CNC metal spinning and flow forming are advanced manufacturing processes widely used in the production of military projectiles, including shells, missile casings, and pressure vessels. These techniques offer exceptional precision, material efficiency, and structural integrity—critical attributes for defense applications.

Military Applications of Metal Spinning & Flow Forming

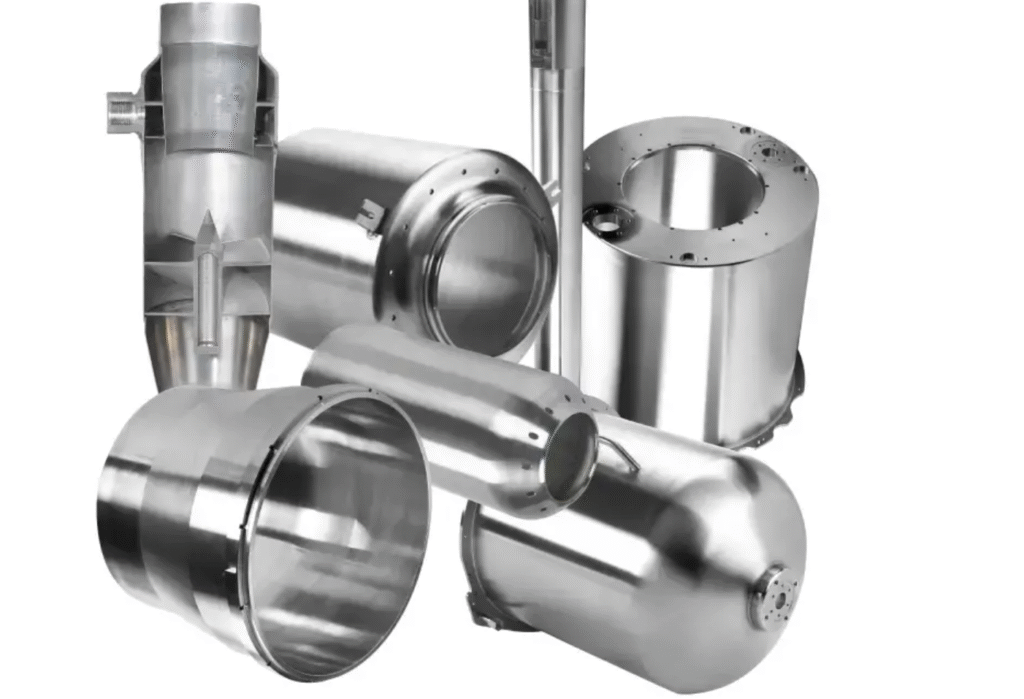

Both processes are integral to producing rotationally symmetric components such as:

- Missile and torpedo shells

- Rocket motor casings

- Pressure vessels and gas cylinders

- Hydraulic and servo cylinders

- Engine housings

- Aerospace and defense components

These methods are particularly effective for materials like aluminum, maraging steel, stainless steel, and high-temperature alloys

Key Technologies & Capabilities

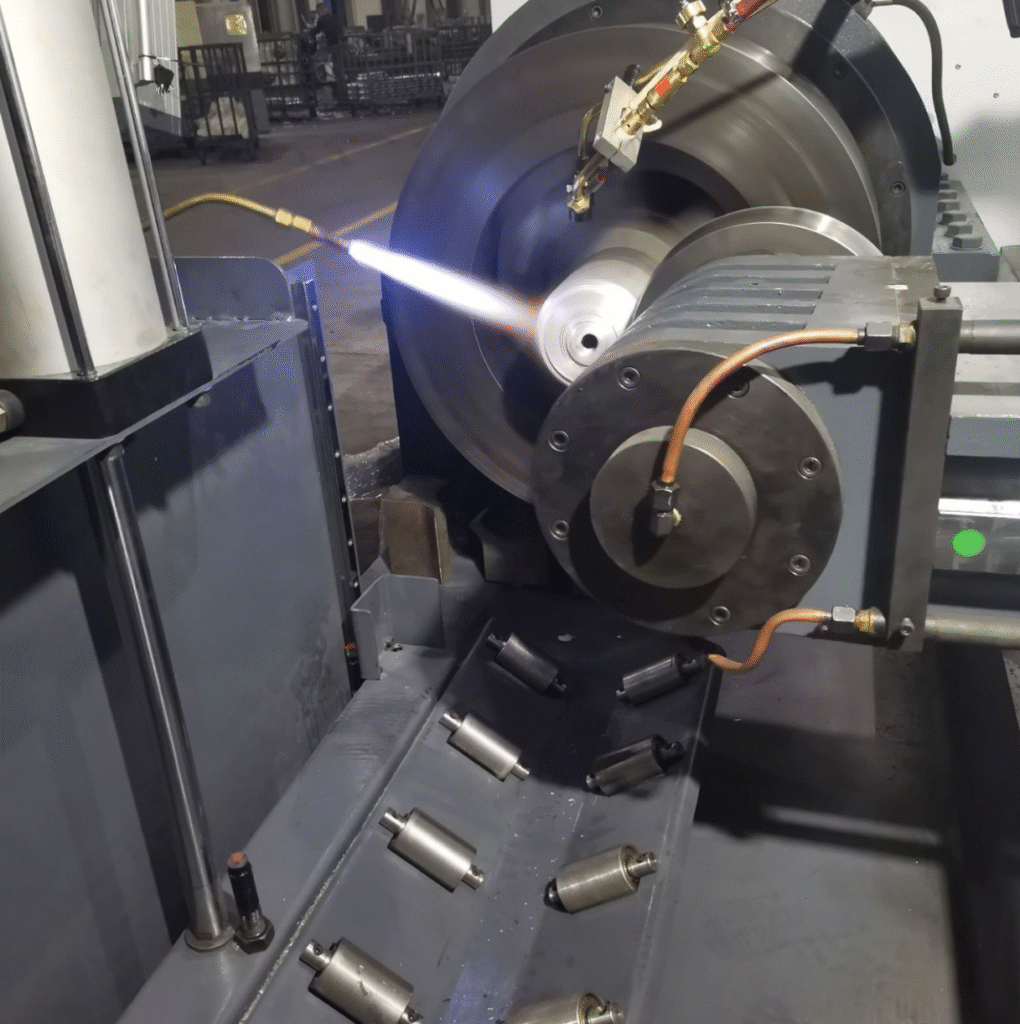

Flow Forming:

- Utilizes multiple CNC-controlled rollers to form tubular components over a mandrel.

- Reduces wall thickness uniformly while maintaining strength and durability.

- Ideal for producing components like rocket motor cases and pressure vessels

Metal Spinning:

- Shapes metal sheets into axially symmetrical parts by rotating them at high speeds.

- Suitable for creating complex geometries with tight tolerances.

- Commonly used for components such as missile nose cones and torpedo shells

Comparison: Metal Spinning vs. Flow Forming

| Feature | Metal Spinning | Flow Forming |

|---|---|---|

| Process | Rotational shaping of metal sheets | Forming of tubular components over a mandrel |

| Material Efficiency | Moderate | High |

| Wall Thickness Control | Limited | Precise and uniform |

| Ideal Applications | Complex geometries, small to medium parts | Tubular components, large parts |

| Common Materials | Aluminum, stainless steel | Maraging steel, high-temperature alloys |

CNC metal spinning and flow forming machines are essential technologies for the production of military projectiles, offering the precision, repeatability, and material efficiency required in defense applications. These processes allow the fabrication of rotationally symmetric components such as missile casings, artillery shells, torpedo bodies, and rocket motor housings with exceptionally tight tolerances and consistent mechanical properties. In metal spinning, a metal blank is rotated at high speed on a CNC-controlled lathe while rollers or a forming tool progressively shape the material against a mandrel, producing complex geometries and smooth surfaces. This method is especially valuable for forming projectile nose cones, warhead housings, and other aerodynamically critical parts, where uniform thickness and structural integrity are crucial for performance under extreme conditions.

