Automation Systems for Production Lines and Forming and Cutting: Industrial metalworking machines are pivotal to the modern manufacturing landscape, transforming raw metal into precision-engineered parts through a variety of machining processes. These machines shape, cut, bend, and finish metal, and they form the backbone of industries ranging from automotive and aerospace to heavy machinery and consumer goods production. Metalworking machinery operates under strict tolerances, providing the high level of accuracy required for complex assemblies.

In today’s manufacturing environment, metalworking machines have evolved to include cutting-edge technology. Traditional manually-operated machines are now supplemented or replaced by computer numerical control (CNC) machines that offer increased efficiency and automation. This shift has led to significant improvements in production times, product quality, and overall cost-effectiveness.

Types of Metalworking Machines

Metalworking machines come in various types, each suited to specific machining tasks. Below are the most common types, along with their typical functions in industrial settings:

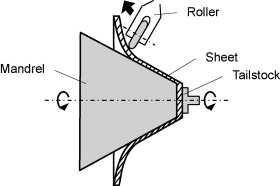

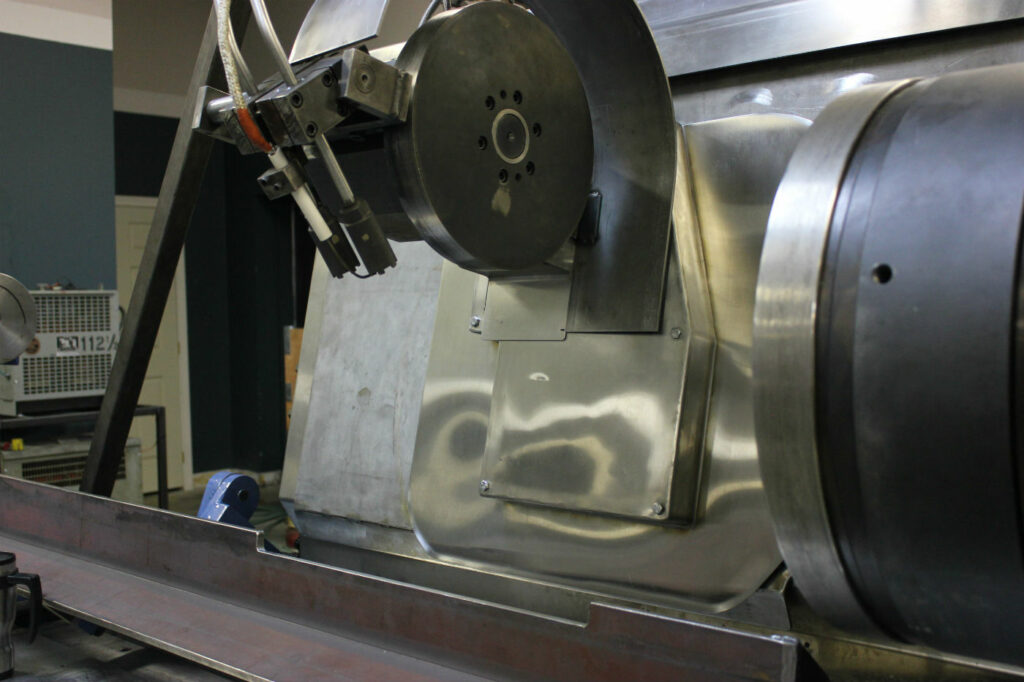

- Lathe Machines

Lathes are one of the most versatile metalworking machines, used to rotate a workpiece on its axis to perform various operations, such as cutting, sanding, knurling, drilling, or deformation. They are essential for producing cylindrical parts. There are several kinds of lathes used in industrial metalworking:- Engine lathes: Typically used for simple turning operations.

- Turret lathes: Designed for high-volume production.

- CNC lathes: Controlled by computers, allowing for highly precise and complex operations.

- Milling Machines

A milling machine uses rotating cutting tools to remove material from a stationary workpiece. These machines are highly adaptable, capable of machining both flat and complex surfaces.- Vertical milling machines: The spindle axis is vertically oriented, offering easier visibility and control.

- Horizontal milling machines: The spindle is oriented horizontally, better suited for heavy-duty work.

- CNC milling machines: Advanced milling machines controlled by CNC programming, suitable for producing complex geometries with high precision.

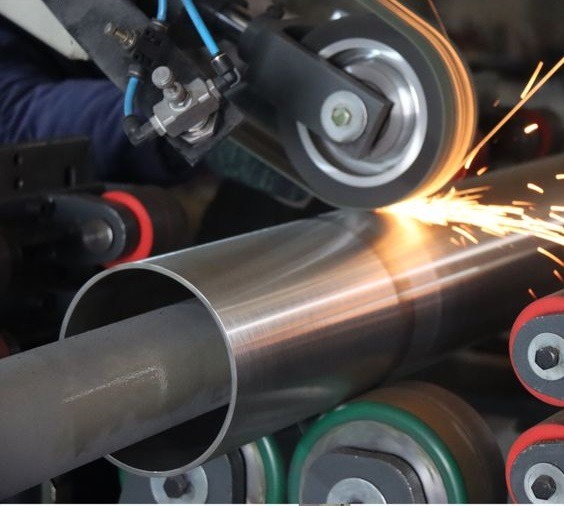

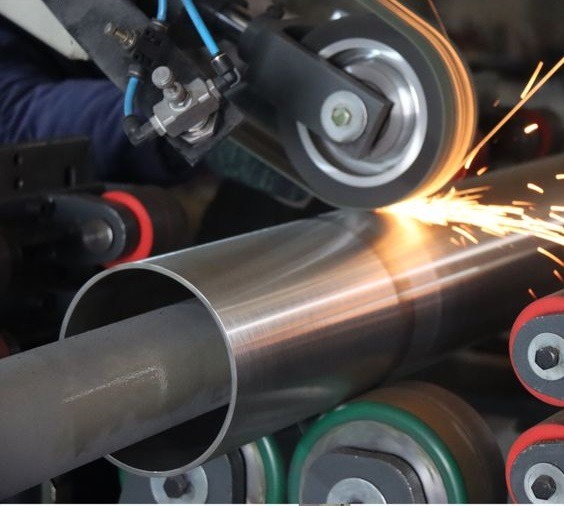

- Grinding Machines

Grinding is a machining process that uses abrasive wheels to finish surfaces and achieve tight tolerances. Grinding machines remove small amounts of material and are often used for surface finishing.- Surface grinders: Used for flat surfaces.

- Cylindrical grinders: Used for precision grinding of cylindrical parts.

- CNC grinders: Provide high-precision grinding for complex parts, such as those used in aerospace.

- Drilling Machines

Drilling machines, or drill presses, are designed to cut holes into metal, wood, or other materials. Industrial drilling machines are often integrated with CNC systems for automatic and repetitive hole cutting in production lines.- Radial drilling machines: Provide high flexibility with a movable arm for drilling large and heavy parts.

- CNC drilling machines: Precision-controlled drilling for mass production.

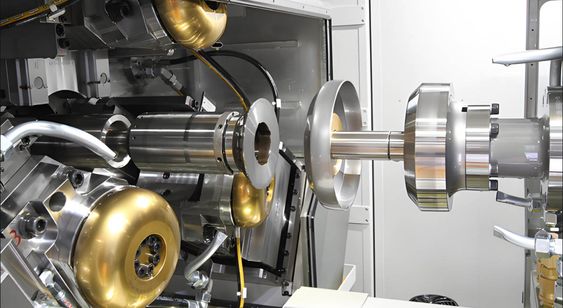

- CNC Machining Centers

CNC machining centers combine various machining operations (such as milling, drilling, and tapping) into a single setup. These machines are capable of performing multiple processes without the need to move the workpiece, making them efficient for mass production.- Horizontal and vertical machining centers: Distinguished by the spindle orientation.

- 5-axis machining centers: Capable of moving a tool on five different axes, allowing for complex geometries and precision machining.

Role in Various Industries

Industrial metalworking machines are critical to a wide range of industries, enabling mass production and customization of metal parts. Here are some key industries where metalworking machines play a significant role:

- Automotive Industry

The automotive industry relies heavily on metalworking machines for the production of engine components, body panels, and suspension parts. Lathes, milling machines, and CNC machining centers are used to create precision parts, while grinding machines finish engine blocks, crankshafts, and gears. - Aerospace Industry

Aerospace manufacturing demands extremely tight tolerances and high-quality finishes, and metalworking machines are at the core of this industry. CNC machines, in particular, are indispensable for producing high-precision turbine blades, airframe components, and landing gear. - Construction and Heavy Machinery

Metalworking machines are used to produce large, durable components for construction machinery, cranes, and agricultural equipment. The production of these heavy-duty parts often requires robust and powerful machinery, such as CNC machining centers and large-scale lathes. - Consumer Electronics

Precision metalworking machines are essential in producing the delicate and precise components found in smartphones, laptops, and other consumer electronics. CNC milling and turning machines are used to fabricate casings, internal frames, and other components with high precision.

Advancements in Metalworking Machinery

As industries evolve, so do the capabilities of metalworking machinery. Innovations in automation, material science, and digital technology have transformed traditional metalworking into a highly sophisticated and efficient process.

