High-Speed Sheet Forming Line: An End-to-End Sheet Forming Automation Line refers to a fully automated production system that takes flat sheet materials (typically metal, plastic, or composite) and processes them through various stages to form, cut, assemble, and finish them into a final product — all with minimal human intervention. Here’s a breakdown of what such a system typically includes:

Core Components of an End-to-End Sheet Forming Automation Line

- Material Loading System

- Coil or Sheet Feeder: Loads raw material (sheet or coil) onto the line.

- Uncoilers / Decoilers: For coil-fed systems, unwinds the coil and straightens it.

- Leveling and Feeding System

- Straightener: Removes coil set and flattens the material.

- Servo Feeder: Precisely feeds the sheet into the forming equipment.

- Punching / Notching / Blanking (optional)

- CNC-controlled punch presses or laser cutters to shape or prepare the sheet.

- Forming Equipment

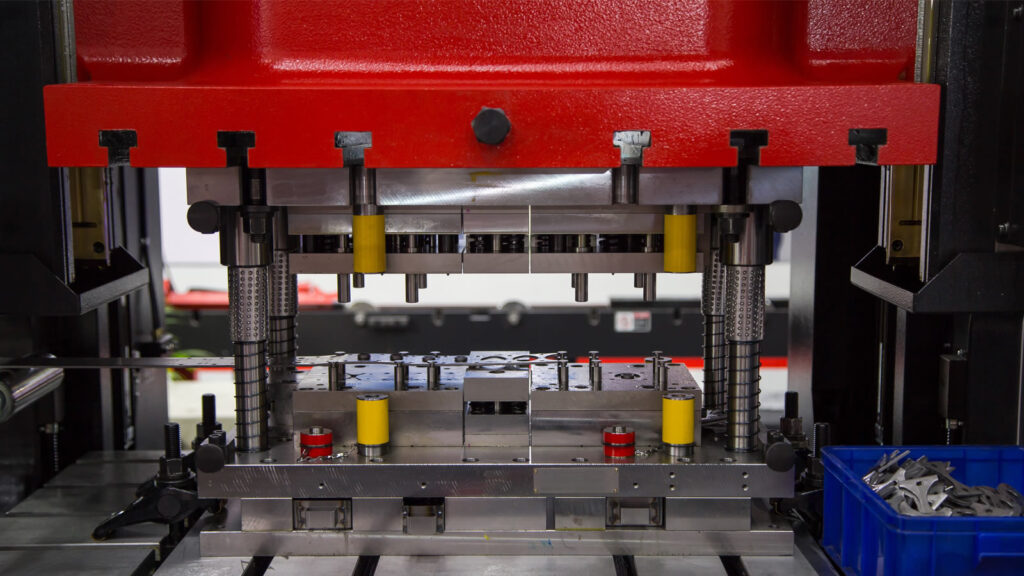

- Press Brake / Hydraulic Press / Roll Forming Machines: These shape the sheet into the required form.

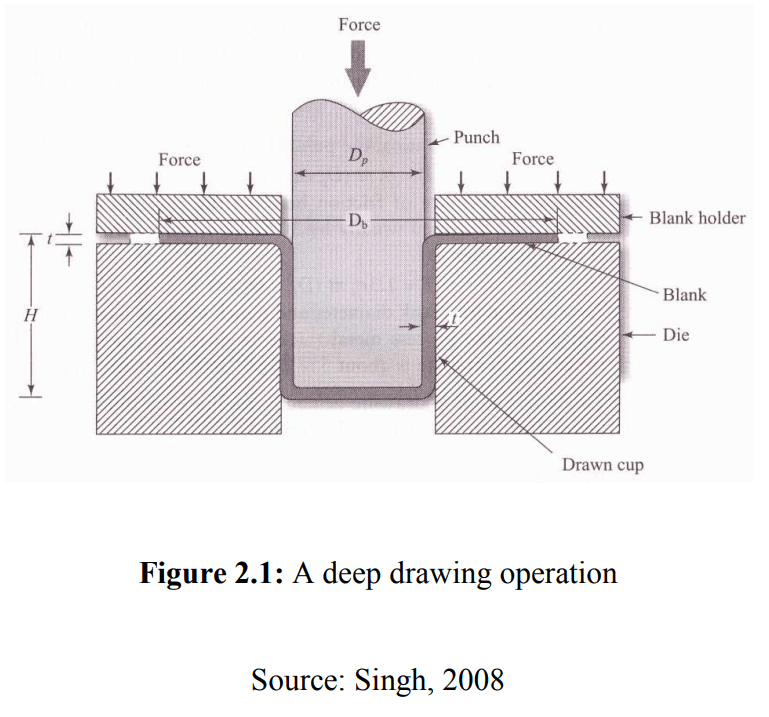

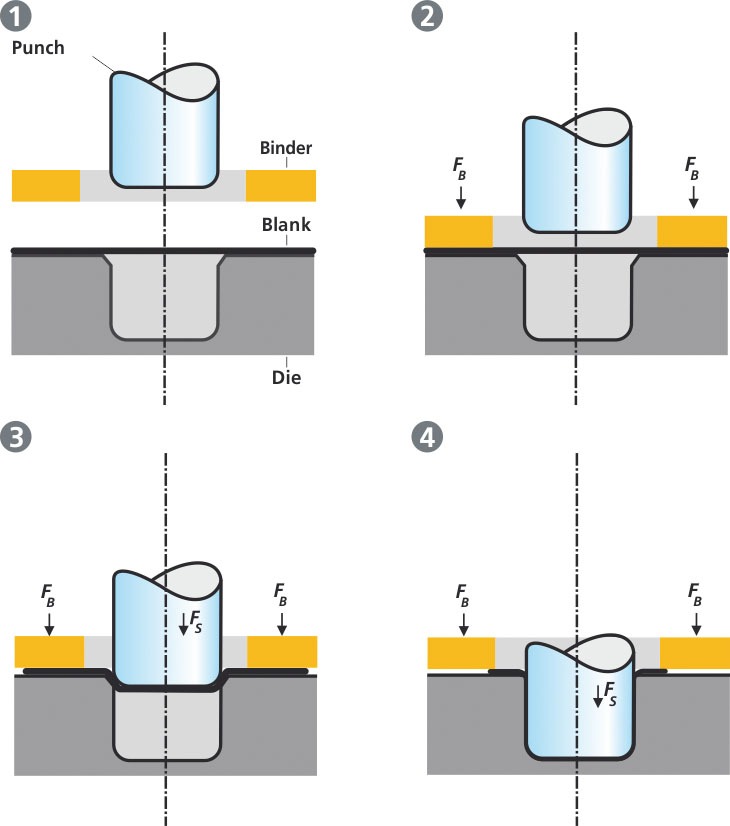

- Can involve deep drawing, stamping, bending, or roll forming depending on application.

- Transfer System / Robot Automation

- Robotic arms or linear transfer systems move sheets between stations.

- Often coordinated with vision systems and sensors for precise handling.

- Welding / Fastening (if needed)

- Integration of spot welding, laser welding, riveting, or other joining methods.

- Quality Inspection & Measurement

- Vision systems or laser measurement for dimensional accuracy and defect detection.

- Inline sensors and cameras ensure part consistency.

- Stacking / Palletizing / Unloading

- Robotic stacking or conveyor systems to collect finished parts.

- Could include sorting, labeling, and packaging.

Smart Automation & Integration

- PLC / SCADA / MES Integration:

- Seamless control and data acquisition throughout the line.

- Real-time monitoring, predictive maintenance, and analytics.

- Industry 4.0 Ready:

- IoT sensors, cloud connectivity, and AI-driven optimizations for smart manufacturing.

Benefits

- Increased throughput and consistency.

- Reduced labor costs and human error.

- Enhanced safety and ergonomics.

- High adaptability for various product types.

Applications

- Automotive body panels

- HVAC ducting

- Electrical enclosures

- Appliance components

- Aerospace structures

An end-to-end sheet forming automation line is a fully integrated manufacturing system designed to transform flat sheet material, such as metal or plastic, into finished components through a continuous and automated process. It begins with the loading of raw material, either in coil or flat sheet form, using uncoilers or sheet feeders. For coil-based lines, straightening equipment flattens the material and ensures it is properly tensioned and aligned. A servo feeder then precisely advances the sheet into the processing stations.

