Wheel forming machines, also known as rim forming machines or wheel spinning machines, are specialized equipment used in the manufacturing of wheels for various applications, ranging from automotive to aerospace industries. These machines employ a process called flow forming or spin forming to shape metal discs or blanks into wheel rims with precise dimensions, mechanical properties, and surface finishes.

Wheel forming machines, often referred to as pottery wheels, are the unsung heroes of the ceramic arts. These seemingly simple machines have captivated artists and hobbyists for centuries, offering a unique blend of precision and creative freedom. While the core concept might appear straightforward – a spinning platform for shaping clay – the world of wheel forming machines is surprisingly intricate, catering to a diverse range of skill levels and artistic visions.

For the beginner, a basic wheel forming machine offers a gateway into the world of ceramics. These machines typically feature a sturdy base supporting a rotating wheelhead, often crafted from durable aluminum or ceramic. Variable speed control allows artists to find their comfort zone, starting slow for centering clay and gradually increasing the speed for shaping. A foot pedal, a key feature of most wheels, frees the artist’s hands to manipulate the clay, allowing for a more intuitive and fluid creative process.

As artists progress, their needs evolve. Intermediate and advanced wheel forming machines introduce a new level of sophistication. Double-bearing construction ensures smooth and balanced rotation, even under heavy pressure. Interchangeable bat heads, the removable tops of the wheelhead, offer a variety of diameters to accommodate different project sizes. Some models even boast splash pans for catching excess water, keeping the working environment clean and organized.

But wheel forming machines are more than just workhorses for shaping clay. They are canvases for artistic expression. Advanced models may feature digital readouts displaying speed and allowing for precise adjustments. For artists who favor larger pieces, some machines offer the option of a counter-rotating head, allowing the artist to throw while the wheel spins in the opposite direction, creating a more stable platform for manipulating larger clay masses.

Beyond basic functionality, a plethora of accessories further expand the creative possibilities. Trimming tools, attached to the machine’s base, enable the precise shaping of finished pieces once they’ve hardened slightly. Ribs, tools with various textures, can be used to add decorative elements to the clay surface while it’s still spinning. Specialized bats with pre-formed shapes can be used for creating specific forms, like bowls or cups, with ease.

The world of wheel forming machines isn’t limited to functionality. Aesthetes will appreciate the sleek designs of modern machines, often boasting clean lines and a minimalist aesthetic. Some manufacturers even offer a range of color options, allowing artists to personalize their workspace and express their individuality.

The impact of wheel forming machines extends far beyond the walls of a pottery studio. They play a vital role in education, fostering creativity and providing a hands-on learning experience for students of all ages. In therapeutic settings, wheel forming offers a calming and therapeutic outlet, allowing individuals to find solace and express themselves through the tactile nature of working with clay.

In conclusion, wheel forming machines are far more than just spinning platforms. They are the catalysts for creative expression, the tools that transform a lump of clay into a work of art. From the basic models empowering beginners to the feature-rich machines catering to seasoned artists, wheel forming machines are the foundation upon which ceramic artistry is built. So, the next time you admire a beautifully crafted ceramic piece, remember, the journey likely began with the gentle spin of a wheel forming machine.

Wheel Forming Machines

Wheel forming machines, often referred to as pottery wheels, are the unsung heroes of the ceramic arts. These seemingly simple machines have captivated artists and hobbyists for centuries, offering a unique blend of precision and creative freedom. While the core concept might appear straightforward – a spinning platform for shaping clay – the world of wheel forming machines is surprisingly intricate, catering to a diverse range of skill levels and artistic visions.

A Symphony of Shapes: Exploring Wheel Types

The magic of wheel forming extends beyond the machine itself. The type of wheel used plays a crucial role in the artist’s creative process and the final form of the piece. Here’s a glimpse into the diverse world of wheel types:

- Standard Wheel: The workhorse of the pottery studio, the standard wheel features a flat throwing surface, typically 12-14 inches in diameter. This versatile option is ideal for throwing a wide range of shapes, from bowls and mugs to plates and vases.

- Bat System Wheels: For artists who favor larger pieces, bat system wheels offer the advantage of interchangeable bat heads. These bats come in various sizes and shapes, allowing for the creation of specific forms with greater ease. Imagine throwing a large platter on a pre-formed bat head – a breeze compared to throwing it on a standard wheel.

- Rib Cage Wheels: These specialized wheels feature a built-in “rib cage” around the perimeter of the throwing surface. These ribs serve a dual purpose – providing support for the artist’s hands while throwing and allowing for the creation of textured surfaces on the clay. Imagine effortlessly adding a ribbed pattern to a vase while it spins on the wheel.

- Counter-Rotating Wheels: For artists venturing into the realm of truly massive pieces, counter-rotating wheels offer a unique advantage. These wheels feature a head that spins in the opposite direction of the artist’s manipulation. This counter-rotation provides a more stable platform for handling large clay bodies, preventing them from collapsing under their own weight.

Beyond Basic Functionality: A World of Creative Possibilities

Of course, wheel types are just one element in the vast world of wheel forming. Variable speed control, interchangeable bat heads, and a plethora of accessories further expand the creative possibilities. From trimming tools for precise shaping to specialized bats for specific forms, wheel forming machines offer a platform for artistic exploration unlike any other.

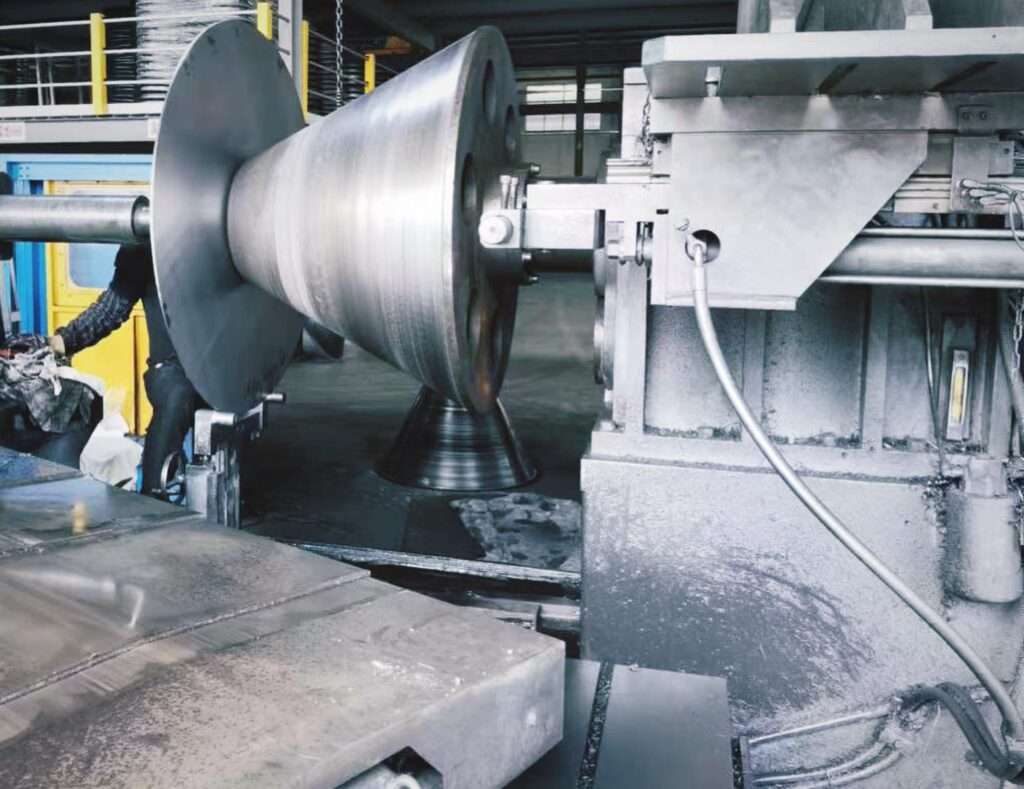

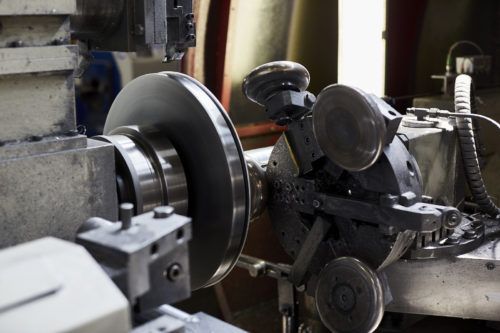

Wheel forming machines operate on principles similar to other flow forming processes:

- Workpiece Mounting: A metal disc or blank is securely mounted onto the machine’s mandrel or chuck. The workpiece can be made from materials such as aluminum, steel, or alloys.

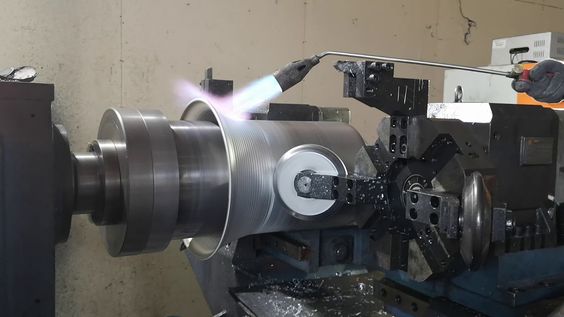

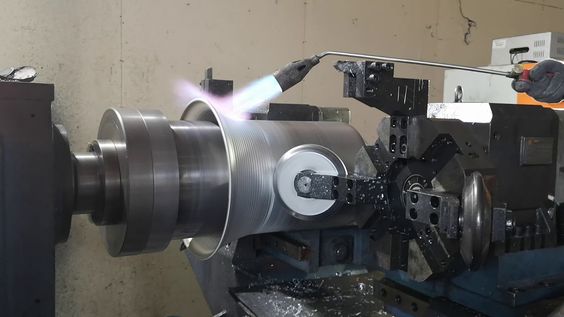

- Rotation and Axial Pressure: The machine rotates the workpiece at high speeds while applying axial pressure using rollers or tooling. This combination of spinning motion and pressure causes the metal to deform plastically and flow into the desired shape.

