeover designs, and robotic integration enable rapid adaptation to new cookware designs or custom orders.

Environmental controls—such as exhaust filtration, powder recovery, and water recycling—are standard components, ensuring compliance with increasingly stringent regulations and reducing the plant’s ecological footprint.

In summary, cookware production and assembly machines and lines form a comprehensive, integrated manufacturing ecosystem. They transform raw metals into finished cookware with precision, efficiency, and high quality, supporting diverse product ranges while meeting modern safety, performance, and sustainability standards.

Cookware production and assembly lines operate as highly coordinated systems designed to maximize efficiency and product quality while minimizing waste and downtime. Starting with raw material preparation, automated feeding systems handle coils or sheets of metals like stainless steel, aluminum, or copper, straightening and cutting them into blanks of precise dimensions. These blanks proceed through presses and deep drawing machines that shape them into the fundamental cookware forms such as pots, pans, and lids. The forming stages may be interspersed with annealing ovens to relieve internal stresses and enhance material ductility, which is critical for preventing cracking during successive deformation steps.

Following forming, trimming machines cleanly cut and finish the edges, while flanging or curling machines roll the rims to add strength and enable better lid fit or stacking. For cookware designed with multilayer bases, bonding machines employ high-frequency induction or impact welding to join layers of different metals. This process is carefully controlled to ensure the layers are fused securely without distortion, enhancing heat distribution and durability—particularly important for cookware compatible with induction cooktops.

Surface preparation involves grinding and polishing machines that smooth out imperfections and create finishes ranging from mirror-like gloss to brushed textures, depending on product specifications. Sandblasting or acid etching equipment may be used on cookware interiors to create microscopic surface roughness that improves adhesion of non-stick coatings. Automated spray booths apply PTFE, ceramic, or other coatings uniformly, often using electrostatic techniques to maximize coverage and minimize waste. After application, curing ovens harden these coatings at precisely controlled temperatures, ensuring durability and safety for cooking use.

The assembly segment integrates handles, knobs, lids, and other components using a combination of riveting machines, robotic arms, and ultrasonic welding systems. Handles may be made of molded silicone, plastic, or metal, produced by injection molding machines and then securely fastened. For specialized cookware such as pressure cookers, assembly lines incorporate gasket installation, valve fitting, and safety testing stations to verify that components meet strict performance and regulatory standards.

Inline quality control is critical and is achieved using sophisticated vision systems, laser measurement tools, and coating thickness gauges. These systems inspect for defects like dents, uneven coatings, or assembly misalignments in real-time. Automated rejection mechanisms remove substandard units to maintain high quality without interrupting the production flow. Additional ultrasonic or leak detection tests may be performed on sealed cookware to ensure safety and integrity.

After inspection, cleaning machines such as ultrasonic washers or high-pressure sprayers remove residual oils, dust, or contaminants before drying ovens prepare products for packaging. Packaging machines automate carton formation, product insertion, protective lining placement, and sealing, including barcode labeling and batch coding for traceability.

All production and assembly equipment is managed by centralized control systems utilizing programmable logic controllers (PLCs) and manufacturing execution systems (MES). These platforms monitor machine status, track production metrics, and facilitate predictive maintenance, reducing downtime and optimizing throughput. The integration of IoT sensors allows continuous data collection and remote monitoring, enabling rapid response to any anomalies or process deviations.

Environmental management systems are integrated throughout the line to reduce emissions, recycle water, and recover coating powders or metal scraps. Energy-efficient motors, heat recovery in curing ovens, and optimized airflow reduce the plant’s carbon footprint and operational costs.

Flexible design and modular machine layouts enable quick changeovers between product lines, supporting both mass production and custom manufacturing runs. This adaptability allows manufacturers to meet diverse market demands and implement new cookware designs without extensive downtime or tooling changes.

Together, cookware production and assembly machines and lines form a sophisticated manufacturing ecosystem that transforms raw metals and materials into high-quality, durable cookware. This system balances automation, precision engineering, and environmental responsibility to produce cookware that meets the highest standards of performance, safety, and consumer satisfaction in today’s competitive kitchenware market.