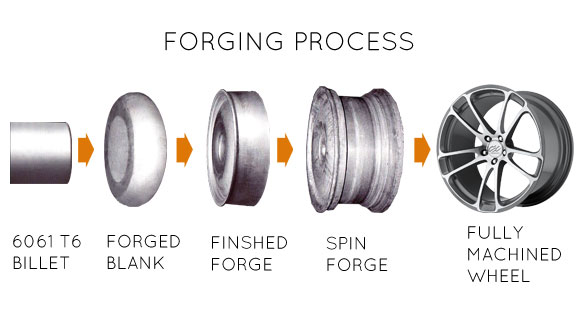

Depending on the product, the sheet may undergo initial operations like punching, notching, or blanking using CNC-controlled presses or lasers. This prepares the material for the main forming operations, which may include bending with press brakes, deep drawing in hydraulic presses, or continuous roll forming. Each forming stage is carefully synchronized to maintain alignment and timing across the line.

Transfer systems, often using robotic arms or linear transfer units, move parts between stages efficiently. These robots may also be equipped with vision systems and sensors for positioning, inspection, and part verification. If the design requires assembly or joining, stations for welding, riveting, or adhesive application are integrated into the line. These are commonly used in automotive and appliance production.

Quality inspection is embedded throughout the process, with cameras, laser scanners, and other non-contact measuring tools ensuring dimensional accuracy and identifying defects in real time. Data collected can be fed into a central control system such as a PLC or SCADA platform, allowing operators to monitor and control the entire process from a central interface. These systems can be tied into higher-level manufacturing execution systems (MES) or enterprise resource planning (ERP) tools, creating a smart factory ecosystem.

The final stages involve stacking, sorting, labeling, and unloading finished components using automated palletizers or conveyor systems. Some lines also include packaging or wrapping units for protection and logistics. Overall, an end-to-end sheet forming automation line dramatically increases production speed and consistency, reduces labor costs, minimizes errors, and enhances safety. It’s a vital setup for high-volume, precision-focused industries like automotive, aerospace, HVAC, and electrical enclosures.

In addition to the mechanical and electrical integration, modern sheet forming automation lines are increasingly incorporating software intelligence and data analytics to boost performance and adaptability. Machine learning algorithms can be used to predict maintenance needs, optimize tool paths, or adapt to material inconsistencies in real time. For example, if a sensor detects minor dimensional drift or material springback, the system can auto-correct forming parameters on the fly, minimizing waste and downtime.

Energy efficiency is another growing focus. Many systems now include regenerative drives, energy monitoring modules, and low-power standby modes. These allow manufacturers to track and reduce their energy consumption, contributing to sustainability goals without compromising throughput.

Flexibility is also key in advanced automation lines. Tooling stations can be designed for rapid changeover, allowing manufacturers to switch between different part designs with minimal interruption. This is especially useful in sectors like automotive or appliances where part variety is high and batch sizes vary. Robotic end-effectors may be modular or adjustable to handle different shapes and weights, and forming tools can be swapped automatically using tool magazines or robotic changers.

Safety is built into every level of the line. Light curtains, safety interlocks, emergency stops, and integrated safety PLCs ensure that the entire system operates within strict safety protocols. In collaborative environments, cobots (collaborative robots) may work alongside humans for tasks that require fine manipulation or flexible decision-making, without compromising safety.

Remote monitoring and diagnostics have also become standard, allowing engineers to track production metrics, receive alerts, or even troubleshoot issues from anywhere. This helps reduce downtime and supports continuous improvement initiatives. With integration into the cloud, companies can compare performance data across facilities, benchmark operations, and implement global process standards.

All of this comes together to create a manufacturing line that is not just automated, but intelligent, responsive, and capable of adapting to changing demands. Whether producing thousands of identical components or handling varied small-batch runs, an end-to-end sheet forming automation line is a cornerstone of modern, scalable manufacturing.

As production demands evolve, one of the strongest advantages of an end-to-end sheet forming automation line is scalability. These systems can be designed to operate in modular fashion, meaning new stations or capabilities—like laser marking, deburring, part washing, or robotic inspection—can be added without needing to overhaul the entire line. This modularity makes it easier to future-proof the operation, accommodate new product lines, or react to shifts in customer requirements.

For example, in automotive panel production, a line might start with basic blanking and roll forming, but over time, expand to include hem flanging, adhesive application, or even in-line surface treatment for paint prep. All of this can be programmed, scheduled, and monitored through centralized control architecture, minimizing training requirements and maintaining process stability.

Automation lines also benefit from closed-loop control systems, which use real-time feedback to fine-tune forming forces, tool positions, and material feeds. Instead of relying solely on fixed settings, the machines “listen” to sensors—measuring tonnage, displacement, heat, and vibration—to dynamically adjust and stay within tight tolerance bands. This level of control ensures consistency in even the most complex formed shapes, like aerospace components or consumer electronics casings, where a tiny deviation can cause misalignment or failure downstream.

Another important aspect is traceability. In regulated industries, every part that passes through the line may need to be tracked by batch, date, material source, or forming parameters. This is often achieved by incorporating part marking (such as QR or dot peen marking) early in the line, then recording all process data against that mark as the part progresses. Should a defect arise, manufacturers can isolate affected units instantly, identify root causes, and prove compliance with quality standards like ISO 9001, IATF 16949, or AS9100.

From a logistics perspective, full automation improves plant layout efficiency. With robotic handling, buffer zones and intermediate storage can be minimized or eliminated entirely. Finished parts can be automatically sorted by type, sent directly to subassembly or packing lines, or even passed to autonomous mobile robots (AMRs) for further distribution in the factory. This creates a tightly integrated, lean production ecosystem.

In the long run, the return on investment (ROI) for an end-to-end sheet forming automation line is driven not just by labor savings, but by cycle time reduction, defect rate elimination, material utilization, and overall equipment effectiveness (OEE). For companies aiming to compete on quality, speed, and flexibility—especially in global markets—this kind of automation line is a strategic enabler.

If you’d like, I can prepare a sample layout or specification sheet for a line suited to a specific product—say, automotive brackets, HVAC ducts, or appliance panels. Just let me know what you’re targeting.

Smart Sheet Metal Production Line

A Smart Sheet Metal Production Line takes traditional sheet metal processing to a whole new level by integrating advanced automation, data analytics, and interconnected systems under the umbrella of Industry 4.0. The result is a self-optimizing, adaptive manufacturing environment that can produce complex parts with minimal human intervention, high efficiency, and full traceability.

In a smart line, the process begins with digitally managed material intake. Whether it’s sheets or coils, the system knows what material is being loaded thanks to barcode or RFID scanning, matching it to a digital job file. A central Manufacturing Execution System (MES) or ERP automatically schedules and routes the job through the line, assigning priority based on deadlines, material availability, and current line load.

Once in motion, each machine along the line is connected through an industrial network (like EtherCAT, Profinet, or OPC UA), sharing real-time data about status, output, and health. Smart feeders use sensors to detect material thickness, flatness, and temperature, adjusting their output accordingly. CNC-controlled punching, laser cutting, or combination machines execute cutting programs that have been optimized using AI-powered nesting software, reducing material waste dramatically.

The forming section—press brakes, roll formers, panel benders—is equally smart. Tools are automatically loaded based on the job ID, with robotic tool changers and digital tool libraries. Cameras or laser alignment systems measure the part during forming, feeding data back to adaptive control systems that tweak bending angles or compensate for springback instantly. If a part is slightly off, it’s corrected in-line—no need to scrap or rerun it.

Smart robotics and AGVs (Automated Guided Vehicles) or AMRs (Autonomous Mobile Robots) move parts between stations. These robots are equipped with machine vision and AI, enabling them to identify, pick, and orient parts correctly without fixtures or manual help. Their paths are calculated dynamically, avoiding bottlenecks and adapting to the current workload on the shop floor.

Along the way, real-time quality control is integrated using cameras, laser scanners, and even AI-based surface defect detection. Every part’s journey and parameters are recorded—force applied, temperature, tool ID, machine status—creating a digital twin of the part for full traceability. This is critical for industries like aerospace, medical devices, or automotive, where compliance is strict.

