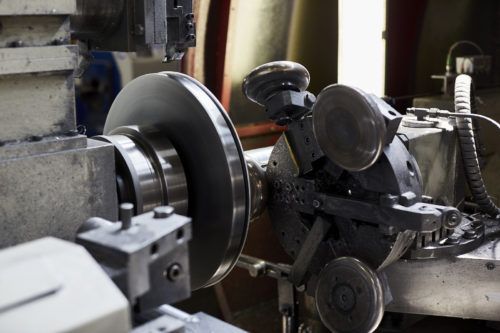

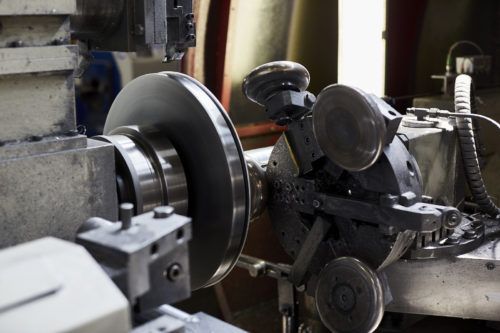

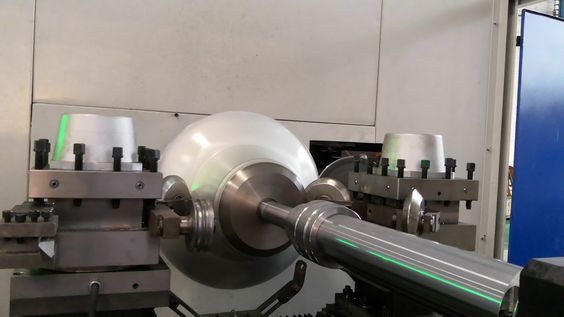

Automated Rotary Forging Machine: A sheet metal spinning machine is a tool used to shape metal sheets into cylindrical or conical forms by rotating the metal sheet while pressing it against a tool or mandrel. It is commonly used in manufacturing processes for producing hollow, symmetrical parts such as tanks, bowls, or decorative pieces. Here’s how it typically works:

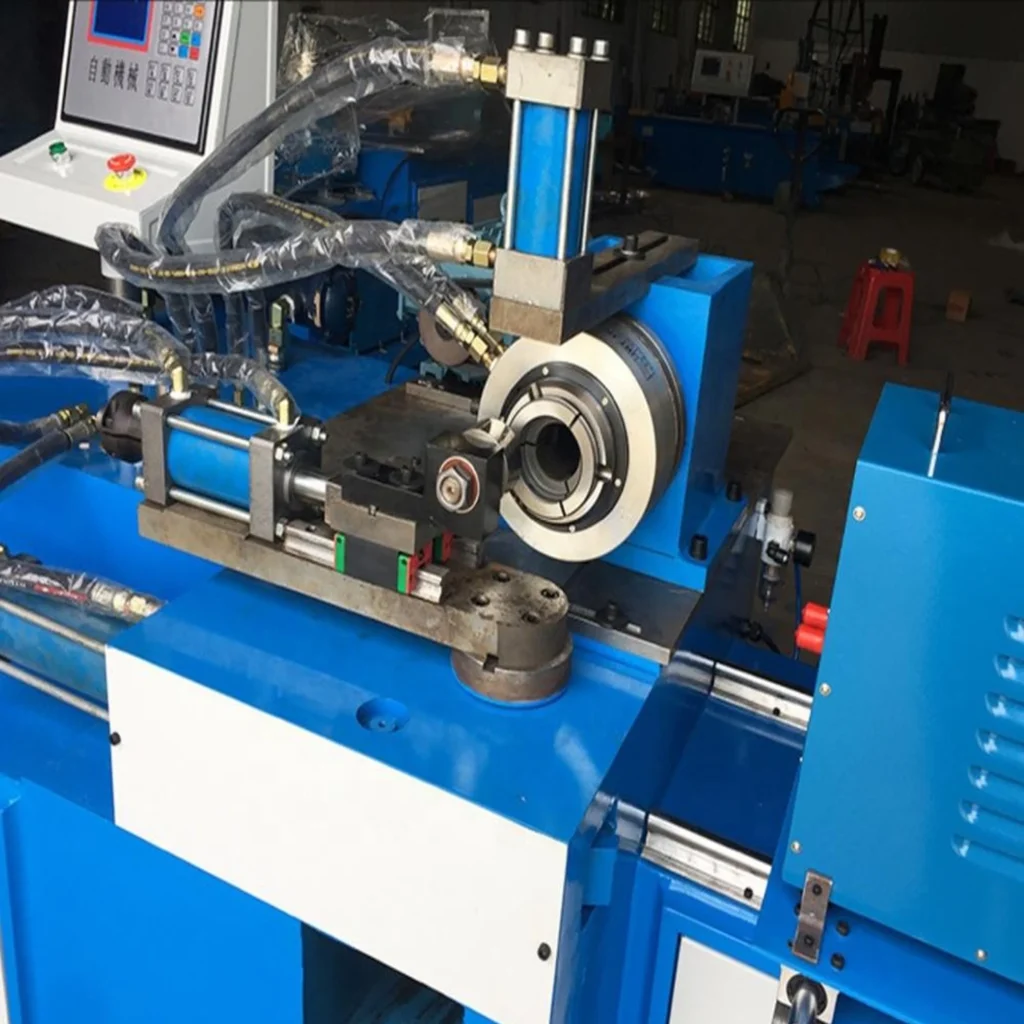

Key Components of the Metal Spinning Machine

- Spindle/Mandrel: The part that holds the sheet metal and rotates it. The shape of the mandrel defines the final product’s shape.

- Tooling: Includes the rollers or form tools that press against the sheet metal to shape it as it rotates.

- Chuck/Clamps: These hold the metal sheet securely in place during the spinning process.

- Drive System: This powers the spindle to rotate the metal sheet at the required speed.

- Support Arms/Rest: They may be used to support larger sheets of metal during the spinning process to ensure they stay in position.

Process Overview:

- Sheet Placement: The metal sheet is placed over the mandrel or spindle and secured by clamps.

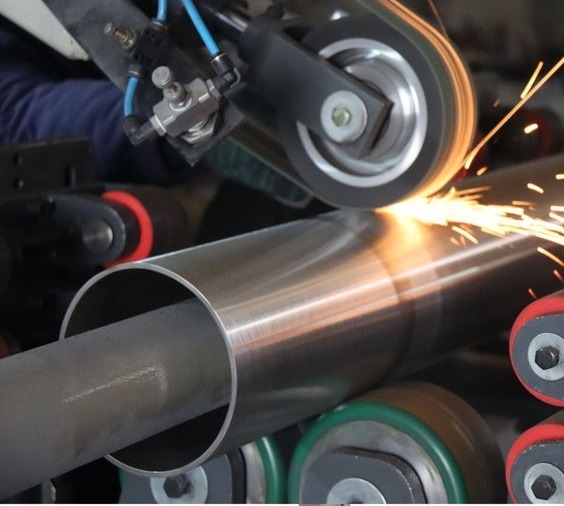

- Spinning: As the mandrel rotates, the tool presses against the sheet, gradually forming it to match the shape of the mandrel.

- Shaping: The sheet is gradually shaped, and the tools are moved along the surface to create the desired thickness and profile.

- Finishing: Once the desired shape is achieved, the product is removed from the mandrel and any excess material is trimmed or smoothed.

Applications:

- Automotive Industry: Manufacturing parts like wheels, cones, or exhaust systems.

- Aerospace: Creating cones, ducts, and other cylindrical components.

- Decorative: Producing artistic metal pieces like lamp shades, bowls, and vases.

- Heat Exchangers and Pressure Vessels: Making components like tanks and cylindrical housings.

A sheet metal spinning machine shapes metal into cylindrical or conical forms by rotating a sheet and applying pressure to mold it around a mandrel. The process starts by securing the sheet over a rotating mandrel, where tools press the metal to gradually conform to the mandrel’s shape. This technique is used to produce symmetrical, hollow parts like tanks, cones, bowls, and decorative items. The spindle, tooling, and drive system are key components, with clamps or chucks holding the metal in place. The process is used in industries like automotive, aerospace, and decorative metalworking. The result is often a seamless, strong, and precisely shaped metal piece.

A sheet metal spinning machine is an essential tool in the metalworking industry, primarily used for forming metal sheets into intricate, hollow, and symmetrical shapes, such as cylinders, cones, and hemispheres. The process, also referred to as “spinning,” involves rotating a flat metal sheet while simultaneously applying force with specialized tools that gradually shape it over a mandrel or spindle. This process allows for the creation of parts without seams or welds, making it ideal for producing strong, durable components.