- Incremental Forming: Wheel forming is an incremental process where the shape of the wheel rim is formed gradually by controlling the movement of the forming tools along the length of the workpiece.

- Material Flow and Deformation: As the workpiece spins, the rollers or tools exert radial pressure, forcing the metal to flow and stretch. This controlled deformation refines the material’s grain structure and enhances its mechanical properties.

- Precision Control: Modern wheel forming machines utilize computer numerical control (CNC) systems to precisely regulate the forming process parameters, including rotational speed, pressure, tool movements, and shaping sequences.

Key Components of the Wheel Forming Machines

Wheel forming machines consist of several essential components:

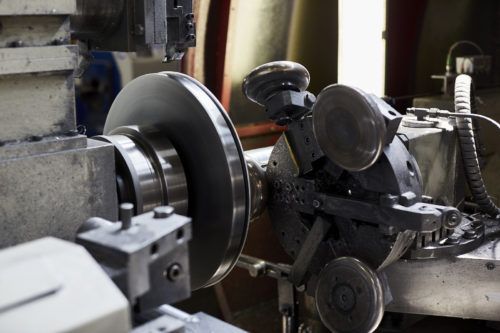

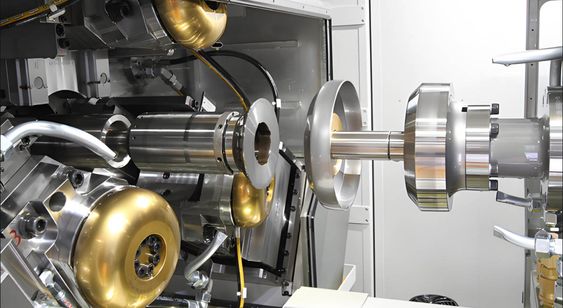

- Mandrel or Chuck: The workpiece is mounted onto a rotating mandrel or chuck, providing stability and support during the forming process.

- Rollers or Tooling: These components apply pressure to the rotating workpiece, shaping it into the desired wheel rim profile. The rollers can be adjusted to achieve different rim shapes and sizes.

- Drive System: Equipped with a powerful motor and drive mechanism to achieve high-speed rotation of the workpiece. Variable speed control allows for precise process optimization.

- Control System: Utilizes advanced CNC systems to control and monitor the forming process parameters, ensuring consistent quality and dimensional accuracy of the finished wheel rims.

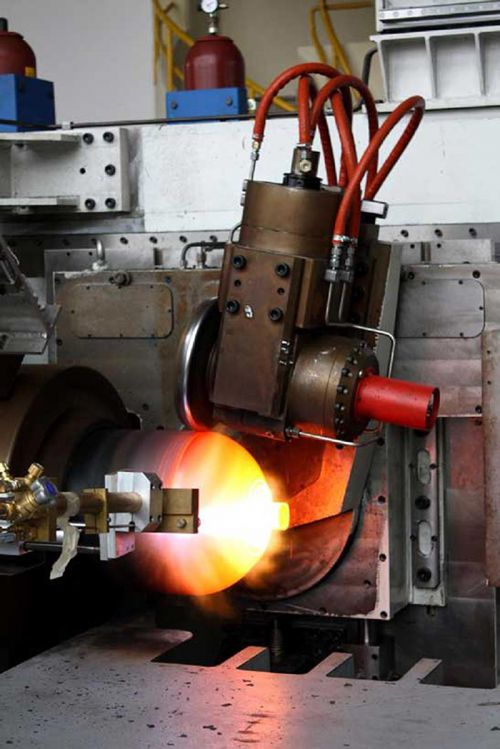

- Coolant System: Incorporates coolant systems to manage heat generated during the forming process, maintaining optimal working temperatures and preventing material overheating.

Parts of a Wheel Forming Machine

Wheel forming machines, used primarily in the automotive industry, are specialized CNC machines designed to manufacture wheels with precision and efficiency. These machines incorporate several key components that work together to shape and finish the wheel. Here are the main parts of a wheel forming machine:

1. Bed

- Function: Provides the foundation for the entire machine, ensuring stability and support for all components.

- Characteristics: Usually made from heavy-duty cast iron or steel to absorb vibrations and maintain precision.

2. Spindle

- Function: Holds and rotates the workpiece (wheel blank) during the forming process.

- Characteristics: High torque and speed capabilities, often supported by precision bearings for smooth rotation.

The spindle is one of the most critical components of a wheel forming machine, playing a central role in the manufacturing process. Here’s an in-depth look at the spindle’s function, characteristics, and importance:

Function

- Rotation: The primary function of the spindle is to rotate the wheel blank at high speeds during the forming process.

- Support: Provides the necessary support to the wheel blank, ensuring stability and precise alignment.

- Power Transmission: Transmits the mechanical power from the drive motor to the wheel blank, enabling the forming tools to shape the material accurately.

Characteristics

- Material: Made from high-strength, durable materials such as hardened steel or alloy to withstand the stresses of high-speed rotation and forming forces.

- Bearings: Equipped with precision bearings that support smooth and stable rotation, reducing friction and wear.

- Speed Control: Capable of varying speeds to accommodate different materials and forming requirements, controlled by the CNC system.

- Torque: Designed to provide high torque for effective forming, especially when working with harder materials.

- Cooling: Often includes cooling channels or external cooling systems to manage heat generated during operation.

- Mounting System: Features a robust mounting system for secure attachment to the machine bed and integration with the drive motor.

Importance in Wheel Forming Machines

- Precision: The spindle’s ability to maintain precise rotational speed and stability is crucial for achieving the high precision required in wheel forming.

- Consistency: Ensures consistent quality in the final product by maintaining uniform rotation and minimizing variations during the forming process.

- Efficiency: High-speed operation and reliable power transmission enable efficient production, reducing cycle times and increasing throughput.

- Durability: The robust construction of the spindle ensures long-term reliability and reduces maintenance needs, minimizing downtime.

Components of the Spindle System

- Spindle Shaft: The main rotating element that holds and turns the wheel blank.

- Bearings: Precision bearings support the spindle shaft, ensuring smooth and stable rotation.

- Drive Motor: Provides the power to rotate the spindle. Can be an electric motor with variable speed control.

- Mounting Flange: The interface for attaching the spindle to the machine bed, ensuring secure and accurate positioning.

- Chucks or Collets: Clamping devices attached to the spindle that securely hold the wheel blank during the forming process.

- Cooling System: May include internal cooling channels or an external cooling system to manage heat and protect the spindle and bearings from overheating.

- Sensors: Integrated sensors monitor rotational speed, temperature, and other parameters, providing feedback to the CNC controller for precise control.

Spindle Operation in Wheel Forming

- Loading: The wheel blank is mounted onto the spindle using chucks or collets. The spindle holds the blank securely in place.

- Rotation: The drive motor powers the spindle, rotating the wheel blank at the programmed speed.

- Forming: As the spindle rotates the blank, forming rollers or tools apply pressure to shape the material. The spindle ensures the blank rotates smoothly and consistently.

- Cooling and Monitoring: The cooling system manages heat, while sensors provide real-time feedback to ensure optimal operation.

- Unloading: Once the forming process is complete, the spindle stops, and the finished wheel is removed.

Types of Spindles in Wheel Forming Machines

- Direct-Drive Spindle: The drive motor is directly connected to the spindle shaft, providing high precision and efficiency.

- Belt-Drive Spindle: Uses a belt to transmit power from the motor to the spindle. Offers flexibility in speed adjustment but may introduce slight variations in torque.

- Gear-Drive Spindle: Employs gears to transmit power, offering high torque and robust performance but may be noisier and require more maintenance.

Conclusion

The spindle is a vital component of wheel forming machines, ensuring the precise and efficient rotation of the wheel blank during the forming process. Its design and performance directly impact the quality, consistency, and productivity of the wheel manufacturing process.

3. Chucks

- Function: Clamps the wheel blank securely in place on the spindle.

- Characteristics: Adjustable to accommodate different wheel sizes and designs, can be mechanical or hydraulic.

4. Tool Turret

- Function: Holds multiple forming tools and can automatically switch between them during the forming process.

- Characteristics: CNC-controlled for precise tool positioning, often with quick-change capabilities to reduce downtime.

5. Forming Rollers

- Function: Apply controlled pressure to shape the wheel blank into the desired profile.

- Characteristics: Made from high-strength materials to withstand the forces involved, often cooled and lubricated during operation.

6. Tailstock

- Function: Provides additional support for the wheel blank, especially for larger wheels, and ensures alignment during forming.

- Characteristics: Can be moved along the bed to accommodate different wheel lengths, typically CNC-controlled for precise positioning.

7. CNC Controller

- Function: The brain of the machine, it interprets the CNC code and controls all movements and operations.

- Characteristics: Includes a user interface for programming and monitoring, with capabilities for storing and executing complex forming sequences.