The smart line also supports predictive maintenance. Sensors continuously monitor machine health—vibration, temperature, tool wear—and AI models predict when maintenance is required before breakdowns happen. This minimizes downtime and maximizes OEE (Overall Equipment Effectiveness).

All data collected flows into dashboards where engineers and managers can monitor KPIs, analyze trends, and make real-time decisions. The system can alert operators to deviations, suggest optimizations, or even auto-correct programs on the fly. In many cases, these systems are cloud-connected, allowing remote diagnostics, over-the-air updates, and benchmarking across multiple facilities globally.

Finally, finished parts are automatically sorted, stacked, labeled, and even packed, ready for shipping or assembly. This seamless integration from raw sheet to packaged part not only accelerates production but also enables mass customization—running multiple part types or customer variants on the same line without manual reconfiguration.

In a smart sheet metal production line, the entire system functions as a connected ecosystem where machines, materials, software, and operators communicate continuously. The intelligence of the line doesn’t just lie in its mechanical precision, but in its ability to adapt in real time, to learn from every cycle, and to optimize both its own performance and the quality of its output without needing manual intervention. As production begins, job data is sent from the central digital control system directly to the machines. This includes not only the geometry of the part to be produced, but also material-specific instructions, toolpath optimizations, bend allowances, laser parameters, and inspection criteria. Each step of the process executes based on this unified data model, ensuring consistency from design to finished product.

Machine learning algorithms running in the background analyze production data continuously. If a press brake, for example, starts to show signs of performance drift due to minor tool wear or material springback, the system automatically compensates for the deviation, often before it even affects the quality of the parts. Over time, the system becomes more accurate, drawing on historical data to improve bending angles, cut paths, or forming sequences, reducing the need for rework and boosting first-pass yield.

Energy management is embedded throughout. Sensors track the energy consumption of each machine and operation, and the system can dynamically adjust production scheduling to balance power loads. For instance, it can delay a high-energy laser cutting task slightly if multiple heavy-forming machines are running simultaneously, thus avoiding spikes in energy usage and lowering operational costs. This level of intelligence allows manufacturers to meet sustainability targets while maintaining throughput.

The logistics side of smart production is equally advanced. With real-time part tracking, managers know exactly where every piece is in the workflow, how long each process takes, and when the final product will be ready. If there’s an urgent order, the system can reshuffle job queues, reroute material, or activate backup machines without manual rescheduling. Parts can be custom-tracked using embedded barcodes or RFID chips that carry not only ID data but also links to the digital production record, including tooling history, process parameters, and inspection outcomes.

Remote visibility into the entire line is another core strength. Engineers can access dashboards from mobile devices or web portals anywhere in the world, seeing live machine status, output counts, scrap rates, or upcoming maintenance needs. In the event of a fault or bottleneck, remote diagnostics tools allow technicians to access machine logs, camera feeds, and sensor data in real time, often resolving issues without ever needing to be on-site.

Smart lines also excel in enabling mass customization. Because job data is managed digitally, switching from one product type to another requires no physical setup beyond automatic tool changes and minor machine adjustments. This allows the production of highly varied part types in sequence, even down to batch sizes of one, without losing time or increasing costs. For industries that rely on rapid response to market demands or customized solutions—such as interior systems, HVAC components, or architectural metalwork—this capability is transformative.

As manufacturing moves into a data-driven era, the smart sheet metal production line becomes not just a factory tool, but a source of strategic advantage. It brings together physical production with virtual modeling, machine automation with human insight, and operational control with cloud-scale intelligence. The result is a system that doesn’t just make things—it continuously learns how to make them better.

Want me to take all this and draft a whitepaper or proposal for a smart sheet metal production line investment or presentation? I can also create diagrams or system architecture layouts to go with it.

As the smart sheet metal production line continues to evolve, it’s also becoming more deeply integrated with enterprise-level systems, closing the loop between design, engineering, production, and even customer feedback. One of the most powerful concepts in this space is the use of a digital twin—a virtual model that mirrors the physical production environment in real time. Every machine, part, tool, and process is represented digitally, enabling simulations, stress testing, and process validation before anything hits the shop floor. Engineers can tweak forming sequences, predict failure points, and optimize workflows in the virtual environment, pushing those updates instantly to the real line when validated.

This tight feedback loop also extends to suppliers and customers. With smart integration, suppliers can get real-time insights into inventory levels and usage rates, enabling just-in-time replenishment without overstock. Likewise, customers can track their orders live, see when their parts are being formed, inspected, and packed, and even get automated reports including measurement data, images, and digital certificates of conformity. This level of transparency is increasingly becoming a differentiator in competitive industries, where speed, traceability, and quality assurance are as valuable as the product itself.

On the workforce side, a smart line doesn’t eliminate the need for skilled labor—it redefines the role. Operators shift from machine controllers to process supervisors, system analysts, and continuous improvement specialists. Human-machine interfaces (HMIs) are now touch-based, intuitive, and multilingual, often supported by voice guidance, augmented reality (AR), and AI assistants. Training time drops dramatically, and operators can quickly be cross-trained across multiple machines and tasks. For complex maintenance or troubleshooting, AR glasses can guide technicians step-by-step through procedures, even overlaying 3D diagrams or allowing remote experts to view what they’re seeing in real time.

Safety is another domain where smart technology excels. Not only do smart lines employ standard safety measures like light curtains, interlocks, and emergency stops, but intelligent systems continuously assess operator location, movement, and machine behavior. Vision systems and LiDAR sensors can identify if a person enters a restricted area and stop or slow machines proactively, creating a safer, more adaptive environment. Collaborative robots (cobots), designed to work safely alongside humans, add flexibility to tasks where a balance of precision and human judgment is needed.

Finally, the smart sheet metal line becomes a source of continuous innovation. Because it captures and stores so much granular data, companies can perform deep process mining, uncovering inefficiencies that would otherwise be invisible. They can benchmark between different lines or facilities, test hypotheses, and trial new forming strategies digitally. This fosters a culture of improvement grounded in hard data rather than guesswork or tradition.

Ultimately, the smart sheet metal production line isn’t just a technological upgrade—it’s a transformation in how products are designed, built, and delivered. It breaks down silos between departments, enables ultra-responsive production, and lays the groundwork for sustainable, scalable, and data-driven manufacturing. Whether for high-volume commodity parts or low-volume complex components, the future of sheet metal lies in these intelligent, fully connected ecosystems.

Let me know if you’d like to take this and build it into a pitch, presentation deck, concept study, or plant layout proposal. I can even help generate visual diagrams or simulate a production flow based on your specific application.

Continuous Sheet Metal Forming System

A Continuous Sheet Metal Forming System is a high-efficiency manufacturing solution designed to shape sheet metal into desired profiles or components through an uninterrupted, streamlined process. Unlike batch forming or individual press operations, this system feeds sheet metal—often from coils—through a sequence of forming stations without stopping, making it ideal for high-volume, consistent production of long or repetitive parts.

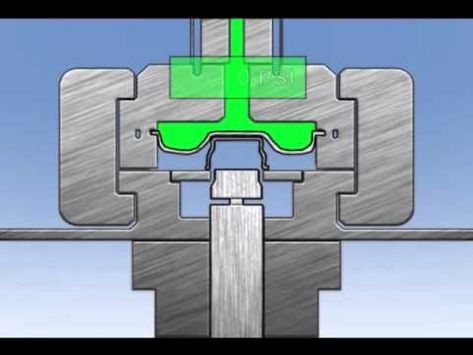

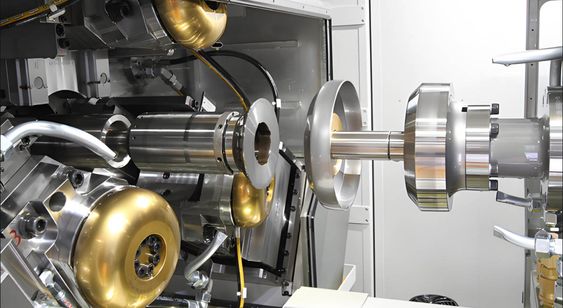

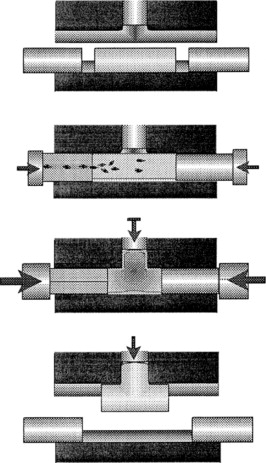

At the heart of the system is the roll forming process, where the sheet is gradually bent into shape as it passes through a series of precisely aligned roller dies. Each station incrementally adjusts the metal, reducing internal stresses and avoiding cracking, even with complex profiles. Because the material remains in motion throughout the entire line, cycle times are minimized, and material handling is simplified.

