Helmet shell forming press for Kevlar helmet manufacturing: Body armor and helmets are crucial protective gear used in various fields such as military, law enforcement, and high-risk professions. Their manufacturing involves advanced materials and engineering processes to provide maximum protection against ballistic threats, blunt force, and other hazards.

Body Armor Manufacturing

- Materials Used:

- Aramid Fibers (e.g., Kevlar): These synthetic fibers are woven into sheets and layered to create a flexible, lightweight armor that can stop bullets.

- UHMWPE (Ultra-High-Molecular-Weight Polyethylene): A lightweight alternative to aramid fibers, often used in soft and hard armor.

- Steel or Ceramic Plates: Hard armor plates made of steel or ceramic are used to stop high-velocity rounds and provide additional protection in “hard” body armor vests.

- Graphene: Emerging in research for its potential to improve the strength-to-weight ratio of body armor.

- Manufacturing Process:

- Weaving or Layering: For soft armor, the aramid or UHMWPE fibers are woven or layered together to form a flexible, strong sheet.

- Molding or Pressing: Hard armor plates (such as ceramic or steel) are molded or pressed into shape.

- Laminating: In some cases, several layers of woven fibers or materials are laminated together to enhance protection.

- Cutting and Shaping: Once the material is prepared, it is cut to the appropriate shape for vests, plates, or inserts.

- Testing:

- Body armor undergoes rigorous testing, including ballistic testing (shooting projectiles at the material) and physical durability tests (e.g., puncture resistance and wear).

- Customization: Armor can be tailored to specific needs, such as for different threat levels (e.g., handgun vs. rifle threats) or to fit the user’s body shape and size.

Helmet Manufacturing

- Materials Used:

- Fiberglass: Offers a lightweight and cost-effective solution for helmets.

- Kevlar and Aramid Fibers: These materials are woven into the shell or used in combination with other materials to form a strong and lightweight helmet.

- Carbon Fiber: Known for its high strength-to-weight ratio, carbon fiber is used in advanced helmets for maximum protection without added weight.

- Polycarbonate or ABS: These thermoplastics are commonly used in riot helmets or lower-cost tactical helmets.

- Manufacturing Process:

- Molding: The outer shell of the helmet is typically molded using a plastic or composite material, followed by curing in an oven to solidify the shape.

- Liner Installation: Helmets have an inner foam or energy-absorbing liner (such as expanded polystyrene) to reduce the impact on the wearer’s head.

- Suspension Systems: Helmets often include suspension systems (e.g., chin straps, padding) for comfort and stability. These systems also help absorb shock in case of impact.

- Testing:

- Ballistic Testing: Helmets undergo ballistic tests to ensure they meet safety standards against various types of projectiles (e.g., small arms fire).

- Impact and Penetration Testing: Helmets are subjected to blunt force trauma testing, simulating impacts from blunt objects and sharp objects.

- Environmental Durability: Helmets are also tested for durability in extreme conditions, such as high and low temperatures, moisture, and saltwater exposure.

- Customization:

- Helmets can be customized for different environments (e.g., combat, riot control, or industrial applications) by adding accessories like visors, communication systems, or night-vision mounts.

Current Trends and Innovations:

- Smart Armor: Some manufacturers are incorporating electronic sensors or integrated communication systems into body armor to monitor the wearer’s health and environmental conditions.

- Lightweight Materials: Continuous research is focused on reducing the weight of armor while maintaining or improving its protective capabilities, often using materials like graphene or advanced composites.

- Modular Armor: Systems that allow the user to adapt the armor configuration (e.g., adding or removing plates or inserts) depending on mission requirements.

Body armor and helmet manufacturing requires precision, rigorous testing, and the use of high-performance materials to ensure the protection and safety of the user.

Body armor and helmet manufacturing is a highly specialized field, involving advanced materials and engineering to create protective gear for military, law enforcement, and other high-risk professions. The process starts with selecting materials that balance strength, weight, and flexibility. For body armor, materials like Kevlar, UHMWPE, and ceramic or steel plates are commonly used. These materials are woven, layered, or molded to form soft or hard armor, which is then tested for its ability to withstand ballistic threats, blunt force, and wear and tear. The manufacturing process also involves cutting and shaping the materials to fit specific body shapes or armor configurations.

In helmet manufacturing, materials like fiberglass, carbon fiber, and polycarbonate are molded into shells that are paired with foam liners to absorb impacts. Suspension systems inside helmets help ensure a snug, comfortable fit while also aiding in shock absorption. Helmets undergo extensive testing to meet safety standards, including ballistic testing and impact resistance. The integration of smart technologies into both body armor and helmets is an emerging trend, with sensors and communication systems being added for monitoring the wearer’s health and environment. Innovations continue to focus on reducing the weight of the gear without compromising protection, as well as improving overall comfort and adaptability. The manufacturing of both body armor and helmets requires a combination of material science, engineering, and rigorous testing to ensure they provide the highest level of protection in a variety of hazardous environments.

The evolution of body armor and helmets has been driven by the constant need to adapt to new threats, emerging technologies, and environmental challenges. As military and law enforcement needs become more specialized, manufacturers are developing more advanced and customizable solutions to meet those demands.

For example, body armor is increasingly becoming modular, with systems that allow the wearer to add or remove plates or inserts depending on the situation. This adaptability is crucial for personnel who may face varying threats, such as handgun rounds in one scenario and rifle fire in another. With modular systems, body armor can be tailored not only to threat levels but also to comfort and mobility, which is critical for soldiers or police officers who need to remain agile.

In helmets, advancements have focused on improving the helmet’s ability to absorb and disperse impact forces. The incorporation of energy-dispersing materials, like advanced foams and composites, allows for helmets that provide better protection against blunt force trauma while remaining lightweight. Additionally, helmets are now designed with additional features like integrated communication systems, night vision mounts, and face shields, offering more versatility in combat or tactical operations.

A major challenge in both body armor and helmet design is maintaining a balance between weight and protection. While stronger materials provide better protection, they often come at the cost of increased weight, which can hinder the wearer’s mobility. To combat this, manufacturers are constantly exploring new materials, such as graphene, which offer superior strength-to-weight ratios. Graphene is particularly attractive because it is incredibly strong yet light, making it a potential game-changer for the future of personal protective equipment.

Research and development are also shifting towards “smart armor,” which can integrate sensors to monitor the wearer’s physical condition, such as heart rate, body temperature, or the impact forces they experience. This data could be sent to a central system for real-time analysis, providing vital information that could improve the effectiveness of operations or lead to timely medical interventions in case of injury.

The future of body armor and helmets will likely see more integrated systems that not only protect physically but also enhance situational awareness and communication. As these technologies continue to develop, the primary goal remains to provide the wearer with the best possible protection without compromising on comfort, weight, or mobility.

Injection molding plays a significant role in the manufacturing of both body armor and helmets, especially for producing hard armor plates, helmet shells, and some of the inner components of protective gear. It is an efficient, precise, and scalable manufacturing technique that allows for the production of complex shapes and components with high consistency and minimal waste. Here’s how injection molding is used in the process:

Injection Molding in Body Armor Manufacturing

While most body armor is made from woven or layered fibers (like Kevlar or UHMWPE), injection molding is primarily used for producing hard armor plates or inserts. These hard plates are typically used in high-threat environments to protect against rifle rounds or armor-piercing ammunition.

- Material Selection:

- Polycarbonate, Nylon, or ABS Plastics: For certain types of hard armor, injection molding is used with high-strength thermoplastics like polycarbonate or nylon. These materials are chosen for their ability to absorb impact energy and their durability.

- Composite Materials: More advanced body armor might use composite materials, such as a blend of thermoplastic resins reinforced with fibers (like carbon fiber or aramid fibers) that can be injected into molds to create armor plates that are both strong and lightweight.

- Molding Process:

- Heating and Injection: The material is heated to a molten state and then injected into a mold under high pressure. The mold shape is pre-designed to match the required body armor plate form, ensuring a precise fit and a consistent thickness of material.

- Cooling and Solidifying: Once the material is injected into the mold, it is rapidly cooled and solidified to form the final armor plate shape. The cooling process needs to be controlled carefully to avoid warping or weakening the structure of the plate.

- Finishing: After removal from the mold, the plates may undergo additional finishing processes such as trimming, polishing, or coating to improve their surface durability and effectiveness.

- Benefits for Body Armor:

- Cost-Effectiveness: Injection molding allows for mass production, making it a cost-effective option for producing a large volume of hard armor components.

