Multi-Station Pipe End Forming Machine: A Pipe End Forming Machine is a specialized piece of equipment used in the metalworking industry, primarily for modifying the ends of pipes. The purpose of the machine is to shape or enlarge the ends of pipes to enable better connections, sealing, or fitment with other components, such as flanges, fittings, or valves.

There are different types of pipe end forming machines, and they can perform various tasks, including:

- Beading – Creating a bead or raised ring around the pipe’s end for a tighter fit with a component.

- Flanging – Expanding the pipe’s end to a wider diameter to fit a flange.

- Swaging – Reducing the diameter or forming a particular shape at the end of the pipe.

- Flaring – Expanding the pipe end outward to a specified angle, often used for making connections like those in HVAC systems or plumbing.

Types of Pipe End Forming Machines

- Hydraulic Pipe End Forming Machines: These use hydraulic force to shape the pipe end. They are ideal for precision work and larger pipes.

- Pneumatic Pipe End Forming Machines: Use compressed air to shape the ends of the pipes. These machines are typically lighter and used for smaller projects.

- Mechanical Pipe End Forming Machines: Operate using mechanical components, often used for simpler operations.

Applications

- Automotive: Used for exhaust systems and fluid lines.

- Construction and HVAC: Pipe end forming is critical in creating joints that are resistant to leaks and pressure loss.

- Oil and Gas: Pipe end forming is essential for creating connections that can handle high pressures.

A Pipe End Forming Machine is designed to modify the ends of pipes for better connection and sealing with other components. It uses different techniques such as beading, flanging, swaging, and flaring to achieve specific shapes. These machines can be hydraulic, pneumatic, or mechanical, with each type offering unique advantages for different pipe sizes and applications. In industries like automotive, construction, HVAC, and oil and gas, pipe end forming machines are crucial for creating strong, leak-proof connections that can withstand pressure and wear.

A Pipe End Forming Machine plays a vital role in industries where pipe fittings and connections are essential. Its primary function is to modify the ends of pipes to facilitate secure and precise connections with other components. The modification typically involves altering the shape, size, or structure of the pipe’s end through various mechanical processes. These machines can handle a variety of tasks depending on the desired pipe end configuration.

Key Techniques Used in Pipe End Forming Machines

- Beading: This process involves creating a raised ring around the pipe’s end, which allows for a tighter and more secure fit with other components, such as flanges or other pipe fittings. Beading is essential when creating a seal that prevents leaks, especially under high pressure.

- Flanging: Flanging is a process where the pipe’s end is expanded to a wider diameter. This is done to allow the pipe to fit snugly into a flange or other fitting. Flanging is especially important in applications where components need to be bolted together, such as in pipelines for the oil and gas industry or HVAC systems.

- Swaging: This technique is used to change the diameter of the pipe’s end or to shape the pipe in a way that it fits into a different part. Swaging can also be used for reducing the pipe’s size or shaping the end into a taper. This process is often used in automotive industries for exhaust systems and other high-heat, high-pressure applications.

- Flaring: In flaring, the pipe’s end is expanded outward to create a bell-shaped opening. This process is commonly used in plumbing and HVAC systems, where pipes need to fit into fittings that require a wide opening at the pipe end. Flaring can also be used in creating certain types of seals, particularly those used in gas lines.

Types of Pipe End Forming Machines

- Hydraulic Machines: These machines use hydraulic force to perform the end forming process. They are capable of handling heavy-duty work and are particularly suitable for larger pipes or when precise and consistent shaping is needed. The hydraulic pressure ensures that the pipe end is shaped evenly, which is crucial for high-pressure applications.

- Pneumatic Machines: Pneumatic machines use compressed air to perform pipe end forming operations. These machines are typically lighter and more compact than hydraulic machines. They are often used for smaller pipe sizes and lighter applications. Pneumatic machines are common in industries where speed and versatility are important, such as in the production of small automotive or HVAC components.

- Mechanical Machines: These machines operate using mechanical force, often powered by motors or gears. Mechanical machines are used for simpler, less demanding tasks and are ideal for mass production of pipe end modifications where precision is not as critical. They are commonly used in applications where the end form does not require high levels of complexity.

Applications

- Automotive: Pipe end forming is crucial in the production of exhaust systems, fuel lines, and fluid transfer pipes, where specific shapes and tight seals are necessary to ensure performance and safety.

- Oil and Gas: In the oil and gas sector, pipe end forming is used to prepare pipes for installation in pipelines, where the connections need to withstand high pressure, temperature extremes, and corrosive environments. The process ensures that the pipes can be securely joined with other components, reducing the risk of leaks or failures.

- HVAC and Plumbing: In the heating, ventilation, and air conditioning (HVAC) industries, as well as plumbing, pipe end forming ensures that pipes are properly shaped to fit connectors, valves, and other system components. The modified pipe ends provide better seals, leading to more efficient and long-lasting systems.

- Construction: In construction, especially in structural and civil engineering projects, pipes are often used in the installation of water and sewage systems, where pipe end forming ensures secure connections that are resistant to pressure and corrosion.

Advantages of Using Pipe End Forming Machines

- Precision and Consistency: These machines allow for high levels of accuracy in pipe modifications, ensuring that each pipe end is uniformly shaped for a perfect fit with connectors and fittings.

- Speed and Efficiency: Automated machines significantly reduce the time and labor needed for manual pipe end forming, increasing production speed and reducing errors.

- Cost-Effective: By improving efficiency and precision, these machines help reduce material waste and the need for costly rework or replacements.

- Flexibility: Many modern pipe end forming machines are versatile, allowing them to handle a wide range of pipe sizes and materials, making them useful for various industries and applications.

Pipe end forming machines have become indispensable in the modern manufacturing and construction industries, enabling companies to produce reliable, high-quality pipe systems that meet the demands of a wide range of applications. As technologies evolve, these machines continue to improve in terms of speed, precision, and versatility, helping industries achieve more efficient production processes while maintaining high standards of safety and durability.

As pipe end forming technology advances, these machines are becoming increasingly sophisticated, integrating automation, smart technologies, and enhanced materials handling capabilities. This has allowed industries to improve both the performance and cost-effectiveness of their operations, ensuring that the pipes and fittings produced can withstand the rigors of modern applications, from high-pressure pipelines to delicate HVAC systems.

Recent Developments in Pipe End Forming Machines

- Automation and CNC Integration: Many modern pipe end forming machines are now equipped with computer numerical control (CNC) systems that allow for precise automation of the forming process. CNC machines can be programmed to handle multiple types of pipe end modifications, with minimal human intervention. This has drastically increased production efficiency, reduced error rates, and made the machines more flexible in handling various pipe sizes, materials, and configurations.

- Smart Machines: Some of the latest pipe end forming machines come with smart sensors and feedback systems that monitor the machine’s operation in real time. These systems can detect issues such as deviations from preset specifications, wear on components, or inconsistencies in pipe material. This data allows operators to adjust the process immediately, ensuring that all products are manufactured to the highest standards. Smart machines also allow for predictive maintenance, reducing downtime and extending the lifespan of the equipment.

- Hybrid Machines: Hybrid machines, combining hydraulic, pneumatic, and mechanical systems, are becoming more common. These machines are able to provide more flexibility and versatility, allowing operators to select the best method of pipe end forming depending on the pipe size, material, and the required output. Hybrid designs can be particularly beneficial in environments where multiple types of pipe modifications are required in a single production line.

- Energy Efficiency: The energy consumption of pipe end forming machines is a major factor in their operating costs. To address this, manufacturers are designing machines that are more energy-efficient, utilizing advanced motors, pressure systems, and intelligent power management. The improved efficiency not only reduces operational costs but also contributes to the sustainability efforts of companies by reducing the carbon footprint of the production process.

Benefits of Enhanced Pipe End Forming Technology

- Higher Throughput and Reduced Lead Time: With automation and improved precision, pipe end forming machines can handle larger production volumes in less time. This is particularly beneficial for industries with high demand for pipes, such as the oil and gas industry, where downtime can be costly.

- Greater Customization: Modern machines allow for more customization in pipe end shapes and sizes. Customization can be crucial for industries that require specialized fittings for unique applications, such as aerospace or custom engineering projects.