A continuous sheet forming line typically begins with a decoiler, which unrolls metal coils and feeds them into a leveling unit to flatten the material and remove coil set. The sheet then enters a servo feeder, ensuring precise advancement into the forming section. As the sheet moves through the roll forming mill, it progressively transforms into the final profile, whether it’s a structural channel, roofing panel, cable tray, or automotive trim component.

Additional inline processes can be integrated, including punching, notching, embossing, or marking, which are synchronized with the material’s movement. For example, CNC-controlled punching heads can operate in tandem with the line speed, enabling features like holes, slots, or part numbers to be added without halting production. Similarly, cut-off units—often flying shear or rotary cutting systems—trim the profile to the required length on the fly, without stopping the line.

In advanced systems, inline quality control technologies are also embedded. Vision systems, laser gauges, or eddy current sensors measure dimensions, check surface finish, and confirm feature placement in real time. If a deviation is detected, the system can adjust forming parameters on the spot or flag the product for rejection downstream.

One of the most powerful aspects of continuous forming is its ability to produce long-length parts without seams or welds, improving structural integrity and reducing post-processing. These systems can run at high speeds—often exceeding 30 meters per minute—while maintaining tight tolerances and consistent repeatability, making them highly efficient for large-scale production.

From an automation standpoint, the entire line is typically governed by a PLC-based control system, integrated with HMI touch panels and often linked to MES or ERP software. This enables centralized job control, production tracking, and data logging. Operators can monitor performance, change job recipes, and adjust line parameters with minimal downtime.

Maintenance and uptime are key factors in these systems. Many modern lines include condition monitoring sensors for predictive maintenance, alerting operators to bearing wear, die misalignment, or lubrication needs before breakdowns occur. Tooling can be changed quickly using cassette systems or servo-actuated die changers, enhancing flexibility.

Applications for continuous sheet metal forming systems span across multiple industries—construction (roofing, studs, gutters), automotive (bumpers, reinforcements), appliances (frames, brackets), logistics (shelving, racking), and energy (solar panel frames, cable trays). The system’s continuous nature and integration-friendly design make it an ideal choice for manufacturers looking to maximize throughput, maintain consistency, and reduce labor and handling costs.

In a continuous sheet metal forming system, the coordination between mechanical components and digital controls is critical. Every motion, from the decoiler’s rotation to the cut-off action at the end of the line, must be precisely timed and synchronized. This is achieved through servo motors and intelligent drive systems that constantly communicate through industrial networks, allowing even small adjustments in speed or pressure to be made on the fly without interrupting the process. The line operates like a living system, adapting in real time to slight changes in material thickness, tension, or environmental conditions such as temperature or humidity, which can subtly affect forming behavior.

As the sheet metal flows through the rollers, the design of the tooling becomes a major determinant of part quality and system efficiency. The roll tooling is carefully engineered using CAD/CAM and FEA (Finite Element Analysis) to predict how the metal will behave under gradual deformation. Advanced simulations help eliminate common issues like warping, bowing, or end flare before any physical tool is cut, shortening development time and minimizing costly trial-and-error runs. Once finalized, these forming rolls are precision-machined and mounted in sequence, each one responsible for just a fraction of the overall shape transformation.

One of the distinctive features of these systems is the ability to add modular capabilities along the line. For instance, embossing stations can create textured surfaces, ribbing can be introduced for added rigidity, or multi-material feeding can allow for hybrid components. In some advanced applications, laser welding or clinching can be done inline, enabling the assembly of complex multi-piece profiles directly as they are formed. The system does not treat the sheet as a static material to be shaped, but as a dynamic flow of raw potential being sculpted at speed.

The control software plays a critical role in managing this complexity. It not only governs machine actions but also collects performance data continuously. Every formed part carries with it a stream of metadata—material batch, tool ID, line speed, ambient temperature, forming pressure, and more. This data is logged and stored, enabling manufacturers to trace every component back to its exact process conditions. This full digital record is invaluable for quality assurance, regulatory compliance, and process optimization. Over time, machine learning algorithms can analyze this data to detect subtle patterns, flag early indicators of tool wear or drift, and recommend corrective actions.

In high-volume manufacturing, line uptime is everything. To support this, predictive maintenance technologies are embedded throughout the system. Sensors monitor vibration levels on rollers, temperature at critical bearings, fluid levels in hydraulic systems, and power draw of motors. When trends begin to move outside normal ranges, alerts are issued automatically, allowing service teams to act before a breakdown occurs. Maintenance windows can be strategically planned, and spare parts pre-positioned, ensuring that production targets are met without unexpected downtime.

Efficiency is not limited to the mechanical line itself. The entire production flow—from raw coil loading to finished part unloading—is often supported by autonomous logistics systems. Coils can be automatically shuttled into place, and formed parts may be robotically sorted, stacked, or transferred to subsequent lines like painting, assembly, or packaging. These post-forming logistics are orchestrated with the same precision as the forming itself, all driven by centralized production scheduling software that balances capacity, demand, and delivery commitments.

The environmental footprint of such systems is also being addressed through energy-efficient drives, regenerative braking, and smart load balancing. Cooling systems, lubrication systems, and waste handling units are optimized to reduce consumption, meet regulatory requirements, and support green manufacturing initiatives. Sustainability is no longer an afterthought—it’s embedded in the system’s design.

A continuous sheet metal forming system, when fully optimized, represents not just a production tool but a strategic manufacturing asset. It enables faster time-to-market, consistent product quality, lower labor costs, and flexible production capabilities that can pivot quickly as market needs evolve. Whether installed in a traditional factory setting or as part of a fully automated, lights-out manufacturing cell, this system is a key enabler of modern industrial competitiveness.

As the continuous sheet metal forming system evolves, its integration with smart factory infrastructure becomes more seamless. The line doesn’t operate in isolation—it connects with upstream and downstream systems, enabling a closed-loop manufacturing environment where information flows as smoothly as material. Orders from customers or ERP systems feed directly into the production planning module, which schedules coil loads, tooling changes, and machine settings automatically based on real-time availability and capacity. Instead of static production plans, the system adapts fluidly to demand fluctuations, rush orders, or unexpected downtime, rebalancing workload across shifts or even across multiple production lines if needed.

Flexibility is becoming a core performance metric. Older forming systems were designed around long production runs of a single profile, but market demands are shifting. Now, the ability to run short batches, switch between part geometries, or introduce product variations without prolonged setup is a competitive advantage. To support this, manufacturers are adopting rapid tool-change systems, modular roll units, and universal forming platforms where different roll sets can be swapped with robotic assistance. With quick recipe changes via touch-panel HMIs and automated calibration routines, the downtime between jobs is reduced to mere minutes, enabling true just-in-time production without compromising throughput.

There’s also a growing move toward multi-profile lines, capable of forming different shapes from the same material input on demand. These systems use servo-driven roll stands that adjust position dynamically, allowing the same rollers to be reconfigured electronically rather than manually replaced. This approach supports high product diversity and is particularly valuable in industries like construction, where product customization by region or client is standard. In addition, hybrid forming lines are emerging—systems that combine roll forming, bending, and even stretch forming capabilities in a single process chain, enabling more complex shapes and design freedom without secondary operations.

Digitalization continues to play a central role. Each part produced can be assigned a unique digital signature or tag—QR codes, RFID, or laser etching—linking it directly to its production data. If a customer reports an issue months later, manufacturers can instantly retrieve that part’s forming pressure, tool wear state, batch ID, and even a video of it moving through the line. This level of traceability transforms both quality control and customer service, giving companies the ability to respond with precision and confidence.