The primary action in spinning involves the rotation of the sheet metal over a mandrel, which serves as the template for the desired shape. The metal is pressed against the mandrel using a combination of rollers and tooling, and as the sheet rotates at high speeds, the force of the tools molds the metal into the shape of the mandrel. This continuous pressure and motion refine the thickness and profile of the part, gradually creating the final form.

A key advantage of sheet metal spinning is its versatility. It can be used to create parts of varying complexity, from simple cylindrical shapes to more complex conical forms. The process allows for high production rates, and the resulting parts typically exhibit excellent strength-to-weight ratios, which is particularly important in industries like aerospace, automotive, and heavy equipment manufacturing.

In terms of materials, spinning is often applied to metals that are relatively malleable, such as aluminum, brass, copper, and mild steel. The choice of material depends on the intended application, as each metal has unique properties such as strength, corrosion resistance, and thermal conductivity.

The spinning process is divided into two categories: manual and CNC (Computer Numerical Control) spinning. Manual spinning involves an operator using hand tools to control the pressure and movement of the rollers as the sheet is spun. While this process can be slower and more labor-intensive, it offers flexibility for smaller runs or custom pieces. On the other hand, CNC spinning automates the process, allowing for faster production times, greater precision, and consistency in the resulting parts. This is particularly advantageous for high-volume production, where precision and speed are critical.

Applications of sheet metal spinning are widespread across various industries. In aerospace, it is used to manufacture parts like airframe components, ducts, and housings. In the automotive industry, spinning is commonly used for creating parts such as wheel rims, exhaust systems, and fuel tanks. Additionally, in the decorative arts, spinning machines are used to create objects like lamp shades, vases, and ornamental pieces. The ability to produce seamless, strong, and lightweight components makes sheet metal spinning an indispensable process in modern manufacturing.

Overall, sheet metal spinning is a highly efficient, versatile, and cost-effective method for producing a wide variety of parts. Whether in small quantities for custom pieces or large-scale production runs, the spinning process offers a unique combination of precision, speed, and durability.

The sheet metal spinning process is not only efficient but also provides the ability to produce parts with minimal material waste. Unlike some traditional methods of metal forming, where excess material is cut away, spinning works by gradually shaping the material, which helps conserve metal. This results in less scrap and a more environmentally friendly manufacturing process.

Additionally, sheet metal spinning allows for the creation of parts with excellent structural integrity. The process work hardens the metal as it is pressed against the mandrel, enhancing its strength without the need for additional treatments. This is especially important when the parts need to withstand high pressures or mechanical stress. For example, in aerospace, spinning is often used to produce pressure vessels or ducts that must handle the extreme conditions of flight, such as varying temperatures and pressures.

The precision and control offered by modern spinning machines, especially CNC (Computer Numerical Control) models, enable the production of highly accurate parts with tight tolerances. CNC machines can precisely control the speed, force, and movement of the rollers, ensuring that the final product meets the exact specifications required. This level of accuracy is especially important for industries like aerospace, where even a small deviation in dimensions can affect the performance of a part.

While manual spinning offers flexibility and the ability to produce custom pieces, CNC spinning is generally preferred for large-scale production due to its speed and consistency. CNC machines can handle complex geometries and intricate designs that would be difficult or impossible to achieve with manual methods. They can also integrate multiple operations into a single setup, such as trimming, forming, and finishing, which further enhances the efficiency of the process.

One of the advantages of sheet metal spinning is its ability to work with a wide range of thicknesses. The material thickness can be controlled throughout the process, allowing manufacturers to create parts that are uniform in thickness, which is essential for parts that must endure specific stress loads or thermal conditions. The process also allows for parts to be created with varying wall thicknesses, which can be particularly useful when the strength of the part needs to vary across its surface.

For industries that require aesthetically pleasing designs, spinning can be used to create complex shapes with smooth, seamless surfaces. Decorative items like bowls, trays, and lampshades, as well as functional parts like automotive wheel rims and kitchen sinks, benefit from the smooth, flawless finish that can be achieved through spinning. The lack of welds or joints contributes to the clean, uninterrupted surface, which is especially valuable for high-end designs.

Moreover, the spinning process is relatively fast compared to other methods of metal forming like casting or stamping. Once the machine is set up, the process can be performed quickly, making it suitable for both low- and high-volume production. The ability to quickly modify the tooling or adjust the spinning parameters means that manufacturers can respond to changing requirements with minimal downtime.

In conclusion, sheet metal spinning is an invaluable technique that combines precision, efficiency, and versatility. Whether for producing high-performance components in aerospace, cost-effective parts in automotive manufacturing, or decorative items for home decor, the process continues to be a crucial part of modern manufacturing. As technology advances, with the integration of more automated systems and sophisticated CNC controls, the capabilities of sheet metal spinning are expected to grow, further expanding its applications and improving the efficiency of metalworking processes across various industries.

As sheet metal spinning continues to evolve, several technological advancements are contributing to its broader adoption and improved capabilities. One of the most significant developments is the integration of robotic systems and advanced automation. Robotic arms and automated tool changers are increasingly used in conjunction with CNC spinning machines, allowing for faster and more flexible production. These systems can automatically load and unload materials, adjust tool positions, and even perform secondary operations like trimming, polishing, or deburring without the need for manual intervention. This further reduces human error, increases production speed, and ensures a higher level of consistency in the final products.

The development of more advanced CNC software is another key factor driving the improvement of sheet metal spinning. Modern CNC systems can simulate the entire spinning process before production begins, enabling engineers to optimize tool paths and adjust machine settings in advance. This not only saves time but also reduces the risk of defects or material waste, as manufacturers can identify potential issues early in the design phase. The use of simulation software is particularly valuable when producing complex or high-precision parts that require tight tolerances or specific geometric features.

In terms of materials, there has been a growing interest in expanding the range of metals and alloys that can be used in sheet metal spinning. Traditionally, aluminum, copper, and brass were the most commonly used metals due to their malleability and ease of forming. However, advances in both material science and machine technology have enabled the use of harder, more durable materials like stainless steel, titanium, and even high-strength alloys. This has opened up new opportunities for industries that require materials with exceptional strength-to-weight ratios, corrosion resistance, or thermal conductivity.

For example, in the aerospace and automotive industries, high-strength alloys are essential for producing lightweight but durable components that can withstand harsh environments. Spinning allows manufacturers to form these materials into complex shapes while maintaining their structural integrity. The process can also be used to produce parts with unique mechanical properties, such as high tensile strength or enhanced fatigue resistance, which are critical in industries where performance and reliability are paramount.

Another emerging trend in sheet metal spinning is the use of hybrid manufacturing techniques. These methods combine traditional spinning with other advanced processes such as additive manufacturing (3D printing) or laser cutting. For example, parts can be spun and then modified using 3D printing techniques to add intricate details or create complex internal geometries that would be difficult to achieve through spinning alone. This approach allows manufacturers to produce highly customized parts with enhanced functionality or unique design features, all while taking advantage of the speed and material efficiency of the spinning process.

Energy efficiency is another area where innovations are being made. Spinning machines are becoming more energy-efficient through the use of variable-speed drives, improved motors, and regenerative braking systems. These advancements help reduce the overall energy consumption of the machines, making them more sustainable and cost-effective to operate. Additionally, by minimizing waste material and maximizing the use of raw metals, spinning contributes to more sustainable manufacturing practices overall.

Despite these advancements, challenges still exist in sheet metal spinning, particularly when it comes to the variability of material properties. Variations in metal thickness, alloy composition, or grain structure can lead to inconsistent results, requiring manufacturers to closely monitor and adjust process parameters to maintain quality. To address this, there is an ongoing effort to develop more sophisticated monitoring and control systems that can track material properties in real-time, allowing the machine to adjust the process dynamically and maintain consistent results.

Another challenge is the skill level required to operate and maintain advanced spinning machines. While automation and CNC systems have made the process more accessible, the technical expertise required to set up, program, and troubleshoot these machines is still significant. This means that manufacturers must invest in training and workforce development to ensure that operators can effectively utilize the full capabilities of modern sheet metal spinning equipment.

Looking ahead, the future of sheet metal spinning holds exciting possibilities. The integration of artificial intelligence (AI) and machine learning into CNC systems could revolutionize the process by enabling machines to learn from past production runs and optimize settings in real-time. AI could also help predict potential failures or defects, allowing for proactive maintenance and reducing downtime. Furthermore, the combination of sheet metal spinning with other emerging manufacturing technologies, such as smart sensors, Internet of Things (IoT) connectivity, and digital twins, could lead to fully automated, self-optimizing production systems.