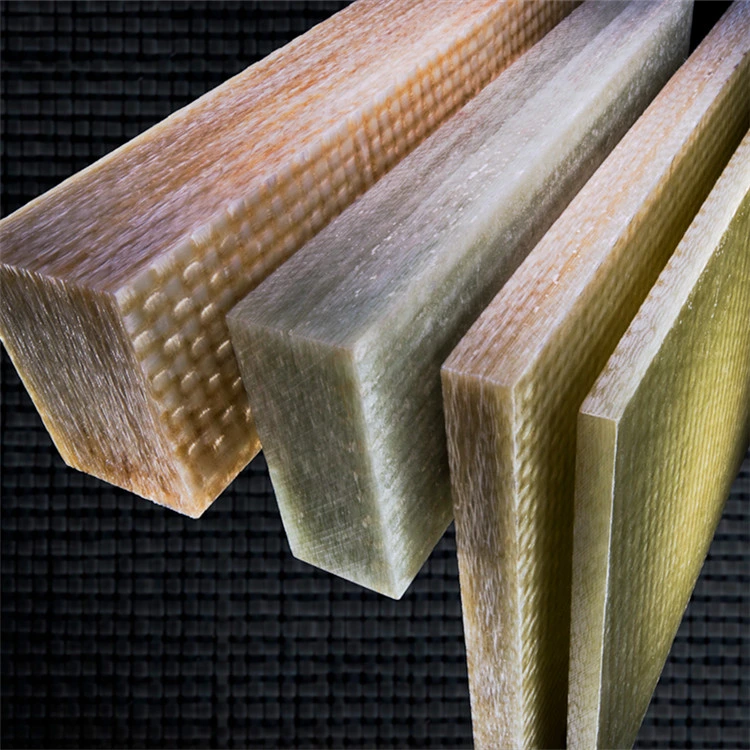

- Better Material Handling: With advancements in materials science, pipe end forming machines are now able to handle more diverse materials, from basic steel to advanced alloys and composites. This has expanded the range of applications, especially in industries that use specialized or high-strength materials.

- Improved Product Quality: The precision and consistency provided by modern machines ensure that pipe ends are shaped to exact specifications, which directly affects the performance and durability of the pipes once they are installed. This reduces the risk of leaks, failures, and other issues that could arise due to poorly formed pipe connections.

- Safety: By automating the pipe end forming process, machines help reduce the risk of injury associated with manual labor. They also provide more consistent results, reducing the likelihood of faulty connections that could lead to safety hazards, particularly in high-pressure systems.

Challenges and Considerations

While the advancements in pipe end forming machines have provided numerous benefits, there are still challenges that manufacturers face when selecting and implementing these machines:

- Initial Investment Costs: High-end, automated, and smart pipe end forming machines can require significant upfront investment. For small-to-medium-sized manufacturers, this can be a barrier to adoption. However, the long-term savings in efficiency, reduced errors, and minimized material waste often offset these initial costs.

- Training and Skill Development: As machines become more complex, operators and maintenance personnel need to be properly trained to handle the new technologies. Companies must invest in training programs to ensure that their workforce is equipped to maximize the potential of these machines.

- Material Variability: While modern machines are capable of handling a wide variety of materials, there can still be challenges related to the variability in material properties, such as hardness, thickness, or tensile strength. These differences can affect how the pipe end is formed, potentially leading to inconsistencies or the need for additional adjustments in the forming process.

- Maintenance and Downtime: Like any mechanical equipment, pipe end forming machines require regular maintenance. If maintenance is not conducted properly or regularly, it can lead to increased wear and tear on machine components, potentially resulting in unexpected downtime. Preventative maintenance and smart monitoring systems can help mitigate these risks.

- Space and Footprint: Some of the latest pipe end forming machines can be quite large, requiring significant floor space in manufacturing facilities. This can be an issue for companies operating in smaller spaces or those that need to maximize their production floor layout.

Future Trends

Looking ahead, several trends are expected to shape the future of pipe end forming machines:

- Increased Use of Artificial Intelligence (AI): AI and machine learning algorithms are expected to play a larger role in optimizing pipe end forming processes. These technologies can help fine-tune parameters in real-time, predict maintenance needs, and suggest process improvements based on data collected from the machines.

- Collaborative Robotics (Cobots): The rise of collaborative robots (or “cobots”) could revolutionize pipe end forming by assisting with certain tasks without the need for complete automation. These robots can work alongside human operators, helping to reduce the physical strain on workers and allowing for a more flexible, adaptable production environment.

- Integration with IoT: The Internet of Things (IoT) is likely to become a more integral part of pipe end forming machines. Machines connected to the IoT can communicate with other parts of the production system, enabling real-time tracking of production progress, predictive maintenance alerts, and improved overall operational efficiency.

In summary, the continued evolution of pipe end forming technology is driving efficiencies, precision, and customization capabilities across a range of industries. As these machines become more advanced, they are helping to meet the growing demands of modern manufacturing while ensuring that pipe systems are safer, more durable, and easier to maintain.

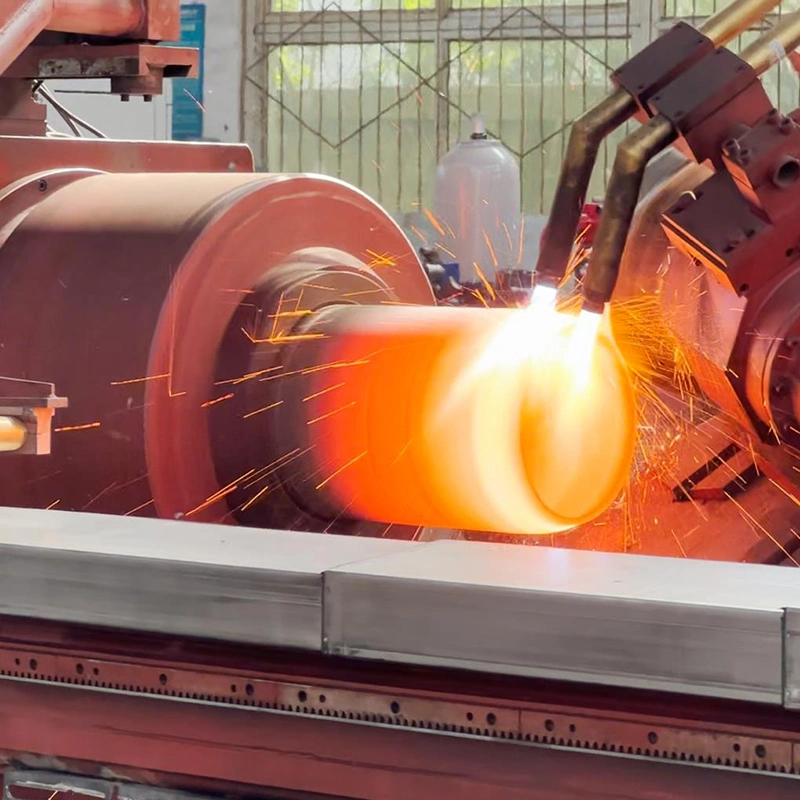

Hot Forming Pipe End Machine

A Hot Forming Pipe End Machine is a type of pipe end forming equipment that uses heat to alter the shape and structure of the pipe’s ends. The process involves heating the end of the pipe to a specific temperature and then applying mechanical force to form or modify the pipe end according to the required specifications. This type of machine is used primarily in applications where high-strength materials or larger pipe sizes need to be shaped, as the heat makes the material more malleable, allowing for easier manipulation.

Key Features of Hot Forming Pipe End Machines

- High-Temperature Heating: Hot forming machines utilize high-temperature heating elements, such as induction coils, gas burners, or electric furnaces, to heat the pipe’s ends to a temperature where the material becomes more pliable. This temperature varies depending on the material being worked on (e.g., steel, stainless steel, or alloys).

- Material Plasticity: The heat softens the metal, making it easier to form, expand, or manipulate. This is particularly important for materials that are difficult to work with at room temperature, like certain high-strength steels or alloys, which would be too brittle or tough to form without heat.

- Precision and Customization: Hot forming pipe end machines are often equipped with precision control systems that allow the operator to control the amount of heat and pressure applied. This ensures that the pipe ends are shaped with high accuracy, meeting the exact specifications required for different applications.

- Versatility: These machines can handle a wide range of pipe sizes, from small diameters to large industrial pipes. The process can be used to create flanged ends, swaged ends, or even more complex geometries depending on the application.