- Automation

Automation in metalworking has greatly enhanced productivity. Robots are now commonly integrated with metalworking machines to handle repetitive tasks such as material loading and unloading, which not only reduces manual labor but also increases safety in hazardous environments. - CNC Technology

CNC machines represent a revolution in metalworking by allowing machines to be controlled through computer programming. This provides unparalleled precision and repeatability in the machining process. Modern CNC systems are capable of handling complex geometries and multi-axis machining, making them suitable for high-performance industries like aerospace and medical devices. - Additive Manufacturing

3D printing, or additive manufacturing, is increasingly being integrated with traditional metalworking machinery. While 3D printing can’t entirely replace traditional metalworking, it offers new possibilities for creating complex shapes that are difficult or impossible to achieve with conventional methods. Metal 3D printing is often combined with CNC machining to create hybrid manufacturing systems. - IoT and Industry 4.0

The integration of IoT (Internet of Things) in metalworking machines has led to the development of smart factories where machines communicate with each other to optimize production processes. Sensors can provide real-time data on machine performance, enabling predictive maintenance and reducing downtime.

Challenges and Solutions in Metalworking

While metalworking machines offer a host of benefits, they also present certain challenges that manufacturers need to address.

- Tool Wear

Continuous operation can lead to tool wear, which reduces precision and quality. This is especially problematic in high-volume production environments. Solutions include advanced materials for tooling (such as carbide or ceramic) and the implementation of tool wear monitoring systems. - Precision and Accuracy

Achieving the necessary level of precision can be challenging, particularly in industries like aerospace, where even small deviations can lead to significant issues. CNC machines and advanced quality control systems have mitigated these concerns by providing real-time monitoring and feedback during the machining process. - Material Hardness

Working with hard materials, such as titanium or hardened steel, can wear down tools quickly and slow the machining process. Advances in cutting tool materials, cooling systems, and machine design have made it possible to machine harder materials more efficiently.

Future Trends in Metalworking Machines

The future of metalworking machines is being shaped by several technological advancements that are poised to further increase efficiency and capability:

- AI Integration

Artificial intelligence is expected to play a larger role in the optimization of metalworking processes. AI can analyze data from IoT sensors, predict machine failures, and optimize tool paths for CNC machines, thus reducing downtime and improving overall efficiency. - Robotics and Automation

Automation systems will continue to evolve, with robots taking on more complex tasks, including machine tending, part inspection, and tool changing. Fully autonomous factories may become a reality, with minimal human intervention needed. - Advanced Materials and Coatings

As new materials are developed, metalworking machines will need to adapt. For instance, machines capable of working with carbon fiber composites or advanced alloys are already becoming necessary in industries like aerospace. - Green Manufacturing

Sustainability is becoming an important factor in metalworking. Energy-efficient machines, better waste management, and the use of recyclable materials are increasingly being prioritized by manufacturers.

Metalworking Machinery Manufacturing

Metalworking machinery manufacturing is a key sector within the broader manufacturing industry. This segment is responsible for designing, producing, and assembling machines that shape and finish metal into usable products. The machines produced range from simple hand-operated tools to complex computer-controlled machinery (CNC). The demand for metalworking machinery is closely tied to the performance of key industries such as automotive, aerospace, construction, and industrial equipment production.

In this section, we’ll explore the processes involved in the manufacturing of metalworking machinery, key materials used, quality standards, challenges faced, and trends shaping the industry’s future.

Manufacturing Processes for Metalworking Machinery

The manufacturing process for metalworking machines involves several distinct phases, each critical to ensuring that the final product meets high standards of performance, durability, and precision. Here’s a detailed look at the steps involved:

- Design and Engineering

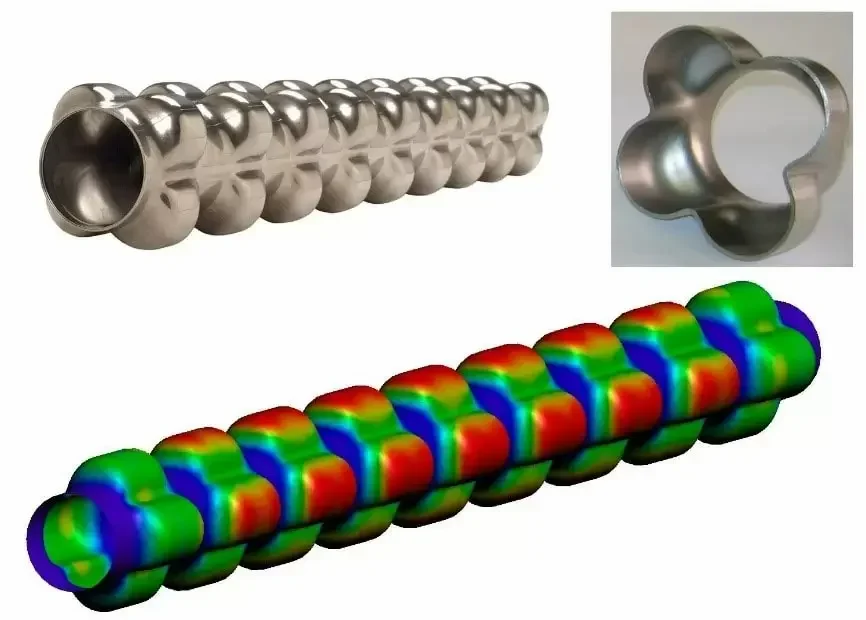

The first step in manufacturing metalworking machinery is the design phase, which involves mechanical and electrical engineers. Engineers must account for the machine’s intended use, size, weight, materials, power requirements, and tolerance levels.- Computer-Aided Design (CAD): Engineers rely on CAD software to create detailed models and simulations of the machinery.

- Finite Element Analysis (FEA): Simulations help predict how a machine will react under stress, thermal loads, and other operating conditions, ensuring reliability and longevity.

- Material Selection

The choice of materials is a critical step, as metalworking machines often endure significant forces, high temperatures, and wear. Materials need to be robust enough to handle these conditions without compromising performance or longevity.Common materials used in metalworking machinery include:- Cast Iron: Excellent for absorbing vibrations, making it ideal for the machine base.

- Steel: Widely used for components that require high strength and durability.

- Aluminum: Utilized in lightweight parts to reduce overall machine weight without sacrificing strength.

- Tungsten Carbide: Frequently used in cutting tools for its hardness and resistance to wear.

- Casting and Forging

Large, structural components of metalworking machines, such as frames or bases, are often made through casting or forging. These processes allow for the creation of strong, durable parts that can withstand the rigors of heavy machining operations.- Casting: Involves pouring molten metal into a mold to form the machine’s parts. Cast iron is commonly used for the structural components of machines due to its excellent vibration damping properties.

- Forging: Involves shaping metal by applying compressive forces, which enhances the strength of the material. This process is often used for components like shafts and gears.

- Machining and Fabrication

After casting and forging, the components undergo precision machining. Metalworking machines, such as lathes and milling machines, are used to shape the parts to exact specifications.- CNC Machining: CNC machines are essential in this stage to achieve the precise dimensions and tolerances required. CNC lathes, milling machines, and grinders shape components like gearboxes, cutting tool holders, and spindles.

- Welding and Assembly: Components are welded and assembled, especially in large machines where multiple parts must be joined together.

- Heat Treatment

Metal components often require heat treatment to enhance their properties, such as hardness, strength, and wear resistance. Processes such as annealing, quenching, and tempering are employed depending on the material and its final use within the machine. - Finishing

The finishing process ensures the machine components have the necessary surface smoothness and aesthetic appeal. It also enhances the machine’s resistance to corrosion and wear. Finishing techniques include:- Grinding: Achieves high precision and smooth surface finishes.

- Buffing and Polishing: Often used to enhance the appearance of exposed metal surfaces and improve resistance to wear.

- Surface Coating: Protective coatings, such as powder coating or plating, provide additional protection against corrosion.

- Assembly

After the individual parts are machined and finished, the final assembly of the machine takes place. This stage includes the integration of the mechanical components with electrical systems, such as the control panel and sensors for CNC machines. Proper alignment and calibration are critical for ensuring the machine operates within the desired tolerances. - Testing and Quality Control

Rigorous testing and quality control are essential to ensure that the machine meets the required specifications before it leaves the factory. Common tests include:- Dimensional accuracy checks: Ensures parts meet design tolerances.

- Operational tests: Simulates real-world operating conditions to verify machine performance.

- Vibration and noise testing: Ensures machines operate smoothly and do not produce excessive noise or vibrations, which could affect performance.

Key Materials in Metalworking Machinery

The materials used in manufacturing metalworking machinery need to meet stringent requirements to handle the high stresses and wear encountered during machining processes. The following materials are commonly used:

- Cast Iron: Known for its excellent damping properties, cast iron is often used in the base and frame of machines to minimize vibrations and ensure stability during operation. It’s also resistant to deformation, making it suitable for long-term use in high-load applications.

- Steel Alloys: Steel alloys are widely used for machine components that require high tensile strength, durability, and resistance to impact. Steel is also preferred for parts like gears, shafts, and spindles because of its ability to maintain strength under high temperatures and loads.