On the innovation frontier, AI-driven process optimization is beginning to take root. Instead of relying on fixed rule-based control logic, the system can learn from historical runs, adjust parameters to match material behavior, and even suggest alternative forming paths to reduce stress concentrations or eliminate cosmetic defects. AI can also identify subtle degradation in tool performance—such as tiny alignment shifts or wear patterns—long before a human could notice, triggering maintenance recommendations or pre-emptive tool swaps. This adds a self-healing quality to the line, where errors are not just corrected, but anticipated and avoided altogether.

All of this contributes to a broader transformation: the sheet metal forming line as not just a machine, but as a dynamic, intelligent manufacturing platform. It’s capable of adapting to new designs with minimal lead time, collaborating with logistics systems, communicating with cloud-based analytics platforms, and providing live feedback to designers and engineers. In effect, it closes the loop between digital product development and physical product realization—turning CAD files into actual components in minutes, at industrial scale.

The competitive edge this delivers is significant. Manufacturers can respond to customer needs faster, enter new markets more confidently, reduce overhead tied to inventory and rework, and maintain higher overall equipment effectiveness over the machine’s lifetime. As technology continues to mature, future systems may incorporate real-time voice control, autonomous self-setup routines, and even swarm robotics for adaptive post-processing—all building toward a factory that thinks, adapts, and evolves alongside its users.

Automated Workflow for Sheet Metal Shaping

An Automated Workflow for Sheet Metal Shaping integrates various stages of the manufacturing process into a cohesive, automated system. This end-to-end solution aims to streamline production, increase efficiency, reduce human error, and enable high flexibility in manufacturing sheet metal parts. Through interconnected systems, real-time data analysis, and intelligent decision-making, the workflow is optimized to meet modern demands for both high volume and mass customization.

The workflow begins with material handling. Coils of sheet metal are automatically loaded onto the decoiler, which unrolls the material into the system. This is done with precision, as the decoiler is integrated with sensors to monitor material thickness and coil tension. The material is then fed into a leveling machine that flattens the metal sheet, ensuring that it is uniform in thickness and free from defects like coil set or waviness. A sensor-based inspection system can detect any issues at this early stage and flag coils that may need further attention.

Next, the sheet enters the servo-driven feeder, which automatically advances the material through the line based on predetermined program parameters. The feeder adjusts for any variations in material thickness or size, ensuring the sheet moves smoothly through the upcoming forming processes. The servo-driven feeder system ensures that the metal is precisely fed without deformation or skewing.

The forming process is driven by roll forming technology, which gradually shapes the sheet into the required profile. This is done through a series of rollers that apply incremental bending, with each station refining the shape step by step. The rollers can be quickly adjusted using servo motors or hydraulic presses to achieve different bending angles or curvatures. For more complex shapes, additional modules like punching, embossing, or stamping stations can be seamlessly integrated into the line. These processes are synchronized with the material feed, allowing the system to create multi-featured parts without stopping.

Inline cut-to-length systems are also automated to ensure that once the desired profile is formed, the sheet is cut to the correct length without delay. Flying shear systems or rotary cutters operate at the same speed as the line, ensuring no interruption to the flow. These automated cutting systems are synchronized with the overall line speed and programmed to cut parts based on the final specifications.

Simultaneously, quality control and inspection systems are embedded throughout the workflow. Inline vision systems or laser measurement devices constantly monitor the dimensions, surface quality, and any potential defects of the formed metal. As each part moves through the line, these systems can identify any deviations from the specified tolerances. If a defect is detected, the system can automatically reject the part, mark it for rework, or adjust the process parameters to correct the issue in real time, ensuring consistently high-quality output.

Once the part is formed and cut to size, automated material handling systems like robotic arms, conveyors, or automated guided vehicles (AGVs) move the parts to the next station or prepare them for packaging and shipment. These robots are integrated with the factory’s Warehouse Management System (WMS) and Material Requirement Planning (MRP), allowing for optimized inventory management and ensuring that the correct parts are processed and dispatched according to the schedule.

In the final stages, automated packing and labeling systems are employed to ensure that parts are correctly stacked, labeled, and packaged for shipment. Each part is tagged with RFID or QR codes, which store production data such as material type, batch ID, processing conditions, and quality assurance results. This ensures complete traceability and provides the customer with a digital record of the part’s production journey.

Throughout the entire workflow, data analytics platforms monitor and collect performance metrics from every stage of the process. These systems analyze machine performance, material usage, output quality, and downtime, providing real-time feedback to operators and managers. Over time, this data is used to optimize the entire workflow, adjusting variables like feed rates, tool changes, and cutting sequences based on historical performance. This continuous feedback loop helps improve efficiency and reduces the risk of human error or suboptimal production.

Moreover, the system’s centralized control software allows operators to monitor the entire production process through HMI (Human Machine Interface) panels or even mobile devices. The control software is also connected to the Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES), enabling seamless integration of production schedules, inventory management, and supply chain processes. This integration supports real-time updates on production progress, delivery timelines, and inventory levels, providing transparency and agility in meeting customer demands.

The beauty of an automated workflow for sheet metal shaping lies in its ability to scale. Whether the factory is running high-volume orders for standardized parts or low-volume, highly customized pieces, the workflow can adapt without significant changes in labor or manual intervention. The system can also run continuously, providing manufacturers with a 24/7 production capability, ideal for industries where quick turnaround times are crucial.

By incorporating advanced features such as predictive maintenance, adaptive tooling, and real-time data feedback, the entire sheet metal shaping process becomes more efficient, cost-effective, and agile. Predictive maintenance systems analyze machine health data, such as vibration or temperature levels, and schedule maintenance before a failure occurs, reducing downtime and increasing operational efficiency. Adaptive tooling allows for quick adjustments to the tooling based on material types or product specifications, minimizing the need for manual reconfiguration.

In conclusion, an automated workflow for sheet metal shaping is a powerful solution for manufacturers looking to improve efficiency, reduce errors, and scale operations. By combining robotics, AI, real-time data analytics, and smart automation, manufacturers can deliver high-quality parts faster, at lower costs, with more consistent results. If you’d like, I can help you design or visualize a custom automated workflow suited for your specific production needs, helping you assess potential hardware, software, and integration points for your operations.

As automated workflows in sheet metal shaping continue to evolve, there are several additional areas where technological advancements are playing a key role in enhancing the system’s capabilities and efficiency.

One such advancement is the integration of additive manufacturing or 3D printing technologies alongside traditional sheet metal forming processes. In certain cases, 3D printing can be used to create complex geometries or tooling inserts that would be difficult or costly to manufacture using conventional methods. For example, 3D-printed forming tools can be quickly prototyped and tested, allowing manufacturers to experiment with new designs or modify existing tools for specific parts without a lengthy lead time. This hybrid manufacturing approach combines the flexibility of additive manufacturing with the high-throughput efficiency of traditional metal forming, enabling the production of both custom parts and high-volume runs in the same system.

The ability to integrate augmented reality (AR) and virtual reality (VR) for both design and maintenance is another significant innovation. In the design phase, AR can be used to visualize how sheet metal parts will behave during forming processes, allowing engineers to make real-time adjustments to tooling, material choice, or process parameters before physical production begins. Operators can use AR glasses to receive live instructions on the factory floor, guiding them through setup procedures, tool changes, or maintenance tasks. For complex troubleshooting, VR can simulate entire production lines, enabling technicians to test different repair scenarios without needing to interact directly with the physical equipment.

In terms of material flexibility, modern automated workflows are increasingly capable of handling a wide variety of sheet metal types and grades, from lightweight aluminum to high-strength steel alloys, all while maintaining high precision. Advanced material tracking systems—often integrated with RFID or barcode technology—allow the system to automatically adjust forming parameters based on the specific material grade being processed. This ensures that each metal type receives the appropriate treatment, whether in terms of heat, pressure, or speed, optimizing the forming process and improving product quality. These systems can also track material consumption and give real-time updates on material availability, helping to prevent shortages or overstock situations.

Automation also extends to the customization of end products. Today, customers demand more than just a “one-size-fits-all” product. Automated workflows are increasingly designed to accommodate small-batch production with minimal downtime. Customizable tooling libraries, which can be called up and adjusted dynamically, allow for the easy switch between different product configurations without halting production. For example, a roof panel production line could easily switch from producing panels with standard profiles to customized profiles for a specific building or client, with no more than a few minutes of automated reconfiguration. Additionally, digital twin technologies enable customers to specify custom features directly into the production system, which can then be validated and produced in real time, reducing lead times and improving customer satisfaction.

