Hydropress Forming: Hydroforming is an advanced manufacturing process that has revolutionized the production of complex and lightweight components in various industries, including automotive, aerospace, and electronics. It involves the use of a high-pressure fluid, typically water, to form malleable metals into desired shapes. Unlike traditional stamping and pressing techniques, hydroforming allows for the creation of intricate designs with a single press operation, significantly reducing the need for welding and assembly.

The hydroforming process is divided into two primary categories: tube hydroforming and sheet hydroforming. Tube hydroforming involves expanding a tubular metal blank inside a die to form complex hollow shapes, while sheet hydroforming uses a similar principle to shape flat metal sheets. Both methods offer unique advantages, such as the ability to produce lighter, stronger components with superior dimensional accuracy.

Importance in Manufacturing

Hydroforming has become a critical technology in the manufacturing sector due to its ability to produce high-strength, lightweight components with reduced material waste. In the automotive industry, for example, hydroforming is widely used to produce structural components such as engine cradles, suspension systems, and exhaust manifolds. The process enables manufacturers to create parts with improved strength-to-weight ratios, contributing to overall vehicle efficiency and performance.

In the aerospace industry, hydroforming is employed to fabricate complex, high-precision components such as aircraft fuselage sections and engine parts. The ability to produce intricate shapes with minimal secondary operations makes hydroforming an ideal choice for aerospace applications, where precision and reliability are paramount.

Moreover, hydroforming’s versatility extends to other industries, including electronics, furniture, and HVAC (Heating, Ventilation, and Air Conditioning). The process is particularly valued for its ability to handle a wide range of materials, including aluminum, stainless steel, copper, and titanium, each offering different benefits depending on the application.

Core Keywords: Hydroforming Press, Hydroforming metal, Hydroforming stainless steel

Types of Hydroforming Presses and Machines

High Pressure Hydroform Press

The high-pressure hydroform press is a critical piece of equipment in the hydroforming process, known for its ability to apply extreme fluid pressure to shape metal components. This type of press is typically used in applications where precise control over the forming process is required, particularly when dealing with complex geometries or materials that require careful handling to avoid defects.

High-pressure hydroform presses operate by filling a die with a hydraulic fluid, usually water or oil, and then applying pressure to the metal blank. The fluid pressure forces the metal to conform to the shape of the die, resulting in a precisely formed part. These presses are capable of generating pressures upwards of 60,000 psi (pounds per square inch), making them suitable for forming high-strength materials like stainless steel and titanium.

The use of a high-pressure hydroform press offers several advantages. First, it enables the production of parts with superior dimensional accuracy and surface finish, reducing the need for secondary machining operations. Second, the process minimizes material waste by utilizing the inherent strength of the metal, allowing for thinner walls and lighter components without compromising strength. Finally, the high-pressure capability allows for the forming of highly complex shapes that would be difficult or impossible to achieve with traditional stamping or pressing methods.

Tube Hydroforming Press

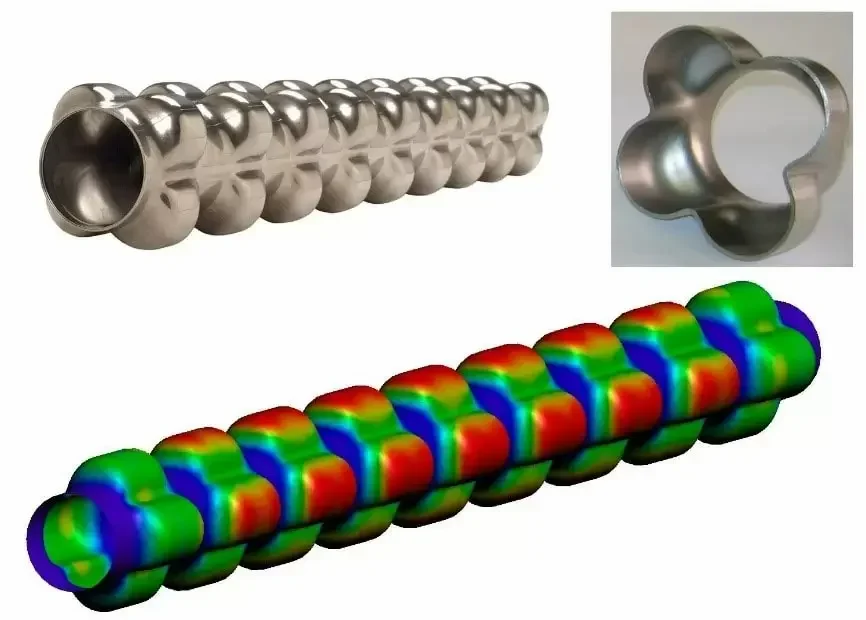

The tube hydroforming press is specifically designed for shaping tubular metal components, making it a cornerstone in industries like automotive and aerospace. Tube hydroforming involves placing a tubular metal blank into a die and then applying internal hydraulic pressure, combined with axial feeding, to expand the tube and conform it to the shape of the die.