8. Hydraulic System

- Function: Powers the movement of the chucks, tailstock, and sometimes the forming rollers.

- Characteristics: Provides high force and precision control, critical for maintaining the necessary pressure during forming.

9. Coolant System

- Function: Delivers coolant to the forming area to manage heat and reduce tool wear.

- Characteristics: Includes pumps, nozzles, and filtration systems to keep the coolant clean and effective.

10. Chip Management System

- Function: Collects and removes metal shavings and debris generated during the forming process.

- Characteristics: Typically includes chip conveyors and filtration systems to keep the work area clean.

11. Safety Enclosures

- Function: Protects the operator and environment from flying debris and moving parts.

- Characteristics: Often equipped with interlocks and emergency stop buttons for added safety.

12. Sensors and Feedback Systems

- Function: Monitor the machine’s operations and provide real-time feedback to the CNC controller.

- Characteristics: Include position sensors, load sensors, and temperature sensors to ensure precise control and maintain quality.

13. Drive Motors

- Function: Provide the necessary power to the spindle, tool turret, and other moving components.

- Characteristics: High-performance motors capable of delivering consistent power and speed control.

14. Forming Dies

- Function: Used in some wheel forming machines to help shape the wheel blank into complex profiles.

- Characteristics: Custom-designed for specific wheel designs, made from hardened materials to withstand repeated use.

Summary of Process

- Loading: The wheel blank is loaded onto the spindle and clamped securely by the chucks.

- Forming: The spindle rotates the wheel blank while the forming rollers apply pressure to shape it. The tailstock provides additional support.

- Tool Changes: The tool turret switches between different forming tools as needed, controlled by the CNC system.

- Cooling: Coolant is applied to manage heat and protect the tools.

- Monitoring: Sensors provide real-time feedback to the CNC controller to ensure precision.

- Unloading: The finished wheel is unclamped and removed from the machine.

Wheel forming machines are highly specialized and incorporate advanced technology to produce high-quality wheels efficiently and with great precision, ensuring consistency and durability in the final products.

Applications

Wheel forming technology is widely used in various industries for manufacturing different types of wheels:

- Automotive Industry: Wheel forming machines are used to produce automotive wheels, including steel wheels, aluminum alloy wheels, and specialty wheels for performance vehicles. Flow-formed wheels are known for their lightweight construction, strength, and precise geometry.

- Aerospace Sector: In aerospace applications, wheel forming machines are employed to manufacture aircraft landing gear wheels, helicopter rotor hubs, and satellite reaction wheels. The process ensures the production of high-strength, lightweight components critical for aircraft performance and safety.

- Industrial and Heavy Machinery: Wheel forming is used in the production of wheels for industrial machinery, construction equipment, agricultural vehicles, and material handling equipment. Flow-formed wheels offer durability and reliability in demanding operating conditions.

- Consumer Goods: Flow-formed wheels are also used in the production of bicycle wheels, motorcycle wheels, and recreational vehicles. The process allows for the fabrication of lightweight, durable wheels suitable for various leisure and transportation applications.

Advantages

Wheel forming machines, often referred to as pottery wheels, are the unsung heroes of the ceramic arts. These seemingly simple machines have captivated artists and hobbyists for centuries, offering a unique blend of precision and creative freedom. While the core concept might appear straightforward – a spinning platform for shaping clay – the world of wheel forming machines is surprisingly intricate, catering to a diverse range of skill levels and artistic visions.

A Symphony of Shapes: Exploring Wheel Types

The magic of wheel forming extends beyond the machine itself. The type of wheel used plays a crucial role in the artist’s creative process and the final form of the piece. Here’s a glimpse into the diverse world of wheel types:

- Standard Wheel: The workhorse of the pottery studio, the standard wheel features a flat throwing surface, typically 12-14 inches in diameter. This versatile option is ideal for throwing a wide range of shapes, from bowls and mugs to plates and vases.

- Bat System Wheels: For artists who favor larger pieces, bat system wheels offer the advantage of interchangeable bat heads. These bats come in various sizes and shapes, allowing for the creation of specific forms with greater ease. Imagine throwing a large platter on a pre-formed bat head – a breeze compared to throwing it on a standard wheel.

- Rib Cage Wheels: These specialized wheels feature a built-in “rib cage” around the perimeter of the throwing surface. These ribs serve a dual purpose – providing support for the artist’s hands while throwing and allowing for the creation of textured surfaces on the clay. Imagine effortlessly adding a ribbed pattern to a vase while it spins on the wheel.

- Counter-Rotating Wheels: For artists venturing into the realm of truly massive pieces, counter-rotating wheels offer a unique advantage. These wheels feature a head that spins in the opposite direction of the artist’s manipulation. This counter-rotation provides a more stable platform for handling large clay bodies, preventing them from collapsing under their own weight.

From Studio to Factory: The Journey of Manufactured Wheels

While the artistry of the wheel forming machine lies in shaping clay, there’s a whole other world of wheel forming happening in factories. Here, the focus shifts from artistic expression to mass production, with high-tech machinery churning out wheels for vehicles of all shapes and sizes.

The Birth of a Wheel: Manufacturing Processes

There are two primary methods for manufacturing wheels: casting and forging.

- Casting: This widely used process starts with molten metal, typically aluminum alloy, being poured into a mold shaped like the final wheel. Once cooled and solidified, the rough cast wheel undergoes a machining process to achieve its final dimensions and surface finish. Casting is a cost-effective method suitable for high-volume production.

- Forging: This process involves heating a solid metal billet (a cylindrical block) and then using immense pressure to shape it into the desired wheel form. Forging results in a stronger, lighter wheel compared to casting, but it’s also a more expensive and time-consuming process.

Beyond Basic Functionality: A World of Creative Possibilities

Of course, wheel types are just one element in the vast world of wheel forming. Variable speed control, interchangeable bat heads, and a plethora of accessories further expand the creative possibilities for the artist. From trimming tools for precise shaping to specialized bats for specific forms, wheel forming machines offer a platform for artistic exploration unlike any other.

Wheel forming technology offers several advantages over traditional wheel manufacturing methods:

- High Strength-to-Weight Ratio: Flow-formed wheels exhibit excellent mechanical properties, including high strength and durability, while maintaining a lightweight design.

- Precision and Consistency: CNC-controlled wheel forming machines ensure precise dimensional accuracy and uniformity of wheel rims, reducing the need for secondary machining operations.

- Material Savings: Flow forming minimizes material waste compared to casting or forging processes, resulting in cost savings and efficient material utilization.

- Customization: The flexibility of wheel forming machines allows for the production of customized wheel designs and sizes to meet specific customer requirements.

- Enhanced Performance: Flow-formed wheels are known for their superior performance characteristics, including improved vehicle handling, fuel efficiency, and ride comfort.

In summary, wheel forming machines play a critical role in the manufacturing of high-quality wheels for automotive, aerospace, industrial, and consumer applications. The technology continues to evolve with advancements in materials science and manufacturing processes, driving innovation and efficiency in wheel production across industries globally.

Article on Metal Spinning, Flow Forming, Shear Forming, and Wheel Forming Machines

Metal forming processes are integral to modern manufacturing, enabling the production of complex and precise components across various industries. Among these processes, metal spinning, flow forming, shear forming, and wheel forming stand out due to their unique methodologies and wide-ranging applications. Each process offers distinct advantages, making them suitable for different industrial requirements.

The importance of these metal forming techniques cannot be overstated, as they play a crucial role in the automotive, aerospace, military, and industrial sectors. From producing lightweight components for aircraft to manufacturing robust parts for automobiles, these processes contribute significantly to technological advancement and economic growth.

In this article, we will delve into the intricacies of metal spinning, flow forming, shear forming, and wheel forming machines. We will explore their principles, processes, machines, applications, advantages, and challenges. By understanding these processes, manufacturers and engineers can make informed decisions about the best techniques to employ for specific projects.

