Hydroforming Bulge Press: Hydroforming is a specialized metal forming process that uses high-pressure hydraulic fluid to press room-temperature metal into a die. A hydroforming metal forming machine is engineered to perform this process efficiently, offering high dimensional accuracy and lightweight yet strong components. These machines are commonly used in the automotive, aerospace, bicycle, and appliance industries.

Key Features of Hydroforming Machines:

- High-pressure hydraulic system: Pressures can range from 10,000 to over 100,000 psi depending on the material and application.

- Die and cavity systems: Typically consist of a lower die with a cavity and an upper seal system that contains the fluid and applies force.

- Tube or sheet hydroforming capability: Machines may be designed for either tubular hydroforming (for exhausts, chassis parts) or sheet hydroforming (for panels, enclosures).

- Programmable logic controls (PLC): For accurate, repeatable, and automated cycle control.

- Robust frames and press structures: To withstand the immense pressures without deflection.

Types of Hydroforming Machines:

- Tube Hydroforming Machines:

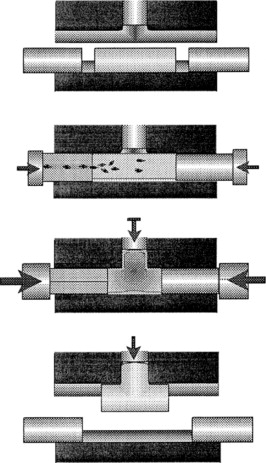

- Load a metal tube into a die.

- Ends are sealed and pressurized fluid is introduced.

- The tube expands to conform to the die shape.

- Sheet Hydroforming Machines:

- A metal sheet is clamped over a die.

- Pressurized fluid forces the sheet into the die cavity from above or below.

- Ideal for complex, shallow-drawn parts.

Advantages:

- Uniform wall thickness and smooth surfaces.

- Reduction in welding and part count.

- Lightweight components with high strength.

- Enhanced formability of complex shapes.

Common Applications:

- Automotive: Frame rails, engine cradles, roof rails, suspension arms.

- Aerospace: Structural supports, fuselage panels, brackets.

- Furniture & appliances: Tubular frames, ergonomic components.

Hydroforming metal forming machines are highly specialized systems that shape metal using high-pressure hydraulic fluid rather than mechanical force. In operation, a piece of metal—either a tube or a sheet—is placed into a die, and then fluid pressure is applied to force the material to conform to the shape of the die. This process allows for the creation of lightweight, structurally rigid, and complex shapes that are difficult or impossible to achieve with conventional stamping or pressing techniques. The machines themselves are built to withstand extremely high pressures, often in excess of 100,000 psi, and are equipped with precision control systems to ensure accurate and repeatable forming cycles. In tube hydroforming, the metal tube is sealed at both ends and filled with hydraulic fluid, then pressurized internally until it expands and molds against the die cavity.

In sheet hydroforming, the sheet metal is clamped over a die and fluid pressure is applied from one side to push the sheet into the die. These machines are favored in industries such as automotive, aerospace, and high-performance bicycles, where reducing weight without compromising strength is crucial. Components like automotive chassis parts, suspension elements, and aerospace brackets are commonly made using hydroforming due to the method’s ability to produce smooth contours and consistent wall thickness. Additionally, hydroforming reduces the number of welds and joints in a part, enhancing its structural integrity and reducing post-processing requirements. The integration of programmable logic controllers, servo hydraulics, and automated loading systems in modern hydroforming machines allows for high production efficiency, real-time quality monitoring, and flexibility in handling different part geometries.

Modern hydroforming metal forming machines are often integrated into fully automated production lines to increase throughput and consistency. Robotic arms or gantry systems load raw tubes or sheets into the forming dies, while sensor systems verify correct positioning before the press cycle begins. During forming, the fluid pressure is carefully controlled to avoid rupturing the material while still achieving full die conformance. Advanced hydroforming setups also feature pressure pulsation techniques or variable pressure zones, which help form extremely complex or asymmetric geometries without thinning or tearing the material.

Machine frames are constructed from high-strength steel to withstand not only the intense pressures but also the stress of continuous industrial operation. Die materials are typically hardened tool steels with precision-machined surfaces to ensure repeatability and long service life. Some systems also include heated dies or thermal regulation to accommodate materials that form better under controlled temperatures.

Another advantage of hydroforming is its ability to reduce part count by combining multiple components into a single, seamless structure. For instance, a car’s roof rail that would traditionally be assembled from several stamped and welded parts can be hydroformed in one piece, enhancing strength and reducing weight and production time. In aerospace applications, hydroforming allows engineers to create structural elements with complex curvatures and minimal fasteners, which is critical for performance and safety.

Some machines offer hybrid capabilities, such as integrating pre-forming with hydroforming or combining hydroforming with secondary operations like piercing, trimming, or laser cutting within the same machine cycle. These features streamline manufacturing by minimizing material handling and reducing cycle times. Additionally, the machines are capable of forming a wide variety of metals, including aluminum, stainless steel, brass, copper, and high-strength alloys, making them suitable for both high-volume production and custom fabrication.

With increasing demand for energy-efficient vehicles and lighter aircraft, the relevance of hydroforming continues to grow. As a result, equipment manufacturers are developing ever more advanced control software, adaptive pressure modulation systems, and real-time monitoring technologies to enhance precision and reduce scrap rates. Hydroforming remains one of the most versatile and high-performance metal forming technologies available for industrial manufacturing.

Hydroforming Press Setup

A hydroforming press setup involves configuring and preparing the machine, tooling, and support systems to shape metal using internal hydraulic pressure. This setup must be precise and secure, as the process operates under extremely high pressures and requires accurate control to produce high-quality parts. The setup process varies slightly between tube and sheet hydroforming, but the fundamental principles are similar.

The process begins with selecting and installing the correct die set into the press. Dies are precision-machined to match the desired part geometry and are mounted securely onto the press base and ram. In tube hydroforming, sealing units are installed at both ends of the tube to contain the pressurized fluid. These seals must be tight and resilient enough to withstand pressures up to 100,000 psi. In sheet hydroforming, a blank holder or clamping ring is set up to secure the sheet metal over the die cavity before pressure is applied.

Next, the workpiece material—either a pre-cut metal sheet or a pre-bent tube—is loaded into the die. For tube hydroforming, accurate positioning is crucial, as the tube must align properly within the die to expand symmetrically. Some setups require pre-forming of the tube to fit better into more complex dies. For sheet hydroforming, the sheet is placed on top of the lower die and clamped tightly to prevent slippage or wrinkling during the press cycle.

The hydraulic system is then configured. Pressure settings are programmed based on the material type, thickness, and complexity of the part. Pressures are ramped up in stages or pulses during the forming cycle to allow gradual deformation and prevent rupture. The system may also incorporate back pressure or counter-pressure functions to control metal flow and maintain uniform wall thickness.

Control systems, typically PLC or CNC-based, manage all press functions, including die movement, pressure application, and cycle timing. These controls also interface with sensors and safety systems, ensuring the operation only proceeds under proper conditions. Many modern hydroforming presses have data logging and feedback systems that monitor strain, pressure distribution, and part conformity in real-time.

Before production begins, a trial cycle is usually performed to verify the setup. Engineers check for material behavior, forming completeness, surface finish, and any sign of failure like cracks or thinning. Adjustments to pressure curves, clamping force, or die alignment may be needed based on these results. Once validated, the press is ready for full production, often supported by automated loading, unloading, trimming, and inspection stations to streamline workflow and maintain consistency.

The hydroforming press setup is a critical step that determines the quality, efficiency, and reliability of the entire forming process. It demands precision, robust equipment, and thorough understanding of material behavior under high-pressure conditions.