Hot Forming Process

- Heating: The pipe is first heated to a specific temperature. The heating can be done using induction heating, flame heating, or electrical resistance. The goal is to raise the temperature of the pipe end to a level that allows the material to become sufficiently soft for forming.

- Forming: Once the pipe has reached the required temperature, it is placed into the forming station, where mechanical forces (such as hydraulic or mechanical pressure) are applied to shape the pipe end. This can include processes such as flanging, beading, or expanding the pipe.

- Cooling: After the forming process, the pipe is cooled, either naturally or through a controlled quenching process, to solidify the newly formed shape. The cooling rate is important as it can influence the final material properties, such as hardness and tensile strength.

- Finishing: Depending on the application, further processes such as machining or polishing may be performed to ensure the pipe end meets the required tolerance levels. In some cases, the formed pipe end may undergo testing for pressure, leak resistance, or dimensional accuracy.

Applications of Hot Forming Pipe End Machines

- Oil and Gas: Hot forming is commonly used in the oil and gas industry, particularly for producing pipe fittings, connectors, and flanged joints that need to withstand high pressures and temperatures. The ability to form large-diameter pipes with high-strength materials is crucial in this industry.

- Aerospace: In the aerospace industry, high-strength alloys often need to be formed into specific shapes for fuel lines, exhaust systems, and other components. Hot forming ensures the material’s structural integrity while achieving the desired pipe end configurations.

- Heavy Manufacturing: For industries like power generation, nuclear, and shipbuilding, hot forming is used to prepare pipes for high-pressure systems. The ability to produce precise, strong, and durable pipe connections is essential for maintaining the integrity of complex systems.

- Automotive: Automotive manufacturers often use hot forming techniques for exhaust systems and other high-performance components, where pipe strength and durability are critical.

Advantages of Hot Forming Pipe End Machines

- Improved Material Flow: The application of heat makes the material more malleable, improving the flow of the material during forming. This reduces the risk of cracks or defects in the pipe end and ensures that the pipe maintains its strength and structural integrity.

- Ability to Handle High-Strength Materials: Hot forming is particularly beneficial for forming materials that are difficult to manipulate at lower temperatures, such as stainless steel, alloy steels, and other high-strength materials. Without heat, these materials might be too tough to shape accurately.

- Larger Pipe Sizes: Hot forming is capable of handling larger pipe sizes and creating more complex geometries. This is essential in industries where large, high-pressure pipes are required, such as in the oil, gas, and power generation sectors.

- Reduced Tool Wear: By softening the material with heat, hot forming reduces the wear on forming tools compared to cold forming processes, where the material is tougher and more resistant to shaping.

- Reduced Stress and Strain: Heat treatment in hot forming processes helps to minimize internal stresses in the pipe material, which can lead to a more consistent product and a reduced likelihood of failures or cracks during later stages of the pipe’s life.

Challenges and Considerations

- Energy Consumption: One of the major drawbacks of hot forming is its high energy consumption due to the need for heating the pipe to elevated temperatures. This can result in higher operational costs, especially for large production runs.

- Material Distortion: While heat can make materials more malleable, it can also cause distortions or warping in the pipe if not controlled properly. It’s important to ensure that the heating process is uniform and that the correct temperatures are reached for each material type to avoid unwanted deformation.

- Process Control: Achieving consistent results with hot forming requires precise control over the temperature and forming pressure. If not carefully monitored, variations in the heating process or the forming pressure can lead to inconsistencies in the final product, such as uneven wall thickness or dimensional errors.

- Post-Processing Needs: After hot forming, pipes often require post-forming processes, such as cooling, stress relief, or machining, to meet the final product specifications. These additional steps can increase the overall production time and costs.

Future Trends in Hot Forming Pipe End Machines

- Automation: The incorporation of robotics and AI into hot forming pipe end machines is on the rise. These technologies can help optimize the heating and forming processes, ensuring that the pipes are consistently produced to specification and reducing human error.

- Advanced Materials Handling: As the demand for more advanced and high-performance materials increases, hot forming machines are being developed to handle more complex materials, including composites and superalloys. These materials often require even more precise heating and forming techniques to maintain their properties.

- Energy-Efficient Systems: With growing concerns over energy consumption and sustainability, manufacturers are developing more energy-efficient hot forming systems. Innovations in induction heating and heat recovery systems are helping to reduce energy costs and improve the sustainability of the process.

- Hybrid Technologies: Combining hot forming with other forming techniques, such as cold forming or warm forming, is becoming more common. These hybrid machines offer the ability to handle a wider range of materials and pipe sizes, improving flexibility while reducing costs and material waste.

In conclusion, hot forming pipe end machines are indispensable in industries that require high-performance pipes and fittings, particularly those involving high-strength materials or large diameters. By utilizing heat to improve material flow and reduce forming challenges, these machines provide a reliable solution for producing pipes that meet stringent operational standards. As technology continues to evolve, hot forming systems are becoming more efficient, flexible, and capable of handling a wider variety of materials, further enhancing their application in critical industries.

Hot forming pipe end machines are vital in industries that require pipes to withstand high-pressure environments, extreme temperatures, and demanding mechanical conditions. The process begins with heating the pipe’s end, using methods such as induction heating or flame heating, to make the material more malleable. Once the pipe reaches the desired temperature, mechanical force is applied to form the pipe end into the required shape, whether it’s for flanging, swaging, or other modifications. This technique is especially useful for materials that are difficult to work with at room temperature, like high-strength alloys or certain steels.

The advantage of using hot forming is that the heat softens the metal, reducing its resistance to deformation. This allows the machine to achieve complex shapes, especially for large pipes, without causing cracks or fractures that might occur during cold forming. Additionally, hot forming ensures that the material’s structural integrity is maintained, which is critical for high-performance applications. For industries such as oil and gas, aerospace, and heavy manufacturing, the ability to form pipes with high precision and strength is essential, especially when dealing with pipes that must handle extreme pressures or high temperatures.

However, the process is energy-intensive due to the need to heat the pipe to elevated temperatures. This can result in higher operational costs, particularly for larger production runs. Despite this, the precision and flexibility of hot forming make it an invaluable process for many industries. One of the key challenges, however, is maintaining consistent temperature control and pressure during the forming process to avoid distortion or material imperfections. If not carefully monitored, the pipe can suffer from uneven wall thickness, warping, or other deformities.

In recent years, there has been a growing trend toward automation in hot forming pipe end machines. With the integration of AI, robotics, and advanced sensors, these machines can operate with greater precision, ensuring that each pipe is formed to the exact specifications. These smart systems can also predict when maintenance is needed, reducing downtime and improving the machine’s longevity. Additionally, there is a focus on improving energy efficiency in these machines. New technologies are being developed to reduce energy consumption during the heating process, such as induction heating systems and heat recovery solutions, which can lower operational costs and improve sustainability.

As industries demand more specialized and high-performance materials, hot forming pipe end machines are also evolving to handle a wider variety of materials, including composites and superalloys. Hybrid systems that combine hot forming with cold or warm forming techniques are becoming more common, providing greater flexibility and reducing material waste. This combination can be especially useful in situations where different parts of the pipe require different forming processes.

The future of hot forming pipe end machines lies in further advancements in automation, energy efficiency, and materials handling. As these machines become more capable and adaptable, they will continue to meet the growing demands of industries that require robust, high-quality pipe connections capable of withstanding harsh environments and heavy-duty applications.

Tapering Pipe End Forming Machine

A Tapering Pipe End Forming Machine is specifically designed to modify the ends of pipes by gradually reducing or enlarging the pipe’s diameter to create a tapered end. This type of machine is used to achieve a conical or tapered shape at the pipe’s end, which is often required for better fitment, sealing, or to accommodate fittings, flanges, or other pipe connections that need a specific angle.

Tapering is a common pipe end modification in industries that require pipes to connect smoothly with other components or systems. The tapered end ensures a tight seal, reduces the risk of leaks, and allows the pipe to fit more securely into a flange, coupling, or other connection point.

The process typically involves applying mechanical force to stretch or compress the pipe’s material at the end, while controlling the angle and dimensions of the taper. Tapering machines can be operated using hydraulic, pneumatic, or mechanical means, depending on the size and material of the pipe.

Tapering pipe end forming machines are used in various industries, including oil and gas, automotive, HVAC, construction, and aerospace, where pipe connections need to withstand high pressure, temperature variations, or vibration.