In conclusion, sheet metal spinning is a dynamic and rapidly evolving manufacturing process with significant potential for innovation. As technology continues to advance, we can expect the process to become even more efficient, versatile, and sustainable, enabling the production of more complex and higher-quality parts across a wide range of industries. Whether through automation, material advancements, or hybrid manufacturing techniques, the future of sheet metal spinning looks promising, and it will undoubtedly remain an essential part of modern manufacturing for years to come.

Advancements in Automation and Robotics

The integration of robotics and automated systems into sheet metal spinning machines is transforming the process. Robotic arms are now commonly used for material handling, tool adjustments, and part removal, significantly improving speed and precision. By automating repetitive tasks, manufacturers can reduce labor costs and increase throughput, making it easier to scale production while maintaining high-quality standards. These advancements also help in reducing human error, which can lead to defects or inconsistencies, thereby improving the overall reliability of the process.

CNC Software and Simulation

Modern CNC software is a game-changer in sheet metal spinning. Before the actual production begins, advanced simulation software allows engineers to create virtual models of the entire spinning process. This means they can predict and optimize tool paths, material deformation, and other critical factors without wasting material or time. By identifying potential issues in the design phase, manufacturers can fine-tune their setups, resulting in more accurate and efficient production. The ability to simulate complex geometries and adjust settings with precision helps in achieving tight tolerances and high-quality results.

Expanding Material Choices

Traditionally, sheet metal spinning was limited to relatively malleable metals such as aluminum, brass, and copper. However, technological advancements have expanded the range of materials that can be spun. Today, harder metals such as stainless steel, titanium, and high-strength alloys are increasingly being used in spinning applications. This is particularly important in industries like aerospace and automotive, where parts need to be lightweight yet durable, resistant to corrosion, and able to withstand high stress. The ability to spin these tougher materials means manufacturers can produce components with superior performance characteristics, which are crucial for demanding applications.

Hybrid Manufacturing Techniques

The combination of sheet metal spinning with other advanced manufacturing methods is another exciting development. Hybrid manufacturing techniques, such as the integration of additive manufacturing (3D printing) or laser cutting, are allowing for more complex and customized parts. For instance, after a part is spun, additional features such as intricate internal geometries or custom textures can be added through 3D printing. This approach broadens the design possibilities and enhances functionality, especially for industries that require parts with unique specifications or geometries that are difficult to achieve through traditional methods.

Improving Energy Efficiency

As sustainability becomes a growing concern in manufacturing, energy efficiency has become a key focus for sheet metal spinning. Advances in motor technology, including variable-speed drives and regenerative braking systems, are making modern spinning machines more energy-efficient. These innovations reduce the overall power consumption of the machines, contributing to lower operating costs and a reduced environmental impact. Additionally, the minimal material waste produced by spinning also plays a role in the sustainability of the process, as less scrap is generated compared to other metal-forming methods.

Real-Time Monitoring and Control Systems

One of the challenges in sheet metal spinning is ensuring consistent quality, especially when dealing with varying material properties such as thickness, alloy composition, or grain structure. To address this, manufacturers are increasingly using real-time monitoring systems that track key parameters like material deformation, tool pressure, and temperature. These systems can dynamically adjust process settings to account for changes in material properties or environmental factors, ensuring consistent quality throughout the production run. The use of sensors and smart control systems is becoming standard practice in modern spinning operations.

Overcoming Skill Gaps

Despite the increasing automation and sophistication of spinning machines, there remains a significant need for skilled operators. Modern sheet metal spinning machines, especially those with CNC capabilities, require operators who can program, set up, and troubleshoot the machines effectively. This means that manufacturers must invest in workforce training and development to ensure that their employees can harness the full potential of these advanced technologies. Without skilled personnel, even the most automated systems can fall short in terms of performance and quality.

Artificial Intelligence and Predictive Maintenance

Looking toward the future, artificial intelligence (AI) holds enormous potential for revolutionizing sheet metal spinning. AI algorithms can be used to analyze data from past production runs, identify patterns, and optimize process settings in real time. These systems could even predict equipment failures before they occur, allowing for proactive maintenance and reducing unexpected downtime. This predictive approach would not only enhance the efficiency of the spinning process but also extend the lifespan of the equipment, providing long-term cost savings.

The Role of IoT and Digital Twins

The Internet of Things (IoT) is beginning to play a role in sheet metal spinning as machines become increasingly connected. IoT-enabled machines can send real-time data about their performance, material usage, and other metrics to centralized systems, enabling manufacturers to monitor production remotely. Digital twins—virtual replicas of physical machines—are being used to simulate the spinning process and monitor machine health, helping operators detect issues before they lead to failures. By integrating IoT and digital twin technology, manufacturers can create more efficient and flexible production environments that respond to real-time conditions.

The Future of Sheet Metal Spinning

In conclusion, the future of sheet metal spinning is promising and filled with possibilities. With continued advancements in automation, material science, hybrid manufacturing, and energy efficiency, the process will become even more versatile, faster, and sustainable. The ongoing integration of AI, machine learning, and IoT will further enhance the precision and adaptability of spinning machines, opening the door for new applications and improved production techniques. As the technology continues to evolve, sheet metal spinning will remain an essential part of manufacturing, driving innovation and efficiency across industries.

Advancements in Automation and Robotics

Automation and robotics are transforming the sheet metal spinning process by streamlining operations, improving consistency, and increasing production efficiency. Robotic arms are increasingly used in conjunction with spinning machines for various tasks such as loading and unloading materials, adjusting tooling, and removing finished parts. These robotic systems can operate continuously without the need for human intervention, reducing labor costs and allowing for 24/7 production. They also help reduce human error, which can lead to defects and inconsistencies in the final product.

Automated tool changers are another innovation that makes it easier to switch between different types of tooling or adjust the size and shape of tools. This allows for quick reconfiguration of the machine to accommodate different parts without manual intervention, improving flexibility and reducing downtime. Additionally, advanced machine controls and sensors integrated with robotic systems enable the machine to automatically adjust parameters based on feedback from the production process, further enhancing the precision and quality of the finished parts.

CNC Software and Simulation

The integration of advanced CNC (Computer Numerical Control) software into sheet metal spinning has revolutionized the way manufacturers approach the process. Modern CNC systems are equipped with sophisticated software that allows for the design, simulation, and optimization of the entire spinning process before physical production begins. Engineers can input the part design into the software, and the system will simulate how the metal will behave as it is spun over the mandrel. This allows for the identification of potential problems such as material deformation, tool wear, or stress points in the design, enabling manufacturers to address issues before they arise.

Simulation also provides the opportunity to optimize tool paths, minimize material waste, and adjust the spinning parameters to ensure uniform thickness and precision. By creating a digital twin of the production process, CNC systems can help manufacturers refine their designs, improve product quality, and reduce production times. This level of planning ensures that the final product meets exact specifications, which is especially important when producing complex or high-precision parts that require tight tolerances.

Expanding Material Choices

Historically, sheet metal spinning was limited to metals that were easy to work with, such as aluminum, brass, copper, and mild steel. These materials are relatively soft and malleable, making them easier to shape under pressure. However, recent advances in both materials science and machine technology have expanded the range of materials that can be effectively spun. Harder, stronger metals like stainless steel, titanium, and high-strength alloys are now increasingly used in sheet metal spinning applications.

For industries such as aerospace and automotive, the ability to spin high-strength alloys is particularly valuable. These materials offer superior strength-to-weight ratios, corrosion resistance, and the ability to withstand extreme conditions, making them ideal for critical components such as engine parts, structural components, and heat exchangers. Spinning these tougher materials requires advanced tooling, more precise control of process parameters (such as temperature and pressure), and robust CNC systems, but the result is a part that combines lightweight properties with exceptional strength and durability.

Hybrid Manufacturing Techniques

The combination of sheet metal spinning with other advanced manufacturing processes—known as hybrid manufacturing—has opened up new possibilities for producing complex and highly customized parts. One example of this is the integration of additive manufacturing (3D printing) into the spinning process. In hybrid setups, parts can be spun to achieve basic geometries and structural integrity, and then additive manufacturing can be used to add intricate details, internal geometries, or even custom textures to the part.

For instance, after spinning a basic cylindrical part, 3D printing could be used to add cooling channels or complex internal structures that would otherwise be difficult or impossible to achieve using traditional methods. This combination of processes allows for greater design flexibility and enhances the functionality of the parts being produced. Hybrid manufacturing also offers the possibility of producing parts in lower quantities while maintaining high precision and reducing material waste.

Another example of hybrid manufacturing is the use of laser cutting or laser welding in combination with spinning. Laser cutting can be used to refine the shape or trim excess material after the spinning process, while laser welding can be employed to join multiple spun components together. By integrating multiple advanced manufacturing methods, manufacturers can produce more complex, high-performance parts in a shorter time frame, while maintaining the benefits of sheet metal spinning’s high material efficiency and low scrap rate.

