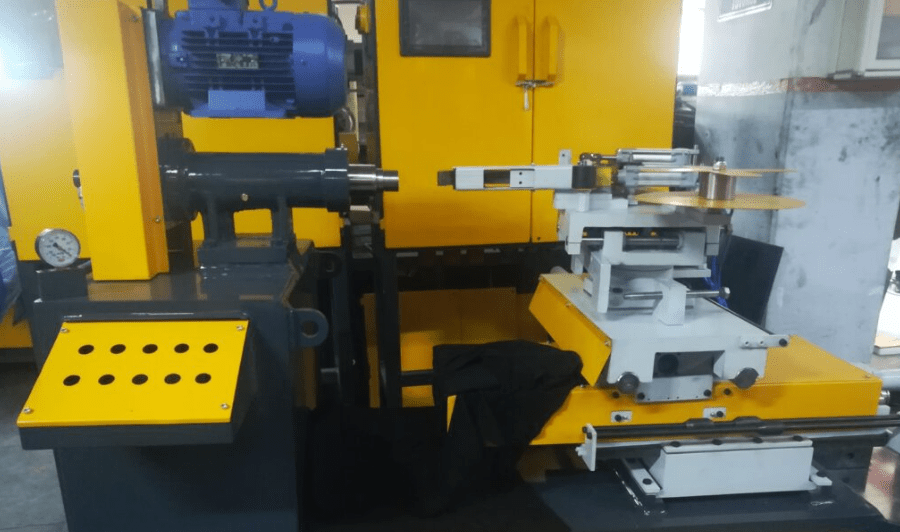

Double-Disc Cylindrical Grinding Machine: Centerless Grinding is a machining process that removes material from the outside of a cylindrical workpiece without using a spindle or fixture to hold the part in place. Instead, the workpiece is supported by a work rest blade and is rotated by a regulating (or control) wheel and ground by a grinding wheel.

Key Components of Grinding Machines:

- Grinding Wheel – Does the actual material removal.

- Regulating Wheel – Controls the rotational speed and axial movement of the workpiece.

- Work Rest Blade – Supports the workpiece during grinding.

Types of Centerless Grinding:

- Through-feed Grinding

- The workpiece passes through the machine in a straight line.

- Ideal for simple cylindrical shapes.

- In-feed (or Plunge) Grinding

- The workpiece is inserted in a fixed position and ground in one area.

- Suitable for more complex shapes (like shoulders, grooves).

- End-feed Grinding

- The workpiece is axially fed into the machine, then withdrawn.

- Used for tapered or complex parts.

Advantages:

- High production rates.

- No need for center holes or fixtures.

- High precision and surface finish.

- Excellent for mass production.

Applications:

- Automotive components (valve stems, piston pins).

- Bearing races.

- Hydraulic rods.

- Pins and bushings.

- Medical devices and tools.

Centerless grinding is a high-precision machining process used to remove material from the outside of a cylindrical workpiece without using a center or chuck. Unlike traditional cylindrical grinding, in which the workpiece is held in place by a spindle or between centers, centerless grinding holds the workpiece between a grinding wheel, a regulating wheel, and a work rest blade. The grinding wheel performs the cutting, while the regulating wheel controls the rotation and feed rate of the workpiece.

The work rest blade supports the workpiece from below, positioning it at the correct height for grinding. There are three primary methods of centerless grinding: through-feed, in-feed (plunge), and end-feed. In through-feed grinding, the workpiece is continuously fed through the grinding and regulating wheels, making it efficient for high-volume production of simple cylindrical parts. In in-feed grinding, the workpiece is placed in position and ground in a fixed location, allowing for more complex shapes like shoulders or steps.

End-feed grinding involves feeding the part axially into the grinding zone and then withdrawing it, which is used for tapered or curved components. Centerless grinding offers several advantages, including high throughput, superior surface finish, tight tolerances, and the ability to grind long or slender workpieces that might deflect under traditional clamping. This process is widely used in industries such as automotive, aerospace, medical device manufacturing, and tool making, where precision cylindrical parts like shafts, rods, bushings, and pins are required in large quantities. Its efficiency and consistency make it ideal for mass production environments where speed and accuracy are crucial.

The effectiveness of centerless grinding largely depends on precise setup and control of the machine parameters. The relationship between the grinding wheel, the regulating wheel, and the work rest blade must be carefully adjusted to maintain the desired tolerance and surface finish. The positioning angle of the regulating wheel is crucial, as it determines the speed at which the workpiece is fed through the wheels. Small changes in this angle can significantly affect part geometry and cycle time. Additionally, the hardness, grit size, and bonding of the grinding wheel must be selected based on the material of the workpiece and the required finish. Proper coolant application is also vital; it reduces heat generation, prevents thermal expansion of the part, and flushes away debris.

Automation has further enhanced centerless grinding, with modern CNC machines allowing for adaptive control, automatic compensation for wheel wear, and real-time quality monitoring. This ensures consistently high-quality results, even in lights-out manufacturing environments. Despite its advantages, centerless grinding requires skilled setup and operation, as improper adjustment can lead to roundness errors, taper, or chatter marks on the workpiece. However, when properly managed, it remains one of the most efficient and precise methods for producing high volumes of round parts with minimal waste and downtime.

In addition to its efficiency and precision, centerless grinding is highly versatile in handling different materials and sizes. It can be used on a wide range of metals including steel, aluminum, brass, and titanium, as well as on hard and brittle materials like ceramics and carbides. The process is particularly well-suited for grinding small-diameter parts, such as needles, pins, or wires, which are difficult to clamp or center in traditional grinding setups. It also performs well on long or flexible workpieces that would otherwise deflect or vibrate under conventional support methods. The absence of a clamping mechanism means there’s no need to reset the machine for each workpiece, reducing cycle time and setup complexity. This makes it ideal for high-throughput environments where consistency and minimal downtime are essential.

Advanced centerless grinders now come equipped with automation features such as part loaders, conveyors, and in-line measurement systems that feed back data to correct the process in real time. These systems ensure dimensional control throughout production runs and reduce the need for manual inspection. Furthermore, centerless grinding supports sustainable manufacturing practices by producing minimal waste, using efficient coolants, and often eliminating the need for secondary finishing operations. As manufacturing demands continue to push for tighter tolerances, faster production, and lower costs, centerless grinding remains a cornerstone technology in precision manufacturing. Its ability to combine speed, accuracy, and repeatability makes it indispensable for producing high-quality cylindrical components in modern industrial applications.

One of the most significant factors contributing to the success of centerless grinding in modern manufacturing is its unique ability to achieve precise dimensional control over long production runs without the need for frequent machine adjustments. Unlike processes that rely on clamping or fixturing each individual part, centerless grinding leverages a dynamic balance between the regulating wheel, the grinding wheel, and the work rest blade to maintain continuous and consistent pressure on the workpiece.

This inherent stability allows the process to hold extremely tight tolerances on part diameters—often within a few microns—while also producing excellent roundness and surface finish. The geometry of the setup plays a critical role in this stability: the workpiece sits slightly above the centerline between the grinding and regulating wheels, a position that enhances the self-centering effect of the process. This means that slight variations in incoming material or minor deflections during grinding tend to be naturally corrected, rather than amplified, resulting in uniformity across thousands of parts.

The design of the regulating wheel is another area where significant advancements have taken place. Traditionally made of rubber or resin-bonded materials, regulating wheels are now available with sophisticated compositions that offer improved wear resistance, better traction, and more consistent speed control. These wheels are adjustable in both speed and angle, allowing operators to fine-tune the process for different materials and part geometries. When combined with servo-driven systems and digital feedback loops, the regulating wheel becomes an active component in maintaining process control, especially in high-precision applications where even minor deviations can lead to rework or scrap.

