Burr Cleaning Machine: Sheet metal forming refers to a broad set of manufacturing processes used to convert flat metal sheets into desired shapes and geometries. It is an essential part of the metalworking industry, widely used in the automotive, aerospace, construction, and electronics industries. This process involves applying force to deform the metal sheet plastically, meaning the sheet undergoes permanent change in shape without breaking or cracking. Sheet metal forming methods can range from simple manual bending to highly automated, computer-controlled processes for mass production.

Sheet metal forming processes are classified into three major categories: bending, drawing, and shearing. Each of these techniques has its specific applications depending on the desired end product and the metal being worked with.

Types of Sheet Metal Forming:

- Bending:

Bending involves deforming the metal sheet along a straight axis to create angular shapes such as “V,” “U,” or channels. Press brakes or die presses are commonly used to bend the sheet metal, either manually or through automated processes. Bending is commonly used in automotive body panels, appliance housings, and structural frameworks. - Deep Drawing:

Deep drawing is a process in which a flat sheet of metal is radially drawn into a forming die by the action of a mechanical punch. This process is used to create cup-shaped parts and is commonly applied in manufacturing cans, containers, and automotive fuel tanks. Deep drawing allows the formation of complex, hollow shapes from a single sheet of metal. - Stretch Forming:

In stretch forming, a metal sheet is clamped at its edges and stretched over a die to form large, smooth, and curved surfaces. This method is often used in the aerospace industry for manufacturing aircraft fuselage panels and structural parts. - Roll Forming:

Roll forming is a continuous process in which a metal sheet is passed through a series of rollers that progressively shape it into the desired cross-sectional profile. This method is highly efficient and is used to produce items like metal roofing panels, door frames, and highway guardrails. - Punching and Blanking:

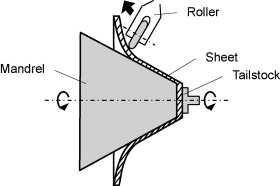

Punching involves the removal of material from the sheet by placing it between a punch and a die. Blanking is a similar process but focuses on cutting out parts of the sheet. Both techniques are commonly used in mass production, such as in the manufacturing of metal parts for electronics, appliances, and cars. - Spinning:

Spinning is a process where a metal disk or tube is rotated at high speed and formed into an axially symmetric part by a roller. This method is typically used for producing conical or cylindrical components, such as pots, pans, and decorative metal objects.

Applications of Sheet Metal Forming:

- Automotive Industry:

Sheet metal forming is integral to the production of automotive body panels, chassis, and structural components. Manufacturers use advanced techniques like deep drawing, hydroforming, and stamping to produce high-quality, lightweight vehicle parts. - Aerospace Industry:

Aerospace companies rely on sheet metal forming to create lightweight yet strong components, such as fuselage panels, wings, and support structures, all of which must meet stringent performance and safety standards. - Construction and Architecture:

In construction, sheet metal forming is used for roofing, cladding, framing, and decorative purposes. Metals such as steel, aluminum, and copper are shaped into durable structures that withstand environmental stresses. - Electronics and Appliances:

Manufacturers of consumer electronics and household appliances use sheet metal forming to create enclosures, panels, and internal structures for products like washing machines, refrigerators, and electronic devices.

Advantages of Sheet Metal Forming:

- Efficiency:

Sheet metal forming can produce large quantities of parts at relatively low cost, making it ideal for mass production in industries like automotive and consumer goods. - Precision:

Modern forming techniques, especially those utilizing CNC-controlled machinery, provide high precision and repeatability, ensuring consistent product quality. - Material Conservation:

Because sheet metal forming reshapes rather than removes material, there is minimal waste, making it an environmentally friendly and cost-effective process. - Versatility:

Sheet metal forming can be applied to a variety of metals, including steel, aluminum, brass, and copper, allowing manufacturers to produce parts for a wide range of applications.

Hydraulic Metal Forming

Hydraulic metal forming is a process where hydraulic pressure is used to shape metal workpieces. This process is ideal for producing complex, high-strength components and is often employed in industries where precision and durability are essential, such as aerospace, automotive, and heavy machinery manufacturing. Hydraulic forming uses hydraulic fluid under extreme pressure to force the metal into a die or mold, allowing for intricate shapes to be formed with high precision.

The main advantage of hydraulic metal forming is its ability to distribute pressure uniformly over the entire surface of the metal, resulting in less localized stress and higher-quality parts. The force applied by hydraulic presses can be finely controlled, making it suitable for delicate operations as well as heavy-duty applications.

Types of Hydraulic Metal Forming:

- Hydroforming:

Hydroforming is a popular hydraulic forming technique used to create hollow parts, such as automotive exhaust components and structural tubes. The process involves placing a metal sheet or tube inside a mold and using hydraulic fluid to press it against the mold walls, forming the desired shape. Hydroforming is highly effective for producing lightweight, high-strength components with complex geometries. - Hydraulic Stamping:

Hydraulic stamping involves placing a flat metal sheet between a punch and die, then using hydraulic pressure to form the metal into the desired shape. This method is commonly used in the production of automotive body panels, appliances, and machinery parts. Hydraulic stamping offers precise control over the applied force, ensuring that the final product is accurate and consistent. - Hydraulic Drawing:

Similar to deep drawing, hydraulic drawing uses hydraulic presses to pull a metal blank into a die, forming cylindrical, cup-shaped, or box-like components. The hydraulic press ensures that the force is evenly distributed, reducing the risk of tearing or wrinkling the metal. - Bulge Forming:

Bulge forming is another hydraulic process where hydraulic fluid is used to press a metal sheet or tube against a die, causing it to bulge outward and take the shape of the mold. This method is often used to create domed or spherical components. - Rubber Pad Forming:

In this process, a metal sheet is placed over a mold, and a flexible rubber pad is pressed against it using hydraulic pressure. The rubber pad deforms around the sheet, forming it to the mold’s shape. Rubber pad forming is used in applications where a smooth, scratch-free finish is essential, such as in the aerospace and medical device industries.

Applications of Hydraulic Metal Forming:

- Automotive Industry:

Hydraulic forming is widely used to create components such as engine mounts, chassis parts, suspension systems, and exhaust systems. The process allows for the production of lightweight yet strong parts, which contribute to improved fuel efficiency and vehicle performance. - Aerospace Industry:

Hydraulic metal forming is used to produce complex, high-strength parts for aircraft and spacecraft. The precise control offered by hydraulic presses ensures that these critical components meet the industry’s stringent safety and performance requirements. - Heavy Machinery:

Hydraulic forming is employed in the production of large, high-strength components used in heavy machinery and industrial equipment. Hydraulic presses can generate the immense force required to shape thick metal plates and components. - Medical Devices:

In the medical field, hydraulic metal forming is used to manufacture surgical instruments, prosthetic devices, and other precision medical components. The ability to form metal with high accuracy and minimal defects is crucial in this industry.

Advantages of Hydraulic Metal Forming:

- Uniform Force Application:

Hydraulic presses distribute force evenly over the entire surface of the metal, reducing the risk of defects such as warping, cracking, or uneven thickness. - Precision:

The finely controlled hydraulic pressure allows for high precision in forming complex geometries, ensuring that the final product meets exact specifications. - Material Efficiency:

Hydraulic metal forming reduces material waste by forming the metal into the desired shape without removing material. This makes it a cost-effective and environmentally friendly process. - Versatility:

Hydraulic forming can be used on a wide range of metals, including steel, aluminum, copper, and titanium, making it suitable for various industries and applications.

Hydraulic metal forming is a key process in modern manufacturing, offering the ability to create high-quality, durable metal parts for critical industries such as aerospace, automotive, and medical device production.

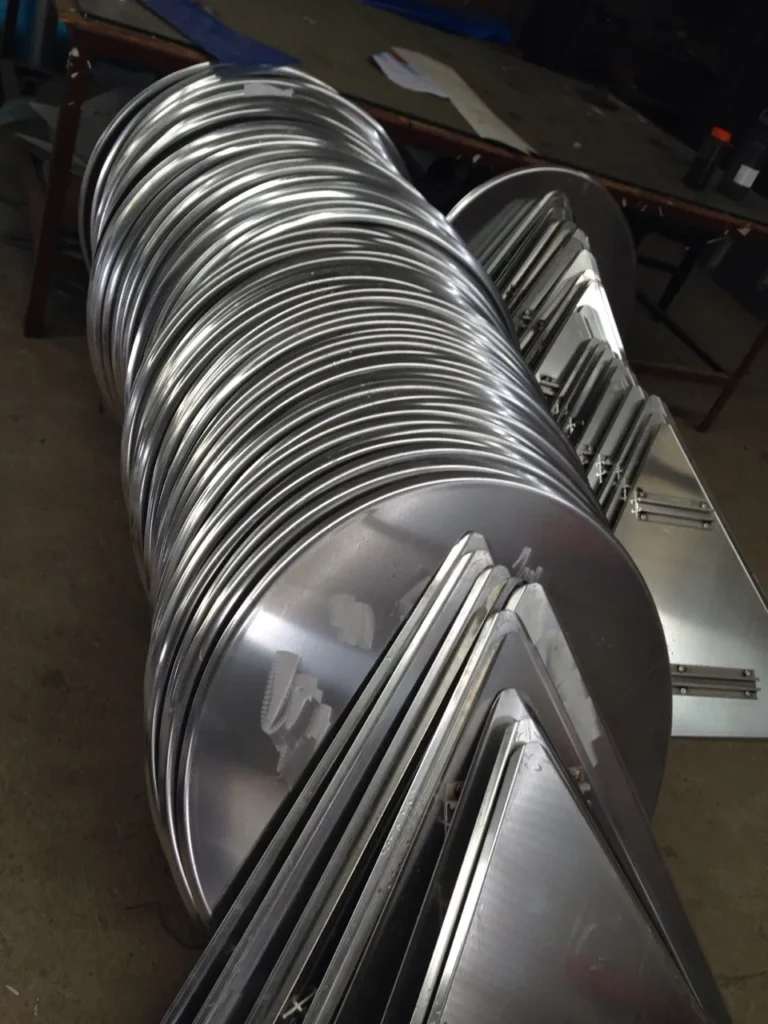

Sheet Metal Rounded Corners

Sheet metal rounded corners refer to the technique of rounding the sharp edges of sheet metal components to improve safety, aesthetics, and structural integrity. This is an important aspect of metalworking, especially in industries where sharp corners can pose a hazard or lead to stress concentration, which could compromise the strength of the component.