Improving Energy Efficiency

As the demand for more sustainable manufacturing practices increases, the need for energy-efficient machinery has become a significant focus in sheet metal spinning. Modern spinning machines are being equipped with energy-saving features, such as variable-speed drives, high-efficiency motors, and regenerative braking systems. These innovations help reduce the overall energy consumption of the machines, making them more environmentally friendly and cost-effective to operate.

Variable-speed drives allow machines to adjust their speed based on the specific requirements of the part being produced, ensuring that energy is used efficiently throughout the process. Regenerative braking systems capture energy during braking and convert it into electrical power, which can be fed back into the machine or grid, reducing energy waste. Additionally, by minimizing material waste through the precise control of material thickness and eliminating the need for additional processes like welding or machining, spinning further reduces the environmental impact of the manufacturing process.

These energy-efficient advancements not only lower operational costs but also align with global efforts to reduce the carbon footprint of manufacturing. As sustainability becomes a key factor in business decisions, the continued development of energy-efficient spinning machines will play a crucial role in the industry’s shift toward more sustainable practices.

Real-Time Monitoring and Control Systems

Real-time monitoring and control systems are increasingly being integrated into sheet metal spinning machines to ensure consistent quality and efficiency throughout the production process. These systems rely on sensors to measure key parameters such as material thickness, temperature, tool pressure, and speed during the spinning process. The data collected from these sensors is continuously analyzed by the machine’s control system, which can make adjustments to process parameters as needed to maintain quality and prevent defects.

For example, if the system detects that a particular area of the part is not being formed properly or that the material is experiencing excessive stress, it can automatically adjust the pressure or speed of the rollers to compensate. This dynamic control helps ensure that each part meets the required specifications and reduces the risk of defects. Moreover, the data collected during production can be used to track machine performance and identify areas for improvement.

Real-time monitoring also allows for predictive maintenance, where the system can analyze the performance of critical components and predict when they are likely to need maintenance or replacement. By addressing potential issues before they lead to machine downtime or defects, manufacturers can avoid costly repairs and production delays.

Overcoming Skill Gaps

Despite the increased automation and sophistication of sheet metal spinning machines, there remains a need for highly skilled operators who can manage and maintain the equipment. Modern spinning machines, especially those equipped with CNC controls, require operators who are proficient in programming, machine setup, troubleshooting, and adjusting process parameters. This expertise is critical for ensuring that machines operate efficiently and produce high-quality parts consistently.

To address this skill gap, manufacturers are increasingly investing in workforce development and training programs. These programs are designed to teach operators the necessary technical skills and knowledge to operate advanced spinning machines. In addition to technical skills, operators must also have a solid understanding of materials science, quality control, and problem-solving to identify and resolve issues during production. As the technology behind sheet metal spinning continues to evolve, the demand for skilled workers with expertise in these areas will only increase.

Artificial Intelligence and Predictive Maintenance

The integration of artificial intelligence (AI) into sheet metal spinning is an exciting development that promises to enhance the capabilities of CNC systems. AI algorithms can analyze large amounts of data from the machine’s sensors, production logs, and historical performance to make real-time decisions about how to optimize the spinning process. For example, AI could adjust the spinning parameters dynamically based on changes in material properties, environmental conditions, or tool wear, ensuring that the process remains stable and efficient.

Predictive maintenance is another area where AI can have a significant impact. By analyzing data from the machine’s sensors, AI systems can detect patterns that indicate impending failures or maintenance needs. This allows manufacturers to schedule maintenance before a failure occurs, reducing unplanned downtime and extending the lifespan of the equipment. Predictive maintenance also helps reduce the cost of repairs by identifying potential issues early, before they become costly problems.

The Role of IoT and Digital Twins

The Internet of Things (IoT) is playing an increasingly important role in sheet metal spinning by enabling machines to communicate with each other and with centralized systems in real time. IoT-enabled machines can transmit data on parameters such as material usage, machine health, and production rates, allowing manufacturers to monitor their entire production process remotely. This connectivity provides valuable insights into machine performance, helping operators identify bottlenecks, optimize workflows, and improve efficiency.

Digital twins, which are virtual representations of physical machines, are another powerful tool in modern sheet metal spinning. Digital twins allow manufacturers to simulate the behavior of a machine or production line under various conditions, providing insights into how changes to the process could impact performance. By using digital twins to test different scenarios, manufacturers can make data-driven decisions that improve production outcomes and reduce risk.

The Future of Sheet Metal Spinning

The future of sheet metal spinning is filled with exciting possibilities, driven by advancements in automation, AI, and hybrid manufacturing techniques. As these technologies continue to evolve, sheet metal spinning will become even more efficient, precise, and adaptable. With the continued integration of advanced materials, real-time monitoring, and predictive maintenance, manufacturers will be able to produce parts faster and with greater accuracy, all while minimizing waste and reducing costs.

As industries demand more complex, customized, and high-performance parts, sheet metal spinning will remain a key part of the manufacturing landscape. With innovations in energy efficiency, materials, and digital technologies, the process will continue to evolve, opening new doors for industries like aerospace, automotive, and beyond.

Expanding the Scope of Sheet Metal Spinning in Custom and Complex Part Production

As industries continue to demand more customized and complex components, sheet metal spinning is proving to be a versatile and effective method for meeting these needs. One of the primary benefits of spinning is its ability to create parts with intricate shapes that would otherwise be difficult or time-consuming to produce using traditional methods like stamping or casting. In particular, spinning excels at producing parts with conical, cylindrical, or spherical geometries, but modern technology has expanded its ability to handle more complex forms.

For example, in aerospace, automotive, and medical device industries, sheet metal spinning is often used to produce custom parts such as specialized enclosures, heat shields, turbine components, or even medical implants. These parts frequently require precise material thickness distribution, complex shapes, and custom dimensions. In these cases, spinning can provide both the accuracy and flexibility needed to produce high-performance, one-of-a-kind parts at scale.

Additionally, as the demand for high-value, low-volume production increases, sheet metal spinning is becoming more prominent in small-batch and prototype manufacturing. The ability to rapidly change tooling and adjust machine parameters makes spinning ideal for industries that require fast prototyping with minimal lead times. Rather than relying on costly and time-consuming tooling modifications or casting molds, manufacturers can leverage the flexibility of spinning to test new designs and bring products to market more quickly.

Integration of Advanced Tooling for Precision

The precision required in modern sheet metal spinning applications has led to significant advancements in tooling technology. In traditional spinning, tools such as rollers, mandrels, and forming tools are essential for shaping the material. The accuracy of these tools directly affects the quality of the final product. As the demand for tighter tolerances and higher-quality components increases, tooling innovations are becoming more crucial.

Recent developments in tool design include the use of high-performance materials for rollers and mandrels that reduce wear and improve the longevity of tooling components. Tools are also being engineered with interchangeable parts, allowing manufacturers to quickly switch between different setups depending on the job. This modularity not only reduces downtime but also provides manufacturers with more flexibility to handle a wider variety of materials, geometries, and production volumes.

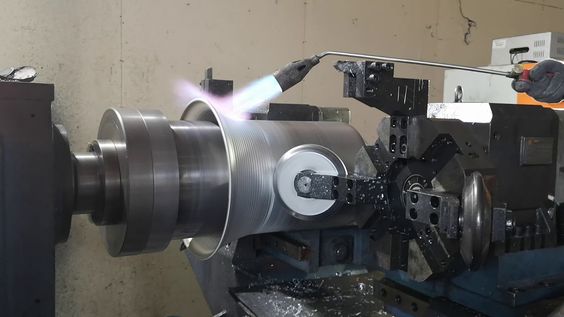

To further improve precision, there are also advances in laser-assisted spinning, which integrates laser heating with the spinning process. The addition of a laser beam helps to preheat the material before it is spun, allowing for better control over material flow and reducing the risk of cracking or distortion in harder metals. This process is particularly beneficial when working with high-strength alloys or metals with poor formability, enabling manufacturers to produce precise, high-quality parts without compromising on material properties.

Tightening Environmental Regulations and Sustainability

With increasing environmental concerns and tighter regulations on industrial emissions and waste, manufacturers are under pressure to adopt more sustainable practices. Sheet metal spinning, as a process that generates minimal waste and has low energy requirements, aligns well with these sustainability goals.

Unlike processes like stamping or die casting, which often produce a significant amount of scrap material, spinning uses the material more efficiently by forming parts from a single piece of metal. This leads to minimal waste, particularly for industries that require high-performance materials that are costly or difficult to obtain, such as titanium or certain high-strength alloys. By reducing material waste, sheet metal spinning contributes to the overall sustainability of the manufacturing process.