Tube hydroforming presses are engineered to handle a wide variety of materials, including aluminum, steel, and stainless steel. These presses are capable of producing components with exceptional structural integrity and reduced weight, which is especially important in automotive applications where reducing vehicle weight is a key factor in improving fuel efficiency and performance.

One of the key advantages of tube hydroforming is its ability to create complex, hollow structures with varying cross-sections in a single step. This capability not only simplifies the manufacturing process but also results in stronger, more reliable components. Examples of parts produced by tube hydroforming include automotive chassis components, exhaust manifolds, and even bicycle frames.

Sheet Hydroforming Machine

The sheet hydroforming machine is another specialized type of hydroforming equipment designed for shaping flat metal sheets into three-dimensional forms. Unlike traditional press forming, sheet hydroforming applies uniform pressure across the surface of the sheet, allowing for more intricate and precise shaping.

Sheet hydroforming machines are widely used in industries that require high precision and complex part geometries, such as aerospace, automotive, and electronics. The process involves placing a metal sheet over a die and then applying fluid pressure from above, forcing the sheet to conform to the shape of the die. This method is particularly advantageous for forming lightweight materials like aluminum and titanium, which are commonly used in aerospace applications.

The benefits of using a sheet hydroforming machine include the ability to produce parts with a high degree of accuracy, minimal material thinning, and excellent surface finishes. Additionally, the process allows for the production of large, complex parts in a single operation, reducing the need for multiple forming steps and lowering production costs.

Hydropress Forming Machine

A hydropress forming machine is a versatile piece of equipment that can be used for both tube and sheet hydroforming processes. These machines are designed to accommodate a wide range of materials and part geometries, making them a valuable asset in any manufacturing environment that requires flexibility and precision.

Hydropress forming machines operate by using a hydraulic fluid to exert pressure on the workpiece, whether it is a tube or a sheet, forcing it to take the shape of a pre-designed die. The machine’s versatility allows it to handle various materials, from softer metals like aluminum to harder ones like stainless steel, with equal efficiency.

The primary advantage of a hydropress forming machine is its ability to perform multiple types of forming operations with a single piece of equipment. This not only reduces the need for multiple machines but also streamlines the production process, leading to faster turnaround times and lower costs. Furthermore, the precision offered by hydropress forming machines ensures that each part meets strict quality standards, which is crucial in industries such as automotive and aerospace.

Core Keywords: High pressure hydroform press, Tube hydroforming press, Sheet hydroforming machine, Hydropress forming machine

Key Components and Equipment in Hydroforming

Hydroforming Equipment Overview

Hydroforming is a highly specialized manufacturing process that relies on sophisticated equipment to shape metals with precision and efficiency. The key components of hydroforming systems include the press itself, dies, hydraulic pumps, control systems, and supporting infrastructure. Each of these elements plays a critical role in ensuring the accuracy, repeatability, and quality of the hydroforming process.

The hydroforming press is the centerpiece of the system, where the actual forming of metal components takes place. These presses are designed to withstand the extreme pressures required to shape metals, often exceeding tens of thousands of psi. The press structure must be robust enough to handle these pressures while maintaining precise alignment of the dies to ensure consistent part quality.

Dies are another crucial component in the hydroforming process. They define the final shape of the metal component and are typically made from high-strength tool steels capable of withstanding the stresses of repeated high-pressure forming operations. The design and fabrication of dies require careful consideration of the material properties, desired part geometry, and the specifics of the hydroforming process being employed.

Hydraulic pumps generate the high-pressure fluid needed to form the metal. These pumps must be capable of delivering consistent pressure throughout the forming cycle to ensure uniform shaping of the metal blank. Depending on the specific requirements of the process, pumps may be powered by electric motors, pneumatic systems, or other energy sources.