- Aluminum: In cases where weight reduction is necessary, aluminum is used for non-load-bearing parts. While it’s lighter than steel, aluminum still offers significant strength and corrosion resistance, making it ideal for certain machine components and enclosures.

- Carbides and Ceramics: Used primarily for cutting tools, carbides and ceramics provide extreme hardness and wear resistance, allowing them to maintain sharp edges even when machining hard materials like steel or titanium. Tungsten carbide tools, for example, are widely used in turning and milling operations.

Quality Standards in Metalworking Machinery Manufacturing

Manufacturers of metalworking machinery are held to high standards of precision, performance, and safety. Several international standards and certifications guide the production process to ensure the machinery meets industry requirements:

- ISO 9001: The most widely recognized standard for quality management systems, ISO 9001 certification ensures that a manufacturer follows strict protocols for producing consistent, high-quality products.

- CE Marking (European Conformity): CE certification is required for machinery sold in the European Union, signifying that the equipment meets the EU’s health, safety, and environmental protection standards.

- ANSI/ASME Standards: In the United States, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) establish guidelines for the design and manufacture of metalworking machinery. These standards cover everything from safety features to dimensional tolerances.

- Industry-Specific Standards: Many industries, such as aerospace and medical device manufacturing, require specialized certifications for the machinery used in production. These standards ensure that equipment meets the stringent requirements for producing parts used in critical applications.

Challenges in Metalworking Machinery Manufacturing

The production of metalworking machinery comes with several challenges that manufacturers must overcome to maintain quality and efficiency.

- High Material Costs

The materials required for metalworking machinery, such as steel alloys and tungsten carbide, are often expensive. This challenge is compounded by fluctuations in the price of raw materials, which can significantly impact production costs. - Technological Advancements

Keeping up with technological advancements, particularly in automation and digitalization, requires significant investment. Manufacturers must continuously upgrade their equipment and software to remain competitive, which can be a financial strain for smaller companies. - Global Competition

The metalworking machinery manufacturing industry is highly competitive, with manufacturers from countries like Germany, Japan, and China dominating the global market. To remain competitive, companies must innovate while keeping costs low, which is a delicate balancing act. - Sustainability and Environmental Regulations

As environmental concerns grow, metalworking machinery manufacturers are increasingly required to reduce their environmental footprint. This includes minimizing energy consumption, reducing waste, and adopting eco-friendly manufacturing processes. Compliance with these regulations often requires substantial investment in new technologies and processes.

Trends Shaping the Future of Metalworking Machinery Manufacturing

The metalworking machinery manufacturing industry is evolving rapidly, driven by advancements in technology and changing market demands. Here are some of the key trends shaping its future:

- Automation and Smart Factories

Automation is transforming the way metalworking machinery is manufactured. From robotic welding systems to automated assembly lines, manufacturers are increasingly relying on automation to increase production speed, reduce labor costs, and improve product consistency. Additionally, smart factories—where machines communicate with each other and provide real-time data to operators—are becoming more common. This connectivity is often achieved through the integration of IoT (Internet of Things) technology. - Additive Manufacturing (3D Printing)

While additive manufacturing is often associated with producing metal parts, it also plays a role in the production of metalworking machines themselves. 3D printing is used to create complex components that would be difficult or impossible to manufacture using traditional methods. This not only reduces lead times but also opens up new possibilities for machine design. - Sustainability Initiatives

As the global manufacturing industry becomes more environmentally conscious, metalworking machinery manufacturers are focusing on sustainability. This includes the development of energy-efficient machines, the use of recyclable materials, and the implementation of waste-reduction programs. - AI and Machine Learning

Artificial intelligence (AI) and machine learning are playing an increasingly important role in the metalworking machinery manufacturing process. These technologies are used to optimize machine design, improve predictive maintenance, and enhance quality control. AI-powered systems can analyze data from IoT sensors to predict when a machine will need maintenance, helping to avoid costly downtime and extend the life of the equipment. - Customization and Flexibility

Manufacturers are placing greater emphasis on creating flexible, customizable machines that can be easily adapted to a variety of production tasks. This is particularly important for companies that produce small batches of specialized parts. Modular machine designs and programmable CNC systems allow for greater flexibility in production, enabling manufacturers to meet the demands of a rapidly changing market.

Automation Systems for Production Lines and Forming and Cutting

Automation systems have become the cornerstone of modern manufacturing, enabling faster production times, higher accuracy, and increased efficiency. In metalworking and related industries, automation is essential for performing forming and cutting operations with minimal human intervention. From automotive manufacturing to aerospace engineering, these systems streamline processes, reduce costs, and improve the consistency of finished products.

Automation systems can range from basic programmable logic controllers (PLCs) that manage simple tasks to sophisticated robotic systems that perform complex operations across multiple stages of production. The integration of advanced technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) into automation systems has further revolutionized production lines, driving industrial efficiency to new levels.

Key Components of Automation Systems

Automation systems for metalworking production lines typically consist of several integrated components that work together to perform forming and cutting operations. These components ensure that the production process is seamless and that the final product meets strict quality standards. Here are the key elements involved in an automated production line for metalworking:

- Programmable Logic Controllers (PLCs)

PLCs are industrial computers used to control manufacturing processes. In metalworking, they govern tasks such as starting and stopping machines, controlling the speed and direction of motors, and managing the sequence of operations. PLCs are highly reliable and can be programmed to handle both simple and complex processes.- Inputs and Outputs: PLCs receive input from various sensors and switches on the production line and then send output signals to actuators, motors, and other machinery to control the process.

- Communication: Modern PLCs are often networked with other control systems and machinery to enable data sharing and remote monitoring.

- Sensors and Actuators

Sensors play a critical role in automation by providing real-time data about the production process. Common types of sensors used in metalworking automation include:- Proximity sensors: Detect the presence of metal parts to ensure proper alignment during cutting and forming.

- Temperature sensors: Monitor the heat generated during forming operations.

- Pressure sensors: Ensure the appropriate force is applied during processes such as stamping and pressing.

- Robotic Systems

Robots are increasingly being integrated into metalworking production lines to handle tasks that are repetitive, hazardous, or require high precision. Robotic systems can perform a variety of functions in forming and cutting processes, including:- Material handling: Robots move raw materials and finished parts between machines, reducing the need for manual labor and increasing efficiency.

- Cutting operations: Robotic arms equipped with cutting tools can perform highly accurate cutting operations, reducing waste and ensuring consistent results.

- Forming operations: Robots can also handle tasks such as bending, punching, and pressing with high repeatability.

- Human-Machine Interface (HMI)

The HMI is the interface through which operators interact with the automation system. Modern HMIs are often touch-screen displays that provide real-time data on machine performance, process status, and any errors or warnings. Operators can use the HMI to adjust parameters, start and stop machines, and monitor the overall production line. - Conveyors and Material Transport Systems

Conveyors are a critical part of automated production lines, as they transport materials and components between different stages of production. Automated conveyors ensure that materials flow smoothly through the line, minimizing delays and reducing manual handling. In metalworking, conveyors are often used to move heavy sheets of metal or formed parts between cutting and forming machines. - Safety Systems

Automation systems in metalworking must prioritize safety due to the high-risk nature of cutting and forming operations. Modern automation systems include a variety of safety features, such as:- Light curtains: Detect the presence of an object or person in a dangerous area and shut down the machine to prevent accidents.

- Emergency stop buttons: Allow operators to quickly halt production in case of an emergency.

- Interlocks: Ensure that machines cannot operate unless safety guards are in place, protecting operators from injury.

Forming and Cutting Processes in Automated Systems

Metal forming and cutting are two of the most critical operations in metalworking. These processes shape metal into its final form, either by removing material (cutting) or by deforming it (forming). In an automated production environment, these processes are tightly controlled to ensure precision and repeatability.