Furthermore, spinning can be integrated with recycling systems to reuse scrap material generated during the process. In the case of certain metals, such as aluminum, the scrap generated during spinning can be easily melted down and reused without compromising the material’s properties. This reduces the need for virgin material and helps manufacturers minimize their environmental impact.

In addition to reducing waste, spinning machines are becoming more energy-efficient. Innovations in machine design, such as the use of more efficient motors, servo drives, and regenerative braking systems, are helping manufacturers lower energy consumption during production. Combined with the trend toward reducing emissions and improving sustainability in the broader manufacturing landscape, sheet metal spinning can be a key player in helping manufacturers meet new environmental standards.

Advancing the Versatility of Spinning for Multi-Functional Parts

Another exciting development in sheet metal spinning is the ability to produce multi-functional parts with integrated features. In the past, components produced by spinning were mostly basic geometric shapes, but as the technology evolves, manufacturers are pushing the limits to create parts with more advanced functionality.

In applications like aerospace and automotive manufacturing, where weight savings and functionality are paramount, manufacturers are starting to use spinning to create parts with integrated features such as mounting holes, brackets, or channels. These features, which would traditionally require additional machining or assembly, can be incorporated directly into the spinning process, reducing production steps and material handling. This not only improves efficiency but also reduces part complexity and assembly costs.

Additionally, some industries are experimenting with the use of spun parts that include embedded components or sensors. For instance, in industries that require high levels of monitoring or control (e.g., the medical or automotive sectors), spun parts might be designed with internal passageways to house sensors or electronics. The ability to form these parts in one continuous process reduces the need for post-processing or assembly, improving both the efficiency and quality of the final product.

Sheet Metal Spinning in the Digital Manufacturing Era

As manufacturing becomes increasingly digital, the role of sheet metal spinning continues to evolve. The introduction of digital twins and smart manufacturing technologies into spinning is reshaping how parts are designed, produced, and monitored. Digital twins—virtual representations of physical spinning machines—allow for real-time monitoring and analysis of the entire production process.

This level of connectivity enables manufacturers to have a digital replica of their entire production line, where they can simulate different process parameters and make adjustments based on real-time data. By using sensors and IoT technology, the machine’s behavior and performance can be tracked, ensuring that the machine operates at optimal levels. This data can then be analyzed to improve future designs, optimize machine settings, and predict maintenance needs.

Furthermore, additive manufacturing is being integrated into digital manufacturing workflows, making it possible to combine spinning with 3D printing for more complex and customized designs. For instance, digital manufacturing platforms allow designers to upload CAD files, and the software can generate the necessary tool paths for both the spinning and 3D printing processes. This seamless integration of spinning and additive manufacturing opens up new possibilities for the production of highly customized parts, especially those that require intricate internal features or complex geometries.

The Role of Artificial Intelligence in Process Optimization

Artificial intelligence (AI) has the potential to revolutionize many aspects of sheet metal spinning, particularly in process optimization. AI can be employed to optimize machine settings, predict material behavior, and improve efficiency across the entire production cycle. For instance, by analyzing data collected during the spinning process, AI algorithms can predict how the material will respond to different spinning parameters, such as tool pressure or speed, and adjust these parameters in real-time to improve the quality of the finished part.

AI can also be used to develop more sophisticated quality control systems. By using computer vision and machine learning algorithms, AI systems can inspect parts during and after the spinning process, identifying defects such as cracks, inconsistent thickness, or surface irregularities. This level of quality control ensures that only high-quality parts make it through the production line, reducing the likelihood of defects reaching the customer and improving overall product reliability.

Additionally, AI-driven predictive maintenance systems are becoming a key tool in reducing machine downtime. By continuously monitoring machine health and analyzing performance data, AI can predict when parts will need maintenance or replacement, preventing unexpected failures that could halt production. This predictive capability helps manufacturers avoid costly repairs and delays, ultimately enhancing the efficiency and profitability of their operations.

Closing Thoughts on the Future of Sheet Metal Spinning

Sheet metal spinning continues to evolve as a critical manufacturing process for producing complex, high-quality parts across a wide range of industries. With the integration of advanced automation, CNC systems, hybrid manufacturing technologies, and AI, the capabilities of spinning machines are expanding rapidly. These innovations make it possible to produce more precise, energy-efficient, and sustainable parts, all while minimizing waste and reducing lead times.

As industries demand more custom, multi-functional, and high-performance parts, sheet metal spinning is poised to meet these challenges and play a central role in the next generation of manufacturing. Whether through advancements in materials, robotics, AI, or digital manufacturing technologies, the future of sheet metal spinning is bright, and it will undoubtedly continue to shape the landscape of modern manufacturing for years to come.

Enhancing Customization with Digital Design Tools

As the demand for highly customized and unique parts continues to grow, digital design tools are playing a crucial role in enabling the next generation of sheet metal spinning. Designers and engineers can now use advanced CAD (Computer-Aided Design) software to create complex geometries that are easily transferred to CNC systems for spinning. These digital design tools allow for precise customization of every aspect of a part, from material selection and geometry to surface finish and functional features.

With CAD software, it’s now possible to incorporate intricate designs that were once difficult or impractical to achieve using traditional manufacturing methods. Designers can experiment with different geometries, create 3D models, and visualize the finished product before production even begins. This greatly reduces the time required for prototyping and ensures that any design flaws or inconsistencies are detected early in the process.

Moreover, the integration of CAD software with CNC machines enables real-time modification of design specifications. If adjustments need to be made to accommodate a change in material, size, or tolerance, manufacturers can easily update the digital model and immediately apply these changes to the machine’s programming. This seamless connection between digital design and physical production is a significant step forward in enhancing flexibility and customization in sheet metal spinning.

Real-Time Quality Control and Inspection Using AI and Computer Vision

Quality control is a critical aspect of sheet metal spinning, especially when dealing with high-precision parts for industries such as aerospace, automotive, and medical devices. Real-time quality control systems, which leverage AI and computer vision technologies, are revolutionizing the way parts are inspected during the spinning process.

AI-powered computer vision systems can continuously monitor the geometry, surface finish, and overall quality of each part during production. These systems use high-resolution cameras and image processing algorithms to detect surface defects, dimensional inconsistencies, or imperfections that might not be visible to the naked eye. By comparing the part’s current state to its digital design, these systems can flag any deviations from the desired specifications and adjust the machine parameters in real-time to correct the issue.

This approach to quality control significantly reduces the likelihood of defects and ensures that only parts meeting the highest standards reach the final stage of production. Furthermore, the data collected by these systems can be used to build a comprehensive quality history, allowing manufacturers to track trends and identify areas for improvement in both the spinning process and machine performance.

The integration of AI and computer vision in quality control not only speeds up inspection but also helps to maintain consistency and reduce human error. In high-stakes applications like aerospace or medical device manufacturing, the ability to ensure flawless parts during production is essential, and these technologies offer a solution to meet these stringent requirements.

Customization and Low-Volume Production

The versatility of sheet metal spinning makes it an ideal process for producing low-volume, high-customization parts. Unlike other manufacturing processes that may require expensive molds or tooling for mass production, spinning can produce a wide variety of parts with different sizes, shapes, and materials using the same set of equipment. This flexibility makes spinning especially useful for industries that need to produce specialized parts in small quantities.

For example, in the aerospace and automotive industries, manufacturers often need to create prototypes, custom components, or replacement parts for older models. Sheet metal spinning allows them to produce these parts quickly and at lower cost compared to methods like die casting or stamping, which require custom molds for each design. This capability is invaluable when dealing with rapidly evolving designs or low-volume orders where tooling costs would be prohibitive.

Spinning is also becoming more prominent in the medical device industry, where custom parts like implants, surgical tools, and enclosures are needed in relatively small quantities but with precise, high-performance specifications. The ability to customize every aspect of the part—from material selection to geometry—makes sheet metal spinning an excellent option for these specialized applications.

Advancements in Tooling Technology for Improved Precision

As the demand for high-precision, complex components increases, the development of advanced tooling technology for sheet metal spinning is crucial. Tooling innovations have focused on improving both the quality of the finished part and the efficiency of the spinning process itself.

For example, the use of multi-axis tooling has gained traction in sheet metal spinning. Traditional spinning machines typically use single-axis tooling that shapes the metal around a fixed mandrel, but multi-axis tooling allows the material to be shaped along multiple directions simultaneously. This leads to greater design flexibility and the ability to create more complex geometries in less time.

Additionally, innovations in materials for tooling components—such as harder, more durable alloys and coatings—are extending the lifespan of tools and improving their performance in demanding applications. These advanced tooling materials help minimize wear and tear, ensuring that the spinning process remains stable and accurate over longer production runs.