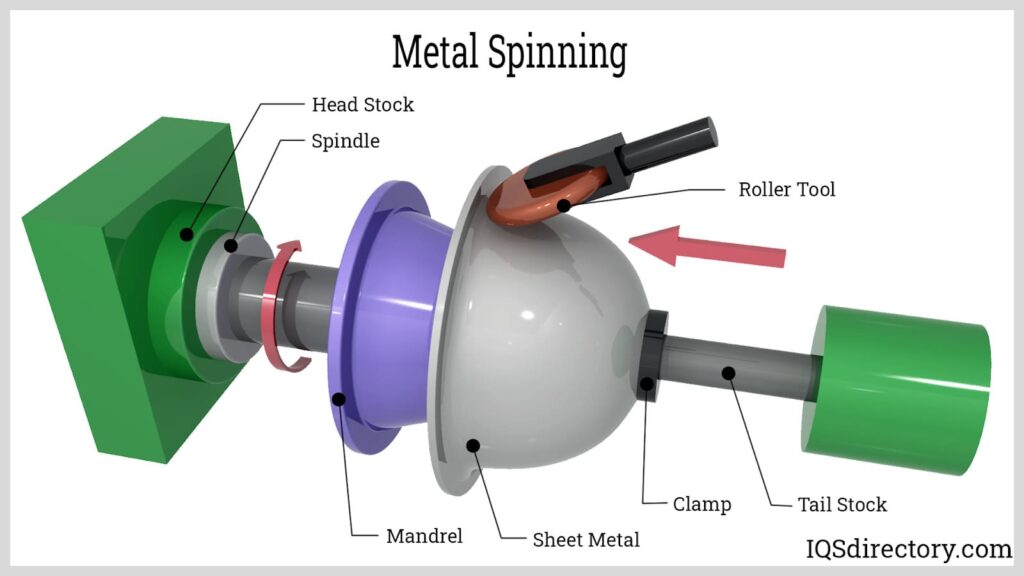

2. Metal Spinning

Principles and Process

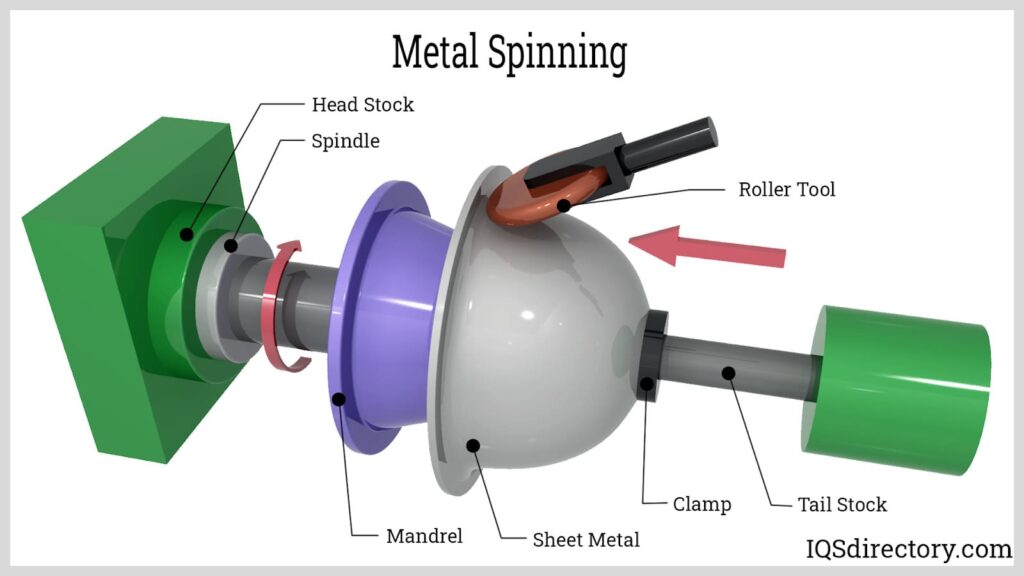

Metal spinning, also known as spin forming or spinning, is a metalworking process that forms a sheet or tube of metal into an axially symmetric part. This process involves rotating a metal disc or tube at high speed while applying pressure with a tool to shape the metal around a mandrel. The metal is stretched and compressed, resulting in a seamless, symmetrical shape.

Historically, metal spinning dates back to ancient Egypt, where artisans used simple tools to spin and shape metals. Today, it has evolved into a sophisticated process that utilizes advanced machinery and technology. Metal spinning is versatile and can be performed manually or using Computer Numerical Control (CNC) machines.

There are several types of metal spinning, including:

- Conventional spinning: Involves manually manipulating the metal using a lathe.

- CNC spinning: Utilizes computerized machines to automate the spinning process, allowing for greater precision and repeatability.

- Shear spinning: Similar to conventional spinning but involves thinning the metal as it is spun.

The basic steps in the metal spinning process are as follows:

- Preparation: The metal blank is cut to the desired size and shape.

- Mounting: The blank is mounted onto a spinning lathe or CNC machine.

- Rotation: The blank is spun at high speed.

- Forming: A tool is applied to the spinning blank, shaping it around the mandrel.

- Finishing: The final product is trimmed and polished to achieve the desired finish.

Machines and Equipment

Metal spinning machines vary in complexity, from simple manual lathes to advanced CNC machines. These machines are designed to provide precise control over the spinning process, ensuring consistent and high-quality results.

Key components of metal spinning machines include:

- Spindle: Rotates the metal blank at high speed.

- Mandrel: Provides a form around which the metal is shaped.

- Tooling system: Includes various tools for applying pressure and shaping the metal.

- Control system: Manages the speed, pressure, and movement of the tools.

Recent advancements in metal spinning machinery have focused on improving efficiency, precision, and automation. CNC machines have revolutionized the metal spinning industry by allowing for complex shapes and designs that were previously impossible to achieve manually. These machines offer enhanced control over the spinning process, reducing material waste and increasing productivity.

Applications

Metal spinning is used across a wide range of industries due to its versatility and ability to produce high-quality, seamless components. Some common applications include:

- Aerospace: Manufacturing lightweight components such as cones, nozzles, and housings for aircraft engines.

- Automotive: Producing parts like wheel rims, exhaust components, and decorative trims.

- HVAC: Creating ductwork, vent hoods, and other components for heating, ventilation, and air conditioning systems.

- Lighting: Fabricating reflectors, lamp bases, and other lighting fixtures.

- Kitchenware: Producing pots, pans, and other cookware.

The ability to create complex shapes with minimal material waste makes metal spinning an attractive option for manufacturers seeking to optimize production and reduce costs.

Advantages and Challenges

Advantages of metal spinning include:

- Cost-efficiency: Metal spinning requires minimal tooling compared to other forming processes, reducing production costs.

- Flexibility: The process can be used with various materials, including aluminum, steel, and copper.

- Seamless components: Metal spinning produces parts without seams or joints, enhancing their structural integrity.

- Customization: The ability to create complex shapes and designs allows for greater customization and innovation.

Despite its advantages, metal spinning also presents certain challenges:

- Limited to symmetrical shapes: Metal spinning is best suited for axially symmetric components, limiting its application for non-symmetrical parts.

- Material limitations: Certain materials may be difficult to spin, requiring specialized equipment and expertise.

- Skill requirement: Manual metal spinning requires skilled operators, although CNC machines have mitigated this challenge.

3. Flow Forming

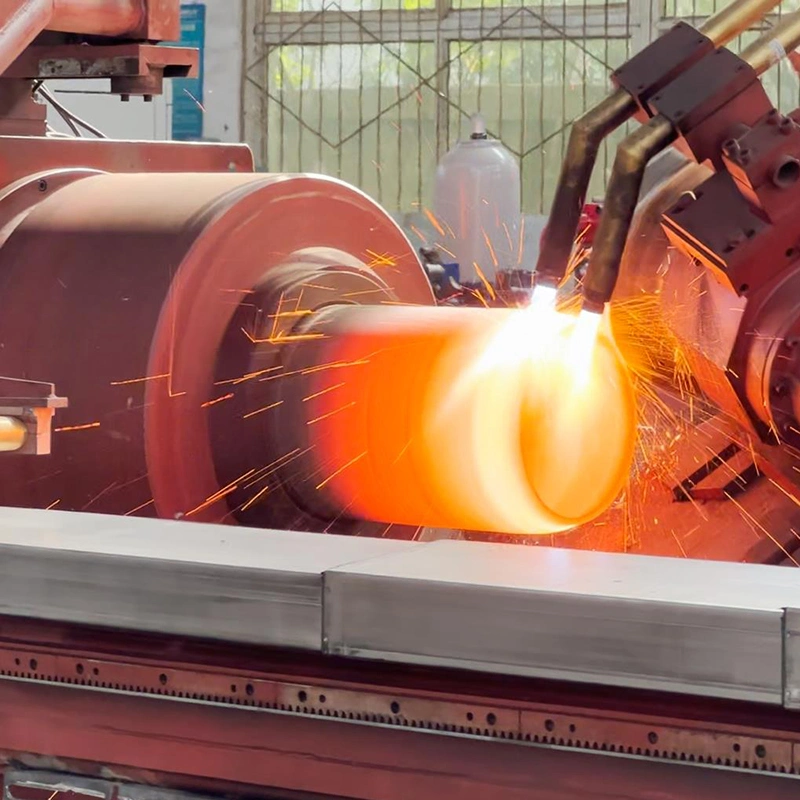

Flow forming, also known as rotary forming or flow turning, is an advanced metal forming process that transforms tubular blanks into precise, high-strength components. This process involves the controlled deformation of the metal blank, reducing its wall thickness and elongating its length.

Metal forming is a fundamental manufacturing process that involves shaping metal materials into desired geometries without adding or removing material. This process leverages mechanical forces to deform metals, transforming raw materials into components with specific dimensions and properties. Metal forming is integral to numerous industries, including automotive, aerospace, construction, and consumer goods, due to its versatility and efficiency in producing a wide range of products.

Metal forming processes can be broadly categorized into hot forming and cold forming. Hot forming involves heating the metal to a temperature above its recrystallization point, which enhances ductility and reduces the force required for deformation. In contrast, cold forming is performed at or near room temperature, leading to increased strength and improved surface finish but requiring higher forces due to reduced material ductility.

Key Types of Metal Forming Processes

- Forging: This process involves shaping metal using localized compressive forces, typically delivered by hammers or presses. Forging can be classified into open-die forging, where the metal is freely deformed between flat or contoured dies, and closed-die forging, which uses shaped dies to produce specific profiles.

- Rolling: Rolling reduces the thickness of metal by passing it through one or more pairs of rollers. It can be performed hot or cold and is essential for producing sheets, plates, and structural shapes like beams and rails.

- Extrusion: In extrusion, metal is forced through a die to create long objects with a fixed cross-sectional profile. This process is commonly used to produce pipes, tubes, and complex profiles for various applications.

- Drawing: Drawing involves pulling metal through a die to reduce its diameter and increase its length. This process is widely used for manufacturing wires, rods, and tubes.