- Forming Operations

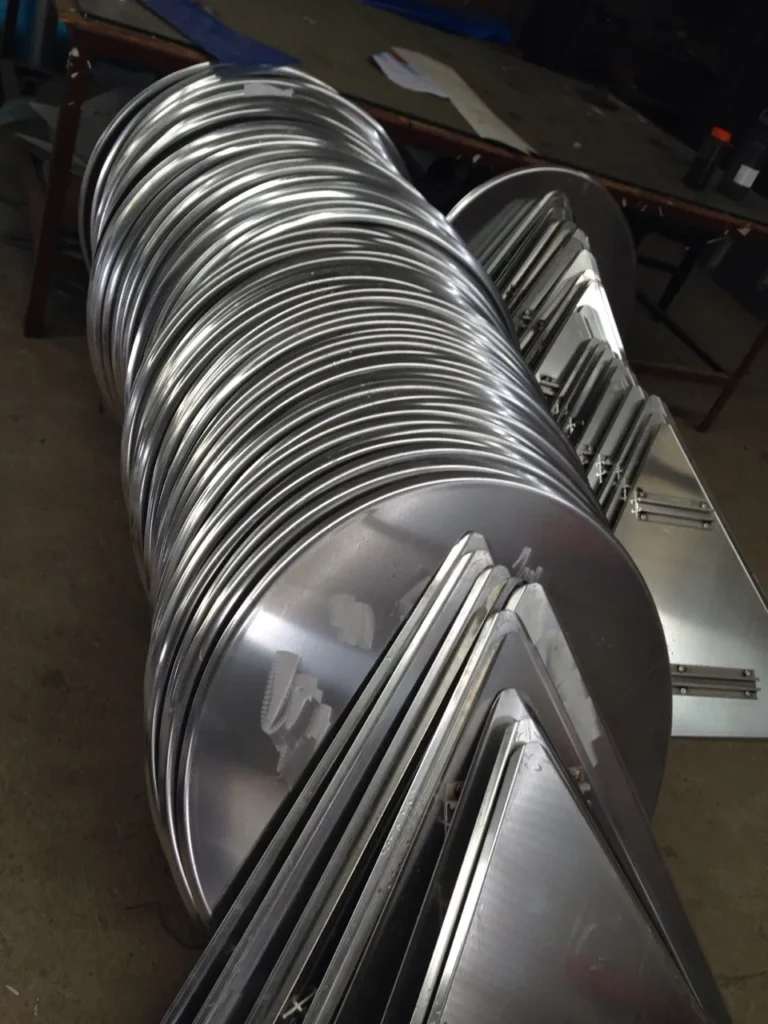

Forming involves deforming metal into a desired shape without removing material. Automated systems for forming are designed to ensure that the correct amount of force is applied and that the material is positioned accurately. Common forming operations in automated metalworking systems include:- Bending: Automated bending machines, such as press brakes, apply force to metal sheets, tubes, or bars, bending them into specific angles. Robotic systems can feed the material into the machine and adjust it for multiple bends, making the process highly efficient.

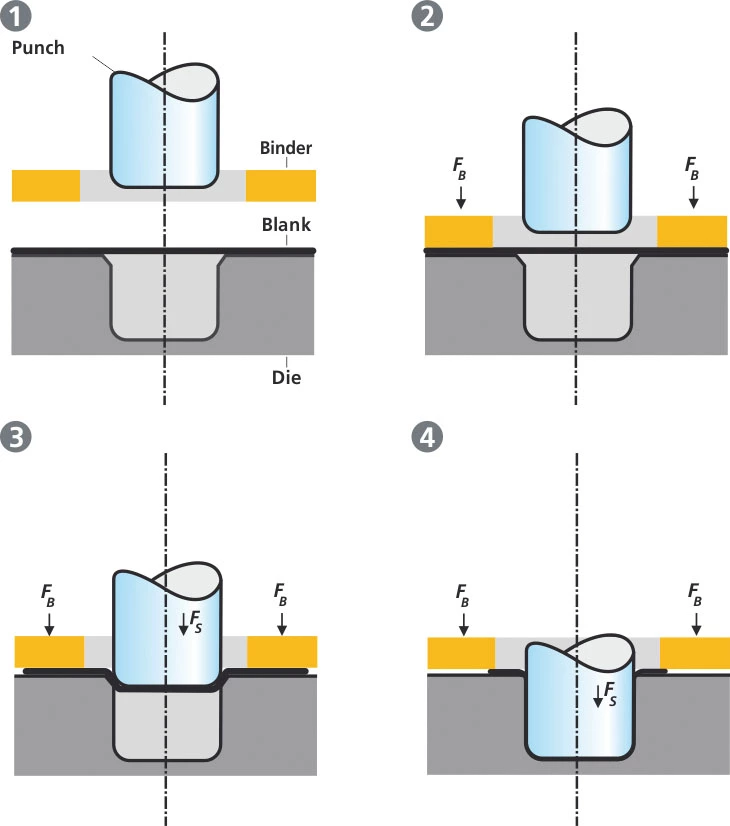

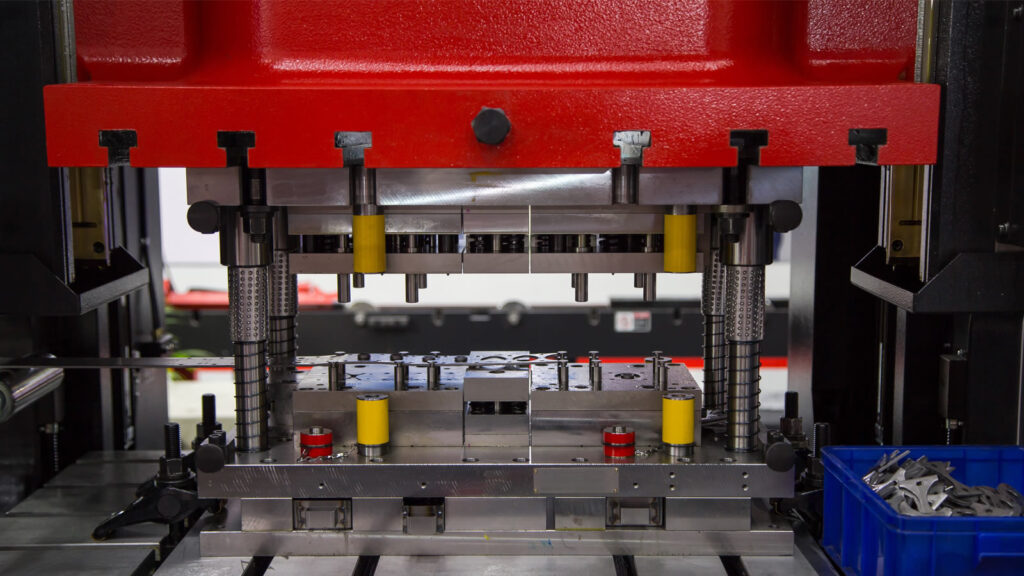

- Stamping: In stamping operations, a punch and die are used to form the metal. Automation systems ensure the precise alignment of the punch and die, as well as the consistent application of force. Stamping is often used in high-volume production, such as automotive part manufacturing.

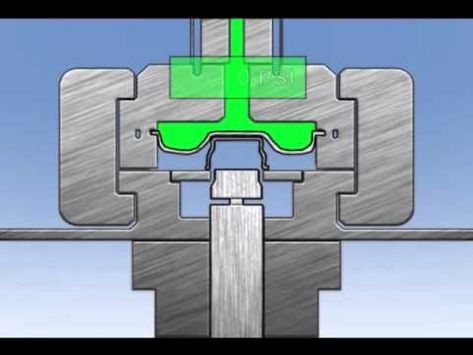

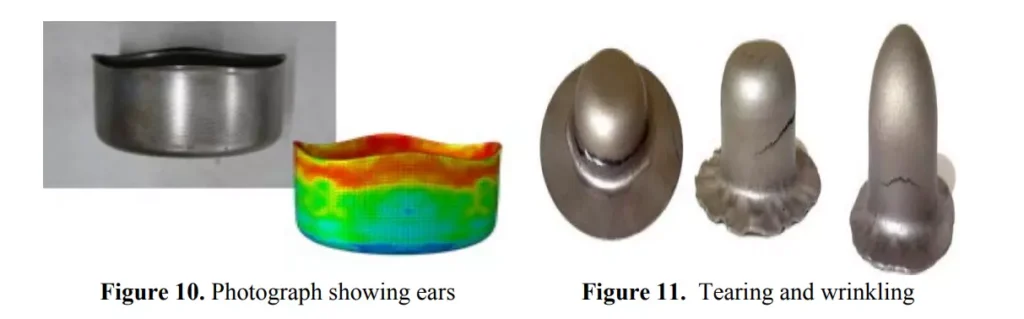

- Deep Drawing: Deep drawing is a process where a sheet of metal is stretched into a desired shape, typically for components like metal cans or kitchen sinks. Automated systems handle the positioning of the blank and the control of the punch, ensuring repeatability and minimizing material waste.

- Hydroforming: Hydroforming uses high-pressure fluids to form metal parts, particularly complex geometries. Automated hydroforming systems can accurately control the pressure applied, ensuring consistent part quality.

- Cutting Operations

Cutting operations involve removing material from a workpiece to create a specific shape or size. Automated cutting systems offer precise control over the cutting tool’s movement, speed, and depth, ensuring that parts are cut with tight tolerances. Common cutting processes in metalworking automation include:- Laser Cutting: Laser cutting is one of the most precise cutting methods available. Automated laser cutting machines use high-powered lasers to cut through metal sheets with incredible accuracy. The laser’s movement is controlled by CNC programming, allowing for intricate patterns and clean edges.

- Plasma Cutting: Plasma cutting uses a jet of ionized gas (plasma) to cut through electrically conductive metals. Automated plasma cutters are used for cutting thick metal plates in industries like shipbuilding and construction.

- Water Jet Cutting: Water jet cutting uses a high-pressure stream of water mixed with abrasive particles to cut metal. This process is suitable for cutting materials that are sensitive to heat, as it does not generate significant heat like laser or plasma cutting. Automated water jet systems can handle complex shapes and are widely used in aerospace and automotive manufacturing.

- Shearing: Shearing is a mechanical cutting process where a sheet of metal is cut along a straight line. Automated shearing machines are common in production lines where large quantities of sheet metal need to be cut quickly and accurately.