Furthermore, as technology advances, automatic tool changers are being introduced to reduce the downtime associated with switching between different tools for various parts. This further increases the machine’s efficiency and versatility, allowing manufacturers to easily switch between producing different geometries or material types without significant delays.

Integration of Robotics for Automation and Precision

Robotic automation is increasingly being integrated into sheet metal spinning systems to enhance both productivity and precision. Robotic arms are used for tasks such as loading and unloading raw materials, adjusting machine settings, and removing finished parts. These robots can work tirelessly around the clock, ensuring a consistent level of productivity while minimizing labor costs.

In addition to handling basic tasks, robots can also assist in fine-tuning the spinning process. For instance, robots equipped with sensors can measure the temperature, pressure, and material deformation during spinning, providing valuable data to the machine’s control system. This data can be used to adjust the spinning parameters dynamically, ensuring that the part is formed with the desired specifications.

Moreover, robotic systems are often equipped with vision systems that allow them to identify defects in the material or in the spun part itself. This visual feedback can be used to halt production or adjust machine settings in real-time, preventing errors and defects from propagating through the production cycle.

The automation of repetitive tasks not only increases efficiency but also frees up human workers to focus on more complex, high-value activities, such as troubleshooting, machine programming, and quality control. The result is a more efficient, cost-effective, and precise production process that meets the demands of modern manufacturing.

The Role of Data Analytics in Spinning Optimization

Data analytics is becoming increasingly important in optimizing the sheet metal spinning process. By collecting and analyzing data from the machine’s sensors, operators can gain valuable insights into the performance of the machine, material behavior, and the efficiency of the overall process. This data can be used to identify patterns and trends, allowing manufacturers to make data-driven decisions that improve both productivity and product quality.

For example, by analyzing historical data, manufacturers can identify recurring issues or inefficiencies in the spinning process and take corrective actions. Predictive analytics can also be used to anticipate maintenance needs and minimize downtime, as data analytics tools can detect early signs of equipment wear or malfunction.

Furthermore, data analytics can provide insights into material usage, helping manufacturers optimize material consumption and reduce waste. By monitoring factors such as material thickness variation and deformation during the spinning process, manufacturers can make adjustments to ensure that the material is used as efficiently as possible.

The integration of data analytics tools with the spinning process provides a higher level of control over production and allows manufacturers to fine-tune their processes, resulting in cost savings, improved quality, and greater efficiency.

Future Trends: AI-Driven Design and Autonomous Spinning Systems

Looking to the future, artificial intelligence (AI) is set to play an even more significant role in sheet metal spinning. AI-driven design tools are already emerging that allow manufacturers to input a basic set of parameters (such as material type, part size, and desired properties) and automatically generate optimized part designs. These AI systems can take into account the complexities of material behavior, machine capabilities, and even environmental factors to suggest the most efficient and effective designs for spinning.

Autonomous spinning systems, which can operate with minimal human intervention, are another exciting future trend. These systems would combine AI, machine learning, and advanced robotics to autonomously carry out the spinning process from start to finish. By learning from historical data, autonomous systems could optimize every aspect of the process, from tool adjustments to material flow and quality control, ensuring that each part is produced with maximum efficiency and accuracy.

These autonomous systems could also improve the flexibility of sheet metal spinning by allowing for real-time, on-the-fly adjustments based on changes in material properties or part design. As AI and machine learning technologies continue to improve, the potential for fully autonomous, AI-driven sheet metal spinning systems could revolutionize the industry by offering unparalleled levels of customization, speed, and precision.

Conclusion: A Bright Future for Sheet Metal Spinning

The future of sheet metal spinning is bright, with a host of technological advancements paving the way for greater efficiency, precision, and flexibility. Automation, AI, robotics, data analytics, and advanced tooling technologies are all contributing to the evolution of the process, allowing manufacturers to meet the growing demand for customized, high-performance parts.

As industries continue to demand more complex geometries, lighter-weight components, and more sustainable practices, sheet metal spinning will remain a vital manufacturing process. With ongoing innovations and the increasing integration of digital tools, spinning is poised to play a central role in the future of modern manufacturing, from high-precision aerospace components to customized medical devices.

In the coming years, sheet metal spinning will continue to evolve alongside the broader trends of automation, digital manufacturing, and Industry 4.0, further establishing its role as a key technology in the production of advanced, high-quality components across diverse industries.