Control systems are essential for managing the complex interactions between the press, dies, and hydraulic pumps. Modern hydroforming systems use advanced computer-based control systems that monitor and adjust pressure, positioning, and timing in real-time. This level of control is crucial for producing parts with tight tolerances and high repeatability.

Supporting infrastructure, including power supplies, cooling systems, and safety features, ensures that the hydroforming equipment operates reliably and safely. Given the high pressures involved, safety is a paramount concern in hydroforming operations, and systems are typically equipped with multiple layers of redundancy and fail-safes to protect operators and equipment.

Sheet Hydroforming Equipment

Sheet hydroforming equipment is specifically designed to handle the unique requirements of forming flat metal sheets into complex three-dimensional shapes. These machines are engineered to apply uniform pressure across the entire surface of the metal sheet, which is critical for avoiding wrinkles, tears, and other defects that can occur with uneven pressure distribution.

The equipment typically includes a pressure chamber, where the metal sheet is placed over the die, and a flexible membrane or punch that applies the fluid pressure to form the metal. The pressure chamber is often designed to accommodate various die shapes and sizes, allowing for flexibility in production.

One of the key advantages of sheet hydroforming equipment is its ability to form large, intricate parts in a single operation. This capability is particularly valuable in industries such as aerospace, where large panels with complex curves and features are common. The equipment is also designed to minimize material thinning, ensuring that the final product maintains consistent thickness and structural integrity.

Sheet hydroforming equipment often includes advanced features such as automated tool changing, which allows for rapid switching between different dies and materials, and integrated quality control systems, which monitor the forming process in real-time to detect and correct any issues that arise.

Core Keywords: Sheet hydroforming equipment, Hydroform sheet metal machine

Hydroforming Processes and Techniques

Understanding the Hydroforming Process

Hydroforming is a highly versatile and efficient forming process that uses high-pressure fluid to shape metals into complex geometries. This process is primarily employed in two forms: tube hydroforming and sheet hydroforming. Both methods offer unique advantages, making hydroforming a preferred choice in industries where precision, strength, and weight reduction are critical.

At its core, hydroforming involves placing a metal blank or tube into a die and then applying hydraulic pressure to the metal. The pressure forces the metal to conform to the shape of the die, creating a precisely formed part. The process can handle a wide range of materials, including aluminum, steel, stainless steel, and other alloys, each with its specific benefits and challenges.

The key to successful hydroforming lies in carefully controlling the pressure, material flow, and die design to achieve the desired shape without causing defects such as wrinkles, tears, or excessive thinning. This precision is achieved through the use of advanced hydraulic systems, computerized control systems, and meticulously designed dies.

Tube Hydroforming Process

The tube hydroforming process is a specialized technique used to form tubular metal components. This process is particularly valuable in the automotive and aerospace industries, where it is used to create lightweight, structurally sound parts with complex geometries.

In tube hydroforming, a tubular metal blank is placed inside a die, and then internal hydraulic pressure is applied to expand the tube outward until it conforms to the shape of the die. Axial feeding, where the tube is pushed into the die during the forming process, is often used in conjunction with hydraulic pressure to achieve more complex shapes.

The tube hydroforming process can be broken down into several key steps:

- Tube Preparation: The process begins with the selection and preparation of the metal tube, which may involve cutting it to length, cleaning, and lubricating the surface.

- Tube Insertion: The prepared tube is placed into the die, which is designed to match the desired final shape of the component.

- Pressure Application: Hydraulic pressure is applied inside the tube, causing it to expand and conform to the shape of the die. Axial force may also be applied to control the flow of material into the die and ensure uniform wall thickness.

- Forming Completion: Once the tube has fully conformed to the die, the pressure is released, and the formed part is removed from the die.

- Post-Processing: The formed part may undergo additional processes such as trimming, heat treatment, or surface finishing to meet final specifications.

Tube hydroforming offers several advantages, including the ability to create complex, seamless parts with uniform wall thickness and superior strength. The process is also highly efficient, often combining multiple forming steps into a single operation, which reduces production time and costs.

Sheet Hydroforming Process

The sheet hydroforming process is used to form flat metal sheets into three-dimensional shapes, making it ideal for creating intricate parts with smooth surfaces and fine details. This process is widely used in industries such as aerospace, where the ability to produce lightweight, high-strength components is essential.

In sheet hydroforming, a metal sheet is placed over a die, and hydraulic pressure is applied from above, forcing the sheet to conform to the shape of the die. The pressure is typically applied through a flexible diaphragm or directly by a punch, depending on the specific equipment and application.