Flow forming, on the other hand, utilizes CNC-controlled rollers to progressively reduce the wall thickness of a preformed tube or cylindrical blank over a precision mandrel while simultaneously elongating the component. This technique produces tubular casings with high strength-to-weight ratios, excellent surface finish, and precise wall uniformity, making it ideal for rocket motor casings, large caliber shell bodies, and high-pressure vessels used in both tactical and strategic military systems. Both processes are compatible with a wide range of materials including aluminum alloys, maraging steels, stainless steels, titanium, and high-temperature nickel-based alloys, allowing designers to optimize weight, toughness, and thermal performance according to the operational requirements of the projectile.

Leading manufacturers of CNC metal spinning and flow forming machines provide fully automated, programmable solutions capable of high-volume production, ensuring repeatability and minimizing material waste. Companies such as Altron and AST offer turnkey systems specifically designed for defense industries, combining advanced motion control, real-time monitoring, and rapid changeover capabilities to meet the demanding production schedules of modern military programs. These machines can handle both small and large-diameter components, with capabilities to spin or flow form items ranging from a few centimeters to several meters in length, depending on the design of the projectile or pressure vessel.

The integration of CNC control allows for precise replication of component geometries, consistent wall thickness, and accurate dimensional tolerances across production batches, which is critical for ensuring the reliability and safety of military munitions. In addition, advancements in process simulation, in-line inspection, and tool wear compensation have further enhanced the performance of metal spinning and flow forming, enabling manufacturers to produce lightweight yet extremely strong projectile casings that can withstand the mechanical stresses of firing, impact, and explosive loads. Overall, the combination of CNC metal spinning and flow forming provides a highly versatile and efficient method for producing military-grade projectiles, offering significant advantages in terms of material conservation, structural integrity, and geometric precision, all of which are essential for the demanding requirements of modern defense applications.

CNC metal spinning and flow forming machines represent some of the most advanced manufacturing technologies in the defense sector, particularly in the production of military projectiles where precision, structural integrity, and material efficiency are paramount. Metal spinning, a process in which a metal blank is rotated at high speed while a CNC-controlled roller or tool gradually shapes it over a mandrel, allows for the creation of highly complex rotationally symmetric components such as artillery shell bodies, missile casings, torpedo housings, and rocket motor tubes.

The process ensures tight tolerances, smooth surfaces, and consistent wall thickness, which are critical for parts that must endure extreme mechanical stresses during firing, flight, or detonation. Flow forming complements this by using CNC-controlled rollers to elongate and thin preformed tubes over precision mandrels, producing high-strength tubular components with uniform wall thickness, excellent surface finish, and superior mechanical properties. This makes it especially suitable for high-pressure applications such as rocket motor casings, large-caliber shells, and structural components in aerospace and defense systems. Both metal spinning and flow forming are compatible with a wide range of materials, including high-strength aluminum alloys, maraging steel, stainless steel, titanium, and nickel-based superalloys, allowing engineers to tailor the balance between weight, durability, and thermal resistance according to specific military requirements.

Modern CNC machines integrate real-time process monitoring, automated tool path control, and in-line inspection systems, which ensure repeatable accuracy and reduce material waste, a critical consideration when working with expensive or high-performance metals. Manufacturers such as Altron, AST, and MJC Engineering provide highly automated, programmable systems capable of producing both small and large-scale components for defense projects, with features like rapid changeover, multi-axis control, and adaptive speed regulation to maintain material integrity and dimensional accuracy. Advances in simulation software, adaptive tooling, and wear-compensated control have further expanded the capabilities of CNC metal spinning and flow forming, enabling the production of projectile components that are both lightweight and extremely robust, capable of withstanding the dynamic stresses of launch, impact, and detonation.

The combination of these two technologies offers a versatile, high-efficiency solution for modern military manufacturing, allowing the defense industry to produce high-quality projectiles with optimized structural performance, minimal material loss, and consistent quality across production runs, ensuring that every shell, missile casing, or rocket tube meets stringent operational and safety standards. This integration of precision machining, material science, and CNC automation makes metal spinning and flow forming indispensable for modern defense manufacturing programs, where performance, reliability, and repeatability are non-negotiable.

CNC metal spinning and flow forming machines are critical technologies for the production of high-performance military projectiles, providing precision, material efficiency, and structural integrity that are essential in defense applications. Metal spinning involves rotating a metal blank at high speed while a CNC-controlled roller or forming tool gradually shapes it over a mandrel, producing rotationally symmetric components such as artillery shells, missile casings, torpedo bodies, and rocket motor tubes.

This process allows for tight tolerances, consistent wall thickness, and smooth surface finishes, all of which are crucial for components that must withstand extreme mechanical stresses during firing, flight, and impact. The ability to shape complex geometries with high accuracy makes metal spinning particularly suitable for projectile nose cones, warhead housings, and aerodynamic surfaces where uniformity and precision directly affect performance and reliability.

Flow forming complements metal spinning by elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers. This process produces tubular components with uniform wall thickness, superior mechanical properties, and high strength-to-weight ratios, which are essential for rocket motor casings, large-caliber shell bodies, and high-pressure vessels used in tactical and strategic defense systems. Flow forming also allows for efficient use of high-strength materials such as aluminum alloys, maraging steel, stainless steel, titanium, and nickel-based superalloys, optimizing weight, durability, and thermal resistance according to the operational requirements of the projectile. The combination of metal spinning and flow forming ensures that components meet stringent military specifications, maintaining structural integrity while reducing material waste, which is critical when working with expensive or high-performance metals.

Modern CNC machines for metal spinning and flow forming integrate advanced features such as multi-axis control, automated tool path programming, adaptive speed regulation, and real-time process monitoring. These capabilities enable manufacturers to achieve repeatable accuracy, minimize defects, and maintain consistent quality across production batches. Leading suppliers in this sector, including Altron, AST, and MJC Engineering, provide fully automated systems tailored for defense applications, capable of handling both small and large-diameter components. These machines also offer rapid changeover and adaptive tooling, allowing manufacturers to respond to evolving project requirements while maintaining efficiency and precision.

Advances in simulation software, in-line inspection, and wear-compensation technology have further enhanced the effectiveness of CNC metal spinning and flow forming. Engineers can now model material flow, stress distribution, and tool interactions before production, ensuring optimal component performance and minimizing costly trial runs. As a result, manufacturers can produce lightweight, extremely strong projectile casings and rocket tubes capable of withstanding the mechanical stresses of launch, flight, and detonation. Overall, the integration of CNC metal spinning and flow forming provides a versatile, high-efficiency solution for modern defense manufacturing, combining precision, repeatability, and material optimization to deliver military projectiles that meet rigorous operational and safety standards.

CNC Metal Spinning and Flow Forming Machine for Howitzer Rounds

CNC metal spinning and flow forming machines are increasingly critical in the production of howitzer rounds, offering the precision, structural integrity, and material efficiency required for modern artillery munitions. Howitzer shells demand high-strength casings capable of withstanding immense pressures and stresses during firing, and both metal spinning and flow forming provide the ideal methods to meet these rigorous requirements. In metal spinning, a cylindrical or conical metal blank is rotated at high speeds while a CNC-controlled roller or forming tool progressively shapes the material over a mandrel, producing perfectly rotationally symmetric components. This technique is especially effective for shaping projectile nose cones, shell bodies, and driving bands, where uniform wall thickness and smooth surface finishes are essential for consistent ballistic performance. The process allows for tight tolerances, minimizing dimensional variations that could affect accuracy or safety, and is compatible with high-strength materials such as maraging steel, aluminum alloys, and stainless steels, which are commonly used in artillery rounds.