- Consistency and Precision: The high-pressure molding process ensures uniformity in shape and size, which is critical for ensuring proper fit and protection.

- Complex Geometries: Injection molding can create plates or inserts with complex geometries, like curved or multi-layered designs, which are crucial for optimizing coverage and comfort.

Injection Molding in Helmet Manufacturing

Helmets, particularly tactical and military helmets, also utilize injection molding for various components, including the helmet shell and inner components like liners and suspension systems.

- Helmet Shells:

- Material Selection: Materials such as fiberglass, polycarbonate, and ABS are commonly used in helmet shells. In some advanced applications, carbon fiber composites or high-performance thermoplastic resins are used for greater strength and reduced weight.

- Molding Process: The injection molding process starts with the creation of the shell using the chosen thermoplastic material. The material is injected into a mold that defines the helmet’s outer shape. For composite helmets, layers of resin and reinforcing fibers may be added before the molding process.

- Surface Finish: Once the molding is completed, the shell can be further treated with coatings for impact resistance, aesthetics, or camouflage. Additional layers of impact-absorbing foam may also be inserted into the shell for added protection.

- Liners and Suspension Systems:

- Foam Liners: Many helmets feature a foam liner that is also manufactured using injection molding techniques. These liners help absorb the energy of impacts and distribute forces across the head to reduce injury. The foam is molded into a specific shape to fit the contours of the helmet shell and the wearer’s head.

- Suspension Systems: The inner suspension systems, which hold the helmet in place and help with comfort, are often made with thermoplastic materials using injection molding. These systems may include adjustable straps, padding, and comfort foam to ensure a snug, secure fit.

- Customization and Integration:

- Add-ons: Injection molding allows for the easy integration of add-ons such as face shields, visors, or mounts for communication devices and night-vision equipment. These components can be molded to exact specifications and fitted into the helmet design.

- Increased Comfort: Since the molding process allows for complex internal geometries, helmets can be designed with optimized comfort features, like ventilation channels or customized padding patterns, which improve wearability during extended use.

- Benefits for Helmet Manufacturing:

- Durability and Strength: The molded helmet shell provides excellent durability, and injection molding allows the production of helmets that are both tough and lightweight, critical for tactical situations where every ounce counts.

- Scalability: Like body armor, helmet production benefits from the scalability of injection molding, allowing manufacturers to produce large quantities at consistent quality and performance.

- Cost Efficiency: The high efficiency of injection molding makes it a cost-effective process, especially when mass-producing helmet shells and components.

Challenges and Considerations

While injection molding offers many benefits, there are some challenges to consider:

- Material Limitations: The process is often limited to certain thermoplastics and composites. Materials that need to be highly impact-resistant or lightweight (such as ceramic plates for armor) may require additional post-processing or other manufacturing methods.

- Complexity of Design: Injection molds are expensive to create, so for highly specialized or low-volume products, it may not always be the most economical choice.

- Material Performance: For body armor, especially, material performance must be carefully tested to ensure that injection-molded parts meet the necessary safety standards, particularly for ballistic resistance.

Injection molding is an essential technology in the production of body armor and helmets, especially when mass production, consistency, and complex design features are required. While it may not be suitable for every part of the gear, its application in hard armor plates, helmet shells, and certain internal components continues to make it a key manufacturing process in the industry.

Injection molding is increasingly used in the manufacturing of body armor and helmets due to its ability to produce high volumes of precise, durable components. In body armor, it’s particularly effective for creating hard armor plates and inserts, which are designed to stop high-velocity rounds. The process involves injecting molten material, such as polycarbonate, nylon, or composite resins, into molds under high pressure. This method ensures uniformity in thickness, shape, and size, which is critical for ensuring the protective gear fits correctly and performs consistently. For helmets, injection molding is utilized to create the outer shell from materials like polycarbonate, fiberglass, or ABS plastic. The mold forms the helmet shell, which is then combined with foam liners that absorb impact and provide comfort. The molding process also enables the integration of complex features like ventilation channels, suspension systems, and mounts for additional equipment. Injection molding is beneficial for these products because it offers cost efficiency, scalability, and the ability to produce components with intricate shapes. However, challenges remain, particularly regarding the material choices and ensuring the final product meets the required standards for protection and durability.

As injection molding continues to evolve, its role in body armor and helmet manufacturing becomes increasingly integral, particularly in meeting the demands for both efficiency and performance. One of the significant advantages of injection molding is its ability to scale production quickly and with precision. For body armor, especially hard armor plates, this means manufacturers can produce large quantities of plates that are uniform in design and meet rigorous safety standards. The ability to mass-produce parts like this is vital in military and law enforcement settings, where large numbers of high-quality protective gear are required quickly. In helmet production, injection molding helps ensure the helmet shell is lightweight yet strong enough to withstand impacts. This is especially important for military and tactical helmets, where weight is a constant concern for users who need to maintain mobility without sacrificing safety.

Another advantage of injection molding in helmet manufacturing is the ease with which additional components can be integrated into the design. With molds, it is possible to create features like built-in communication system mounts, visors, and even modular attachment points for accessories. These integrated systems allow for a more streamlined design, where all necessary features are part of the initial mold, making assembly faster and more cost-effective.

Moreover, the process’s precision allows for better customization of helmets and body armor. For example, helmets can be designed with custom internal geometries for different head shapes and sizes, improving comfort and fit. The suspension systems and padding inside helmets, which are critical for comfort and shock absorption, can also be produced through injection molding, allowing for consistent and reliable comfort features that enhance the user experience.

Despite these advantages, there are still limitations. The choice of materials is a critical factor because some materials required for optimal protection—such as certain ceramics for hard armor plates—may not lend themselves well to injection molding. Additionally, the complexity of the molds can make them expensive to design and produce, especially for highly specialized components or low-volume production runs. However, for large-scale manufacturing where uniformity, durability, and cost-efficiency are priorities, injection molding remains an essential tool in the production of body armor and helmets.

Looking ahead, the future of injection molding in this field is likely to be influenced by new materials and technologies. For example, advancements in thermoplastics, composites, and even 3D printing techniques could allow for more lightweight, yet highly protective, materials to be injected into molds. The integration of smart technologies, such as sensors embedded in the armor or helmets, could also benefit from injection molding, enabling the seamless production of multifunctional gear that not only protects but also communicates real-time data about the wearer’s status.

Ultimately, the continuous advancements in injection molding will support the development of more efficient, durable, and versatile body armor and helmet designs, improving both the safety and comfort of those who rely on this protective gear.

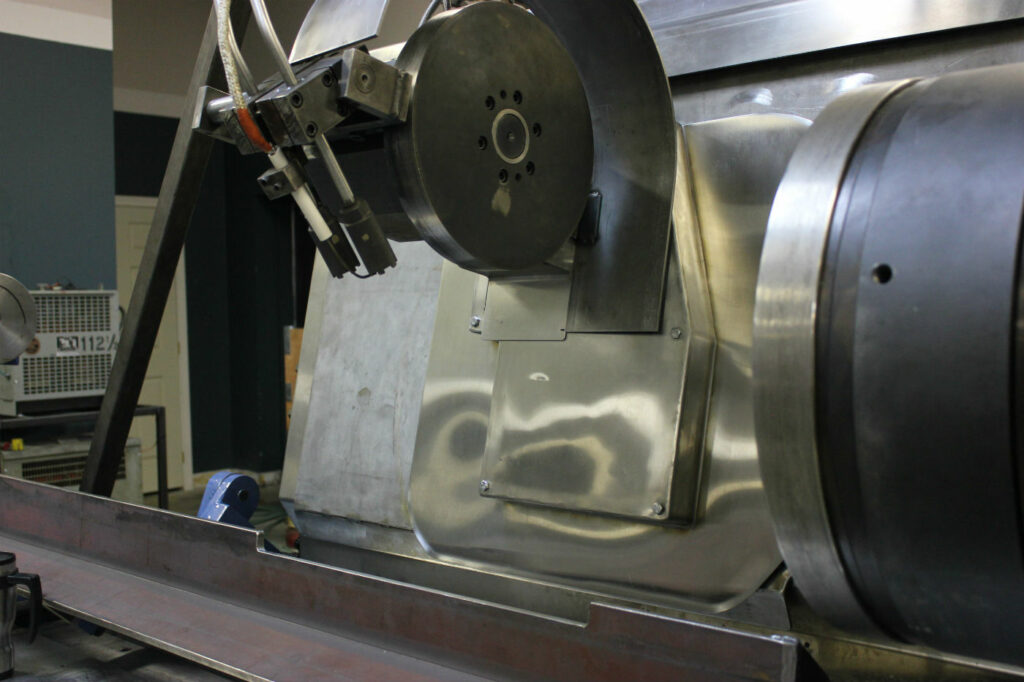

Laminating machine for body armour and helmet manufacturing

Laminating machines are crucial in the manufacturing of both body armor and helmets, particularly for producing multi-layered protective materials that offer enhanced strength and flexibility. The lamination process involves bonding multiple layers of materials together to form a composite structure, which improves the overall performance of body armor and helmets in terms of impact resistance, durability, and comfort.