One of the main benefits of using a tapering machine is the ability to produce accurate, repeatable tapered pipe ends that conform to industry standards. The machine ensures the proper angle, smooth surface finish, and consistent dimensions, which are essential for ensuring reliable and durable connections.

Tapering pipe end forming machines can also be equipped with features like CNC control systems for increased precision, automation for improved efficiency, and smart sensors that monitor the process in real-time to maintain quality control. These features help streamline production, reduce errors, and improve the overall consistency of the pipe ends.

In some cases, these machines can handle a range of materials, from steel and stainless steel to aluminum and even plastic, depending on the specific needs of the application. Tapering machines can also accommodate different pipe sizes and can be customized to meet specific dimensional requirements, making them highly versatile for various production environments.

The tapering process can be essential for industries such as aerospace, where pipes may need to fit into components that require tapered connections, or in the oil and gas sector, where pipes need to be connected to valves and other equipment that require specific angles for a secure, leak-proof seal. Additionally, in HVAC systems, tapered pipe ends allow for the easy connection of pipes in tight spaces or with fittings that require a specific taper.

In conclusion, tapering pipe end forming machines are crucial for creating precisely tapered ends for a wide range of applications. Their versatility, precision, and ability to handle various materials make them an essential tool in industries that require reliable, high-quality pipe connections.

Tapering pipe end forming machines are essential for creating conical shapes at the ends of pipes to ensure they can fit securely with other components like flanges, couplings, or valves. This tapered shape allows for a tight, leak-proof seal, which is crucial in industries where pipes need to handle high-pressure, high-temperature, or vibration-heavy environments. The process of tapering generally involves gradually reducing or expanding the pipe’s diameter at the end to a specific angle or dimension, making it easier to connect the pipe to other parts of a system.

These machines can be powered by hydraulic, pneumatic, or mechanical systems, depending on the pipe size and the material being formed. The mechanical force applied during the tapering process deforms the pipe’s material, stretching or compressing it to achieve the desired taper. The process requires careful control of the applied force, temperature, and pipe alignment to ensure the taper is even and the final product meets the required specifications. For this reason, advanced tapering machines often come with automated control systems, such as CNC (Computer Numerical Control), to provide precise adjustments and repeatable results.

In industries like oil and gas, aerospace, and automotive, the ability to produce accurately tapered pipe ends is crucial for ensuring the integrity and reliability of pipe connections. For example, in the oil and gas sector, tapered ends are often used in the connection of pipes to valves or pumps, where a tight and secure fit is required to prevent leaks. Similarly, in aerospace applications, pipes with tapered ends are needed for various fluid systems, where space and performance requirements demand both precision and reliability.

Tapering machines can be designed to accommodate a wide range of materials, such as steel, stainless steel, aluminum, and certain plastics. The versatility of tapering machines allows manufacturers to use the same equipment to create tapered ends for a variety of pipe sizes, which is particularly useful in industries where multiple pipe types and dimensions are needed. Additionally, some tapering machines are customizable to fit specific dimensional requirements or angles, allowing for tailored solutions based on the needs of a particular application.

One of the primary advantages of tapering pipe end forming machines is their ability to produce consistent, high-quality results. With modern automation and smart sensors, the tapering process can be monitored and adjusted in real-time, ensuring that each pipe end is formed to exact specifications. This level of precision helps reduce the likelihood of errors or defects that could compromise the integrity of the pipe connection and cause costly downtime or failures.

Although the process can be energy-intensive due to the mechanical forces and, in some cases, the heating involved, tapering machines are becoming more energy-efficient with advancements in technology. Newer machines incorporate energy-saving features such as more efficient motors and heat recovery systems, which help reduce operating costs and improve sustainability in manufacturing.

As industries continue to demand more specialized and high-performance pipe systems, tapering machines are evolving to meet these needs. The growing use of automation, robotics, and advanced sensors is making these machines more capable of producing tapered ends with higher precision, while reducing the need for manual intervention. Moreover, as new materials and alloys are developed, tapering machines are being designed to handle a wider variety of materials, giving manufacturers more flexibility in production.

In conclusion, tapering pipe end forming machines play a vital role in producing pipes that can securely connect to other components, ensuring the safety, reliability, and performance of piping systems in critical industries. Their ability to handle various materials and pipe sizes, along with the precision and repeatability they offer, makes them indispensable tools in modern manufacturing environments where quality and consistency are paramount. As technology continues to improve, these machines are likely to become even more efficient, versatile, and capable of meeting the growing demands of industries worldwide.

As the demand for precision and efficiency in pipe fabrication increases, tapering pipe end forming machines are evolving to meet new challenges in the industry. Innovations in automation and machine learning are transforming these machines into even more sophisticated tools, capable of handling more complex designs and varying pipe sizes with greater ease. These advancements enable manufacturers to produce tapered pipe ends with high consistency, ensuring that each part meets stringent specifications while reducing the potential for human error.

In addition to increased automation, there’s also a focus on enhancing the flexibility of tapering machines. Modern machines are being designed to handle an even broader range of materials, including some of the most challenging alloys and composites. This makes them valuable not only in traditional industries like oil and gas or aerospace but also in emerging sectors that require highly specialized pipe systems, such as renewable energy or pharmaceutical manufacturing. As these sectors grow, the need for customized, high-quality pipe connections continues to rise, driving the demand for more adaptable tapering technologies.

One area of innovation is the integration of artificial intelligence (AI) and machine learning into tapering machines. AI systems can monitor and adjust the tapering process in real-time, identifying patterns and making automatic adjustments to optimize the outcome. For example, if a sensor detects a slight deviation in the pipe’s temperature or material properties during the forming process, the AI system can immediately correct the issue, ensuring that the tapering process continues without interruption or defects. This capability enhances the overall efficiency of the production line while maintaining the quality of the final product.

Another trend is the integration of real-time data collection and analysis. With the growing popularity of the Industrial Internet of Things (IIoT), tapering machines can now be connected to centralized systems that gather data on machine performance, material quality, and production output. This data can be used to predict when maintenance is needed, monitor the performance of the equipment, and even provide insights for optimizing future production runs. As these machines become more interconnected, manufacturers will have the ability to make data-driven decisions that enhance efficiency and reduce costs.

Additionally, there is increasing interest in the sustainability aspect of tapering machines. In many industries, there is a strong push to reduce energy consumption and minimize waste. As a result, many tapering machines are now being designed with energy efficiency in mind. This includes implementing more advanced heating systems, such as induction heating, which are more energy-efficient compared to traditional methods. There is also a trend toward utilizing recycled or lower-impact materials in the pipe forming process to support sustainability goals.

The versatility of tapering machines also continues to expand with the adoption of hybrid forming techniques. These machines combine the benefits of both cold and hot forming processes, providing manufacturers with more flexibility to handle different materials and pipe sizes. Hybrid systems can achieve complex tapering shapes while offering the ability to work with both high-strength materials and softer metals, which is particularly useful in industries where multiple pipe configurations are required on the same production line.

Moreover, the speed at which these machines operate is improving as well. With better control mechanisms, higher-speed operations can be achieved without sacrificing the quality of the tapered end. This increase in speed helps manufacturers meet high-volume demands, ensuring that production runs are completed in a shorter time while maintaining the necessary quality standards.

As manufacturers continue to look for ways to streamline production, tapering machines are also being developed with increased ease of use. User-friendly interfaces, advanced diagnostics, and remote monitoring capabilities allow operators to easily manage and troubleshoot the tapering process. These improvements make it easier for operators to maintain the machines, troubleshoot issues, and optimize the production cycle, all of which contribute to a more efficient and cost-effective operation.

Looking into the future, the role of tapering pipe end forming machines will only continue to grow, driven by the ongoing needs for high-performance pipes in industries that demand both precision and reliability. With the combination of automation, AI, and better energy efficiency, these machines are poised to become even more integral to pipe manufacturing. They will not only help meet the growing demands of traditional industries but also support the needs of new sectors that require specialized, high-quality pipe connections for complex systems.

In conclusion, tapering pipe end forming machines are evolving rapidly to meet the changing needs of modern manufacturing. By incorporating advanced technologies like automation, AI, and real-time data analysis, these machines are becoming more efficient, versatile, and capable of producing high-quality, customized pipe ends for a variety of industries. As these innovations continue to develop, tapering machines will play a crucial role in producing the reliable, high-performance pipe systems required in industries worldwide.