Cloud-based monitoring is also playing an increasingly important role in managing these automated workflows. By connecting production lines to the cloud, manufacturers can access real-time data on machine performance, part quality, and overall system health from anywhere in the world. This remote accessibility allows factory managers to monitor operations during off-hours, troubleshoot issues remotely, and even optimize production schedules to meet shifting demand. In addition, cloud connectivity allows for the aggregation of data across multiple factories or lines, enabling global performance benchmarking and facilitating the identification of trends, inefficiencies, and opportunities for continuous improvement across the entire operation.

The energy efficiency of automated sheet metal shaping workflows is another important consideration. As sustainability becomes a higher priority in manufacturing, automated systems are being designed with energy consumption in mind. From regenerative braking systems in servo motors to optimized heating and cooling processes, each part of the workflow is examined to minimize energy use while maintaining output. Energy recovery systems can capture and store excess energy from one part of the system—such as from hydraulic presses or forming stations—and redirect it to power other parts of the line. This can result in significant cost savings over time, as well as a reduced environmental impact.

Finally, one of the most critical elements of an automated workflow is its ability to scale without sacrificing quality or efficiency. As manufacturers are tasked with producing increasingly complex parts with diverse designs, automated systems can scale up to meet higher volumes or handle larger product variations with minimal adjustments. Flexible manufacturing systems (FMS) allow the workflow to switch seamlessly between high-volume, standardized parts and small-batch, custom orders. This scalability is further enhanced by intelligent scheduling systems that optimize production runs based on real-time order demand, production capacity, and material availability, ensuring that manufacturers can stay agile in the face of market shifts.

By combining all of these technologies, automated workflows for sheet metal shaping can achieve unprecedented levels of efficiency, flexibility, and quality control. The factory becomes more responsive, adaptable, and integrated, with fewer human interventions required at each stage of the production process. These systems not only improve operational metrics but also foster innovation in product development and customer service, ultimately creating a more sustainable and competitive manufacturing environment.

Should you wish to explore specific technologies, product configurations, or integration possibilities for your application, I can assist in further detailing the setup and flow tailored to your needs. Feel free to share more details about the type of products you’re producing or the scale you’re operating at.

Building on the advancements mentioned, as automated workflows continue to evolve, there’s an increasing push towards fully autonomous factories where the system operates with minimal human intervention. These factories, often referred to as lights-out manufacturing, are able to run continuously, 24/7, with the majority of operations being self-monitored and self-adjusting. With AI-driven process control and machine learning algorithms, these systems are able to analyze vast amounts of production data to predict and preemptively address inefficiencies or failures before they occur.

For instance, machine learning can be employed to continuously analyze the conditions of the material being processed. The system can track factors like temperature, humidity, and material variations across multiple batches and adapt the machine’s settings dynamically. This ensures that the optimal process parameters are always applied to every part, increasing efficiency, reducing scrap rates, and improving product consistency. The system can also learn from historical performance to refine its processes and predict future needs, such as when tooling needs maintenance or when material properties are likely to change.

In these smart, autonomous factories, human roles shift to higher-level decision-making and system oversight, rather than direct interaction with the machines. Operators, engineers, and managers can monitor the system remotely, receiving real-time notifications about potential issues, performance statistics, or production KPIs. Augmented reality (AR) or virtual reality (VR) can assist in remote diagnostics, enabling workers to “see” the production line and troubleshoot problems without physically being on-site.

One of the most exciting developments is the integration of cobots (collaborative robots) into these automated workflows. Unlike traditional robots that are often fenced off for safety, cobots are designed to work side-by-side with humans. They can assist in material handling, packaging, inspection, or even in adjusting tooling for specific parts. For instance, cobots can help load sheet metal onto automated feeders or make fine adjustments to parts on the fly. These robots are equipped with sensors that allow them to adapt to human movements and environments, ensuring that they work in harmony with the human workforce, rather than replacing them entirely.

Another emerging trend is the use of digital twins for real-time simulation and performance monitoring. A digital twin is a virtual replica of the physical production line, created using data from sensors and other monitoring systems. This digital representation can be used for a variety of purposes, from optimizing workflows and predicting machine failures to performing virtual tests on new parts or tooling before they are implemented on the factory floor. A digital twin of the sheet metal forming process can simulate material flow, part quality, and even energy consumption, helping manufacturers fine-tune their operations for maximum efficiency and output.

The use of edge computing is another important factor in the ongoing automation of sheet metal shaping. Traditionally, data from factory machines would be sent to a centralized cloud for processing, which could introduce delays due to bandwidth limitations or latency. With edge computing, data is processed locally at the machine level, reducing response times and enabling faster decision-making. This is particularly useful for time-sensitive operations, such as adjusting the speed of the sheet feeder or the pressure of the forming rollers in real-time. Edge computing can also help ensure that machines continue to operate optimally even if the network connection to the cloud is temporarily disrupted.

Additionally, 5G connectivity is beginning to revolutionize the way manufacturing systems operate. With its ability to support ultra-fast data transfer and low latency, 5G allows for real-time communication between machines, robots, sensors, and control systems, enabling faster adjustments and more efficient workflows. This is particularly advantageous for systems that rely on continuous feedback and high-speed operation, such as sheet metal forming lines that require constant monitoring and adjustment.

Sustainability continues to be a key focus in the design of these automated systems. Green technologies are being integrated into every stage of the workflow, from reducing waste and scrap through more precise forming techniques to optimizing energy usage across the entire production process. For example, closed-loop cooling systems that recycle water and reduce energy consumption or energy-efficient motors and drives that reduce the factory’s overall energy footprint are becoming standard. In addition, the use of recyclable materials and eco-friendly lubricants is being emphasized to reduce the environmental impact of the manufacturing process.

In terms of logistics, the integration of autonomous mobile robots (AMRs) is transforming the way materials and finished products are transported throughout the factory. These robots can autonomously navigate the factory floor, picking up and delivering materials to the correct stations based on real-time demand. They also assist in moving finished products to the packaging area or directly to shipping. The flexibility and scalability of AMRs make them ideal for factories that need to adapt to changing production schedules or manage varying order sizes.

Furthermore, as the sheet metal shaping process becomes more automated, integrated supply chain management is gaining importance. Automated workflows can now be directly connected to supplier networks, ensuring that raw materials are ordered and delivered just in time for production. AI-driven supply chain algorithms help anticipate material shortages or delays and proactively adjust production schedules to minimize disruptions. By continuously monitoring global supply chain data, manufacturers can optimize inventory levels and reduce material waste, further improving efficiency and cost-effectiveness.

As for quality control, advanced techniques such as X-ray inspection, ultrasonic testing, and laser-based metrology are increasingly being used in automated sheet metal shaping workflows. These non-destructive testing methods ensure that parts meet stringent quality standards while minimizing the need for manual inspection. These inspection systems are often fully integrated into the production line, enabling real-time quality assurance without interrupting the manufacturing process. If any issues are detected, the system can immediately stop the line, adjust settings, or flag defective parts for removal.

Finally, advanced analytics and big data are becoming indispensable in the continuous improvement of automated workflows. By collecting data from every stage of the process—such as machine performance, material properties, tool wear, and part quality—manufacturers can perform deep data analysis to identify bottlenecks, predict maintenance needs, and optimize the entire production system. Over time, these insights can lead to significant improvements in product quality, process efficiency, and overall factory performance.

In conclusion, the future of automated sheet metal shaping is characterized by a convergence of cutting-edge technologies, all working together to create a more intelligent, efficient, and flexible manufacturing environment. By embracing AI, robotics, IoT, edge computing, and digital twin technologies, manufacturers are well-equipped to meet the demands of an increasingly dynamic market, while improving quality, sustainability, and overall competitiveness. The evolution of automation is not only transforming the production process but is also enabling manufacturers to respond more quickly to customer demands, reduce costs, and drive innovation across industries.

Should you need more specifics, be it a deeper dive into any technology or the design of a specific automated system tailored to your production needs, feel free to let me know. I’d be happy to assist you further.