In the context of body armor and helmet manufacturing, laminating machines are used to combine materials such as aramid fibers (like Kevlar), UHMWPE, carbon fiber, or fiberglass with resins to create strong, lightweight, and flexible layers that can withstand impacts, ballistic threats, and other hazards. The laminating process typically involves applying heat, pressure, and sometimes vacuum, to bond these layers together while ensuring consistency and uniformity in the final product.

For body armor, laminating machines are essential in creating the soft armor layers. These layers are typically made from fibers such as Kevlar or UHMWPE, which are woven or braided to form sheets. These sheets are then layered with resin or adhesives and passed through a laminating machine, which consolidates the layers by applying controlled heat and pressure. The result is a rigid, flexible armor that provides protection without adding excessive weight. The laminated structure enhances the energy-absorbing properties of the armor, ensuring it can dissipate the force of a bullet or other projectile effectively.

In helmet manufacturing, laminating machines are used to bond the helmet’s composite materials, such as fiberglass or carbon fiber, with resin. The laminating process can create the outer shell of the helmet, which is strong yet lightweight, to protect against impacts. Additionally, helmet linings or internal padding materials, often made from foam or other shock-absorbing materials, can be laminated for enhanced comfort and to improve the helmet’s overall performance in absorbing and dissipating impact energy.

The laminating process can be done using several techniques, such as heat-pressing, vacuum-bagging, or autoclaving. Each method has its advantages and is chosen based on the type of materials used, the desired thickness of the laminated structure, and the overall design of the body armor or helmet. For example, autoclaving is a common method used in advanced helmet manufacturing, where the layers of composite materials are sealed in a vacuum bag and then subjected to high pressure and heat in an autoclave to form the helmet shell. This method ensures a strong bond between layers and reduces the chance of defects in the final product.

The use of laminating machines offers several advantages in the production of body armor and helmets. The process ensures consistent and uniform layer bonding, reducing material waste and improving the overall strength of the finished product. It also allows for the production of complex, multi-layered designs that can be tailored to specific threat levels and requirements. Additionally, laminating machines can be adjusted to accommodate various materials, enabling manufacturers to experiment with new composites or hybrid structures that can provide superior protection.

One of the challenges in using laminating machines is ensuring that the process is optimized for each material and layer combination. For example, if the heat and pressure are not carefully controlled, the layers may not bond properly, compromising the strength and effectiveness of the armor or helmet. Furthermore, the choice of adhesive or resin used in the laminating process must be carefully selected to ensure it provides the necessary bond strength while maintaining the flexibility and weight characteristics required for comfort and performance.

In conclusion, laminating machines are a critical tool in the production of body armor and helmets, enabling manufacturers to create high-performance, multi-layered protective materials. By applying controlled heat, pressure, and sometimes vacuum, these machines ensure that the various layers are bonded together to form a strong, durable, and lightweight product that offers superior protection against ballistic threats and impacts. With continued advancements in materials and lamination technologies, the role of laminating machines will remain essential in producing cutting-edge personal protective equipment.

Laminating machines are essential in creating the multi-layered composites used in body armor and helmet manufacturing, ensuring the performance of protective gear. These machines apply controlled heat and pressure to bond different layers of materials, such as aramid fibers, UHMWPE, fiberglass, or carbon fiber, with resins or adhesives. The laminating process enhances the strength, durability, and flexibility of the finished product, ensuring it can effectively absorb and dissipate impact forces from ballistic threats or blunt trauma.

For body armor, laminating machines enable the production of soft armor layers that combine fibers like Kevlar or UHMWPE with resins, creating a flexible yet tough material capable of stopping bullets and other projectiles. The layers are consolidated under heat and pressure to form a durable, lightweight composite that provides the necessary protection. In helmet manufacturing, the same process is applied to create composite shells made from fiberglass or carbon fiber, which are lightweight yet strong enough to resist impacts. These laminating machines can use various techniques, such as heat-pressing, vacuum-bagging, or autoclaving, depending on the materials used and the desired performance characteristics.

The main advantage of laminating machines is their ability to produce consistent, uniform layers that contribute to the overall strength and quality of the armor or helmet. They also allow for the customization of materials, enabling manufacturers to experiment with different composites or hybrid materials that offer superior protection. However, careful control of heat, pressure, and resin application is crucial in ensuring the integrity of the final product, as improper bonding could compromise its protective capabilities. With the continuous evolution of materials and lamination technologies, these machines will remain a fundamental part of manufacturing high-performance protective gear, ensuring that body armor and helmets offer the best possible protection while remaining lightweight and comfortable.

As laminating technology continues to improve, the precision and efficiency of laminating machines are increasingly pivotal in meeting the growing demands for high-performance protective gear. In the case of body armor, the evolution of materials and their integration into the lamination process is key. For instance, researchers are exploring more advanced composite materials, including high-strength, lightweight fibers and new resin formulations that offer enhanced resistance to heat, moisture, and chemical exposure, which could further improve the overall protection of body armor. These innovations in materials require laminating machines that can handle more advanced processing methods, allowing for tighter control over temperature and pressure during the bonding process.

Similarly, the use of laminating machines in helmet manufacturing is benefiting from advancements in materials like graphene and other nanomaterials. These materials offer exceptional strength-to-weight ratios, which could lead to helmets that are both more protective and lighter, without compromising comfort or mobility. As new materials are developed, the laminating process will have to evolve to accommodate these advanced composites, ensuring that the bond between layers remains consistent and secure.

Moreover, the introduction of automation and smart technology into the laminating process is streamlining production, improving both consistency and efficiency. Automated laminating machines can monitor factors such as temperature, pressure, and resin flow in real-time, ensuring that each layer is properly bonded for optimal performance. This integration of advanced sensors and control systems helps reduce the risk of human error and material defects, ultimately leading to higher-quality products with fewer variations.

One of the exciting prospects for the future of laminating machines in body armor and helmet manufacturing is the possibility of creating “smart” armor systems that combine traditional protective materials with embedded sensors. These sensors could monitor the condition of the wearer, providing real-time data on their health, such as heart rate, body temperature, and stress levels. With these smart features, laminating machines would play a crucial role in integrating both passive protective materials and active sensing technologies into a single, unified system.

As these technologies continue to advance, laminating machines will not only serve the purpose of ensuring the structural integrity of body armor and helmets but also help create more advanced, multi-functional gear. This could lead to protective equipment that is not just protective but also adaptive and responsive, offering wearers both physical safety and real-time data that can enhance situational awareness and safety.

Ultimately, the ongoing development of laminating technologies will allow manufacturers to keep up with the growing demands for more sophisticated protective gear. With each improvement, the process will become more efficient, more customizable, and better equipped to handle the diverse range of materials and design complexities required for next-generation body armor and helmets. This will ensure that personal protective equipment continues to evolve in line with the latest advancements in materials science, manufacturing techniques, and wearable technology.