Flow forming complements metal spinning by elongating and thinning preformed tubular blanks over precision mandrels using CNC-controlled rollers. This produces howitzer shell bodies with highly uniform wall thickness, superior mechanical properties, and optimized weight-to-strength ratios. Flow forming is particularly useful for producing larger caliber rounds, where the structural demands on the casing are extreme, and material efficiency is important to reduce both weight and cost. The combination of CNC control, adaptive tool paths, and precise wall thickness regulation ensures that each round maintains consistent internal and external dimensions, critical for compatibility with the howitzer’s chamber, rifling, and ballistic requirements.

Modern CNC machines designed for metal spinning and flow forming of howitzer rounds incorporate advanced features such as multi-axis control, real-time process monitoring, automated tool path adjustment, and in-line quality inspection systems. These capabilities enable manufacturers to achieve repeatable precision, minimize material waste, and maintain high production rates while ensuring each shell meets military specifications. Leading suppliers in this space provide turnkey solutions capable of producing both small and large-diameter howitzer rounds, with the flexibility to handle different calibers, shell lengths, and material types. The integration of simulation software, wear-compensated tooling, and automated monitoring further enhances production reliability, allowing engineers to predict and control material flow, stress distribution, and wall thickness with exceptional accuracy.

Overall, the use of CNC metal spinning and flow forming machines in the manufacture of howitzer rounds represents a highly efficient and precise approach to artillery production. These technologies ensure that each round achieves optimal structural integrity, consistent ballistic performance, and high material efficiency, which are essential for the operational effectiveness and safety of modern artillery systems. By combining precision machining, advanced material handling, and CNC automation, metal spinning and flow forming provide a reliable, repeatable, and scalable solution for the manufacture of high-quality howitzer munitions.

CNC metal spinning and flow forming machines play a vital role in the production of howitzer rounds, combining precision engineering with material efficiency to meet the exacting requirements of modern artillery systems. Howitzer shells must withstand extreme pressures, high-speed acceleration, and the mechanical stresses generated during firing, and the integrity of the casing is critical for both performance and safety. Metal spinning achieves this by rotating a metal blank at high speed while a CNC-controlled roller or forming tool gradually shapes the material over a mandrel, producing perfectly symmetrical, aerodynamically optimized shells. This process ensures uniform wall thickness and smooth surface finishes, which are essential for predictable ballistic behavior and for maintaining tight tolerances between the shell and the rifling of the howitzer barrel. It is particularly effective for forming complex geometries such as the projectile nose, driving bands, and shell body contours, where dimensional accuracy directly impacts trajectory, range, and stability. Materials such as maraging steel, high-strength aluminum alloys, stainless steel, and other specialty metals are commonly used, allowing engineers to balance weight, toughness, and resistance to heat and pressure according to the design specifications of each round.

Flow forming complements metal spinning by providing precise control over wall thickness and material distribution in tubular components. In this process, preformed cylindrical blanks are progressively stretched and thinned over precision mandrels using CNC-controlled rollers, resulting in shell bodies that are lightweight yet exceptionally strong. The combination of controlled elongation, uniform wall thickness, and high structural integrity makes flow forming ideal for larger caliber howitzer rounds, where the demands on the casing are extreme and material efficiency is crucial. By maintaining consistent dimensions along the entire length of the shell, flow forming ensures compatibility with the howitzer chamber and rifling, reducing the risk of barrel wear or misfires while enhancing projectile performance. The process also minimizes material waste, which is particularly important when working with high-performance alloys, and allows for the optimization of mechanical properties such as tensile strength, ductility, and impact resistance.

Modern CNC systems for metal spinning and flow forming integrate advanced features such as multi-axis control, adaptive tool path programming, real-time monitoring, and in-line quality inspection. These technologies enable manufacturers to produce howitzer rounds with exceptional repeatability and precision, ensuring that each shell meets strict military specifications for safety, dimensional accuracy, and performance. Leading manufacturers provide turnkey solutions that accommodate a wide range of calibers, lengths, and materials, with automated changeover capabilities and wear-compensated tooling to maintain efficiency across production batches. Simulation software and predictive modeling allow engineers to anticipate material flow, stress distribution, and potential defects before production, further improving reliability and reducing costly trial runs. The synergy of CNC metal spinning and flow forming in artillery manufacturing allows for the production of lightweight, high-strength, and precisely dimensioned howitzer rounds that perform consistently under extreme conditions, ensuring operational readiness and effectiveness in the field. These combined technologies represent a sophisticated and highly efficient approach to modern artillery production, where precision, durability, and efficiency are essential for the safety and performance of military munitions.

CNC metal spinning and flow forming machines are essential for the manufacture of howitzer rounds, providing the precision, repeatability, and material efficiency that modern artillery systems demand. Howitzer shells are subjected to extreme pressures, rapid acceleration, and high rotational forces when fired, and the structural integrity of each casing is critical to ensure both performance and safety. Metal spinning achieves this by rotating a metal blank at high speeds while a CNC-controlled roller or forming tool gradually shapes it over a mandrel, producing rotationally symmetric components with consistent wall thickness, smooth surfaces, and highly accurate dimensions. This process is particularly valuable for forming the nose cones, driving bands, and cylindrical shell bodies of howitzer rounds, where tight tolerances are crucial for proper fit within the rifled barrel, consistent ballistic performance, and optimal aerodynamic behavior. High-strength materials such as maraging steel, aluminum alloys, stainless steel, and titanium are commonly used in this process, allowing engineers to optimize the balance between weight, toughness, and heat or pressure resistance according to the requirements of each round.

Flow forming complements metal spinning by elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular shell bodies that are lightweight yet extremely strong. This method ensures uniform wall thickness, superior mechanical properties, and high strength-to-weight ratios, which are critical for larger-caliber howitzer rounds that experience significant internal pressures during firing. The combination of controlled elongation and precise material distribution allows for highly efficient use of expensive alloys while maintaining structural integrity along the entire length of the shell. This is particularly important for large artillery munitions, where uniformity and dimensional accuracy directly affect performance, safety, and barrel compatibility. Flow forming also minimizes material waste, reduces the risk of defects, and allows manufacturers to achieve predictable, repeatable results across high-volume production runs, making it ideal for modern defense manufacturing programs.

Modern CNC systems for metal spinning and flow forming integrate advanced features such as multi-axis control, automated tool path programming, adaptive speed regulation, real-time process monitoring, and in-line quality inspection. These technologies allow manufacturers to produce howitzer rounds with exceptional precision, ensuring that each shell meets stringent military specifications for dimensional accuracy, structural integrity, and ballistic performance. Leading manufacturers provide fully automated solutions capable of producing a wide range of calibers and shell lengths, with features such as wear-compensated tooling, rapid changeover, and process simulation to predict material flow and stress distribution before production. The synergy of metal spinning and flow forming allows engineers to manufacture lightweight, high-strength howitzer shells that perform consistently under extreme conditions while optimizing material usage and minimizing production costs. By combining CNC automation, precise material handling, and advanced forming techniques, these machines ensure that each round achieves the necessary balance of durability, weight, and accuracy, providing reliable and effective artillery munitions for modern military operations.