- Flow Forming: Flow forming is a specialized form of rotary metal forming that combines aspects of spinning and stretching. It is highly effective for producing seamless, high-precision components such as aerospace parts, automotive wheels, and pressure vessels.

How Flow Forming Relates to Metal Forming

Flow forming is a subset of metal forming that specifically focuses on the precise shaping of metal tubes and cylindrical parts. Unlike traditional metal forming techniques that might require multiple steps to achieve complex geometries, flow forming can produce high-precision components in fewer operations, enhancing efficiency and reducing material waste.

Flow forming differs from conventional metal forming in several key ways:

- Rotary Motion: Flow forming employs a rotating mandrel or chuck that facilitates the continuous deformation of the metal as it is fed through the machine. This rotary motion ensures uniform material flow and consistent wall thickness.

- Controlled Material Flow: The process meticulously controls the flow of material by applying localized forces, which allows for intricate shapes and tight tolerances. This precision is particularly advantageous for industries requiring high-quality components with minimal deviations.

- Seamless Production: Flow forming produces seamless parts, eliminating the need for welding or joining separate components. This seamlessness enhances the structural integrity and performance of the final product.

Applications in Different Industries

Metal forming, including flow forming, plays a pivotal role across various industries by enabling the creation of components that meet stringent performance and quality standards.

- Aerospace: The aerospace industry relies on metal forming to produce lightweight, high-strength components such as fuselage sections, engine parts, and landing gear. Flow forming is particularly valuable for manufacturing turbine disks and other critical components that demand exceptional precision and reliability.

- Automotive: In the automotive sector, metal forming is essential for producing engine parts, chassis components, and wheels. Flow forming contributes to the manufacturing of lightweight yet strong wheels, improving vehicle performance and fuel efficiency.

- Industrial Machinery: Metal forming processes are used to create various machinery parts, including shafts, gears, and housings. These components require precise dimensions and robust material properties to ensure optimal functionality and longevity.

- Consumer Goods: Even in consumer products, metal forming is indispensable. Items such as cookware, tools, and sporting equipment benefit from the versatility and precision offered by metal forming techniques.

Metallurgical Properties

Metal forming processes significantly influence the metallurgical properties of the final product. During deformation, the metal undergoes changes in its microstructure, which can enhance certain properties while potentially introducing others.

- Grain Refinement: The plastic deformation involved in metal forming leads to grain refinement, where the grain size of the metal decreases. Finer grains typically enhance the strength and toughness of the material.

- Strain Hardening: Also known as work hardening, strain hardening occurs as dislocations within the metal’s crystal structure multiply and interact during deformation. This process increases the material’s tensile strength and hardness but may reduce its ductility.

- Texture Development: The directional flow of material during forming can lead to the development of crystallographic textures, which influence the anisotropic properties of the metal. Understanding and controlling texture development is crucial for achieving desired mechanical properties.

- Residual Stresses: Metal forming can introduce residual stresses within the material, which may affect the component’s performance and dimensional stability. Proper process control and subsequent heat treatments can mitigate undesirable residual stresses.

Latest Advancements in Metal Forming Technologies

The metal forming industry continues to evolve with advancements aimed at enhancing precision, efficiency, and material capabilities. Key innovations include:

- Automation and Robotics: The integration of automation and robotic systems in metal forming processes has led to increased production rates, improved consistency, and reduced labor costs. Automated systems ensure precise control over process parameters, enhancing overall quality.

- Advanced Materials: The development of new alloys and composite materials expands the possibilities of metal forming. These materials often exhibit superior strength-to-weight ratios, corrosion resistance, and thermal stability, making them ideal for high-performance applications.

- Simulation and Modeling: Advanced computer simulations and modeling tools allow engineers to predict and optimize metal forming processes. These tools help in understanding material behavior under various conditions, reducing trial-and-error approaches and accelerating product development.

- Additive Manufacturing Integration: Combining traditional metal forming with additive manufacturing techniques, such as hybrid manufacturing, enables the creation of complex geometries that were previously difficult or impossible to achieve. This integration opens new avenues for innovation in component design and functionality.

- Sustainable Practices: There is a growing emphasis on sustainability within metal forming. Innovations include the use of energy-efficient machinery, recycling of scrap materials, and the development of eco-friendly lubricants and coatings. These practices contribute to reducing the environmental impact of metal forming processes.

- Enhanced Surface Treatments: Advanced surface treatments, such as coating technologies and surface hardening, are being integrated with metal forming to improve the wear resistance, corrosion resistance, and aesthetic qualities of the final products. These treatments extend the lifespan and performance of metal components.

Conclusion

Metal forming is a cornerstone of modern manufacturing, enabling the creation of a vast array of components essential to various industries. The versatility and efficiency of metal forming processes, including specialized techniques like flow forming, make them indispensable for producing high-quality, high-performance products. Advances in technology continue to push the boundaries of what is possible in metal forming, driving innovation and enhancing the capabilities of manufacturers worldwide. As industries demand more precise, durable, and lightweight components, metal forming will remain a critical area of focus, continually evolving to meet the challenges of the future.

Cold Working

Overview of Cold Working

Cold working, also known as cold forming, is a metalworking process in which metals are shaped at temperatures below their recrystallization point, typically at or near room temperature. Unlike hot working, which involves heating the material, cold working uses mechanical forces to deform the metal. This process results in increased strength, improved surface finish, and dimensional accuracy while maintaining the structural integrity of the material.

Cold working is an integral process in manufacturing industries where high precision and enhanced mechanical properties are required. It is particularly valuable in the production of components for the aerospace, automotive, medical, and industrial sectors. Some common cold working techniques include rolling, drawing, forging, and flow forming.

Cold Working vs. Flow Forming

Flow forming is a specialized type of cold working that combines aspects of metal spinning and extrusion. Both cold working and flow forming share the principle of shaping metal without heating it, leading to strain hardening and improved mechanical properties. However, flow forming is unique in its ability to create seamless, thin-walled, cylindrical components with high precision and tight tolerances.

- Cold Working: In conventional cold working, deformation is achieved through processes like stamping or drawing, where the metal is stretched or compressed into shape. Cold working can produce parts with increased strength but often requires multiple steps or secondary processes to achieve complex geometries.

- Flow Forming: Flow forming, on the other hand, achieves complex shapes in fewer steps by controlling material flow with precise force application. This technique not only enhances the material properties but also allows for more intricate and uniform designs, making it ideal for producing parts like wheel rims, pressure vessels, and aerospace components.

Mechanics of Cold Working

The mechanics of cold working revolve around the plastic deformation of metals. When a metal is subjected to mechanical forces, the crystal lattice structure is disrupted, causing dislocations to multiply and interact. This process increases the strength and hardness of the material through what is known as strain hardening or work hardening.

Key aspects of cold working mechanics include:

- Dislocation Movement: In cold working, dislocations within the metal’s crystal structure move and accumulate as the material is deformed. The more the metal is deformed, the greater the number of dislocations, which eventually impede further movement, increasing the material’s strength.

- Strain Hardening: As the dislocation density increases, the metal becomes harder and stronger but less ductile. This phenomenon, known as strain hardening, is a critical factor in cold working, as it allows for the creation of components with superior mechanical properties.

- Yield Strength: Cold working increases the metal’s yield strength, the point at which it begins to deform plastically. This improvement is especially beneficial in industries where components are subjected to high loads and stresses.

- Ductility Reduction: While cold working increases strength, it also reduces the metal’s ductility, or its ability to undergo plastic deformation without fracturing. To balance this, manufacturers may employ annealing to relieve internal stresses and restore ductility, depending on the application.

Effect on Material Properties

Cold working significantly alters the material properties of metals. By manipulating the microstructure of the material, cold working enhances several key attributes:

- Increased Strength and Hardness: Cold working processes, such as rolling, drawing, and flow forming, increase the material’s strength and hardness through strain hardening. This is particularly important for components that need to withstand high-stress environments, such as aerospace parts, automotive components, and medical implants.

- Improved Surface Finish: The precise nature of cold working ensures a smooth surface finish, which is critical in applications where surface quality impacts performance, such as in hydraulic cylinders, medical devices, and automotive parts.

- Dimensional Accuracy: Cold working offers high precision and tight tolerances, making it ideal for producing components with exact dimensions. This is crucial in industries like aerospace and automotive, where even minor deviations in part dimensions can affect performance and safety.

- Residual Stresses: Cold working can introduce residual stresses into the material, which may affect its long-term performance, particularly in high-temperature or corrosive environments. However, these stresses can be managed or relieved through post-processing techniques like annealing.

- Reduced Ductility: While cold working increases strength, it reduces ductility. The trade-off between strength and ductility must be carefully managed depending on the specific application. In cases where ductility is critical, post-process heat treatments may be employed to restore it.

- Fatigue Resistance: Cold working generally improves the material’s resistance to fatigue, which is the progressive failure of a material due to cyclic loading. This is especially beneficial in applications like aerospace and automotive, where components are subjected to repeated stress cycles.

Cold Working in Flow Forming Machines

In flow forming machines, cold working plays a crucial role in shaping cylindrical components with precision. The process involves a mandrel (a rotating core) and rollers that apply radial pressure to the metal, gradually stretching and thinning it into the desired shape.

Key steps of cold working in flow forming machines include:

- Material Loading: The process begins by loading a preformed cylindrical blank, often made of materials like aluminum, steel, or titanium, onto the mandrel.

