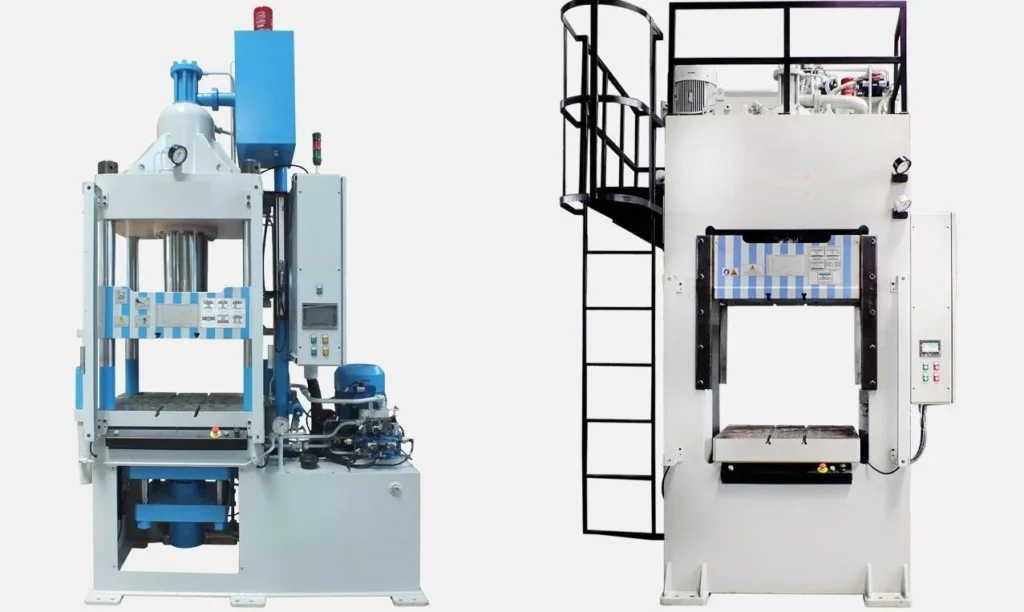

A hydraulic deep drawing press is used due to its versatility in sheet metal and plastic molding. Pressing forces, ram stroke, and speeds are adjustable. Further economic aspects are developed through the design of the drive and the use of modern control technology. Hydraulic units of deep drawing presses that embody tailor-made systems with high demands on the press technology are developed by internationally recognized specialists.

A deep drawing press is a type of machine used in the manufacturing industry to form sheet metal into shapes using a process known as deep drawing. The press is designed to exert a high amount of force on the metal in order to shape it into the desired form. The main parts of a typical deep drawing press include:

- Frame: The frame is the main structural component of the press, which provides support for all of the other parts.

- Bed: The bed is the flat surface on which the metal sheet is placed for processing. It must be sturdy and level to ensure proper operation of the press.

- Ram: The ram is the movable component of the press that exerts a force on the metal sheet. It is driven by a hydraulic or mechanical system.

- Blankholder: The blank holder is a device that holds the metal sheet in place during the deep drawing process, preventing it from slipping or wrinkling.

- Die: The die is the tool that is used to shape the metal sheet. It is typically made of hardened steel and can be customized to create a specific shape.

- Punch: The punch is the component of the press that presses the metal sheet into the die, creating the desired shape.

- Hydraulic System: The hydraulic system provides the power necessary to operate the press. It typically consists of a hydraulic pump, a reservoir, and a series of valves and cylinders.

- Control Panel: The control panel is used to monitor and adjust the various settings of the press, such as the force applied, the speed of operation, and the position of the ram.

Overall, a deep drawing press is a complex machine that requires precise engineering and careful operation to ensure proper functioning. Each of its main parts plays an important role in the deep drawing process, and the press must be properly maintained to ensure long-term performance and reliability.

Hydraulic deep drawing presses are critical tools in modern manufacturing, enabling the production of complex metal components with precision and efficiency. These machines use hydraulic power to form metal sheets into desired shapes, offering unmatched versatility in various industries, from automotive to aerospace.

At its core, a hydraulic deep drawing press applies controlled pressure to metal blanks, forcing them to flow into a die cavity and create intricate parts. The process is known for its ability to produce deep, seamless shapes without compromising material strength. By relying on hydraulic power, these presses deliver consistent force throughout the entire stroke, providing greater control over the forming process. This advantage is particularly important for parts with complex geometries, varying thicknesses, or materials with unique forming characteristics.

For potential buyers, understanding the significance of a hydraulic deep drawing press is crucial. These machines are ideal for manufacturers seeking high-quality, precision-formed products across various applications. Whether you are producing automotive parts, household appliances, or aerospace components, hydraulic deep drawing presses offer a range of capabilities that make them indispensable in the production line.

Why Choose Hydraulic Deep Drawing Presses?

Hydraulic presses are a preferred choice for deep drawing processes due to their superior ability to control pressure and speed, as well as their flexibility in working with different materials and shapes. Unlike mechanical presses that rely on fixed stroke lengths and speeds, hydraulic presses can be adjusted to meet specific forming needs, making them suitable for a wide range of applications. This precision enables manufacturers to achieve consistent results, reduce material waste, and improve overall production efficiency.