CNC metal spinning and flow forming machines are indispensable in the production of howitzer rounds, providing the precision, structural integrity, and material efficiency necessary for modern artillery munitions. Howitzer shells must endure extreme internal pressures, rapid acceleration, and high rotational forces during firing, making the quality and consistency of each casing critical for both safety and performance. In metal spinning, a metal blank is rotated at high speed while a CNC-controlled roller or forming tool progressively shapes it over a mandrel, producing rotationally symmetric components with uniform wall thickness and smooth surfaces. This technique is particularly effective for forming the nose cones, driving bands, and cylindrical shell bodies of howitzer rounds, where tight tolerances are essential for proper fit within the barrel, reliable ballistic performance, and optimal aerodynamic properties. Materials such as maraging steel, stainless steel, aluminum alloys, and titanium are commonly used, allowing engineers to achieve the ideal balance between weight, toughness, and thermal or pressure resistance according to the design specifications of each round.

Flow forming complements metal spinning by gradually elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, resulting in lightweight yet extremely strong shell bodies. The process provides precise control over wall thickness and material distribution, producing tubular components with high strength-to-weight ratios and superior mechanical properties. This makes flow forming particularly valuable for larger-caliber howitzer rounds, where uniformity and structural integrity are critical to withstand the high stresses generated during firing. The method also reduces material waste and ensures consistent dimensional accuracy along the entire length of the shell, which is vital for chamber fit, barrel engagement, and overall ballistic consistency. By combining the advantages of metal spinning and flow forming, manufacturers can optimize material usage while achieving the precise geometries and tolerances required for modern artillery shells.

Advanced CNC systems for metal spinning and flow forming integrate multi-axis control, automated tool path programming, adaptive speed regulation, real-time process monitoring, and in-line quality inspection, ensuring repeatable precision and high production efficiency. Leading manufacturers provide fully automated solutions capable of handling various shell calibers and lengths, with features such as wear-compensated tooling, rapid changeover, and simulation-driven process optimization. These technologies allow engineers to model material flow, stress distribution, and potential defects before production, further reducing waste and improving reliability. The combination of CNC metal spinning and flow forming enables the production of lightweight, high-strength howitzer rounds that consistently meet stringent military specifications, ensuring optimal performance, safety, and durability. By leveraging precision machining, advanced material handling, and automated control, these technologies provide a highly efficient and reliable solution for manufacturing artillery munitions, delivering rounds that perform consistently under the most demanding operational conditions.

CNC Metal Spinning and Flow Forming Machine for Large-caliber Shells

CNC metal spinning and flow forming machines are crucial in the production of large-caliber shells, where precision, structural integrity, and material efficiency are of paramount importance. Large-caliber artillery rounds must withstand extreme pressures, rapid acceleration, and intense mechanical stresses during firing, making the consistency and strength of the shell casing essential for safety and performance. Metal spinning enables the formation of rotationally symmetric components by rotating a metal blank at high speed while a CNC-controlled roller or forming tool progressively shapes it over a mandrel. This process allows for highly accurate wall thickness, smooth surface finishes, and tight dimensional tolerances, making it ideal for forming the nose cones, driving bands, and cylindrical bodies of large-caliber shells. High-performance materials such as maraging steel, stainless steel, aluminum alloys, titanium, and other specialty alloys are commonly used, allowing engineers to optimize weight, toughness, and resistance to thermal and pressure stresses according to the design requirements of each shell.

Flow forming complements metal spinning by elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular shells with highly uniform wall thickness, superior strength-to-weight ratios, and excellent mechanical properties. This technique is especially effective for large-caliber shells, where the structural demands on the casing are extreme, and material efficiency is critical to reduce both weight and production costs. Flow forming ensures that the entire length of the shell maintains precise dimensions and consistent internal and external diameters, which is essential for barrel compatibility, proper rifling engagement, and predictable ballistic performance. The combination of metal spinning and flow forming allows manufacturers to produce lightweight, high-strength shell bodies that are capable of withstanding the forces of firing and impact, while minimizing material waste and maximizing operational efficiency.

Modern CNC machines designed for metal spinning and flow forming of large-caliber shells incorporate advanced features such as multi-axis control, adaptive tool path programming, real-time process monitoring, automated speed and pressure adjustments, and in-line quality inspection. These capabilities ensure repeatable precision, reduce the risk of defects, and allow high-volume production while maintaining the stringent dimensional and mechanical specifications required for large-caliber ammunition. Leading manufacturers provide turnkey solutions capable of producing a wide range of shell diameters and lengths, with automated tooling, wear-compensation systems, and process simulation software that predicts material flow and stress distribution before production. The synergy of CNC metal spinning and flow forming enables the creation of large-caliber shells that are both lightweight and exceptionally strong, delivering consistent performance, durability, and safety under extreme operational conditions. By combining precision machining, advanced material handling, and CNC automation, these technologies provide a highly efficient and reliable solution for modern artillery manufacturing, ensuring that every shell meets the rigorous standards demanded by contemporary military operations.

CNC metal spinning and flow forming machines are essential for the production of large-caliber shells, providing the precision, repeatability, and structural integrity required for modern artillery systems. Large-caliber shells are subjected to extreme internal pressures, rapid acceleration, and high rotational forces during firing, making the quality and consistency of each casing critical for both safety and operational performance. Metal spinning allows for the gradual shaping of a metal blank over a mandrel while it rotates at high speed, with CNC-controlled rollers or forming tools ensuring highly precise geometries, uniform wall thickness, and smooth surface finishes. This method is particularly effective for forming the nose cones, driving bands, and cylindrical bodies of large-caliber shells, where tight tolerances are essential to ensure proper fit within the rifled barrel and consistent ballistic behavior. High-strength materials such as maraging steel, stainless steel, aluminum alloys, titanium, and other specialty metals are commonly used, allowing engineers to optimize the balance between weight, toughness, and resistance to heat and pressure according to the design specifications of each shell.

Flow forming complements metal spinning by elongating and thinning preformed tubular blanks over precision mandrels using CNC-controlled rollers, producing lightweight yet extremely strong shell bodies. This process ensures uniform wall thickness, excellent mechanical properties, and high strength-to-weight ratios, which are particularly important for large-caliber shells that experience significant internal stresses during firing. Flow forming also allows for precise dimensional control along the entire length of the shell, ensuring consistent compatibility with the howitzer or artillery barrel, proper engagement with rifling, and predictable ballistic performance. By reducing material waste and optimizing the use of high-performance alloys, flow forming enhances efficiency while maintaining the structural integrity and reliability required for military munitions. The combination of metal spinning and flow forming provides manufacturers with the ability to produce shells that meet exacting standards for performance, durability, and safety, while also improving production efficiency and material utilization.

Modern CNC machines for metal spinning and flow forming incorporate advanced technologies such as multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection systems. These features allow manufacturers to achieve repeatable precision, maintain consistent production quality, and minimize the risk of defects across large production runs. Leading manufacturers provide fully automated systems capable of handling a wide range of shell diameters and lengths, with wear-compensated tooling, rapid changeover capabilities, and simulation-driven process optimization to predict material flow and stress distribution before production. By combining CNC automation with advanced forming techniques, manufacturers can produce large-caliber shells that are both lightweight and exceptionally strong, capable of withstanding the extreme conditions of firing and impact while delivering consistent ballistic performance. The synergy of metal spinning and flow forming ensures that every shell meets stringent military standards, providing reliable, efficient, and high-quality artillery munitions suitable for modern defense operations.

CNC metal spinning and flow forming machines are critical in the production of large-caliber shells, offering the precision, repeatability, and material efficiency required for modern artillery applications. Large-caliber shells are subjected to extreme pressures, rapid acceleration, and high rotational forces during firing, making the structural integrity and dimensional accuracy of each shell essential for safety and performance. Metal spinning achieves this by rotating a metal blank at high speeds while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with uniform wall thickness, smooth surfaces, and highly accurate dimensions. This method is particularly suited for forming the nose cones, driving bands, and cylindrical bodies of large-caliber shells, where tight tolerances are critical to ensure proper engagement with the barrel rifling, consistent ballistic behavior, and reliable aerodynamic properties. High-strength alloys such as maraging steel, aluminum alloys, stainless steel, and titanium are commonly used, allowing engineers to optimize the balance between weight, durability, and resistance to heat and pressure according to the operational requirements of each shell.