Advantages of Automation in Forming and Cutting Processes

The integration of automation into forming and cutting processes brings several advantages to manufacturers, particularly in terms of efficiency, quality, and cost savings:

- Increased Productivity

Automation allows for faster production cycles, as machines can operate continuously with minimal human intervention. Robots and automated conveyors ensure that materials are moved efficiently between machines, reducing downtime and speeding up the overall process. - Improved Precision and Consistency

Automated systems offer higher precision than manual processes, as they eliminate the variability introduced by human error. CNC-controlled machines can cut or form metal to exact specifications, ensuring that every part meets the required tolerances. - Cost Reduction

While the initial investment in automation systems can be significant, the long-term cost savings are substantial. Automated systems reduce labor costs by minimizing the need for human operators, and they also reduce waste by improving material utilization. Additionally, automation helps reduce the cost of rework, as parts are more likely to meet quality standards on the first pass. - Enhanced Safety

Automation removes workers from dangerous environments, such as those involving heavy machinery, cutting tools, or high temperatures. By using robots and other automated systems to perform hazardous tasks, manufacturers can significantly reduce the risk of workplace accidents and injuries. - Scalability and Flexibility

Automated systems are highly scalable, making them ideal for both small-scale and large-scale production. Additionally, modern automation systems can be reprogrammed or reconfigured to handle different tasks, providing manufacturers with the flexibility to adapt to changing production needs. - Real-Time Monitoring and Optimization

With the integration of IoT and AI technologies, automated production lines can provide real-time data on machine performance, process efficiency, and product quality. This data can be used to optimize the production process, identify potential issues before they cause downtime, and improve overall equipment effectiveness (OEE).

Challenges in Implementing Automation for Forming and Cutting

Despite the many benefits of automation in forming and cutting processes, there are also several challenges that manufacturers must overcome to implement these systems successfully:

- High Initial Costs

The upfront investment in automation systems, including robots, CNC machines, and control software, can be prohibitive for some manufacturers. However, many companies find that the long-term cost savings, increased productivity, and improved quality justify the initial expense. - Complex Integration

Implementing automation requires careful planning and integration with existing production lines. Machines, sensors, and control systems must work together seamlessly to ensure efficient operation. This often involves custom engineering solutions, which can be time-consuming and costly. - Maintenance and Downtime

While automation systems are highly reliable, they do require regular maintenance to keep them operating at peak performance. Downtime due to machine failures or maintenance can be costly, especially in high-volume production environments. Predictive maintenance systems, powered by AI and IoT, are becoming increasingly common to address this issue. - Skilled Labor Shortages

While automation reduces the need for manual labor, it increases the demand for highly skilled workers who can design, operate, and maintain these advanced systems. Manufacturers must invest in training and education to ensure their workforce is equipped to handle the complexities of automation.

Future Trends in Automation for Forming and Cutting

The future of automation in forming and cutting processes is being shaped by several emerging trends that promise to further improve efficiency, flexibility, and precision:

- AI-Driven Automation

Artificial intelligence is playing an increasingly important role in automated production lines. AI systems can analyze large amounts of data in real-time, making adjustments to the production process to optimize efficiency and product quality. For example, AI can predict tool wear and automatically adjust cutting parameters to ensure consistent quality throughout a production run. - Collaborative Robots (Cobots)

Cobots are designed to work alongside human operators, assisting with tasks such as material handling and machine tending. Unlike traditional industrial robots, cobots are equipped with advanced safety features that allow them to work safely in close proximity to humans. This opens up new possibilities for automating smaller production lines or tasks that require human oversight. - Additive Manufacturing Integration

Additive manufacturing, or 3D printing, is increasingly being integrated with traditional forming and cutting processes to create hybrid production systems. In these systems, parts can be 3D-printed and then finished using automated cutting or forming machines, providing manufacturers with greater flexibility in part design and production. - Green Automation

Sustainability is becoming a key consideration for manufacturers, and automation systems are evolving to support greener production methods. Energy-efficient machines, waste reduction strategies, and the use of recyclable materials are all becoming more common in automated production lines.

Challenges in Implementing Automation for Forming and Cutting

Despite the many benefits of automation in forming and cutting processes, there are also several challenges that manufacturers must overcome to implement these systems successfully:

- High Initial Costs

The upfront investment in automation systems, including robots, CNC machines, and control software, can be prohibitive for some manufacturers. However, many companies find that the long-term cost savings, increased productivity, and improved quality justify the initial expense. - Complex Integration

Implementing automation requires careful planning and integration with existing production lines. Machines, sensors, and control systems must work together seamlessly to ensure efficient operation. This often involves custom engineering solutions, which can be time-consuming and costly. - Maintenance and Downtime

While automation systems are highly reliable, they do require regular maintenance to keep them operating at peak performance. Downtime due to machine failures or maintenance can be costly, especially in high-volume production environments. Predictive maintenance systems, powered by AI and IoT, are becoming increasingly common to address this issue. - Skilled Labor Shortages

While automation reduces the need for manual labor, it increases the demand for highly skilled workers who can design, operate, and maintain these advanced systems. Manufacturers must invest in training and education to ensure their workforce is equipped to handle the complexities of automation.

Future Trends in Automation for Forming and Cutting

The future of automation in forming and cutting processes is being shaped by several emerging trends that promise to further improve efficiency, flexibility, and precision:

- AI-Driven Automation

Artificial intelligence is playing an increasingly important role in automated production lines. AI systems can analyze large amounts of data in real-time, making adjustments to the production process to optimize efficiency and product quality. For example, AI can predict tool wear and automatically adjust cutting parameters to ensure consistent quality throughout a production run. - Collaborative Robots (Cobots)

Cobots are designed to work alongside human operators, assisting with tasks such as material handling and machine tending. Unlike traditional industrial robots, cobots are equipped with advanced safety features that allow them to work safely in close proximity to humans. This opens up new possibilities for automating smaller production lines or tasks that require human oversight. - Additive Manufacturing Integration

Additive manufacturing, or 3D printing, is increasingly being integrated with traditional forming and cutting processes to create hybrid production systems. In these systems, parts can be 3D-printed and then finished using automated cutting or forming machines, providing manufacturers with greater flexibility in part design and production. - Green Automation

Sustainability is becoming a key consideration for manufacturers, and automation systems are evolving to support greener production methods. Energy-efficient machines, waste reduction strategies, and the use of recyclable materials are all becoming more common in automated production lines.

Introduction to Sheet Metal Edge Finishing

In industrial metalworking, sheet metal edge finishing is a critical process that improves the quality, appearance, and functionality of metal parts. When sheet metal is cut, punched, or otherwise formed, the edges are often left rough, sharp, or with burrs. These imperfections can not only affect the appearance of the final product but also pose safety risks and interfere with the part’s fit and performance in an assembly. Edge finishing tools are designed to remove these imperfections and ensure that the sheet metal has smooth, precise edges.

Edge finishing processes, often referred to as deburring, can be automated or manual, depending on the scale of the operation and the complexity of the part being processed. This section explores the types of tools used for sheet metal edge finishing, the importance of edge treatment, various techniques, and advancements in automated edge finishing systems.

Types of Sheet Metal Edge Finishing Tools

Edge finishing tools vary widely based on the material of the sheet metal, the thickness of the material, and the precision required. Here are some of the most commonly used tools and techniques for edge finishing in metalworking:

- Hand Deburring Tools

Hand tools are commonly used for smaller-scale operations or for finishing complex geometries where automated systems might struggle. These tools typically have a blade or abrasive tip that is used to manually scrape away burrs and sharp edges.- Deburring blades: These handheld tools feature replaceable blades that can be guided along the edges of the metal to remove burrs. They are useful for irregular or complex shapes.

- Abrasive files: Used for finer edge finishing, abrasive files are used to smooth rough edges on metal sheets, tubes, or bars. They come in various shapes and sizes, depending on the type of edge being finished.

- Rotary burr tools: These tools feature a rotating head with an abrasive or cutting surface and are used for more aggressive burr removal in thicker metal sheets.

- Power Deburring Tools

For larger-scale operations or thicker sheet metals, power tools are used to remove burrs and finish edges more efficiently than manual tools. These tools are often powered by electric motors and provide consistent, high-speed removal of burrs.- Rotary deburring tools: These tools use rotating burrs or abrasive heads to remove metal more quickly and efficiently than hand tools. They are commonly used in industrial applications where large quantities of sheet metal need to be finished.

- Edge routers: These are motorized tools that cut and smooth the edges of sheet metal in a single pass. They are often used in precision industries, such as aerospace or automotive manufacturing, where smooth, burr-free edges are critical.

- Automatic Deburring Machines

Automated deburring machines are widely used in industries that deal with high production volumes or large sheet metal parts. These machines can handle both internal and external edges and are often equipped with adjustable settings to accommodate different metal thicknesses and edge profiles.- Belt sanders: These machines use a continuous abrasive belt to sand down the edges of metal sheets. They are effective for large, flat surfaces and are commonly used in industries like shipbuilding or construction.

- Rotary tumblers: In this process, metal parts are placed into a drum with abrasive media and rotated to remove burrs from all edges simultaneously. This method is often used for small or intricate parts that would be difficult to finish by hand.

- CNC deburring machines: CNC-controlled deburring machines can perform precise edge finishing on complex parts. These machines are programmable, allowing for consistent results in large production runs.