Rounding the corners of sheet metal is typically done after the cutting or punching process, which leaves sharp edges. These sharp edges can be dangerous during handling, assembly, or during the product’s use. Additionally, rounded corners help prevent the metal from cracking or tearing under stress, especially during bending or forming operations.

Methods for Creating Rounded Corners:

- Bending:

Bending is one of the simplest methods used to create rounded corners. Instead of making a sharp bend at a 90-degree angle, the metal is bent into a smooth curve, reducing stress concentrations at the corners. Bending machines, such as press brakes, are commonly used for this purpose. - Edge Rolling:

Edge rolling is a technique where the edges of the sheet metal are rolled over to form a smooth, rounded corner. This process is often used in the production of metal enclosures, containers, or other parts where the edges need to be safe and aesthetically pleasing. - Chamfering:

Chamfering is the process of removing the sharp edges of metal by cutting a beveled edge along the corner. Although this does not create a fully rounded corner, it softens the sharp edge and reduces the risk of injury or damage. Chamfering is commonly used in applications where a completely rounded corner is not necessary but where the sharp edge must be eliminated. - Grinding and Filing:

Manual or automated grinding and filing can be used to round off sharp edges after cutting or punching. Abrasive tools are used to smooth out the edges, creating a safe and visually appealing corner. This method is often used in custom or small-scale metal fabrication projects. - Laser Cutting:

Modern laser cutting machines can be programmed to cut metal sheets with pre-rounded corners. This allows for high precision and eliminates the need for additional edge rounding steps. Laser cutting is especially useful for complex shapes or high-volume production runs where precision and consistency are important.

Applications of Rounded Corners in Sheet Metal:

- Safety:

Rounded corners are crucial in industries where workers frequently handle metal parts, such as in construction, automotive assembly, or manufacturing. By rounding the edges, the risk of cuts and injuries is significantly reduced. - Aesthetics:

In consumer products like electronics, appliances, and furniture, rounded corners provide a sleek, modern look. They also help improve the ergonomics of the product by making it more comfortable to handle. - Structural Integrity:

Rounded corners reduce the likelihood of cracks or fractures developing in metal components during use. Sharp corners tend to concentrate stress, which can lead to failure over time. By rounding the corners, the stress is distributed more evenly, improving the durability of the part. - Electronics Enclosures:

In the electronics industry, rounded corners are commonly used in the design of metal enclosures for devices like computers, smartphones, and appliances. Rounded corners not only improve the appearance of the product but also protect internal components by reducing sharp edges that could cause damage during assembly or use.

Advantages of Rounded Corners in Sheet Metal:

- Improved Safety:

Sharp edges pose a safety risk during manufacturing, handling, and use. Rounded corners minimize the chance of injury and improve the usability of metal products. - Enhanced Durability:

By eliminating sharp corners, stress concentrations are reduced, which helps prevent cracks, warping, or other types of failure. Rounded corners enhance the overall durability of the component. - Better Coating and Finishing:

Rounded corners are easier to coat with paint, powder coatings, or anodized finishes. Sharp edges can cause uneven coating thickness, leading to weak spots where corrosion or wear can occur. Rounded corners allow for more uniform coating, extending the lifespan of the product.

Rounded corners in sheet metal are a critical design feature that improves both the safety and durability of metal products while also enhancing their aesthetic appeal.

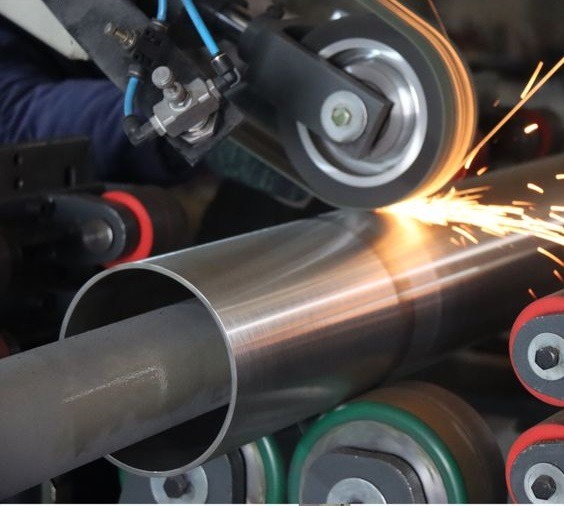

Sheet Metal Edge Rounding

Sheet metal edge rounding is the process of smoothing and shaping the edges of a metal sheet after it has been cut, punched, or machined. This process is essential for improving safety, product quality, and durability. Sharp, unfinished edges on metal parts can pose hazards to workers, cause damage to other components during assembly, and lead to stress concentrations that can weaken the material. By rounding the edges, these risks are mitigated.

Edge rounding is commonly used in industries such as automotive, aerospace, electronics, and metal fabrication, where parts need to be safe to handle and durable enough to withstand long-term use.

Methods of Sheet Metal Edge Rounding:

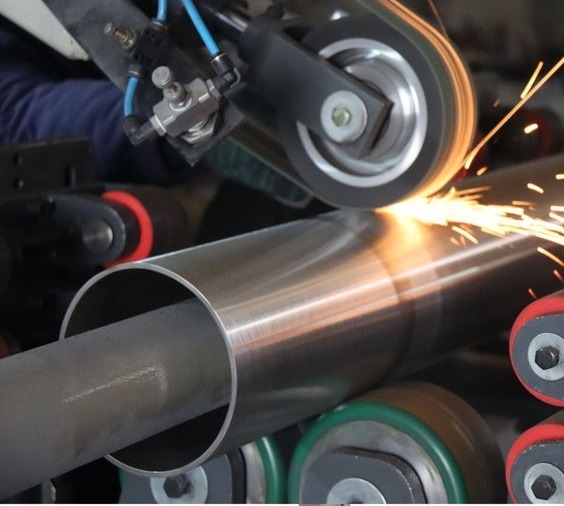

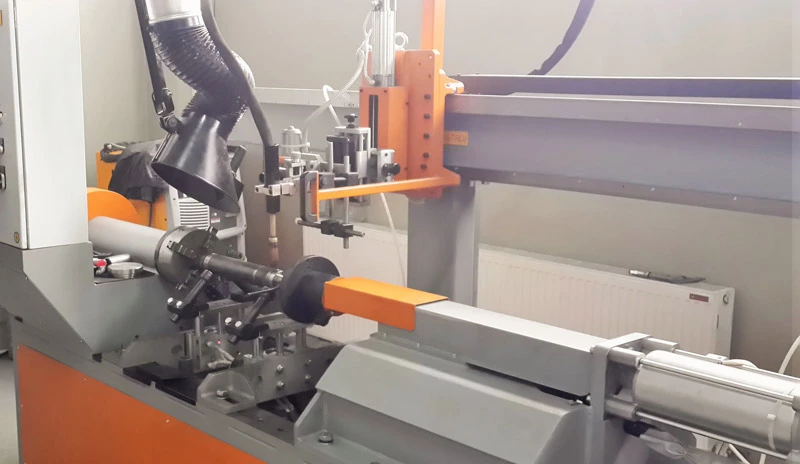

- Deburring Machines:

Deburring machines are specifically designed to remove sharp burrs and round the edges of metal sheets. These machines use abrasive belts, brushes, or discs to grind down the sharp edges and create a smooth, rounded profile. Deburring is an essential step in many manufacturing processes to ensure that the edges are safe to handle and that the final product meets quality standards. - Grinding and Sanding:

Manual or automated grinding and sanding tools are often used to round the edges of metal sheets. Abrasive materials are used to wear down the sharp edges, leaving a smooth, rounded finish. This method is especially useful for custom or low-volume production where precise control over the rounding process is needed. - Laser Cutting with Edge Rounding:

Advanced laser cutting machines can be programmed to cut metal sheets with pre-rounded edges. This eliminates the need for additional edge rounding steps and provides a high level of precision. Laser cutting with edge rounding is commonly used in the production of parts that require tight tolerances and clean, smooth edges. - Tumbling:

Tumbling is a process where metal parts are placed in a rotating drum along with abrasive media. As the drum rotates, the media polishes and rounds the edges of the metal parts, creating a smooth finish. Tumbling is an effective method for rounding the edges of small parts or components with complex geometries. - Electropolishing:

In some applications, electropolishing is used to round and smooth the edges of metal parts. This chemical process removes a thin layer of material from the surface of the metal, leaving a smooth, rounded finish. Electropolishing is commonly used for stainless steel parts in the medical, food, and pharmaceutical industries.

Applications of Sheet Metal Edge Rounding:

- Automotive Industry:

In automotive manufacturing, edge rounding is critical for ensuring that parts like body panels, brackets, and supports are safe to handle and free from sharp edges that could cause injuries or damage other components. - Electronics and Appliances:

Metal enclosures and components used in electronics and appliances often undergo edge rounding to improve their appearance and make them safer for consumers to handle. Rounded edges also help prevent the metal from cutting into wires or other sensitive components inside the device. - Aerospace Industry:

In aerospace applications, edge rounding helps reduce stress concentrations at the edges of metal parts, improving their fatigue resistance and overall structural integrity. This is essential for components that must endure extreme conditions and long service life. - Construction and Metal Fabrication:

In construction and metal fabrication, rounded edges make metal parts easier to work with and safer for workers to handle during installation. They also improve the overall aesthetics of the finished product.