Flow forming complements metal spinning by progressively elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers. This produces tubular shells that are lightweight yet extremely strong, with highly uniform wall thickness, excellent mechanical properties, and optimized strength-to-weight ratios. Flow forming is particularly advantageous for large-caliber shells, where uniform material distribution and structural integrity are critical to withstand the high internal stresses experienced during firing. By maintaining precise dimensions along the entire length of the shell, flow forming ensures compatibility with the artillery barrel, proper rifling engagement, and predictable ballistic performance. The process also reduces material waste, optimizes the use of high-performance metals, and enables the production of shells that are both reliable and efficient to manufacture, making it ideal for large-scale defense manufacturing programs where consistency and repeatability are essential.

Modern CNC systems for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection, ensuring that every shell produced meets strict military specifications. Leading manufacturers provide turnkey solutions capable of producing a wide range of shell diameters and lengths, with features such as wear-compensated tooling, rapid changeover, and simulation-based process optimization that predicts material flow and stress distribution before production begins. The combination of CNC metal spinning and flow forming enables the creation of large-caliber shells that are lightweight, strong, and highly precise, capable of performing reliably under extreme operational conditions. By merging advanced material handling, precision machining, and automated process control, these technologies deliver high-quality artillery munitions with consistent dimensional accuracy, structural integrity, and ballistic performance, ensuring that each shell meets the rigorous demands of modern military operations while optimizing efficiency and material utilization.

CNC metal spinning and flow forming machines are essential technologies for manufacturing large-caliber shells, providing the precision, repeatability, and material efficiency that modern artillery systems demand. Large-caliber shells are subjected to extreme internal pressures, rapid acceleration, and intense mechanical stresses during firing, making the structural integrity and dimensional consistency of each casing critical for both safety and performance. Metal spinning allows a metal blank to rotate at high speeds while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with uniform wall thickness, smooth surfaces, and tight tolerances. This process is particularly effective for forming complex geometries such as nose cones, driving bands, and cylindrical shell bodies, where precision is essential for proper barrel engagement, consistent ballistic performance, and reliable aerodynamic behavior. High-strength materials like maraging steel, aluminum alloys, stainless steel, titanium, and other specialty metals are commonly used, enabling engineers to balance weight, toughness, and resistance to heat and pressure to meet specific operational requirements of large-caliber ammunition.

Flow forming complements metal spinning by progressively elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing lightweight yet extremely strong shell bodies with uniform wall thickness and optimized mechanical properties. This technique is particularly suitable for large-caliber shells, where structural integrity and material efficiency are critical. Flow forming ensures precise dimensional control along the entire length of the shell, enabling consistent barrel fit, proper rifling engagement, and predictable ballistic performance. The process minimizes material waste, maximizes the use of high-performance alloys, and allows for highly repeatable production, which is vital in defense manufacturing where quality and consistency cannot be compromised. The combination of metal spinning and flow forming allows manufacturers to produce shells that are not only durable and structurally robust but also optimized for weight and performance, ensuring that each round functions reliably under extreme conditions.

Modern CNC machines designed for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection, ensuring consistent production of shells that meet stringent military specifications. Leading manufacturers provide fully automated systems capable of handling various diameters and lengths of large-caliber shells, with features such as wear-compensated tooling, rapid changeover, and simulation-based process optimization to predict material flow and stress distribution before production. By combining precision machining, advanced material handling, and CNC automation, these machines enable the manufacture of large-caliber shells that are lightweight, high-strength, and dimensionally precise, delivering reliable performance and structural integrity under extreme operational conditions. The integration of CNC metal spinning and flow forming represents a highly efficient and reliable approach to artillery shell production, ensuring that every shell meets the rigorous standards required for modern military operations while optimizing efficiency, material utilization, and overall quality.

CNC Metal Spinning and Flow Forming Machine for Ballistic Projectiles

CNC metal spinning and flow forming machines are highly specialized manufacturing technologies that play a critical role in the production of ballistic projectiles, providing the precision, consistency, and material efficiency required for modern ammunition. Ballistic projectiles, including artillery shells, tank rounds, and mortar munitions, must withstand extreme internal pressures, high-velocity acceleration, and significant mechanical stresses during firing, which makes the structural integrity of the projectile casing essential for both performance and safety. Metal spinning allows a metal blank to rotate at high speeds while a CNC-controlled roller or forming tool gradually shapes it over a mandrel, producing rotationally symmetric components with highly uniform wall thickness, smooth surfaces, and tight dimensional tolerances. This technique is particularly effective for forming the nose cones, driving bands, and cylindrical bodies of ballistic projectiles, where geometric precision directly influences flight stability, barrel engagement, and terminal performance. High-strength materials such as maraging steel, aluminum alloys, stainless steel, titanium, and other advanced alloys are commonly used, enabling engineers to optimize the balance between weight, toughness, and resistance to thermal and mechanical stress according to the specific requirements of each projectile type.

Flow forming complements metal spinning by elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular projectile bodies with uniform wall thickness, superior strength-to-weight ratios, and enhanced mechanical properties. This process is especially suitable for large-caliber and high-pressure munitions, where maintaining structural integrity and precise dimensions along the entire length of the projectile is critical for predictable ballistic performance. Flow forming minimizes material waste, ensures efficient use of high-performance alloys, and allows manufacturers to produce components with consistent dimensional accuracy, which is vital for repeatable performance across production batches. By combining metal spinning and flow forming, manufacturers can create ballistic projectiles that are lightweight yet exceptionally strong, capable of withstanding the extreme forces generated during firing, barrel friction, and impact.

Modern CNC systems designed for metal spinning and flow forming integrate advanced features such as multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection. These capabilities allow manufacturers to achieve repeatable precision, reduce the risk of defects, and maintain high production efficiency while meeting strict military specifications for projectile dimensions, material properties, and ballistic performance. Leading manufacturers provide turnkey solutions capable of handling a wide range of projectile sizes, calibers, and materials, with features like wear-compensated tooling, rapid changeover, and simulation-driven process optimization to predict material flow and stress distribution prior to production. The combination of CNC metal spinning and flow forming ensures that ballistic projectiles possess the necessary strength, dimensional accuracy, and aerodynamic stability required for modern military operations, delivering reliable performance, consistent quality, and operational safety across all munitions production. By leveraging precision machining, advanced material handling, and CNC automation, these technologies provide a highly efficient and dependable method for manufacturing high-performance ballistic projectiles, meeting the rigorous standards demanded by contemporary defense applications.

CNC metal spinning and flow forming machines are indispensable technologies in the production of ballistic projectiles, providing the precision, repeatability, and material efficiency that modern ammunition manufacturing requires. Ballistic projectiles, including artillery shells, tank rounds, mortar munitions, and specialized defense ordnance, are subjected to extreme internal pressures, rapid acceleration, and intense mechanical stresses during firing, making the structural integrity and dimensional accuracy of the casing critical for performance, safety, and reliability. Metal spinning allows a metal blank to rotate at high speeds while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with uniform wall thickness, smooth surfaces, and tight dimensional tolerances. This process is particularly effective for forming complex geometries such as nose cones, driving bands, and cylindrical bodies of ballistic projectiles, where precision directly impacts flight stability, barrel engagement, and terminal effects. High-strength materials such as maraging steel, aluminum alloys, stainless steel, titanium, and other advanced alloys are commonly used in metal spinning, enabling engineers to balance weight, toughness, and resistance to thermal and mechanical stresses to meet the stringent requirements of each projectile type.