- Abrasive Brushes

Abrasive brushes are commonly used to remove burrs and round the edges of sheet metal without removing too much material. These brushes can be mounted on automated machines or used in handheld tools, depending on the scale of the operation.- Wire brushes: Wire brushes are used for heavy-duty deburring, especially on thicker metals like steel. The brushes can be mounted on a bench grinder or attached to handheld deburring tools.

- Nylon abrasive brushes: These brushes are embedded with abrasive particles, offering a softer deburring process that is suitable for thinner metals like aluminum or stainless steel.

- Laser Edge Finishing

Laser technology is increasingly being used in high-precision industries to achieve clean, burr-free edges during the cutting process. Laser edge finishing can significantly reduce the need for additional deburring, as the laser melts and seals the edge of the metal during the cutting process. While lasers are primarily used for cutting, their ability to leave a smooth edge makes them a valuable tool in the edge finishing process, especially for materials like stainless steel and titanium.

The Importance of Sheet Metal Edge Finishing

Edge finishing plays a critical role in the functionality, safety, and appearance of sheet metal components. Here are some of the key reasons why edge finishing is an essential part of the metalworking process:

- Improved Safety

Rough, sharp edges on sheet metal parts can pose significant safety risks to workers who handle the parts or to consumers who use the final products. By removing burrs and sharp edges, edge finishing tools help to create safer working environments and reduce the risk of cuts and injuries during handling and assembly. - Enhanced Product Quality

Edge finishing improves the overall appearance and quality of metal parts. In industries like aerospace, automotive, and electronics, the final product’s aesthetic and functional quality is paramount. Burrs or rough edges can interfere with the assembly process or lead to functional issues, such as improper fits or the accumulation of debris between parts. - Improved Durability and Performance

In some cases, burrs or rough edges can lead to premature wear or failure of metal parts. For example, burrs can create stress concentrations, which may cause cracking or failure under load. Smoothing the edges of sheet metal ensures that parts can withstand operational stresses and perform as intended over time. - Tighter Fit and Tolerances

Sheet metal components often need to fit precisely within larger assemblies. Burrs and rough edges can affect the fit of the part, leading to gaps, misalignments, or poor sealing. By removing imperfections on the edges, edge finishing tools help manufacturers meet tight tolerances, ensuring that parts fit together seamlessly. - Corrosion Resistance

Rough edges can make metal parts more susceptible to corrosion, especially in environments where moisture or corrosive chemicals are present. By smoothing and finishing the edges, manufacturers can improve the corrosion resistance of sheet metal parts, extending their lifespan and performance in harsh environments.

Common Techniques for Sheet Metal Edge Finishing

Different finishing techniques are used depending on the type of metal, the shape of the part, and the desired quality of the finish. Below are some common techniques:

- Deburring

The most basic form of edge finishing, deburring removes sharp burrs left from cutting or punching operations. This is often done using rotary tools, abrasive brushes, or specialized deburring machines. Hand deburring is common for small or intricate parts, while automated deburring is used for high-volume production. - Chamfering

Chamfering is the process of cutting or grinding a bevel along the edge of a piece of sheet metal. This not only improves the appearance of the part but also allows for easier assembly, especially in situations where two parts need to fit together at an angle. - Rounding Edges

In many applications, sharp corners are rounded to reduce the risk of injury or to prevent damage to other components during assembly or use. Edge rounding is often performed using abrasive belts, discs, or brushes, and the degree of rounding can be adjusted depending on the application. - Polishing and Buffing

Polishing and buffing are used to achieve a high-quality surface finish on the edges of sheet metal parts. This process is especially important in industries where appearance matters, such as in consumer goods or architectural metalwork. Polishing removes surface imperfections, while buffing brings the metal to a shine. - Electropolishing

Electropolishing is a finishing process that uses an electrolytic solution to remove material from the surface of a metal part. This process not only smooths rough edges but also improves corrosion resistance and creates a bright, reflective finish. Electropolishing is commonly used for stainless steel parts, especially in industries like food processing or pharmaceuticals, where cleanliness and corrosion resistance are critical.

Automation in Edge Finishing

Automation has become increasingly prevalent in edge finishing, especially for industries that require high-volume production or parts with complex geometries. Automated systems provide consistent results, reduce labor costs, and improve overall efficiency.

- CNC Edge Finishing Machines

CNC (Computer Numerical Control) technology has revolutionized the edge finishing process by allowing machines to be programmed with precise specifications. CNC edge finishing machines can perform complex deburring, chamfering, and polishing operations with a high degree of accuracy and repeatability. - Robotic Deburring Systems

Robotic systems are commonly used in edge finishing to automate tasks that are repetitive or require high precision. Robots can be equipped with deburring tools, abrasive brushes, or polishing heads, and programmed to finish the edges of parts in a consistent and efficient manner. These systems are particularly useful for parts with complex geometries, such as automotive body panels or aerospace components. - Automated Belt Sanders

Automated belt sanders are widely used for edge finishing in industries like metal fabrication and construction. These machines use abrasive belts to smooth and round the edges of sheet metal parts. They are often equipped with sensors that adjust the pressure and speed of the sanding process based on the thickness and hardness of the metal. - Vision-Based Systems

Advanced automation systems often incorporate vision-based inspection systems that check the quality of the edge finish in real-time. These systems use cameras and sensors to detect imperfections, such as burrs or rough spots, and can automatically adjust the finishing process to correct any issues. This level of automation ensures that parts meet strict quality standards without the need for manual inspection.

Challenges in Sheet Metal Edge Finishing

Despite the advancements in tools and automation, there are still several challenges associated with sheet metal edge finishing:

- Complex Geometries

Parts with intricate shapes, curves, or internal features can be difficult to finish using traditional deburring tools. Automated systems, such as robotic arms, help address this challenge, but achieving consistent results on complex parts remains difficult without custom tooling or programming. - Material-Specific Challenges

Different metals respond to edge finishing in different ways. For example, aluminum is softer than steel and more prone to galling (material build-up on the cutting tool), which requires specialized tools and techniques. Harder metals, like titanium, are more resistant to wear but may require more aggressive finishing techniques that risk damaging the part. - Balancing Efficiency and Quality

In high-volume production, manufacturers must balance the need for speed with the need for quality. Rushing the edge finishing process can lead to inconsistent results, but slowing down the process can reduce productivity. Automated systems that adjust parameters in real-time are helping to solve this issue, but it remains a challenge for many manufacturers. - Environmental Impact

Some finishing processes, such as chemical deburring or electropolishing, can have negative environmental impacts due to the use of hazardous chemicals or the generation of waste materials. Manufacturers are increasingly adopting more eco-friendly processes, such as water-based polishing or mechanical deburring, to reduce their environmental footprint.

Future Trends in Edge Finishing Technology

As technology continues to advance, several trends are shaping the future of sheet metal edge finishing:

- Laser Finishing Technology

Laser-based finishing systems are gaining traction due to their ability to create smooth, precise edges without the need for mechanical tools. These systems can cut and finish the edges of sheet metal in a single operation, reducing the need for multiple machines and processes. - Adaptive Machining Systems

Adaptive machining systems are equipped with sensors and AI algorithms that can adjust the finishing process in real-time based on the material, thickness, and shape of the part. These systems can optimize the finishing process for each individual part, improving both quality and efficiency. - 3D Printing Integration

3D printing technology is increasingly being used in conjunction with traditional sheet metal forming processes. In the future, edge finishing tools may be integrated with additive manufacturing systems to finish parts immediately after they are printed, reducing the need for post-processing. - Eco-Friendly Finishing Solutions

As environmental regulations become stricter, manufacturers are looking for ways to reduce the environmental impact of edge finishing. This includes developing new, eco-friendly abrasive materials, adopting water-based polishing techniques, and reducing the use of hazardous chemicals.

Square Tube Bending Machine

Square tube bending machines are specialized industrial machines designed to bend square or rectangular tubing into various shapes without compromising the integrity or structural properties of the material. Bending square tubes is a more challenging task compared to round tubes due to the risk of deformation, wrinkling, or collapsing of the sides. However, advances in technology and machine design have made it possible to achieve precise and repeatable bends in square tubing for a wide range of applications, including automotive, construction, furniture manufacturing, and architectural design.

These machines come in various configurations, including manual, hydraulic, and CNC-controlled versions, offering different levels of automation and flexibility depending on the complexity of the bend and the production volume required. This section will provide an in-depth look at how square tube bending machines operate, the types available, the processes involved, and the challenges and innovations within the industry.

Types of Square Tube Bending Machines

Square tube bending machines can be broadly classified into several categories based on their mode of operation and level of automation. Each type of machine is suited to different applications, materials, and production requirements.

- Manual Tube Bending Machines

Manual tube benders are simple, hand-operated machines used for bending smaller, lighter tubes. They are often used for one-off jobs, small production runs, or situations where complex automation is not required.- Simplicity: These machines are straightforward, relying on the operator to manually control the bending process.

- Applications: Typically used in small workshops or for custom fabrication, where the flexibility to make small, precise adjustments is important.

- Hydraulic Tube Bending Machines

Hydraulic tube bending machines use hydraulic power to bend square tubing, offering more power and precision than manual benders. These machines are commonly used in industrial settings where larger, thicker tubes are being processed.- Advantages: Hydraulically powered machines can handle larger tube sizes and provide consistent bending pressure, reducing the risk of material deformation.