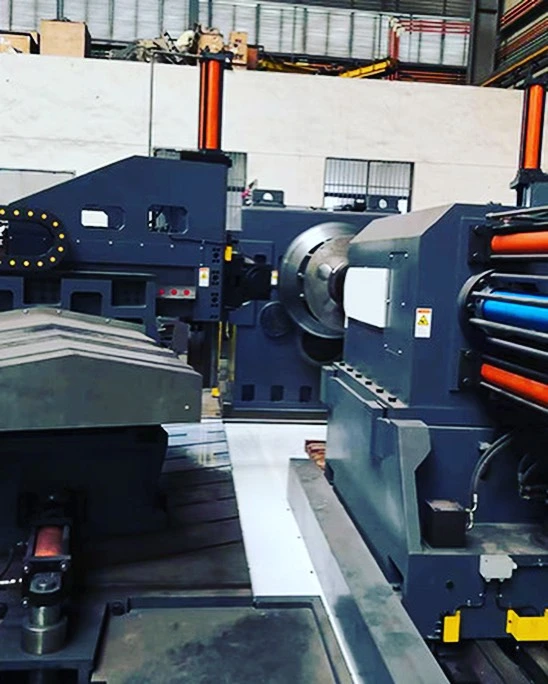

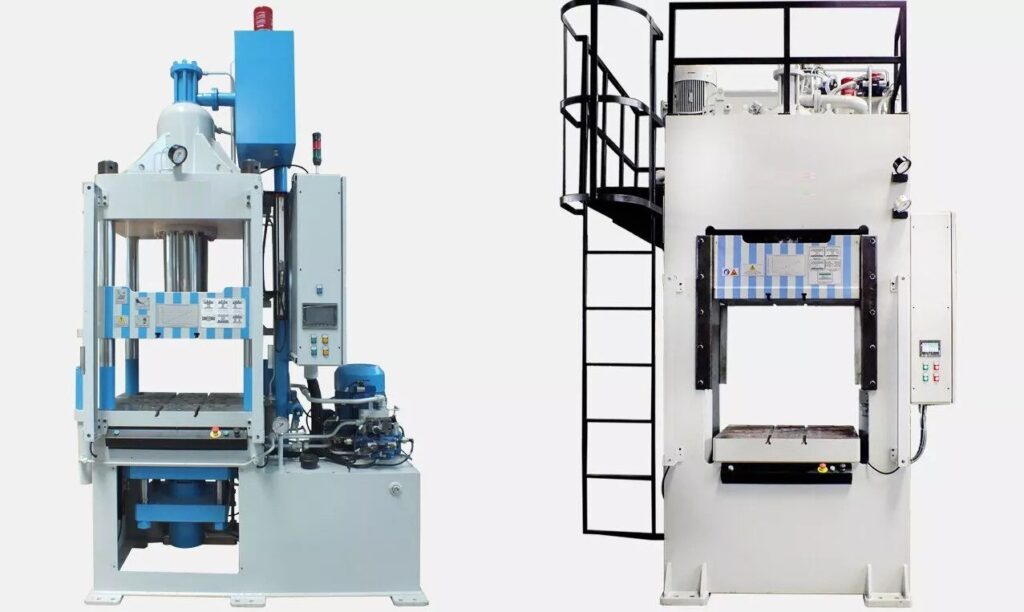

Hydraulic press for body armour and helmet manufacturing

Hydraulic presses are critical in the manufacturing of body armor and helmets, as they provide the force needed to shape, bond, and compress materials into the desired forms. These presses use hydraulic power to exert a consistent and controlled amount of pressure, which is essential for processes like molding, lamination, and compression, where precision and uniformity are key. In both body armor and helmet manufacturing, hydraulic presses ensure that materials are processed correctly to meet the necessary strength, durability, and protection standards.

In body armor manufacturing, hydraulic presses are often used to shape and compress composite materials like fiberglass, aramid fibers (such as Kevlar), and polyethylene into rigid, durable plates. These plates are the hard armor inserts that provide protection against high-velocity threats like bullets. The press applies even pressure across the composite layers, ensuring that they bond tightly together and that the resulting plate is uniform in thickness, shape, and structure. This uniformity is crucial, as any inconsistencies in the armor plate could reduce its ability to effectively stop a bullet or other projectile.

For helmets, hydraulic presses are used to mold the outer shell of the helmet from materials such as polycarbonate, fiberglass, or carbon fiber composites. In the case of composite helmets, the press applies the necessary pressure to bond layers of resin and reinforcing fibers, creating a strong yet lightweight shell. Additionally, hydraulic presses can be used to compress foam materials or other padding that form the inner liner of the helmet. The foam liners help absorb impacts and provide comfort to the wearer. The press ensures that these components are tightly compressed to maintain their structural integrity and protective properties.

The hydraulic press’s role is also crucial in the process of forming multi-layered structures, such as the combination of ballistic-resistant materials with foam or other shock-absorbing layers. These multi-layered designs are typical in both body armor and helmets, where different materials are combined to offer protection against various types of threats. For example, in helmet manufacturing, a high-strength composite outer shell may be combined with an inner foam layer for impact resistance, and the hydraulic press ensures that these layers bond together effectively, maintaining both the integrity of the shell and the cushioning properties of the foam.

One of the advantages of using hydraulic presses in these manufacturing processes is the ability to apply consistent and uniform pressure over large areas. This consistency ensures that every part produced is of the same high quality, which is essential in the production of personal protective equipment. Variations in pressure or molding can lead to weak points in the final product, which could compromise its effectiveness in real-world situations.

Hydraulic presses are also relatively adaptable. Different types of materials, such as thermoplastics, resins, and composites, can be processed effectively using these presses, making them versatile tools for producing a wide range of body armor and helmet components. For example, for helmets made from advanced materials like carbon fiber, the hydraulic press can help ensure the material is molded into the correct shape while maintaining its strength-to-weight ratio.

One of the ongoing challenges in the use of hydraulic presses in body armor and helmet manufacturing is the optimization of pressure and heat settings for different materials. Some materials require higher or lower pressure, and the process must be carefully controlled to ensure that the final product maintains its protective qualities without being overly rigid or brittle. The flexibility of the hydraulic press makes it easier to adjust settings for different materials, but close monitoring and precision are necessary to avoid damaging the materials or compromising their performance.

Another aspect of hydraulic press use is its role in the development of new materials and designs. As manufacturers continue to experiment with new composites and multi-material designs, the hydraulic press will be instrumental in shaping and compressing these innovative materials into final products that meet the required protective standards. The press’s ability to apply precise and consistent force makes it an indispensable tool in the development of next-generation body armor and helmets.

In summary, hydraulic presses are essential to the manufacturing of body armor and helmets, offering the ability to mold, shape, and compress materials into the required forms with high precision. The consistency, versatility, and adaptability of hydraulic presses make them indispensable for producing the high-quality, protective gear needed by military personnel, law enforcement, and other professionals who rely on body armor and helmets for their safety. As material science continues to advance, the role of hydraulic presses in producing cutting-edge protective gear will only grow, allowing manufacturers to create stronger, lighter, and more comfortable protective equipment.

Hydraulic presses play a pivotal role in the production of body armor and helmets by applying controlled pressure to mold, bond, and shape various materials into the final protective gear. In body armor, these presses are used to shape composite materials like Kevlar, UHMWPE, fiberglass, and carbon fiber into hard plates and inserts that are designed to withstand high-velocity impacts, such as bullets or shrapnel. The even, consistent pressure from the hydraulic press ensures that the materials are uniformly compacted, which is crucial for achieving the required strength and ballistic resistance. By molding these composite layers together, the press ensures that the final product is strong, lightweight, and capable of absorbing and dispersing the energy from incoming projectiles.

In helmet manufacturing, hydraulic presses are used in the production of the outer shell and the inner components. For the shell, materials like polycarbonate, fiberglass, or carbon fiber are shaped by the press to create a protective outer layer that is both tough and lightweight. The press also helps in molding foam or padding materials that are used for the inner lining of the helmet, which provides comfort and additional impact absorption. The press ensures that the foam is compacted correctly, maintaining its shock-absorbing properties while ensuring the helmet’s structure is sound and reliable.

The versatility of hydraulic presses is evident in their ability to handle a wide range of materials and processing requirements. Whether it’s forming thermoplastic materials, compressing resins into composites, or molding advanced fibers into protective layers, hydraulic presses provide the necessary force and precision for these complex tasks. However, careful control of pressure and temperature is essential. Too much pressure can lead to material deformation or loss of protective qualities, while too little pressure can result in weak bonds or improperly formed products.

As new materials and designs continue to emerge in the field of body armor and helmets, hydraulic presses will remain integral to their production. Their ability to handle complex, multi-layered composite structures is especially important as manufacturers work to combine new lightweight materials with high-performance resins or adhesives. The hydraulic press will continue to be a vital tool in creating protective gear that balances strength, weight, and comfort for those who rely on body armor and helmets for their safety in high-risk environments.

The continuous advancement of hydraulic press technology is enabling even more precise control over the forming and bonding processes, which is particularly important as manufacturers push the limits of material performance in both body armor and helmet applications. Modern hydraulic presses often feature programmable control systems that allow for exact adjustments in pressure, temperature, dwell time, and speed, all of which are critical in ensuring the integrity of the final product. These controls help avoid inconsistencies and ensure repeatability across large production runs, which is vital for ensuring that every piece of armor or helmet meets the stringent performance standards required for life-saving equipment.