Flow forming complements metal spinning by gradually elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing projectile bodies with highly uniform wall thickness, enhanced mechanical properties, and optimized strength-to-weight ratios. This process is particularly beneficial for large-caliber or high-pressure projectiles, where maintaining consistent dimensions and material distribution along the entire length is essential for predictable ballistic performance and safe firing. Flow forming reduces material waste, maximizes the efficiency of expensive alloys, and ensures that each projectile meets rigorous specifications for internal and external diameters, wall thickness, and overall structural integrity. By combining metal spinning and flow forming, manufacturers can produce lightweight yet extremely strong projectile casings that can withstand the stresses of launch, barrel friction, flight, and impact without compromising accuracy or performance.

Modern CNC systems for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection, ensuring that every ballistic projectile produced meets strict military standards. Leading manufacturers provide fully automated solutions capable of handling a wide range of calibers, lengths, and materials, with wear-compensated tooling, rapid changeover capabilities, and simulation-driven process optimization to predict material flow, stress distribution, and potential defects before production begins. The combination of these technologies enables the production of projectiles that are lightweight, high-strength, and dimensionally precise, delivering reliable performance, consistent ballistic behavior, and operational safety across all rounds. By integrating precision machining, advanced material handling, and CNC automation, metal spinning and flow forming offer a highly efficient and dependable approach to manufacturing high-performance ballistic projectiles, ensuring that each round achieves the necessary balance of durability, accuracy, and efficiency demanded by contemporary defense applications.

CNC metal spinning and flow forming machines are fundamental in the production of ballistic projectiles, providing the high level of precision, repeatability, and material efficiency required for modern defense applications. Ballistic projectiles, including artillery shells, tank rounds, mortar munitions, and specialized military ordnance, must withstand extreme internal pressures, rapid acceleration, and severe mechanical stresses during firing, making the strength and dimensional consistency of each casing critical for performance, safety, and operational reliability. In metal spinning, a metal blank rotates at high speed while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with highly uniform wall thickness, smooth surfaces, and precise geometries. This process is particularly suited for forming complex features such as nose cones, driving bands, and cylindrical bodies of ballistic projectiles, where small variations in dimensions can significantly affect flight stability, barrel engagement, and terminal performance. High-strength materials such as maraging steel, aluminum alloys, stainless steel, titanium, and other specialized alloys are commonly used, allowing engineers to optimize the balance between weight, toughness, and resistance to thermal and mechanical stresses for each specific projectile design.

Flow forming complements metal spinning by progressively elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing projectile bodies with uniform wall thickness, high strength-to-weight ratios, and exceptional mechanical properties. This technique is especially valuable for large-caliber and high-pressure projectiles, where maintaining consistent material distribution and structural integrity along the entire length is critical for predictable ballistic performance and safe operation. Flow forming also minimizes material waste and optimizes the use of high-performance metals, allowing manufacturers to produce projectiles with consistent dimensional accuracy, repeatable quality, and superior structural strength. By combining the capabilities of metal spinning and flow forming, manufacturers are able to produce projectile casings that are lightweight yet incredibly robust, capable of withstanding the forces generated during launch, barrel travel, flight, and impact without compromising accuracy or durability.

Modern CNC machines designed for metal spinning and flow forming integrate advanced features such as multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection. These technologies enable manufacturers to achieve repeatable precision, reduce the risk of defects, and maintain high production efficiency while ensuring every projectile meets strict military specifications for dimensional accuracy, material properties, and ballistic performance. Leading suppliers provide turnkey solutions capable of producing a wide range of projectile sizes, calibers, and materials, with wear-compensated tooling, rapid changeover, and simulation-driven process optimization that predicts material flow, stress distribution, and potential defects prior to production. The combination of CNC metal spinning and flow forming allows the manufacture of ballistic projectiles that are both lightweight and extremely strong, delivering consistent performance, structural integrity, and operational reliability under the most demanding conditions. By leveraging precision machining, advanced material handling, and CNC automation, these technologies provide an efficient and dependable solution for producing high-performance ballistic projectiles that meet the rigorous standards of modern military operations.

CNC Metal Spinning and Flow Forming Machine for Munition Rounds

CNC metal spinning and flow forming machines are critical technologies for the manufacture of munition rounds, offering the precision, structural integrity, and material efficiency required for modern ammunition production. Munition rounds, including artillery shells, tank rounds, mortar rounds, and other military ordnance, must endure extreme internal pressures, rapid acceleration, and high-impact forces during firing, making the consistency and strength of each casing essential for operational safety and performance. Metal spinning allows a metal blank to rotate at high speeds while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with uniform wall thickness, smooth surfaces, and tight dimensional tolerances. This method is particularly effective for forming nose cones, driving bands, and cylindrical shell bodies, where precise dimensions directly affect barrel engagement, ballistic trajectory, and overall flight stability. High-strength alloys such as maraging steel, aluminum, stainless steel, titanium, and other advanced materials are commonly used in this process, allowing engineers to optimize the balance between weight, toughness, and resistance to thermal and mechanical stress according to the design requirements of each munition type.

Flow forming complements metal spinning by gradually elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular shell bodies with uniform wall thickness, excellent mechanical properties, and high strength-to-weight ratios. This process is particularly valuable for larger-caliber or high-pressure rounds, where consistent material distribution and structural integrity are critical to predictable ballistic performance. Flow forming ensures that the dimensions along the entire length of the round remain accurate and consistent, enabling proper barrel fit, rifling engagement, and reliable terminal performance. In addition, the process minimizes material waste and maximizes efficiency when working with high-performance alloys, allowing manufacturers to produce munition rounds that are both lightweight and structurally robust, capable of withstanding the forces generated during firing, barrel friction, flight, and impact.

Modern CNC machines for metal spinning and flow forming integrate advanced technologies such as multi-axis control, adaptive tool path programming, real-time process monitoring, automated speed and pressure adjustments, and in-line quality inspection, ensuring that each munition round meets strict military specifications. Leading manufacturers offer fully automated systems capable of handling a wide range of calibers, lengths, and materials, with wear-compensated tooling, rapid changeover capabilities, and simulation-driven process optimization that predicts material flow and stress distribution before production begins. By combining metal spinning and flow forming, manufacturers can produce munition rounds that are lightweight, dimensionally precise, and exceptionally strong, providing consistent ballistic performance and operational reliability. The integration of CNC automation with advanced forming processes ensures that every round meets the rigorous standards required for modern military applications, delivering efficiency, repeatable quality, and the structural integrity necessary for safe and effective use in combat scenarios.

CNC metal spinning and flow forming machines are essential in the production of munition rounds, providing the precision, repeatability, and structural integrity necessary for modern ammunition. Munition rounds, including artillery shells, tank rounds, mortar rounds, and other ordnance, are subjected to extreme pressures, rapid acceleration, and significant mechanical stresses during firing, making the quality and consistency of each casing critical for safety, reliability, and operational performance. Metal spinning achieves this by rotating a metal blank at high speed while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with uniform wall thickness, smooth surfaces, and precise geometries. This process is particularly effective for forming nose cones, driving bands, and cylindrical bodies of munition rounds, where dimensional accuracy directly affects barrel engagement, ballistic trajectory, and overall flight stability. High-strength materials such as maraging steel, aluminum alloys, stainless steel, titanium, and other specialty metals are commonly used, allowing engineers to optimize the balance between weight, toughness, and resistance to thermal and mechanical stress in accordance with the specific requirements of each type of round.