The sheet hydroforming process can be summarized in the following steps:

- Sheet Preparation: The metal sheet is selected, cut to size, and prepared with any necessary surface treatments such as cleaning or lubrication.

- Sheet Placement: The sheet is positioned over the die, which is mounted on the lower part of the press.

- Pressure Application: Hydraulic pressure is applied through a diaphragm or punch, forcing the sheet to conform to the shape of the die. The pressure is carefully controlled to ensure even forming and avoid defects.

- Forming Completion: Once the sheet has fully conformed to the die, the pressure is released, and the formed part is removed.

- Post-Processing: Like tube hydroforming, sheet hydroformed parts may require additional processes such as trimming, heat treatment, or surface finishing.

Sheet hydroforming offers several distinct advantages. The process allows for the creation of large, complex parts with minimal thinning and excellent surface finish. Additionally, sheet hydroforming can accommodate a wide range of materials, including lightweight alloys like aluminum and high-strength materials like titanium and stainless steel.

Innovations in Hydroforming Technology

Hydroforming technology continues to evolve, with ongoing innovations aimed at improving efficiency, precision, and material capabilities. Some of the latest advancements in hydroforming include:

- Advanced Simulation and Modeling: Modern hydroforming processes benefit from sophisticated simulation software that allows engineers to model and optimize the forming process before actual production. This reduces trial-and-error and helps achieve better results with less material waste.

- Multi-Material Hydroforming: New techniques are being developed to enable the hydroforming of multi-material components, combining metals with different properties to create parts with enhanced performance characteristics.

- High-Speed Hydroforming: Advances in hydraulic systems and control technologies have led to the development of high-speed hydroforming processes, which significantly reduce cycle times and increase production rates.

- Hydroforming of Advanced Materials: Research is ongoing to expand the range of materials that can be effectively hydroformed, including high-strength steels, magnesium alloys, and composites.

- Adaptive Hydroforming: Adaptive control systems that adjust pressure, feed rates, and other parameters in real-time during the forming process are being developed to improve quality and reduce the occurrence of defects.

These innovations are driving the continued adoption of hydroforming in industries where precision, efficiency, and material performance are critical.

Core Keywords: Tube hydroforming machine, Sheet hydroforming machine, Hydroforming metal

Applications of Hydroforming in Various Industries

Automotive Industry

The automotive industry is one of the largest adopters of hydroforming technology, leveraging its unique capabilities to produce lightweight, durable, and complex components. As vehicle manufacturers continuously strive to improve fuel efficiency and meet stringent environmental regulations, hydroforming has become an essential process in automotive production.

Hydroforming is particularly valued for its ability to create high-strength components with complex geometries, often in a single forming step. This ability to consolidate parts not only reduces the overall weight of vehicles but also improves their structural integrity. For example, hydroformed components such as engine cradles, roof rails, and suspension parts are integral to modern automotive designs, contributing to enhanced safety and performance.

Tube hydroforming is widely used in the automotive industry to produce structural components that require both strength and lightness. By using hydroforming to shape tubes into complex forms, manufacturers can create parts that would be difficult or impossible to produce using traditional stamping or welding techniques. These parts often have better load-bearing capacity and can be made with fewer welds, which improves the overall safety of the vehicle.

Another advantage of hydroforming in automotive applications is the reduction in material usage. The process allows for the precise control of material thickness, enabling the production of thinner-walled components without compromising strength. This not only reduces the weight of the vehicle but also leads to material cost savings, making hydroforming an economically attractive option for manufacturers.

Sheet hydroforming is also employed in the automotive sector, particularly for producing body panels and other exterior components that require high precision and surface quality. The ability to form large, intricate shapes with minimal thinning and excellent surface finishes makes sheet hydroforming ideal for creating aesthetically pleasing and aerodynamically efficient vehicle designs.

Aerospace Industry

In the aerospace industry, hydroforming plays a critical role in the fabrication of lightweight, high-precision components that must withstand extreme conditions. The aerospace sector demands materials and processes that offer exceptional strength-to-weight ratios, and hydroforming meets these requirements by enabling the production of complex shapes from high-strength materials like titanium, aluminum, and stainless steel.