In the case of advanced composite materials, such as those used in military-grade armor or combat helmets, the pressing process may involve multiple stages. For example, a series of layers—each with specific orientations or materials—may be laid up manually or via automation, and then transferred into a mold where the hydraulic press applies heat and pressure. This staged process can help optimize fiber alignment and resin distribution, which directly impacts the strength and ballistic resistance of the finished product. In some systems, presses are combined with vacuum or autoclave environments to further enhance resin flow and eliminate air pockets, ensuring the composite structure is fully consolidated and free from internal weaknesses.

Another key area where hydraulic presses are becoming increasingly relevant is in the production of ergonomic or contoured designs. Unlike flat armor plates or standard helmet shapes, newer designs often include curvature to better fit the human body or improve aerodynamics and comfort. Forming these shapes reliably and efficiently requires presses with specialized dies and molds that maintain uniform pressure distribution even across complex geometries. This capacity is particularly valuable in producing customized armor panels for female personnel or mission-specific helmet shapes for airborne or mechanized forces.

Furthermore, the integration of advanced monitoring systems into hydraulic presses is enhancing quality assurance. Sensors embedded within the press can detect fluctuations in temperature, pressure, or material flow, allowing for real-time adjustments and reducing the risk of defective parts. These systems also enable comprehensive data logging for traceability, which is increasingly important in defense and law enforcement procurement where rigorous certification and quality records are mandatory.

As sustainability becomes a more pressing concern, hydraulic presses are also being adapted to support greener manufacturing practices. This includes the ability to process bio-based or recyclable composites, as well as more energy-efficient press systems that minimize waste heat and use hydraulic fluids with lower environmental impact. In addition, by allowing for more accurate material forming and bonding, hydraulic presses reduce the amount of scrap material generated, contributing to more sustainable production cycles.

In short, the hydraulic press is not just a shaping tool but a cornerstone of modern body armor and helmet production. Its ability to adapt to new materials, complex shapes, and high-volume production while maintaining precision and repeatability makes it indispensable. As protective gear continues to evolve toward lighter, smarter, and more ergonomic designs, hydraulic presses will remain central to turning advanced material science into real-world, field-ready protection.

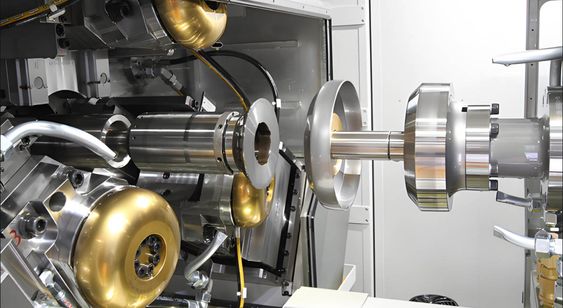

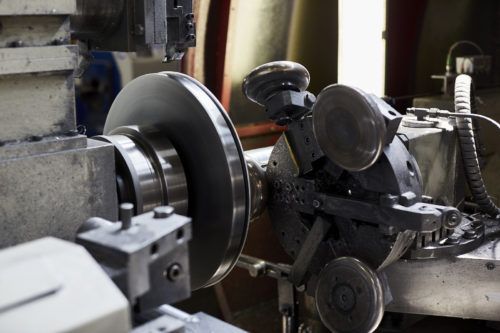

Helmet shell forming for body armour and helmet manufacturing

Helmet shell forming is a critical stage in the manufacturing process of protective helmets used by military, law enforcement, and security personnel, and it directly determines the structural integrity, impact resistance, and overall effectiveness of the helmet. This process involves shaping high-performance materials—typically advanced composites like aramid fibers (e.g., Kevlar), ultra-high-molecular-weight polyethylene (UHMWPE), carbon fiber, or fiberglass—into a hardened outer shell that can absorb and deflect kinetic energy from ballistic threats, blunt impacts, and fragmentation.

The shell forming process typically begins with material preparation, where sheets or fabrics impregnated with resin are cut into specific patterns. These are then carefully laid into a mold that corresponds to the helmet’s design—often using a multi-layer stacking method to ensure optimal fiber orientation and maximum strength. Once the layup is complete, the mold is closed and subjected to heat and pressure through processes such as compression molding, vacuum-assisted resin transfer molding (VARTM), or autoclaving. These forming techniques ensure that the resin flows uniformly through the layers and that the composite material conforms precisely to the helmet’s shape while eliminating voids or air pockets that could compromise protection.

Compression molding, which uses a hydraulic press, is one of the most common methods for helmet shell forming. In this process, the material layup is placed into a heated mold, and a matching upper mold applies pressure. The heat softens the resin, and the pressure causes it to flow, impregnating all fiber layers while curing the shell into its final hardened form. This results in a smooth, consistent, and high-strength shell that forms the core of the protective helmet.

In high-end applications, autoclave curing may be used. This involves placing the mold and helmet layup into a sealed chamber where heat and pressure are uniformly applied under vacuum conditions. This method allows for extremely tight control of resin content and distribution, often resulting in superior mechanical properties and a high-quality finish, but it is more time- and cost-intensive.

After the shell is cured and removed from the mold, it undergoes trimming to remove excess material and to create openings for accessories such as visors, straps, communication systems, or ventilation ports. The shell may also be post-cured in an oven to ensure complete resin hardening, improving thermal stability and durability. The outer surface is then often sanded, coated, or painted for UV protection, camouflage, and durability.

Helmet shell forming must also consider ergonomic and anatomical factors. The shell must fit comfortably while accommodating the padding, harness system, and additional attachments. Therefore, molds are designed with careful attention to anthropometric data to provide optimal coverage, balance, and wearer comfort without compromising mobility or field of view.

Ongoing developments in materials and forming techniques are pushing the boundaries of helmet performance. Hybrid constructions using layered combinations of carbon fiber and aramid, for example, are becoming more common to achieve a balance between lightweight construction and ballistic protection. New shell designs incorporating modular or reconfigurable components are also being explored, especially for integrated systems that include electronics, night vision mounts, and communications.

In conclusion, helmet shell forming is a sophisticated, precision-driven process that transforms flat composite fabrics into contoured, high-strength protective shells. It requires careful material selection, expertly engineered molds, and controlled thermal and pressure environments to ensure the final product meets stringent performance standards. As combat and operational requirements evolve, the technology behind helmet shell forming continues to advance, delivering helmets that are lighter, stronger, more comfortable, and better integrated with modern battlefield systems.

The precision required in helmet shell forming extends to the smallest details of the process, as even minor defects in the shell can compromise its protective capabilities. Factors such as fiber alignment, resin-to-fiber ratio, curing temperature, and pressure all play a significant role in the final mechanical properties of the helmet. Any inconsistency in these parameters can lead to weak spots or delamination within the composite structure, which would reduce the helmet’s ability to absorb impact or withstand ballistic threats. This is why modern helmet manufacturing often includes rigorous quality control measures during and after shell forming, including non-destructive testing methods like ultrasonic inspection or X-ray analysis to detect internal flaws without damaging the product.

In addition to the structural performance, the forming process is also critical in achieving uniform thickness and proper contouring, especially around high-stress areas like the crown, side edges, and rim of the helmet. These areas are subject to greater forces during impact and need precise reinforcement to maintain consistent protection. Advanced forming techniques allow for variable thickness across the shell, increasing material where it is most needed while reducing unnecessary weight elsewhere. This optimization helps to improve balance and comfort, which are essential in long-duration operational scenarios.

Another important consideration is compatibility with other components, as today’s helmets are not just standalone protection devices but are often part of integrated soldier systems. Helmet shells must accommodate rails, mounts, and ports for communication devices, night vision systems, face shields, and ballistic visors. Therefore, the forming process must ensure that the shell not only provides ballistic integrity but also maintains dimensional accuracy to align with these modular systems. In some cases, embedded reinforcements or inserts are added during shell forming to provide additional structural support at mounting points, further enhancing the helmet’s durability and utility.

As innovations in materials continue to emerge, the shell forming process must adapt to accommodate the properties of newer high-performance fibers and resins. For example, the use of thermoplastic composites, which can be reheated and reshaped, introduces possibilities for repairable and recyclable helmets, offering sustainability benefits alongside functional performance. These materials require different forming protocols, including lower temperature ranges and potentially faster cycle times, which can improve throughput in mass production without compromising quality.