Another critical aspect of centerless grinding is the selection of abrasive materials and wheel construction. Modern grinding wheels often utilize advanced ceramic or superabrasive materials like cubic boron nitride (CBN) or diamond, depending on the hardness and thermal properties of the workpiece. These abrasives are embedded in carefully engineered bonding systems designed to provide the right balance of cutting aggressiveness, wheel wear resistance, and surface quality. Wheel conditioning through dressing—reshaping and cleaning the grinding wheel surface—is also a vital routine task that ensures the abrasive grains remain sharp and effective. In automated systems, wheel dressing can be integrated into the cycle, maintaining optimal performance without manual intervention.

Coolant application in centerless grinding, though sometimes overlooked, plays an essential role in process stability and tool life. Coolants serve multiple functions: they reduce heat generated during grinding, which helps maintain part dimensional stability; they remove swarf (ground particles and debris) from the contact area to prevent wheel loading; and they help extend the life of both the grinding and regulating wheels. Proper coolant delivery systems ensure that fluid reaches the point of contact with sufficient pressure and flow, often through specially designed nozzles and manifold systems. In high-production environments, these systems are often closed-loop, recycling and filtering the coolant to maintain performance while minimizing environmental impact.

The integration of automation and digital technologies into centerless grinding has revolutionized its capabilities. CNC (Computer Numerical Control) centerless grinders now allow for real-time process monitoring, adaptive control algorithms, and predictive maintenance. These systems gather data on machine vibrations, wheel wear, workpiece dimensions, and thermal conditions, then use this information to make adjustments on the fly or alert operators to potential issues before they result in defects.

With the rise of Industry 4.0, many centerless grinding systems can also be connected to a centralized data hub, where performance metrics from multiple machines are analyzed to identify trends, optimize production scheduling, and improve overall equipment efficiency (OEE). This level of connectivity not only enhances quality assurance but also supports lean manufacturing goals by reducing waste, minimizing downtime, and maximizing throughput.

Centerless grinding’s ability to combine mechanical precision, high-volume capacity, and digital adaptability ensures its ongoing relevance in industries such as aerospace, automotive, medical, and consumer electronics. In aerospace applications, it is often used for grinding engine components, fuel injector parts, and hydraulic pins that must meet strict tolerance and performance criteria.

In the medical field, centerless grinders produce surgical tools, implants, and precision guide wires with micro-level accuracy and biocompatible surface finishes. Even in the consumer electronics sector, the process is used to manufacture tiny pins, rollers, and shafts for devices where space is at a premium and performance is critical.

Ultimately, centerless grinding is more than just a machining technique—it is a sophisticated production methodology that balances mechanical principles, material science, and digital intelligence. Its continued evolution is a testament to its unmatched ability to deliver precision, consistency, and efficiency in an increasingly competitive and quality-driven manufacturing landscape.

CNC Centerless Grinding

CNC Centerless Grinding is a highly advanced form of centerless grinding that incorporates Computer Numerical Control (CNC) to automate and enhance the precision, repeatability, and versatility of the grinding process. It builds upon the traditional principles of centerless grinding—where a workpiece is supported between a grinding wheel and a regulating wheel without the use of centers or chucks—and introduces programmable control over virtually every aspect of the operation. This evolution has significantly improved the capabilities of centerless grinding, making it suitable for complex geometries, tighter tolerances, and higher production efficiency.

At its core, CNC centerless grinding uses servo motors, programmable logic controllers (PLCs), and digital feedback systems to control the movement and position of key machine components such as the grinding wheel, regulating wheel, work rest blade, and part loaders or unloaders. These systems allow operators to program grinding parameters like infeed rates, wheel speeds, dressing cycles, and even real-time dimensional compensation with high accuracy. Unlike manual or mechanically controlled machines, CNC grinders can switch between part types with minimal setup time, which is especially valuable in high-mix, low-volume production environments.

One of the most important advantages of CNC centerless grinding is automated infeed control. In processes like plunge grinding, the infeed movement of the grinding wheel must be extremely precise to ensure that the correct amount of material is removed without overcutting or leaving excess stock. CNC systems allow this movement to be tightly programmed, often down to the micron level, with repeatable results over long production runs. Similarly, CNC machines offer programmable dressing of both grinding and regulating wheels. Dressing is the process of cleaning and reshaping the wheels to maintain their cutting ability and profile. CNC machines automate this task at scheduled intervals or based on sensor input, ensuring consistent grinding performance without the need for operator intervention.

In modern CNC centerless grinders, feedback and monitoring systems play a critical role in maintaining quality. Sensors can track the exact size of the workpiece during grinding and adjust the wheel position accordingly. This closed-loop system enables automatic compensation for wheel wear, thermal expansion, or material inconsistencies, resulting in extremely stable and precise output. Advanced systems may also monitor forces during grinding, vibration, and spindle load, enabling predictive maintenance and preventing potential failures before they cause downtime or damage.

The automation aspect of CNC centerless grinding extends to material handling as well. Integrated loading and unloading mechanisms, such as robotic arms, conveyors, or part feeders, eliminate the need for manual handling, reducing labor costs and the risk of operator error. This is particularly valuable in high-volume production lines where consistent cycle times and unattended operation are critical. In some cases, multiple grinders are linked in a production cell, communicating via a central control system that manages workflow, quality checks, and production data logging.

The flexibility of CNC centerless grinding also allows for more complex geometries and multiple diameter features on a single part. While conventional centerless grinding is well suited for uniform cylindrical parts, CNC machines can accommodate parts with steps, tapers, grooves, and even polygonal shapes by using infeed and angular adjustments on the wheels or specially designed work rest blades. This opens up new possibilities for part design and eliminates the need for secondary operations, reducing lead time and increasing manufacturing efficiency.

CNC centerless grinding is widely used in industries that demand high accuracy and high-volume production. In the automotive sector, it is used for producing transmission components, piston pins, and fuel injector parts. In medical manufacturing, it is essential for grinding orthopedic implants, surgical instruments, and precision guide wires. In the aerospace industry, CNC grinders are used for high-strength alloy parts that require flawless surface finishes and tight dimensional control. Even in electronics and consumer goods, this technology is employed to produce miniature components with micrometer-level precision.

As Industry 4.0 continues to drive the digital transformation of manufacturing, CNC centerless grinding machines are increasingly being integrated into smart factories. These machines can share performance data with enterprise systems, track tool life, schedule maintenance automatically, and even adapt to real-time production demands using machine learning and AI-based optimization tools.

In summary, CNC centerless grinding represents a major technological leap over conventional grinding methods. Its combination of automation, precision, flexibility, and digital intelligence makes it an essential technology for manufacturers looking to achieve high-quality, cost-effective, and scalable production of cylindrical parts. It has not only expanded the range of applications for centerless grinding but has also redefined what is possible in terms of productivity and quality in precision machining.

CNC centerless grinding continues to evolve as one of the most reliable and productive technologies in precision machining, largely due to its ability to operate with minimal human intervention while maintaining exceptional quality and throughput. At the heart of this process is the fundamental principle of centerless grinding: the workpiece is not clamped but rather supported between a high-speed grinding wheel and a slower-speed regulating wheel, with a work rest blade providing vertical support. This configuration allows for continuous grinding of cylindrical surfaces without the need for repositioning, making it particularly efficient for high-volume production.