- Mandrel Rotation: The mandrel rotates at a controlled speed, while rollers apply radial pressure to the blank. This rotation helps control material flow, ensuring consistent deformation.

- Radial Force Application: The rollers gradually thin the material by applying a controlled radial force. This cold working action leads to strain hardening and an increase in the part’s strength.

- Wall Thickness Control: One of the advantages of flow forming is the ability to create parts with uniform wall thickness, which is critical for components like pressure vessels, tubes, and rocket motor casings.

- Final Component: Once the part reaches the desired dimensions, it is removed from the machine. The resulting component has improved mechanical properties, such as higher tensile strength and enhanced fatigue resistance, making it suitable for high-performance applications.

Advantages of Cold Working in Flow Forming

Cold working in flow forming offers several advantages that make it an ideal process for producing high-quality, high-precision components:

- Improved Mechanical Properties: The cold working process leads to strain hardening, which increases the component’s strength and hardness. This is especially beneficial in industries that require lightweight yet durable parts.

- Material Efficiency: Cold working in flow forming minimizes material waste. The process creates seamless parts with near-net shapes, reducing the need for post-processing and material scrap.

- High Precision and Consistency: Flow forming machines offer tight control over material flow, resulting in components with precise dimensions and uniform wall thickness. This level of precision is crucial for applications like aerospace and automotive, where tolerances are extremely tight.

- Cost-Effective Production: While the initial setup costs for flow forming machines may be high, the process is cost-effective for high-volume production runs. It reduces the need for secondary operations like welding, grinding, and machining, ultimately saving time and labor.

Examples of Cold Working Applications

Cold working is widely used in several industries due to its ability to produce components with superior strength, dimensional accuracy, and surface finish. Some key applications include:

- Automotive Industry: Cold working is used to manufacture structural components, drive shafts, and gear parts that require high strength and wear resistance. Cold-formed parts are also used in electric vehicle manufacturing for lightweighting purposes.

- Aerospace Industry: In aerospace, cold working techniques are essential for producing lightweight, high-strength parts, such as landing gear, fuselage components, and turbine blades. Flow forming is particularly valuable for creating turbine disks and engine cases.

- Medical Devices: Cold working is used to manufacture implants, stents, and surgical instruments. These components require excellent surface finish, dimensional accuracy, and biocompatibility, all of which are achievable through cold working processes.

- Industrial Applications: In industrial machinery, cold working is employed to produce shafts, bearings, and couplings that require high strength and durability. The process is also used for tubes and piping in power plants, refineries, and chemical processing facilities.

Conclusion

Cold working is a critical manufacturing process that enhances the mechanical properties of metals, providing increased strength, hardness, and precision. Its application in flow forming machines further exemplifies its value in producing high-performance, seamless components for industries such as aerospace, automotive, and medical. The ability to achieve tight tolerances, improved surface finish, and strain-hardened materials makes cold working indispensable in modern manufacturing. As technology continues to advance, cold working techniques will evolve, offering even greater efficiencies, precision, and material capabilities in the years to come.

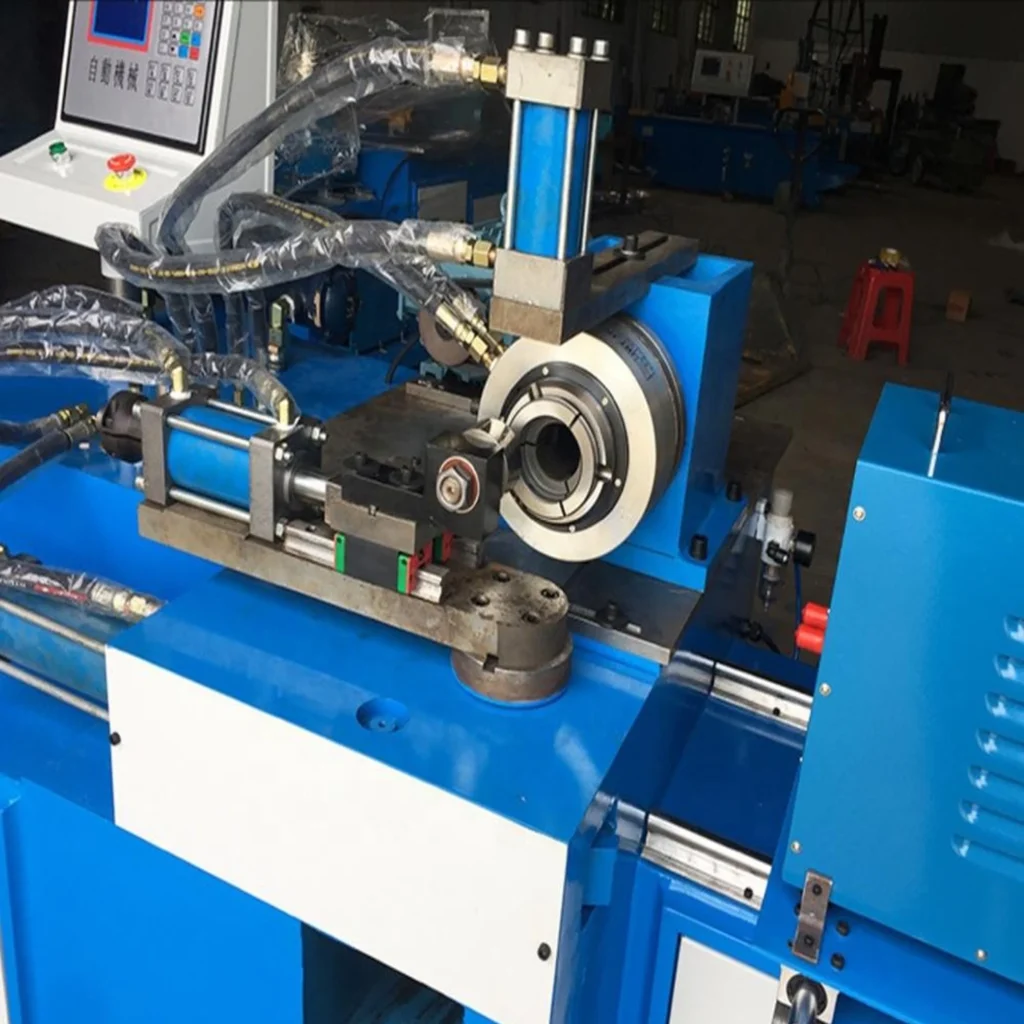

CNC Technology

Introduction to CNC Technology

CNC (Computer Numerical Control) technology refers to the automated control of machining tools and equipment using a computer. CNC machines are fundamental to modern manufacturing, enabling precise and efficient production of parts by controlling complex mechanical processes. This technology is employed in a wide range of industries, including metalworking, automotive, aerospace, and electronics, where high precision, consistency, and efficiency are critical.

In CNC systems, a computer interprets CAD (Computer-Aided Design) models and CAM (Computer-Aided Manufacturing) programs, converting them into instructions that control the movement and operation of the machine. These instructions guide actions like cutting, drilling, milling, and forming with incredible accuracy, making CNC machines indispensable in creating parts with tight tolerances and intricate geometries.

CNC Technology in Flow Forming Machines

Flow forming is a process that significantly benefits from the integration of CNC technology. Flow forming machines rely on multi-axis CNC control to manipulate tools and apply the precise radial forces required to shape metal components. The precision and flexibility of CNC systems allow flow forming machines to produce complex cylindrical geometries, maintain uniform wall thickness, and meet tight dimensional tolerances.

Key roles of CNC technology in flow forming machines include:

- Multi-Axis Control: CNC technology in flow forming machines enables simultaneous control of multiple axes. This is critical in controlling the mandrel’s rotation speed, roller positioning, and the feed rate of the material. By coordinating these parameters, CNC machines ensure precise material deformation and uniform part geometry.

- Precision Control: CNC systems enable operators to fine-tune parameters such as roller force, feed rates, and rotational speed, resulting in high precision in the final product. This is especially important for industries like aerospace and automotive, where even small deviations can lead to performance issues or safety concerns.

- Automated Material Flow Monitoring: Flow forming machines equipped with CNC systems can monitor the material’s flow during the forming process in real-time. This enables dynamic adjustments to parameters, ensuring consistent wall thickness and material distribution.

- Reduced Human Error: The integration of CNC in flow forming minimizes the reliance on manual operations, reducing human error and leading to improved repeatability. With CNC machines, manufacturers can produce large quantities of components that consistently meet stringent specifications.

Advantages of CNC Integration

The integration of CNC technology into flow forming machines provides several key advantages:

- Enhanced Precision: CNC systems allow for micrometer-level accuracy, making it possible to manufacture components with extremely tight tolerances. This is crucial for industries such as aerospace and medical devices, where precise dimensions can impact performance and safety.

- Repeatability: CNC technology ensures that each part produced is identical to the last, making it ideal for high-volume production. This repeatability reduces waste, minimizes material costs, and ensures that every component meets the necessary specifications.

- Complex Geometry Handling: CNC machines are capable of handling complex shapes and contours that would be difficult or impossible to achieve through manual methods. In flow forming, CNC systems can manage intricate details, such as varying wall thicknesses, stepped diameters, or tapering geometries, with ease.

- Efficient Production: CNC automation significantly reduces production time by eliminating manual adjustments between operations. Once a program is set up, the machine can operate continuously, completing multiple steps of a process in a single setup, which improves overall efficiency and throughput.

- Less Tool Wear: By precisely controlling feed rates, speeds, and forces, CNC machines help reduce tool wear. This not only extends the lifespan of expensive tooling but also maintains the quality of parts over longer production runs.