The push for lighter and more adaptive helmets has also driven interest in hybrid material systems and complex shell geometries. Multi-axial fiber reinforcements, gradient material layouts, and embedded sensor technologies are now being explored within the shell structure itself, adding layers of functionality while maintaining core protective roles. These advancements rely on precise forming conditions, which further underscore the importance of continually evolving helmet shell forming equipment and methods.

Ultimately, helmet shell forming represents a convergence of materials science, mechanical engineering, and ergonomic design. It is the foundational process that defines the helmet’s strength, weight, comfort, and ability to integrate with other technologies. As threats become more diverse and operational demands increase, the development of more sophisticated shell forming techniques will continue to be essential in delivering next-generation protective helmets that enhance survivability and performance across military, law enforcement, and specialized civilian applications.

As helmet shell forming continues to evolve, manufacturers are increasingly exploring automation and digital technologies to improve efficiency, precision, and consistency. Automated systems and robotic arms are being integrated into the production process to handle repetitive tasks such as material placement, mold handling, and shell trimming. These systems help reduce human error and increase throughput, allowing for higher production volumes without sacrificing the quality of the finished product. Automation also supports the scalability of production, making it easier to meet large demands while maintaining tight tolerances and uniformity across multiple units.

Another area of innovation in helmet shell forming is the use of 3D printing technologies, which are being explored for creating complex internal structures or customized helmet components. While 3D printing of entire helmet shells is still in its infancy due to material limitations, it holds potential for producing intricate inner frameworks that can be integrated with traditional helmet shells. These structures could enhance the helmet’s impact resistance, ventilation, or energy absorption by optimizing the internal geometry, while the outer shell retains its ballistic integrity. This could lead to helmets that are not only lighter but also more efficient in terms of impact energy management.

The integration of smart technologies within the helmet, such as sensors for monitoring vital signs, environmental conditions, or the wearer’s position, is also influencing the shell forming process. These technologies require specialized slots, connectors, or even built-in wiring channels within the helmet’s structure, which must be seamlessly incorporated into the shell without weakening its protective capabilities. Forming processes are becoming more advanced to allow for these embedded technologies, with precise mold designs and additional reinforcement at critical points to support integrated electronics.

Additionally, the demand for helmets that can withstand a broader range of threats—such as fragmentation, blunt force trauma, and chemical exposure—is prompting manufacturers to rethink the design of the shell and the materials used in forming. Some helmets are now being designed to provide multi-threat protection, which involves creating shells with multiple layers of different materials, each optimized for a specific type of threat. For example, a helmet might have a base layer of high-strength aramid fibers for ballistic protection, followed by a layer of shock-absorbing foam to protect against blunt force trauma, and an outer layer of polycarbonate or composite for added durability and resistance to abrasions. Each of these materials must be formed with the appropriate pressure, temperature, and curing times to ensure that they perform as intended when combined.

The continued development of advanced coatings is another area that complements the helmet shell forming process. Protective coatings that add resistance to environmental factors like heat, cold, moisture, or chemicals are increasingly applied during or after shell forming. These coatings can be integral to the helmet’s performance in extreme conditions, ensuring it doesn’t degrade over time or become vulnerable to external threats like acids or salts. Some coatings also provide anti-glare or anti-reflective properties, enhancing the helmet’s effectiveness in tactical environments where stealth and visibility are critical.

As global standards for protective equipment continue to evolve, helmet shell forming processes must also adapt to meet more stringent regulations and certification requirements. These standards ensure that helmets provide reliable protection against a range of hazards, including high-velocity projectiles, blunt trauma, and environmental factors. As a result, manufacturers must stay ahead of regulatory changes and continually refine their forming processes to maintain compliance with these evolving requirements.

The overall trend in helmet manufacturing is toward producing lighter, stronger, and more multifunctional helmets that are not only protective but also adaptable to a range of operational needs. Whether it’s for military personnel in combat, law enforcement officers in tactical situations, or first responders in hazardous environments, helmets are being designed to integrate more seamlessly with other gear, enhance wearer comfort, and provide advanced protection from a wider array of threats.

Ultimately, the helmet shell forming process is at the heart of this innovation. By continuously refining materials, improving manufacturing techniques, and incorporating new technologies, manufacturers can create helmets that not only meet but exceed the performance expectations of modern protective gear. As demands for advanced protection, comfort, and adaptability continue to grow, the process of helmet shell forming will remain a critical area of focus for the next generation of protective headgear.

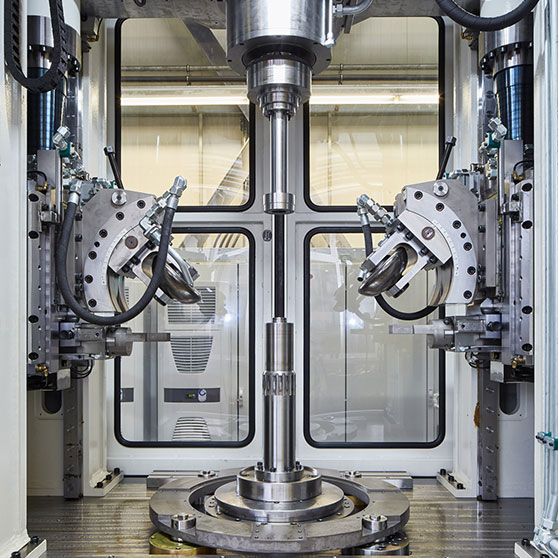

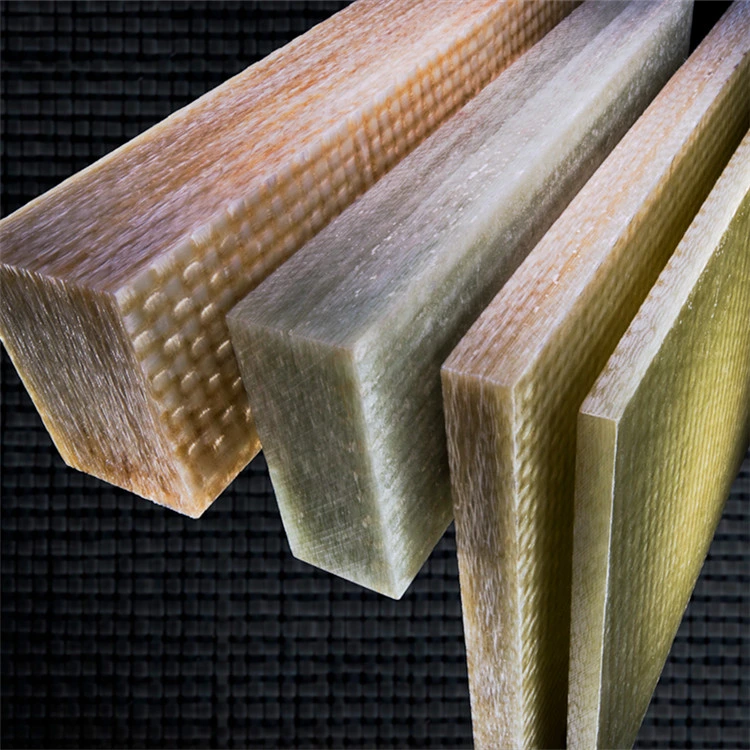

Kevlar preform molding machine for helmet manufacturing

Kevlar preform molding machines are specialized equipment used in the production of helmet shells, particularly in the manufacturing of ballistic helmets. These machines are designed to shape Kevlar fibers, which are known for their high tensile strength, durability, and resistance to impact, into preforms or molded shells that serve as the foundational protective structure of the helmet. The preform molding process is key to creating the helmet’s outer shell, which is the first line of defense against ballistic and blunt-force impacts.

The process of using a Kevlar preform molding machine typically starts with the preparation of Kevlar fabric or fiber, which is cut into specific patterns or layers that will be stacked to form the helmet shell. The Kevlar fibers are impregnated with resin to provide the material with rigidity and to enhance its ballistic properties. Once the fibers are prepared, they are loaded into the preform molding machine.

The preform molding machine utilizes high heat and pressure to mold the Kevlar layers into a desired shape, typically the outer shell of a helmet. The machine applies even pressure across the entire mold, ensuring that the fibers are uniformly compressed and bonded together. This pressure helps the resin to cure, forming a solid, durable structure. The heat is essential for activating the resin and ensuring it fully bonds the fibers together, while the pressure ensures that the fibers are properly aligned and compacted, creating a consistent thickness and strength across the entire shell.