Multi-Station Pipe End Forming Machine

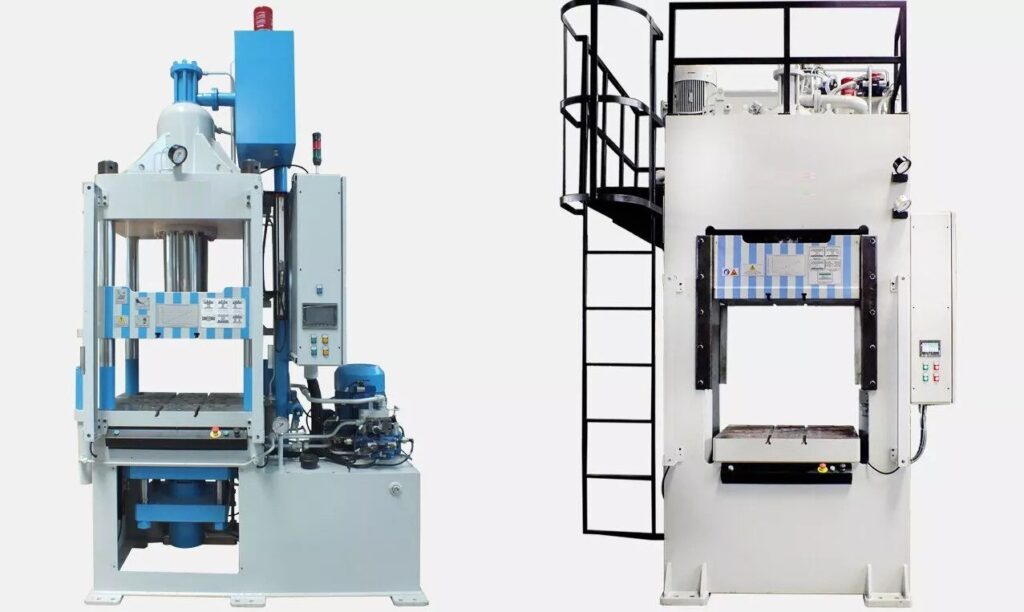

A Multi-Station Pipe End Forming Machine is a type of equipment used in pipe manufacturing that incorporates multiple stations to carry out different processes sequentially or simultaneously to modify the ends of pipes. These machines are particularly useful for high-volume production, where various pipe end configurations, such as flanging, swaging, tapering, beading, or other modifications, need to be performed on multiple pipes in one setup. The ability to process multiple stations in a single machine allows for enhanced productivity, precision, and reduced setup times.

The multi-station setup typically includes a combination of different tools or stations, each designed to perform a specific task. These stations are arranged in a sequence, and the pipe is moved through each station in turn, where different forming actions take place. The machine may be equipped with automated features, such as robotic arms or conveyor systems, to handle the movement of pipes between stations and ensure smooth operation. Multi-station machines can be used to process pipes of varying sizes and materials, offering versatility across different applications.

The primary benefit of a multi-station machine is its efficiency. By consolidating several processes into a single machine, manufacturers can significantly reduce the time and cost associated with separate operations. Instead of performing each pipe-end forming task on separate machines, the entire process can be completed in one go, which improves throughput and consistency. This setup minimizes downtime between operations and reduces the need for manual handling, further enhancing production speed and safety.

Each station in the machine can be customized to handle different types of forming techniques. For example, one station might be dedicated to flanging, another to swaging, and a third for tapering or beading. Additionally, some machines may allow for simultaneous operations, such as performing two or more forming actions on a pipe at the same time, thereby improving the overall efficiency of the process.

Multi-station pipe end forming machines are widely used in industries that require high levels of automation and precision, such as the oil and gas, aerospace, automotive, and construction sectors. In the oil and gas industry, for example, pipes often need to be modified with flanged ends, while in aerospace, specialized fittings or connections might be required. The versatility of multi-station machines makes them ideal for these types of applications, as they can be configured to meet specific production needs.

These machines can also be integrated with advanced control systems, such as CNC (Computer Numerical Control), to ensure high precision and consistency across large production runs. CNC integration allows for the fine-tuning of parameters such as pressure, speed, and the amount of material deformation, ensuring that the pipe end modifications meet the exact specifications required for each application. Some systems may also be equipped with real-time monitoring capabilities to ensure that the entire process runs smoothly and any potential issues are addressed promptly.

The adaptability of multi-station pipe end forming machines is another key advantage. Depending on the production requirements, different tooling setups can be incorporated, allowing the machine to perform a range of pipe-end modifications without the need for extensive reconfiguration. This flexibility is particularly valuable in industries that need to produce a variety of pipe sizes and shapes for different applications.

In summary, a multi-station pipe end forming machine is a highly efficient and versatile piece of equipment used for modifying pipe ends in industries requiring high production volumes and precision. By combining several forming processes into one machine, manufacturers can streamline production, reduce costs, and improve quality control. These machines offer significant benefits in terms of speed, flexibility, and automation, making them an essential tool in modern pipe fabrication.

A multi-station pipe end forming machine offers significant advantages in the manufacturing process, particularly in industries where high precision and speed are crucial. By integrating multiple forming processes into one machine, it allows for continuous operation, reducing the need for separate machines or setups for each stage of the pipe modification. The pipe is moved through different stations where various forming techniques, such as flanging, swaging, beading, tapering, and threading, can be applied. This setup maximizes productivity while maintaining the high quality of the pipe modifications, which is essential in industries like oil and gas, aerospace, automotive, and manufacturing.

The main benefit of a multi-station system is its ability to handle a wide variety of pipe-end configurations in a single automated process. Instead of dedicating different machines to each specific forming task, the multi-station machine consolidates these tasks into a streamlined operation. This leads to reduced machine downtime, lower labor costs, and fewer handling errors, making it especially effective for high-volume production runs where consistency and speed are essential. Automation further improves this by reducing the need for manual intervention, which enhances both efficiency and safety.

Multi-station pipe end forming machines also stand out due to their flexibility. They can be designed to process pipes of various sizes, materials, and specifications, adapting quickly to the changing needs of production lines. The system’s modular design means that the stations can be customized or reconfigured based on the requirements of the specific project. For example, additional stations can be added for unique operations or to accommodate new pipe types and material configurations. This versatility is crucial for manufacturers dealing with diverse client needs or industries that require custom pipe modifications for specialized applications.

Automation plays a central role in these machines. Advanced control systems, such as CNC technology, allow for precise management of each forming process. Parameters like pressure, speed, and material deformation can be adjusted with pinpoint accuracy, ensuring that the final product meets exact specifications. Additionally, real-time monitoring systems can detect any discrepancies or malfunctions, minimizing the risk of defects and ensuring continuous quality control throughout production. This automated capability allows for longer production runs with minimal human oversight, further improving operational efficiency.

Moreover, the use of multi-station machines also enhances overall quality and consistency. Since each forming station works on the same pipe in sequence, the result is a highly accurate and uniform modification of the pipe ends. This uniformity is especially important for applications where the pipes will be subjected to high pressure, extreme temperatures, or corrosive environments. The consistent quality helps ensure the structural integrity of the pipe, making it suitable for use in demanding applications such as in the oil and gas industry, where the reliability of every connection is critical.

One of the challenges of using multi-station machines is the initial investment in the equipment, which can be higher than single-station machines due to the complexity and integration of multiple forming stations. However, the long-term savings on labor costs, maintenance, and time make it a cost-effective solution in the right contexts. For manufacturers that require frequent production of different types of pipe modifications, the upfront cost is quickly outweighed by the reduced operational expenses and increased throughput.

Another advantage of these machines is their ability to reduce material waste. Since the process is controlled with high precision and the stations are designed to apply only the necessary amount of force or deformation, there is less chance of overprocessing or wasting raw material. This not only leads to cost savings but also supports sustainability efforts by reducing material consumption and ensuring that scrap material is minimized during production.

Overall, multi-station pipe end forming machines are essential tools for modern pipe manufacturing, offering a combination of speed, precision, flexibility, and automation. As industries continue to demand high-quality, custom pipe solutions, these machines provide the ability to meet these needs efficiently. With advancements in technology, such as increased automation, data-driven control, and better energy efficiency, the capabilities of multi-station machines are only expected to improve, making them even more indispensable in the future of pipe manufacturing.