Flow forming complements metal spinning by elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular round bodies with uniform wall thickness, high strength-to-weight ratios, and enhanced mechanical properties. This technique is particularly valuable for larger-caliber or high-pressure rounds, where consistent material distribution and structural integrity along the entire length of the casing are critical for predictable ballistic performance. Flow forming also reduces material waste and optimizes the use of high-performance alloys, enabling the production of munition rounds that are lightweight yet exceptionally strong and capable of withstanding the forces generated during launch, barrel travel, flight, and impact. By combining metal spinning and flow forming, manufacturers are able to produce rounds with precise dimensions, consistent internal and external diameters, and superior structural performance, ensuring that every round meets rigorous military specifications while maximizing efficiency and repeatability in production.

Modern CNC machines designed for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection, allowing manufacturers to achieve repeatable precision and high production efficiency. Leading suppliers provide fully automated systems capable of producing a wide range of munition sizes, calibers, and materials, with features such as wear-compensated tooling, rapid changeover, and simulation-driven process optimization to predict material flow, stress distribution, and potential defects before production. The combination of CNC metal spinning and flow forming ensures that munition rounds are dimensionally precise, structurally robust, and capable of reliable performance under extreme operational conditions. By integrating precision machining, advanced material handling, and CNC automation, these technologies provide an efficient and dependable solution for manufacturing high-performance munition rounds that meet the stringent demands of contemporary military applications, delivering consistent quality, operational safety, and optimal ballistic performance.

CNC metal spinning and flow forming machines are crucial in the production of munition rounds, providing the precision, repeatability, and structural strength necessary for modern military ammunition. Munition rounds, which include artillery shells, tank rounds, mortar rounds, and other ordnance, must withstand extreme internal pressures, rapid acceleration, and intense mechanical forces during firing, making the integrity and consistency of each casing critical for both performance and safety. Metal spinning allows a metal blank to rotate at high speeds while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with highly uniform wall thickness, smooth surfaces, and tight dimensional tolerances. This method is particularly effective for forming complex geometries such as nose cones, driving bands, and cylindrical bodies of munition rounds, where precise dimensions directly affect barrel engagement, flight trajectory, and aerodynamic stability. Materials commonly used include maraging steel, aluminum alloys, stainless steel, titanium, and other specialty metals, allowing engineers to optimize the balance between weight, strength, and resistance to thermal and mechanical stress for each type of round.

Flow forming complements metal spinning by elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing shell bodies with uniform wall thickness, enhanced mechanical properties, and high strength-to-weight ratios. This process is particularly advantageous for larger-caliber or high-pressure rounds, where maintaining structural integrity and precise dimensions along the entire length is essential for predictable ballistic performance and operational safety. Flow forming also reduces material waste and optimizes the use of expensive high-performance alloys, ensuring that each munition round is both lightweight and exceptionally strong. By combining metal spinning and flow forming, manufacturers can produce rounds with consistent internal and external diameters, precise wall thickness, and superior structural performance, which ensures reliability and repeatability across production batches. The combination of these processes allows for efficient production of munition rounds that meet the rigorous requirements of modern military specifications while maximizing material utilization and minimizing production costs.

Advanced CNC machines for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection, ensuring that every munition round produced meets strict military standards. Leading manufacturers offer fully automated systems capable of handling a wide range of calibers, lengths, and materials, with features such as wear-compensated tooling, rapid changeover, and simulation-driven process optimization to predict material flow, stress distribution, and potential defects before production. The integration of CNC metal spinning and flow forming allows the production of munition rounds that are dimensionally precise, structurally robust, and capable of reliable performance under the extreme conditions of firing, barrel friction, flight, and impact. By combining advanced material handling, precision machining, and automated CNC control, these technologies provide a highly efficient and dependable solution for producing high-performance munition rounds, ensuring consistent quality, operational safety, and optimal ballistic performance for modern military operations.

CNC metal spinning and flow forming machines are indispensable in the manufacture of munition rounds, delivering the precision, repeatability, and structural strength required for modern military applications. Munition rounds, including artillery shells, tank rounds, mortar shells, and other high-performance ordnance, are subjected to extreme internal pressures, rapid acceleration, and substantial mechanical stresses during firing, making the integrity and uniformity of each casing critical for performance, safety, and reliability. Metal spinning enables the gradual shaping of a metal blank as it rotates at high speeds, while CNC-controlled rollers or forming tools progressively form it over a mandrel. This produces rotationally symmetric components with highly uniform wall thickness, smooth surfaces, and extremely tight dimensional tolerances. The process is particularly effective for forming complex geometries such as nose cones, driving bands, and cylindrical bodies of munition rounds, where precise dimensions and uniformity are essential for barrel engagement, flight stability, and consistent ballistic behavior. High-strength materials, including maraging steel, aluminum alloys, stainless steel, titanium, and other specialty metals, are commonly used, allowing engineers to achieve the optimal balance between weight, toughness, and resistance to thermal and mechanical stresses for each specific round.

Flow forming complements metal spinning by progressively elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular munition bodies with uniform wall thickness, high strength-to-weight ratios, and enhanced mechanical properties. This technique is especially critical for larger-caliber or high-pressure rounds, where structural integrity and precise dimensional control along the entire length of the shell are essential for predictable performance and safe operation. Flow forming also reduces material waste and maximizes the efficiency of high-performance alloys, enabling manufacturers to produce rounds that are both lightweight and exceptionally robust. By combining metal spinning and flow forming, manufacturers can achieve consistent internal and external diameters, precise wall thickness, and reliable structural performance across production batches, ensuring that every munition round meets the demanding specifications of modern military standards.

Advanced CNC systems designed for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure regulation, real-time process monitoring, and in-line quality inspection. These features allow manufacturers to achieve repeatable precision, minimize defects, and maintain high-volume production efficiency while ensuring that each round meets stringent dimensional, mechanical, and ballistic requirements. Leading equipment suppliers provide turnkey solutions capable of handling a wide range of calibers, lengths, and materials, offering wear-compensated tooling, rapid changeover, and simulation-driven process optimization to predict material flow, stress distribution, and potential defects before production. The combination of CNC metal spinning and flow forming enables the creation of munition rounds that are both lightweight and structurally resilient, capable of withstanding the extreme conditions of firing, barrel travel, flight, and impact. By integrating precision machining, advanced material handling, and automated CNC control, these technologies provide a highly efficient and reliable approach to producing high-performance munition rounds, ensuring consistent quality, operational safety, and optimal ballistic performance across all military applications.

CNC Metal Spinning and Flow Forming Machine for Cannon Shells

CNC metal spinning and flow forming machines are essential technologies in the production of cannon shells, offering the precision, structural integrity, and material efficiency required for modern artillery munitions. Cannon shells must withstand extreme pressures, rapid acceleration, and high mechanical stresses during firing, making the strength and dimensional accuracy of each shell critical for both performance and safety. Metal spinning allows a metal blank to rotate at high speeds while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with highly uniform wall thickness, smooth surfaces, and precise geometries. This process is particularly effective for forming nose cones, driving bands, and cylindrical shell bodies, where tight tolerances are crucial for proper barrel engagement, predictable ballistic behavior, and flight stability. High-strength materials such as maraging steel, aluminum alloys, stainless steel, titanium, and other advanced alloys are commonly used, enabling engineers to optimize the balance between weight, toughness, and resistance to thermal and mechanical stresses for each shell type.