The CNC control system enhances this setup by allowing precise programming of all machine movements and operational parameters. Machine operators can define exact infeed paths, set wheel speeds, control dwell times, and automate dressing cycles through a user interface, which often includes graphical simulation tools and digital diagnostics. These capabilities reduce setup time dramatically and ensure consistency from the first part to the last in any production run.

Modern CNC centerless grinders are equipped with highly responsive servo motors and ball screw-driven slides that replace traditional hydraulic systems. These servo systems offer faster and more precise positioning, especially during infeed or plunge grinding operations where micron-level adjustments are required. Because CNC machines can store multiple part programs and automatically adjust to each, they are ideal for flexible manufacturing environments where product mix changes frequently. Furthermore, with the use of bar feeders, automatic loaders, and integrated gauging systems, entire grinding cycles can be performed in lights-out conditions, often for extended periods without operator oversight. This automation dramatically increases machine utilization rates and reduces labor costs, which is a key competitive advantage in sectors where margins are tight and product demand is variable.

The integration of real-time measurement systems in CNC centerless grinding machines is another transformative feature. These systems can measure the diameter of a part as it is being ground and send feedback to the CNC controller, which can then adjust the position of the grinding wheel to compensate for wheel wear or thermal drift. This closed-loop control ensures that every part meets the required specifications without the need for manual inspection or off-line quality checks.

In applications like aerospace and medical manufacturing, where precision and compliance are non-negotiable, this kind of process reliability is essential. Additionally, modern machines log all process parameters and dimensional data automatically, creating a digital quality record that can be reviewed or audited at any time. This traceability is especially important in regulated industries and supports continuous improvement initiatives by identifying trends, root causes of variation, and areas for process optimization.

As materials become more advanced, CNC centerless grinding machines are increasingly being adapted to handle high-performance alloys, composites, and heat-resistant metals. The grinding wheels used in these machines are matched to the application, often utilizing superabrasives like diamond or CBN, which provide excellent cutting efficiency and long service life even when working with difficult-to-machine materials. Wheel selection is guided by sophisticated software that considers not only the material type but also part geometry, required surface finish, and cycle time objectives. Moreover, programmable wheel dressing systems ensure that the wheel profile remains sharp and consistent, which is crucial for complex infeed or form grinding tasks. As tolerances tighten and product specifications become more demanding, the precision of these dressing operations directly influences the overall part quality and process repeatability.

Thermal management in CNC centerless grinding is another critical area where technology plays a major role. High-speed grinding generates significant heat, which can lead to thermal expansion of the workpiece or wheel, resulting in dimensional errors. To mitigate this, CNC machines are equipped with advanced coolant delivery systems that apply high-pressure, filtered coolant directly to the grinding zone. Some systems use multiple nozzles and variable flow controls to target the fluid precisely, maximizing cooling and swarf removal while minimizing waste. In more advanced setups, coolant temperature is actively monitored and controlled to prevent thermal shock and ensure consistent grinding conditions, even as ambient shop temperatures fluctuate.

Looking ahead, the future of CNC centerless grinding is likely to be shaped by artificial intelligence, machine learning, and further integration into digital manufacturing ecosystems. Machines will increasingly be capable of self-optimization, adjusting feed rates, wheel pressures, and dressing intervals based on real-time performance data. AI algorithms may eventually predict part defects before they occur by analyzing machine behavior patterns, thus proactively suggesting maintenance or corrective actions. Meanwhile, digital twins of grinding operations could be used to simulate new part programs, optimize them virtually, and then deploy them to physical machines with minimal trial-and-error. As manufacturing continues to adopt these smart technologies, CNC centerless grinding will not only remain relevant but will become even more central to precision production strategies.

As CNC centerless grinding machines become more intelligent and interconnected, their role within the broader context of smart manufacturing continues to expand. These machines no longer operate in isolation; they are increasingly part of fully integrated production cells that communicate with enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and quality assurance platforms in real time. This level of integration allows for live monitoring of production status, tool wear, machine health, and output quality from remote locations. Plant managers and engineers can receive alerts on their devices when anomalies are detected or when a machine requires maintenance, allowing them to make immediate data-driven decisions. This improves not only efficiency but also accountability, as the entire history of a production run can be traced and audited digitally—from raw material input to final inspection.

The ability to program and store multiple part configurations also means that CNC centerless grinding machines are ideal for both high-volume and high-mix production environments. In job shops and contract manufacturing settings, where short runs of complex parts are common, the ability to change over quickly without sacrificing precision gives CNC machines a clear advantage. Setups that would take hours on a manual machine—such as adjusting work rest heights, re-positioning wheels, and trial-running parts—can be completed in minutes by simply loading a saved program and verifying tool conditions. This agility not only increases machine uptime but also opens the door to just-in-time (JIT) production strategies, reducing inventory costs and improving responsiveness to customer demands.

In terms of operational control, modern CNC centerless grinding machines offer a level of repeatability that manual systems simply cannot match. Once a process has been dialed in and validated, it can be repeated with virtually no variation across hundreds or thousands of parts. This is critical in industries such as automotive, aerospace, and medical device manufacturing, where even slight deviations can lead to functional issues or non-compliance with stringent industry standards. The capability of CNC systems to log and store process data also aids in statistical process control (SPC), allowing manufacturers to analyze output variability, optimize parameters, and implement corrective actions proactively. Over time, this leads to more robust processes, lower scrap rates, and greater customer confidence in product quality.

As machine builders continue to innovate, we’re seeing the emergence of hybrid machines that combine CNC centerless grinding with other technologies such as laser measurement, ultrasonic cleaning, or even robotic polishing—all within the same footprint. These multi-function platforms reduce the need for secondary operations and additional handling, streamlining the overall production workflow. In some cases, machines are designed to perform both rough and finish grinding in a single pass, using multiple wheels or dual-station setups. Such configurations not only save time but also improve geometric accuracy by eliminating the misalignments that can occur when parts are moved between different machines.

Environmental considerations are also becoming more central in the design and operation of CNC centerless grinding systems. With stricter regulations on waste management and sustainability, modern machines are built with closed-loop coolant systems that filter, recycle, and monitor fluid use automatically. Energy-efficient motors, smart standby modes, and reduced power consumption during idle times contribute to lower operational costs and a smaller environmental footprint. As more manufacturers aim for carbon-neutral or environmentally certified production, having a grinding system that supports sustainability goals can provide a competitive edge in global markets.

Training and workforce development are also evolving alongside the technology. Because CNC centerless grinding involves both mechanical principles and digital controls, operators now need hybrid skill sets that combine traditional machining knowledge with computer programming, data analysis, and systems thinking. To support this, manufacturers and machine builders are investing in virtual training environments, simulation software, and augmented reality tools that help operators visualize setups, learn machine functions interactively, and troubleshoot problems with guided assistance. This new generation of training not only reduces learning curves but also enhances safety, since operators can practice procedures in a risk-free environment before working on live equipment.

The continued development of CNC centerless grinding represents a convergence of precision engineering, intelligent control, and production agility. By automating complex grinding tasks, ensuring dimensional consistency, and reducing human error, CNC centerless grinders have transformed what’s possible in high-precision manufacturing. As industries demand faster lead times, tighter tolerances, and more adaptable production systems, this technology is not just keeping up—it is defining the future of machining. Whether used to produce thousands of identical automotive shafts or a small batch of intricately shaped surgical implants, CNC centerless grinding delivers the efficiency, accuracy, and repeatability that modern manufacturing demands.