Tube hydroforming is used extensively in the aerospace industry to create components such as fuselage sections, engine nacelles, and landing gear parts. These components often require complex shapes and tight tolerances that can be difficult to achieve with conventional forming methods. Hydroforming allows for the creation of seamless, structurally sound parts with uniform wall thickness, which is crucial for maintaining the integrity and performance of aerospace components under high stress.

In addition to structural components, hydroforming is also used to produce intricate parts for aircraft engines, where precision and material integrity are paramount. The ability to form complex geometries with minimal secondary operations reduces the overall weight of the engine, contributing to improved fuel efficiency and performance.

Sheet hydroforming is particularly valuable in the production of large, contoured panels for aircraft bodies and wings. The process allows for the creation of smooth, continuous surfaces with precise curvature, which is essential for aerodynamic performance. The resulting panels are not only lighter but also exhibit superior structural integrity, which is critical for the safety and efficiency of modern aircraft.

Other Industries

Beyond automotive and aerospace, hydroforming is utilized in a variety of other industries where the ability to produce lightweight, durable, and complex components is essential. In the electronics industry, for instance, hydroforming is used to create enclosures and structural parts that require high precision and minimal material usage.

In the HVAC (Heating, Ventilation, and Air Conditioning) sector, hydroforming is employed to produce components such as heat exchangers and ductwork, where the ability to form intricate shapes with thin walls is highly advantageous. The process ensures that these components meet the required performance standards while minimizing material costs and waste.

The furniture industry also benefits from hydroforming, particularly in the production of metal frames and supports for modern furniture designs. The process allows for the creation of sleek, lightweight structures that are both aesthetically pleasing and structurally sound.

In the medical industry, hydroforming is used to produce components for medical devices and equipment, where precision and reliability are critical. The ability to form complex shapes from biocompatible materials like stainless steel and titanium makes hydroforming an ideal choice for medical applications.

Hydroforming’s versatility extends even further, with applications in the production of bicycle frames, exhaust systems, musical instruments, and artistic sculptures. The process’s ability to create strong, lightweight, and intricate components from a wide range of materials continues to open new possibilities across various industries.

Core Keywords: Hydroforming stainless steel, Hydroform sheet metal machine, Hydroforming metal

Advantages and Challenges of Hydroforming

Advantages

Hydroforming offers numerous advantages that make it a preferred manufacturing process in industries where precision, efficiency, and material utilization are critical. Below are some of the key benefits of hydroforming:

- Material Efficiency: Hydroforming allows for the production of parts with uniform wall thickness and complex shapes in a single forming step. This efficiency reduces material waste, as the process can precisely control material flow and thinning. The ability to use thinner sheets or tubes without sacrificing strength contributes to significant cost savings, particularly when working with expensive materials like titanium or stainless steel.

- Weight Reduction: One of the most significant advantages of hydroforming is its ability to create lightweight components without compromising structural integrity. By optimizing the strength-to-weight ratio of parts, hydroforming enables the production of components that are lighter than those made with traditional methods, making it ideal for applications in the automotive and aerospace industries, where weight reduction is paramount for fuel efficiency and performance.

- Enhanced Strength and Durability: The hydroforming process enhances the mechanical properties of the formed parts. The uniform distribution of material and the elimination of welds (common in multi-piece assemblies) result in components with superior strength and durability. This improved structural integrity is especially important in applications where parts are subjected to high stress or harsh operating conditions.

- Design Flexibility: Hydroforming offers unparalleled design flexibility, allowing for the creation of complex geometries that would be challenging or impossible to achieve with conventional stamping or machining processes. This flexibility enables manufacturers to design parts with integrated features, such as flanges, ribs, or holes, reducing the need for additional processing steps and assembly operations.

- Surface Finish Quality: The high-pressure forming process used in hydroforming ensures excellent surface finishes, which often require little to no post-processing. This is particularly beneficial for parts that require a high degree of aesthetic appeal or where smooth surfaces are essential for performance, such as in aerodynamic components.

- Cost-Effectiveness: Despite the initial investment in hydroforming equipment, the process can be highly cost-effective in the long run. The reduction in material waste, elimination of secondary operations, and the ability to produce complex parts in a single step contribute to lower overall production costs. Additionally, the durability of hydroformed parts reduces the need for frequent replacements, further driving down lifecycle costs.

Challenges

While hydroforming offers many advantages, it also presents certain challenges that must be carefully managed to ensure successful implementation:

- High Initial Investment: The cost of acquiring and setting up hydroforming equipment can be significant. This includes the cost of the press, dies, hydraulic systems, and control systems, as well as the infrastructure required to support these components. For smaller manufacturers or those producing lower volumes, the initial investment may be a barrier to entry.