Advantages of Sheet Metal Edge Rounding:

- Safety:

Sharp edges on metal parts can cause injuries to workers during handling and assembly. Edge rounding eliminates these hazards, making the parts safer to work with and reducing the risk of accidents. - Improved Durability:

Rounding the edges of metal parts reduces stress concentrations, which can lead to cracks, fractures, or other types of failure. Edge rounding helps extend the lifespan of metal components, especially those subjected to mechanical or thermal stress. - Enhanced Aesthetics:

Rounded edges give metal parts a more polished, professional appearance. This is especially important for consumer-facing products like electronics, appliances, and furniture, where visual appeal is a key factor. - Better Coating Adherence:

Rounded edges provide a smoother surface for applying coatings like paint, powder coating, or anodizing. This ensures more even coverage and improves the part’s resistance to corrosion, wear, and damage.

Sheet metal edge rounding is a vital process in modern metalworking, contributing to the safety, quality, and durability of metal products across a wide range of industries.

Special Finishing Machines

Special finishing machines are used in metalworking and manufacturing to refine the surface of metal parts after they have been formed, machined, or welded. These machines provide the final touches to ensure the metal components meet the desired specifications in terms of smoothness, texture, and appearance. Special finishing machines are crucial for enhancing the performance, longevity, and aesthetic appeal of metal products across industries such as automotive, aerospace, construction, and consumer goods.

Finishing processes can range from deburring rough edges to applying polished finishes that give parts a high-gloss or mirror-like appearance. These machines come in various types, each designed for specific finishing tasks such as polishing, grinding, buffing, or coating.

Types of Special Finishing Machines:

- Polishing Machines:

Polishing machines use abrasives to create smooth, reflective surfaces on metal parts. These machines can range from simple handheld polishers to advanced automated systems that can handle large-scale production. Polishing is often used for stainless steel, aluminum, and other metals where a high-gloss finish is required, such as in cookware, automotive parts, and architectural elements.- Rotary Polishers: Rotary polishing machines use spinning wheels and abrasive compounds to smooth and polish metal surfaces.

- Vibratory Polishers: These machines are designed for polishing smaller metal components in bulk. They use vibration to rub the metal parts against an abrasive medium, resulting in a smooth finish.

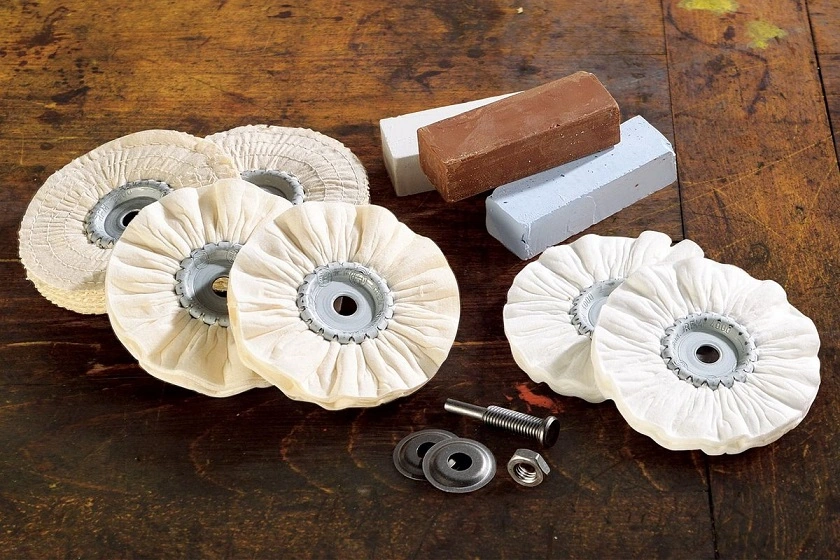

- Buffing Machines:

Buffing machines are similar to polishing machines but focus on achieving a higher level of shine and smoothness. Buffing is typically the final step in the finishing process and is used to remove fine scratches or imperfections that remain after polishing. Buffing machines are essential in industries such as automotive, where a high-quality surface finish is necessary for body panels and other visible components. - Sanding Machines:

Sanding machines use abrasive belts or discs to smooth out rough surfaces or remove small amounts of material from the surface of metal parts. Sanding is often the first step in the finishing process, especially after metal parts have been cut, welded, or machined. It is commonly used in industries such as furniture manufacturing, construction, and metal fabrication. - Shot Blasting Machines:

Shot blasting machines use high-velocity streams of abrasive material, such as steel shots or sand, to clean and smooth metal surfaces. This process is particularly useful for removing rust, paint, or other surface contaminants from metal parts. Shot blasting also helps prepare metal surfaces for painting, coating, or welding by creating a uniform surface texture.- Air Blasting: Uses compressed air to propel the abrasive material onto the metal surface.

- Centrifugal Blasting: Uses a mechanical wheel to throw the abrasive material at high speed, making it suitable for larger surfaces or more aggressive cleaning tasks.

- Electropolishing Machines:

Electropolishing is an electrochemical process used to smooth and polish metal surfaces. It removes a thin layer of material, leaving a shiny, reflective finish. Electropolishing is especially important for stainless steel and medical-grade materials, where hygiene, corrosion resistance, and surface finish are critical.

Applications of Special Finishing Machines:

- Automotive Industry:

Special finishing machines are used to create smooth, aesthetically pleasing surfaces on car body panels, trim, and engine components. Polishing and buffing are particularly important for enhancing the visual appeal of vehicles, while sanding and shot blasting are used to prepare surfaces for painting or coating. - Aerospace Industry:

In aerospace, surface finishing is essential for components that must withstand high stress and harsh environmental conditions. Polishing, buffing, and electropolishing are commonly used to improve corrosion resistance and reduce surface friction on aircraft parts. - Medical Devices and Instruments:

In the medical field, electropolishing is used to create ultra-smooth surfaces on surgical instruments, implants, and other medical devices. A smooth surface reduces the risk of contamination and makes the parts easier to clean and sterilize. - Consumer Goods:

Special finishing machines are used to improve the appearance and durability of consumer products such as kitchen appliances, furniture, and electronics. Polishing and buffing are crucial for achieving a high-quality surface finish that appeals to consumers.

Advantages of Special Finishing Machines:

- Improved Durability:

By removing surface defects and imperfections, finishing machines help improve the strength and durability of metal parts. Smooth surfaces are less prone to corrosion, wear, and fatigue. - Enhanced Aesthetic Appeal:

Polishing and buffing create visually attractive surfaces, making finished metal products more appealing to consumers. This is especially important in industries like automotive, architecture, and consumer goods. - Better Coating Adhesion:

Finishing processes such as sanding and shot blasting help prepare metal surfaces for painting or coating. A smooth, uniform surface ensures better adhesion and coverage, resulting in a longer-lasting finish. - Hygiene and Cleanliness:

In industries such as medical devices and food processing, smooth, polished surfaces are essential for maintaining hygiene and reducing the risk of contamination.

Special finishing machines play a crucial role in modern manufacturing, ensuring that metal parts meet the highest standards of quality, performance, and appearance.

Burr Cleaning Machine

A burr cleaning machine is used to remove burrs, which are small, unwanted projections or rough edges left on metal parts after cutting, machining, or drilling. Burrs can interfere with the functionality and safety of metal components, leading to problems such as improper assembly, increased wear, and safety hazards. Burr cleaning is a crucial step in the metalworking process, ensuring that parts meet quality standards and are safe to handle and use.

Burrs are formed during processes such as stamping, milling, or shearing when the metal is deformed or displaced. Burr cleaning machines use a variety of methods to smooth out these rough edges, depending on the type of metal, the part’s geometry, and the required surface finish.

Types of Burr Cleaning Machines:

- Brush Deburring Machines:

Brush deburring machines use rotating wire or abrasive brushes to clean burrs from the edges and surfaces of metal parts. These machines are often used for deburring sheet metal, stamped parts, or machined components where a light, non-invasive cleaning process is required. - Vibratory Deburring Machines:

Vibratory deburring involves placing metal parts in a vibrating container filled with abrasive media. As the machine vibrates, the media rubs against the parts, removing burrs and smoothing the edges. This process is particularly useful for deburring small or intricate parts that are difficult to clean manually. - Electrochemical Deburring:

Electrochemical deburring uses a chemical process to remove burrs from hard-to-reach areas, such as holes, grooves, or internal features. A mild electrical current is applied to the metal part, causing a controlled reaction that dissolves the burrs. This method is ideal for precision parts used in industries like aerospace, automotive, and medical devices. - Thermal Deburring Machines:

Thermal deburring, also known as explosive deburring, is a process where a gas mixture is ignited in a chamber containing the metal parts. The resulting explosion vaporizes the burrs, leaving the part clean and free from sharp edges. Thermal deburring is highly effective for removing burrs from internal features and complex geometries. - Water Jet Deburring Machines:

Water jet deburring uses high-pressure streams of water to clean burrs from the surface of metal parts. This method is particularly effective for soft metals such as aluminum or copper, where other deburring methods may be too aggressive.

Applications of Burr Cleaning Machines:

- Automotive Industry:

Burr cleaning machines are used to remove burrs from engine components, gears, and other metal parts used in automotive manufacturing. Clean, burr-free parts are essential for ensuring proper fit and function, as well as preventing excessive wear or damage during assembly. - Aerospace Industry:

In aerospace, burr cleaning is critical for ensuring the safety and reliability of components used in aircraft, satellites, and space exploration vehicles. Burrs can cause stress concentrations or interfere with precision tolerances, leading to potential failures. - Medical Devices:

Burr cleaning is essential in the production of medical devices, surgical instruments, and implants. Burr-free parts are easier to clean and sterilize, reducing the risk of infection or contamination during use. - Precision Engineering:

In precision engineering applications, such as electronics, robotics, and optics, even the smallest burrs can affect performance and assembly. Burr cleaning machines ensure that parts meet tight tolerances and are free from imperfections.