Once the hydroforming press setup is validated and optimized, production can proceed continuously with minimal manual intervention. The system typically operates on a cycle-based process where each press stroke forms one part, and automated systems handle loading of raw material and unloading of finished components. The operator’s role is primarily supervisory, monitoring system indicators, checking for alarms, and occasionally inspecting parts to confirm ongoing quality. Any deviation in cycle time, pressure response, or material behavior is flagged by the control system, which can pause the operation to prevent damage or waste.

Maintaining die alignment is crucial during the production run. Even a slight misalignment can result in uneven material flow, localized thinning, or part distortion. High-precision guide systems and self-centering mechanisms in the press help maintain consistent alignment throughout repeated cycles. Cooling channels may also be integrated into the die to manage heat buildup, especially during extended runs, as temperature variations can affect forming behavior and material properties. In advanced systems, temperature sensors are embedded in the tooling and linked to the control system to dynamically adjust process parameters.

Tool wear is another factor considered in hydroforming press setups. Because forming is done under high pressure, even hardened die surfaces gradually degrade. Regular inspection and surface treatment or re-polishing ensure dimensional accuracy and surface finish are maintained. Some facilities rotate die sets or use modular tooling to enable quick changeovers, increasing machine uptime and reducing setup time between different part models.

Hydraulic oil condition is also monitored closely, as any contamination or breakdown of fluid properties can compromise the pressure system and damage seals or pumps. Filtration systems, cooling units, and routine maintenance of the hydraulic circuit are integral to long-term machine reliability. The press frame and all mechanical linkages must also be routinely checked for stress or fatigue, especially in high-tonnage systems handling structurally demanding components.

Over time, machine learning algorithms and historical process data can be used to fine-tune press setups. By analyzing variables such as forming pressure curves, metal springback behavior, and rejection rates, engineers can refine the setup for future production runs. In high-volume environments, digital twins or simulation software may be used before physical setup to test parameters virtually, minimizing trial-and-error during initial press configuration.

The hydroforming press setup is not just a mechanical procedure but a complex orchestration of tooling design, fluid dynamics, materials science, and automation. When done correctly, it enables the efficient production of strong, lightweight, and intricately shaped metal parts with excellent surface quality and minimal waste.

As production continues, the stability of the hydroforming press setup ensures consistent part quality across long runs. One of the key aspects that sustains this consistency is process repeatability. The combination of precise hydraulic control, rigid machine structure, and well-maintained tooling ensures that each part follows the same deformation path. In fully optimized systems, cycle times can be reduced to under a minute per part, depending on complexity, while maintaining dimensional tolerances within fractions of a millimeter.

Quality control becomes tightly integrated with the hydroforming process. Many machines are equipped with in-line inspection systems such as laser scanners, vision systems, or contact probes to detect shape conformity, surface defects, and dimensional integrity right after forming. Parts that fall outside preset tolerance limits are automatically ejected or flagged for manual inspection. These feedback loops reduce scrap rates and prevent defective components from entering downstream assembly processes.

In terms of safety, hydroforming presses are designed with multiple interlocks and redundant safety features. High-pressure operations carry inherent risks, so access to the press area is restricted during forming cycles. Safety light curtains, enclosure doors, and pressure relief valves are standard. Emergency shutdown procedures are built into the control system to quickly depressurize and halt machine movement in case of malfunction or unexpected material behavior.

Changeovers between part models or material types require careful planning. Tooling must be swapped, pressure profiles adjusted, and press timing recalibrated. In highly automated environments, these changeovers are optimized using preset recipes stored in the machine’s control system. Operators can select a job profile, and the press automatically adjusts stroke length, pressure stages, clamping forces, and other critical parameters. This minimizes downtime and allows for flexible production of multiple part types on the same machine.

Energy efficiency is another consideration in hydroforming press operations. Because these machines operate with high-pressure hydraulic systems, energy consumption is significant. To reduce this, modern presses incorporate variable displacement pumps, servo-hydraulic drives, and energy recovery systems that reduce power usage during idle periods or return energy during pressure release phases. Monitoring systems help track energy per part and optimize the process further.

Finally, the data collected throughout the setup and production phases plays a central role in continuous improvement. Detailed logs of forming pressures, material batch properties, and production output enable engineers to trace defects, optimize cycle times, and adapt the setup to new alloys or geometries. In high-volume manufacturing settings, this data-driven approach turns the hydroforming press into a precision production tool capable of delivering consistent, lightweight, and structurally strong components at industrial scale.

Hydroforming Press Tool

A hydroforming press tool is the die and associated components used within a hydroforming press to shape metal parts using high-pressure fluid. It is the core element that defines the final geometry of the formed component and must be engineered to withstand extreme pressures while ensuring dimensional precision and surface quality. The tool consists of multiple elements, each playing a critical role in the forming process.

The primary component of the hydroforming press tool is the die cavity, which is precision-machined to the shape of the final part. This cavity can be fixed into the lower platen or the upper portion of the press, depending on the machine configuration. For tube hydroforming, the die includes a channel where the tube is positioned before high-pressure fluid expands it outward into the cavity walls. For sheet hydroforming, the tool includes a punch or cavity under or over the sheet, depending on whether the fluid pressure is applied from below or above.

Alongside the die, sealing tools or axial punches are used in tube hydroforming to close the ends of the tube and apply axial forces to prevent wrinkling and control length changes. These sealing systems must resist not only the pressure of the internal fluid but also provide uniform axial movement if needed during the forming process. These punches may also serve as fluid delivery channels, allowing pressurized fluid to enter the tube during forming.

Blank holders and clamps are critical in sheet hydroforming tools. They ensure that the sheet metal stays in place and does not move or wrinkle during pressurization. These holders must provide enough force to secure the material without damaging it, and they are sometimes designed with variable clamping force to allow controlled flow of material into the cavity during forming.

Hydroforming press tools often include cooling or heating channels, especially when working with metals that are sensitive to temperature, such as aluminum or high-strength steels. Controlled die temperature ensures material flow is predictable and reduces the risk of defects such as tearing or springback. Cooling channels also help maintain dimensional consistency across long production runs by dissipating heat generated through material deformation and hydraulic compression.

The materials used in hydroforming press tools are typically hardened tool steels, sometimes with coatings like nitriding or hard chrome to resist wear and extend tool life. Tool surfaces are often polished or finely textured, depending on whether a high-gloss finish or a more matte surface is desired on the finished part.

Hydroforming press tools may also integrate secondary features, such as internal trimming blades, integrated sensors for force and displacement, or embedded pressure transducers. These allow real-time monitoring of tool performance and early detection of misalignment, cracking, or underforming. In automated lines, the tools are often modular, allowing for quick changeovers when switching part geometries, which is essential for maintaining production efficiency.

In essence, the hydroforming press tool is a complex, high-precision system tailored to the specific geometry and material properties of the part being formed. Its design and condition directly influence part quality, cycle time, and the overall efficiency of the hydroforming process.

Designing and manufacturing a hydroforming press tool requires a deep understanding of metal behavior under pressure, fluid dynamics, and the mechanical limits of both the workpiece and the press system. During the design phase, engineers use computer-aided design (CAD) and finite element analysis (FEA) to simulate how the metal will flow within the die cavity under various pressure and axial loading conditions. These simulations help identify potential issues like excessive thinning, wrinkling, or incomplete filling before any physical tooling is made. Once the design is finalized, the tool is manufactured using precision CNC machining, heat treatment, and surface finishing processes to achieve the necessary hardness and dimensional accuracy.