The future of multi-station pipe end forming machines is likely to be shaped by ongoing technological advancements, particularly in the areas of automation, artificial intelligence, and machine learning. These developments will further enhance the machine’s ability to optimize the forming process, ensuring that pipes are produced with even higher precision and efficiency. For instance, AI could be used to predict wear and tear on the machinery, allowing for preventative maintenance before a malfunction occurs, which would minimize downtime and improve overall productivity. Machine learning algorithms might also be employed to continuously fine-tune the forming process based on real-time data, ensuring the machine adapts to different pipe materials and conditions with ease.

Another exciting development is the integration of advanced sensors and real-time data analytics into multi-station machines. Sensors can monitor parameters such as temperature, pressure, and material strain throughout the forming process. By continuously analyzing this data, the machine can make instant adjustments to optimize the process, reducing the chance of errors and improving product quality. This real-time feedback loop can be particularly valuable in ensuring that the pipe’s structural integrity remains intact, especially for high-performance applications in industries like aerospace and oil and gas, where even minor imperfections can lead to significant consequences.

Energy efficiency is also an area where multi-station pipe end forming machines are likely to see improvements. As the global manufacturing industry shifts toward more sustainable practices, energy consumption will continue to be a key focus. Innovations in electric drives, more efficient heating systems, and regenerative energy technologies can help reduce the machine’s overall environmental impact. Induction heating systems, for example, could replace traditional flame or resistance heating methods, offering better control and more efficient energy use. Similarly, energy recovery systems could be integrated into the machine to capture and reuse heat generated during the forming process, further reducing energy waste and operational costs.

The growing demand for customization and flexibility in manufacturing is another trend that will impact the development of multi-station pipe end forming machines. With more industries looking to produce bespoke or small-batch pipes with specific requirements, the ability to quickly reconfigure a multi-station system for different pipe sizes, materials, or modifications will become increasingly important. Future machines are likely to include modular components that allow for easy reconfiguration or addition of new stations, making them adaptable to a wide variety of production needs. This flexibility will be particularly beneficial for industries that require frequent changes in pipe specifications, such as construction, automotive, and industrial manufacturing.

As the global supply chain becomes increasingly complex, there will be a greater emphasis on integrating multi-station pipe end forming machines into broader Industry 4.0 systems. These systems rely on data-driven decision-making and connectivity between machines, processes, and operators. Multi-station machines, equipped with IoT (Internet of Things) technology, will be able to communicate with other machines on the production line, sharing information about the status of the operation and providing insights into potential bottlenecks or areas for improvement. This level of integration will allow manufacturers to achieve greater control over their production processes, ensuring higher efficiency, less waste, and improved quality control across the board.

The potential for hybrid forming processes will also shape the future of these machines. Hybrid machines, which combine hot and cold forming processes, offer more versatility in handling a range of materials with varying strength and flexibility. In the future, multi-station pipe end forming machines could be designed to seamlessly transition between different forming techniques to suit specific material properties or production requirements, allowing manufacturers to work with an even broader spectrum of pipe materials, including exotic alloys, composites, and polymers.

Moreover, as industries like renewable energy and advanced manufacturing grow, multi-station machines will likely evolve to accommodate new materials and applications. In sectors such as wind energy or solar power, where custom pipe fittings are increasingly required, these machines will need to adapt to specific requirements such as lightweight materials, corrosion-resistant alloys, or pipes designed for use in extreme environments. The need for highly specialized pipes will continue to drive innovation in forming machines, making multi-station technology a vital part of the advanced manufacturing landscape.

In summary, multi-station pipe end forming machines are poised to become even more powerful, efficient, and adaptable in the future. Through the integration of automation, AI, real-time monitoring, and energy-efficient technologies, these machines will continue to meet the evolving demands of industries requiring high-quality, custom pipe solutions. Their ability to streamline production, reduce costs, and maintain precision will make them indispensable in manufacturing environments, ensuring that they remain a cornerstone of modern pipe fabrication for years to come.

Orbital Pipe End Forming Machine

An Orbital Pipe End Forming Machine is a specialized machine used for creating precise modifications to the ends of pipes, primarily in industries where high-quality, durable connections are required. The term “orbital” refers to the unique movement of the forming tool, which rotates around the pipe’s axis, allowing for a uniform and consistent pipe end modification process. This machine is particularly useful for creating smooth, high-precision ends for pipes that need to connect to other components or equipment, such as in the oil and gas, aerospace, chemical, and power generation industries.

The key advantage of orbital pipe end forming is its ability to produce consistent and accurate pipe ends, which are critical for ensuring tight seals and reliable connections, particularly in high-pressure and high-temperature applications. The orbital action allows the forming tool to work around the entire circumference of the pipe end, creating smooth, uniform modifications without causing deformation or irregularities. This is essential for applications where the pipe needs to fit precisely with other components, such as flanges, valves, or fittings.

Orbital pipe end forming machines are typically used to perform a range of operations, such as flaring, beading, swaging, and expanding pipe ends. The forming tool, which is positioned on a rotating mechanism, moves along the length of the pipe’s end while applying pressure to the pipe material. The pressure, combined with the orbital motion, ensures that the pipe end is formed evenly, achieving the desired shape without causing damage to the pipe itself. This makes orbital pipe end forming machines ideal for working with materials that require precise shaping, such as stainless steel, alloy metals, and other high-performance materials.

One of the main benefits of an orbital pipe end forming machine is the high level of control it provides during the forming process. The machine allows operators to fine-tune parameters like the amount of force applied, the rotational speed of the tool, and the pressure exerted on the pipe. This precision ensures that the pipe end is formed consistently, meeting exact specifications for diameter, shape, and surface finish. In industries like aerospace or oil and gas, where even the smallest deviation in pipe end shape can lead to operational failures, this level of control is invaluable.

The orbital forming process is highly efficient, particularly when multiple pipes need to be processed in quick succession. The machine is typically automated, with advanced control systems that manage the entire process. Operators can input specifications for the pipe end modification, and the machine will automatically adjust its settings to meet those requirements. This level of automation reduces the risk of human error and increases throughput, making orbital pipe end forming machines well-suited for high-volume production environments.

In addition to its efficiency and precision, the orbital pipe end forming machine is versatile. It can handle a variety of pipe sizes and materials, making it useful for a broad range of applications. The machine can be equipped with different tooling and attachments to perform various pipe end modifications, from creating smooth flanged ends to more complex shapes. This versatility is especially important in industries that require custom pipe configurations, as it allows manufacturers to quickly adapt the machine to meet specific production requirements.

The orbital pipe end forming machine is also known for its ability to improve the overall quality of the pipe end. The orbital action helps to eliminate common issues associated with other forming methods, such as uneven material thickness, distortion, or surface damage. This results in a higher-quality finished product that requires less post-processing and is ready for use in high-performance applications.

One of the challenges of orbital pipe end forming machines is the initial cost, as they are typically more expensive than traditional pipe end forming machines due to their advanced technology and precision. However, for manufacturers who need high-precision pipe modifications or need to meet strict industry standards, the investment is often justified by the improved product quality and increased productivity over time.

In conclusion, orbital pipe end forming machines are critical tools in industries that require high-precision pipe modifications. Their ability to create uniform, smooth, and accurate pipe ends through orbital motion makes them ideal for applications in sectors such as aerospace, oil and gas, and power generation. The combination of precision, efficiency, and versatility ensures that these machines continue to be an indispensable part of modern pipe fabrication. As technology advances, we can expect further improvements in automation, energy efficiency, and the ability to handle more complex materials and shapes, making orbital pipe end forming machines even more valuable for future production needs.

Orbital pipe end forming machines are designed to handle high-precision tasks where accuracy and uniformity are paramount. By employing orbital motion, the tool maintains consistent contact around the pipe’s circumference, ensuring a smooth and even modification at the pipe’s ends. This method reduces the risk of inconsistencies that can arise from traditional pipe end forming techniques, where manual intervention or irregular tooling might lead to surface defects, distortions, or dimensional inaccuracies. The result is a uniform pipe end that is perfectly shaped to match the required specifications, making it ideal for critical applications where reliability is non-negotiable.