In-feed Centerless Grinding

In-feed centerless grinding (also known as plunge grinding) is a specialized method within centerless grinding designed to machine parts with complex shapes or varying diameters along their length. Unlike through-feed grinding, where parts pass continuously between the grinding and regulating wheels, in in-feed grinding the part is fed radially into the wheels and ground in a fixed position. This allows for precise control over specific features such as shoulders, tapers, grooves, and multiple diameters, which cannot be achieved using traditional through-feed methods.

In this process, the workpiece is positioned on a stationary work rest blade between the grinding wheel and the regulating wheel, just like in conventional centerless setups. However, instead of being guided axially through the wheels, the part remains static during the grinding cycle. The grinding wheel, mounted on a precisely controlled slide, moves into the part at a programmed rate to remove material. This plunge motion can be carried out once for simple shapes or in multiple steps to create stepped or contoured profiles. The regulating wheel rotates the workpiece slowly, maintaining its position while ensuring it spins evenly for symmetrical grinding. The accuracy of this process depends on the rigidity and alignment of the setup, the profile of the wheels, and the stability of the machine’s infeed system.

One of the key benefits of in-feed centerless grinding is its ability to produce parts with tight tolerances and excellent surface finishes, even on components with interrupted or non-cylindrical features. This makes it ideal for automotive components such as transmission shafts with bearing journals and grooves, medical devices like bone screws and surgical pins, and aerospace parts that require stepped diameters and flawless finishes. The setup can be customized with profiled grinding wheels, which are dressed to match the specific contour of the part being produced. In CNC in-feed grinding machines, this dressing can be automatically executed with high precision and repeated during the cycle, ensuring consistent geometry and surface quality across large batches.

Unlike through-feed grinding, which is limited to simple cylindrical shapes, in-feed centerless grinding demands precise alignment and synchronization of all elements: the wheels, the work rest blade, and the axial location of the workpiece. Because the part is stationary in the axial direction, careful attention must be paid to how it is supported and to how the grinding forces are distributed during the plunge. Any imbalance or instability can lead to deflection or chatter, negatively affecting both the dimensional accuracy and the finish. As such, machine rigidity, wheel truing, and coolant delivery are especially critical in this process.

Modern CNC in-feed centerless grinders have expanded the process’s capability by incorporating programmable wheel paths, automatic gauging, servo-driven infeed systems, and digital control of dressing tools. These enhancements allow for real-time adjustment of the infeed cycle, enabling the machine to adapt to material variations or tool wear without human intervention. Additionally, software-based simulation and machine learning techniques can optimize grinding parameters before actual machining begins, saving time and reducing scrap.

Ultimately, in-feed centerless grinding offers an excellent combination of flexibility and precision for parts that cannot be ground efficiently using simpler methods. Its ability to handle intricate profiles with minimal part handling makes it a go-to choice for high-precision, high-complexity cylindrical components.

In-feed centerless grinding continues to play a crucial role in modern manufacturing, particularly where component geometry is more complex and dimensional precision is critical. One of the defining aspects of this method is the ability to control the exact point and depth of material removal by shaping the grinding wheel to mirror the desired form of the workpiece. This means that the grinding wheel can be dressed to contain radii, steps, or taper angles that match the part’s profile, allowing intricate shapes to be ground in a single plunge or in multiple coordinated in-feed motions. The use of specially profiled wheels ensures that all features are generated simultaneously, which not only speeds up the cycle time but also improves geometric consistency across the part.

In-feed grinding typically requires more setup time than through-feed grinding because each part geometry demands its own unique wheel profile, blade height, and machine positioning. However, this investment in setup is often offset by the precision and repeatability that in-feed grinding offers. Once properly configured, the machine can produce thousands of identical parts with minimal variation. This makes in-feed centerless grinding well suited to high-volume production of parts with high geometric complexity, such as valve spools, gear shafts, or components with multiple journal diameters separated by narrow shoulders. Moreover, the elimination of axial movement during grinding helps prevent the type of taper errors that can occur in through-feed operations, especially on shorter parts or those with interrupted surfaces.

Another advantage of in-feed grinding is its ability to maintain excellent roundness and surface finish, even when working with difficult materials. Because the part is supported continuously along its length by the work rest blade and is precisely rotated by the regulating wheel, the forces generated during grinding are evenly distributed. This stability is essential when grinding hardened steels, exotic alloys, or parts with thin walls that might otherwise deform under load.

Additionally, since the grinding wheel is fed directly into the part, thermal control becomes especially important. Coolant must be delivered precisely and at sufficient volume to prevent thermal expansion or burning of the workpiece surface. In modern systems, temperature-controlled coolants and variable-pressure delivery help manage heat effectively, especially when paired with high-performance CBN or diamond wheels.

In recent years, the automation of in-feed centerless grinding has become more advanced. CNC controls allow for dynamic adjustments to be made during the grinding process. For example, if an in-process gauge detects that a diameter is slightly out of spec, the machine can automatically modify the infeed path or initiate a dressing cycle without stopping production.

This type of closed-loop control has elevated the accuracy of the process while reducing the need for manual inspection or rework. In complex production cells, robots may be used to load and unload parts, orient them properly on the work rest blade, and even inspect them with vision systems. These capabilities make in-feed grinding an integral part of high-throughput, high-mix manufacturing environments where uptime, repeatability, and precision are paramount.

As components become smaller, more intricate, and are required to perform in increasingly demanding applications, the precision and flexibility of in-feed centerless grinding ensures its continued relevance. Whether used for grinding small medical pins or large industrial rollers, the process offers unmatched control over form, finish, and dimensional accuracy. As with many traditional machining processes, its capabilities have been significantly expanded by digital technologies, allowing manufacturers to push tolerances tighter, cycle times shorter, and quality levels higher than ever before. In-feed centerless grinding is thus not just a niche solution but a cornerstone of precision manufacturing in the age of automation and smart factories.

The evolution of automation and CNC control in in-feed centerless grinding has dramatically transformed the process, bringing enhanced precision, greater efficiency, and the ability to handle more complex parts with a higher degree of consistency. In traditional methods, operators were required to manually adjust settings like wheel feed rates, grinding depths, and part positioning, which often led to variations and inconsistent quality. With the advent of CNC technology, all of these parameters are controlled by sophisticated software, which ensures that the grinding process is not only repeatable but can be adapted to handle different part designs with minimal downtime.

CNC-controlled in-feed centerless grinding machines allow operators to store and retrieve multiple grinding programs, each tailored to a specific part configuration. This means that machine setups can be quickly switched from one part type to another, minimizing the setup time that would otherwise be required for manual adjustments. In a typical high-mix production environment, where multiple different parts need to be ground on the same machine, CNC controls offer the flexibility to run diverse batches with precision and speed. This level of automation reduces the risk of human error, ensures tighter tolerances, and boosts production throughput, making the technology especially valuable in industries like aerospace, automotive, and medical device manufacturing, where parts often have stringent dimensional and surface finish requirements.

The use of in-process gauging systems is another critical feature in modern CNC in-feed centerless grinders. These systems automatically measure the part’s diameter as it’s being ground, ensuring that it remains within the specified tolerance limits. If a deviation is detected—whether due to material inconsistency, wheel wear, or changes in grinding conditions—the CNC system can immediately adjust the grinding parameters, such as the infeed rate or regulating wheel speed, to bring the part back within tolerance. This dynamic feedback loop helps to reduce scrap, increase process reliability, and minimize the need for operator intervention during the grinding process. Additionally, the part’s data can be logged in real time, allowing for detailed traceability and analysis. In industries where compliance and quality control are critical, such as medical or aerospace manufacturing, this built-in quality assurance system is invaluable.