During production, the performance of the hydroforming press tool must be closely monitored. High pressures can cause microscopic wear even on hardened surfaces, so regular inspection is essential. Dimensional checks on formed parts are used to detect gradual tool wear or surface degradation. In some cases, tools are designed with replaceable inserts or wear plates in high-contact areas to reduce maintenance costs and extend the life of the main die body. Additionally, press tools are often mounted with quick-release systems or modular die plates to allow rapid changeovers, which is especially valuable in operations that produce multiple part types or variations.

Another important aspect of the hydroforming press tool is its compatibility with the machine’s hydraulic system. The tool must be able to contain and channel high-pressure fluid in a controlled manner. This requires precision-sealed interfaces, often using O-rings, gaskets, or metallic sealing rings designed to maintain integrity over many cycles. If the seal fails, fluid leaks not only interrupt production but can damage parts, the press, or the surrounding equipment. Therefore, the design of the sealing system is as critical as the die cavity itself.

In automated hydroforming cells, sensors may be embedded in the tool body to monitor real-time forming pressure, temperature, and strain. These sensors provide data back to the control system, which can adjust the press cycle dynamically to ensure consistent results. For example, if material springback is detected, the control software can modify the pressure profile slightly on the next cycle to compensate. These feedback systems turn the hydroforming tool into an intelligent, adaptive component of the overall production system.

Over time, even the best tools will require rework. Tooling maintenance includes re-polishing die surfaces, replacing worn seals, and checking alignment. In some cases, 3D scanning is used to compare the tool’s current geometry to its original design, allowing technicians to identify areas that need repair. For high-volume production environments, duplicate tool sets are often kept in rotation to ensure minimal downtime during maintenance.

Because of the high value and complexity of hydroforming press tools, they are typically stored in climate-controlled environments and handled with precision equipment. Damage to a single surface or seal can compromise forming accuracy, so every stage from storage to setup is managed carefully. The investment in high-quality tooling pays off in the form of lower scrap rates, more consistent part geometry, and greater overall process efficiency. In industries such as automotive and aerospace, where structural integrity and precision are non-negotiable, the role of the hydroforming press tool is absolutely central to successful production.

In addition to the mechanical and material considerations, the hydroforming press tool must also be designed with ergonomics and maintenance accessibility in mind. Since these tools can be heavy and complex, provisions for safe handling—such as lifting points, guide rails, and quick-mount systems—are integrated into the design. This reduces setup time and minimizes the risk of damage or injury during tool changes. Some advanced hydroforming setups also feature automated tool changing systems, allowing for rapid swaps with minimal human intervention, which is especially beneficial in flexible manufacturing environments with multiple product variants.

Environmental factors also influence tool design. Hydroforming presses generate considerable hydraulic fluid mist, heat, and sometimes noise, so tools and press cells are often enclosed or shielded to protect operators and maintain a clean production area. Tool designs may include integrated drainage or containment systems to manage any incidental leaks, ensuring workplace safety and compliance with environmental regulations.

Material choice for tooling is evolving as well. While traditional hardened tool steels remain the standard, newer materials like advanced composites or ceramic coatings are being explored to extend tool life, reduce weight, or improve thermal management. These innovations can lower operating costs by reducing wear and energy consumption during forming cycles.

Furthermore, the hydroforming press tool plays a crucial role in enabling innovations in product design. Because hydroforming allows for complex, seamless shapes with varying wall thicknesses, designers are no longer limited to conventional stamping constraints. This freedom means that engineers can design lighter, stronger, and more aerodynamically efficient components that improve overall product performance. The press tool acts as the physical realization of these designs, translating digital models into precise, repeatable parts.

Continuous advancements in digital manufacturing technologies, such as additive manufacturing for rapid prototyping of tooling components or embedded sensor arrays, are further pushing the boundaries of what hydroforming press tools can achieve. These tools are becoming smarter and more adaptable, reducing downtime, improving quality control, and supporting increasingly sophisticated part geometries.

Ultimately, the hydroforming press tool is a critical asset in modern manufacturing. Its design, construction, maintenance, and integration directly influence the efficiency, quality, and cost-effectiveness of hydroforming operations. Successful hydroforming production relies on a well-engineered tool that balances strength, precision, and adaptability to meet the demands of high-pressure metal forming processes.

Select Hydroforming Press Unit Hydroforming Press Unit

A Hydroforming Press Unit is the complete machinery system designed to perform hydroforming metal shaping processes, integrating hydraulic power, control systems, and tooling to produce complex metal components. Selecting the right hydroforming press unit depends on several key factors including part geometry, material type, production volume, and precision requirements.

Typically, a hydroforming press unit consists of:

- Press frame and platen: A rigid structure to withstand the very high pressures generated during forming, often made of heavy-duty steel with precise alignment features.

- Hydraulic system: High-pressure pumps, accumulators, valves, and piping that generate and control the hydraulic fluid pressure used to expand or shape the metal.

- Control system: Usually a PLC or CNC-based system that manages press operations, pressure profiles, cycle timing, safety interlocks, and integrates sensor feedback.

- Tooling interfaces: Mechanisms to hold, align, and quickly change dies and sealing components.

- Auxiliary equipment: This can include automated loading/unloading systems, robotic arms, trimming stations, and inspection devices to streamline production.

When selecting a hydroforming press unit, the following criteria are crucial:

- Press Tonnage and Pressure Capacity: The unit must be rated to deliver the necessary hydraulic pressure—often up to 100,000 psi or more—and the structural tonnage to contain these forces safely.

- Bed Size and Stroke: The size of the press bed and the maximum ram stroke should accommodate the largest part dimensions and forming depth expected.

- Control Precision: For complex parts, precise control of pressure ramping, hold times, and clamping force is essential to avoid defects.

- Automation Compatibility: If high-volume or flexible manufacturing is planned, the unit should support integration with robotic systems and automated tooling change.

- Material Compatibility: The unit must be able to handle the specific metal types (aluminum, stainless steel, brass, etc.) and thicknesses involved.

- Energy Efficiency: Modern units often incorporate servo-hydraulics or variable-displacement pumps to reduce power consumption.

- Safety and Compliance: The unit should include certified safety systems and meet local workplace regulations.

By carefully considering these factors and collaborating with experienced hydroforming press manufacturers, businesses can select a press unit that optimizes production efficiency, part quality, and cost-effectiveness for their specific application.

Once the basic specifications of the hydroforming press unit are defined, it’s important to evaluate the system’s overall reliability and maintainability. A press with robust construction and high-quality components will ensure consistent performance under demanding operating conditions. The hydraulic system should have redundancy features such as multiple pumps or backup accumulators to prevent downtime during maintenance or component failure. Additionally, the unit should allow easy access to key components like valves, filters, and seals for routine inspection and service, minimizing production interruptions.

Another vital consideration is the integration of advanced control and monitoring technologies. Modern hydroforming press units often include real-time data acquisition systems that track parameters such as pressure curves, cycle times, temperature, and tool wear indicators. These data streams can be analyzed to optimize the forming process, predict maintenance needs, and reduce scrap rates. Some units come equipped with touchscreen interfaces and remote monitoring capabilities, allowing operators and engineers to adjust settings and troubleshoot issues quickly.

The adaptability of the hydroforming press unit also plays a significant role in long-term productivity. Modular designs that support quick tooling changes and adjustments enable manufacturers to switch between different parts or product lines with minimal downtime. This flexibility is particularly important for companies producing smaller batch sizes or customized components, as it maximizes the return on investment for the equipment.

In addition, environmental and energy considerations are increasingly influencing the choice of hydroforming press units. Units with energy recovery systems, servo-driven hydraulics, and efficient cooling circuits not only reduce operating costs but also help manufacturers meet sustainability goals. Noise reduction features and enclosed press cells contribute to a safer and more comfortable working environment.

Lastly, vendor support and training services should be factored into the selection process. A reliable supplier will provide comprehensive installation, commissioning, and operator training, ensuring that the hydroforming press unit is used to its full potential from day one. Ongoing technical support and access to spare parts are crucial for maintaining continuous operation, especially in high-volume production settings.

In summary, selecting a hydroforming press unit involves balancing technical capabilities with operational flexibility, maintenance ease, energy efficiency, and supplier partnership. Thoughtful evaluation of these factors helps manufacturers deploy equipment that delivers consistent quality, efficient throughput, and long-term value.

Beyond the initial selection and installation, the operational lifecycle of a hydroforming press unit requires continuous optimization to maintain peak performance. As production progresses, process engineers collect and analyze data on forming pressures, cycle times, and part quality to fine-tune press parameters. This iterative adjustment ensures the machine adapts to slight variations in material batches or environmental conditions, preserving part consistency and minimizing defects.

Periodic preventive maintenance schedules are critical to the longevity of the hydroforming press unit. Components such as hydraulic seals, valves, pumps, and sensors have finite lifespans and must be replaced or recalibrated before failure occurs. Routine checks of hydraulic fluid cleanliness and viscosity, along with filter replacements, help prevent contamination that could degrade system responsiveness and accuracy. Structural inspections detect any frame fatigue or platen wear that might compromise press alignment.

Upgrading the hydroforming press unit’s control software and hardware is another avenue to enhance productivity. Manufacturers frequently release firmware updates that improve control algorithms, enable new sensor integrations, or provide better diagnostics. Retrofitting older machines with modern servo-hydraulic drives or more precise pressure transducers can extend equipment usability and reduce energy consumption.

Operator training remains an ongoing priority. Skilled operators not only run the press efficiently but can detect subtle anomalies early, preventing costly downtime. Training programs that incorporate simulation and troubleshooting exercises empower personnel to respond effectively to process deviations and equipment alerts.

In larger production facilities, integrating the hydroforming press unit into a connected manufacturing execution system (MES) allows seamless coordination with upstream and downstream processes like material feeding, trimming, inspection, and assembly. This connectivity supports real-time production tracking, quality control, and inventory management, enabling just-in-time manufacturing and reducing lead times.

Finally, sustainability considerations are becoming more prominent. Efforts to recycle hydraulic fluids, optimize energy use, and minimize scrap contribute to environmentally responsible production. Selecting a hydroforming press unit that supports these initiatives not only reduces operational costs but also aligns with corporate social responsibility goals and regulatory compliance.

Overall, a well-selected and properly managed hydroforming press unit becomes a cornerstone of efficient, high-quality metal forming operations, capable of adapting to evolving manufacturing demands while delivering consistent value throughout its service life.

High-Pressure Hydroforming Press

A High-Pressure Hydroforming Press is a specialized metal forming machine designed to shape metal components using extremely high hydraulic fluid pressures, often exceeding 10,000 psi and sometimes reaching up to 100,000 psi or more. This elevated pressure capability enables the forming of complex shapes, thin-walled structures, and lightweight parts with excellent dimensional accuracy and structural strength.

The core advantage of a high-pressure hydroforming press lies in its ability to apply uniform internal pressure to the metal workpiece—whether it’s a tube, sheet, or blank—causing it to expand precisely into the contours of a die cavity. This process minimizes mechanical contact stresses compared to traditional stamping, reducing the risk of cracks, wrinkles, and springback.

Structurally, these presses feature reinforced frames and platens engineered to withstand the intense forces generated during high-pressure operations. The hydraulic system incorporates high-capacity pumps, accumulators, and pressure intensifiers capable of generating and sustaining these pressures safely and reliably throughout the forming cycle. Precision valves and servo-hydraulic controls regulate the pressure ramping and holding stages, allowing for optimized forming sequences tailored to the material and part geometry.

High-pressure hydroforming presses are widely used in industries such as automotive, aerospace, and appliance manufacturing, where lightweight, complex parts with high strength-to-weight ratios are essential. Examples include structural automotive components, exhaust manifolds, and complex airframe sections.

Safety is paramount due to the extreme pressures involved. These presses are equipped with multiple redundant safety interlocks, pressure relief valves, and robust enclosures to protect operators and equipment. Maintenance routines emphasize regular inspection of hydraulic seals, tubing, and pressure vessels to prevent leaks or failures.

In summary, a high-pressure hydroforming press is a powerful, precision machine that expands the possibilities of metal forming by combining fluid power and advanced control to produce high-quality, lightweight components with intricate shapes and superior mechanical properties.

High-pressure hydroforming presses demand advanced hydraulic systems that can generate and maintain extremely high fluid pressures consistently throughout the forming cycle. These systems often use accumulators that store hydraulic energy and pressure intensifiers that step up the pressure from standard hydraulic pumps to the required levels. The control system must be capable of finely tuning pressure application rates and holding times to avoid defects like bursting or incomplete forming. Achieving this level of control requires sophisticated servo valves and real-time feedback from pressure sensors integrated into the tooling or press hydraulics.

The mechanical design of the press frame is equally critical. Since the forces generated inside the tool cavity can be enormous, the frame must have exceptional rigidity and strength to prevent deformation that could compromise part accuracy or damage the tooling. High-strength alloy steels and heavy ribbed structures are typical in these presses to resist bending and twisting. Platen surfaces are precisely machined and hardened to provide accurate and repeatable die alignment under load.

Tooling for high-pressure hydroforming must be engineered to withstand these pressures while maintaining tight dimensional tolerances. Sealing systems are a major design focus to contain the fluid pressure within the workpiece without leakage. Additionally, the tooling often incorporates cooling channels to dissipate heat generated during forming, which can affect material behavior and dimensional stability. Wear-resistant coatings and surface treatments extend tool life despite the severe conditions.

Due to the complexity and cost of high-pressure hydroforming presses, their operation typically involves highly trained personnel who understand both the mechanical and process aspects. Operators and engineers monitor process parameters closely, often through integrated data acquisition systems that provide real-time insights into pressure curves, cycle times, and material response. This data is used to optimize forming profiles, reducing scrap rates and improving consistency.

Integration with automated material handling and downstream operations is common in industrial settings. Robots may load blanks, position tubes, or remove finished parts, improving cycle times and operator safety by minimizing manual intervention near high-pressure equipment. Automated trimming, inspection, and assembly stations further streamline production.

Energy efficiency is an ongoing challenge with high-pressure systems. Advanced presses use servo-driven hydraulic pumps, energy recovery during pressure release phases, and optimized fluid circuits to minimize power consumption without compromising forming quality. This reduces operating costs and environmental impact.

Safety systems are comprehensive, including physical barriers, interlocks, emergency stops, and pressure relief devices. Regular inspections and preventative maintenance ensure hydraulic components, seals, and structural elements remain in safe operating condition. Given the high stakes of failure, many facilities implement rigorous protocols and certifications for equipment and operators.

In applications where extremely complex geometries or lightweight parts are required, high-pressure hydroforming presses provide a unique combination of precision, flexibility, and mechanical performance that other forming methods struggle to match. Their ability to produce single-piece, seamless components with reduced welds and joints contributes to stronger, lighter, and more durable products, meeting the increasing demands of modern manufacturing sectors.

Beyond the core forming process, high-pressure hydroforming presses often incorporate advanced process monitoring and quality assurance technologies. In-line sensors embedded within the tooling or press structure can measure strain, pressure distribution, and temperature in real time, providing detailed feedback on how the material behaves under the applied hydraulic forces. This data enables adaptive control systems to fine-tune pressure profiles dynamically during each cycle, compensating for variations in material thickness, temperature fluctuations, or tooling wear. Such closed-loop control improves part consistency, reduces scrap rates, and extends tool life.

Moreover, the increasing use of digital twins—virtual replicas of the hydroforming press and tooling—allows engineers to simulate and optimize forming processes before actual production. By integrating sensor data and material properties into these models, potential issues like excessive thinning or springback can be predicted and mitigated through design adjustments or process parameter tweaks. This approach shortens development times and improves first-pass yield.

From a materials perspective, high-pressure hydroforming presses enable the efficient forming of lightweight alloys like aluminum and advanced high-strength steels (AHSS), which are critical in industries focused on weight reduction and fuel efficiency, such as automotive and aerospace. The uniform pressure distribution reduces localized stresses, allowing for thinner sections and complex shapes that might otherwise crack or deform using conventional stamping.

The ability to produce large, integrated components with fewer welds and joints also improves structural integrity and corrosion resistance. This is especially valuable in safety-critical parts, such as automotive chassis components or aircraft fuselage sections, where performance and durability are paramount.

In terms of scale, high-pressure hydroforming presses range from compact laboratory units used for prototyping and small batch production to massive industrial presses capable of forming large automotive body panels or structural aerospace parts. This scalability makes hydroforming adaptable to various production volumes, from bespoke manufacturing to high-throughput assembly lines.

As sustainability gains importance, manufacturers increasingly focus on reducing waste generated during hydroforming. The process inherently produces less scrap compared to stamping, but ongoing improvements in tooling design, pressure control, and material usage further enhance resource efficiency. Some facilities are also exploring closed-loop hydraulic systems that recycle fluid and recover energy, lowering the environmental footprint of high-pressure hydroforming operations.

Finally, the integration of artificial intelligence (AI) and machine learning into hydroforming press controls promises to further revolutionize the field. By analyzing vast datasets from production runs, AI algorithms can detect subtle patterns indicating tool wear or process drift before defects occur. Predictive maintenance schedules and automated parameter optimization driven by AI help maintain peak press performance, reduce downtime, and enhance overall manufacturing agility.

In conclusion, the high-pressure hydroforming press is a sophisticated, high-value asset that combines mechanical strength, precise hydraulic control, advanced monitoring, and digital technologies to produce complex, lightweight, and high-quality metal components. Its evolving capabilities continue to open new possibilities in design innovation and manufacturing efficiency across multiple high-tech industries.

Hydroforming Sheet Press

A Hydroforming Sheet Press is a specialized machine designed to form sheet metal into complex shapes using hydraulic fluid pressure. Unlike traditional mechanical stamping, which relies on mechanical force from a die, a hydroforming sheet press applies a controlled fluid pressure that pushes the metal sheet into a die cavity, enabling the creation of intricate geometries, smooth contours, and varying thicknesses with minimal springback or distortion.

The hydroforming sheet press typically consists of a rigid frame and platen, a hydraulic system capable of generating high fluid pressures, and a tooling setup including a blank holder, die, and sealing components. During operation, the metal sheet is placed between the die and a flexible diaphragm or bladder filled with hydraulic fluid. When the fluid pressure increases, the diaphragm presses the sheet into the die, conforming it precisely to the desired shape.

This process offers several advantages over conventional forming methods, including reduced tooling costs since a single die can often be used with varying pressure profiles to create multiple shapes. It also produces parts with fewer defects such as wrinkles, cracks, or uneven thickness, improving strength and surface finish quality. Hydroforming sheet presses are widely used in automotive body panels, appliance housings, and aerospace components where lightweight, strong, and visually appealing parts are essential.

The control system in a hydroforming sheet press manages pressure ramp-up, hold times, and release sequences to optimize material flow and prevent failures. Some presses use multi-stage pressure cycles or combined mechanical-hydraulic forming to handle more challenging shapes or thicker materials.

Overall, the hydroforming sheet press is a versatile and efficient tool for shaping sheet metals into complex, high-quality parts with precision and repeatability.

Hydroforming sheet presses require precise synchronization between hydraulic pressure and mechanical clamping to ensure the metal sheet is securely held and evenly formed without slippage or wrinkling. The blank holder pressure is carefully controlled alongside the hydraulic fluid pressure to regulate material flow into the die cavity, which is critical for achieving uniform thickness distribution and preventing defects. In some systems, flexible diaphragms made from high-strength elastomers or metallic membranes transmit the hydraulic pressure to the sheet while maintaining a reliable seal to prevent fluid leakage.

The hydraulic system itself must be capable of generating smooth and controllable pressure curves, often reaching pressures in the range of several thousand psi, depending on the material and part complexity. Pressure sensors and flow meters provide real-time feedback to the control unit, which adjusts the pump output and valve positions accordingly. This precise control allows for complex forming sequences, such as multi-stage pressure increases or pressure holding phases, that optimize metal flow and part accuracy.

Tooling for hydroforming sheet presses is designed to withstand repeated exposure to high pressures and mechanical loads while maintaining tight tolerances. Dies are usually made from hardened tool steel with surface treatments to resist wear and corrosion. Because the hydroforming process can be less harsh on tooling compared to mechanical stamping, die life is often extended, reducing tooling replacement costs. Additionally, tooling may incorporate cooling channels to manage temperature during the forming cycle, as excessive heat can affect both material behavior and dimensional stability.

The flexibility of hydroforming sheet presses enables manufacturers to produce parts with complex geometries and varying wall thicknesses without the need for multiple stamping operations or welds. This capability reduces assembly time and improves structural integrity. It also supports the use of advanced materials such as aluminum alloys and high-strength steels, which can be challenging to form using traditional methods.

Automation integration is common in modern hydroforming sheet press systems, with robotic loading and unloading, inline inspection, and trimming stations improving throughput and consistency. Data from the press can be fed into manufacturing execution systems for real-time production monitoring and quality control, supporting lean manufacturing principles.

Maintenance of hydroforming sheet presses focuses on hydraulic system upkeep, including fluid quality management, seal replacement, and valve calibration, as well as mechanical inspections of the frame and tooling. Preventive maintenance schedules help avoid unplanned downtime and ensure consistent part quality.

In summary, hydroforming sheet presses combine hydraulic power, precise control, and durable tooling to efficiently produce high-quality, complex sheet metal parts with improved performance and reduced manufacturing costs compared to conventional forming methods. This technology continues to gain traction across automotive, aerospace, appliance, and other industries seeking advanced metal forming solutions.

Hydroforming Tube Press

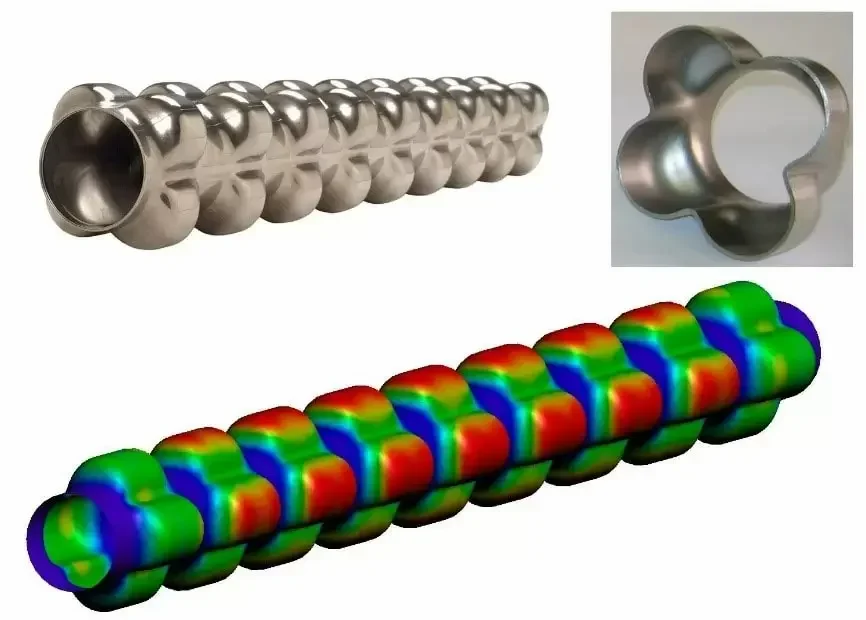

A Hydroforming Tube Press is a specialized machine used to shape hollow metal tubes or pipes into complex, lightweight, and strong components by applying high internal hydraulic pressure. Unlike traditional mechanical forming, this process uses a pressurized fluid—typically oil or water—to expand the tube inside a rigid die, enabling intricate shapes such as bends, bulges, and tapered sections without compromising structural integrity.