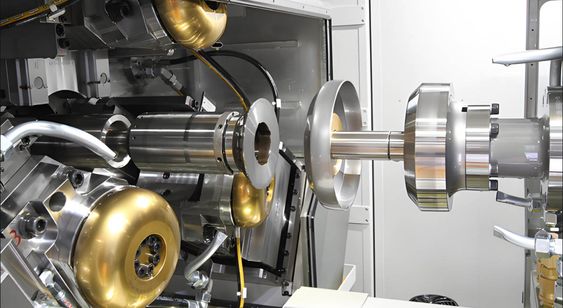

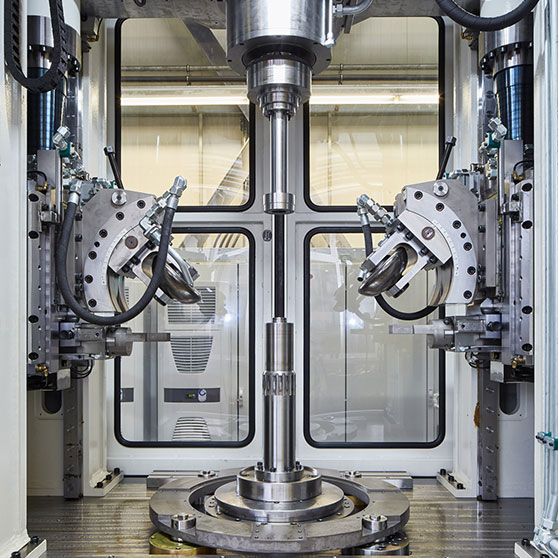

High-Speed Rotary Forging Machine: An Overview

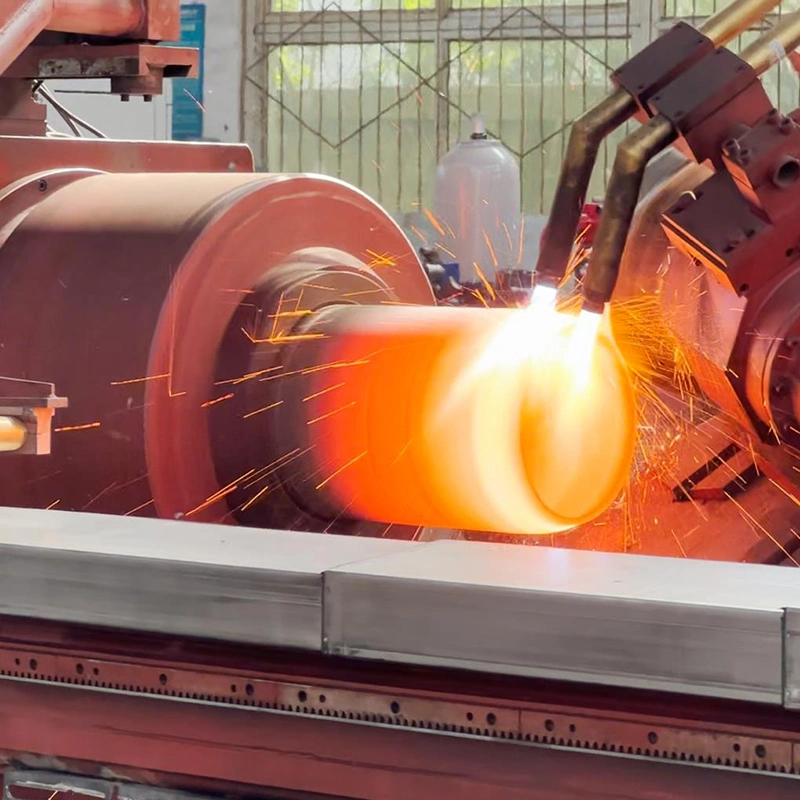

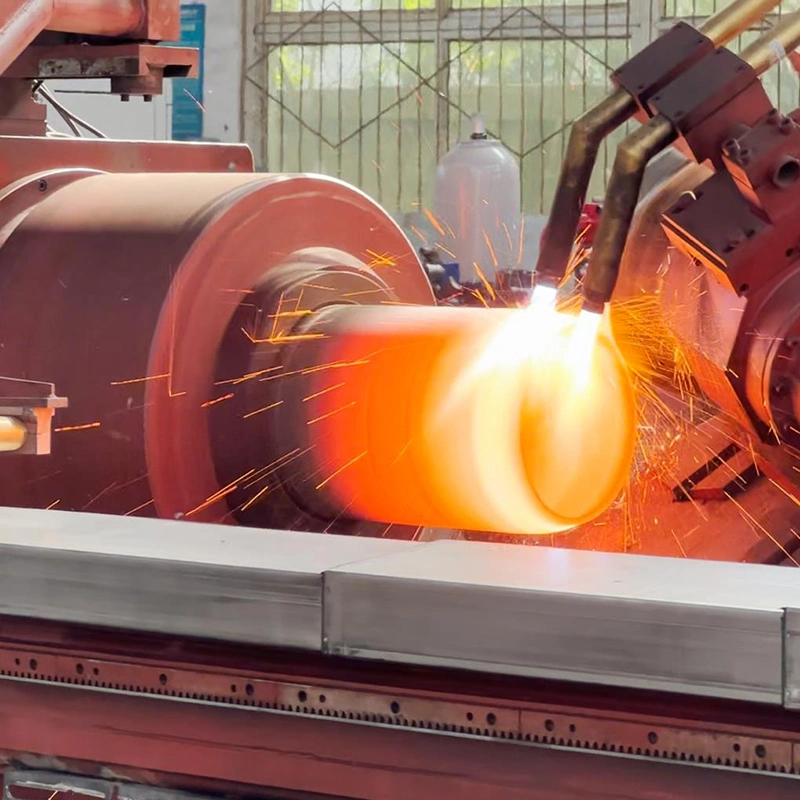

A high-speed rotary forging machine is a specialized piece of equipment used in the forging industry to create high-precision components from metal billets. It operates through the principle of rotary forging, where a rotating die applies localized pressure to a rotating workpiece, causing it to deform plastically and take the shape of the die cavity. This process is often used to produce parts that require superior mechanical properties and fine tolerances, such as automotive components, aerospace parts, and medical devices.

The high-speed aspect of the rotary forging machine refers to its ability to operate at much faster speeds than traditional forging machines. By utilizing high rotational speeds, these machines can significantly reduce cycle times while maintaining high levels of precision and part quality. The fast rotation generates a large amount of energy, which facilitates rapid deformation of the material, allowing for the creation of parts with complex shapes and geometries.

Here’s a detailed breakdown of the key features, advantages, and applications of high-speed rotary forging machines:

1. Principle of Operation

In rotary forging, the workpiece (usually a metal billet) is rotated while a set of dies applies force in a controlled manner. The dies compress the material, causing it to flow into the die cavity and form the desired shape. Unlike traditional forging methods, where the die simply presses the workpiece into shape, rotary forging involves both rotational motion and axial force, which leads to more efficient material flow and reduced internal stresses.

The high-speed operation is achieved by rotating the workpiece at a much faster speed, which increases the impact force applied to the metal. This enhanced speed allows for faster production times and the ability to forge parts with greater precision.

2. Key Components of High-Speed Rotary Forging Machines

- Rotating Workpiece: The core element of the machine, where the billet is secured and rotated at high speeds. The workpiece may rotate at speeds ranging from several hundred to several thousand RPM (revolutions per minute), depending on the material and required forging characteristics.

- Dies: The dies are designed to apply the forging force and shape the workpiece. They are typically made from hardened tool steel or other wear-resistant materials to withstand the stresses of high-speed operation.

- Spindle and Motor: The motor and spindle system are responsible for driving the workpiece and rotating it at the desired speed. These components must be designed for durability and reliability under high rotational speeds.

- Hydraulic or Pneumatic Actuators: These provide the axial force necessary to press the dies against the rotating workpiece. The force can be adjusted based on the material being forged and the complexity of the part.

- Control System: The machine is often equipped with a sophisticated control system that monitors and adjusts the speed, force, and rotation to ensure precise and repeatable results. This system may use sensors and feedback loops to adjust the process parameters in real time.

3. Advantages of High-Speed Rotary Forging Machines

- Reduced Cycle Time: By rotating the workpiece at high speeds, rotary forging machines significantly reduce the amount of time needed to shape a part. This makes the process much faster than traditional forging methods.

- Improved Material Properties: High-speed forging allows for better grain refinement, which leads to superior mechanical properties in the finished part. This is particularly beneficial for applications that require parts with high strength, durability, and resistance to wear.

- High Precision and Tolerance: The controlled application of force and the rotating motion ensure that the material flows evenly, reducing defects and improving dimensional accuracy. This is essential for producing parts with tight tolerances and high-quality finishes.

- Energy Efficiency: High-speed rotary forging uses less energy compared to traditional forging methods that rely on slow, massive press movements. The process is more efficient because the rotational energy is concentrated and used to deform the material quickly and precisely.

- Complex Geometries: Rotary forging machines can create parts with complex shapes, including those with intricate internal features, without the need for extensive secondary machining. This capability is useful in industries like aerospace, where parts often require lightweight, yet structurally strong components with complicated geometries.

4. Applications of High-Speed Rotary Forging Machines

- Aerospace Industry: The aerospace sector relies on rotary forging for producing lightweight, high-strength parts such as turbine blades, engine components, and landing gear parts. The ability to forge parts with complex geometries and high mechanical properties makes rotary forging ideal for these applications.

- Automotive Industry: High-speed rotary forging is used to create components such as gears, shafts, and crankshafts. These parts require excellent wear resistance and strength, which can be achieved through rotary forging, even in challenging materials like high-strength steel or titanium alloys.

- Medical Devices: In the medical industry, rotary forging is employed to manufacture components like orthopedic implants, surgical tools, and dental products. These parts need to meet high standards of strength, biocompatibility, and precision, making high-speed rotary forging a preferred method.

- Oil and Gas: The oil and gas industry uses rotary forging to produce parts like valves, pump shafts, and downhole equipment. These parts need to endure extreme pressure and corrosive environments, which can be achieved by forging high-quality materials with fine grain structures.

- Energy Sector: Components for turbines, generators, and other energy-producing equipment benefit from the strength and precision provided by rotary forging. High-speed forging ensures that these components are manufactured quickly while maintaining the necessary structural integrity.

5. Challenges and Considerations

While high-speed rotary forging offers numerous benefits, there are some challenges and considerations to keep in mind:

- Material Limitations: Some materials may not be well-suited for high-speed rotary forging, especially if they have low ductility or tend to work-harden quickly. Proper material selection is crucial to ensure the forging process is successful.

- Tool Wear: The high-speed operation places significant stress on the dies and other tooling components, leading to increased wear. Tooling materials need to be highly durable and resistant to deformation to maintain part quality and minimize downtime.

- Complex Setup: While rotary forging machines can produce highly precise parts, they require careful setup and calibration to ensure that the machine operates at optimal efficiency. The setup process can be complex, especially for parts with intricate geometries.

- Cost of Equipment: High-speed rotary forging machines can be expensive to purchase and maintain. However, the benefits in terms of precision and speed often justify the investment for manufacturers producing high-volume, high-quality parts.

6. Recent Advancements in High-Speed Rotary Forging Technology

- Automation and Integration: The integration of automation systems, including robotic arms and automated material handling systems, has further improved the efficiency of high-speed rotary forging machines. These systems can automate tasks such as loading and unloading billets, reducing labor costs and improving overall throughput.

- Enhanced Control Systems: Modern rotary forging machines now feature advanced computer control systems that enable real-time monitoring of the forging process. These systems can adjust parameters such as speed, pressure, and rotation to optimize part quality and reduce waste.

- Hybrid Technologies: Some manufacturers are experimenting with hybrid systems that combine high-speed rotary forging with other processes, such as additive manufacturing or heat treatment. These hybrid systems allow for even more complex part designs and improved material properties.

- Advanced Tooling Materials: The development of advanced materials for tooling, such as coated carbide or ceramic dies, has helped extend the lifespan of tooling components and improve the durability of the forging process.

7. Future Outlook for High-Speed Rotary Forging

As industries continue to demand parts with higher precision, strength, and complexity, the role of high-speed rotary forging is expected to grow. The demand for lightweight and high-performance materials, especially in aerospace and automotive applications, will drive further adoption of this technology. Additionally, as manufacturing processes become more automated and integrated with digital technologies, rotary forging will continue to evolve, offering even faster production times and better material utilization.

In conclusion, high-speed rotary forging machines are an essential tool in modern manufacturing, offering a range of benefits from improved cycle times and material properties to the ability to produce complex geometries. As technological advancements continue, the capabilities of these machines will expand, enabling manufacturers to meet the ever-increasing demands of industries requiring high-performance, precision-engineered components.

High-speed rotary forging machines have revolutionized the manufacturing of high-precision components by enabling the rapid production of parts with excellent mechanical properties and fine tolerances. This technology uses the principle of rotating the workpiece while applying localized pressure through dies, facilitating the deformation of the material into the desired shape. The high-speed aspect of the machine significantly reduces cycle times, making it an ideal solution for industries where speed and precision are paramount.