The integration of advanced sensor technologies into CNC in-feed centerless grinding systems further enhances the machine’s performance and reliability. Vibration sensors, force sensors, and acoustic emission monitoring are commonly used to detect issues such as chatter, wheel glazing, or excessive forces that could lead to part distortion or poor surface finishes. By continuously monitoring these parameters, the machine can adjust its operation proactively to avoid potential problems before they affect the part’s quality. These sensors also play a role in predictive maintenance by detecting wear patterns and indicating when parts like bearings, motors, or grinding wheels need to be serviced or replaced.

Another exciting development in CNC in-feed centerless grinding is the use of artificial intelligence (AI) and machine learning algorithms to optimize grinding parameters. AI can analyze historical production data to predict the ideal settings for specific parts, factoring in variations in material hardness, part geometry, and other environmental factors. This predictive capability allows manufacturers to fine-tune their grinding processes for maximum efficiency and precision, even before they start grinding. Machine learning algorithms can also adapt in real time, learning from each grinding cycle and adjusting settings to improve outcomes over time. This level of intelligent optimization is particularly beneficial for operations that require high uptime and low scrap rates, as it helps prevent over-grinding or under-grinding, reducing material waste and enhancing part quality.

In terms of production integration, CNC in-feed centerless grinders are often linked to smart factory systems that enable full process control and real-time data exchange between machines and enterprise-level systems. These grinders can share key performance metrics, such as throughput rates, machine health, and part quality, with broader manufacturing execution systems (MES). This enables real-time monitoring of the entire production process and facilitates seamless coordination with other machines and production lines. For example, if a CNC grinder detects a variation in part quality, the MES can alert upstream processes, such as material handling or assembly, to ensure that they are prepared to accommodate the change. This level of integration is a key component of Industry 4.0, where machines not only perform tasks but also contribute to a data-driven decision-making ecosystem that optimizes the entire production process.

The robotic integration within CNC in-feed centerless grinding systems is also revolutionizing how parts are handled before, during, and after grinding. Robots can load and unload parts with high precision, reducing human involvement and increasing consistency. In some advanced setups, robots are even capable of measuring parts and adjusting the part position on the work rest blade to ensure optimal grinding conditions. Furthermore, robots can facilitate automatic part inspection after grinding, using high-precision vision systems to check dimensions, surface finishes, and detect any defects. The ability to fully automate the part handling process reduces labor costs, eliminates the risk of contamination, and allows for lights-out operations, where the machine runs unattended for extended periods, increasing production capacity and efficiency.

Looking ahead, CNC in-feed centerless grinding will continue to evolve with advances in additive manufacturing and smart tooling. For example, machines may eventually incorporate hybrid processes where additive techniques, like laser cladding or metal 3D printing, are used to repair or build up worn or damaged grinding wheels, significantly extending tool life. Similarly, smart grinding wheels that include embedded sensors could communicate directly with the CNC system to adjust their parameters dynamically based on wear patterns or part geometry, further enhancing the precision and longevity of the grinding process.

In conclusion, CNC in-feed centerless grinding is becoming increasingly sophisticated, combining precision mechanics, digital control, and automation to produce high-quality, complex cylindrical parts with unparalleled efficiency. Its ability to grind multiple diameters, profiles, and complex geometries in a single operation makes it invaluable in industries where part complexity and precision are paramount. As manufacturing continues to adopt Industry 4.0 principles, the integration of AI, predictive maintenance, and advanced sensor technologies will only increase the capabilities and performance of in-feed grinding systems, further solidifying their role as a cornerstone of high-precision, high-volume production.

Through-feed Centerless Grinding

Through-feed centerless grinding is a highly efficient method of grinding cylindrical parts, particularly suited for high-volume production where parts are relatively simple in shape, typically round and of uniform diameter. In this process, the workpiece is fed continuously through the grinding and regulating wheels without any need for stopping, repositioning, or manual intervention during the cycle. The workpiece is supported by a work rest blade, while the regulating wheel drives it along the grinding path, and the grinding wheel removes material to achieve the desired diameter.

Through-feed grinding is characterized by its simplicity and speed. Unlike in-feed grinding, where parts are held in place and fed into the wheels, through-feed grinding uses the continuous motion of the part to move through the grinding zone. The regulating wheel is typically set at a slight angle to the grinding wheel, causing the part to rotate and move forward through the grinding process. This is achieved without the part being held on both sides of the wheels, making the process more efficient for producing long, straight, cylindrical parts with consistent diameters and finishes along their length. Because the part moves through the grinding zone, the entire length is ground in one pass, reducing cycle times significantly.

Through-feed centerless grinding is commonly used for mass production of parts like shafts, pins, rods, and tubing, where each part has a constant diameter and needs to be ground with high precision. It’s often employed in industries like automotive manufacturing for parts such as axle shafts, piston pins, and other cylindrical components. This grinding method excels when it comes to handling parts with simple geometries, typically those that do not require stepped, tapered, or complex profiles, making it a go-to solution for parts that need to be ground uniformly along their entire length.

The key advantage of through-feed grinding lies in its efficiency. Since the parts are continuously fed through the machine, the system can achieve very high throughput rates, which is ideal for situations where large quantities of parts need to be produced with minimal downtime. Additionally, because there is no need for in-depth setup changes between parts, the process is relatively simple and easy to automate, especially when paired with automated loading and unloading systems such as vibratory bowl feeders or robotic arms. These systems can continuously feed parts into the machine, enabling the grinding process to run uninterrupted for long periods, often in lights-out operations, where minimal human supervision is needed.

However, through-feed grinding does have its limitations. It is most effective when grinding parts that are relatively uniform in size and shape. For example, parts with multiple diameters, varying lengths, or interrupted surfaces are not ideal candidates for through-feed grinding. The process is also limited to parts that can be continuously fed through the machine. For parts that require more intricate geometries or complex features like shoulders or steps, in-feed grinding would be a more suitable choice. In cases where parts feature complex cross-sections or non-cylindrical shapes, an in-feed approach can be used to grind specific sections or profiles.

The precision of through-feed grinding is largely dictated by the alignment and geometry of the grinding wheel, regulating wheel, and work rest blade. As with all centerless grinding processes, achieving the desired surface finish and dimensional accuracy depends on these components working together with minimal deflection and vibration. The position of the regulating wheel, in particular, is crucial in maintaining the correct part positioning during grinding. Any instability can result in irregularities in part diameter, roundness, or surface finish, which can affect the final part quality.

Coolant systems are also a critical component in through-feed grinding. Since the workpiece is moving continuously through the grinding zone, proper coolant delivery is essential to keep both the workpiece and the grinding wheel cool, minimizing heat buildup and ensuring an optimal surface finish. High-pressure coolant systems are often used in through-feed grinding to efficiently remove heat and grinding swarf from the cutting area, preventing thermal distortion of the workpiece and maintaining grinding efficiency.

In more advanced setups, CNC-controlled through-feed grinders incorporate automatic in-process gauging, which continuously measures the part diameter as it passes through the grinding zone. This real-time feedback allows the machine to adjust parameters like the regulating wheel speed or the infeed rate, compensating for wheel wear or variations in the material being ground. By maintaining tight control over the grinding process, this system enhances part consistency, reduces scrap, and minimizes the need for post-grinding inspection.