Advancements in automation and digital technologies continue to push cookware production and assembly lines toward greater efficiency and intelligence. The integration of robotics has revolutionized handling, assembly, and finishing tasks that were once labor-intensive or ergonomically challenging. Collaborative robots (cobots) work alongside human operators, performing repetitive actions like handle fastening, lid placement, or packaging with high precision and consistency. These robots can be easily programmed and redeployed for different products, adding flexibility to production lines.

Vision-guided robotic systems utilize cameras and AI algorithms to detect part orientation and surface conditions in real time, allowing for adaptive adjustments during assembly or coating processes. This results in fewer defects, less rework, and higher throughput. Additionally, these systems can inspect complex geometries and subtle surface flaws that traditional inspection methods might miss, ensuring only top-quality cookware reaches consumers.

Manufacturing execution systems (MES) and enterprise resource planning (ERP) software play a crucial role in synchronizing the entire production ecosystem. They enable seamless communication between machines, inventory management, procurement, and sales departments. This connectivity supports just-in-time manufacturing, reducing inventory costs and improving responsiveness to changing market demands or custom order requests. Predictive analytics, powered by machine learning, analyze historical and real-time data to forecast maintenance needs, optimize energy consumption, and anticipate production bottlenecks.

Sustainability considerations are increasingly central to cookware production line design. Modern lines incorporate closed-loop systems for water and chemical reuse in cleaning and coating processes. Waste reduction initiatives recover and recycle metal scraps, coating powders, and packaging materials. Energy-saving measures such as variable-frequency drives on motors, LED lighting, and waste heat recovery in curing ovens contribute to lower operational costs and environmental impact.

Customization is also a growing trend, driven by consumer demand for personalized and specialty cookware. Flexible production lines equipped with quick-change tooling, modular stations, and digital controls allow manufacturers to switch rapidly between different designs, sizes, finishes, or handle styles without lengthy downtime. This agility enables small batch production and limited-edition runs alongside high-volume manufacturing, expanding market reach.

In terms of safety, production lines are designed with multiple layers of protection including physical barriers, emergency stop systems, sensors to detect abnormal conditions, and ergonomic workstation designs. These features protect operators from mechanical hazards, reduce repetitive strain injuries, and improve overall workplace conditions.

Emerging technologies like augmented reality (AR) and virtual reality (VR) are being explored to train operators and technicians more effectively, providing immersive simulations of assembly line processes and maintenance tasks. This reduces human error and accelerates workforce readiness.

Overall, cookware production and assembly machines and lines represent the convergence of mechanical engineering, automation, materials science, and digital innovation. Their continuous evolution enables manufacturers to produce cookware that not only meets stringent quality and safety standards but also aligns with sustainability goals and consumer preferences for variety and customization. This dynamic, integrated approach ensures that cookware manufacturing remains competitive, adaptable, and future-ready in a rapidly changing global market.

Kitchen Utensil Forming Unit

A Kitchen Utensil Forming Unit is a specialized section or machine setup within a manufacturing line dedicated to shaping raw materials—usually metal sheets, rods, or strips—into finished kitchen utensils such as spoons, forks, ladles, spatulas, tongs, and whisks. This unit focuses on precision forming, shaping, and sometimes initial surface treatment, creating the fundamental shapes that will later be finished, polished, coated, or assembled.

The forming unit typically begins with material feeding equipment that straightens and guides metal strips or rods into the production line. For flat utensils like spatulas or spoons, blanking machines punch out flat shapes from metal sheets. These blanks then pass through press forming or stamping machines, which use dies and punches to bend, curve, or emboss the utensil’s profile—for example, shaping a spoon’s bowl or a fork’s tines. Multi-stage presses may be used for complex forms requiring gradual shaping to avoid cracking or distortion.