Advantages of Burr Cleaning Machines:

- Improved Safety:

Burrs can create sharp edges that pose a risk to workers handling the parts. By removing these burrs, burr cleaning machines improve workplace safety and reduce the risk of injury during assembly or use. - Enhanced Product Quality:

Burr cleaning ensures that metal parts have smooth edges and surfaces, improving their functionality, performance, and appearance. Parts with burrs may not fit together properly, leading to assembly issues or premature wear. - Precision and Consistency:

Automated burr cleaning machines provide consistent results across large production runs, ensuring that all parts meet the required quality standards. This is especially important in industries like automotive and aerospace, where reliability is critical. - Reduced Wear and Tear:

Burrs can cause friction, leading to excessive wear on moving parts or machinery. By removing burrs, burr cleaning machines help extend the life of metal components and reduce maintenance costs.

Burr cleaning machines are indispensable in the manufacturing process, ensuring that metal parts are safe, functional, and of high quality. These machines play a key role in industries where precision, performance, and safety are paramount.

Longitudinal Groove Weld

A longitudinal groove weld is a type of welding technique used to join two pieces of metal along their length, typically in cylindrical or tubular structures such as pipes, tanks, or pressure vessels. In this process, a groove is prepared between the edges of the metal parts to be welded, and the weld is deposited into the groove, filling it and creating a strong, continuous bond.

Longitudinal groove welds are commonly used in industries such as oil and gas, chemical processing, shipbuilding, and construction, where high-strength, leak-proof joints are required. The weld must be of high quality to ensure that the joined components can withstand pressure, temperature fluctuations, and mechanical stresses.

Types of Longitudinal Groove Welds:

- Single-V Groove Weld:

In a single-V groove weld, the edges of the metal parts are beveled at an angle to form a “V” shape. The welder fills the groove with molten metal, creating a strong bond between the two pieces. Single-V groove welds are commonly used for thicker materials where a single pass is not sufficient to achieve full penetration. - Double-V Groove Weld:

For thicker materials, a double-V groove weld is often used. This involves beveling both sides of the joint to create a V-shaped groove on each side. The welder deposits metal into both grooves, ensuring full penetration and strength throughout the joint. - U-Groove Weld:

In a U-groove weld, the edges of the metal parts are shaped into a U-configuration. This type of weld is typically used for thicker materials because it requires less filler material compared to a V-groove, making it more efficient for heavy-duty applications. - J-Groove Weld:

A J-groove weld involves beveling one side of the joint into a J-shape, while the other side remains straight. This weld type is commonly used in situations where one side of the joint is more accessible than the other, allowing for easier welding in tight spaces.

Applications of Longitudinal Groove Welds:

- Pipe Welding:

Longitudinal groove welds are essential in pipe welding, where two sections of pipe must be joined together to form long pipelines for transporting liquids or gases. The weld ensures that the joint is leak-proof and strong enough to withstand high internal pressures. - Pressure Vessels:

Pressure vessels, such as boilers, tanks, and reactors, rely on longitudinal groove welds to join sections of metal and maintain structural integrity. The welds must be able to endure high pressures and temperatures without failing. - Shipbuilding:

In shipbuilding, longitudinal groove welds are used to join large metal plates that form the hull, deck, and other structural components of ships. These welds are crucial for ensuring the ship’s strength and durability in harsh marine environments. - Structural Components:

Longitudinal groove welds are used in the construction of large metal structures, such as bridges, cranes, and towers, where strong, continuous joints are required to bear heavy loads and resist environmental stresses.

Advantages of Longitudinal Groove Welds:

- High Strength:

Longitudinal groove welds create strong, continuous joints that can withstand significant mechanical stresses. This makes them ideal for critical applications such as pipelines, pressure vessels, and structural components. - Leak-Proof Joints:

In applications such as piping and pressure vessels, it is essential that the joints are leak-proof to prevent the escape of fluids or gases. Longitudinal groove welds create tight, secure seals that prevent leaks, even under high pressure. - Full Penetration:

Longitudinal groove welds ensure full penetration of the weld material into the joint, providing maximum strength and durability. This is especially important for thick materials where incomplete penetration could lead to weak spots or joint failure. - Versatility:

Longitudinal groove welds can be applied to a wide range of materials and thicknesses, making them suitable for various industries and applications. Whether working with thin-walled pipes or thick structural components, the groove weld can be tailored to meet specific requirements.

Longitudinal groove welding is a critical process in industries that require high-strength, durable joints. It ensures the integrity and performance of structures and components under demanding conditions.

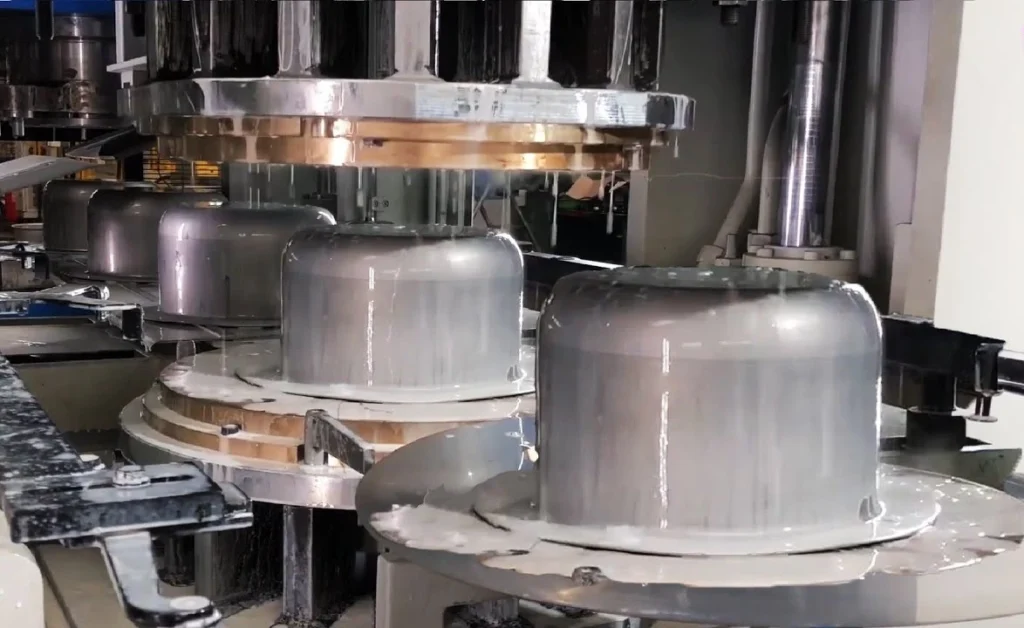

Cookware Production Machine

A cookware production machine is specialized equipment designed for the manufacturing of pots, pans, and other types of cookware. These machines handle various stages of the production process, from shaping and forming the metal to applying coatings and performing finishing touches. Cookware production machines are used by manufacturers to produce high-quality, durable kitchenware at scale, meeting the demands of both consumers and professional kitchens.

The manufacturing of cookware typically involves working with metals like aluminum, stainless steel, and copper, which provide excellent heat conductivity and durability. Each material has unique properties that require specific machinery and processes to shape, finish, and coat the final product.

Types of Cookware Production Machines:

- Press Machines:

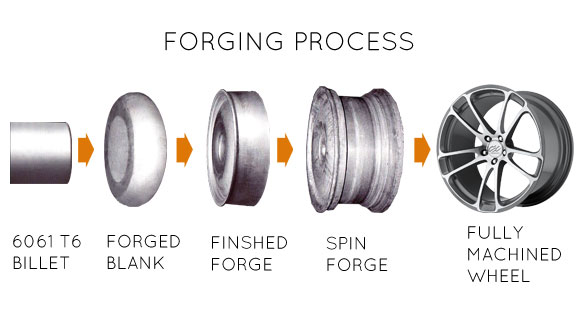

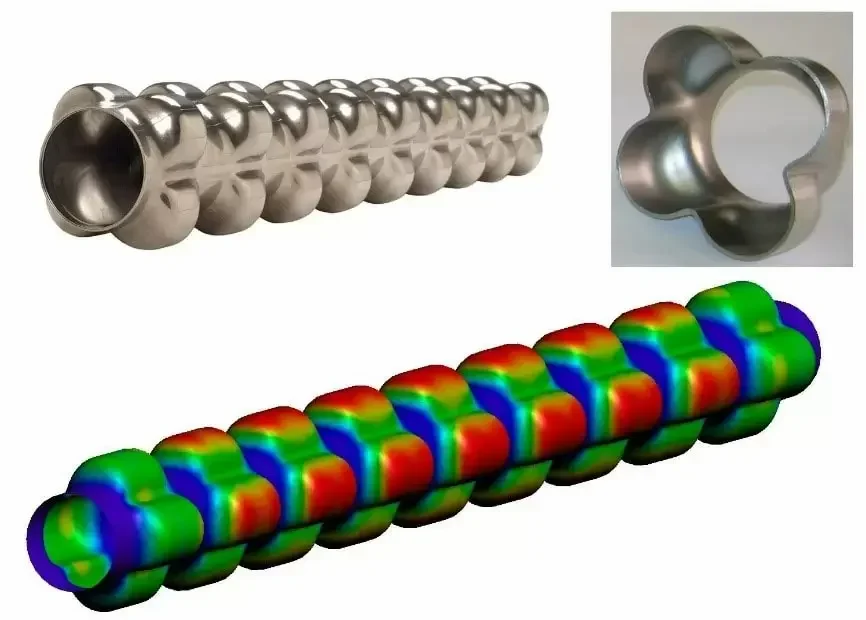

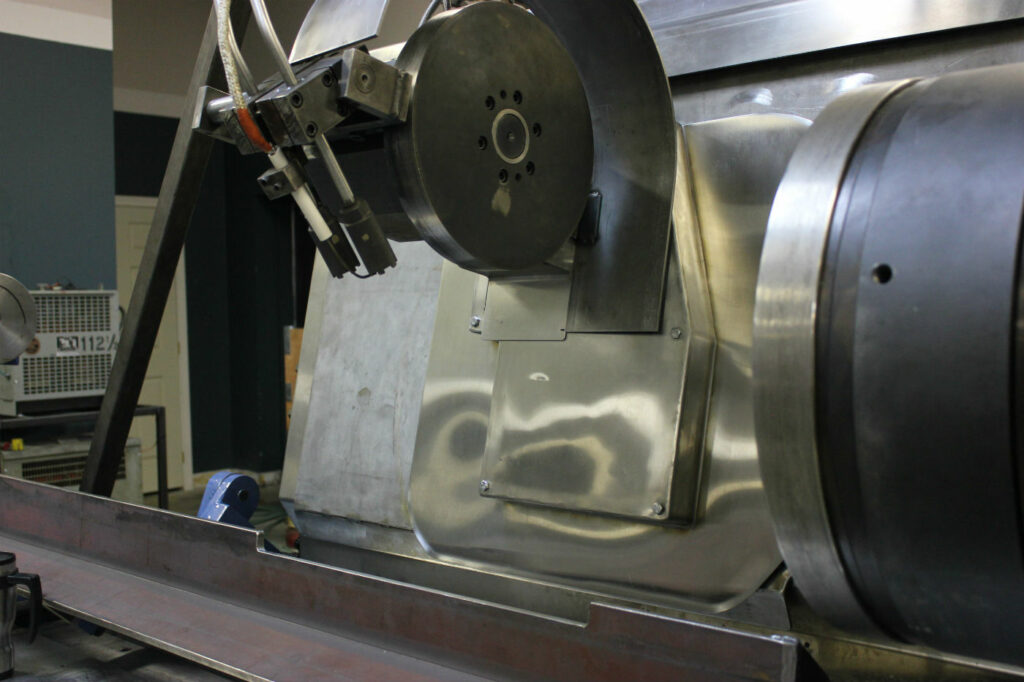

Press machines are used to shape flat metal sheets into the desired cookware form, such as pots, pans, or lids. The metal sheets are placed in a mold or die, and the press applies significant force to shape the sheet into the required form. Hydraulic or mechanical presses are commonly used, depending on the thickness and type of metal. - Spinning Machines:

Spinning machines are used to create round, symmetrical cookware items such as bowls, pans, or lids. In the spinning process, a flat metal disk is rotated at high speed while a forming tool presses it against a mold to shape the metal into the desired shape. This process is particularly useful for creating deep, rounded cookware items like stockpots or mixing bowls. - Polishing Machines:

After the cookware has been formed, polishing machines are used to smooth the surface and give it a shiny, reflective finish. Polishing is important not only for aesthetic reasons but also for improving the non-stick properties of the cookware and preventing food from sticking to the surface during use. - Coating Machines:

Many cookware items, especially non-stick pans, require the application of a specialized coating. Coating machines are used to apply layers of non-stick material (such as Teflon or ceramic) to the surface of the cookware. These machines ensure even coverage and proper adhesion of the coating, which is essential for both performance and durability. - Edge Rolling Machines:

Edge rolling machines are used to round the edges of the cookware, giving it a smooth, safe edge that is comfortable to handle. This process is important for both safety and durability, as sharp edges can be dangerous and more prone to damage.

Applications of Cookware Production Machines:

- Consumer Cookware:

Cookware production machines are primarily used to manufacture pots, pans, and other kitchen tools for home use. High-quality cookware is essential for efficient and enjoyable cooking, and consumers expect durable, easy-to-clean products that distribute heat evenly. - Professional Cookware:

Professional-grade cookware, used in commercial kitchens, requires a higher level of durability and heat performance. Cookware production machines are used to manufacture heavy-duty products that can withstand the demands of professional chefs. - Specialty Cookware:

Specialty cookware, such as cast iron skillets or copper pans, may require additional or specific production processes. For example, copper cookware often undergoes a tinning process to coat the inside surface with a layer of tin, preventing the copper from reacting with food.

Advantages of Cookware Production Machines:

- High Efficiency:

Cookware production machines allow manufacturers to produce large quantities of cookware quickly and efficiently. Automation and precision machinery ensure consistent quality across all products. - Customizability:

These machines can be adjusted to produce a wide variety of cookware shapes, sizes, and designs. Whether manufacturing frying pans, saucepans, or stockpots, cookware production machines provide the flexibility to meet diverse market demands. - Durability:

The machines used in cookware production are designed to handle heavy-duty materials like stainless steel and aluminum, ensuring that the final products are durable and long-lasting. - Precision:

Precision is crucial in cookware manufacturing to ensure that the pots and pans have the correct dimensions, thickness, and heat conductivity. Cookware production machines provide the necessary control to achieve consistent results.

Cookware production machines are essential tools in the kitchenware industry, enabling manufacturers to produce high-quality, reliable products that meet the needs of both home cooks and professional chefs.

Brake Pads Machine

A brake pads machine is a specialized piece of equipment used in the manufacturing of brake pads, a critical component of the braking systems in automobiles, motorcycles, and other vehicles. Brake pads play a key role in ensuring the safe operation of vehicles by converting kinetic energy into heat during braking, which slows the vehicle down. Manufacturing brake pads requires precision, quality control, and specialized machinery to ensure that they meet safety and performance standards.

Brake pads are typically made from a combination of materials, including metal shavings, ceramics, and organic compounds. The manufacturing process involves molding these materials under high pressure and heat to create durable, reliable brake pads.

Types of Brake Pads Machines:

- Molding Machines:

Molding machines are used to shape the brake pad material into its final form. In this process, the brake pad compound is placed into a mold, and high pressure and heat are applied to compress the material into the desired shape. The molded brake pads are then cooled and removed from the mold for further processing. - Curing Ovens:

After molding, brake pads are placed in curing ovens to harden and strengthen the material. The curing process is critical for ensuring that the brake pads can withstand the high temperatures generated during braking. Curing ovens are designed to maintain consistent temperatures and ensure uniform hardening across all pads. - Grinding Machines:

Grinding machines are used to shape and finish the brake pads after molding and curing. These machines grind the brake pad to its final thickness and smooth out any rough surfaces. Precision grinding is essential for ensuring that the brake pads fit properly in the brake caliper and perform effectively during braking. - Coating Machines:

Many brake pads are coated with specialized materials to reduce noise, prevent corrosion, or improve performance in extreme conditions. Coating machines apply these materials evenly across the surface of the brake pad, ensuring that they adhere properly and provide the desired benefits. - Testing Machines:

Brake pads must undergo rigorous testing to ensure that they meet safety standards and perform well under various conditions. Testing machines simulate real-world braking scenarios to measure the pad’s performance, wear resistance, and heat tolerance. This testing ensures that the brake pads will perform reliably in the field.

Applications of Brake Pads Machines:

- Automotive Industry:

The automotive industry relies heavily on brake pads machines for the production of brake components for cars, trucks, and motorcycles. High-quality brake pads are essential for vehicle safety, and manufacturers use specialized machines to ensure that the pads meet strict regulatory standards. - Heavy-Duty Vehicles:

Brake pads for heavy-duty vehicles, such as trucks, buses, and industrial machinery, must be able to withstand higher loads and more extreme conditions than those used in passenger vehicles. Brake pads machines used in this sector are designed to produce durable, high-performance pads that can handle heavy braking forces. - Motorcycle Manufacturing:

Motorcycle brake pads are typically smaller and lighter than those used in cars, but they still require high levels of precision and performance. Brake pads machines in this sector are calibrated to produce pads that provide reliable stopping power for motorcycles.

Advantages of Brake Pads Machines:

- Precision Manufacturing:

Brake pads machines are designed to ensure precise control over the molding, curing, and finishing processes. This precision is critical for producing brake pads that perform consistently and safely in real-world driving conditions. - High Efficiency:

Automated brake pads machines allow manufacturers to produce large quantities of brake pads quickly and efficiently, meeting the demands of the automotive industry while maintaining high quality. - Customization:

Brake pads machines can be adjusted to produce brake pads of different sizes, materials, and specifications, allowing manufacturers to cater to a wide range of vehicles and performance requirements. - Quality Control:

These machines are equipped with advanced quality control systems that ensure every brake pad meets safety and performance standards. Automated testing and inspection processes help identify defects and ensure that only high-quality pads reach the market.

Brake pads machines are vital in the production of high-performance, reliable brake pads that ensure the safety and effectiveness of vehicle braking systems.

How to Make Aluminum Pots

Making aluminum pots is a manufacturing process that involves several key steps to transform raw aluminum into durable, lightweight cookware. Aluminum is a popular material for pots and pans because of its excellent heat conductivity, corrosion resistance, and lightweight properties. It is commonly used in both household and commercial cookware due to its affordability and performance in the kitchen.

The process of making aluminum pots requires precision machinery and careful attention to detail to ensure that the final product meets quality standards in terms of heat distribution, durability, and safety.