The automation and integration of machine learning in CNC through-feed grinders is transforming the process further. These grinders are increasingly capable of self-optimizing by analyzing historical data and adjusting parameters to improve efficiency and reduce downtime. For example, the machine can adjust the grind cycle based on feedback from gauges or sensors, and it can also predict when components like grinding wheels will need dressing or replacement, minimizing the risk of downtime. This “smart” grinding is particularly useful in high-production environments where uptime is critical.

Through-feed centerless grinding is also becoming more energy-efficient, with the integration of variable-speed drives and energy-saving motors. By adjusting the motor speed according to load conditions, the system can save energy during lighter grinding cycles. Additionally, more energy-efficient coolant systems that require less fluid and power are helping to further reduce the environmental impact and operating costs of through-feed grinding.

In summary, through-feed centerless grinding is a robust, high-speed, and cost-effective solution for producing large quantities of cylindrical parts with tight tolerances and consistent finishes. It is particularly suited for industries where high-volume production is key, such as automotive, aerospace, and heavy equipment manufacturing. Its simplicity, speed, and automation capabilities make it an indispensable tool in mass production, but it does require a certain degree of consistency in part geometry to achieve optimal results. When paired with modern automation, real-time gauging, and smart control systems, through-feed grinding offers unmatched efficiency and precision in high-volume manufacturing environments.

Through-feed centerless grinding is a critical technology in the production of high-volume, precision cylindrical parts. One of its standout advantages is its ability to provide continuous, high-speed operation without the need for frequent stops or adjustments. This efficiency is perfect for situations where large quantities of parts need to be ground quickly and consistently. The simplicity of the process, where parts are fed through the grinding zone, makes it an excellent choice for basic cylindrical shapes. The constant motion of the workpiece through the grinding process ensures a uniform surface finish and diameter, which is ideal for manufacturing products like shafts, pins, rods, and tubes. In high-volume applications, through-feed grinding systems can operate around the clock with minimal downtime, further enhancing productivity.

The continuous nature of the process also means that parts experience less handling, which reduces the risk of contamination or damage during transport. This is particularly valuable in industries where cleanliness and precision are essential, such as in the aerospace or medical sectors. Through-feed grinding is also relatively easy to automate. With automated part feeders, robots, or conveyors, parts can be loaded into the system continuously without the need for manual intervention. This not only increases throughput but also lowers labor costs while ensuring a consistent process. Additionally, automated systems can incorporate in-process gauging, which measures the part’s diameter as it moves through the grinding machine, allowing for immediate adjustments to maintain tight tolerances and ensure part quality.

Despite its advantages, through-feed grinding does have limitations. One key drawback is that it is best suited for parts with a simple, uniform geometry. Parts with varying diameters, complex profiles, or multiple shoulders cannot be effectively processed using this method. For parts that require more intricate shapes, in-feed grinding would be a better option, as it allows for more controlled material removal in specific areas. Through-feed grinding also requires a certain level of consistency in material properties. If parts have inconsistent hardness or surface conditions, the process may struggle to maintain uniform grinding conditions, leading to variations in the finished part.

The grinding wheels used in through-feed grinding are typically made of materials like aluminum oxide, silicon carbide, or even diamond for more specialized applications. These wheels are continuously dressed to maintain their cutting efficiency and ensure a consistent surface finish. The grinding process itself is highly sensitive to the alignment and positioning of the wheels. Any misalignment can result in parts that are not perfectly round, or that exhibit surface defects such as chatter marks. For this reason, precision in machine setup and maintenance is key to ensuring the process produces high-quality results.

The use of coolant in through-feed grinding is another important consideration. As parts pass through the grinding zone, it is essential to maintain a steady flow of coolant to remove heat and keep both the workpiece and the grinding wheel cool. Coolant also helps to flush away grinding debris, which could otherwise clog the cutting surface or damage the workpiece. Proper coolant management ensures that the grinding process runs smoothly and helps extend the life of the grinding wheel by reducing wear and preventing thermal damage.

Through-feed grinding systems are also becoming increasingly sophisticated with the integration of digital controls and feedback loops. With CNC technology, these systems can adjust grinding parameters in real time, allowing for more precise control over the grinding process. For example, if the system detects any deviation in part diameter or surface finish, it can immediately adjust the regulating wheel speed or infeed rate to bring the part back within tolerance. These automated systems also allow for greater flexibility, enabling manufacturers to switch between different part types with minimal downtime. The integration of machine learning and AI further enhances the system’s ability to optimize grinding conditions, predict tool wear, and improve overall grinding efficiency.

The demand for more energy-efficient and environmentally friendly manufacturing processes has also driven innovation in through-feed grinding. Newer systems use variable-speed drives and energy-efficient motors that adjust the power consumption based on the grinding load. This helps reduce energy use during lighter grinding cycles and makes the overall process more sustainable. Additionally, advanced coolant systems now use less fluid while still providing adequate cooling, further lowering environmental impact.

Through-feed centerless grinding, with its speed, consistency, and capacity for high-volume production, is a key process in industries that require mass production of cylindrical components. Its ability to maintain tight tolerances and surface finishes, combined with its relatively low maintenance requirements, makes it an attractive option for manufacturers looking to optimize production lines and reduce costs. As technologies continue to evolve, the integration of automation, real-time feedback, and AI will likely continue to improve the precision and efficiency of through-feed grinding, ensuring that it remains a critical tool in modern manufacturing.

Through-feed centerless grinding is evolving alongside advances in automation and digitalization, making it a highly adaptable and efficient process in today’s manufacturing landscape. As industries demand more precise parts with tighter tolerances, especially in sectors like automotive, aerospace, and medical devices, the benefits of through-feed grinding continue to expand. One area where significant progress is being made is the integration of real-time monitoring and diagnostics. These technologies can detect deviations in the grinding process almost immediately, alerting operators to potential issues before they result in quality defects or downtime. For instance, sensors that monitor the temperature, vibration, or load on the grinding wheel can trigger automatic adjustments to keep the machine running smoothly. This type of predictive maintenance is increasingly common in modern CNC grinding systems, as it helps minimize costly repairs and production delays by addressing wear and tear before it becomes a significant problem.

A key element in the ongoing evolution of through-feed grinding is intelligent part tracking. With advanced vision systems and AI algorithms, machines are capable of tracking each part’s progression through the grinding process, adjusting for any variations in shape or size automatically. This means that each part can be processed at an optimal pace, and adjustments can be made dynamically to ensure consistent quality across the entire batch. For example, if a part is detected to be slightly out of specification in terms of diameter or surface finish, the system can correct this without stopping the entire operation, minimizing scrap and rework. This is especially useful for high-volume production where keeping each part within tolerance is crucial to maintain overall product quality.

Furthermore, data analytics is playing a more prominent role in through-feed grinding operations. Manufacturers are increasingly collecting detailed data on every aspect of the grinding process—wheel wear, coolant usage, part measurements, machine performance, etc.—and using this data to identify trends or inefficiencies. This wealth of information can then be used to optimize future operations by adjusting parameters to improve yield, reduce energy consumption, or extend the life of tooling. By leveraging big data, companies can not only ensure better immediate performance but also build predictive models to improve long-term decision-making and operational strategies.

Another interesting trend in through-feed centerless grinding is the integration of robotic automation for part handling. While traditional systems might rely on manual intervention or simple conveyors to move parts through the machine, the latest setups often include robotic arms that load and unload parts, move them between different stages of production, and even inspect parts post-grinding. These robots can be programmed to handle a variety of part sizes and configurations, further increasing the flexibility and throughput of the system. Additionally, robotic arms can often handle parts with greater precision than human operators, reducing the risk of contamination and ensuring that each part is positioned correctly in the grinding zone.