- Applications: These machines are commonly used in construction, automotive production, and industries requiring heavy-duty bending of square tubing.

- CNC Tube Bending Machines

CNC (Computer Numerical Control) tube bending machines represent the highest level of automation and precision. These machines are programmable, allowing for highly accurate and repeatable bends in complex shapes. The CNC system controls multiple axes of movement, ensuring precision in the positioning and rotation of the tube during the bending process.- Automation: CNC machines can be pre-programmed to bend tubes to exact specifications, making them ideal for high-volume production.

- Flexibility: These machines can handle a wide range of tube sizes, materials, and bend angles, making them suitable for industries such as aerospace, automotive, and structural metalwork.

- Rotary Draw Bending Machines

Rotary draw benders are a common type of tube bending machine used for making precise and tight radius bends in square tubing. This method is particularly useful when high-quality, consistent bends are required.- Precision: These machines maintain the tube’s cross-sectional shape during bending, reducing the risk of deformation.

- Applications: Used in industries like automotive, where high-quality bends are required for exhaust systems, roll cages, and chassis components.

- Roll Bending Machines

Roll bending machines use a set of rollers to gradually bend the tube into the desired shape. This process is ideal for large-radius bends and is particularly useful for long sections of tubing.- Gentle Bends: Roll bending is a gradual process that minimizes the risk of tube distortion, making it suitable for bending longer sections of square tubing.

- Applications: Common in architectural projects, construction, and large-scale manufacturing.

How Square Tube Bending Machines Work

The process of bending square tubes requires special considerations compared to round tubes, primarily due to the risk of the tube’s walls collapsing, wrinkling, or deforming during bending. The design of the bending machine and the process it employs help to mitigate these risks. Below is an overview of the key components and working principles of square tube bending machines.

- Clamp and Die Setup

The bending process starts by securing the tube in place using a clamp die, which holds the tube tightly against the bending die. The bending die is designed with a specific radius that matches the desired bend, ensuring that the tube is bent smoothly without kinking or deforming. - Mandrel Support

For tight radius bends, a mandrel is often used to support the interior of the tube. The mandrel is inserted into the tube to prevent the walls from collapsing or wrinkling during the bending process. Mandrels are typically used in CNC and hydraulic bending machines when precision is required, and they are crucial for bending thin-walled or delicate materials. - Bend Radius and Angle Control

Square tube bending machines can be adjusted to produce various bend radii and angles. The desired angle of the bend is programmed into the machine (in CNC models) or controlled manually or hydraulically in other models. For most applications, the bend radius must be carefully controlled to avoid flattening the sides of the square tube. - Pressure Die

A pressure die is used to apply force to the tube during the bending process, guiding it along the desired path. This die works in conjunction with the bending die to ensure that the tube maintains its cross-sectional shape and does not deform. - Springback Compensation

One of the challenges in tube bending is compensating for the natural “springback” of the material. When metal is bent, it tends to spring back slightly once the pressure is removed. CNC machines automatically compensate for springback by over-bending the tube slightly, ensuring that the final shape matches the specifications.

Bending Techniques for Square Tubes

Bending square tubing requires different techniques compared to round tubing, primarily due to the flat surfaces and sharp corners that must be maintained throughout the bend. Here are the most common techniques used in square tube bending:

- Rotary Draw Bending

Rotary draw bending is the most common method for bending square tubes with tight radii. The tube is clamped into place, and a rotating die draws the tube around a fixed bend die to create the desired shape. This method ensures that the tube’s cross-section is maintained throughout the bend, preventing deformation. - Mandrel Bending

Mandrel bending is typically used for bending thin-walled square tubing or when a very tight radius is required. The mandrel is inserted into the tube to provide internal support during the bend, preventing the walls from collapsing. Mandrel bending is often used in industries that require high precision, such as aerospace or automotive manufacturing. - Compression Bending

Compression bending involves pushing the tube into a bending die, compressing it to form the desired angle. This method is often used for simpler bends but is not ideal for tight-radius bends or for maintaining the tube’s structural integrity. - Roll Bending

Roll bending is used for creating large, gradual bends in square tubing. The tube is passed through a series of rollers that apply pressure gradually, allowing the tube to bend without deforming. This method is ideal for applications requiring large radii, such as in structural or architectural metalwork.

Applications of Square Tube Bending

Square tubing is used across a wide range of industries, and the ability to bend it into precise shapes is crucial for many applications. Some of the most common applications of square tube bending include:

- Automotive Industry

Square tube bending machines are used extensively in the automotive industry to produce parts such as roll cages, exhaust systems, and structural components for vehicle frames. The ability to create precise, repeatable bends is critical for ensuring the safety and performance of these components. - Construction and Structural Fabrication

In the construction industry, square tubing is often used in the framework of buildings, bridges, and other structures. Bending machines allow for the creation of complex, custom shapes that are used in everything from support columns to decorative architectural elements. - Furniture Manufacturing

Square tubing is commonly used in the manufacture of metal furniture, such as chairs, tables, and shelving units. Tube bending machines are essential for creating the smooth, consistent bends needed for modern furniture designs. - Architectural Metalwork

In architecture, square tubing is used for both structural and decorative purposes. Bending machines allow architects and builders to create custom designs for railings, staircases, and façades, giving buildings a unique and modern appearance. - Aerospace Industry

The aerospace industry requires highly precise components made from lightweight but strong materials. Square tube bending machines are used to create structural components and frames that meet the stringent requirements of the aerospace sector. - Agricultural Equipment

Square tubing is used in the manufacture of agricultural machinery and equipment, such as frames, support structures, and conveyors. Bending machines allow manufacturers to produce custom shapes and components that are essential for the proper functioning of farming equipment.

Challenges in Square Tube Bending

Despite advancements in technology, square tube bending presents several challenges that manufacturers must address to ensure high-quality results:

- Deformation and Wall Collapse

One of the biggest challenges in bending square tubing is maintaining the integrity of the tube’s shape during the bend. Without proper support, the walls of the tube can collapse or become deformed, resulting in a compromised product. The use of mandrels, internal supports, and precise machine settings is essential to avoid these issues. - Springback

Metal has a natural tendency to spring back after being bent, which can cause inaccuracies in the final product. CNC bending machines are equipped with springback compensation features that adjust the bend angle to account for this effect, but manual and hydraulic machines require skilled operators to account for it. - Material Properties

Different materials react differently to bending forces. Softer metals, such as aluminum, are prone to cracking or wrinkling if not bent correctly, while harder metals, like stainless steel, require more force and precision to bend without deformation. Each material requires specific settings on the bending machine, as well as the use of appropriate tooling, to achieve the desired results. - Tight Radius Bends

Creating tight-radius bends in square tubing is particularly challenging, as the material is more likely to deform or collapse under the pressure. Mandrel bending and rotary draw bending are often used to mitigate these risks, but the complexity of the bend and the thickness of the tube can still make tight bends difficult to achieve. - Maintaining Consistency in Production

In high-volume production environments, maintaining consistency between each bend is crucial. CNC machines offer a high degree of repeatability, but in manual or hydraulic systems, operator skill plays a significant role in ensuring that each part is identical.

Advancements in Square Tube Bending Technology

Recent innovations in tube bending technology have significantly improved the capabilities of square tube bending machines, making them more efficient, precise, and versatile. Some of the key advancements include:

- CNC Automation and Software Integration

CNC-controlled square tube bending machines have revolutionized the industry by allowing for precise, repeatable bends with minimal operator intervention. These machines are often integrated with advanced software systems that can simulate the bending process, detect potential issues such as springback, and automatically adjust machine settings to achieve the desired results. - Hybrid Machines

Hybrid bending machines combine hydraulic and electric power to provide greater flexibility and precision. These machines are capable of handling both large and small tubes, offering manufacturers the ability to switch between different materials and bend specifications with ease. - Laser Measurement Systems

Advanced bending machines are now equipped with laser measurement systems that provide real-time feedback on the angle and radius of each bend. This allows the machine to automatically adjust the bend parameters mid-process, ensuring that each bend meets exact specifications. - 3D Bending Capabilities

Newer machines offer 3D bending capabilities, allowing for complex shapes and multi-plane bends to be created in a single process. This is particularly useful for industries such as automotive and aerospace, where intricate part geometries are often required. - Energy Efficiency

Modern bending machines are designed with energy efficiency in mind. Electric and hybrid machines use less energy than traditional hydraulic machines, reducing operating costs and minimizing the environmental impact of the bending process.

Future Trends in Square Tube Bending

The future of square tube bending is being shaped by several emerging trends and technologies, including:

- Industry 4.0 and IoT Integration

As Industry 4.0 and the Internet of Things (IoT) continue to transform manufacturing, square tube bending machines are increasingly being connected to larger production networks. IoT sensors provide real-time data on machine performance, maintenance needs, and production metrics, allowing for more efficient and predictive operations. - Artificial Intelligence (AI) in Bending Processes

AI-powered systems are being integrated into tube bending machines to optimize the bending process. These systems can analyze vast amounts of data to predict material behavior, optimize bend sequences, and reduce the need for trial-and-error during setup. - Additive Manufacturing and Hybrid Fabrication

Additive manufacturing (3D printing) is being explored as a complementary technology to traditional tube bending. In the future, manufacturers may be able to combine 3D-printed components with bent tubes in a single production process, reducing lead times and material waste. - Sustainability and Eco-Friendly Manufacturing

As environmental concerns continue to grow, the tube bending industry is focusing on sustainability. This includes reducing material waste, improving energy efficiency, and adopting greener production methods. Manufacturers are also exploring the use of recyclable materials in tube production, which will require new bending techniques and equipment adjustments.