Flow forming complements metal spinning by progressively elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular cannon shells with uniform wall thickness, enhanced mechanical properties, and high strength-to-weight ratios. This process is especially valuable for large-caliber or high-pressure shells, where consistent material distribution and structural integrity along the entire length are critical to reliable performance and operational safety. Flow forming also reduces material waste, ensures efficient use of high-performance alloys, and enables manufacturers to produce shells that are both lightweight and extremely strong. By combining metal spinning and flow forming, manufacturers can achieve precise internal and external diameters, consistent wall thickness, and superior structural performance, ensuring that every cannon shell meets stringent military specifications and performs reliably under extreme firing conditions.

Modern CNC machines for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection, allowing manufacturers to produce cannon shells with repeatable precision and high efficiency. Leading suppliers offer fully automated systems capable of handling a wide range of shell diameters, lengths, and materials, with features such as wear-compensated tooling, rapid changeover, and simulation-driven process optimization to predict material flow, stress distribution, and potential defects before production begins. The combination of CNC metal spinning and flow forming ensures that cannon shells are dimensionally accurate, structurally robust, and capable of consistent ballistic performance. By leveraging precision machining, advanced material handling, and CNC automation, these technologies provide a highly efficient and dependable method for manufacturing high-performance cannon shells, delivering operational reliability, safety, and optimal performance in modern military applications.

CNC metal spinning and flow forming machines are indispensable for the production of cannon shells, offering the precision, consistency, and material efficiency that modern artillery demands. Cannon shells are subjected to extreme internal pressures, rapid acceleration, and intense mechanical stresses during firing, making the strength, uniformity, and dimensional accuracy of each shell essential for operational reliability and safety. Metal spinning achieves this by rotating a metal blank at high speed while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with highly uniform wall thickness, smooth surfaces, and precise geometries. This process is particularly effective for forming complex features such as nose cones, driving bands, and cylindrical shell bodies, where tight tolerances are critical to ensure proper barrel engagement, flight stability, and consistent ballistic behavior. High-performance materials, including maraging steel, aluminum alloys, stainless steel, titanium, and other specialty metals, are commonly used, allowing engineers to optimize the balance between weight, toughness, and resistance to thermal and mechanical stresses for each specific shell design.

Flow forming complements metal spinning by progressively elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular cannon shells with uniform wall thickness, enhanced mechanical properties, and superior strength-to-weight ratios. This process is especially advantageous for larger-caliber or high-pressure shells, where structural integrity and precise material distribution along the entire length are vital for predictable performance and safe operation. Flow forming also reduces material waste, optimizes the use of expensive high-performance alloys, and enables the production of shells that are both lightweight and structurally robust. By combining metal spinning and flow forming, manufacturers can achieve consistent internal and external diameters, precise wall thickness, and superior overall structural performance, ensuring that every cannon shell meets the stringent specifications required by modern military standards while maintaining efficiency and repeatability in production.

Modern CNC systems for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure regulation, real-time process monitoring, and in-line quality inspection, allowing manufacturers to produce cannon shells with repeatable precision and high throughput. Leading suppliers provide turnkey solutions capable of handling a wide range of shell calibers, lengths, and materials, incorporating wear-compensated tooling, rapid changeover capabilities, and simulation-based process optimization to predict material flow, stress distribution, and potential defects prior to production. The combination of CNC metal spinning and flow forming enables the manufacture of cannon shells that are lightweight, dimensionally precise, and exceptionally strong, capable of withstanding the extreme forces generated during firing, barrel travel, flight, and impact. By integrating advanced material handling, precision machining, and CNC automation, these technologies offer a highly efficient and reliable approach to producing high-performance cannon shells, ensuring consistent quality, operational safety, and optimal ballistic performance for modern artillery systems.

CNC metal spinning and flow forming machines are central to the production of cannon shells, providing the precision, repeatability, and material efficiency required for modern artillery munitions. Cannon shells endure extreme internal pressures, rapid acceleration, and intense mechanical stresses during firing, making the integrity and uniformity of each shell critical for performance, safety, and operational reliability. In metal spinning, a metal blank is rotated at high speeds while CNC-controlled rollers or forming tools progressively shape it over a mandrel, producing rotationally symmetric components with highly uniform wall thickness, smooth surfaces, and precise dimensional tolerances. This process is particularly effective for forming nose cones, driving bands, and cylindrical bodies of cannon shells, where even minor deviations can affect barrel engagement, flight stability, and ballistic accuracy. High-performance materials such as maraging steel, aluminum alloys, stainless steel, titanium, and other specialty alloys are commonly used, allowing engineers to balance weight, toughness, and resistance to thermal and mechanical stresses according to the operational requirements of each shell.

Flow forming complements metal spinning by gradually elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing tubular cannon shells with uniform wall thickness, excellent mechanical properties, and high strength-to-weight ratios. This process is especially valuable for large-caliber or high-pressure shells, where consistent structural integrity and precise material distribution along the entire length are critical to predictable performance and safe operation. Flow forming also minimizes material waste, maximizes the efficiency of high-performance alloys, and enables the production of shells that are both lightweight and extremely robust. By combining the capabilities of metal spinning and flow forming, manufacturers can produce cannon shells with consistent internal and external diameters, precise wall thickness, and superior structural performance, ensuring reliable and repeatable ballistic behavior across production batches.

Advanced CNC systems for metal spinning and flow forming integrate multi-axis control, adaptive tool path programming, automated speed and pressure adjustments, real-time process monitoring, and in-line quality inspection, allowing manufacturers to achieve precise, repeatable production of cannon shells at high throughput. Leading suppliers offer turnkey systems capable of handling a wide range of shell diameters, lengths, and materials, with wear-compensated tooling, rapid changeover capabilities, and simulation-driven process optimization to predict material flow, stress distribution, and potential defects prior to production. The combination of CNC metal spinning and flow forming ensures that cannon shells are dimensionally accurate, structurally robust, and capable of consistent ballistic performance under the extreme conditions of firing, barrel travel, flight, and impact. By integrating precision machining, advanced material handling, and CNC automation, these technologies provide an efficient, reliable, and highly precise solution for manufacturing high-performance cannon shells, meeting the stringent requirements of modern military operations while delivering optimal performance, safety, and operational effectiveness.

CNC metal spinning and flow forming machines are critical technologies in the production of cannon shells, providing the precision, structural integrity, and repeatability essential for modern artillery munitions. Cannon shells are subjected to extreme internal pressures, rapid acceleration, and high mechanical stresses during firing, making the dimensional accuracy and consistency of each shell critical to performance, safety, and operational reliability. Metal spinning enables a metal blank to rotate at high speeds while CNC-controlled rollers or forming tools gradually shape it over a mandrel, producing rotationally symmetric components with uniform wall thickness, smooth surfaces, and highly precise geometries. This process is particularly effective for forming nose cones, driving bands, and cylindrical shell bodies, where even minor deviations can impact barrel engagement, flight stability, and ballistic performance. High-performance materials such as maraging steel, stainless steel, aluminum alloys, titanium, and other specialty metals are commonly used in this process, allowing engineers to optimize the balance between weight, toughness, and resistance to thermal and mechanical stresses for each specific shell design.

Flow forming complements metal spinning by progressively elongating and thinning preformed cylindrical blanks over precision mandrels using CNC-controlled rollers, producing cannon shells with uniform wall thickness, enhanced mechanical properties, and superior strength-to-weight ratios. This technique is particularly important for larger-caliber or high-pressure shells, where maintaining consistent structural integrity and precise material distribution along the entire length is critical for predictable performance and operational safety. Flow forming also reduces material waste and maximizes the efficiency of high-performance alloys, enabling manufacturers to produce shells that are both lightweight and extremely robust. The combination of metal spinning and flow forming allows manufacturers to achieve consistent internal and external diameters, precise wall thickness, and superior overall structural performance, ensuring that each cannon shell meets the rigorous specifications required for modern military standards while enabling repeatable and efficient production.