Steps to Make Aluminum Pots:

- Aluminum Sheet Selection:

The first step in making aluminum pots is selecting high-quality aluminum sheets or blanks. The thickness and grade of the aluminum are chosen based on the desired characteristics of the final product, such as weight, heat conductivity, and durability. Thicker sheets are typically used for professional-grade pots, while thinner sheets may be used for consumer cookware. - Blanking:

Blanking is the process of cutting the aluminum sheet into circular blanks, which will form the base of the pot. A blanking press is used to punch out these circular shapes from the larger sheet of aluminum. The size of the blank is determined by the size of the pot being manufactured. - Deep Drawing:

Deep drawing is the process of shaping the flat aluminum blank into a cylindrical or round form, which becomes the body of the pot. This is done by placing the aluminum blank into a die and using a punch to draw the metal into the desired shape. The deep drawing process is critical for creating the smooth, rounded sides of the pot without causing wrinkles or tears in the material. - Trimming and Edge Rolling:

After deep drawing, the excess material around the rim of the pot is trimmed off to achieve the desired height and diameter. Edge rolling is then used to round off the rim of the pot, creating a smooth, safe edge. This step is important for both the safety of the user and the aesthetic appearance of the pot. - Annealing:

In some cases, the aluminum pots may undergo an annealing process, which involves heating the metal to a specific temperature and then allowing it to cool slowly. Annealing helps relieve internal stresses in the metal, making it more malleable and easier to work with during further forming processes. - Polishing and Finishing:

Once the pot has been formed, it undergoes a polishing process to smooth the surface and give it a shiny, attractive finish. Polishing is typically done using buffing machines with abrasive compounds that remove surface imperfections and create a reflective surface. - Non-Stick Coating Application (Optional):

Many aluminum pots are coated with a non-stick material, such as Teflon or ceramic, to improve their cooking performance and make them easier to clean. Coating machines are used to apply these materials evenly to the interior surface of the pot. The coating is then cured in a high-temperature oven to ensure proper adhesion and durability. - Handle Attachment:

Handles are attached to the pot either by riveting, welding, or screwing them in place. Aluminum pots often feature plastic or stainless steel handles for safe and comfortable handling during cooking. - Quality Inspection:

Before the pots are packaged and shipped, they undergo a final inspection to ensure that they meet quality standards. This includes checking for surface imperfections, coating adhesion, and proper handle attachment. Any defective pots are rejected and either reworked or recycled.

Advantages of Aluminum Pots:

- Lightweight:

Aluminum is much lighter than other metals like cast iron or stainless steel, making aluminum pots easier to handle, especially in commercial kitchens where large pots are frequently used. - Excellent Heat Conductivity:

Aluminum is one of the best conductors of heat, allowing for even heat distribution during cooking. This helps prevent hot spots and ensures that food cooks uniformly. - Corrosion Resistance:

Aluminum naturally forms a thin oxide layer on its surface, which protects it from corrosion. This makes aluminum pots long-lasting and suitable for use in humid or acidic environments. - Affordability:

Aluminum is a relatively inexpensive material, making aluminum pots a cost-effective option for both home cooks and professional chefs. - Versatility:

Aluminum pots come in various shapes and sizes, from small saucepans to large stockpots, and can be used for a wide range of cooking applications, including boiling, frying, simmering, and sautéing.

The process of making aluminum pots combines precision engineering, high-quality materials, and advanced manufacturing techniques to produce cookware that is both functional and affordable. Whether for home use or in a professional kitchen, aluminum pots are a staple in kitchens around the world.

Sheet Metal Forming

Sheet metal forming encompasses a wide array of manufacturing processes used to manipulate flat metal sheets into desired geometries. It is a critical process across industries such as automotive, aerospace, construction, electronics, and household goods manufacturing. Sheet metal forming involves the application of force to plastically deform a metal sheet, permanently changing its shape without removing material. The goal is to produce parts with precise dimensions and properties suitable for end-use applications.

The forming process can range from simple operations like bending and shearing to more complex techniques like deep drawing and hydroforming. The versatility of sheet metal forming allows manufacturers to produce everything from intricate components with fine details to large-scale structural elements.

Key Techniques in Sheet Metal Forming

- Bending:

Bending is one of the most basic and widely used methods in sheet metal forming. It involves deforming the sheet along a straight axis to form an angular shape, such as a V, U, or channel. Bending can be achieved using tools like press brakes, roll benders, and folding machines. Press brakes are highly accurate and can create precise bends with controlled angles and radii, making them indispensable in the production of parts like enclosures, panels, brackets, and frames. Roll bending, on the other hand, is used to form larger cylindrical shapes such as tubes or pipes. - Stamping and Punching:

Stamping is the process of using a press to force a sheet metal blank into a die, creating various shapes and patterns. Punching, on the other hand, involves removing material by shearing through the metal with a punch and die. Both methods are highly efficient for mass production, allowing manufacturers to produce hundreds or thousands of parts in a short period. Common applications include automotive body panels, appliance casings, and electronic housings. - Deep Drawing:

Deep drawing is the process of pulling a sheet of metal into a die cavity using a punch to form a hollow or cup-like shape. This technique is particularly useful for producing complex parts such as fuel tanks, kitchen sinks, and cookware, where seamless construction and uniform thickness are crucial. Deep drawing requires precise control over material flow to prevent defects like wrinkling, tearing, or thinning. - Roll Forming:

Roll forming is a continuous bending process in which a long strip of sheet metal is passed through a series of rollers to gradually form it into the desired profile. This method is especially suited for producing long parts with consistent cross-sections, such as metal roofing, gutters, and structural beams. Roll forming is highly efficient, especially for high-volume production runs, and it allows for the creation of complex shapes without requiring significant secondary operations. - Hydroforming:

Hydroforming is an advanced sheet metal forming technique that uses high-pressure hydraulic fluid to shape the sheet into a die. This process is highly effective for creating lightweight, high-strength parts with complex geometries, such as automotive chassis components, aerospace structural parts, and exhaust systems. Hydroforming allows for precise control of material thickness and results in parts with improved structural integrity due to the uniform application of force. - Spinning:

Metal spinning is a process in which a metal disc or tube is rotated at high speed and pressed against a mandrel to form axially symmetric parts. This technique is often used to produce conical or cylindrical components, such as lampshades, cookware, and decorative items. Spinning is particularly useful for creating large, smooth surfaces without the need for welding or seams. - Laser Cutting:

Laser cutting is a non-contact process that uses a high-energy laser beam to cut or engrave precise shapes into the sheet metal. It offers unparalleled accuracy and is used for intricate designs or when complex shapes are needed. Laser cutting is often combined with other forming processes to create parts with both functional and aesthetic qualities, such as perforated metal sheets, intricate enclosures, and decorative elements.

Applications of Sheet Metal Forming

- Automotive Industry:

In automotive manufacturing, sheet metal forming is used to produce body panels, structural components, chassis parts, and engine components. The ability to form lightweight yet strong parts is critical for improving vehicle performance, fuel efficiency, and safety. Techniques like stamping, hydroforming, and deep drawing allow automakers to produce complex geometries with precision and repeatability. - Aerospace Industry:

Aerospace companies rely heavily on sheet metal forming to manufacture lightweight components that can withstand the stresses of flight. Parts such as fuselage panels, wing ribs, and turbine housings are formed from high-strength aluminum, titanium, and stainless steel. Advanced forming techniques like hydroforming and stretch forming are often used to achieve the intricate shapes required for aerodynamic efficiency. - Construction and Architecture:

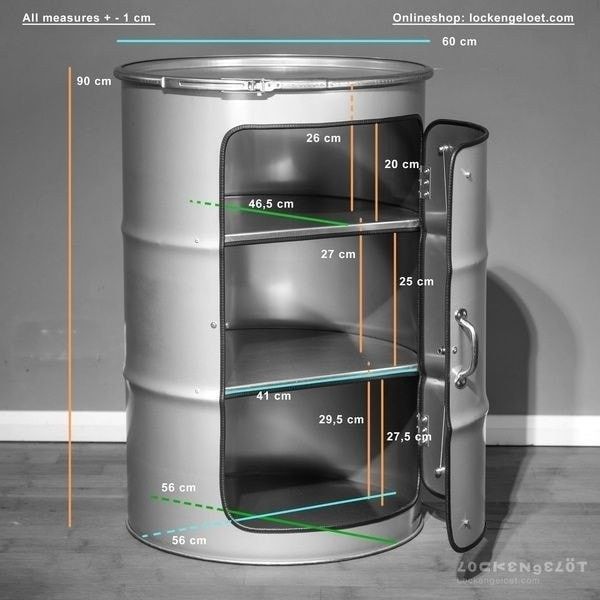

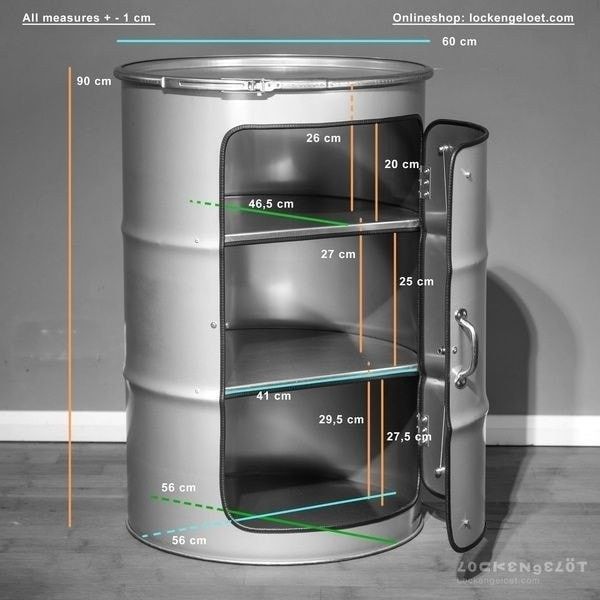

In construction, sheet metal is used for roofing, cladding, framing, and architectural elements like facades and decorative panels. Sheet metal forming allows for the production of components that are both functional and aesthetically pleasing. Roll forming is often used to produce long structural elements, while stamping and punching are employed to create custom designs in metal sheets for decorative purposes. - Consumer Goods:

Many everyday household items, from kitchen appliances to furniture, are made using sheet metal forming processes. Cookware, sinks, storage cabinets, and electronic enclosures are all examples of products manufactured through deep drawing, stamping, and bending techniques. The versatility of sheet metal forming allows for the mass production of durable, affordable goods with consistent quality.