For utensils made from wire or rods—like whisks or tongs—the unit includes wire forming machines that bend, coil, or twist the wire into precise shapes. CNC-controlled wire bending machines provide high repeatability and can produce intricate designs or handles.

Additional forming processes may include drawing, where metal is stretched into thinner or more contoured shapes; roll forming, which progressively bends metal strips into U-shapes or channels; and extrusion, used less frequently but sometimes applied for specialty handles or components.

Some forming units integrate heat treatment ovens to anneal metal parts during or after forming, enhancing flexibility or hardness depending on the utensil requirements.

Once formed, the utensils proceed to secondary processes like trimming, deburring, polishing, or coating, either within the same unit or downstream in the production line.

Overall, a kitchen utensil forming unit is essential for converting raw metal stock into accurately shaped components, enabling efficient mass production of a wide variety of functional and ergonomic kitchen tools.

A kitchen utensil forming unit operates with a series of machines and tools that progressively shape raw metal into finished utensil components. The process starts with feeding systems that manage coils, sheets, or rods of metal, ensuring smooth, continuous supply and precise positioning. Blanking presses cut the raw material into initial flat shapes or blanks, which serve as the starting point for forming complex profiles.

Press forming machines then apply controlled force through matched dies and punches to bend, curve, or emboss the blanks. This may involve single or multiple forming stages, depending on the complexity of the utensil’s design. For example, shaping a spoon’s bowl or creating the distinct tine pattern of a fork requires carefully sequenced operations to prevent metal fatigue or cracking. Progressive die presses allow several forming actions to be completed in one press cycle, increasing speed and accuracy.

For wire-based utensils such as whisks, tongs, or certain types of forks and ladles, wire forming machines use CNC-controlled bending, twisting, and coiling mechanisms. These machines can produce intricate shapes with high precision and repeatability, essential for ensuring consistent utensil performance and ergonomic comfort.

The forming unit may include integrated trimming and deburring stations to remove sharp edges or excess material left after stamping or bending. These finishing steps are crucial to prepare the utensil for polishing or coating and to ensure user safety and comfort.

In some cases, heat treatment ovens are incorporated to anneal or harden formed parts. Annealing softens the metal after forming to relieve internal stresses, improving ductility for further processing. Alternatively, hardening treatments can increase wear resistance or strength, depending on the utensil’s intended use.

Automation plays a significant role in modern utensil forming units. Robotic arms and automated conveyors transfer parts between machines, minimizing manual handling and speeding up production. Sensors and vision systems monitor part alignment, forming accuracy, and detect defects in real time, allowing immediate adjustments or rejection of faulty pieces.

The forming unit is designed for flexibility, enabling quick changeovers to produce different utensil styles, sizes, or materials without lengthy downtime. Modular tooling and programmable controls support a wide range of product variations, from simple flatware to specialized kitchen tools.

Overall, the kitchen utensil forming unit transforms raw metal stock into precisely shaped components through a combination of stamping, bending, wire forming, trimming, and heat treatment processes. Its efficient, automated workflow is key to producing high-quality, durable utensils at scale, meeting the demands of modern kitchens and consumers.

Following the forming processes, the utensils often move directly into polishing and finishing stations to enhance their surface quality and aesthetics. Polishing machines use abrasive belts, brushes, or tumbling barrels to smooth surfaces, remove any remaining burrs, and create finishes ranging from matte to mirror-like shine. This step not only improves appearance but also helps prevent corrosion and ensures comfort during use.

Surface treatments such as electroplating or coating may be applied next to increase durability, corrosion resistance, or provide decorative effects. Common finishes include stainless steel polishing, chrome plating, or application of protective lacquers. These coatings are applied through automated spray or dipping systems followed by curing ovens, ensuring uniform coverage and adhesion.

For utensils that incorporate multiple materials—such as plastic or silicone handles attached to metal heads—the forming unit feeds parts into assembly stations. Here, automated riveting, ultrasonic welding, or adhesive bonding techniques securely join different components. Precision robotic arms handle alignment and placement, reducing errors and increasing throughput.