Flexible Sheet Metal Forming Line

A Flexible Sheet Metal Forming Line is an advanced manufacturing system designed to process a variety of sheet metal materials and product designs with minimal downtime or manual intervention. It integrates various automation technologies and modular equipment that enable it to adapt quickly to different products, materials, and production requirements. The flexibility in such a system is crucial for manufacturers who need to meet diverse market demands, produce a wide range of part sizes, or rapidly switch between different product configurations without significant reconfiguration time.

Key Features of a Flexible Sheet Metal Forming Line

- Modular Tooling System: One of the core features of a flexible sheet metal forming line is a modular tooling system. The tooling, which includes rolls, dies, and punches, can be quickly changed or adjusted according to the specifications of the product being produced. Instead of using fixed tooling for a specific product, modular tooling allows for the easy reconfiguration of the production line for different product profiles and sizes. With a quick-change system, operators can swap out tooling within minutes, minimizing downtime and maintaining high production rates.

- Servo-Driven Roll Stands and Benders: Servo-driven technology plays a crucial role in enabling flexibility. By replacing traditional mechanical drives with servos, the line can adjust forming parameters—such as pressure, speed, and position—dynamically during operation. This means that the system can handle a variety of metal thicknesses, alloys, and profiles while maintaining precision. Servo-driven roll stands, for example, automatically adjust their settings for each batch or part, optimizing the forming process without requiring manual intervention.

- Automatic Material Handling and Feeders: A flexible sheet metal forming line typically incorporates automatic material handling systems that ensure smooth material flow without interruptions. Feeder systems equipped with advanced sensors and vision systems can automatically adjust to different sheet sizes and thicknesses. Automated coil handling ensures that coils are accurately fed into the line, maintaining constant material tension and positioning. These systems also allow for easy integration of different material types, from aluminum to high-strength steels, ensuring that the line can switch between materials without slowing down production.

- Inline Quality Control Systems: To maintain high standards of product quality, flexible forming lines integrate inline quality control systems. These systems use a combination of vision sensors, laser measurements, and ultrasonic testing to continuously monitor the sheet’s quality during the forming process. Any defects, such as dimensional errors, surface imperfections, or structural issues, are detected in real-time, and corrective actions can be taken immediately. If defects are identified, the system can automatically adjust process parameters, reject defective parts, or trigger an alert to the operator.

- Integrated Automation and Control Systems: The entire flexible sheet metal forming line is managed by a central automation and control system, which coordinates the movements of all equipment and integrates with ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System). This central system allows for the real-time management of production schedules, material tracking, tool changeovers, and quality checks. It provides operators with an intuitive HMI (Human Machine Interface) that displays relevant data such as machine status, product specifications, and system health. This level of integration ensures smooth communication between different stages of the production process and enables quick adaptation to changing conditions.

- Customization Capabilities: Flexibility in the forming line is also driven by the ability to accommodate customized product designs. In the past, changing a production line for custom products required significant downtime. However, modern flexible forming lines allow for easy integration of custom part profiles. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems directly feed production data to the forming line, automatically adjusting machine parameters, tooling, and even the forming sequence based on the part specifications. This automation allows for quick transitions between standard and custom designs, reducing the need for dedicated production lines for each product.

- Hybrid Forming Techniques: A flexible sheet metal forming line may incorporate multiple forming techniques, including roll forming, punching, press braking, stamping, and even stretch forming. These processes can be combined seamlessly in a single line to create complex parts. For instance, a line might roll-form a base shape, then automatically switch to a stamping station to add holes or embossing, followed by a press brake for additional bending, and then finish with a stretch-forming process to create a more complex geometry. This hybrid approach significantly increases the line’s flexibility, allowing it to produce a diverse range of products without the need for specialized equipment or dedicated production lines.

- Robotic Integration: Robots are increasingly integrated into flexible sheet metal forming lines to handle repetitive tasks and improve flexibility. Robots can handle tasks such as material loading, unloading, part handling, and even complex assembly tasks. For example, robots might load sheets into the press brake station, remove finished parts from the line, or load them into packaging stations. Collaborative robots (cobots) can also work alongside human operators, assisting with tasks that require precision or lifting heavy loads, further enhancing the system’s overall flexibility and productivity.

- Energy Efficiency and Sustainability: A flexible sheet metal forming line can be designed with energy-efficient technologies to reduce its environmental impact. Servo motors, intelligent energy recovery systems, and automated load-balancing reduce energy consumption. Additionally, automated systems for recycling scrap material and using eco-friendly lubricants contribute to a greener manufacturing process. The system can also be designed to be more modular, allowing the manufacturer to scale the production line up or down based on demand, which helps avoid overproduction and waste.

- Data-Driven Optimization: The integration of IoT (Internet of Things) sensors and cloud-based analytics plays a significant role in optimizing flexible sheet metal forming lines. These sensors collect real-time data from each stage of the process, feeding it into advanced analytics platforms. By analyzing this data, manufacturers can identify inefficiencies, reduce scrap, predict when tools will need maintenance, and optimize the overall production flow. With predictive analytics, the system can even forecast potential bottlenecks, ensuring that corrective measures are taken before they impact production.

Benefits of a Flexible Sheet Metal Forming Line

- Quick Adaptability: The ability to switch between different products, material types, and production requirements with minimal downtime is a major advantage. This makes the system ideal for manufacturers that need to handle varying customer demands, complex product designs, or rapid order changes.

- Higher Efficiency: Automation, intelligent feedback systems, and modular tooling contribute to increased throughput and reduced manual intervention. This results in less wasted time, lower operational costs, and improved overall equipment effectiveness (OEE).

- Reduced Lead Times: Flexible forming lines can reduce lead times, as they can handle both high-volume runs and small, customized orders. Automated changeovers and reconfiguration allow the production of smaller batches without the need for a dedicated line for each product.

- Customization and Innovation: The system enables greater design flexibility, allowing manufacturers to explore more complex shapes and parts that were previously difficult to produce. This can lead to innovation in product offerings and provide a competitive edge in markets that demand customization.

- Reduced Inventory Costs: With increased flexibility, manufacturers can produce parts just-in-time (JIT) based on actual demand, reducing the need for large inventory stockpiles and minimizing inventory holding costs.

- Improved Quality Control: Continuous inline inspection and quality monitoring reduce the risk of defects, ensuring that only high-quality products leave the line. Real-time feedback allows for immediate adjustments to maintain quality throughout the production process.

Conclusion

A Flexible Sheet Metal Forming Line is the next generation of automated manufacturing, designed to meet the ever-increasing demands for customization, efficiency, and precision in sheet metal processing. Through a combination of modular tooling, servo-driven automation, integrated robotics, and advanced quality control systems, manufacturers can produce a diverse range of high-quality products with minimal downtime and waste. The ability to seamlessly switch between different products and materials with minimal reconfiguration makes this system ideal for industries that require high flexibility, such as automotive, construction, and consumer electronics.

A flexible sheet metal forming line is designed to seamlessly adapt to various products, materials, and production needs, ensuring manufacturers can stay competitive and agile in a dynamic market. At the heart of its operation lies advanced automation, modular equipment, and intelligent control systems, enabling rapid adjustments and high customization without compromising efficiency or quality. With the demand for increasingly complex, custom-designed metal parts, the need for flexibility in production has never been more critical.

The line’s ability to quickly switch between different products is driven by modular tooling systems. These systems allow for easy swapping of dies, punches, and other tools, reducing setup time and enabling manufacturers to move swiftly from one part design to another. Unlike traditional lines that may require extensive retooling or downtime for changes, a flexible forming line can maintain a continuous flow of production. Additionally, servo-driven technology enhances the system’s flexibility, enabling precise control over critical parameters like pressure, speed, and force, while adapting to varying material thicknesses and types.

Automatic material handling is also an essential feature in ensuring a smooth flow of materials throughout the production process. Advanced feeder systems, equipped with sensors and vision systems, can automatically adjust to different material dimensions, ensuring precise alignment without manual intervention. This capability allows for the use of various sheet metal materials, such as aluminum, steel, or composites, with no need for time-consuming adjustments or reconfigurations between material types. Such systems can also handle automatic coil loading, which helps streamline the process and eliminate the risk of human error.