One of the advantages of using Kevlar preform molding machines is the precision with which the machine can control the molding process. By adjusting temperature, pressure, and curing time, manufacturers can optimize the material’s performance, ensuring the helmet meets the required ballistic standards and is lightweight yet strong. Kevlar is a material known for its high strength-to-weight ratio, which is particularly important in helmet manufacturing, as it provides optimal protection without adding unnecessary weight that would hinder mobility or comfort.

These machines also help in creating more intricate and complex helmet shapes, accommodating different designs and customizations that may be required for specific end users, such as military personnel or law enforcement officers. This level of customization is possible due to the flexibility of the preform molding process, which allows for the incorporation of different layers, reinforcements, or even hybrid materials within the helmet design.

Moreover, the Kevlar preform molding machine can be adapted for use with other composite materials. As the demand for advanced helmets increases, manufacturers are exploring the use of hybrid materials, such as a combination of Kevlar and carbon fiber or aramid blends, to create even stronger, lighter, and more flexible helmet shells. In such cases, the preform molding machine must be able to handle the unique requirements of each material, ensuring that all layers are properly integrated during the molding process.

In addition to its role in molding the outer shell, the Kevlar preform molding machine can be used to mold inner components of the helmet, such as padding or impact-resistant liners. These components contribute to the helmet’s overall ability to protect the wearer from blunt-force trauma, and the molding machine ensures that each component is shaped to fit precisely within the shell.

While the use of Kevlar preform molding machines provides significant advantages in terms of efficiency, precision, and material optimization, they also come with a set of challenges. For example, the cost of the machinery and the specialized skills required to operate it can be significant. Additionally, ensuring that each molded helmet meets strict safety and quality standards requires continuous monitoring and testing, both during and after the molding process.

As the helmet manufacturing industry evolves, the integration of automation and digital technologies in Kevlar preform molding machines is becoming more common. Automated systems can help streamline the production process, reduce human error, and ensure consistency in the final product. These advancements may include real-time monitoring systems that track temperature, pressure, and curing time, as well as advanced robotic arms for handling the molded helmets and adding additional components, such as visors or chin straps.

In conclusion, Kevlar preform molding machines are a vital component in the production of high-performance helmets, providing the precision and consistency necessary to create helmets that meet rigorous safety standards. By optimizing the molding process for Kevlar, manufacturers can produce helmets that offer excellent ballistic protection while remaining lightweight and comfortable for the wearer. As technology continues to advance, these machines will likely evolve to accommodate new materials, designs, and manufacturing techniques, ensuring that protective headgear keeps pace with the ever-changing demands of safety and performance.

Kevlar preform molding machines are integral to the production of modern ballistic helmets because they offer a combination of speed, precision, and efficiency. These machines ensure that Kevlar’s exceptional properties—such as its high tensile strength, durability, and resistance to abrasion—are fully realized in the final helmet shell. By applying a controlled amount of pressure and heat to the pre-impregnated Kevlar material, these machines mold the fiber into the precise shape required for the helmet. This process not only ensures uniformity in the finished product but also enhances the overall structural integrity of the helmet.

With the increasing demand for lightweight and high-performance helmets, manufacturers have focused on improving the molding techniques. Advanced systems are now capable of adjusting various parameters, such as molding time, temperature, and pressure, during the production process to optimize the material properties of the Kevlar preform. This allows manufacturers to tailor the helmet’s mechanical characteristics, such as its resistance to penetration, impact absorption, and deflection, to meet specific safety standards. Fine-tuning these parameters also helps in achieving the best balance between strength and weight, which is critical for helmets that need to provide protection without being overly burdensome for the wearer.

The ability of Kevlar preform molding machines to handle complex geometries is particularly beneficial in meeting the growing demand for ergonomic designs. Helmet shells are no longer just flat or simple shapes; modern helmets are designed to fit a wide range of head sizes and shapes while providing optimal protection and comfort. The molding machines are capable of creating custom contours that align with the human head’s natural curvature, providing a better fit and reducing pressure points. This is vital, especially for long-term wear, where comfort plays a crucial role in ensuring that the helmet remains effective in real-world scenarios.

Beyond standard ballistic helmets, Kevlar preform molding machines can be adapted for the production of specialized headgear, such as riot helmets, combat helmets, or even helmets used for space exploration. These machines can be customized to handle varying material combinations, such as adding carbon fiber or other high-strength materials to the Kevlar layers to further enhance impact resistance or reduce weight. Hybrid helmets, which combine different materials, are becoming increasingly popular because they allow for tailoring of the helmet’s properties to meet the exact needs of the wearer. For example, helmets designed for specific military units may incorporate additional features like mounts for communication systems, night vision devices, or ballistic visors, all of which require careful molding to ensure the helmet shell can accommodate these additions without compromising its protective capabilities.

In addition to improving the molding process itself, innovations in quality control and testing are also helping to ensure the helmets meet stringent performance standards. Automated inspection systems are now being integrated into the production line to detect any inconsistencies or defects in the molded helmets. These systems use advanced sensors and imaging technologies to check for issues such as surface imperfections, dimensional inaccuracies, or structural flaws. Real-time data analytics can track the entire production process, ensuring that the molding parameters are within acceptable ranges and that each helmet is produced to specification.

Another factor driving innovation in Kevlar preform molding machines is the push for sustainability. As environmental concerns grow, there is increasing interest in producing helmets from recyclable materials or making helmets that are easier to recycle after their useful life. Some manufacturers are investigating the use of bio-based resins and fibers in the molding process, as well as exploring ways to reduce waste material during production. These advancements could lead to more sustainable helmet production processes, reducing the environmental impact of manufacturing while maintaining high standards of protection.

With the ongoing advancements in materials science and manufacturing technology, Kevlar preform molding machines will continue to evolve. The future of helmet production may see even greater integration of automation, artificial intelligence, and smart technology to improve manufacturing processes, reduce lead times, and enhance the overall quality of the product. These technologies will also likely enable greater customization, allowing helmets to be made to measure for specific individuals or use cases. As threats become more diverse and protective gear requirements become more complex, the ability to quickly and efficiently mold helmets with superior protective qualities will remain a cornerstone of the industry, ensuring that the helmets of tomorrow provide the necessary defense against a wide range of dangers.

As technology advances, the future of Kevlar preform molding machines in helmet manufacturing may also embrace innovations in automation, material science, and smart manufacturing techniques. The development of AI-driven systems capable of optimizing the molding process in real time is already in progress. These systems can use data from sensors embedded in the machinery to monitor pressure, temperature, and curing times, adjusting the process dynamically to ensure the optimal molding of each helmet shell. By continuously learning from previous production cycles, AI systems could significantly reduce the risk of defects, improve consistency, and allow manufacturers to adapt quickly to new material formulations or design changes.

In addition to machine intelligence, digital twin technology—where a virtual replica of the manufacturing process is created and monitored in real-time—holds potential for the future of helmet manufacturing. By creating a digital model of the production process, manufacturers can simulate different scenarios and predict the outcomes of various changes to parameters like pressure, temperature, and resin formulations. This could enable faster innovation, reduced prototyping costs, and more efficient quality control by catching potential issues before they arise in physical production.

The trend toward lightweight yet robust protective gear will continue to drive the development of new composite materials. In addition to traditional Kevlar, materials like graphene, carbon nanotubes, and ultra-high-molecular-weight polyethylene (UHMWPE) are being explored for their exceptional strength-to-weight ratios. Integrating these materials with Kevlar in the preform molding process could create helmets that are even lighter and more resistant to high-velocity impacts while maintaining or enhancing the level of protection against blunt force trauma and fragmentation. These new materials might require further adjustments in molding machines, such as modified temperature settings or more sophisticated pressure systems to accommodate the different characteristics of the composites.

Another area of interest is the exploration of helmets with adaptive features, such as smart helmets that integrate sensors for monitoring the wearer’s physical condition or environmental conditions in real time. In this context, Kevlar preform molding machines could be adapted to create specialized cavities or channels for the seamless integration of such electronics, ensuring that the helmet maintains its structural integrity while providing additional functionality. For instance, sensors embedded within the helmet could monitor impact forces during a blast or collision, alerting medics to potential injuries, or track the wearer’s biometric data to ensure they are operating within safe physical limits.

Moreover, as defense and law enforcement requirements become more specialized, there will likely be an increasing demand for customized helmets. The rise in individualized equipment design could lead to helmets that are tailored not only for specific mission profiles (e.g., airborne units, special forces, or riot police) but also to individual anatomical needs. A helmet designed with a custom-fit preform molding process could provide better protection, improved comfort, and reduced fatigue over long periods of use. The preform molding machine’s ability to adjust its pressure and molding cycle could allow for more personalized features, such as additional padding or reinforcement in specific areas of the shell where protection is most needed.