The shift toward lean manufacturing and continuous improvement also plays a significant role in the development of through-feed grinding systems. Lean principles aim to eliminate waste, increase efficiency, and reduce variability in production processes. Through-feed grinding is naturally well-suited for these goals because of its streamlined process and high throughput rates. However, companies are continually refining the process by reducing cycle times, cutting unnecessary handling steps, and increasing the level of automation in part inspection and sorting. In this way, through-feed grinding not only improves in speed but also in overall efficiency, quality, and cost-effectiveness, aligning well with modern production philosophies that prioritize just-in-time manufacturing and zero-defect production.

Sustainability is another growing consideration in the future of through-feed centerless grinding. The push toward eco-friendly manufacturing practices has led to innovations aimed at reducing energy consumption, waste, and emissions in the grinding process. For example, newer coolant systems use less fluid but maintain effective cooling and filtration, reducing the overall environmental impact. Similarly, energy-efficient motors and drives are being integrated into more systems, helping to lower energy consumption during non-peak operations. As pressure increases for manufacturers to meet environmental standards, innovations like these will continue to play a key role in the adoption of through-feed grinding as an environmentally responsible process.

The continued miniaturization of parts is another trend influencing through-feed grinding. As industries like medical device manufacturing and electronics evolve, the need for smaller, more intricate parts grows. Through-feed grinding, which has traditionally been used for larger parts, is adapting to meet these new demands by incorporating finer wheels, tighter tolerances, and more sensitive automation controls to handle the micro-manufacturing needs of modern industries. The ability to grind tiny components with high precision, such as miniature shafts or small medical pins, is pushing the boundaries of what can be achieved with through-feed grinding. In this context, it’s not just the size of the parts that matters, but also the precision of the grinding process, which is becoming more attainable through the integration of advanced feedback systems and real-time adjustments.

Through-feed grinding also benefits from modular system designs, which allow for easier customization and upgrades. Manufacturers can adapt their grinding machines to meet specific production requirements by swapping out or adding different grinding wheels, regulating wheels, or support systems depending on the type of part being processed. This flexibility enhances the adaptability of the system across various product lines, reducing downtime when switching between different parts and enabling manufacturers to respond quickly to changing demands.

In summary, through-feed centerless grinding continues to evolve as a key technology in precision manufacturing, driven by advances in automation, real-time process monitoring, AI integration, and sustainability efforts. As these technologies converge, the process becomes not only faster and more efficient but also more intelligent, adaptable, and sustainable. With these advancements, through-feed grinding will continue to play a critical role in industries requiring high-volume production of precision cylindrical parts, meeting the ever-increasing demands for both speed and quality.

Would you like a more specific look at the applications of through-feed grinding in any particular industry or how some of these innovations are being integrated into current production systems?

Precision Cylindrical Grinding Machine

A precision cylindrical grinding machine is a type of grinding equipment used to achieve highly accurate dimensions and surface finishes on cylindrical workpieces. The process involves rotating the workpiece between a rotating grinding wheel and a regulating wheel, with the material being gradually removed to achieve the desired shape, size, and surface finish. These machines are vital for manufacturing high-tolerance components used in industries such as aerospace, automotive, medical devices, and tooling, where dimensional precision is paramount.

The key components of a precision cylindrical grinding machine include:

- Grinding Wheel: This is the main tool used to remove material from the workpiece. It is typically made of abrasive materials like aluminum oxide, silicon carbide, or diamond, depending on the material being ground and the required finish. The grinding wheel rotates at high speed and performs the actual cutting process on the workpiece.

- Regulating Wheel: Positioned opposite the grinding wheel, the regulating wheel controls the rotational speed of the workpiece and feeds it through the grinding zone. It allows for precise control of the feed rate and determines the material removal rate.

- Work Rest Blade: This component provides support for the workpiece, keeping it in position while it is ground. It plays a crucial role in ensuring that the part remains stable during grinding, contributing to accuracy and preventing any potential distortion.

- Machine Bed and Control System: The machine bed provides the foundation and structural stability for the grinding process. The control system, typically CNC (Computer Numerical Control) or manual, manages the movement of the grinding and regulating wheels, as well as the positioning of the workpiece. The accuracy of the control system is critical for ensuring that the part remains within the specified tolerances.

Types of Precision Cylindrical Grinding:

- External Cylindrical Grinding: This is the most common type of cylindrical grinding, used to grind the outer surfaces of the workpiece. The workpiece is held between centers or chucking mechanisms and rotated while the grinding wheel removes material from the surface. External cylindrical grinding is commonly used to create shafts, pins, and other cylindrical components.

- Internal Cylindrical Grinding: In this process, the grinding wheel is used to grind the internal surface of the workpiece, such as the bore or inner diameter. The workpiece is held stationary, and the grinding wheel is fed into the interior of the part. This type of grinding is used for components like bearings, tubes, or hollow shafts.

- Universal Cylindrical Grinding: As the name suggests, this type of grinding machine can handle both external and internal cylindrical grinding tasks. It features a versatile design with multiple attachments and accessories, allowing it to process a wide range of part geometries and sizes.

- Centerless Cylindrical Grinding: This method involves grinding the workpiece without the use of centers or chucks to hold it in place. Instead, the workpiece is supported by a work rest blade and fed between a rotating grinding wheel and a regulating wheel. Centerless grinding is suitable for high-volume production of parts that are relatively simple in shape, such as shafts and pins.

Key Features of Precision Cylindrical Grinding Machines:

- High Precision and Tolerances: Precision cylindrical grinders are designed to achieve extremely tight tolerances, often in the range of microns (1 micron = 0.001mm). This makes them suitable for manufacturing components where dimensional accuracy and surface finish are critical, such as aerospace or medical device components.

- Surface Finish Control: Precision grinders are equipped with advanced controls that allow for fine adjustments to achieve a desired surface finish. Depending on the grinding wheel, speed, and coolant used, operators can achieve a mirror-like finish or a rougher surface, depending on the application.

- Automation and CNC Integration: Many modern precision cylindrical grinders are equipped with CNC controls, allowing for automatic operation, enhanced repeatability, and integration with advanced features such as in-process gauging and feedback loops. This automation reduces the potential for human error and increases throughput in high-production environments.

- Advanced Coolant Systems: Coolant plays a significant role in maintaining the temperature of both the workpiece and grinding wheel during the grinding process. Modern machines often include high-pressure coolant delivery systems that ensure a consistent cooling effect, which helps prevent overheating, wheel wear, and distortion of the workpiece.

- Dressing Systems: To maintain the grinding wheel’s cutting ability and surface finish, precision cylindrical grinding machines often include automatic dressing systems. These systems periodically reshape or recondition the grinding wheel to ensure it maintains optimal performance throughout the grinding process.

Applications of Precision Cylindrical Grinding Machines:

- Automotive Industry: Precision cylindrical grinding is used extensively in the production of engine components such as camshafts, crankshafts, and pistons, as well as components like valves, bearings, and gears. These parts require exact dimensions, surface finishes, and high wear resistance.

- Aerospace: Aerospace components often demand extremely tight tolerances due to the critical nature of parts like landing gear, turbine shafts, and bearings. Precision cylindrical grinding ensures the parts meet the stringent standards for strength, reliability, and performance.

- Medical Devices: Precision cylindrical grinding is used to produce high-quality components for the medical industry, such as surgical instruments, implants, and devices that require exact dimensional accuracy and smooth surfaces to function correctly in a biological environment.