Quality control becomes more advanced in a flexible forming line as inline inspection systems provide continuous monitoring of the metal parts being produced. Vision sensors, laser measurement tools, and even ultrasonic testing ensure that defects or variations in the part are detected immediately. The system’s ability to adjust in real time based on this feedback means that problems are addressed before they result in a large batch of defective products. For example, if the system detects dimensional deviations or surface imperfections, it can automatically adjust the forming parameters, preventing defective parts from continuing down the production line.

The integration of robotics plays a key role in improving the overall flexibility of the system. Robotic arms or collaborative robots (cobots) can be used for material handling, assembly, and inspection. These robots can work alongside humans, assisting in loading parts onto the line, removing finished products, or adjusting parts during the forming process. By automating repetitive or physically demanding tasks, robots help to enhance the speed and accuracy of the line while reducing human error. Furthermore, their ability to handle custom or delicate parts allows for a higher degree of versatility.

At the core of the line’s operation is a centralized automation and control system, which manages the entire production flow. This system integrates data from sensors, machines, and operators, providing real-time insights into machine status, part quality, and production progress. With an intuitive human-machine interface (HMI), operators can easily oversee the line, make adjustments on the fly, and ensure that everything is running smoothly. This centralization of control allows for optimized scheduling, precise tracking of materials, and automatic adjustments to tooling or process parameters based on product specifications.

Incorporating advanced technologies like IoT (Internet of Things), cloud-based analytics, and edge computing allows the system to monitor performance, predict potential issues, and offer actionable insights for continuous improvement. IoT sensors track data from every stage of the production process, providing feedback on everything from machine performance to material conditions. This data is analyzed to optimize operations, reduce energy consumption, and predict when maintenance will be required, reducing unplanned downtime.

The flexibility of such a system doesn’t just extend to product design; it also allows for rapid customization of parts without significantly affecting production speed. When switching between orders with different specifications, the system can make rapid adjustments to tooling, material handling, and processing speeds. This reduces the time it takes to meet customer demands for customized products while ensuring that throughput remains high.

Energy efficiency is another area where flexible sheet metal forming lines excel. As industries increasingly prioritize sustainability, these systems integrate energy-saving technologies like servo motors, regenerative braking, and closed-loop cooling systems. These technologies help minimize energy waste, lower operating costs, and contribute to a greener manufacturing process. Additionally, the ability to switch between different materials and product designs without overstocking inventory reduces material waste, further contributing to sustainability goals.

In terms of production speed, flexible forming lines are designed to keep up with varying batch sizes and product configurations. Whether producing high-volume standard parts or low-volume custom orders, these systems can switch between production schedules quickly. The ability to seamlessly transition from one configuration to another makes the system ideal for just-in-time (JIT) manufacturing, where demand can shift rapidly, and production needs must remain agile.

Finally, the flexibility of such systems allows manufacturers to stay ahead of market trends. As industries evolve and new product designs emerge, manufacturers need to adapt quickly. A flexible sheet metal forming line allows them to do so, offering the scalability, adaptability, and precision needed to produce a wide range of products with minimal downtime. This system also supports innovation by allowing for the rapid prototyping of new parts, designs, and tooling configurations.

In conclusion, a flexible sheet metal forming line represents the future of manufacturing, where automation, precision, and adaptability combine to create highly efficient, sustainable production environments. These systems allow manufacturers to meet diverse customer demands, reduce lead times, and improve both quality and profitability. As the industry continues to evolve, the integration of robotics, advanced sensors, and AI-driven analytics will continue to enhance the capabilities of flexible forming lines, making them even more agile and efficient. Whether the goal is mass production, custom orders, or rapid prototyping, these systems provide the versatility needed to thrive in a competitive marketplace.

The continued evolution of flexible sheet metal forming lines holds significant potential for the future of manufacturing, especially with the integration of emerging technologies like artificial intelligence (AI), machine learning (ML), and advanced data analytics. These technologies will provide manufacturers with even more precise control over the production process, allowing them to optimize performance and improve output with greater efficiency.

One of the most promising areas is the incorporation of AI and machine learning algorithms that enable the system to “learn” and improve over time. By analyzing vast amounts of data from sensors, quality control systems, and operator inputs, AI systems can predict future production needs, optimize machine settings, and reduce the occurrence of defects. For example, machine learning algorithms can analyze past production runs to detect subtle patterns that lead to failures or inefficiencies, allowing the system to proactively adjust in real-time to avoid these issues in future batches. This predictive maintenance capability is a major asset, as it minimizes the need for manual inspections or repairs, reducing downtime and extending the lifespan of equipment.

Another exciting development is the integration of digital twins, which are virtual representations of the physical production line. A digital twin allows manufacturers to simulate and test production scenarios in a virtual environment before they are implemented on the factory floor. This not only allows for the optimization of machine settings, tooling configurations, and material handling processes but also helps to identify potential bottlenecks or inefficiencies in the workflow. By virtually testing different production scenarios, manufacturers can make more informed decisions and implement changes with a higher degree of confidence. Moreover, digital twins can also provide real-time monitoring, providing insights into the condition of machines and systems, which helps prevent unexpected downtime.

Cloud computing also plays a critical role in the future of flexible sheet metal forming lines. With the increasing amount of data generated by sensors and machines, cloud-based platforms offer the scalability needed to store and process this information. Cloud computing allows manufacturers to access data from any location, enabling remote monitoring, analysis, and troubleshooting of production lines. By combining cloud computing with edge computing, which processes data at the machine level, manufacturers can create a hybrid system that offers both real-time decision-making capabilities and long-term analytics to improve overall production efficiency.

Moreover, the ongoing push toward Industry 4.0 is pushing the boundaries of automation and interconnectedness. As manufacturers adopt IoT (Internet of Things) devices, machines are becoming more intelligent and capable of autonomously communicating with each other to coordinate tasks and share critical data. For example, machines on a flexible forming line can alert each other when they require maintenance or when material is running low, creating a seamless, self-adjusting production environment. IoT-enabled machines and equipment can also track the performance of the production line in real time, providing managers with immediate access to data such as throughput, efficiency, and energy consumption.

As part of the move towards a smarter manufacturing environment, robotic systems will continue to evolve, becoming even more autonomous and adaptive. Future robots will be equipped with more advanced sensors, cameras, and AI-driven capabilities, enabling them to handle an even wider range of tasks, including intricate assembly, packaging, or quality inspections. This evolution will lead to a further reduction in human labor for repetitive or physically demanding tasks, allowing workers to focus on higher-level decision-making or specialized work.

For instance, future robotic arms could not only load and unload materials but also perform complex quality checks in real time. Using machine vision and AI-powered image recognition, robots could scan parts for even the slightest imperfections, automatically making adjustments to the forming process to correct errors. Such robots could also inspect the sheet metal for dimensional accuracy, ensuring that the final product meets the required specifications.

The incorporation of augmented reality (AR) and virtual reality (VR) is also set to revolutionize the way operators interact with the production line. With AR, workers can wear smart glasses or headsets that overlay important production data and instructions directly onto their field of view. For example, during a tool changeover, an operator could see step-by-step guidance on how to swap tools efficiently. In more advanced scenarios, AR and VR could be used for remote troubleshooting or training, where an experienced technician can guide operators through difficult tasks without being physically present, reducing downtime and improving worker productivity.

The focus on sustainability will also drive advancements in flexible sheet metal forming lines. As manufacturers face increasing pressure to reduce their carbon footprint, these systems are incorporating greener technologies to minimize energy consumption and material waste. For example, advanced energy recovery systems can capture excess energy from the machines during operations, which can be used to power other parts of the line or even returned to the grid. Furthermore, companies are increasingly using recyclable materials and eco-friendly lubricants in their production processes, helping to reduce their environmental impact.

Additionally, smart factory analytics and supply chain integration will continue to improve. With real-time data collected from every machine, tool, and process, manufacturers can make more informed decisions about inventory management, ordering materials, and production scheduling. Integration with cloud-based supply chain management systems ensures that materials arrive just in time for production, reducing storage costs and minimizing excess inventory. This also allows for better planning around demand fluctuations, reducing the risk of overproduction and material waste.

In the long term, the combination of these emerging technologies will result in a fully autonomous manufacturing system where human involvement is limited to high-level decision-making and oversight. The automation of routine tasks, the integration of AI for predictive maintenance, and the ability to switch between different products and materials seamlessly will provide manufacturers with unprecedented flexibility, productivity, and agility.