The ability of orbital pipe end forming machines to work with a wide range of materials is another significant advantage. Stainless steels, alloys, and other high-strength metals that are commonly used in industries like aerospace, oil and gas, and power generation can be difficult to form with other methods due to their hardness and toughness. However, the controlled, orbital motion applied by these machines allows operators to work with these materials efficiently, ensuring that the integrity of the pipe is maintained throughout the process. This makes the orbital forming machine suitable for applications in harsh environments, where the pipes must withstand extreme pressure, temperature fluctuations, or corrosive substances.

Additionally, orbital forming provides the ability to work with varying pipe sizes, from small-diameter pipes used in medical or chemical applications to larger pipes required for construction, power plants, or even large-scale oil and gas operations. By adjusting the tool’s pressure, speed, and motion, orbital pipe end forming machines can accommodate different pipe specifications, allowing manufacturers to produce a wide range of pipe modifications using the same equipment. This versatility helps businesses meet the diverse needs of their customers without having to invest in multiple machines for different pipe types.

The advanced control systems in orbital pipe end forming machines contribute to the overall process efficiency. With CNC (Computer Numerical Control) technology, operators can pre-program the machine with specific pipe end configurations, reducing the need for manual adjustments and providing consistent results across multiple production runs. These machines can also be equipped with sensors that monitor the forming process in real-time, allowing for instant adjustments to ensure that the pipe end meets the desired specifications. This automation not only improves precision but also minimizes operator error and downtime, leading to higher productivity rates and cost savings.

As industries continue to demand more complex pipe solutions, orbital pipe end forming machines are evolving to meet new challenges. Future iterations may include enhanced AI capabilities, where machine learning algorithms can optimize the forming process based on historical data and real-time feedback. These advancements could further improve the machine’s ability to adapt to different materials, pipe sizes, and shapes, providing even greater flexibility and precision. Moreover, the integration of IoT (Internet of Things) technology could allow for remote monitoring and control, enabling operators to monitor and adjust the machine’s performance from anywhere, further improving efficiency and reducing the need for on-site intervention.

Energy efficiency is also becoming a major consideration in the design of these machines. As manufacturing industries focus more on sustainability, there is a growing demand for equipment that minimizes energy consumption while maintaining high-performance output. In response, future orbital pipe end forming machines may incorporate more energy-efficient drives, heating systems, and regenerative technologies that reduce waste and lower operating costs.

In industries where custom, high-performance pipes are essential, orbital pipe end forming machines will continue to be a vital part of the manufacturing process. Their ability to provide precise, reliable modifications that meet stringent industry standards makes them indispensable for creating components used in critical applications. The ongoing development of automation, AI, and energy-efficient technologies ensures that these machines will only become more powerful and versatile, supporting industries’ needs for customized, durable, and high-quality pipes in the years to come.

The continued evolution of orbital pipe end forming machines is driving innovation in the way pipes are manufactured, with the potential for even more significant breakthroughs in material science and manufacturing processes. One such advancement is the growing use of advanced materials that may require specialized forming techniques. For example, composite materials, which are becoming more common in industries like aerospace and renewable energy, present challenges in pipe forming due to their differing thermal properties and mechanical characteristics. As orbital pipe end forming machines evolve, they could be adapted to handle these advanced materials, ensuring that pipes made from composites or other high-tech materials maintain the same level of precision and quality as those made from traditional metals.

The integration of real-time process control and quality monitoring will also shape the future of orbital pipe end forming machines. As manufacturing processes become more complex, the need for instantaneous monitoring of pipe conditions during the forming process will increase. By integrating machine vision systems and other sensor technologies, future orbital forming machines could automatically detect even the smallest imperfections or variations in pipe geometry. These systems could adjust the forming parameters in real-time to correct any deviations, ensuring that the final product consistently meets the required standards without the need for extensive post-processing or rework.

Additionally, smart manufacturing techniques are likely to become a key feature in the development of orbital pipe end forming machines. These machines will not only be able to collect data during the forming process but will also use that data to make intelligent decisions. For example, using historical data and machine learning algorithms, an orbital forming machine could identify patterns in material behavior, predict wear on tools, or even optimize the forming process based on the specific batch of material being used. This level of intelligence would further reduce the chance of errors, improve overall machine performance, and ensure that production runs are more efficient and cost-effective.

The trend toward increased automation is also pushing the boundaries of what orbital pipe end forming machines can achieve. These machines are increasingly being integrated into fully automated production lines, where robotic arms or automated conveyor systems can load and unload pipes, reducing the need for manual labor. This automation helps to further speed up the forming process, particularly in high-demand industries where large quantities of pipes need to be produced in a short amount of time. The automation of not only the forming process but also the pipe handling and inspection processes can dramatically increase throughput and reduce the likelihood of human error.

Integration with digital twin technology could also become a significant feature of orbital pipe end forming machines. A digital twin is a virtual model of a physical object, in this case, the forming machine and the pipe being processed. By using sensors and data analytics, a digital twin could simulate the entire forming process and track the machine’s performance in real-time. This would allow operators to identify potential issues before they occur and make necessary adjustments without halting production. It could also assist with predictive maintenance, where the digital twin provides insights into when parts are likely to wear out or fail, allowing for proactive replacements and minimizing downtime.

Another area of potential growth is the expansion of customized tooling solutions for orbital pipe end forming machines. As the demand for specialized pipes increases, machine manufacturers may design customizable tooling systems that can easily be swapped or adjusted to handle a variety of pipe configurations. This customization would allow manufacturers to cater to niche markets or custom projects without investing in separate machines or processes for each type of pipe.

Furthermore, sustainability will play a growing role in shaping the future of these machines. As industries push for more environmentally friendly practices, manufacturers will likely seek ways to reduce material waste and minimize the environmental footprint of their operations. Orbital pipe end forming machines could be designed with energy-efficient components and processes, reducing power consumption while maintaining high throughput and precision. In addition, machines might incorporate systems that can reuse or recycle scrap material generated during the forming process, further contributing to sustainability efforts.

In conclusion, the future of orbital pipe end forming machines looks promising, with continuous advancements in automation, precision, material science, and sustainability. These machines will play a critical role in meeting the growing demands for high-performance pipes across a range of industries. As they become smarter, more adaptable, and more efficient, orbital pipe end forming machines will continue to be an essential part of modern pipe fabrication, providing high-quality solutions for industries that rely on pipes for critical infrastructure and operations. With innovations on the horizon, the capabilities of these machines will likely expand, enabling manufacturers to tackle even more complex pipe forming challenges and pushing the boundaries of what is possible in the world of pipe production.