- Complexity of Tooling: The design and fabrication of hydroforming dies are complex and require a high level of expertise. The dies must be precisely engineered to accommodate the specific material properties, desired part geometry, and the dynamics of the hydroforming process. Any errors in die design can result in defects in the final part, leading to costly rework or scrap.

- Material Limitations: While hydroforming is versatile and can handle a wide range of materials, there are limitations. Materials with low ductility or those prone to cracking under high pressure may not be suitable for hydroforming. Additionally, certain materials require specialized handling or processing conditions, which can complicate the hydroforming process.

- Process Control: Achieving consistent results in hydroforming requires precise control of process parameters such as pressure, material feed rates, and temperature. Variations in these parameters can lead to defects such as wrinkles, tears, or uneven wall thickness. Advanced control systems and real-time monitoring are essential to maintaining process stability and ensuring the quality of the final parts.

- Limited Material Flow: In some cases, the material may not flow sufficiently to fill the entire die cavity, leading to incomplete or malformed parts. This is particularly challenging when forming very complex shapes or when working with materials that have low elongation capabilities. To address this, careful consideration must be given to the design of the dies and the selection of process parameters.

Environmental Impact

Hydroforming has a favorable environmental profile compared to traditional manufacturing processes. The reduction in material waste, energy efficiency, and elimination of welding and other secondary operations contribute to a lower overall environmental impact. Additionally, the ability to produce lightweight components plays a significant role in reducing the fuel consumption and emissions of vehicles and aircraft, contributing to broader sustainability goals.

However, the use of hydraulic fluids and the disposal of used materials must be managed carefully to avoid environmental contamination. Advances in fluid recycling and the development of eco-friendly hydraulic fluids are helping to mitigate these concerns, making hydroforming an increasingly sustainable manufacturing option.

Core Keywords: Hydroforming metal, Hydroforming stainless steel

Hydroforming in Türkiye: A Growing Industry

Current State of Hydroforming in Türkiye

Türkiye has rapidly emerged as a significant player in the global hydroforming industry, leveraging its strategic location, growing industrial base, and skilled workforce. The country’s manufacturing sector, particularly in automotive and aerospace, has embraced hydroforming technology to meet the increasing demand for lightweight, high-strength components. This adoption is driven by both domestic manufacturers and international companies that have established operations in Türkiye to capitalize on its competitive advantages.

The hydroforming industry in Türkiye is characterized by a diverse range of applications, from the production of automotive parts to aerospace components. The automotive sector, in particular, has seen substantial growth, with Turkish manufacturers utilizing hydroforming to produce chassis components, exhaust systems, and structural elements. This growth is supported by Türkiye’s strong automotive industry, which is among the largest in Europe and continues to attract significant foreign investment.

In the aerospace sector, Turkish companies are increasingly adopting hydroforming to manufacture high-precision components such as fuselage panels, engine parts, and landing gear elements. The country’s growing role as a hub for aerospace manufacturing, coupled with its focus on innovation and quality, positions Türkiye as a key player in the global hydroforming landscape.

Key Players and Manufacturers

Several key players have emerged in the Turkish hydroforming industry, ranging from established manufacturers to innovative startups. These companies are driving the adoption of hydroforming technology and contributing to the industry’s growth through investments in advanced equipment, research and development, and workforce training.

Future Prospects

The future of hydroforming in Türkiye looks promising, with several factors contributing to the industry’s expected growth. The increasing demand for lightweight, high-strength components in automotive and aerospace applications is likely to drive further adoption of hydroforming technology. Additionally, Türkiye’s strategic location as a bridge between Europe and Asia makes it an attractive destination for foreign investment, which is expected to bolster the hydroforming industry.

Research and development will play a critical role in the future of hydroforming in Türkiye. Companies and academic institutions are increasingly collaborating on projects aimed at advancing hydroforming techniques, improving material capabilities, and developing more efficient processes. These efforts are expected to lead to innovations that will further enhance the competitiveness of Turkish manufacturers on the global stage.

Moreover, the Turkish government’s support for industrial growth, including incentives for technology adoption and export promotion, is likely to fuel the expansion of the hydroforming industry. As Türkiye continues to strengthen its position as a manufacturing hub, the demand for hydroforming equipment and expertise is expected to rise, creating new opportunities for both domestic and international companies.