- Tooling and Dies: Grinding tools, molds, and dies to precise shapes and sizes is essential for ensuring high-quality and repeatable manufacturing of parts. Precision cylindrical grinding helps maintain the required dimensions for tooling used in mass production.

- Electronics and Telecommunications: Components like spindle shafts, connectors, and precision bearings used in electronics and telecommunications equipment are often ground with high precision to ensure the proper functionality and reliability of the final product.

Advantages of Precision Cylindrical Grinding Machines:

- High Accuracy and Repeatability: These machines can grind parts with tolerances in the microns, making them ideal for applications where high precision is required. CNC-controlled machines also offer high repeatability, ensuring that every part produced is within specification.

- Wide Range of Applications: Precision cylindrical grinding can be applied to a broad range of materials, including metals, ceramics, and some polymers, making it suitable for a variety of industries and applications.

- Cost-Effective for High-Volume Production: Once set up, precision cylindrical grinding is highly efficient and can be used to produce large quantities of identical parts with minimal labor involvement, making it cost-effective in mass production.

- Excellent Surface Finish: The grinding process is capable of producing superior surface finishes, often with minimal post-processing required, reducing the time and cost associated with finishing operations.

Challenges and Considerations:

- Wheel Wear and Dressing: As the grinding wheel wears down during use, its cutting ability decreases. Regular dressing is needed to maintain the wheel’s performance, and this can introduce additional downtime or complexity in the grinding process.

- Heat Generation: Grinding generates heat, which can distort the workpiece if not properly managed. Ensuring proper coolant application and maintaining an optimal grinding environment is essential for preventing thermal damage to the part.

- Material and Shape Limitations: Precision cylindrical grinding is typically used for parts with simple, symmetrical geometries. Parts with irregular shapes or complex features may require additional processes or different types of grinders.

In summary, a precision cylindrical grinding machine is a crucial tool for manufacturing high-precision cylindrical parts. Whether for mass production or single-piece fabrication, these machines offer exceptional accuracy, surface finish, and repeatability, making them essential for industries requiring strict dimensional and performance standards. Modern machines increasingly integrate CNC technology, automation, and real-time monitoring, ensuring that manufacturers can produce high-quality parts with reduced human intervention and increased efficiency. Would you like more details on machine models or specific features related to these machines?

Precision cylindrical grinding machines are designed to offer high-accuracy machining for cylindrical parts, where dimensional tolerances, surface finishes, and part consistency are crucial. These machines are vital in industries such as automotive, aerospace, medical device manufacturing, and tooling, where every component must meet exact specifications. The grinding process involves using a rotating abrasive wheel to remove material from the surface of the workpiece, which is held either between centers or supported on a work rest, depending on the type of machine and process. The regulating wheel, which often runs at a slower speed, helps control the feed rate and ensures that the workpiece rotates at a steady pace through the grinding zone, where material is removed precisely to achieve the desired finish.

The machines are capable of achieving extremely tight tolerances, often within microns, which is critical for parts that will be used in high-performance applications. Advanced systems can even monitor the grinding process in real-time, adjusting parameters like feed rate, wheel speed, or coolant flow to compensate for variations in material properties, ensuring a high level of precision and repeatability across multiple parts. This makes precision cylindrical grinders invaluable for mass production of identical components that require consistency.

One of the key aspects that make these machines stand out is their ability to achieve fine surface finishes on cylindrical components. Surface finish is a critical requirement for parts in the medical, aerospace, and automotive sectors. For example, medical implants or critical aerospace components must not only fit together precisely but also have smooth surfaces to prevent wear, ensure reliability, and maintain performance over time. The ability to grind parts with minimal roughness and within a narrow range of tolerances makes these machines indispensable in producing parts that are both functional and durable.

The flexibility of modern precision cylindrical grinding machines has also increased with the advent of CNC (Computer Numerical Control) systems. With CNC, manufacturers can control the grinding process with extreme precision, adjusting parameters automatically based on feedback from sensors or gauging systems. CNC grinders allow for faster setup times, higher repeatability, and easier transitions between different part types, all of which contribute to a more efficient and flexible production environment. The integration of automation and robotics into the system further reduces human intervention, lowering the chances of error and minimizing the time spent on each cycle.

Another key advantage of precision cylindrical grinding machines is their ability to work with a wide range of materials. Depending on the abrasives used, these machines can grind metals like steel, aluminum, and titanium, as well as harder materials such as ceramics and composites. This versatility allows manufacturers to adapt to varying customer demands, whether it’s for parts that need to resist high temperatures, corrosion, or wear. For example, in the aerospace sector, titanium and other high-performance alloys are often used, and the grinding machines must be capable of handling these tough materials without compromising precision or surface finish.

In addition to grinding, these machines often come with advanced coolant and filtration systems that ensure the grinding process remains smooth and efficient. Coolant not only cools the workpiece and grinding wheel but also helps flush away debris created during grinding, preventing it from clogging the wheel or affecting the finish of the part. With the increasing emphasis on sustainability and reducing environmental impact, many modern machines are designed to minimize coolant use, while still maintaining effective cooling and lubrication.

Despite their advantages, there are challenges associated with precision cylindrical grinding. The grinding wheel wears down over time, which can lead to changes in the surface finish or tolerance of the finished parts. To combat this, automatic wheel dressing systems are incorporated into the machines, allowing the grinding wheel to be reconditioned as it wears. This ensures that the wheel remains in optimal condition throughout the process, extending its useful life and ensuring consistent results.

Another challenge is thermal damage, as grinding generates heat, and if not managed properly, it can distort the workpiece or negatively affect its properties. The use of coolants, in combination with precise control of the grinding process, helps mitigate this issue. However, it requires careful monitoring to ensure that the correct temperature is maintained throughout the operation.

The versatility and high precision of cylindrical grinding machines make them essential in industries where the smallest deviations from the specified dimensions could lead to serious failures or performance issues. As technology continues to advance, precision cylindrical grinders are becoming more sophisticated, incorporating more advanced sensors, automated systems, and real-time feedback to ensure that parts meet the most stringent quality standards. This is especially important in applications where safety and performance are non-negotiable, such as in the production of components for the aerospace or medical industries.

As the need for customized and high-performance parts increases, precision cylindrical grinding machines will continue to evolve to meet these demands. Manufacturers are increasingly integrating features like AI-driven predictive maintenance, where machine learning algorithms predict when components will need maintenance or replacement based on historical data, further improving machine uptime and production efficiency. With these innovations, precision cylindrical grinding remains at the forefront of precision manufacturing, providing manufacturers with the tools needed to produce parts that meet the exacting standards of today’s most demanding industries.

As precision cylindrical grinding machines continue to evolve, several emerging technologies and innovations are shaping the future of the industry. These advancements are driving improvements in speed, accuracy, automation, and sustainability. Let’s dive into some of the key trends and features that are enhancing the capabilities of precision cylindrical grinding machines.

One of the most significant trends in the field of precision cylindrical grinding is the integration of machine learning and artificial intelligence (AI) into the grinding process. These technologies allow grinding machines to adapt in real-time based on sensor data, learning from past performance to optimize grinding parameters. By analyzing factors such as wheel wear, part consistency, and thermal conditions, AI algorithms can predict when adjustments are needed to maintain precision, ensuring a smoother and more consistent grinding process. For instance, AI can adjust the grinding wheel speed or regulate the coolant flow based on real-time feedback, preventing common issues like overheating, chatter, or dimensional variations before they occur. This proactive approach not only improves the overall quality of the finished parts but also extends the lifespan of the grinding equipment, leading to lower maintenance costs.