Joggling in Sheet Metal

Joggling is a specific metalworking technique that involves creating a series of bends or notches along the edge of a sheet metal part to facilitate interlocking, fit-up, or to allow for a tighter assembly in various applications. This process is crucial in industries where precision and tight tolerances are necessary, such as in automotive, aerospace, and construction sectors. Joggling not only enhances the functionality of metal components but also contributes to their structural integrity and overall aesthetic.

This section will delve into the jiggling process, its various applications, tools used, and the advancements in jiggling technology.

Understanding the Joggling Process

The jiggling process typically involves creating a series of alternating bends or notches along the edge of the sheet metal. This can be accomplished through various methods, including manual techniques and automated processes. The key steps involved in joggling are as follows:

- Material Preparation

Before jiggling, the sheet metal must be prepared by cutting it to the desired dimensions. This involves using shearing or laser cutting methods to ensure precise edges. - Marking and Layout

Accurate marking of the sheet metal is critical for effective jiggling. This includes indicating where bends and notches will be created. Advanced CAD (Computer-Aided Design) software can help streamline this process, ensuring that measurements are precise. - Bending Techniques

There are two primary bending techniques used in joggling:- Manual Bending: For small-scale production or custom work, manual jiggling can be performed using hand tools such as hammers and bending brakes.

- Automated Bending: In high-volume production environments, CNC bending machines are used. These machines can perform complex jiggling operations with high precision and repeatability.

- Inspection and Quality Control

After the joggling process, it is essential to inspect the parts to ensure that the bends and notches meet the required specifications. This may involve visual inspections as well as dimensional checks using tools such as calipers and gauges.

Applications of Joggling in Metalworking

Joggling serves several important functions in metalworking and is employed in a variety of applications across different industries:

- Structural Components

In construction and structural applications, joggling is used to create interlocking joints in steel frames, enabling better load distribution and enhancing structural stability. - Automotive Manufacturing

Joggling is frequently used in the automotive industry to create components that fit together tightly, such as brackets and panels. This technique helps reduce vibrations and improve the overall durability of automotive structures. - Aerospace Components

In aerospace applications, joggling is employed to create lightweight yet strong connections in fuselage structures and wing assemblies. The precision offered by joggling ensures that components meet stringent safety and performance standards. - HVAC Ductwork

Joggled seams are commonly used in HVAC (heating, ventilation, and air conditioning) ductwork to facilitate the assembly of ducts and ensure airtight connections. - Consumer Products

In the manufacturing of consumer products, joggling can be seen in items like metal furniture and appliances, where aesthetic appeal and structural integrity are essential.

Tools and Equipment for Joggling

Several tools and machines are commonly used to perform joggling in sheet metal, ranging from manual tools to sophisticated automated systems:

- Manual Joggling Tools

- Bending Brakes: Used for making precise bends in sheet metal. They can be manual or powered and are essential for creating consistent joggles.

- Hand Tools: Hammers, chisels, and pliers can be utilized for manual jiggling, especially in low-volume or custom jobs.

- CNC Joggling Machines

CNC machines can perform jiggling operations with high precision. They can be programmed to create specific joggle patterns, ensuring repeatability and accuracy in high-volume production. - Hydraulic Presses

Hydraulic presses are often used in conjunction with dies to create joggles in thicker materials. The high force provided by hydraulic systems allows for the bending of robust materials with minimal risk of deformation. - Notching Machines

Notching machines are specifically designed to create notches in sheet metal. They are valuable for preparing materials for jiggling, particularly in applications that require interlocking features.

Challenges in Joggling

While joggling is a valuable technique in metalworking, it comes with its own set of challenges that manufacturers must address:

- Material Limitations

Different metals respond differently to jiggling. Softer metals, like aluminum, may be more prone to deformation, while harder metals, like stainless steel, require more force and precision. Selecting the right material for the application is crucial. - Precision and Tolerances

Achieving precise joggles is essential for ensuring proper fit-up and assembly. Tolerances must be strictly controlled, especially in industries like aerospace, where safety is paramount. - Production Speed

In high-volume manufacturing, maintaining production speed while ensuring quality can be challenging. Automated jiggling processes help, but the initial setup and programming can be time-consuming. - Post-Processing Requirements

After joggling, additional processes such as deburring or polishing may be necessary to achieve the desired finish. This adds time and complexity to the overall manufacturing process.

Innovations in Joggling Technology

Recent advancements in technology have improved the efficiency and effectiveness of joggling processes, making them more accessible and versatile:

- Advanced Software Integration

CAD and CAM (Computer-Aided Manufacturing) software allow manufacturers to design complex joggle patterns with precision. This integration streamlines the production process and reduces errors. - Automated Inspection Systems

Automated inspection systems equipped with sensors and cameras can verify the quality of joggles in real-time, reducing the need for manual checks and ensuring high-quality output. - Robotic Joggling Systems

Robotics are being integrated into jiggling operations to enhance flexibility and efficiency. Robotic arms can perform joggling tasks quickly and accurately, allowing for greater production speeds. - Sustainable Manufacturing Practices

As environmental concerns grow, manufacturers are adopting eco-friendly practices, such as using recyclable materials and minimizing waste during the joggling process. Innovative techniques are being developed to reduce energy consumption and improve overall sustainability.

Future Trends in Joggling Technology

As the industry continues to evolve, several trends are shaping the future of joggling in metalworking:

- Increased Automation

The trend towards automation in manufacturing will likely continue, with more companies investing in robotic systems and CNC machines to perform joggling tasks efficiently and accurately. - Customization and Flexibility

As customer demands for customized products increase, joggling processes will need to adapt to accommodate a wider range of shapes and designs. This may involve the development of more versatile jiggling machines capable of handling various materials and sizes. - Integration with Additive Manufacturing

The integration of joggling techniques with additive manufacturing processes could allow for new product designs and innovative applications, enabling manufacturers to create complex geometries with ease. - Focus on Sustainability

The metalworking industry is likely to continue its push toward sustainable practices, with a focus on reducing waste and environmental impact throughout the joggling process. This will include exploring new materials and processes that align with eco-friendly manufacturing standards.

Buffing Grinder Machines

Buffing grinder machines are essential tools in the metalworking and manufacturing industries, used primarily for the surface finishing of metals and other materials. These machines enhance the appearance of parts by polishing and smoothing surfaces to achieve a mirror-like finish. Buffing is a critical step in various processes, particularly in industries such as automotive, aerospace, and consumer goods, where the aesthetic and functional qualities of metal components are vital.

This section explores the workings of buffing grinder machines, their applications, advantages, challenges, and recent advancements in technology.

Understanding Buffing Grinder Machines

Buffing grinder machines utilize rotating abrasive wheels or pads to polish surfaces. The process involves applying a compound to the surface of the workpiece while the machine rotates, effectively removing imperfections and enhancing the overall finish. Key components of a buffing grinder machine include:

- Abrasive Wheels

Buffing wheels come in various materials, such as cotton, felt, and synthetic composites, each suited for different applications and finishes. The choice of abrasive affects the polishing efficiency and the final surface quality. - Drive Mechanism

Buffing machines typically use electric motors to drive the rotation of the wheels. These motors can vary in power and speed, allowing for flexibility in operations based on the requirements of the job. - Compound Application

Buffing compounds, which can be wax-based or chemical, are applied to the workpiece. These compounds contain abrasive particles that assist in smoothing the surface and removing any residual oxidation or tarnish. - Workpiece Fixtures

Many buffing machines include fixtures or jigs to hold the workpieces securely in place during the buffing process. This ensures uniform application and helps prevent movement that could lead to inconsistent finishes.

Applications of Buffing Grinder Machines

Buffing grinder machines are utilized across a range of industries for various applications, including:

- Metal Finishing

Buffing is commonly employed to finish metal parts, such as automotive components, kitchen appliances, and decorative hardware. A smooth, shiny finish not only enhances aesthetics but also improves corrosion resistance. - Jewelry Making

In the jewelry industry, buffing machines are vital for polishing precious metals and stones, ensuring that the final products meet high-quality standards for both appearance and durability. - Machinery Components

Buffing grinder machines are used to polish and smooth critical machinery parts, including gears, shafts, and bearings, improving their performance and extending their service life. - Furniture and Fixtures

Buffing is also used in the production of furniture and fixtures made from metal or metal-coated materials, providing a clean and polished finish that enhances their marketability. - Artistic Metalwork

Artists and craftsmen use buffing machines to achieve fine finishes on sculptures, decorative items, and custom metalwork, where detail and quality are paramount.

Advantages of Buffing Grinder Machines

Buffing grinder machines offer several benefits that make them indispensable in various manufacturing processes:

- Improved Surface Quality