In conclusion, Hydroforming in Türkiye is poised for significant growth, driven by the country’s robust industrial base, strategic investments in technology, and a focus on innovation. As the global demand for advanced manufacturing solutions continues to rise, Türkiye’s hydroforming industry is well-positioned to capitalize on these trends and contribute to the future of manufacturing.

Core Keywords: Hydroforming Türkiye, Hydroform sheet metal machine

Selecting the Right Hydroforming Equipment and Press

Factors to Consider

Selecting the right hydroforming equipment and press is a crucial decision that can significantly impact the efficiency, quality, and cost-effectiveness of your manufacturing operations. When choosing hydroforming equipment, several factors must be considered to ensure that the selected system meets the specific needs of your production environment.

- Material Type: The type of material you intend to form plays a significant role in determining the appropriate hydroforming equipment. Different materials, such as aluminum, stainless steel, titanium, and high-strength alloys, have varying properties that require specific handling. For example, materials like titanium and stainless steel require presses capable of generating higher pressures to achieve the desired shapes without compromising material integrity.

- Production Volume: The scale of production is another critical factor. High-volume production environments may require more robust, automated hydroforming presses that can handle continuous operation with minimal downtime. Conversely, for low-volume or specialized production, a more flexible, adaptable system might be more appropriate, allowing for quick tool changes and customization.

- Part Complexity: The complexity of the parts you need to produce will influence the choice of equipment. Highly intricate components with complex geometries may require advanced hydroforming presses with precise control over pressure, material flow, and tooling. Multi-axis control systems and sophisticated die designs are often necessary to achieve the high precision required for these parts.

- Tolerances and Precision: If your parts require tight tolerances and high precision, it’s essential to select equipment that offers fine control over the forming process. This includes the ability to adjust pressure and material feed rates in real-time, as well as advanced monitoring systems that can detect and correct any deviations from the desired specifications.

- Size and Shape of Parts: The physical size and shape of the parts being produced are also important considerations. Larger parts may require larger presses with greater tonnage capabilities, while smaller, more delicate parts may benefit from equipment designed for precision and gentle handling. The choice of die size and press capacity should align with the dimensions and weight of the components you plan to manufacture.

- Customization and Flexibility: Consider whether the hydroforming equipment offers the flexibility to accommodate different materials, part sizes, and geometries. This is particularly important in industries where product designs frequently change or where multiple products are produced using the same equipment. Equipment that allows for quick tool changes and process adjustments can be invaluable in such environments.

Customization and Vendor Selection

Customization is often necessary when selecting hydroforming equipment, as each manufacturing environment has unique requirements. Many equipment manufacturers offer custom solutions tailored to specific industry needs, whether it’s adapting the press for particular materials, integrating automation systems, or designing specialized dies.

When selecting a vendor, consider the following factors:

- Experience and Expertise: Choose a vendor with a proven track record in hydroforming technology, particularly in your specific industry. Experienced vendors can provide valuable insights into the best practices and innovations that can enhance your manufacturing process.

- Support and Service: Ensure that the vendor offers comprehensive support services, including installation, training, maintenance, and troubleshooting. Reliable after-sales support is critical to minimizing downtime and ensuring the smooth operation of your equipment.

- Technology and Innovation: Look for vendors that are at the forefront of hydroforming technology, offering the latest advancements in equipment design, control systems, and process optimization. Cutting-edge technology can provide a competitive advantage by improving efficiency, precision, and product quality.

- Customization Options: Assess the vendor’s ability to provide customized solutions that meet your specific needs. This could involve modifying existing equipment or designing entirely new systems to accommodate unique production requirements.

- Cost and Return on Investment (ROI): While cost is an important factor, it’s essential to consider the long-term ROI of the equipment. Investing in high-quality, reliable hydroforming equipment may have a higher upfront cost but can result in significant savings over time through improved efficiency, reduced waste, and lower maintenance costs.

By carefully evaluating these factors and selecting the right equipment and vendor, you can optimize your hydroforming operations for maximum efficiency and quality.

Core Keywords: Hydroforming Press, Sheet hydroforming equipment, Hydropress forming machine

Case Studies and Real-world Applications

Case Study 1: Automotive Industry

In the automotive industry, hydroforming has become a key technology for producing lightweight and durable vehicle components. A prime example of hydroforming’s application can be seen in the manufacturing of engine cradles and subframes for high-performance vehicles.