The hydroforming tube press consists of a sturdy frame with platens to hold the tooling, a hydraulic system capable of generating high-pressure fluid, and precision control systems that manage pressure application and cycle timing. The tube is placed inside a die cavity, sealed at both ends, and then filled with hydraulic fluid. As pressure increases, the tube walls expand outward to conform exactly to the die’s internal geometry.

This method allows manufacturers to produce lightweight, strong, and seamless tubular components with fewer welds and joints, which improves strength, reduces weight, and enhances corrosion resistance. Hydroforming tube presses are widely used in automotive chassis parts, bicycle frames, aerospace structures, and industrial piping where complex shapes and high strength-to-weight ratios are essential.

Control over pressure ramp-up, hold, and release stages is crucial to prevent material failure such as bursting or wrinkling. Many presses employ multi-stage pressure profiles and use feedback from sensors embedded in the tooling or hydraulic lines to adjust parameters in real time.

The tooling in a hydroforming tube press is designed to withstand high pressures and maintain tight tolerances for accurate part dimensions. Tool steel with specialized coatings and cooling channels is common to extend tool life and maintain process consistency.

Integration with automated loading, unloading, and trimming systems enhances production efficiency. Operators typically monitor forming parameters through advanced software interfaces that provide real-time data and diagnostics.

In summary, the hydroforming tube press is a powerful and precise machine that transforms simple tubular blanks into complex, high-performance components through controlled hydraulic expansion within a die, offering superior part quality and manufacturing flexibility.

Hydroforming tube presses rely heavily on the precise coordination of hydraulic pressure and mechanical clamping to ensure the tube remains securely positioned during forming. Sealing systems at the tube ends must be robust enough to contain extremely high internal pressures without leakage, often using specialized end plugs or mandrels that support the tube internally and help control wall thickness distribution during expansion. Mandrels can be fixed or flexible, depending on the complexity of the shape and the need to prevent collapse or wrinkling in bends or tight radii.

The hydraulic system must be capable of delivering smooth and accurately controlled pressure profiles, sometimes exceeding tens of thousands of psi. Pressure sensors and flow meters continuously monitor the system, feeding data back to sophisticated controllers that adjust pump speeds and valve positions in real time. This dynamic control helps optimize material flow and prevents defects like thinning, tearing, or excessive springback.

The press frame is designed to withstand substantial forces generated not only by the hydraulic pressure but also by the mechanical clamping required to hold tooling and tubes in place. Heavy-duty steel construction with reinforced platens and precise alignment features ensures repeatability and dimensional accuracy of formed parts over long production runs.

Tooling in hydroforming tube presses is complex and engineered to balance strength, precision, and longevity. Dies are often made from hardened tool steels with wear-resistant coatings to withstand repeated high-pressure contact with expanding tubes. Cooling channels may be integrated to manage thermal stresses that arise during forming cycles, which helps maintain tool integrity and dimensional stability.

Because hydroforming allows for the creation of complex shapes in a single forming step, it reduces the need for multiple welds, joints, or assembly processes, thereby improving structural integrity and lowering production costs. This makes it particularly attractive for applications in automotive frames, exhaust systems, bicycle components, and aerospace structural parts where strength-to-weight ratio and design flexibility are paramount.

Automation is commonly integrated with hydroforming tube presses to improve throughput and safety. Robotic systems handle tube loading, positioning, and unloading, minimizing manual interaction with high-pressure equipment. Inline inspection systems may check for dimensional accuracy and surface quality immediately after forming, ensuring only parts that meet specifications proceed to the next stage.

Maintenance focuses on hydraulic system health, including regular checks of fluid cleanliness, seal integrity, and valve function. Structural inspections verify that press frames and tooling maintain alignment and show no signs of fatigue or wear that could compromise part quality or operator safety. Preventive maintenance and predictive diagnostics, sometimes supported by real-time monitoring data, help minimize downtime and extend equipment life.

Energy efficiency is also a consideration; modern hydroforming tube presses may use servo-hydraulic drives and energy recovery systems to reduce power consumption without sacrificing performance. These advances help manufacturers meet environmental goals and reduce operating costs.

Overall, the hydroforming tube press is a versatile and high-precision tool that transforms simple tubular stock into complex, lightweight, and strong components with excellent surface finish and dimensional control, making it indispensable in advanced manufacturing sectors focused on innovation and efficiency.

Beyond standard operation, advanced hydroforming tube presses increasingly incorporate digital technologies to enhance process control and part quality. Real-time data acquisition systems collect information on pressure, force, temperature, and displacement throughout each forming cycle. This data is analyzed using machine learning algorithms and predictive models to detect subtle changes in material behavior or tooling conditions that might indicate wear, misalignment, or process drift.

Such intelligent systems can automatically adjust forming parameters on the fly, optimizing pressure profiles and cycle times to maintain consistent part dimensions and surface quality. This adaptive control reduces scrap rates and tooling damage while improving overall equipment effectiveness (OEE).

Digital twins—virtual replicas of the hydroforming press, tooling, and process—are used to simulate forming scenarios before actual production. By inputting real-time sensor data and material characteristics, engineers can predict potential defects like thinning, wrinkling, or excessive springback, allowing them to modify process parameters or tooling designs preemptively. This reduces trial-and-error cycles, shortens product development timelines, and lowers costs.

The trend toward Industry 4.0 connectivity means hydroforming tube presses are often integrated into broader manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. This integration facilitates seamless data flow across production, quality, and supply chain functions, enabling better planning, inventory control, and traceability of formed parts.

On the materials front, hydroforming tube presses enable the efficient forming of advanced alloys and composites that are difficult to shape with conventional methods. Lightweight metals such as aluminum, magnesium, and titanium alloys, as well as high-strength steels, benefit from hydroforming’s uniform pressure distribution, which minimizes localized stresses and material failure.

This capability supports industries striving for lighter, stronger components to meet fuel efficiency, performance, and environmental standards—most notably automotive and aerospace sectors. The reduction or elimination of welding and joining in hydroformed tubes also enhances structural integrity and corrosion resistance.

Environmental sustainability is an increasing priority in hydroforming operations. Modern presses employ energy-efficient hydraulic systems, fluid recycling, and waste minimization strategies. The reduction in scrap and secondary processing due to near-net-shape forming further reduces resource consumption and environmental impact.

Safety remains a paramount concern with high-pressure hydroforming tube presses. These machines incorporate comprehensive physical guarding, emergency stops, pressure relief valves, and advanced diagnostic systems to detect anomalies and prevent accidents. Operators receive specialized training to safely manage high-pressure processes and respond to alarms or irregularities.

In conclusion, the hydroforming tube press represents a cutting-edge manufacturing technology that combines mechanical robustness, hydraulic precision, digital intelligence, and advanced materials capability. It empowers manufacturers to produce complex, lightweight, and high-strength tubular components efficiently and consistently, meeting the evolving demands of modern industry.