The focus on sustainability will further shape the evolution of Kevlar preform molding machines. Manufacturers are already exploring the possibility of using recycled materials, including Kevlar waste from the production process itself, or incorporating bio-based resins that are less harmful to the environment. In this context, molding machines could become more energy-efficient, with improved heat management and reduced cycle times, which would not only lower operational costs but also reduce the environmental footprint of helmet manufacturing. This trend toward sustainability is also pushing the development of recycling programs that could allow end-users to return old helmets for repurposing, reducing waste in the long term.

Global standards and certifications for protective headgear continue to evolve as new threats emerge and technologies develop. This ensures that helmets are not just effective against traditional dangers, such as ballistic impacts and blunt trauma, but also against new and increasingly sophisticated threats like cyber-attacks (via helmet-integrated electronics) or environmental hazards (such as extreme heat or chemical exposure). The need to meet these standards may prompt further innovations in the molding process, leading to helmets that can provide multi-threat protection while maintaining the comfort, mobility, and adaptability needed for modern operations.

Finally, Kevlar preform molding machines are likely to play a central role in the continued evolution of body armor systems. As the boundaries between helmets, body armor, and other personal protective equipment (PPE) continue to blur, manufacturers may look to integrate helmet shells into larger protective suits. These integrated systems could offer uniform protection from head to toe, with Kevlar preform molding machines enabling the molding of interconnected layers that work together seamlessly, providing a higher level of protection against multiple types of threats.

In conclusion, as the demand for advanced, lightweight, and multifunctional protective gear continues to grow, the role of Kevlar preform molding machines in helmet manufacturing will only become more crucial. The continued refinement of these machines, driven by innovations in automation, smart manufacturing, and materials science, will ensure that future helmets meet increasingly sophisticated safety standards while being lighter, more comfortable, and more adaptable. Whether for military, law enforcement, or industrial use, Kevlar helmet shells will remain at the forefront of personal protective equipment, providing a vital line of defense for wearers across a wide range of high-risk environments.

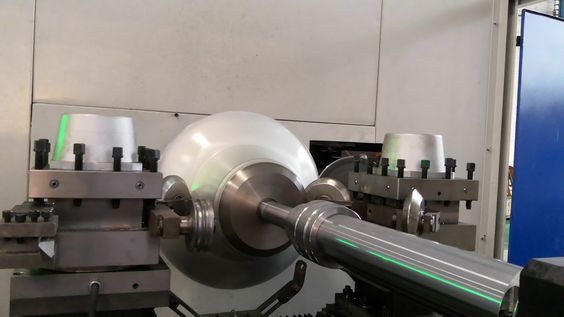

Compression molding press for Kevlar body armour manufacturing

Compression molding presses are essential pieces of equipment in the manufacturing of Kevlar-based body armor. This molding technique involves placing pre-impregnated Kevlar fabric or composite materials into a heated mold, where heat and pressure are applied to form the desired shape. Compression molding is widely used in the production of advanced body armor, including ballistic vests and plates, because it offers several advantages, such as uniform material distribution, controlled thickness, and the ability to produce complex shapes with high precision.

The process begins with the preparation of Kevlar fibers, which are typically woven into fabric and then pre-impregnated with a resin or polymer matrix. This pre-impregnated material, often referred to as prepreg, is crucial for ensuring that the resin is evenly distributed throughout the Kevlar fibers, ensuring that the final product will have consistent strength and durability. The pre-impregnated Kevlar is cut to the appropriate size and placed into the mold cavity of the compression molding press.

Once the material is in place, the mold is closed, and the press applies heat and pressure to the material. The heat activates the resin, allowing it to bond the Kevlar fibers together, while the pressure ensures that the fibers are compacted and aligned in the desired orientation. This combination of heat and pressure results in a dense, strong, and uniform structure that retains the high-impact resistance and ballistic protection that Kevlar is known for.

Compression molding presses are particularly well-suited for body armor manufacturing because they allow for precise control over the molding parameters, including temperature, pressure, and cycle time. The ability to fine-tune these parameters is crucial in achieving the correct material properties for ballistic protection. For example, increasing the pressure may enhance the density of the Kevlar layers, making the body armor stronger and more resistant to penetration. Adjusting the temperature can affect the curing process of the resin, ensuring that the bonding of the fibers occurs uniformly and fully.

The molding press also allows for the production of complex, multi-layered body armor. Multiple layers of Kevlar can be stacked in the mold, and the press will apply pressure to bond them together in a uniform manner. This multi-layered structure is critical for increasing the armor’s protective capabilities, as each layer absorbs and disperses impact energy, significantly enhancing the overall strength of the body armor. The layering process also provides flexibility, as manufacturers can incorporate different types of materials or composites into each layer to optimize the performance of the body armor in specific threat scenarios.

One of the key advantages of compression molding presses is their ability to produce body armor with consistent thickness and high-quality surface finishes. The even distribution of pressure ensures that the material is uniformly compacted across the entire mold, which is critical for ensuring that the body armor performs reliably. In addition, the use of precision molds allows manufacturers to produce body armor components with complex shapes and contours, ensuring that they fit comfortably and securely on the wearer’s body.

These presses can also be equipped with automated systems to further improve the efficiency of the manufacturing process. For example, automated loading and unloading systems can reduce cycle times and human intervention, allowing for faster production rates. Temperature and pressure sensors can be incorporated into the molding press to provide real-time feedback, ensuring that each cycle is consistent and that the final product meets quality standards. In some cases, robotic arms or conveyor systems may be used to handle the finished body armor pieces, streamlining the overall production process and reducing the risk of damage to the materials.

The development of compression molding presses for Kevlar body armor manufacturing has been accompanied by the emergence of advanced materials and new molding technologies. For example, hybrid composites that combine Kevlar with materials like carbon fiber or UHMWPE (Ultra-High Molecular Weight Polyethylene) are being explored to enhance the protective properties of body armor. Compression molding presses must be adaptable to handle these new material combinations, ensuring that they can deliver the same level of high-quality results.

As the need for more advanced, lighter, and stronger body armor continues to grow, manufacturers are increasingly turning to compression molding presses that integrate the latest in smart technology. These presses are becoming more automated and integrated with digital systems for real-time monitoring and adjustments. This allows manufacturers to optimize the molding process for different designs, materials, and production volumes, ensuring that the final product meets the ever-evolving requirements of modern body armor.

In summary, compression molding presses play a crucial role in the production of high-performance Kevlar body armor by providing precise control over the molding process and enabling the creation of multi-layered, complex designs that offer superior ballistic protection. With continued advancements in materials and manufacturing technology, compression molding presses are poised to remain a cornerstone of body armor production, enabling manufacturers to meet the increasing demand for lighter, stronger, and more protective armor solutions.

Compression molding presses continue to evolve with the increasing demand for high-performance body armor. These presses provide a critical advantage by ensuring that each layer of Kevlar or composite material is consistently molded to meet the specific performance requirements, whether it’s for military, law enforcement, or civilian protective gear. As armor technology progresses, these presses are being refined to accommodate newer materials, improving not only strength but also flexibility, comfort, and weight reduction. The precision of the molding process, with its ability to control temperature, pressure, and cycle time, ensures that each piece of body armor provides reliable protection against various threats such as ballistic impacts, stab wounds, and blunt-force trauma.

With advancements in automation, the molding process is becoming more efficient, with reduced human intervention leading to increased production speeds and decreased likelihood of errors. These automated systems are designed to monitor and adjust parameters in real time, guaranteeing that the desired material properties are achieved consistently throughout the production batch. This automation reduces cycle times and enhances the ability to produce body armor in larger quantities without sacrificing quality. Additionally, automation improves the ergonomics of the manufacturing process, reducing the physical strain on workers and increasing safety in the production environment.

The integration of artificial intelligence and machine learning into compression molding presses is also improving the manufacturing process. AI systems can analyze data collected from sensors embedded in the presses, such as temperature, pressure, and curing time, to identify patterns and predict the best adjustments needed for optimal results. Over time, these systems learn from previous production cycles, optimizing each subsequent run and making the process more efficient and accurate. By fine-tuning the molding process, manufacturers can ensure that the final body armor pieces meet or exceed stringent safety standards, providing wearers with maximum protection.