Background: A leading automotive manufacturer sought to reduce the weight of its vehicles to improve fuel efficiency and performance. The traditional method of assembling subframes involved multiple stamped steel parts welded together, resulting in a heavier structure with numerous potential points of failure.

Hydroforming Solution: The manufacturer adopted tube hydroforming to produce a one-piece engine cradle and subframe. By using hydroforming, the company was able to create complex, hollow structures that were both lighter and stronger than the multi-piece assemblies previously used. The hydroformed parts had fewer welds, which reduced the potential for failure and improved the overall strength and durability of the components.

Outcome: The switch to hydroforming resulted in a 20% reduction in the weight of the subframe, contributing to improved vehicle fuel efficiency and handling. Additionally, the simplified manufacturing process led to cost savings by reducing the number of components and assembly steps. The success of this application has led the manufacturer to expand the use of hydroforming across other vehicle components, further enhancing the performance and efficiency of their vehicles.

Case Study 2: Aerospace Industry

The aerospace industry demands components that are both lightweight and capable of withstanding extreme conditions. A notable case study involves the use of hydroforming in the production of aircraft fuselage panels.

Background: An aerospace manufacturer faced the challenge of producing large, curved fuselage panels that required precise shaping and a high strength-to-weight ratio. The traditional methods of forming these panels involved multiple stages of stamping and welding, which added weight and compromised the structural integrity of the final product.

Hydroforming Solution: The manufacturer implemented sheet hydroforming to produce the fuselage panels. This process allowed for the forming of large, complex shapes in a single operation, with precise control over material thickness and minimal residual stresses. The hydroforming press used was capable of applying uniform pressure across the entire surface of the metal sheet, ensuring a smooth and consistent finish.

Outcome: The hydroformed fuselage panels were significantly lighter than their traditionally manufactured counterparts, leading to an overall reduction in the aircraft’s weight. This reduction translated into improved fuel efficiency and payload capacity. Furthermore, the superior surface finish and dimensional accuracy achieved through hydroforming reduced the need for secondary machining operations, thereby lowering production costs and time.

Additional Real-world Applications

- Bicycle Frame Manufacturing: Hydroforming is widely used in the production of lightweight and strong bicycle frames. By using tube hydroforming, manufacturers can create frames with intricate geometries that optimize strength and stiffness while minimizing weight. This has led to the production of high-performance bicycles that are both durable and responsive.

- HVAC Systems: In the HVAC industry, hydroforming is used to produce components such as heat exchanger plates and ductwork. The ability to form complex shapes with precise dimensions ensures that these components meet the required performance standards for energy efficiency and durability.

- Medical Devices: Hydroforming is employed in the medical industry to manufacture components for medical devices, such as surgical instruments and implants. The process allows for the creation of intricate, biocompatible parts with high precision, which is critical for ensuring the safety and effectiveness of medical devices.

- Furniture and Home Appliances: Hydroforming is also used in the production of metal frames for furniture and structural components for home appliances. The process allows for the creation of sleek, modern designs that are both aesthetically pleasing and structurally sound.

These case studies and examples demonstrate the versatility and effectiveness of hydroforming across a wide range of industries. The ability to produce complex, lightweight, and durable components with high precision makes hydroforming an invaluable technology in modern manufacturing.

EMS Metalworking Machines

We design, manufacture and assembly metalworking machinery such as:

- Hydraulic transfer press

- Glass mosaic press

- Hydraulic deep drawing press

- Casting press

- Hydraulic cold forming press

- Hydroforming press

- Composite press

- Silicone rubber moulding press

- Brake pad press

- Melamine press

- SMC & BMC Press

- Labrotaroy press

- Edge cutting trimming machine

- Edge curling machine

- Trimming beading machine

- Trimming joggling machine

- Cookware production line

- Pipe bending machine

- Profile bending machine

- Bandsaw for metal

- Cylindrical welding machine

- Horizontal pres and cookware

- Kitchenware, hotelware

- Bakeware and cuttlery production machinery

as a complete line as well as an individual machine such as:

- Edge cutting trimming beading machines

- Polishing and grinding machines for pot and pans

- Hydraulic drawing presses

- Circle blanking machines

- Riveting machine

- Hole punching machines

- Press feeding machine

You can check our machinery at work at: EMS Metalworking Machinery – YouTube

Applications:

Flange-punching

Beading and ribbing

Flanging

Trimming

Curling

Lock-seaming

Ribbing