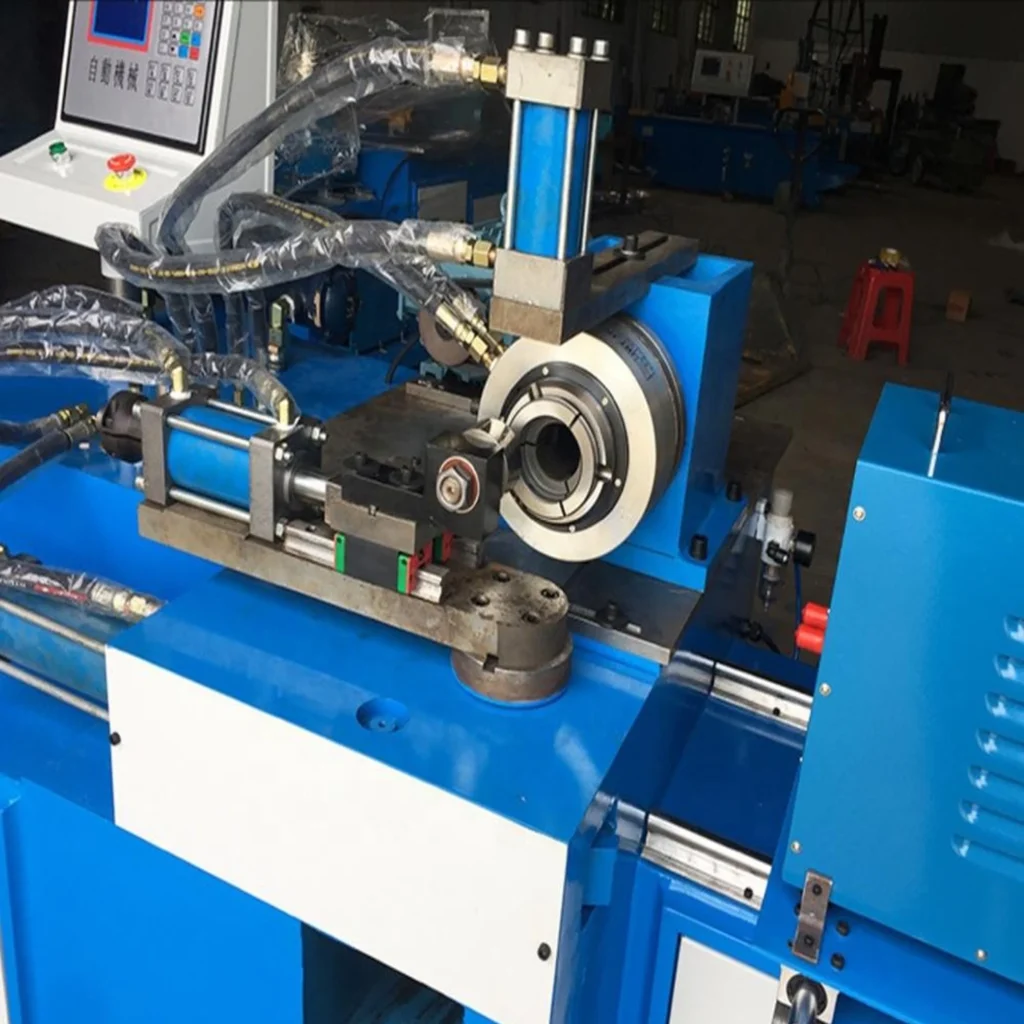

Rotary Spinning Pipe End Forming Machine

A Rotary Spinning Pipe End Forming Machine is a specialized piece of equipment used for shaping the ends of pipes through a rotational process, often referred to as “spinning” or “rotary forming.” This machine is particularly useful for creating smooth, accurate modifications to pipe ends, such as flaring, beading, or reducing the diameter of the pipe. The rotary spinning process is characterized by the rotation of the pipe while a forming tool applies pressure to shape the pipe’s end. It is most commonly used in industries that require high-strength, precision pipes with smooth, uniform modifications, such as in aerospace, automotive, and heavy industrial applications.

The key feature of a rotary spinning pipe end forming machine is its ability to manipulate the material of the pipe while it rotates at high speeds. This rotational motion creates centrifugal forces that allow the material at the pipe’s end to flow smoothly under pressure, enabling the formation of precise shapes without the risk of cracking, distortion, or surface defects. The machine typically uses a forming tool that is in direct contact with the pipe, either from the inside or outside, depending on the type of modification being applied.

One of the most significant advantages of rotary spinning over other methods of pipe end forming is the smoothness and precision it achieves. The spinning action helps eliminate wrinkles, material thinning, or uneven surfaces, which can be common in other forming methods like hammering or bending. This smooth surface is especially important when the pipe needs to be welded, threaded, or connected to other components, as a uniform, defect-free end ensures a better seal and structural integrity.

In addition to its high-quality output, rotary spinning is energy-efficient and relatively fast compared to other traditional pipe end forming methods. Since the machine rotates the pipe at a consistent speed while the forming tool applies pressure, the process can be automated to a high degree, leading to faster production cycles. This makes rotary spinning an excellent choice for mass production or applications where high-volume manufacturing is required.

Another key benefit of the rotary spinning process is its versatility. These machines can handle pipes made from a wide range of materials, including metals like stainless steel, aluminum, and titanium, as well as alloys and composite materials. The pressure and speed applied during the spinning process can be adjusted to accommodate the material’s specific properties, ensuring the pipe is shaped without compromising its strength or structure. This makes the rotary spinning pipe end forming machine highly adaptable, able to serve industries as varied as aerospace, automotive, chemical processing, and construction.

Rotary spinning is also cost-effective in certain applications, especially when it comes to producing pipes with a large number of similar modifications. The reduction in material waste is a significant factor, as the process uses precise force to shape the material without overworking it. This minimizes scrap material and leads to a higher yield per production run.

The process itself is controlled by a programmable control system that allows for fine-tuning of the machine’s speed, pressure, and tooling angle. This control ensures that each pipe end modification is completed according to strict specifications, improving the consistency and accuracy of the final product. Operators can adjust these settings to achieve different pipe-end configurations, such as flaring, swaging, or necking, depending on the specific needs of the project.

Automation is another key feature of modern rotary spinning pipe end forming machines. Automated systems can handle the loading and unloading of pipes, making the process more efficient and reducing the need for manual labor. In high-volume environments, this automation also reduces the chance of human error and increases throughput, which is essential for industries with tight production schedules. Moreover, the use of sensors and feedback systems allows the machine to detect and correct potential issues in real-time, ensuring that the final product meets the required quality standards.

Customization is a major advantage of rotary spinning machines. They can be designed to accommodate a variety of pipe sizes and shapes, making them suitable for both large-scale industrial projects and smaller, custom applications. Whether for high-precision aerospace components or heavy-duty industrial pipes, rotary spinning can be adjusted to meet the specific needs of the application. This flexibility makes rotary spinning an attractive option for industries that require custom pipe modifications or specialty products.

However, rotary spinning does come with some limitations. While it is an excellent choice for many pipe end modifications, it may not be ideal for every type of material or pipe shape. For instance, some materials may not flow as easily under pressure, or pipes with extremely thick walls may require additional processes or tooling to achieve the desired results. Furthermore, the initial investment in rotary spinning equipment can be significant, particularly when considering the automation and customization features that may be required for specific applications.

Despite these challenges, the future of rotary spinning pipe end forming machines looks promising. As industries continue to push for more efficient, precise, and cost-effective manufacturing solutions, rotary spinning will likely play an increasingly important role in pipe fabrication. Advancements in automation, sensor technology, and material science will further enhance the capabilities of these machines, allowing for even greater precision, flexibility, and energy efficiency in pipe end forming processes.

In conclusion, rotary spinning pipe end forming machines are crucial tools in industries that require precise, high-quality pipe modifications. By leveraging rotational motion and controlled pressure, these machines can create smooth, accurate pipe ends that meet the demanding requirements of sectors like aerospace, automotive, and heavy industry. With benefits including precision, speed, versatility, and cost-effectiveness, rotary spinning will continue to be a valuable method for manufacturers who rely on custom pipe solutions and high-performance applications.

The rotary spinning pipe end forming machine continues to evolve, offering even greater precision, efficiency, and adaptability as industries demand more advanced manufacturing solutions. With ongoing developments in automation and digital control systems, these machines are becoming smarter, more capable of handling complex tasks, and more cost-effective for high-volume production. The use of advanced sensors and real-time data feedback is enabling machines to perform more precise adjustments during the forming process, ensuring that each pipe end is shaped to exact specifications without the need for constant manual intervention. This not only improves overall quality but also reduces the likelihood of errors, ultimately enhancing the reliability of the pipes produced.

One of the most exciting areas of innovation is the integration of machine learning and artificial intelligence. These technologies could enable the rotary spinning pipe end forming machine to learn from previous production runs and optimize future ones based on historical data. For example, by analyzing the way different materials respond to the spinning process, the machine could adjust parameters like rotational speed and pressure dynamically, ensuring optimal results for each batch without requiring constant operator adjustments. This would not only improve efficiency but also allow manufacturers to handle more complex materials and customized pipe specifications with ease.

Another aspect of growth in rotary spinning technology is the increased focus on sustainability. With rising environmental concerns, there is pressure for manufacturing processes to reduce their carbon footprint and waste. Rotary spinning, with its ability to create highly precise pipe end modifications with minimal material waste, is already an environmentally friendly process. However, future iterations of these machines are likely to incorporate even more sustainable features, such as energy recovery systems, more efficient use of raw materials, and the ability to recycle scrap materials. These innovations will allow manufacturers to meet the growing demand for eco-friendly manufacturing practices while still producing high-quality, durable pipes.

As the global manufacturing industry continues to focus on Industry 4.0 and smart factories, the rotary spinning machine will be an integral part of this transformation. With the ability to connect to the broader production network, these machines can share data with other systems on the production line, allowing for a more seamless and coordinated manufacturing process. Operators will be able to track machine performance remotely, analyze data in real time, and make adjustments based on real-time conditions, ultimately improving overall productivity and reducing downtime.