Advantages of Sheet Metal Forming

- High Efficiency:

Sheet metal forming is ideal for mass production due to its ability to produce large quantities of parts with consistent quality. Automated forming machines, such as stamping presses and roll formers, can run continuously, maximizing output and minimizing downtime. - Material Efficiency:

Forming processes shape the metal without removing material, which reduces waste compared to subtractive methods like machining. This makes sheet metal forming an environmentally friendly and cost-effective option for manufacturing. - Precision and Versatility:

Modern sheet metal forming techniques, especially those using CNC-controlled machines, offer high precision and repeatability, ensuring that parts meet strict tolerances. Additionally, forming processes can be applied to a wide range of metals, including steel, aluminum, copper, and alloys, making it suitable for diverse applications. - Cost-Effectiveness:

Once the tooling is set up, sheet metal forming is highly cost-effective, especially for high-volume production. The process minimizes material waste, reduces the need for secondary operations, and allows for rapid production cycles, all of which contribute to lower overall manufacturing costs.

Sheet metal forming is a cornerstone of modern manufacturing, providing the flexibility, precision, and efficiency needed to produce high-quality metal parts for a variety of industries.

Hydraulic Metal Forming

Hydraulic metal forming is a specialized process that utilizes hydraulic pressure to shape metal components. This technique is primarily used for forming large, thick, or complex metal parts that require significant force to deform. Hydraulic metal forming is versatile and is widely used across industries such as automotive, aerospace, heavy machinery, and construction. The key advantage of hydraulic metal forming is the ability to apply uniform pressure over large areas of material, allowing for precise control and the production of high-strength parts.

Hydraulic forming processes rely on hydraulic presses, which use a hydraulic cylinder to generate force by compressing a fluid (usually oil) within a sealed chamber. The force generated is transmitted to a ram or punch, which deforms the metal blank into the desired shape. Hydraulic presses are highly adaptable, capable of performing various forming operations such as deep drawing, punching, bending, and embossing.

Key Techniques in Hydraulic Metal Forming

- Hydroforming:

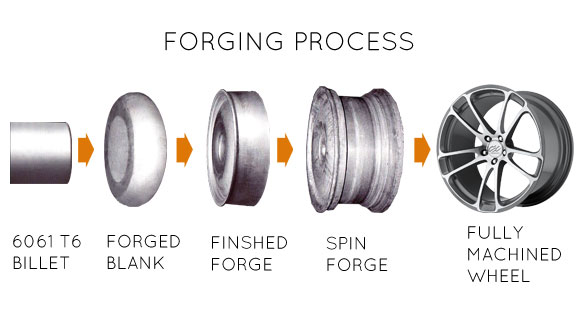

Hydroforming is a popular hydraulic forming technique used to create hollow parts, such as automotive exhaust components, structural tubes, and chassis members. In this process, a metal sheet or tube is placed inside a mold, and hydraulic fluid is used to press the material against the mold walls, forming the desired shape. Hydroforming allows for the creation of lightweight, high-strength parts with minimal material waste. It is particularly effective for producing complex geometries that would be difficult to achieve with traditional stamping or bending methods. - Deep Drawing with Hydraulic Presses:

Deep drawing is a process where a flat metal blank is drawn into a die using a hydraulic press, forming a deep, cup-like shape. This process is widely used to produce components like fuel tanks, pressure vessels, and kitchen sinks. Hydraulic presses are ideal for deep drawing because they can apply consistent force, ensuring uniform material flow and preventing defects like wrinkling or tearing. - Hydraulic Stamping:

Hydraulic stamping involves placing a metal blank between a punch and die, and using hydraulic pressure to shape the metal into the desired form. This process is used for producing parts with complex shapes, such as automotive body panels, appliance casings, and industrial machinery components. Hydraulic presses are favored in stamping applications because they offer precise control over the force applied, ensuring high-quality, defect-free parts. - Bulge Forming:

Bulge forming is a hydraulic process where a metal sheet or tube is placed in a die, and hydraulic pressure is applied to cause the material to bulge outward, taking the shape of the die. This technique is often used to produce domed, spherical, or cylindrical components. Bulge forming is particularly useful in the production of pressure vessels, lighting fixtures, and decorative metal items. - Rubber Pad Forming:

In rubber pad forming, a metal sheet is placed over a die, and a flexible rubber pad is pressed against it using hydraulic pressure. The rubber pad conforms to the shape of the die, forming the metal into the desired shape without damaging the surface. This process is commonly used in aerospace and automotive applications, where surface quality is critical. Rubber pad forming is especially beneficial when producing small batches or custom parts, as it reduces the need for complex tooling. - Hydraulic Coining:

Coining is a precision forming process where a metal blank is pressed between two dies under high pressure, resulting in the material flowing into intricate die cavities. This process is often used for minting coins, producing decorative metal parts, or creating high-precision components with fine details. Hydraulic presses are ideal for coining because they provide the consistent, high-pressure force needed to ensure sharp, accurate details.

Applications of Hydraulic Metal Forming

- Automotive Industry:

Hydraulic metal forming is widely used in automotive manufacturing to produce chassis components, body panels, exhaust systems, and suspension parts. The ability to form lightweight yet strong parts is essential for improving vehicle fuel efficiency and performance. Hydroforming, in particular, is extensively used to create hollow structural components that reduce vehicle weight without sacrificing strength. - Aerospace Industry:

In aerospace, hydraulic forming is used to produce high-strength, lightweight components such as fuselage panels, wing spars, and engine housings. The precision offered by hydraulic presses ensures that these critical parts meet the stringent performance and safety requirements of the aerospace industry. Rubber pad forming is often used to produce smooth, defect-free surfaces on aircraft parts, while deep drawing and hydroforming are employed for structural components. - Heavy Machinery and Industrial Equipment:

Hydraulic forming is essential in the production of large, thick metal parts used in heavy machinery, construction equipment, and industrial tools. The high force generated by hydraulic presses allows for the forming of thick steel plates and heavy-duty components, such as gears, housings, and frames, which must withstand extreme stress and harsh operating conditions. - Medical Devices and Instruments:

Hydraulic metal forming is used in the production of precision medical devices and instruments, such as surgical tools, prosthetics, and implantable devices. The ability to form intricate shapes with high precision and repeatability is crucial in the medical field, where quality and reliability are paramount. - Energy Sector:

In the energy sector, hydraulic metal forming is used to produce components for power plants, wind turbines, and oil and gas pipelines. These components must withstand high pressures, temperatures, and corrosive environments, making hydraulic forming an ideal solution for creating durable, high-performance parts.

Advantages of Hydraulic Metal Forming

- Uniform Force Application:

One of the primary advantages of hydraulic metal forming is the ability to apply uniform pressure over the entire surface of the material. This ensures that the metal is formed evenly, reducing the risk of defects such as warping, thinning, or cracking. The consistent force application also allows for better control over material flow, resulting in parts with uniform thickness and strength. - Versatility:

Hydraulic presses can be used for a wide range of forming operations, including deep drawing, stamping, bending, and coining. They can handle various types of metals, including steel, aluminum, copper, and titanium, making hydraulic forming suitable for diverse applications across multiple industries. - Precision and Control:

Hydraulic presses offer precise control over the amount of force applied, allowing manufacturers to achieve tight tolerances and fine details. This level of precision is especially important in industries like aerospace, automotive, and medical devices, where high-quality, defect-free parts are essential. - High Strength Parts:

Hydraulic forming processes, such as hydroforming and deep drawing, produce parts with excellent structural integrity and strength-to-weight ratios. These parts are often stronger than those produced by traditional stamping or bending methods because the hydraulic pressure distributes evenly, reducing stress concentrations and improving overall material performance. - Material Efficiency:

Hydraulic forming reduces material waste by shaping the metal without removing material. This makes it a cost-effective and environmentally friendly manufacturing process, particularly for high-volume production runs.

Hydraulic metal forming is a versatile and powerful process that provides manufacturers with the ability to produce complex, high-strength parts with precision and efficiency. Whether used in automotive, aerospace, or industrial applications, hydraulic forming is a critical component of modern metalworking.

Sheet Metal Rounded Corners

Sheet metal rounded corners refer to the process of softening or rounding off the sharp edges of a sheet metal part to improve its functionality, safety, and appearance. In many manufacturing applications, sharp corners can be problematic for several reasons: they pose a safety hazard to workers, they can cause stress concentrations in the material, and they can detract from the aesthetic quality of the final product. By rounding the corners, manufacturers can address these issues while enhancing the durability and usability of the metal component.

Rounded corners are especially important in industries such as automotive, electronics, aerospace, and consumer goods, where safety, appearance, and functionality are critical factors. In addition to improving the physical properties of the metal, rounded corners can also make parts easier to handle during assembly and reduce the risk of injury during use.

Methods for Creating Sheet Metal Rounded Corners

- Bending with a Press Brake:

One of the most common methods for creating rounded corners in sheet metal is bending. By using a press brake, manufacturers can bend the metal into a radius instead of a sharp 90-degree angle. The size of the radius can be controlled by adjusting the tooling and the bending force applied. Press brakes are ideal for producing consistent, smooth bends on metal sheets, making them a go-to solution for creating rounded corners on parts such as enclosures, panels, and brackets. - Edge Rolling:

Edge rolling is a process in which the edges of a metal sheet are rolled over or rounded off using specialized rolling machines. This technique is often used to create smooth, rounded edges on metal parts like containers, enclosures, and trays, where sharp edges would pose a risk of injury or damage. Rolling the edges also adds strength to the part by eliminating weak points at the corners. - Chamfering and Grinding:

Chamfering involves cutting a beveled edge along the corner of the metal to reduce its sharpness. This can be done manually using grinders or chamfering machines, or automatically using CNC-controlled equipment. While chamfering does not produce a fully rounded corner, it softens the edge and reduces the risk of injury. For parts requiring a more refined finish, grinding can be used to smooth out the chamfered edges and create a more rounded profile. - Laser Cutting with Rounded Corners:

Modern laser cutting machines can be programmed to cut metal sheets with pre-rounded corners, eliminating the need for additional edge rounding processes. Laser cutting offers high precision and is ideal for producing parts with complex shapes or intricate designs. By incorporating rounded corners into the initial cutting process, manufacturers can save time and improve the quality of the final product. - Waterjet Cutting:

Waterjet cutting is another method used to create rounded corners in sheet metal. This process uses high-pressure water mixed with abrasive materials to cut through metal, allowing for smooth, precise edges. Waterjet cutting is particularly useful for metals that are sensitive to heat, as the process does not generate heat-affected zones that could compromise the material’s properties.