Throughout the entire forming and finishing process, quality control systems continuously monitor product dimensions, surface condition, and mechanical integrity. Vision cameras detect defects such as cracks, scratches, or deformities, while laser measurement tools verify critical dimensions to ensure compliance with design specifications. Any defective items are automatically separated from the production flow to maintain overall quality standards.

The kitchen utensil forming unit is often integrated into larger production lines that include packaging systems. Automated packing machines count, group, and insert utensils into blister packs, boxes, or display trays. Labeling and barcoding equipment finalizes the product for shipment, with data tracked for inventory and quality assurance.

Energy efficiency and sustainability are important considerations in the design of forming units. Modern machines use variable-speed drives, energy-saving motors, and advanced lubrication systems to reduce power consumption. Scrap metal and trimming waste are collected and recycled, minimizing environmental impact and raw material costs.

Operators are supported by user-friendly control interfaces that provide real-time data on machine performance, production rates, and maintenance alerts. Remote monitoring capabilities allow plant managers to oversee operations from centralized locations, improving responsiveness and minimizing downtime.

In sum, the kitchen utensil forming unit is a highly automated, precise, and flexible system essential to transforming raw metals into finished utensils. By combining advanced forming technologies with finishing, assembly, and quality control, these units enable efficient mass production of reliable, ergonomic, and attractive kitchen tools that meet both consumer expectations and regulatory standards.

Cookware Making Machine

A Cookware Making Machine is a specialized industrial machine designed to manufacture various types of cookware items such as pots, pans, saucepans, and kettles from raw materials like metal sheets or aluminum coils. These machines perform key operations such as cutting, shaping, forming, and sometimes surface treatment to produce cookware bodies and components ready for finishing and assembly.

Typically, a cookware making machine integrates multiple processes in a single setup or a linked series of machines to optimize production speed and accuracy. The process often begins with feeding the raw metal material—usually stainless steel, aluminum, copper, or clad metals—into the machine. The material is straightened and cut into blanks or discs with precise dimensions using shearing or blanking units.

Next, forming operations such as deep drawing or stamping shape these blanks into hollow cookware bodies. Deep drawing presses employ matched dies and punches to gradually stretch and mold the metal into pots or pans, ensuring uniform wall thickness and preventing cracks or wrinkles. Some machines use progressive die technology allowing multiple forming steps within one press cycle, enhancing throughput.

Trimming and edge finishing stations are often integrated to cleanly cut excess material from rims and create smooth, safe edges. Flanging or curling mechanisms roll or bend the edges to strengthen rims and prepare cookware for lid fitting or stacking.

For cookware that includes multilayer bases or composite materials, bonding machines may be part of the system. These units join layers of different metals—such as an aluminum core clad between stainless steel sheets—using methods like impact welding or induction heating to create cookware with superior heat distribution properties.

Some cookware making machines incorporate surface treatment stations, such as polishing, brushing, or sandblasting units, to prepare surfaces for coating or to achieve desired textures. Automated spray booths may apply non-stick coatings, which are then cured in high-temperature ovens integrated into the line.

Automation and robotics are increasingly embedded in cookware making machines to handle part transfer, alignment, and assembly tasks. Sensors and vision systems monitor forming quality, dimensions, and surface finish in real time, allowing immediate corrections and reducing scrap rates.

The machine controls typically rely on programmable logic controllers (PLCs) with touchscreen interfaces, offering flexible parameter adjustments for different cookware designs and materials. Quick-change tooling and modular components facilitate rapid setup changes, supporting production of varied cookware models with minimal downtime.

Energy-efficient motors, servo drives, and waste recovery systems help reduce operational costs and environmental impact. Scrap metal and coating overspray are collected for recycling, and energy recovery systems improve oven efficiency.

In summary, cookware making machines are sophisticated, multi-functional systems engineered to efficiently transform raw metal materials into high-quality cookware bodies and components. They combine forming, trimming, surface preparation, and sometimes coating processes into streamlined workflows, enabling manufacturers to meet high production demands with consistent quality and adaptability.

Cookware making machines operate through a carefully coordinated sequence of mechanical and automated processes designed to transform raw metal materials into finished cookware bodies and components efficiently and accurately. The workflow begins as raw metal sheets or coils are fed into the machine, where they undergo straightening to remove any curvature or distortion. Once flattened, the metal is cut into precise blanks or discs using high-speed shearing or blanking tools.

These blanks then enter forming stations, most commonly deep drawing presses, where matched punches and dies progressively shape the metal into the desired cookware form such as pots, pans, or lids. The deep drawing process carefully controls metal flow to maintain consistent wall thickness and avoid defects like cracking or wrinkling, which can compromise cookware strength and appearance. For complex shapes or thicker materials, multiple forming steps or multi-stage presses are used to gradually achieve the final profile.

After forming, trimming units cleanly remove excess material from edges, ensuring smooth, safe rims. Edge finishing devices such as flanging or curling machines roll the rims to strengthen them and create profiles suitable for lids or stacking. Some machines also include beading operations that add structural reinforcement or decorative detail to cookware walls or rims.

In cases where cookware incorporates multilayer bases or composite constructions, bonding machines join layers of different metals like aluminum and stainless steel. Techniques such as impact welding or high-frequency induction bonding fuse these layers without warping or weakening, producing bases that offer superior heat conduction and durability. These bonding processes are carefully controlled by temperature, pressure, and timing parameters to ensure consistent quality.

Surface preparation stations integrated into the machine or line smooth and texture cookware surfaces as needed. Polishing machines remove imperfections and create finishes ranging from brushed to mirror-like. Sandblasting or chemical etching can roughen interior surfaces to improve coating adhesion. Automated coating systems apply non-stick or decorative layers with precise control over thickness and uniformity. These coatings are then cured in ovens with carefully regulated temperatures to form durable, heat-resistant finishes.

Throughout the entire process, automated handling systems such as robotic arms, conveyors, and part feeders move cookware pieces between stations, reducing manual labor and speeding up production. Sensors and vision inspection systems continuously monitor key parameters including part dimensions, surface quality, and coating consistency. These systems enable immediate adjustments and reject defective pieces to maintain high production standards.

Control systems based on programmable logic controllers (PLCs) provide centralized management of machine functions, allowing operators to set parameters for different cookware models, monitor machine status, and log production data. Quick-change tooling systems enable rapid switching between different shapes and sizes, supporting flexible manufacturing and minimizing downtime.

Energy efficiency measures are incorporated into machine design, including servo motors, energy recovery in ovens, and optimized lubrication systems. Waste materials such as metal trimmings and coating overspray are collected for recycling, aligning with sustainability goals and reducing operational costs.

Together, these features make cookware making machines essential in modern manufacturing environments. They enable high-volume, consistent production of cookware that meets demanding quality, durability, and aesthetic standards while offering the flexibility to adapt quickly to changing market trends and product innovations.

Beyond the core forming and finishing functions, modern cookware making machines increasingly integrate advanced technologies to enhance productivity and product quality. Digital sensors embedded throughout the machine collect real-time data on temperature, pressure, force, and speed, allowing fine-tuning of process parameters on the fly. This data-driven approach minimizes defects, reduces material waste, and ensures repeatability across production batches.

Many machines now feature adaptive control systems powered by artificial intelligence or machine learning algorithms that analyze historical and current production data. These systems can predict tool wear, detect subtle deviations in forming quality, and automatically adjust settings to maintain optimal operation. This predictive maintenance reduces unplanned downtime and extends the life of expensive tooling components.

Cookware making machines also often incorporate modular design principles, allowing manufacturers to customize or upgrade their production lines easily. Modules such as additional forming stations, bonding units, or coating systems can be added or removed based on product requirements or capacity needs. This scalability is particularly valuable for manufacturers targeting diverse markets with varying cookware styles, materials, or sizes.

Robotics plays a critical role in automating labor-intensive or precision tasks. Robotic arms perform functions such as transferring hot or delicate cookware parts between stations, assembling handles or lids, and loading finished products onto conveyors or packaging lines. These robots operate with high speed and accuracy, reducing human error and improving workplace safety.

The use of vision inspection systems integrated within cookware making machines has become widespread. High-resolution cameras and laser scanners inspect surface finishes, measure dimensions, and detect microscopic defects like cracks or coating inconsistencies. Real-time feedback from these systems enables immediate rejection of defective items or process adjustments, maintaining stringent quality control standards demanded by consumers and regulatory bodies.

Energy efficiency and environmental sustainability remain major focuses in the development of cookware making machinery. Innovations include the use of low-energy servo motors, optimized heating elements with rapid temperature ramp-up and recovery, and waste heat recovery systems that recycle energy from ovens back into the process. Material scrap is minimized by precision cutting and forming, and residual metal is routinely collected and recycled on-site.

User interfaces for cookware making machines have become more intuitive, with touchscreen controls, graphical process visualization, and remote monitoring capabilities. These features empower operators to manage complex production processes more easily, troubleshoot issues quickly, and access real-time performance metrics from anywhere. Some systems also offer integration with enterprise resource planning (ERP) and manufacturing execution systems (MES), enabling end-to-end production management and traceability.

In summary, cookware making machines today represent highly sophisticated, interconnected systems that blend mechanical precision with cutting-edge digital technologies. They deliver high-quality cookware products efficiently while adapting to evolving design trends, sustainability requirements, and manufacturing demands. This ongoing evolution ensures that cookware manufacturers remain competitive and capable of meeting the diverse needs of global consumers.

Metal Kitchenware Production Machine

A Metal Kitchenware Production Machine is an industrial system designed to manufacture a wide variety of kitchenware items made primarily from metals such as stainless steel, aluminum, copper, or alloys. These machines handle processes ranging from raw material preparation to forming, shaping, finishing, and sometimes assembling components for products like bowls, trays, containers, strainers, graters, and utensils.

The production machine typically starts with metal feeding systems that supply sheets, coils, or rods of metal into the line. Precision cutting tools such as shears, blanking presses, or laser cutters cut raw material into blanks or segments sized for specific kitchenware items.

Following cutting, forming processes like deep drawing, stamping, pressing, or roll forming shape the metal blanks into functional forms. Deep drawing presses are common for hollow items like bowls and pots, where the metal is stretched over dies to form a smooth, uniform wall thickness. Stamping and pressing are used to create textured or embossed patterns, rims, or handles, enhancing both function and aesthetics.

Additional machines perform trimming, deburring, and edge finishing to remove excess metal and sharp edges, ensuring user safety and product durability. Flanging or curling machines reinforce edges and rims, improving strength and enabling easy stacking or lid fitting.

Surface treatment units polish, brush, or sandblast metal surfaces to achieve the desired finish and prepare them for coating if required. Coating stations may apply protective layers such as anti-corrosion coatings or decorative finishes through automated spraying or dipping methods, followed by curing ovens.

For kitchenware that includes multiple parts—such as handles attached to metal bodies—assembly machines automate fastening through riveting, welding, or adhesive bonding, improving consistency and speed compared to manual assembly.

Throughout production, integrated quality control systems with vision inspection, laser measurement, and thickness gauges monitor product conformity and surface quality. Defective items are automatically rejected, ensuring only high-quality kitchenware reaches packaging.

Modern metal kitchenware production machines emphasize automation, energy efficiency, and flexibility. Programmable controls and modular tooling allow quick changeovers between different products and designs, supporting small batch and mass production. Energy-saving motors, waste recycling systems, and optimized process flows minimize environmental impact and operating costs.

In essence, metal kitchenware production machines are comprehensive, automated systems that convert raw metal into finished kitchenware efficiently and reliably. They enable manufacturers to meet diverse market demands with consistent quality, safety, and attractive designs.