These machines operate by rotating the workpiece at speeds ranging from several hundred to several thousand RPM, depending on the material and specifications of the part. The rotation generates energy that aids in the efficient deformation of the metal, resulting in faster cycle times compared to traditional forging methods. As the workpiece spins, it is subjected to axial pressure from the dies, which compress the metal and cause it to flow into the cavity of the die, forming the part.

The high-speed forging process also enhances the material properties of the final part. The rapid deformation reduces internal stresses, and the controlled application of pressure leads to fine grain refinement, which improves the strength and toughness of the part. This is particularly advantageous for producing components that require high strength-to-weight ratios, such as aerospace and automotive parts. The process also enables the production of complex geometries and intricate features that would be difficult or impossible to achieve with traditional forging techniques. As a result, high-speed rotary forging is becoming increasingly popular in industries like aerospace, automotive, medical, and energy production, where the demand for lightweight, durable, and high-performance parts is growing.

In addition to the enhanced material properties, high-speed rotary forging machines offer a significant reduction in cycle time, which leads to increased production efficiency and reduced costs. The rapid rotation and deformation allow manufacturers to produce parts more quickly than with traditional forging methods. Furthermore, the process is highly precise, with tight tolerances and minimal need for secondary machining. This makes it an attractive option for manufacturers looking to streamline production and reduce the overall cost per part.

One of the key advantages of high-speed rotary forging is its ability to produce parts with complex shapes and features without the need for additional machining. The process allows for the creation of intricate internal geometries, such as holes, flanges, and ribs, which can be difficult to achieve with other methods like casting or stamping. This ability to forge complex shapes directly reduces the need for costly post-processing steps, further improving the cost-effectiveness of the process.

Despite its numerous benefits, there are challenges associated with high-speed rotary forging. One of the main challenges is the wear on tooling due to the high rotational speeds and pressures involved. The dies and other tooling components are subjected to significant stresses, and therefore, durable materials like hardened tool steel or carbide are used to withstand the abrasive forces. Manufacturers also need to ensure that the machine is properly calibrated for each specific part to avoid defects and ensure optimal material flow.

The material selection for rotary forging is another crucial factor. While the process works well for a wide range of metals, some materials may not be suitable due to their low ductility or tendency to work-harden quickly. It is important to choose materials that can handle the high pressures and rotational speeds required by the machine without cracking or failing during the forging process. Common materials used for high-speed rotary forging include steel alloys, titanium, and aluminum, which offer good balance between strength and formability.

The integration of automation and advanced control systems has further enhanced the capabilities of high-speed rotary forging machines. Modern machines are equipped with sophisticated control systems that monitor parameters like speed, pressure, and material deformation in real-time. These systems help maintain consistent quality and precision, adjusting the machine’s settings as needed to accommodate different materials and part designs. In some cases, robotic arms and automated material handling systems are integrated into the forging process, reducing the need for manual labor and further increasing production efficiency.

Looking ahead, the future of high-speed rotary forging is promising. With advancements in machine design, materials, and automation, the capabilities of these machines will continue to evolve. Manufacturers are exploring hybrid systems that combine rotary forging with other processes, such as additive manufacturing or heat treatment, to produce even more complex and high-performance parts. The growing demand for custom, lightweight, and high-strength components, especially in industries like aerospace, automotive, and medical devices, is expected to drive further adoption of high-speed rotary forging technologies.

Overall, high-speed rotary forging machines are an essential tool in modern manufacturing. They provide manufacturers with a fast, precise, and efficient method for producing high-quality components that meet the rigorous demands of various industries. As technology continues to advance, the ability to produce complex geometries, improve material properties, and reduce cycle times will further solidify the role of rotary forging in the future of manufacturing.

As the industry evolves, the integration of digital technologies will play a crucial role in enhancing the capabilities of high-speed rotary forging machines. One of the key advancements expected to shape the future of rotary forging is the use of smart manufacturing techniques. By embedding sensors and using Internet of Things (IoT) technology, manufacturers can monitor every aspect of the forging process in real-time. This connectivity will enable predictive maintenance, process optimization, and greater control over part quality. For example, sensors placed in the machine can monitor temperature, pressure, and force during the forging process, and the system can use this data to predict when maintenance is required or adjust parameters automatically to optimize the process for each specific part.

Another area of growth lies in machine learning and artificial intelligence (AI). By applying AI algorithms to the data collected from the machines, manufacturers can refine their processes over time, allowing the machine to “learn” from previous forging cycles and optimize future production runs. For example, AI can analyze patterns in the data and suggest modifications in rotational speed, pressure, or material handling to improve the final product quality and reduce waste. This level of automation can further enhance the speed and precision of high-speed rotary forging machines, ensuring that manufacturers can meet increasing demands for complex and high-quality parts.

Additionally, virtual simulations are becoming an increasingly important tool in the design and planning stages of rotary forging. Before a part is even forged, manufacturers can use simulation software to model how the material will behave under specific conditions, taking into account factors such as material properties, die geometry, and applied forces. These simulations can help engineers optimize part designs, tooling, and process parameters, allowing for faster development cycles and reduced trial-and-error during physical production.

Additive manufacturing (3D printing) is also expected to influence the future of rotary forging. In some cases, additive manufacturing technologies can be used to create complex, high-precision parts that can later be forged using high-speed rotary machines. The combination of both technologies could enable the creation of intricate geometries that were once impossible or prohibitively expensive to produce using traditional methods. This could be especially beneficial in industries like aerospace, where weight savings and component complexity are paramount.

With these advancements, the demand for sustainability and resource efficiency in manufacturing is also growing. High-speed rotary forging offers inherent advantages in terms of material utilization, as the process typically generates minimal waste compared to casting or machining. However, manufacturers will continue to explore ways to reduce energy consumption, optimize material usage, and improve the recyclability of scrap metal. Innovations in tooling materials, such as coatings that reduce wear and improve the lifespan of dies, can also contribute to more sustainable manufacturing practices.

In addition to technological advancements, the global shift towards Industry 4.0 is also influencing high-speed rotary forging. As part of this movement, companies are embracing smart factories that integrate advanced automation, real-time data analysis, and supply chain connectivity. High-speed rotary forging machines will increasingly be part of these connected systems, providing real-time updates on production status, part quality, and machine performance. This level of integration will enhance overall efficiency and responsiveness, helping manufacturers to quickly adapt to changes in demand and ensure high levels of product consistency.

The globalization of manufacturing also plays a significant role in the future of high-speed rotary forging. As industries across the world demand high-performance parts, the ability to produce them quickly, efficiently, and at scale is essential. High-speed rotary forging machines, with their ability to reduce cycle times and maintain high levels of precision, are well-suited to meet the needs of global markets. Additionally, the ability to produce high-quality parts in lower volumes, with minimal tooling changes, is particularly advantageous for manufacturers catering to industries with rapidly changing specifications or low-volume production runs.

In conclusion, the future of high-speed rotary forging is closely tied to continued technological advancements in automation, data analytics, AI, and sustainability. These innovations will further enhance the precision, speed, and cost-effectiveness of the process, making it an even more attractive solution for industries that demand high-performance components. As manufacturers continue to push the boundaries of what’s possible with high-speed rotary forging, we can expect to see even more sophisticated and complex components produced with greater efficiency, higher quality, and less waste. The combination of these innovations will help shape the next generation of manufacturing and allow high-speed rotary forging to remain at the forefront of precision engineering for years to come.

As the demand for high-performance components increases across various industries, the role of high-speed rotary forging will continue to evolve. Future developments are expected to improve the machine’s versatility, allowing manufacturers to produce a broader range of materials and parts with more intricate designs. One of the significant future directions is the ability to forge advanced composite materials or non-ferrous alloys that are becoming more popular in industries like aerospace and automotive. These materials often require specialized forging techniques due to their unique properties, such as lightweight characteristics or resistance to high temperatures. High-speed rotary forging’s ability to produce such parts with precision will be a crucial asset as industries move towards more advanced materials.

Another anticipated advancement is in the development of multi-material forging capabilities. The ability to combine different materials in a single forging process opens up new possibilities for creating parts that offer a combination of the best properties from multiple materials. For example, a part could have a tough outer layer to resist wear while maintaining a lighter, more flexible inner core. Multi-material forging requires a high level of precision and control, and high-speed rotary forging is uniquely suited to this challenge due to its precise force application and the ability to manipulate material flow in complex ways.

The integration of robotics is expected to become more prominent in high-speed rotary forging systems. Robots could be used for tasks such as part handling, die changing, and post-forging operations like quality inspection. This would not only increase efficiency but also enhance consistency in the production process. Furthermore, the introduction of robotic systems could reduce operator exposure to the high-speed machinery, improving safety in the workplace.