Applications of Rounded Corners in Sheet Metal

- Safety:

One of the primary reasons for rounding the corners of sheet metal parts is to improve safety. Sharp edges can cause cuts or injuries during handling, assembly, or use. Rounded corners eliminate these hazards, making the parts safer to work with and reducing the risk of injury to workers or end-users. - Stress Reduction:

Sharp corners are more likely to concentrate stress, which can lead to cracks, fractures, or failure under load. Rounding the corners distributes stress more evenly across the part, improving its durability and resistance to fatigue. This is especially important in structural components, automotive parts, and aerospace applications, where parts are subjected to significant mechanical loads. - Aesthetic Appeal:

Rounded corners enhance the visual appeal of sheet metal products by creating a smoother, more polished appearance. This is particularly important in consumer goods, such as electronic enclosures, appliances, and furniture, where aesthetics play a key role in the product’s marketability. Rounded corners give the product a modern, professional look and can improve its ergonomics by making it more comfortable to handle. - Improved Coating and Finishing:

Rounded corners provide a better surface for applying coatings, such as paint, powder coating, or anodizing. Sharp corners can cause uneven coating thickness, leading to weak spots that are prone to corrosion or wear. Rounded corners allow for more uniform coverage, resulting in a longer-lasting finish and improved protection against environmental factors. - Assembly and Handling:

Parts with rounded corners are easier to handle during assembly, especially in automated manufacturing environments where robotic systems may be used. Rounded edges reduce the risk of snagging, jamming, or damage to other components during assembly. In addition, parts with rounded corners are often easier to fit together, improving the overall efficiency of the assembly process.

Advantages of Sheet Metal Rounded Corners

- Enhanced Durability:

By reducing stress concentrations, rounded corners help improve the overall durability of the metal part. This makes the part more resistant to mechanical stress, vibrations, and impact, extending its lifespan and reducing the likelihood of failure. - Improved Safety:

Rounding the corners of sheet metal parts eliminates sharp edges, making the parts safer to handle during manufacturing, assembly, and use. This reduces the risk of workplace injuries and ensures that the final product is safe for consumers. - Aesthetic and Ergonomic Benefits:

Rounded corners give sheet metal parts a more refined, professional appearance, which is especially important in consumer-facing products. Additionally, rounded edges make the product more ergonomic, improving comfort for the user and reducing strain during handling. - Better Coating Adhesion:

Rounded corners provide a more consistent surface for applying coatings, resulting in better adhesion and more even coverage. This improves the product’s resistance to corrosion, wear, and environmental damage, ensuring a longer-lasting finish.

Sheet metal rounded corners are a critical design feature that improves the safety, functionality, and appearance of metal parts across a wide range of industries. By employing techniques such as bending, edge rolling, and laser cutting, manufacturers can produce high-quality, durable products with rounded corners that meet the demands of modern applications.

Sheet Metal Edge Rounding

Sheet metal edge rounding is a finishing process that involves smoothing or rounding the sharp edges of metal components after cutting, punching, or machining. This process plays a critical role in improving the safety, functionality, and aesthetics of metal parts. Sharp edges left after cutting operations can pose safety hazards, cause damage to other components during assembly, and lead to premature wear or failure. By rounding the edges, manufacturers can enhance both the structural integrity and appearance of metal parts.

Edge rounding is commonly used in industries such as automotive, aerospace, electronics, and consumer goods, where high-quality finishes and safety are paramount. The process is typically employed in conjunction with other metalworking techniques, such as bending, forming, and coating, to produce a complete, ready-to-use part.

Methods of Sheet Metal Edge Rounding

- Mechanical Deburring and Edge Rounding:

Mechanical deburring machines are among the most commonly used tools for rounding the edges of sheet metal. These machines employ abrasive belts, brushes, or discs to remove burrs and sharp edges from the metal surface. The result is a smooth, rounded edge that is safe to handle and enhances the performance of the part.- Brush Deburring Machines: These machines use rotating wire or abrasive brushes to smooth the edges of metal parts. They are particularly effective for rounding off fine edges after processes such as laser cutting or punching. Brush deburring is widely used in industries where safety and surface finish are critical, such as automotive manufacturing and electronics production.

- Disc or Belt Sanding Machines: Disc or belt sanders are used to grind down rough or sharp edges. These machines are highly efficient and can process large quantities of metal parts in a relatively short time. Sanding is often used as a preliminary step in preparation for further finishing operations, such as coating or polishing.

- Vibratory Tumbling:

Vibratory tumbling is a popular method for edge rounding, especially for small parts or components with intricate geometries. In this process, metal parts are placed in a vibrating container filled with abrasive media. As the container vibrates, the abrasive material rubs against the edges of the parts, rounding them off and creating a smooth finish. Vibratory tumbling is a batch process, making it highly efficient for producing large quantities of parts simultaneously.- Advantages of Tumbling: This method is ideal for small parts or components with complex shapes that are difficult to deburr manually. Vibratory tumbling also provides a uniform finish, ensuring that all edges are consistently rounded without requiring manual intervention.

- Electropolishing:

Electropolishing is an electrochemical process used to smooth and round the edges of metal parts by selectively removing a thin layer of material. The process involves submerging the metal part in an electrolyte solution and applying a direct current, which dissolves the high points on the surface and edges. Electropolishing is commonly used for stainless steel parts and is especially important in industries such as medical device manufacturing, where hygiene and precision are critical.- Applications in Medical Devices: Electropolishing is often used to remove sharp edges on surgical instruments, implants, and other medical devices, ensuring that the parts are safe to handle and sterilize. The process also improves the corrosion resistance and surface finish of the part, making it more durable and suitable for use in sterile environments.

- Laser and Waterjet Edge Rounding:

Modern cutting technologies, such as laser and waterjet cutting, can be programmed to produce rounded edges directly during the cutting process. This eliminates the need for secondary edge rounding operations and results in a highly precise and consistent finish. Laser and waterjet cutting are particularly effective for producing parts with complex shapes or tight tolerances, where manual edge rounding would be difficult or time-consuming.- Precision Edge Rounding with Laser Cutting: Laser cutting offers extremely precise control over the cut and edge quality, allowing manufacturers to achieve smooth, rounded edges with minimal post-processing. This is particularly useful for high-end applications such as aerospace components, electronics enclosures, and decorative metalwork.

Applications of Sheet Metal Edge Rounding

- Automotive Industry:

In the automotive industry, edge rounding is essential for ensuring that metal parts such as body panels, structural components, and brackets are safe to handle during assembly. Sharp edges can cause injuries to workers or damage to other parts during installation. Additionally, rounded edges improve the durability of components by reducing stress concentrations, which can lead to cracks or failure over time.- Edge Rounding for Car Body Panels: Automotive manufacturers often use edge rounding on body panels to enhance both the safety and aesthetics of the vehicle. Rounded edges help prevent damage to painted surfaces and ensure a smooth, professional appearance.

- Aerospace Industry:

In aerospace manufacturing, edge rounding is critical for improving the structural integrity of components. Sharp edges can act as stress concentrators, leading to premature failure under high loads or vibration. By rounding the edges, manufacturers can ensure that parts meet the stringent safety and performance requirements of the aerospace industry.- Edge Rounding for Aircraft Components: Aerospace components, such as wing panels, fuselage sections, and engine parts, often undergo edge rounding to prevent fatigue and cracking. This is especially important in high-stress areas where sharp edges could compromise the structural integrity of the part.

- Electronics and Electrical Enclosures:

Sheet metal is widely used to create enclosures for electronic devices and electrical systems. These enclosures often require edge rounding to ensure that the sharp edges do not damage internal components or wiring. Additionally, edge rounding improves the safety of the enclosure by reducing the risk of injury to users during assembly or maintenance.- Edge Rounding for Electronics: In consumer electronics, such as smartphones, computers, and appliances, edge rounding is used to create sleek, modern designs while ensuring that the device is safe to handle. This process is particularly important for handheld devices, where sharp edges could pose a safety hazard or detract from the product’s ergonomics.

- Architectural and Decorative Metalwork:

In architectural and decorative applications, edge rounding is used to enhance the visual appeal of metal components such as handrails, staircases, metal cladding, and sculptures. Rounded edges provide a smoother, more refined look that is aesthetically pleasing while also improving safety in high-traffic areas.- Edge Rounding for Handrails: Metal handrails and stair components often undergo edge rounding to prevent sharp edges from causing injury. Rounded edges also improve the tactile experience for users, making the handrails more comfortable to grip.

Advantages of Sheet Metal Edge Rounding

- Improved Safety:

Rounding the edges of metal parts significantly reduces the risk of injury to workers during handling and assembly. It also ensures that the final product is safe for consumers to use. This is particularly important in industries like automotive, electronics, and construction, where sharp edges could pose serious safety hazards. - Enhanced Durability:

Sharp edges tend to concentrate stress, which can lead to cracking, fatigue, or failure over time. Rounding the edges helps distribute stress more evenly across the part, improving its overall durability and resistance to wear. - Aesthetic Improvement: