Metal Sheet Hydroforming: Hydroforming is a specialized manufacturing process that uses hydraulic fluid pressure to shape metal components. Unlike traditional stamping or pressing, where mechanical forces are applied directly to the material, hydroforming involves pressurizing a fluid to shape a metal sheet or tube against a die. This method allows for the creation of complex, lightweight, and structurally robust components that are difficult or impossible to produce using other methods.

The roots of hydroforming date back to the 1950s, when it was first developed for use in the automotive industry. With the growing need for lightweight yet strong vehicle components, hydroforming offered an efficient solution by reducing the number of welded joints and allowing the formation of intricate shapes in a single step. Over time, hydroforming has evolved to be applied in a wide range of industries, including aerospace, consumer products, and even electronics.

Advantages of Hydroforming: One of the key advantages of hydroforming is its ability to create lightweight structures with a high strength-to-weight ratio, which is critical for industries such as automotive and aerospace where fuel efficiency and strength are paramount. The process allows manufacturers to create more complex shapes with fewer parts, reducing the need for assembly, minimizing material waste, and improving overall production efficiency.

Hydroforming is also more material-efficient compared to other processes such as stamping or forging, as it allows manufacturers to use thinner materials while maintaining the required strength and durability. This makes it particularly suitable for working with high-strength materials such as aluminum and steel. Additionally, hydroforming reduces the number of welds and joins in components, enhancing the overall strength and aesthetic quality of the final product.

Sheet Hydroforming Process

Overview of Sheet Hydroforming: Sheet hydroforming involves the use of hydraulic fluid to press a sheet of metal against a die to form complex shapes. The process typically starts with placing a metal sheet on a male die, and hydraulic pressure is applied to force the sheet into conformity with the die. This allows for the creation of high-precision, detailed parts with minimal material stress.

There are two primary types of sheet hydroforming: conventional sheet hydroforming and deep-draw hydroforming. In conventional sheet hydroforming, the sheet is pressed between a punch and a die using hydraulic fluid. The fluid distributes the force evenly over the surface of the metal, which helps in producing intricate shapes. In contrast, deep-draw hydroforming involves drawing the metal deeper into the die cavity to form more complex shapes. This process is often used to create parts that require a higher depth-to-width ratio.

Applications in Industry: Hydroforming is widely used in various industries due to its ability to produce lightweight, high-strength components. One of the key sectors that benefit from sheet hydroforming is the automotive industry. For example, automotive manufacturers use the process to create components such as body panels, chassis parts, and engine cradles, which need to be strong, durable, and lightweight. In addition, the aerospace industry uses sheet hydroforming to create parts like fuselage sections and wing structures, where precision and strength are critical.

The process is also used in the production of consumer goods such as kitchen appliances and lighting fixtures, where manufacturers can benefit from hydroforming’s ability to create aesthetically pleasing and functional shapes.

Challenges and Limitations: While sheet hydroforming offers many advantages, it also has certain limitations. One of the primary challenges is material compatibility. Not all metals are suitable for hydroforming, as some materials may not respond well to the high pressures involved. For example, very thick materials or brittle metals can crack under pressure, limiting the types of products that can be produced using this method.

Another limitation is the tooling cost. Hydroforming requires specialized tools such as high-strength dies and presses capable of withstanding immense pressures. This makes it less cost-effective for small production runs, where the cost of tooling may outweigh the benefits of the process.

Hydroforming Machines

Key Components of Hydroforming Machines: Hydroforming machines are complex systems made up of several critical components. At the heart of every hydroforming machine is the hydraulic system, which generates the high-pressure fluid needed to shape the metal. The hydraulic system consists of pumps, valves, and pressure controllers that ensure the right amount of force is applied during the forming process.

Another essential component is the press, which houses the die and holds the metal sheet or tube in place. Dies, which can be custom-made depending on the required shape, are typically made from high-strength materials such as hardened steel or carbide to withstand repeated high-pressure forming cycles. The forming chamber, where the metal is placed, is sealed to prevent leaks, ensuring that hydraulic pressure is evenly distributed during the process.

Types of Hydroforming Machines: Hydroforming machines are generally categorized into sheet hydroforming machines and tube hydroforming machines, depending on the type of metal being formed. Sheet hydroforming machines are used for flat or slightly curved materials, while tube hydroforming machines are designed specifically for shaping hollow tubes and pipes.

Custom-built hydroforming machines are also available for specific applications, such as forming large, complex parts for aerospace or military uses. These machines often incorporate advanced automation and CNC (computer numerical control) systems for enhanced precision and control over the forming process.

Hydroforming Machine Design Considerations: Designing a hydroforming machine requires careful consideration of various factors, including the type of material being formed, the pressure capacity needed, and the size and complexity of the parts being produced.

Pressure control is a key consideration in hydroforming machine design. The hydraulic system must be capable of generating and maintaining the necessary pressure to form the metal without causing it to crack or tear. This is particularly challenging when working with materials like aluminum, which are prone to work-hardening under pressure. Therefore, advanced pressure monitoring systems and feedback loops are often incorporated to ensure consistent and precise forming.

In addition to pressure control, machine automation is an important feature of modern hydroforming systems. Automation helps improve production efficiency, reduce operator error, and enhance safety. Many machines are now equipped with CNC systems, which allow for precise control over the forming process, from adjusting pressure levels to controlling the movement of the dies and punches. This level of control is especially critical in industries such as aerospace and automotive, where tight tolerances and consistency are essential.

Hydroforming Presses

Types of Hydroforming Presses: Hydroforming presses are specifically designed to handle the unique challenges of forming metal using hydraulic pressure. They are categorized based on the type of metal forming process they support, the most common being sheet hydroforming presses, deep-draw hydroforming presses, and tubular hydroforming presses.

- Sheet Hydroforming Presses:

- These presses are used to form flat metal sheets into complex shapes. They use a single die, and hydraulic fluid is applied on one side of the sheet, pressing it against the die. Sheet hydroforming presses are ideal for producing large, intricately shaped components with minimal joints and welds.

- Deep-Draw Hydroforming Presses:

- Deep-draw presses are designed for forming deeper components, where the material needs to be pulled deeper into the die cavity. This type of press is commonly used in the automotive industry to create parts like fuel tanks, body panels, and structural components.

- Tubular Hydroforming Presses:

- Tubular hydroforming presses are specialized for forming hollow tubes and pipes. These presses use hydraulic fluid to expand the tube against a die, creating parts with varying diameters and cross-sections. The automotive industry, in particular, benefits from tubular hydroforming to produce lightweight and structurally strong components like exhaust systems and chassis frames.

Hydroforming Press Capacity and Features: The capacity of a hydroforming press is determined by the maximum pressure it can exert, which typically ranges from 5,000 psi to over 100,000 psi, depending on the material being formed and the complexity of the part. Modern hydroforming presses are equipped with various advanced features to enhance efficiency, precision, and safety.

- Modular Designs: Many presses feature modular designs that allow manufacturers to customize the machine to their specific needs. This could include interchangeable dies for different part geometries, as well as adjustable pressure settings to accommodate different materials.

- Speed and Accuracy: The speed at which the press operates is another critical factor, especially for high-volume production environments. Some presses are equipped with high-speed hydraulics to reduce cycle times, while still maintaining the accuracy required for complex shapes.

- Automation and Safety: Automation systems play a significant role in modern hydroforming presses. CNC controls, robotic loading systems, and automatic pressure adjustments all contribute to improved safety and efficiency. Additionally, safety features such as pressure sensors, overload protection, and emergency shut-off systems are standard in most industrial presses to protect both the operator and the machine.

Hydroforming of Tubes

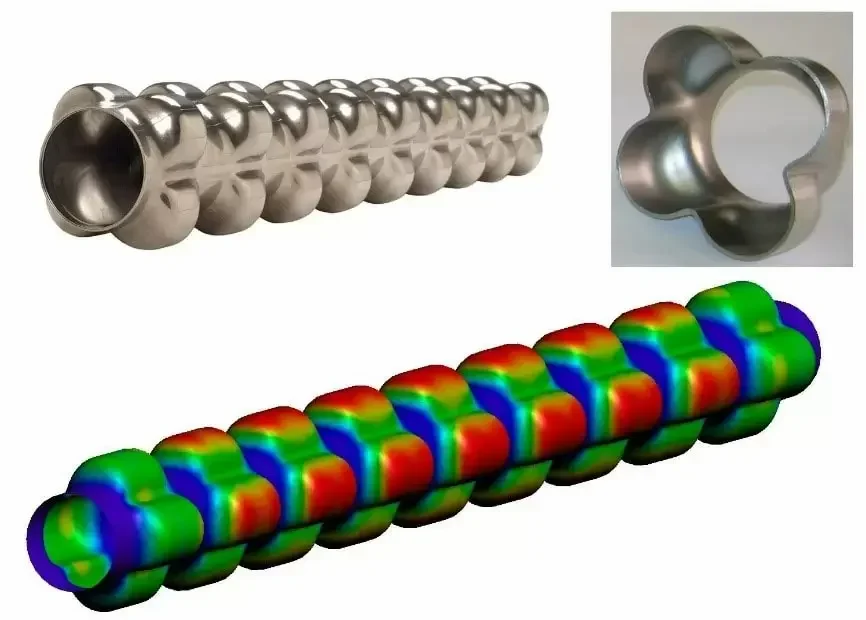

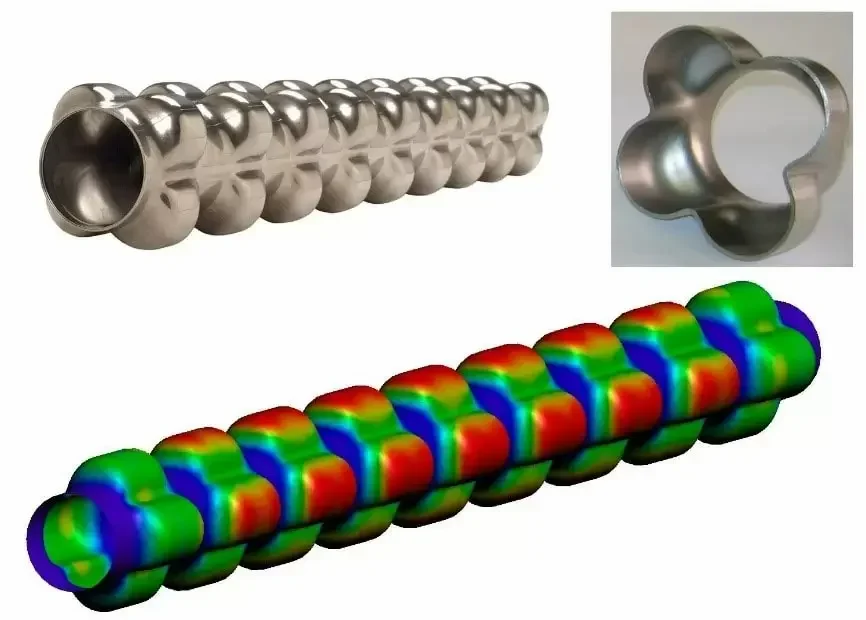

Tube Hydroforming Process: Tube hydroforming is a process specifically used for shaping hollow metal tubes. Unlike sheet hydroforming, which works with flat materials, tube hydroforming involves placing a hollow tube into a die and applying internal hydraulic pressure. As pressure is applied, the tube expands and conforms to the shape of the die, creating a part with complex cross-sections and varying diameters.

The tube hydroforming process typically follows these steps:

- Tube Placement: A metal tube, often made of aluminum, steel, or stainless steel, is placed into a die.

- Sealing and Pressurization: The ends of the tube are sealed, and hydraulic fluid is injected into the tube. This creates internal pressure.

- Tube Expansion: The hydraulic pressure forces the tube to expand against the die, forming it into the desired shape.

- Final Forming: In some cases, additional tools, such as external punches, may be used to create specific features like holes or bends in the tube.

- Cooling and Removal: After forming, the part is cooled and removed from the die.

Advantages for Manufacturing Lightweight, Structurally Strong Components: Tube hydroforming offers several advantages over traditional methods like stamping or welding for manufacturing hollow components:

- Weight Reduction: Tube hydroforming allows for the creation of lightweight, structurally strong parts by using thinner materials without sacrificing strength. This is crucial for industries like automotive and aerospace, where reducing weight improves fuel efficiency and performance.

- Complex Geometries: The process enables manufacturers to create components with complex shapes, such as varying cross-sections and intricate contours, in a single forming step. This reduces the need for multiple parts and welding, which in turn enhances strength and durability.

- Enhanced Structural Integrity: Since the process uses internal pressure to shape the tube, there are fewer seams or welds in the final part, which improves the overall structural integrity of the component.

Applications in the Automotive Industry: Tube hydroforming has revolutionized the automotive industry by enabling manufacturers to produce lightweight, high-strength components with improved performance. Common applications include:

- Chassis Components: Hydroformed tubes are used to create vehicle chassis components such as frame rails, subframes, and crossmembers. These parts need to be strong enough to support the weight of the vehicle while remaining lightweight to improve fuel efficiency.

- Exhaust Systems: Tube hydroforming is used to produce exhaust systems with complex shapes and bends, which are necessary for fitting into tight spaces within the vehicle while maintaining optimal airflow and performance.

- Suspension Parts: Hydroforming is also used to create lightweight suspension parts that can withstand the stress of driving while contributing to the vehicle’s overall weight reduction.

Tubular Hydroforming in Aerospace: The aerospace industry also benefits from tube hydroforming for the production of lightweight, durable components that meet the strict performance and safety standards required for aircraft. Hydroformed tubes are used in applications such as:

- Fuel and Fluid Transmission Systems: Tubular hydroforming is used to create intricate fuel and fluid transmission systems that are lightweight and resistant to pressure.

- Structural Components: In addition to fuel systems, hydroformed tubes are used for structural components that need to withstand high levels of stress while minimizing weight.

Hydroforming of Aluminum

Why Aluminum?: Aluminum is one of the most commonly used materials in hydroforming due to its excellent properties, including a high strength-to-weight ratio, corrosion resistance, and ease of formability. Its lightweight nature makes it an ideal choice for industries such as automotive and aerospace, where reducing weight is critical for improving fuel efficiency and overall performance.

Aluminum’s ductility allows it to be formed into complex shapes without cracking or breaking, making it well-suited for the hydroforming process. However, its work-hardening properties require precise control of the forming pressure to avoid material failure during the process.

Hydroforming Aluminum Tubes: Hydroforming aluminum tubes involves placing a hollow aluminum tube into a die and applying internal hydraulic pressure to expand the tube into the desired shape. Aluminum tubes are commonly used in automotive applications, such as exhaust systems and structural components, where lightweight materials are essential for improving fuel efficiency.

The process of hydroforming aluminum tubes includes several key steps:

- Preforming: The aluminum tube is first pre-formed into a rough shape that approximates the final geometry.

- Hydraulic Pressurization: Internal hydraulic pressure is applied, expanding the tube against the die.

- Cooling and Removal: After the part has been formed, it is cooled and removed from the die.

Challenges in Hydroforming Aluminum: While aluminum offers many advantages, there are also challenges in hydroforming this material. One of the primary challenges is managing the material’s tendency to harden as it is deformed, known as work-hardening. If not properly controlled, this can lead to cracking or failure during the forming process. As a result, precise pressure control and temperature management are crucial when hydroforming aluminum.

Additionally, aluminum’s relatively low melting point means that heat generated during the forming process needs to be carefully monitored to avoid softening the material and compromising the integrity of the final part.

Hydroforming Aluminum Sheets: In addition to tubes, hydroforming is also used to shape aluminum sheets. This process follows a similar approach, where hydraulic pressure is used to press the sheet against a die to form complex, high-precision shapes. Aluminum sheet hydroforming is commonly used in the automotive industry to produce body panels, as well as in the aerospace industry for fuselage and wing components.

The benefits of using aluminum sheets in hydroforming include:

- Lightweight Structures: Aluminum sheets allow for the creation of lightweight structures that improve fuel efficiency without sacrificing strength.

- Corrosion Resistance: Aluminum’s natural resistance to corrosion makes it an ideal material for components exposed to the elements, such as vehicle body panels and aircraft parts.

Industrial Hydroforming Equipment

Sheet Metal Hydroforming Equipment: Sheet metal hydroforming machines are designed to form large, flat sheets of metal into complex shapes using hydraulic pressure. These machines typically feature a hydraulic press with a die, into which the metal sheet is placed. The press then uses hydraulic fluid to apply pressure uniformly across the sheet, pressing it into the die and forming the desired shape.

Features of high-performance sheet metal hydroforming equipment include:

- Precision Forming: Modern sheet metal hydroforming machines are equipped with advanced pressure control systems to ensure that the metal is formed with high precision and consistency.

- High Capacity: These machines are capable of handling large sheets of metal, making them ideal for producing large parts such as automotive body panels, aircraft fuselages, and structural components.

- Automation: Many sheet metal hydroforming machines are equipped with automated loading and unloading systems to increase efficiency and reduce operator involvement.

Advanced Equipment for Deep-Draw Hydroforming: Deep-draw hydroforming machines are specialized for creating parts with significant depth, such as fuel tanks, structural components, and other deep-drawn parts. These machines typically feature a hydraulic press with a deep cavity die, into which the metal is drawn by applying hydraulic pressure.

Advanced Equipment for Deep-Draw Hydroforming: Deep-draw hydroforming equipment is engineered to handle the forming of materials into shapes that have a deep cavity relative to their surface dimensions. This process requires specialized machinery that can control both the hydraulic pressure and the drawing force to avoid tearing or thinning the material excessively. These machines are often equipped with multi-axis systems that allow for precise control over the movement of the material and the die, ensuring that complex, high-depth parts are formed with high accuracy.

- Multi-stage Forming: For parts with very deep draws, the equipment may be capable of multi-stage forming. This involves a series of steps where the material is progressively drawn deeper into the die, reducing the risk of material failure and ensuring the part maintains its structural integrity throughout the process.

- Pressure Monitoring: Deep-draw hydroforming presses are equipped with advanced pressure monitoring systems that can detect and adjust the hydraulic pressure in real-time to prevent defects such as wrinkling or tearing.

- Custom Tooling: Because deep-draw parts often have unique geometries, custom tooling is an essential feature of these machines. The dies and punches are designed specifically for the part being produced, ensuring that the metal is formed into the desired shape without compromising quality.

Tubular Hydroforming Equipment: Tubular hydroforming machines are specifically designed to shape hollow tubes into complex cross-sectional geometries. These machines use internal hydraulic pressure to expand the tube within a die, allowing for the production of lightweight and structurally strong parts, often with varying diameters and contours. Tubular hydroforming machines are commonly used in the automotive and aerospace industries, where lightweight yet strong components are essential.

Key features of tubular hydroforming equipment include:

- Multi-axis Control: Advanced tubular hydroforming machines use multi-axis control systems that allow for precise movement of the tube and the die. This ensures that complex geometries, such as varying diameters and shapes, can be formed in a single operation.

- Internal Pressure Control: Tubular hydroforming relies heavily on the precise control of internal hydraulic pressure. Too much pressure can cause the tube to burst, while too little can result in incomplete forming. Modern machines are equipped with pressure sensors that provide real-time feedback and adjust the pressure accordingly.

- Tooling and Dies: Similar to sheet and deep-draw hydroforming equipment, tubular hydroforming machines require custom tooling. The dies are designed to match the final shape of the tube, ensuring accurate and repeatable results across multiple production runs.

Explosive Hydroforming

Overview of Explosive Hydroforming: Explosive hydroforming is a unique variation of the traditional hydroforming process that utilizes the energy generated by controlled explosions to form metal components. This method is particularly useful for forming large, complex parts that require high forces, which would be difficult to achieve with conventional hydraulic presses.

In explosive hydroforming, a metal blank is placed inside a die, and a controlled explosive charge is detonated in a surrounding fluid medium, typically water. The explosion generates a shockwave that applies uniform pressure to the metal, forcing it to conform to the shape of the die. Because of the intense forces involved, explosive hydroforming is often used for large-scale applications in the aerospace, military, and heavy industrial sectors.

Advantages and Challenges: Explosive hydroforming offers several unique advantages:

- High Force Generation: The explosive energy used in this process can generate extremely high forces, making it possible to form very thick or hard-to-shape metals, such as titanium or Inconel, into complex geometries.

- Single-Step Forming: In many cases, explosive hydroforming can produce complex parts in a single step, reducing the need for additional forming or welding operations.

- Cost-Effective for Large Parts: For large-scale parts that require substantial forming forces, explosive hydroforming can be more cost-effective than building large hydraulic presses, especially for low-volume production.

However, there are also significant challenges and limitations:

- Safety Concerns: The use of explosives introduces inherent safety risks, requiring strict safety protocols and specialized facilities.

- Environmental Impact: The detonation of explosives can have environmental consequences, including noise pollution and potential water contamination, depending on the medium used.

- Precision Limitations: While explosive hydroforming is effective for large-scale parts, it lacks the precision of conventional hydroforming processes, making it less suitable for applications where tight tolerances are required.

Hydroforming Press for Dished Ends

Specialized Applications: Hydroforming presses designed for forming dished ends are used in industries such as oil and gas, chemical processing, and manufacturing, where pressure vessels and tanks are common. Dished ends are the concave or convex ends of cylindrical tanks, and they need to be formed with high precision and strength to withstand internal pressure. These parts are typically made from steel or other high-strength materials, and hydroforming allows for the production of dished ends with minimal welding, which improves their structural integrity.

In the traditional manufacturing of dished ends, multiple pieces of metal may be welded together to form the final part. Hydroforming eliminates much of this by shaping a single piece of metal into the desired shape, reducing the risk of weak points where the metal has been joined.

Press Design and Pressure Requirements: Hydroforming presses for dished ends are designed to handle large, thick metal sheets. The press must apply uniform hydraulic pressure to form the sheet into a dished shape while maintaining the material’s structural integrity.

- High Pressure: The pressure requirements for forming dished ends are typically very high, especially when working with thicker materials like steel. Presses designed for this application must be able to generate and sustain the necessary pressure to form the metal without causing defects such as thinning or cracking.

- Precision and Forming Accuracy: Given that dished ends must withstand significant internal pressure once installed, precision is critical. The hydroforming process must ensure that the thickness of the material remains uniform across the part and that the final shape matches the required specifications exactly.

Deep-Draw Hydroforming

Deep-Draw Hydroforming Process: Deep-draw hydroforming is an advanced metal forming technique used to produce parts with a high depth-to-width ratio. It is an alternative to conventional deep drawing, where a punch is used to mechanically force the material into a die. In hydroforming, hydraulic pressure replaces the punch, which reduces the mechanical stress on the material and allows for the production of more complex geometries.

The process involves the following steps:

- Blank Placement: A flat metal blank is placed over a die cavity.

- Hydraulic Pressure Application: Hydraulic fluid is pressurized to force the metal into the die cavity, drawing it into the desired shape. This pressure is applied gradually to avoid material tearing.

- Forming: The metal is stretched and drawn deeper into the die, forming a part with high precision and minimal wrinkling or thinning.

- Cooling and Removal: After the part is formed, it is cooled and removed from the die.

Advantages Over Conventional Deep Drawing: Deep-draw hydroforming offers several advantages compared to traditional deep drawing:

- Reduced Material Stress: Because the process uses hydraulic pressure rather than mechanical force, the material is subjected to less stress, which reduces the likelihood of tearing or cracking during the forming process.

- Improved Precision: The uniform pressure provided by the hydraulic fluid results in higher precision and fewer defects, such as wrinkling or thinning of the material.

- Complex Geometries: Deep-draw hydroforming allows for the production of parts with complex geometries that would be difficult to achieve using conventional deep drawing techniques.

Applications in Manufacturing: Deep-draw hydroforming is widely used in industries where high-strength, lightweight components are essential. Some common applications include:

- Automotive Industry: Fuel tanks, transmission housings, and other structural components that require deep, complex shapes are often produced using deep-draw hydroforming. The ability to create lightweight, high-strength parts improves vehicle performance and fuel efficiency.

- Aerospace Industry: The aerospace sector uses deep-draw hydroforming to produce parts like fuselage sections, engine housings, and structural supports. The process allows for the creation of lightweight, high-strength components that meet the strict performance and safety standards required in aviation.

- Medical Devices: The medical industry also benefits from deep-draw hydroforming for producing components like surgical instruments and implantable devices. These parts often require complex shapes and tight tolerances, which hydroforming can provide.

Hydroforming Steel

Steel in Hydroforming: Steel is one of the most commonly used materials in hydroforming due to its strength, durability, and availability. High-strength steels, stainless steel, and alloy steels are frequently used in applications that require components to withstand significant mechanical stress and pressure, such as automotive chassis parts, pressure vessels, and structural components in buildings and bridges.

Steel’s formability, particularly when it is subjected to high pressure during the hydroforming process, makes it an ideal material for producing large, intricate parts that require a combination of strength and precision.

Challenges of Hydroforming Steel: Although steel is well-suited to hydroforming, it presents certain challenges due to its high strength and hardness. These challenges include:

- High Pressure Requirements: Steel requires significantly higher pressures than softer materials like aluminum to achieve the desired shapes. Hydroforming equipment must be designed to handle these higher pressures, which can increase the cost of the process.

- Springback: Steel tends to spring back after forming, meaning that it attempts to return to its original shape once the pressure is released. To compensate for this, hydroforming dies must be carefully designed to account for springback and ensure that the final part meets the desired specifications.

- Material Thickness: Thicker steel sheets or tubes require more pressure to form, and there are limits to how thick the material can be before it becomes impractical to hydroform.

Hydroforming Tools and Equipment

Types of Hydroforming Tools: Hydroforming requires specialized tooling, including dies, punches, and seals. These tools are critical to the success of the hydroforming process, as they define the shape of the final part and ensure that the metal is formed with high precision and accuracy.

- Dies: The dies used in hydroforming are typically made from hardened steel or carbide to withstand the high pressures involved in the process. These dies are custom-designed for each part, and they determine the final shape of the component being formed.

- Punches: In some hydroforming processes, such as deep-draw hydroforming, punches are used to push the material into the die. The punch works in conjunction with the hydraulic pressure to form the metal.

- Seals: To prevent hydraulic fluid from leaking during the process, seals are used around the edges of the die. These seals are critical for maintaining the high pressures needed to form the metal effectively.

Tool Maintenance and Longevity: Hydroforming tools, especially dies and punches, are subjected to significant wear and tear due to the high pressures involved in the process. To ensure the longevity of these tools and maintain consistent part quality, regular maintenance is essential.

- Die Wear: Over time, dies can become worn, especially when working with hard materials like steel. Regular inspection and refurbishment of dies are necessary to ensure they continue to produce parts with the correct dimensions.

- Tool Material Selection: The materials used for hydroforming tools play a key role in their longevity. Hardened steels and carbide are commonly used due to their durability and resistance to wear.

- Lubrication: Proper lubrication is critical to reduce friction and prevent excessive wear on tools. Many hydroforming processes use specialized lubricants to reduce tool wear and improve the overall efficiency of the process.

Hydroforming Pressure

Hydraulic Pressure in Hydroforming: Hydraulic pressure is the driving force behind the hydroforming process. The amount of pressure required depends on the material being formed, the thickness of the material, and the complexity of the part’s geometry. For example, materials like aluminum require lower pressure compared to steel, while thick or complex parts require higher pressures to achieve the desired shape.

The pressure applied during hydroforming serves two primary functions:

- Shaping the Metal: The hydraulic pressure forces the metal into the die, shaping it according to the desired geometry.

- Maintaining Uniform Thickness: The pressure also helps to maintain uniform material thickness throughout the part, which is important for structural integrity and aesthetic quality.

Factors Influencing Pressure Requirements: Several factors influence the amount of pressure required in a hydroforming process:

- Material Properties: Softer materials like aluminum require less pressure, while harder materials like steel need significantly higher pressures to achieve the same results.

- Part Geometry: Complex geometries with deep draws or sharp angles require higher pressures to ensure that the metal conforms to the die without wrinkling or tearing.

- Material Thickness: Thicker materials require more pressure to deform, while thinner materials need less pressure but are more prone to tearing if the pressure is not carefully controlled.

Pressure Control in Modern Machines: Modern hydroforming machines are equipped with advanced pressure control systems that allow for precise regulation of hydraulic pressure throughout the forming process. These systems often include feedback loops that monitor the pressure in real-time and adjust it as needed to prevent defects.

- Real-Time Monitoring: Pressure sensors monitor the hydraulic pressure during forming, ensuring that it remains within the required range for the material and part being produced.

- Automatic Adjustments: If the pressure deviates from the desired level, modern machines can automatically adjust the hydraulic system to bring the pressure back into range. This helps to prevent issues such as material cracking or incomplete forming.

Environmental and Economic Impact of Hydroforming

Material Efficiency and Waste Reduction: One of the major environmental benefits of hydroforming is its ability to minimize material waste. Traditional metal forming processes, such as stamping or forging, often result in significant material waste, especially when complex shapes are involved. In contrast, hydroforming allows manufacturers to use thinner materials and form parts in a single step, reducing the need for additional trimming, welding, or joining.

- Minimization of Scrap: Because hydroforming forms parts with fewer steps, less material is wasted in the process. This is particularly beneficial when working with expensive materials like aluminum or titanium, where material costs can represent a significant portion of the overall production expense.

- Optimized Material Use: Hydroforming makes it possible to use thinner materials without sacrificing strength, which further reduces material consumption. For industries such as automotive and aerospace, this leads to lighter components that improve fuel efficiency and reduce emissions over the product’s life cycle.

Cost Considerations: While hydroforming equipment can represent a significant upfront investment, the long-term economic benefits often outweigh the initial costs. The ability to produce parts with fewer operations, reduced material waste, and higher precision can lead to substantial cost savings over time.

- Reduction in Manufacturing Steps: Hydroforming allows for the creation of complex parts in a single forming step, which reduces the number of operations required in the manufacturing process. This, in turn, leads to reduced labor costs, shorter production times, and lower overall costs per part.

- Lower Material Costs: The material savings achieved through hydroforming also contribute to cost reductions. By using thinner, high-strength materials, manufacturers can achieve the same or better performance compared to traditional forming methods while using less raw material.

- Longer Tool Life: Although hydroforming tools and dies are subjected to high pressures, the overall wear on these tools is often lower compared to traditional methods due to the even distribution of pressure. This can result in longer tool life and reduced tooling costs over time.

Environmental Benefits: In addition to material efficiency, hydroforming offers several environmental benefits that make it an attractive option for manufacturers focused on sustainability:

- Reduced Energy Consumption: Hydroforming processes typically consume less energy compared to other metal forming methods, such as forging or stamping. This is because hydroforming uses hydraulic pressure rather than mechanical force, which reduces the amount of energy required to shape the metal.

- Lower Emissions: The production of lighter components, especially in the automotive and aerospace industries, leads to reduced fuel consumption and lower emissions over the lifetime of the vehicle or aircraft. By enabling the production of lighter, stronger parts, hydroforming contributes to the overall reduction of greenhouse gas emissions.

- Minimized Secondary Processing: Since hydroforming often produces near-net-shape parts, there is less need for secondary processing steps such as machining, welding, or grinding. This reduces the overall energy consumption and environmental impact associated with manufacturing.

Conclusion

Hydroforming is a transformative manufacturing technology that offers significant advantages in terms of material efficiency, structural integrity, and the ability to produce complex geometries. From its origins in the automotive industry to its widespread adoption across aerospace, medical, and consumer goods sectors, hydroforming continues to evolve as new materials and technologies emerge.

The ability to form lightweight, high-strength components with minimal material waste makes hydroforming a crucial process for industries focused on improving performance while reducing environmental impact. With advances in equipment, tooling, and automation, hydroforming is poised to play an even more significant role in future manufacturing trends.

Whether it’s deep-draw hydroforming, sheet hydroforming, or tubular hydroforming, the process allows for the creation of parts that meet the increasingly stringent demands for strength, durability, and precision. As industries continue to prioritize sustainability and efficiency, hydroforming’s role in shaping the future of manufacturing will only continue to grow.

In conclusion, the diverse applications of hydroforming, from the automotive to the aerospace industries, underscore its versatility and efficiency. With ongoing innovations in technology, tooling, and pressure control, hydroforming will remain at the forefront of advanced manufacturing processes for years to come.

Comprehensive Guide to the Sheet Hydroforming Process

Definition and History: Sheet hydroforming is an advanced metal forming process that uses hydraulic pressure to shape metal sheets into complex geometries. Unlike traditional stamping or pressing methods, where mechanical force is applied directly to the sheet, sheet hydroforming involves applying fluid pressure to push the metal sheet against a die. This results in higher precision, minimal material waste, and the ability to form complex shapes in one step.

The history of hydroforming can be traced back to the 1950s when it was first developed for the automotive industry to create lightweight, strong components. Over time, the process has evolved and found applications in a variety of industries, including aerospace, consumer electronics, and medical devices.

Importance in Modern Manufacturing: Sheet hydroforming has become a cornerstone in industries where precision, lightweight materials, and strength are critical. It enables manufacturers to create intricate designs with fewer components, reducing the need for welding and joints, which enhances the structural integrity of the final product. In addition, the ability to work with a wide range of metals, from aluminum to titanium, makes sheet hydroforming versatile and applicable to high-performance industries.

Principles of Sheet Hydroforming

Fundamental Concepts: The core principle of sheet hydroforming revolves around the use of hydraulic pressure to shape metal sheets. A flat sheet of metal is placed over a die, and a flexible diaphragm (or similar mechanism) is used to apply hydraulic pressure on the sheet, forcing it to conform to the shape of the die. The hydraulic fluid distributes the pressure evenly across the surface, reducing stress on the material and enabling the formation of complex geometries without cracking or tearing.

The forming process typically requires high pressure, ranging from 3,000 psi to over 20,000 psi, depending on the material’s thickness and properties. The uniform application of pressure is one of the main reasons hydroforming produces superior results compared to traditional stamping or mechanical pressing.

Comparison to Traditional Metal Forming Methods: Traditional metal forming methods like stamping, forging, and deep drawing rely on mechanical force to shape metal sheets. While these methods are efficient for certain applications, they often result in high material waste, particularly in the production of complex shapes. Stamping can also lead to inconsistent material thickness and weak points due to the localized force applied during the process.

In contrast, hydroforming allows for more uniform material distribution, reducing thinning in critical areas and improving the overall strength of the part. This makes it a preferred choice for industries that demand lightweight yet strong components, such as aerospace and automotive manufacturing.

Key Terminology:

- Hydraulic Press: A machine that uses hydraulic pressure to shape the material.

- Diaphragm: A flexible membrane used to apply hydraulic pressure to the sheet.

- Blank: The flat metal sheet placed over the die before the forming process.

- Die: The tool that provides the shape to be formed by the sheet.

Types of Sheet Hydroforming Processes

There are several variations of sheet hydroforming, each suited for different applications and types of parts. These include conventional sheet hydroforming, deep-draw hydroforming, and matched-die hydroforming.

Conventional Sheet Hydroforming: In conventional sheet hydroforming, a flat metal sheet is placed over a single die, and hydraulic pressure is applied using a diaphragm or fluid chamber. The pressure forces the sheet into the die, shaping it into the desired geometry. This method is particularly useful for forming large, shallow parts with smooth curves, such as automotive body panels or aerospace fuselage sections.

- Applications: Automotive body parts, consumer electronics cases, and aircraft skin panels.

- Advantages: High precision, minimal material waste, and the ability to form large parts with complex geometries.

- Limitations: Not suitable for parts requiring deep draws or sharp angles.

Deep-Draw Sheet Hydroforming: Deep-draw hydroforming is used for parts with a high depth-to-width ratio, such as fuel tanks or complex structural components. The process involves drawing the metal deeper into the die cavity using hydraulic pressure, which stretches the material more than in conventional hydroforming.

- Applications: Fuel tanks, transmission housings, and deep-cavity components.

- Advantages: Ability to create deep, complex shapes with high structural integrity.

- Limitations: Requires careful pressure control to prevent tearing or wrinkling of the material.

Matched-Die Hydroforming: In matched-die hydroforming, two dies are used—one on the top and one on the bottom—similar to traditional stamping. However, hydraulic pressure is applied during the forming process to provide more control and precision. This method is used when high levels of detail and sharp corners are required.

- Applications: High-precision parts with complex geometries and sharp features.

- Advantages: Superior accuracy and control, ideal for intricate part designs.

- Limitations: More expensive tooling compared to single-die processes.

Materials Used in Sheet Hydroforming

Sheet hydroforming is highly versatile and can be used to form a wide range of materials, including aluminum, steel, titanium, and specialty alloys.

Aluminum: Aluminum is one of the most commonly used materials in sheet hydroforming due to its lightweight properties and high strength-to-weight ratio. It is widely used in industries like automotive and aerospace, where weight reduction is critical for performance and fuel efficiency.

- Properties: Lightweight, corrosion-resistant, and highly formable.

- Applications: Automotive body panels, aerospace components, and consumer electronics.

Steel: Steel, including high-strength steel and stainless steel, is another popular material for sheet hydroforming. Steel’s durability and strength make it suitable for parts that need to withstand heavy loads or extreme conditions.

- Properties: Strong, durable, and capable of handling high pressures during forming.

- Applications: Automotive chassis components, structural parts, and pressure vessels.

Titanium: Titanium is valued for its exceptional strength, lightweight, and corrosion resistance. While it is more challenging to form than aluminum or steel, hydroforming allows manufacturers to take advantage of titanium’s unique properties, making it a key material in aerospace and medical applications.

- Properties: Lightweight, highly resistant to corrosion, and extremely strong.

- Applications: Aircraft components, medical implants, and high-performance sports equipment.

Material Properties and Compatibility: The selection of material for hydroforming depends on several factors, including the required strength, weight, and formability. Softer metals like aluminum are easier to form but may not offer the same durability as steel or titanium. Conversely, harder metals require higher pressures and more precise control to avoid tearing or cracking during the forming process.

Material Thickness and Formability Considerations: Material thickness is a critical factor in sheet hydroforming. Thinner materials are more prone to tearing during the forming process, especially when subjected to high pressures or deep draws. On the other hand, thicker materials require more pressure to form, which may necessitate more advanced equipment. Finding the right balance between material thickness and formability is essential for successful hydroforming.

Sheet Hydroforming Equipment

The equipment used in sheet hydroforming is designed to handle the high pressures and precision required to shape metal sheets into complex geometries. Key components of this equipment include hydraulic presses, tooling and dies, and seals and pressure control systems.

Hydraulic Presses: The hydraulic press is the centerpiece of the hydroforming process. It generates the hydraulic pressure needed to force the metal sheet into the die and create the desired shape. Hydraulic presses used in sheet hydroforming typically have large capacities, ranging from 5,000 psi to over 20,000 psi, depending on the material and complexity of the part.

- High-Pressure Capabilities: Modern hydraulic presses are equipped with advanced pressure control systems that allow for precise adjustment of pressure levels throughout the forming process.

- CNC Integration: Many presses are now integrated with CNC (Computer Numerical Control) systems, enabling automated control over pressure, timing, and movement of the forming tools for enhanced accuracy and repeatability.

Tooling and Dies: Dies are custom-designed tools that give the final shape to the metal sheet. They are made from high-strength materials such as hardened steel or carbide to withstand the extreme pressures involved in the hydroforming process. Depending on the complexity of the part, dies can be either simple single-cavity designs or more complex, multi-part tools.

- Die Design: The design of the die is crucial to achieving the desired part geometry. Factors such as material thickness, depth of draw, and the presence of intricate details all influence the die design.

- Tool Longevity: Tooling materials are selected to ensure longevity, as hydroforming tools are subjected to repeated high-pressure cycles. Regular maintenance and refurbishment of tools are necessary to prevent wear and maintain part accuracy.

Seals and Pressure Control Systems: Seals play a critical role in the hydroforming process by preventing hydraulic fluid from leaking during forming. The seals are located around the edges of the die and the diaphragm and are designed to maintain the high pressures needed for effective forming.

- Pressure Control Systems: Advanced hydraulic presses are equipped with pressure control systems that monitor and adjust the pressure in real-time. These systems ensure that the pressure remains within the optimal range for the material and part being formed, reducing the risk of defects such as tearing or wrinkling.

- Sealing Materials: Seals are typically made from high-strength elastomers or composite materials that can withstand repeated exposure to high pressures and temperatures.

Step-by-Step Breakdown of the Sheet Hydroforming Process

The sheet hydroforming process can be broken down into several key steps, from die design and material preparation to forming, cooling, and finishing.

1. Design and Setup of Dies: Before the forming process begins, the dies must be designed to match the desired part geometry. This involves using CAD (Computer-Aided Design) software to model the part and create the necessary tooling. Once the design is finalized, the dies are manufactured from high-strength materials capable of withstanding the pressures involved in hydroforming.

2. Preparing the Material Sheet: The metal sheet, also known as a blank, is prepared for forming. The blank is typically cut to size and shape using laser cutting, waterjet cutting, or other precision cutting methods. The surface of the sheet may also be treated with lubricants to reduce friction during the forming process and prevent damage to the tooling.

3. Placing the Blank Over the Die: Once the material sheet is prepared, it is placed over the die in the hydraulic press. The press may be equipped with an alignment system to ensure the sheet is positioned correctly before forming begins.

4. Forming Process Using Hydraulic Pressure: The core of the hydroforming process involves applying hydraulic pressure to the metal sheet using a diaphragm or fluid chamber. The pressure is applied gradually to avoid tearing or wrinkling the material, and it forces the sheet to conform to the shape of the die. The hydraulic fluid distributes the pressure evenly across the sheet, ensuring that the material forms uniformly.

- Pressure Application: Depending on the material and complexity of the part, the pressure may be applied in stages, with adjustments made to prevent defects. In deep-draw hydroforming, additional pressure may be needed to stretch the material into the deeper parts of the die.

- Cooling Systems: In some cases, cooling systems may be used to control the temperature of the sheet and the die during forming. This is particularly important for materials like aluminum, which can soften if overheated.

5. Cooling, Removal, and Finishing: Once the forming process is complete, the part is allowed to cool, and the pressure is released. The formed part is then removed from the die, and any excess material is trimmed away. Depending on the part’s requirements, additional finishing operations, such as deburring, polishing, or heat treatment, may be performed to achieve the desired surface finish and mechanical properties.

- Inspection and Quality Control: After forming, the part is inspected for dimensional accuracy, surface finish, and any potential defects. Non-destructive testing methods, such as ultrasonic or dye-penetrant inspection, may be used to identify internal defects or surface cracks.

- Post-Processing: Depending on the application, the formed part may undergo additional processes such as welding, machining, or coating to prepare it for assembly or final use.

Applications of Sheet Hydroforming

Sheet hydroforming is a versatile process used in a wide range of industries, including automotive, aerospace, consumer products, and medical devices. Each industry benefits from hydroforming’s ability to produce lightweight, high-strength components with complex geometries.

Automotive Industry: In the automotive sector, sheet hydroforming is commonly used to create body panels, chassis components, and structural parts. These parts need to be lightweight to improve fuel efficiency while maintaining the strength necessary to meet safety standards.

- Body Panels: Sheet hydroforming allows manufacturers to produce large, intricately shaped body panels with minimal joints or seams. This improves both the aesthetics and the structural integrity of the vehicle.

- Chassis Components: Hydroformed chassis components, such as engine cradles and subframes, are lighter and stronger than those produced using traditional stamping or welding methods. This contributes to overall vehicle performance and fuel economy.

Aerospace Industry: The aerospace industry relies heavily on hydroforming to produce lightweight, high-strength components that meet stringent performance and safety requirements.

- Fuselage Sections: Hydroforming is used to create large sections of aircraft fuselages, which need to be both lightweight and capable of withstanding the stresses of flight.

- Wing Components: Hydroforming is also used to form complex wing structures that require high precision and uniform material thickness.

Consumer Products and Electronics: In the consumer products sector, hydroforming is used to create aesthetically pleasing and functional designs. From smartphone casings to high-end kitchen appliances, hydroforming allows for the production of sleek, intricate designs with smooth, curved surfaces.

- Smartphone Housings: The sleek, seamless designs of modern smartphones often rely on hydroforming to create complex, curved shapes that are both lightweight and durable.

- Appliances: Kitchen appliances, such as refrigerators and ovens, benefit from hydroforming’s ability to create smooth, aesthetically pleasing surfaces that are easy to clean and maintain.

Medical Devices: In the medical field, hydroforming is used to produce components that require high precision and biocompatibility.

- Surgical Instruments: Many surgical instruments are made using hydroforming due to the process’s ability to produce intricate, high-precision shapes with minimal material stress.

- Implants: Hydroformed titanium implants, such as joint replacements and dental implants, are lightweight, strong, and biocompatible, making them ideal for medical applications.

Advantages of the Sheet Hydroforming Process

Sheet hydroforming offers numerous advantages over traditional metal forming processes, making it a popular choice for industries that require high precision, material efficiency, and complex geometries.

Material Efficiency and Reduction of Waste: One of the most significant advantages of sheet hydroforming is its ability to minimize material waste. Because the process uses hydraulic pressure to form the sheet, there is less material thinning and fewer scraps compared to stamping or forging.

- Thinner Materials: Hydroforming allows manufacturers to use thinner materials without compromising strength, which reduces the overall amount of material used in production.

- Reduction in Scrap: Traditional stamping processes often result in significant material waste due to excess trimming and cutting. Hydroforming, by contrast, produces near-net-shape parts, minimizing the need for additional material removal.

Lightweight and High-Strength Component Production: Hydroforming enables the production of lightweight components with high structural integrity, which is critical in industries such as automotive and aerospace.

- Improved Strength-to-Weight Ratio: Hydroformed parts typically have a higher strength-to-weight ratio than parts produced using traditional methods. This is particularly important in automotive and aerospace applications, where weight reduction leads to improved fuel efficiency and performance.

- Uniform Material Thickness: The hydraulic pressure used in hydroforming ensures that the material thickness remains uniform throughout the part, reducing weak points and improving overall strength.

Cost-Effectiveness in Large-Scale Manufacturing: While the initial investment in hydroforming equipment can be high, the process is highly cost-effective in large-scale manufacturing due to its material efficiency and reduced need for secondary operations.

- Fewer Operations: Hydroforming allows for the production of complex parts in a single forming step, reducing the need for additional processes such as welding, machining, or finishing.

- Lower Tooling Costs: Compared to traditional stamping, which requires multiple dies for different stages of forming, hydroforming often requires only one die, reducing tooling costs over time.

Challenges and Limitations of Sheet Hydroforming

While sheet hydroforming offers many advantages, it also comes with certain challenges and limitations.

Material Constraints (Thicker vs. Thinner Sheets): One of the primary challenges in sheet hydroforming is balancing material thickness with the pressure required to form the part. Thicker sheets require more pressure to form, which can strain the equipment and increase the risk of material cracking. On the other hand, thinner sheets are more prone to tearing or wrinkling under high pressure.

- Pressure Requirements: Materials with higher strength, such as steel or titanium, require significantly higher pressures to form, which may necessitate specialized equipment.