- Real-Time Adjustments: CNC systems can make real-time adjustments based on feedback from sensors or pre-set instructions, compensating for variables such as material inconsistencies or temperature changes. This feature is essential for achieving consistent part quality, especially in critical applications like pressure vessels or aerospace components.

Automation in CNC Machines

The automation of CNC machines has revolutionized manufacturing processes by introducing a high level of efficiency and accuracy in production. CNC machines can run autonomously, requiring minimal human intervention, which reduces labor costs and increases production speeds.

Key elements of CNC automation in flow forming machines include:

- Unmanned Operation: CNC machines can operate for extended periods without the need for constant supervision. This allows for lights-out manufacturing, where machines run overnight or during off-peak hours, maximizing productivity and reducing downtime.

- Automated Tool Changing: CNC machines can be equipped with automatic tool changers, allowing them to switch between different operations (e.g., drilling, cutting, or forming) without manual intervention. This improves cycle times and reduces the potential for human error during tool changes.

- Integration with Robotics: In advanced setups, CNC machines can be integrated with robotic arms that load and unload workpieces, further reducing the need for human intervention. This integration enhances the efficiency of the manufacturing process and ensures continuous, high-speed production.

- Process Monitoring and Data Logging: Modern CNC machines are equipped with sensors and software that provide real-time process monitoring. Operators can track key metrics such as spindle speed, torque, and material feed rate. The data is logged and analyzed, allowing manufacturers to identify inefficiencies or potential issues before they affect production quality.

- Feedback Systems: CNC machines utilize closed-loop control systems that continuously monitor the process and make adjustments as needed. This capability is particularly beneficial in flow forming, where the precise control of material flow is critical to maintaining part quality.

Advances in CNC Systems for Metal Forming

Over the years, CNC technology has undergone significant advancements that have improved the capabilities of flow forming machines and other metalworking equipment. Some of the most notable innovations include:

- Multi-Axis Machining: Traditional CNC machines operate in three axes (X, Y, and Z). However, modern CNC systems can control five or more axes simultaneously, allowing for more complex and precise machining of parts. In flow forming, multi-axis control enables the production of components with varying diameters, tapered sections, and complex profiles.

- High-Speed Machining: CNC machines are now capable of high-speed machining, which significantly reduces cycle times while maintaining part quality. This is particularly useful in high-volume production environments, where minimizing downtime is critical to maximizing output.

- Adaptive Control Systems: CNC systems now include adaptive control features that allow machines to adjust their operating parameters based on real-time conditions, such as tool wear or material variation. In flow forming, adaptive control ensures consistent material flow and prevents defects.

- CAD/CAM Integration: The integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software has streamlined the CNC programming process. Engineers can create detailed part designs in CAD software and seamlessly transfer them to CAM software, which generates the CNC code for machining.

- Advanced Simulation Tools: Modern CNC systems come equipped with simulation software that allows manufacturers to visualize the entire machining process before production begins. This reduces the risk of errors and helps optimize tool paths for faster, more efficient machining.

- Internet of Things (IoT) and Industry 4.0: CNC machines are increasingly being integrated into Industry 4.0 environments, where they are connected to networks that enable remote monitoring, predictive maintenance, and data-driven decision-making. This connectivity helps manufacturers improve efficiency, reduce downtime, and maintain a high level of product quality.

CNC Machines and the Future of Manufacturing

The future of CNC technology in flow forming and other metalworking processes is poised to become even more advanced with the continued development of artificial intelligence (AI), machine learning, and smart manufacturing technologies. Some future trends include:

- AI-Driven CNC Systems: Artificial intelligence will further improve the efficiency of CNC machines by optimizing tool paths, adjusting feed rates, and predicting maintenance needs based on real-time data. AI can also help identify the best material flow parameters in flow forming processes, leading to more consistent and reliable production.

- Additive and Hybrid Manufacturing: CNC technology is being integrated with additive manufacturing techniques to create hybrid machines capable of both subtractive (e.g., cutting, milling) and additive (e.g., 3D printing) processes. This combination allows manufacturers to produce complex parts with fewer steps, greater material efficiency, and enhanced design flexibility.

- Increased Automation: As robotics and automation technologies continue to advance, CNC systems will become even more autonomous, with minimal human intervention required. This will enable faster production times and the ability to produce increasingly complex geometries.

- Sustainability: CNC technology is also evolving toward more sustainable manufacturing practices. By optimizing material usage, reducing waste, and incorporating energy-efficient processes, CNC machines are helping manufacturers lower their environmental impact while maintaining high levels of productivity.

Conclusion

CNC technology has transformed the landscape of modern manufacturing, offering unparalleled precision, repeatability, and efficiency. In the realm of flow forming, CNC integration allows for the production of complex, high-strength components with exacting tolerances. The continued advancement of CNC systems, particularly in terms of automation, adaptive control, and multi-axis machining, is pushing the boundaries of what can be achieved in metalworking. As industries like aerospace, automotive, and medical devices demand ever-higher levels of precision and performance, CNC technology will continue to play a crucial role in meeting these requirements and driving innovation.

Material Flow

Definition and Importance of Material Flow in Manufacturing

Material flow refers to the movement and deformation of materials during the manufacturing process, particularly in forming operations such as flow forming, forging, rolling, and extrusion. In metal forming, material flow describes how the material is distributed and reshaped under external forces, affecting the final part’s geometry, strength, and internal structure. Controlling material flow is crucial to ensure that the component produced meets the required specifications, including dimensional accuracy, surface finish, and mechanical properties.

Material flow is especially important in processes like flow forming, where cylindrical shapes are formed by gradually stretching the metal over a rotating mandrel. Poor control of material flow can lead to defects like thickness variations, cracks, or inconsistent surface finishes, all of which can compromise the functionality of the final part. Proper understanding and manipulation of material flow allow manufacturers to achieve uniform thickness, fine surface texture, and enhanced mechanical properties, making it a critical factor in high-precision manufacturing.

Material Flow in Flow Forming

In the flow forming process, material flow is carefully controlled to ensure that metal is deformed uniformly as it is thinned and stretched over the mandrel. Flow forming machines apply radial forces through rollers that press the material against the mandrel, guiding it into the desired shape. The precision of material flow in this process is essential for achieving the target dimensions and maintaining the material’s structural integrity.

Key aspects of material flow in flow forming include:

- Axial and Radial Flow: In flow forming, material flow occurs in both axial (along the length of the workpiece) and radial (toward or away from the mandrel) directions. The balance between these two flow directions is critical for maintaining the part’s uniform wall thickness and structural integrity.

- Deformation Zone: The deformation zone is where the rollers apply pressure to the material, causing it to flow along the mandrel. In this zone, material flow is governed by the amount of pressure applied, the rotational speed of the mandrel, and the temperature of the material (in cold working, temperature increases due to friction).

- Material Elongation: As the material is pressed against the mandrel, it elongates axially while thinning radially. The degree of elongation is controlled by adjusting the roller feed rate and the number of passes over the workpiece. Proper control of material elongation is vital to prevent excessive thinning, which could compromise the part’s strength.

- Control Over Flow Rate: CNC technology integrated with flow forming machines ensures precise control over the material flow rate. This control allows for real-time adjustments to roller force and feed rate to compensate for variables like material inconsistencies or tool wear.

Factors Affecting Material Flow

Several factors affect the flow of material during the forming process, and understanding these factors is key to achieving the desired part properties:

- Material Properties: The composition and mechanical properties of the material being formed play a significant role in how it flows. For example, aluminum and titanium exhibit different flow characteristics due to their differences in ductility and strength. Materials with high ductility tend to flow more easily, whereas harder materials require more force to deform.

- Temperature: While flow forming is typically a cold working process, temperature still affects material flow. The friction between the rollers and the workpiece generates heat, softening the material and improving its flow. This is particularly important when working with materials like steel or superalloys, where frictional heat can help facilitate material flow.

- Pressure Applied: The amount of radial pressure exerted by the rollers on the workpiece significantly affects material flow. Insufficient pressure can result in uneven material distribution and poor surface finish, while excessive pressure may cause cracks or buckling in the material.

- Rotational Speed: The speed at which the mandrel rotates also influences material flow. Higher rotational speeds tend to facilitate more uniform flow, but if the speed is too high, it may cause the material to overheat or result in defects like surface tears.

- Tooling Design: The design of the mandrel and rollers determines how the material is guided and shaped during flow forming. Mandrels with specific profiles help control the material’s path, while roller geometry influences the degree of thinning and elongation. Proper tooling design ensures smooth material flow and uniform part dimensions.

- Number of Passes: The number of passes that the rollers make over the workpiece affects the overall quality of the material flow. Multiple passes allow for gradual thinning and stretching, ensuring consistent material flow and reducing the likelihood of defects like cracking or wrinkling.

Material Flow Control

Achieving precise control over material flow is critical for ensuring the quality of the final product in flow forming. Modern flow forming machines incorporate advanced control systems that allow manufacturers to manipulate various parameters and monitor the material flow in real-time.

- CNC-Based Control: CNC technology plays a vital role in controlling material flow during flow forming. By setting parameters like roller feed rate, rotational speed, and force application, CNC systems ensure consistent material flow throughout the process. Adjustments can be made during the operation based on real-time feedback, allowing for dynamic process control.