Hydraulic Forming Press

A Hydraulic Forming Press is a versatile machine used to shape metal and other materials by applying controlled hydraulic pressure. Unlike mechanical presses that rely on direct mechanical force, hydraulic forming presses use fluid pressure—typically oil—to exert force evenly and smoothly over the workpiece. This method allows for precise control of pressure, speed, and stroke, enabling the forming of complex shapes with high accuracy and minimal risk of material damage.

Hydraulic forming presses consist of a hydraulic power unit (pump, valves, and reservoir), a press frame with a ram or platen, and tooling designed for the specific forming operation. The hydraulic system generates force by pressurizing fluid that moves the ram, which then applies pressure to the material either directly or through a die or mold. The pressure can be finely regulated throughout the forming cycle, allowing gradual application, holding at peak pressure, and controlled release to optimize material flow and part quality.

These presses are widely used in metal forming operations such as deep drawing, bending, punching, and embossing. They are especially valuable for forming thick or high-strength materials, where mechanical presses may struggle or cause damage. Hydraulic forming presses also enable larger strokes and longer dwell times, useful for complex or precise forming tasks.

The flexibility of hydraulic forming presses makes them suitable for a range of industries including automotive, aerospace, appliance manufacturing, and heavy equipment. They accommodate various materials like steel, aluminum, copper, plastics, and composites.

Modern hydraulic forming presses often feature computer numerical control (CNC) for automated and repeatable operations, along with sensors for monitoring pressure, position, and force. This enables sophisticated forming cycles and integration into automated production lines.

Overall, hydraulic forming presses combine power, precision, and flexibility, making them essential tools for advanced manufacturing processes that require high-quality, complex-shaped components.

Hydraulic forming presses offer several advantages over traditional mechanical presses, primarily due to the nature of hydraulic power which provides a smooth and consistent force application. This smoothness reduces shock loads on both the machine and the tooling, extending their service life and reducing maintenance costs. The ability to control pressure and ram speed independently allows operators to tailor the forming process to the specific material and part geometry, improving product quality and reducing defects such as cracking, wrinkling, or springback.

The press frame of a hydraulic forming machine is typically robust and built to handle high forces generated by the hydraulic system. These frames are often constructed from heavy-duty steel with reinforced sections to maintain rigidity and alignment under load. Proper alignment is critical to ensure even force distribution across the workpiece and to prevent uneven wear on tooling components.

Hydraulic systems in these presses use pumps—either fixed or variable displacement—to supply pressurized fluid to cylinders that move the ram. Control valves regulate the flow and pressure of the hydraulic fluid, enabling precise adjustment of forming parameters during the stroke. Modern presses incorporate proportional and servo valves, allowing for highly dynamic and responsive control compared to older on/off valve systems.

The tooling in hydraulic forming presses is designed to work harmoniously with the press’s capabilities. Dies and molds must withstand high forces and repeated impacts while maintaining tight tolerances for part dimensions. Cooling channels within tooling can help manage heat generated during forming cycles, especially in high-volume production, preserving tool integrity and preventing dimensional changes due to thermal expansion.

Hydraulic forming presses are capable of handling a wide range of materials, from soft metals like aluminum and copper to harder steels and exotic alloys. The pressure and speed settings can be optimized for each material to maximize formability while minimizing material stress.

In applications such as deep drawing, hydraulic forming presses allow for greater blank holder force flexibility, which helps control material flow and reduce defects like wrinkles. They are also widely used in bending and embossing where precise force application is essential for consistent results.

Safety features are an important aspect of hydraulic forming presses. Modern machines are equipped with pressure relief valves, emergency stop systems, and overload protection to prevent accidents and equipment damage. Guarding and interlocks ensure operator safety during operation, especially when presses are integrated into automated production cells.

Maintenance of hydraulic forming presses includes regular inspection of hydraulic fluid condition, filter changes, seal replacements, and monitoring of cylinder and valve performance. Keeping the hydraulic system clean and well-maintained is crucial for consistent press performance and longevity.

Integration with automation and digital controls allows hydraulic forming presses to be part of sophisticated manufacturing lines. CNC systems enable repeatable and programmable forming cycles, while sensors and feedback loops provide real-time process monitoring and quality control.

Energy efficiency is an ongoing focus, with newer presses using servo-hydraulic systems and energy recovery technologies to reduce power consumption without compromising performance. This contributes to lower operating costs and reduced environmental impact.

In summary, hydraulic forming presses provide a powerful, precise, and flexible solution for shaping a wide variety of materials into complex forms. Their smooth force application, advanced control capabilities, and compatibility with automation make them essential tools in modern manufacturing environments focused on quality, efficiency, and innovation.

Hydraulic forming presses also excel in applications requiring variable force throughout the forming cycle. Unlike mechanical presses with fixed strokes and forces, hydraulic presses can apply different pressure levels at different stages, such as a slow initial pressure to pre-form the material, followed by higher pressure for final shaping. This staged approach helps minimize material stress and reduces the risk of defects like cracking or tearing, particularly in difficult-to-form materials or complex geometries.

Another key advantage is the ability to hold pressure at the end of the stroke, allowing the material to “set” in the desired shape. This hold time can relieve internal stresses and improve dimensional stability, which is critical for precision parts that require tight tolerances. This feature also aids in forming thicker materials or parts with intricate features that need time for the metal to flow properly.

Hydraulic presses can be configured for multiple types of forming operations, including blanking, piercing, coining, and powder compaction, in addition to deep drawing and bending. This versatility makes them valuable assets in job shops and flexible manufacturing setups where production demands may change frequently.

The size range of hydraulic forming presses varies widely—from small tabletop units used for research and prototyping to massive industrial presses capable of delivering thousands of tons of force. This scalability allows manufacturers of all sizes to leverage hydraulic forming technology tailored to their specific production needs.

In terms of control technology, integration with programmable logic controllers (PLCs) and human-machine interfaces (HMIs) provides operators with intuitive control over press parameters, diagnostics, and safety systems. Advanced presses also support remote monitoring and troubleshooting, reducing downtime and maintenance costs.

Hydraulic forming presses have found important roles in emerging manufacturing trends such as lightweight vehicle structures, where high-strength but formable materials are necessary. The ability to precisely control forming parameters enables the use of advanced high-strength steels and aluminum alloys, supporting industry goals of fuel efficiency and emission reduction.

Environmental considerations are increasingly important, and hydraulic presses benefit from designs that minimize fluid leaks, use biodegradable hydraulic oils, and incorporate energy-saving features. Recycling and proper disposal of hydraulic fluids are standard practices to reduce environmental impact.

Finally, ongoing research and development in hydraulic press technology focus on improving system responsiveness, reducing cycle times, and increasing forming accuracy. Innovations such as electro-hydraulic servo systems, adaptive control algorithms, and integration with additive manufacturing for hybrid forming processes are shaping the future of hydraulic forming.

In conclusion, hydraulic forming presses are vital in modern manufacturing due to their force control precision, operational flexibility, and adaptability to a wide range of materials and applications. They continue to evolve alongside industry needs, enabling the production of high-quality, complex parts efficiently and sustainably.

Further advancements in hydraulic forming press technology are driving improvements in cycle times and overall productivity. Traditional hydraulic systems, while precise, often faced limitations in speed due to fluid compressibility and valve response times. To overcome these challenges, modern presses increasingly incorporate electro-hydraulic servo drives that combine the high force capacity of hydraulics with the fast, accurate positioning of electric servo motors. This hybrid approach significantly improves responsiveness and repeatability, enabling faster forming cycles without sacrificing control.

Another area of innovation involves the use of advanced materials and coatings for key hydraulic components such as pistons, cylinders, and valves. These enhancements reduce friction and wear, leading to longer service intervals and improved machine uptime. Additionally, sensor technologies embedded within the hydraulic system monitor component health in real time, facilitating predictive maintenance and minimizing unexpected failures.