- Risk of Material Failure: Without precise control over the pressure and forming process, there is a risk of material failure, particularly when working with complex shapes or deep draws.

Dimensional Accuracy and Forming Complexities: Hydroforming offers high precision, but it can still present challenges when working with complex geometries or tight tolerances.

- Springback: Some materials, particularly high-strength steels, have a tendency to spring back after forming, meaning they attempt to return to their original shape once the pressure is released. This can affect the dimensional accuracy of the part.

- Complex Geometries: While hydroforming excels at forming large, smooth shapes, it can struggle with intricate details or sharp angles. These complexities may require additional post-processing or more advanced die designs.

Technological Innovations in Sheet Hydroforming

Recent technological innovations have significantly improved the capabilities and efficiency of sheet hydroforming, making it even more valuable for modern manufacturing.

CNC-Controlled Hydraulic Systems: The integration of CNC systems with hydraulic presses has revolutionized the hydroforming process. CNC control allows for precise regulation of hydraulic pressure, timing, and movement of the die, ensuring consistent results across production runs.

- Automated Pressure Control: CNC systems can monitor and adjust hydraulic pressure in real-time, reducing the risk of material defects and improving overall process efficiency.

- Repeatability and Consistency: CNC-controlled presses ensure that each part is formed with the same precision, reducing variability in large-scale manufacturing.

Advanced Tooling and Die Materials: Advances in materials science have led to the development of more durable and wear-resistant tooling materials. These materials, such as carbide and ceramic composites, extend the life of hydroforming dies and improve their ability to withstand high pressures.

- Tool Coatings: Specialized coatings, such as diamond-like carbon (DLC) or titanium nitride (TiN), can be applied to dies to reduce friction, improve wear resistance, and extend tool life.

- Multi-Die Systems: Some advanced hydroforming systems now use multi-die setups, allowing for the simultaneous production of multiple parts or more complex geometries.

Integration of Sensors and Automation: Modern hydroforming equipment is increasingly equipped with sensors that monitor various aspects of the process, from pressure levels to material deformation. These sensors provide real-time feedback to the CNC system, allowing for immediate adjustments to ensure optimal forming conditions.

- Force Sensors: These sensors detect the amount of force being applied to the material, ensuring that the pressure remains within the required range for the specific material and part.

- Deformation Monitoring: Sensors can also monitor how the material is deforming during the process, alerting operators to potential issues such as wrinkling or tearing.

Environmental Impact of Sheet Hydroforming

Sheet hydroforming offers several environmental benefits, making it an attractive option for manufacturers focused on sustainability.

Energy Efficiency in Manufacturing: Compared to traditional metal forming processes like stamping or forging, hydroforming is generally more energy-efficient. This is because it uses hydraulic pressure rather than mechanical force, which requires less energy to achieve the same results.

- Reduced Energy Consumption: Hydraulic systems are more efficient than mechanical presses, particularly when forming complex parts or deep draws. This reduces the overall energy consumption of the manufacturing process.

- Lower Emissions: By reducing the energy required for forming, hydroforming also helps lower the carbon emissions associated with manufacturing, contributing to a more sustainable production process.

Waste Reduction and Material Recycling: Hydroforming is a near-net-shape forming process, meaning that it produces parts that are very close to their final dimensions, reducing the need for additional trimming or machining. This leads to less material waste compared to traditional methods like stamping or forging.

- Minimized Scrap: The precision of hydroforming results in less scrap material, which not only reduces waste but also lowers the cost of raw materials.

- Recyclable Materials: Many of the metals used in hydroforming, such as aluminum and steel, are fully recyclable. The reduced material waste and the ability to recycle scrap metal contribute to a more environmentally friendly manufacturing process.

Role in Sustainable Manufacturing: As industries move toward more sustainable manufacturing practices, hydroforming is playing a key role in helping manufacturers reduce their environmental impact. The process’s ability to produce lightweight, high-strength components with minimal waste makes it ideal for industries like automotive and aerospace, where reducing weight and improving fuel efficiency are critical for sustainability.

- Lightweight Parts for Fuel Efficiency: In the automotive and aerospace industries, reducing the weight of vehicles and aircraft is essential for improving fuel efficiency and reducing emissions. Hydroforming allows manufacturers to produce lightweight components that meet the required strength and safety standards.

- Sustainable Design Practices: Many manufacturers are incorporating hydroforming into their sustainable design practices, using the process to create parts that are both environmentally friendly and cost-effective.

Case Studies in Sheet Hydroforming

Several industries have successfully integrated sheet hydroforming into their manufacturing processes, resulting in improved product quality, material efficiency, and cost savings. Here are some case studies that highlight the versatility of the hydroforming process.

Automotive Chassis Production: In the automotive industry, hydroforming is used to produce chassis components that are lighter and stronger than those produced using traditional methods. For example, a major automotive manufacturer used hydroforming to create engine cradles and subframes for a new line of vehicles.

- Results: The hydroformed parts were 20% lighter than their stamped counterparts, resulting in improved fuel efficiency and lower emissions. The reduced number of joints and welds also enhanced the structural integrity of the chassis components, leading to better crash performance.

- Cost Savings: By using hydroforming, the manufacturer reduced the number of forming steps and the amount of material waste, resulting in significant cost savings over the course of the production run.

Aerospace Structural Components: In the aerospace industry, hydroforming has been used to produce lightweight structural components for aircraft. A leading aerospace company employed sheet hydroforming to create fuselage sections and wing components for a new commercial aircraft.

- Results: The hydroformed parts met the strict weight and strength requirements for the aircraft, helping to reduce overall weight and improve fuel efficiency. The process also allowed for the creation of complex shapes that would have been difficult to achieve using traditional methods.

- Improved Durability: The uniform material thickness achieved through hydroforming improved the durability and lifespan of the components, reducing the need for maintenance and repairs.

Manufacturing of Complex, High-Precision Consumer Goods: Hydroforming is also used in the production of high-precision consumer goods, such as smartphone housings and kitchen appliances. A leading electronics manufacturer used hydroforming to create sleek, curved smartphone cases that were both lightweight and durable.

- Results: The hydroformed cases had a seamless design with no visible joints, improving the aesthetics and strength of the product. The process also allowed for the creation of thinner, more lightweight cases without compromising durability.

- Production Efficiency: By using hydroforming, the manufacturer was able to produce the cases in a single forming step, reducing the need for additional machining or finishing operations.

Future Trends in Sheet Hydroforming

As industries continue to push the boundaries of manufacturing technology, several trends are emerging that could shape the future of sheet hydroforming.

Emerging Materials in Hydroforming: New materials are constantly being developed, and many of these materials are being adapted for use in the hydroforming process. Advanced alloys, composites, and lightweight metals such as magnesium are being tested for their formability and compatibility with hydroforming.

- Magnesium Alloys: Magnesium is lighter than aluminum but offers comparable strength. As manufacturers look for ways to further reduce the weight of their products, magnesium alloys could become a popular choice for hydroforming, particularly in the automotive and aerospace sectors.

- High-Strength Alloys: Advances in metallurgy are leading to the development of new high-strength alloys that are more resistant to wear and corrosion. These materials could expand the range of applications for hydroforming, particularly in industries such as oil and gas, where components need to withstand harsh environments.

Hybrid Manufacturing Techniques: As manufacturing technology continues to evolve, hybrid techniques that combine hydroforming with other processes are emerging. For example, manufacturers are experimenting with combining hydroforming and additive manufacturing (3D printing) to create complex parts with enhanced performance characteristics.

- Additive Manufacturing and Hydroforming: By using 3D printing to create the initial part and then using hydroforming to fine-tune its shape and structural integrity, manufacturers can produce highly complex components that would be difficult or impossible to achieve using traditional methods alone.

- Integration with Machining: In some cases, hydroforming can be combined with precision machining to create parts with intricate features and tight tolerances. This hybrid approach allows manufacturers to take advantage of the strengths of both processes, resulting in parts that are both strong and precise.

Integration with 3D Printing and Additive Manufacturing: Additive manufacturing has gained significant traction in recent years, and its integration with hydroforming could open up new possibilities for producing highly customized parts. For example, 3D-printed tools or dies could be used in the hydroforming process, reducing the cost and time required to produce custom tooling.

- 3D-Printed Dies: By using 3D printing to create custom dies, manufacturers can reduce the lead time and cost associated with producing dies for short production runs. This is particularly useful in industries like aerospace and medical devices, where highly customized parts are required.

- Custom Part Production: The combination of 3D printing and hydroforming could also enable the production of highly customized parts, such as prosthetics or medical implants, that are tailored to the specific needs of the individual.

Conclusion: The Evolution of Sheet Hydroforming

Sheet hydroforming has come a long way since its inception in the mid-20th century, evolving into one of the most versatile and efficient metal forming processes available today. Its ability to produce lightweight, high-strength components with minimal material waste has made it a vital tool in industries ranging from automotive and aerospace to consumer electronics and medical devices.

As technology continues to advance, the capabilities of sheet hydroforming are only set to expand. The integration of CNC-controlled hydraulic systems, advanced tooling materials, and sensors has already improved the precision and efficiency of the process, while emerging trends such as additive manufacturing and new materials like magnesium alloys promise to take hydroforming to the next level.

In an era where sustainability and efficiency are increasingly important, sheet hydroforming stands out as a process that can meet the demands of modern manufacturing while minimizing environmental impact. Its ability to produce parts with fewer materials, lower energy consumption, and reduced emissions makes it an ideal choice for manufacturers looking to improve both their performance and their sustainability.

Looking ahead, the future of sheet hydroforming is bright. As industries continue to explore new applications and technologies, hydroforming will remain at the forefront of advanced manufacturing, helping to shape the future of everything from automobiles to airplanes, smartphones to surgical instruments.

In conclusion, the sheet hydroforming process represents the perfect blend of precision, efficiency, and sustainability, making it an indispensable part of modern manufacturing. Its continued evolution and adaptation to new materials, technologies, and applications will ensure that hydroforming remains a critical process for many industries in the years to come.

Comprehensive Guide to Hydroforming Machines

Hydroforming machines represent a specialized category of metal-forming equipment that utilize hydraulic pressure to shape metals into complex, high-strength components. Unlike traditional metal forming processes like stamping or forging, which rely on mechanical force, hydroforming uses pressurized fluid to force metal sheets or tubes into a die, creating intricate shapes with minimal material stress and waste.

Historical Background: The concept of hydroforming was developed in the early 1950s, primarily for the automotive industry, to produce lighter, stronger, and more intricate components. The method has since evolved, finding applications in industries like aerospace, consumer goods, and even medical devices. Hydroforming machines have become critical tools in modern manufacturing, allowing for the production of lightweight, high-performance components that are essential in today’s increasingly competitive market.

Role in Modern Manufacturing: Today, hydroforming machines are used in the production of everything from car body panels to aircraft structural components and medical devices. Their ability to create complex shapes from a single piece of metal reduces the need for welding and assembly, which enhances the strength and integrity of the final product. The precision and efficiency offered by hydroforming machines have made them indispensable in industries where weight reduction, strength, and material efficiency are key priorities.

Principles of Hydroforming

What is Hydroforming?: Hydroforming is a metal-forming process that uses high-pressure hydraulic fluid to shape metal sheets or tubes into predefined shapes. Unlike traditional forming methods, hydroforming evenly distributes the pressure across the entire surface of the metal, resulting in high-precision parts with minimal material waste and better mechanical properties. This makes it particularly suited for applications requiring lightweight, structurally strong components.

Hydroforming machines are designed to generate and control the hydraulic pressure required to form the metal into the desired shape. The process typically involves placing a sheet or tube of metal into a die, after which hydraulic fluid is injected, pressurizing the material and forcing it to take the shape of the die.

Key Concepts:

- Hydraulic Pressure: The defining feature of hydroforming is the use of fluid pressure to shape the metal. Depending on the material and the complexity of the part, pressures can range from 3,000 psi to over 20,000 psi.

- Dies: Dies are specially designed molds that define the final shape of the metal part. They are typically made from high-strength materials like steel or carbide to withstand the extreme pressures involved in the hydroforming process.

- Material Forming: The hydraulic pressure forces the metal sheet or tube to stretch and conform to the shape of the die. This process is highly controlled to prevent tearing, wrinkling, or other defects.

Comparison with Traditional Metal Forming: Hydroforming differs from traditional metal forming processes such as stamping, forging, or deep drawing in several key ways:

- Uniform Pressure Application: Traditional methods often apply localized mechanical force to specific areas of the material, which can result in thinning, uneven material distribution, and weak points. Hydroforming, on the other hand, applies uniform pressure across the entire surface, producing more consistent results.

- Complex Geometries: Hydroforming is particularly well-suited for creating complex shapes and contours that would be difficult or impossible to achieve using other methods.

- Material Efficiency: Since hydroforming uses less material and reduces the need for welding or assembly, it is generally more material-efficient than traditional forming processes.

Types of Hydroforming Machines

Hydroforming machines can be broadly classified based on the type of material they form and the specific process they use. The four primary types of hydroforming machines are sheet hydroforming machines, tube hydroforming machines, deep-draw hydroforming machines, and hybrid hydroforming machines.

1. Sheet Hydroforming Machines: Sheet hydroforming machines are designed to form large, flat metal sheets into complex shapes. These machines use a combination of hydraulic pressure and a single die to press the sheet into the desired shape. A flexible diaphragm or fluid chamber is used to apply uniform pressure to the metal sheet, which is then pressed into a die.

- Applications: Automotive body panels, aerospace fuselage sections, and large consumer product components.

- Advantages: Precision forming with minimal material waste, ideal for large, shallow parts with complex curves.

2. Tube Hydroforming Machines: Tube hydroforming machines are specifically designed to form hollow metal tubes into complex, three-dimensional shapes. These machines use internal hydraulic pressure to expand the tube within a die, forming parts with variable cross-sections and intricate geometries. Tube hydroforming is widely used in industries that require lightweight yet strong components, such as the automotive and aerospace industries.

- Applications: Automotive chassis frames, exhaust systems, structural components in aircraft.

- Advantages: Allows for the creation of lightweight, structurally strong components with fewer joints and welds, improving both strength and durability.

3. Deep-Draw Hydroforming Machines: Deep-draw hydroforming machines are used to create parts with a high depth-to-width ratio. This process involves drawing the metal deeper into the die, often using a combination of hydraulic pressure and mechanical force to achieve greater depth.

- Applications: Fuel tanks, transmission housings, and other deep-cavity components.

- Advantages: Capable of forming deeper parts without compromising material integrity, reducing stress on the material compared to traditional deep drawing.

4. Hybrid Hydroforming Machines: Hybrid hydroforming machines combine different forming techniques, such as explosive hydroforming or hydro-pneumatic forming, with traditional hydraulic pressure. Explosive hydroforming, for example, uses a controlled explosion to create high-pressure shockwaves that form the metal into the desired shape. These hybrid machines are typically used for specialized applications, such as forming very thick or hard-to-shape metals.

- Applications: Aerospace components, military applications, and heavy industrial equipment.

- Advantages: Capable of generating extremely high forces, ideal for forming tough or hard-to-shape materials.

Components of Hydroforming Machines

Hydroforming machines are made up of several key components, each of which plays a critical role in the forming process. The major components include the hydraulic system, dies and tooling, seals and diaphragms, and the control system.

1. Hydraulic Systems: The hydraulic system is the heart of every hydroforming machine. It generates the pressure needed to form the metal, typically using a combination of hydraulic pumps, valves, and pressure regulators. The system must be capable of generating and maintaining extremely high pressures, sometimes in excess of 20,000 psi.

- Hydraulic Pumps: These pumps generate the fluid pressure needed for forming. Modern machines often use high-efficiency pumps to reduce energy consumption and improve cycle times.

- Pressure Regulators: These devices monitor and control the hydraulic pressure throughout the process, ensuring that the material is formed within the desired parameters without tearing or wrinkling.