- Force Monitoring: Advanced flow forming machines are equipped with force sensors that continuously monitor the radial force applied by the rollers. If the force deviates from the set parameters, the system can automatically adjust the roller pressure to maintain consistent material flow and prevent defects.

- Process Simulation: Prior to actual production, manufacturers can use finite element analysis (FEA) and process simulations to predict how the material will flow during the forming process. These simulations help optimize process parameters, tooling design, and material selection to ensure smooth material flow and avoid issues such as tearing or buckling.

- Lubrication: Lubricants are often used during the flow forming process to reduce friction between the rollers and the workpiece. This improves material flow by minimizing heat generation and reducing the risk of surface defects.

Impact on Final Product Quality

Material flow has a direct impact on the quality of the final product in terms of strength, dimensional accuracy, and surface finish. Proper control of material flow ensures that the formed component meets the necessary specifications for its intended application.

- Uniform Wall Thickness: One of the primary goals in flow forming is to achieve uniform wall thickness throughout the part. Proper material flow control ensures that the material is distributed evenly along the length of the workpiece, avoiding areas of excessive thinning or thickening.

- Enhanced Mechanical Properties: Controlled material flow during forming processes like flow forming enhances the material’s mechanical properties. For example, cold working during flow forming induces strain hardening, which increases the part’s tensile strength and fatigue resistance. The flow of material also influences grain orientation, which can improve the part’s toughness and wear resistance.

- Improved Surface Finish: The precision control of material flow contributes to a smooth surface finish, which is critical in applications where the surface quality impacts performance, such as in aerospace or automotive components. A poor surface finish may lead to premature wear or corrosion, affecting the part’s longevity.

- Dimensional Accuracy: Consistent material flow ensures that the final part maintains its geometric accuracy and meets the required tolerances. In industries like aerospace, where components must meet tight dimensional specifications, achieving precise material flow is essential for ensuring the part’s performance and safety.

- Reduced Defects: Proper control over material flow helps prevent defects such as cracking, buckling, or wrinkling in the final product. These defects can compromise the part’s structural integrity and require costly rework or scrapping. By optimizing material flow, manufacturers can minimize waste and improve overall production efficiency.

Examples of Material Flow in Industry Applications

Material flow is a critical consideration in various industries that rely on metal forming techniques:

- Aerospace: In aerospace manufacturing, flow forming is used to produce turbine disks, rocket casings, and landing gear components, where uniform material flow is essential for achieving the necessary strength-to-weight ratios and fatigue resistance. The controlled flow ensures that these components can withstand extreme forces and high temperatures without failure.

- Automotive: The automotive industry uses flow forming to manufacture wheels, drive shafts, and chassis components. Achieving optimal material flow in these parts ensures that they are lightweight, durable, and resistant to fatigue, contributing to vehicle performance and safety.

- Pressure Vessels: In the production of pressure vessels for industries such as energy and petrochemical, material flow must be carefully controlled to ensure that the vessels can withstand high internal pressures. Flow forming provides the precision needed to maintain consistent wall thickness and prevent weaknesses that could lead to catastrophic failure.

- Medical Devices: Material flow is also important in the manufacture of medical implants and surgical instruments, where biocompatibility, precision, and surface finish are critical. Flow forming is used to produce stents and prosthetic components, where controlled material flow ensures that the devices meet stringent quality and performance standards.

Conclusion

Material flow is a fundamental aspect of metal forming processes, particularly in flow forming, where precise control over the deformation and distribution of material is essential for producing high-quality, high-performance components. Factors such as material properties, tooling design, and process parameters all influence how material flows during forming operations. By understanding and optimizing material flow, manufacturers can achieve improved mechanical properties, dimensional accuracy, and surface finishes, while minimizing defects and waste. As manufacturing technologies continue to advance, the ability to control material flow with greater precision will play a crucial role in meeting the ever-increasing demands for lightweight, durable, and high-precision parts across industries like aerospace, automotive, and medical devices.

Rotary Forming

Understanding Rotary Forming

Rotary forming is a metalworking process that involves the shaping of metal components by applying force through a rotating tool or mandrel. This technique is a subset of incremental forming, where small deformations are applied repeatedly to gradually shape the material into the desired form. Rotary forming is often used to manufacture parts with symmetrical geometries, such as cylinders, cones, or disks, which are common in industries like aerospace, automotive, and manufacturing.

The rotary forming process typically employs rotating dies or rollers that gradually apply pressure to the material, causing it to flow and conform to the shape of the tool. Unlike processes like stamping, where a single large force is applied, rotary forming relies on the continuous application of smaller forces, which enables more precise control over material flow and deformation.

Rotary Forming vs. Flow Forming

Rotary forming and flow forming are similar in that both processes involve the use of rotational forces to shape metal, but there are key differences in their mechanics and applications.

- Rotary Forming: In rotary forming, metal is typically deformed through rolling or spinning against a rotating tool. This process allows for gradual shaping of the material, often producing parts like cones or spherical shapes. Rotary forming is suitable for manufacturing shells, vessels, or domes and is widely used in processes like metal spinning and shear forming.

- Flow Forming: Flow forming is a more specialized process that focuses on producing thin-walled, cylindrical components by gradually stretching the metal over a mandrel. Flow forming allows for precise control of wall thickness and material properties, making it ideal for producing parts such as pressure vessels, wheels, and turbine components.

While both processes involve rotating tools and deformation forces, flow forming typically achieves more precise control over material thickness and dimensional tolerances, whereas rotary forming is more flexible for producing varied shapes with less emphasis on uniform thickness.

Applications of Rotary Forming

Rotary forming is used across several industries to produce lightweight, high-strength components that meet demanding performance criteria. Key applications include:

- Aerospace: Rotary forming is widely used to manufacture engine components, structural parts, and aerodynamic shapes. Parts like turbine rings, engine housings, and nose cones are commonly made through this process due to its ability to create complex geometries with high precision.

- Automotive: In the automotive industry, rotary forming is employed to create wheel rims, drive shafts, and exhaust system components. These parts require high strength-to-weight ratios and fatigue resistance, which rotary forming can achieve through its precise control of material properties.

- Industrial Machinery: Components such as gears, shafts, and pressure vessel parts are produced using rotary forming in various industrial applications. These parts need to withstand high loads and extreme conditions, and rotary forming provides the necessary mechanical properties.

- Consumer Goods: Rotary forming is also used to manufacture consumer goods like kitchenware, lighting fixtures, and decorative items, where symmetry, strength, and smooth surface finishes are essential.

Role in Flow Forming Machines

Rotary forming mechanisms are often integrated into flow forming machines to enhance their capabilities, especially in the production of cylindrical and conical shapes. The ability to rotate the workpiece while applying controlled pressure allows for the precise manipulation of material flow, ensuring that the final part meets exact specifications.

- Mandrel Rotation: In flow forming machines, the mandrel (a rotating cylindrical tool) is key to guiding the material during deformation. The mandrel’s rotation, combined with pressure from rollers, ensures that the material flows evenly, resulting in uniform wall thickness and consistent part geometry.

- Roller Positioning: The rollers in rotary forming machines are strategically positioned to apply incremental force to the workpiece. The rollers control the radial flow of material, determining the final thickness and elongation of the part. In flow forming machines, the precise positioning of rollers ensures the accuracy of complex geometries like stepped diameters or variable wall thicknesses.

- Tooling Design: Rotary forming relies on customized tooling to shape the workpiece. The shape and design of the mandrel, combined with the rollers’ positioning and movement, enable the creation of parts with complex profiles. The tooling must be carefully designed to ensure smooth material flow and prevent defects such as wrinkling, tearing, or cracking during the forming process.

Key Parameters in Rotary Forming

Several parameters play a critical role in determining the success of the rotary forming process. Proper control of these factors ensures that the final product meets the required specifications in terms of geometry, strength, and surface finish.

- Rotational Speed: The speed at which the workpiece rotates is a critical parameter in rotary forming. Higher rotational speeds allow for faster material deformation, but excessive speed can lead to surface defects or overheating of the material. Finding the optimal speed ensures that the material flows uniformly and maintains its structural integrity.

- Roller Force: The force exerted by the rollers on the workpiece determines how much the material is deformed. Insufficient force may result in incomplete deformation, while excessive force can cause cracking or wrinkling of the material. In advanced rotary forming machines, CNC systems control roller force to ensure precise deformation.

- Feed Rate: The rate at which the rollers advance along the workpiece (axial feed) affects the degree of material elongation. A slower feed rate allows for more gradual shaping and better control over material flow, which is critical for producing components with thin walls and complex profiles.

- Material Thickness: The thickness of the starting material influences the forming process. Thicker materials require more force to deform and may need multiple passes to achieve the desired thickness, while thinner materials can be shaped more easily but may be more prone to tearing or wrinkling.

- Material Composition: Different materials behave differently during rotary forming. Ductile metals like aluminum or copper are easier to form and flow more readily under pressure, while high-strength alloys like titanium or steel require greater force and careful control to avoid defects.

Advantages of Rotary Forming

Rotary forming offers several advantages that make it a preferred process for manufacturing high-precision, symmetrical components:

- High Precision: Rotary forming provides excellent control over dimensional accuracy and surface finish, making it ideal for parts that require tight tolerances. The gradual application of force ensures that the material is deformed uniformly, reducing the likelihood of defects.

- Flexibility in Design: The process allows for the creation of complex shapes with symmetrical geometries, such as cylinders, cones, and domes. This flexibility makes rotary forming suitable for producing components with varying wall thickness, stepped profiles, and intricate contours.