The adoption of Industry 4.0 principles is transforming hydraulic forming presses into intelligent machines that communicate with other equipment and production management systems. Data collected during forming cycles are analyzed not only for quality assurance but also for process optimization, allowing manufacturers to fine-tune parameters and adapt quickly to material or design changes.

Energy recovery systems have also been introduced to capture and reuse energy during the press’s return stroke or deceleration phases. These systems reduce power consumption and lower operational costs, contributing to more sustainable manufacturing processes.

Hydraulic forming presses are also being adapted for specialized forming methods such as warm or hot forming, where materials are heated to improve ductility. Integrated heating systems and temperature controls allow presses to handle these processes safely and efficiently, expanding the range of materials and shapes that can be formed.

Safety technology continues to advance, with modern presses featuring comprehensive monitoring of pressure, position, and force to detect abnormalities early. Automated shutdown procedures, redundant safety circuits, and ergonomic machine designs help protect operators and ensure regulatory compliance.

Training and simulation tools, including virtual reality (VR) and augmented reality (AR), are being used to enhance operator skills and maintenance procedures. These technologies provide immersive environments where personnel can practice setup, troubleshooting, and emergency response without risk to equipment or themselves.

Looking ahead, the integration of additive manufacturing with hydraulic forming is opening new possibilities. For instance, custom tooling created by 3D printing can accelerate prototyping and allow for complex die geometries that were previously impractical. Combining additive processes with hydraulic forming offers a hybrid approach that leverages the strengths of both technologies.

In summary, the hydraulic forming press continues to evolve through technological innovation, digital integration, and process enhancements. These developments ensure it remains a cornerstone of advanced manufacturing, capable of meeting increasing demands for precision, efficiency, and sustainability in producing complex formed parts across diverse industries.

Expanding on the evolving role of hydraulic forming presses, customization and modularity have become key trends in their design. Manufacturers now offer presses with configurable frames, multiple ram sizes, and interchangeable tooling systems, enabling rapid adaptation to different production runs and product variants. This flexibility is especially valuable in industries with fast-changing demands or low-volume, high-mix production environments.

The rise of smart manufacturing has also pushed hydraulic presses to integrate more sensors not only for pressure and force but also for vibration, temperature, and acoustic emissions. These data streams provide a holistic view of the press’s condition and the forming process. Advanced analytics can detect subtle patterns indicating tool wear or material inconsistencies before defects occur, allowing for preemptive adjustments or maintenance.

Remote diagnostics and cloud connectivity further enhance the value of these machines by enabling experts to monitor performance and troubleshoot issues from anywhere in the world. This capability shortens downtime and supports continuous improvement initiatives without the need for frequent on-site visits.

Sustainability efforts extend beyond energy efficiency. Hydraulic fluid management has become more sophisticated, using biodegradable or synthetic fluids that reduce environmental impact while maintaining performance. Closed-loop fluid recycling systems minimize waste, and advances in seal technology prevent leaks that can harm both equipment and the workplace environment.

In terms of process innovation, combining hydraulic forming with other methods such as incremental forming or superplastic forming offers new possibilities for shaping materials with complex geometries or challenging properties. Multi-stage processes leveraging hydraulic presses enable manufacturers to push the boundaries of design freedom while maintaining structural integrity.

Material science developments, like high-entropy alloys and metal matrix composites, present fresh challenges and opportunities for hydraulic forming presses. Adapting press parameters and tooling to these advanced materials requires close collaboration between material scientists, process engineers, and machine designers.

The human-machine interface (HMI) is evolving to become more user-friendly and intuitive, incorporating touchscreen controls, gesture recognition, and voice commands. These interfaces reduce operator training time and enhance safety by simplifying complex operations and providing clear real-time feedback.

Training simulators using VR and AR are being combined with actual press control systems to create hybrid learning environments. Operators can practice forming sequences and emergency procedures virtually, improving readiness and reducing the risk of errors during real production.

Finally, global supply chain integration allows hydraulic forming presses to be designed and manufactured with components sourced worldwide, ensuring cost competitiveness and access to cutting-edge technologies. Standardization and interoperability between equipment from different vendors promote flexible and scalable production lines.

In conclusion, hydraulic forming presses are becoming smarter, more adaptable, and environmentally responsible. Their continued advancement supports manufacturers in meeting stringent quality, efficiency, and sustainability targets while enabling the creation of increasingly complex and high-performance formed parts across diverse sectors.

Hydroforming Hydraulic Machine

A Hydroforming Hydraulic Machine is a specialized type of hydraulic press designed to perform hydroforming—a metal forming process that uses a high-pressure hydraulic fluid to shape ductile metals into complex, lightweight, and precise components. This machine integrates hydraulic technology to apply fluid pressure inside a metal blank or tube, forcing it against a die or mold to create intricate shapes with smooth contours and high dimensional accuracy.

The core principle behind a hydroforming hydraulic machine is the use of a pressurized fluid—typically oil or water-based hydraulic fluid—that acts uniformly on the internal surfaces of a metal workpiece. Unlike traditional mechanical presses that apply force through rigid punches and dies, hydroforming employs fluid pressure that distributes evenly, allowing complex shapes, thin walls, and hollow parts to be formed with less tooling complexity and reduced risk of defects like wrinkling or tearing.

Hydroforming hydraulic machines come in different configurations depending on the part being formed. For sheet hydroforming, a flat metal sheet is sealed within a die and fluid pressure pushes it into the die cavity to form the desired shape. For tube hydroforming, a hollow tube is sealed at both ends, and internal fluid pressure expands it outward to fill a die, creating complex tubular geometries such as automotive chassis components, exhaust manifolds, or aerospace frames.

The machine’s hydraulic system consists of a high-pressure pump, pressure intensifiers, valves, and accumulators capable of generating and controlling pressures often exceeding several thousand bars (tens of thousands of psi). Precision control of pressure and timing is crucial to achieve optimal material flow and part quality.

The press frame is robustly built to withstand both the internal fluid pressure acting on the workpiece and the clamping forces that hold the material and tooling securely in place during forming. Advanced hydroforming machines incorporate computer numerical control (CNC) systems to program pressure profiles, clamping sequences, and cycle times with high repeatability.

Sealing technologies are a critical component of hydroforming hydraulic machines, especially for tube hydroforming, where end plugs or mandrels must prevent fluid leakage while supporting the tube internally. These seals must withstand extreme pressures and maintain tight tolerances to ensure dimensional accuracy.

Hydroforming hydraulic machines enable manufacturers to reduce part count by forming complex shapes in one operation, eliminating welds or joints that add weight and potential failure points. This contributes to lighter, stronger, and more cost-effective components, particularly valuable in automotive, aerospace, and industrial applications.

Automation is often integrated with hydroforming hydraulic machines to handle material loading, unloading, and quality inspection. Sensors monitor pressure, flow, and temperature, feeding data to control systems that adapt forming parameters in real time for consistent results.

Energy efficiency and environmental considerations are addressed by optimizing hydraulic circuits, using energy recovery systems, and employing environmentally friendly hydraulic fluids. Maintenance protocols focus on fluid cleanliness, seal integrity, and hydraulic component condition to ensure long-term reliability.

In summary, a hydroforming hydraulic machine is a high-pressure, precision-controlled hydraulic press engineered specifically for the hydroforming process. Its unique combination of hydraulic force application and advanced control systems allows the efficient production of complex, lightweight metal components with superior strength and finish quality.

Hydroforming hydraulic machines are widely valued for their ability to produce intricate, lightweight parts with high structural integrity and excellent surface finish, often outperforming traditional stamping or welding methods. The uniform pressure exerted by the hydraulic fluid ensures consistent material flow into the die, which reduces the occurrence of defects such as wrinkles, thinning, or springback that can compromise part quality.