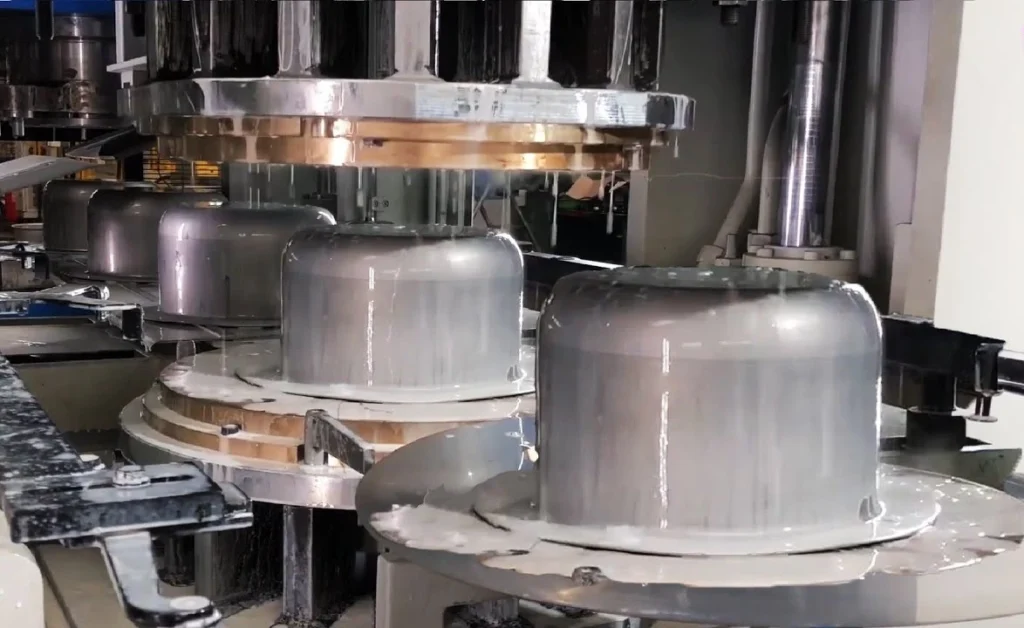

In industries where metal forming plays a vital role in product design and functionality, hydraulic presses stand out for their ability to produce complex parts with high repeatability and minimal defects. They are commonly used to create items like car body panels, kitchen sinks, pressure vessels, and fuel tanks—all products that require precise shaping and reliable performance.

Moreover, with increasing demands for lightweight materials and fuel-efficient designs, especially in the automotive and aerospace sectors, hydraulic deep drawing presses are becoming even more valuable. Their ability to handle aluminum, stainless steel, and high-strength alloys makes them ideal for manufacturers aiming to meet these evolving market requirements.

2. Working Principles and Technology

The core of a hydraulic deep drawing press lies in its reliance on hydraulic power to apply pressure and shape metal into specific forms. The process is highly precise and enables the production of complex, deep-drawn parts that mechanical presses often struggle to achieve. To understand how a hydraulic deep drawing press works, it’s essential to grasp the basic principles of hydraulic technology and how it is applied to the deep drawing process.

Basic Mechanism of Hydraulic Deep Drawing Presses

Hydraulic presses operate based on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle is used to generate immense force by exerting pressure on hydraulic fluid within a confined system. In the case of deep drawing presses, this pressure is directed to a hydraulic cylinder, which moves the press ram vertically. The ram applies force to a metal blank, pushing it into a die cavity, forming the required shape.

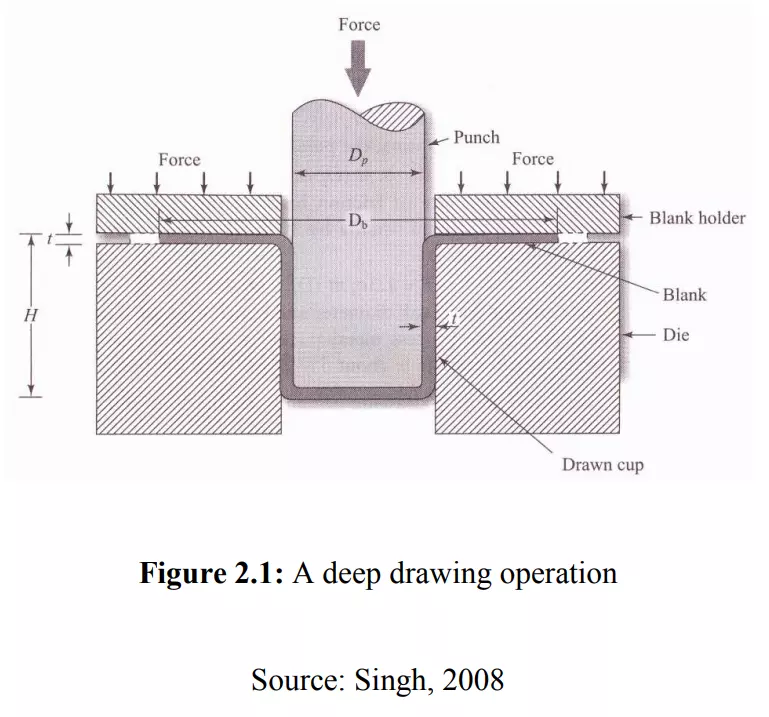

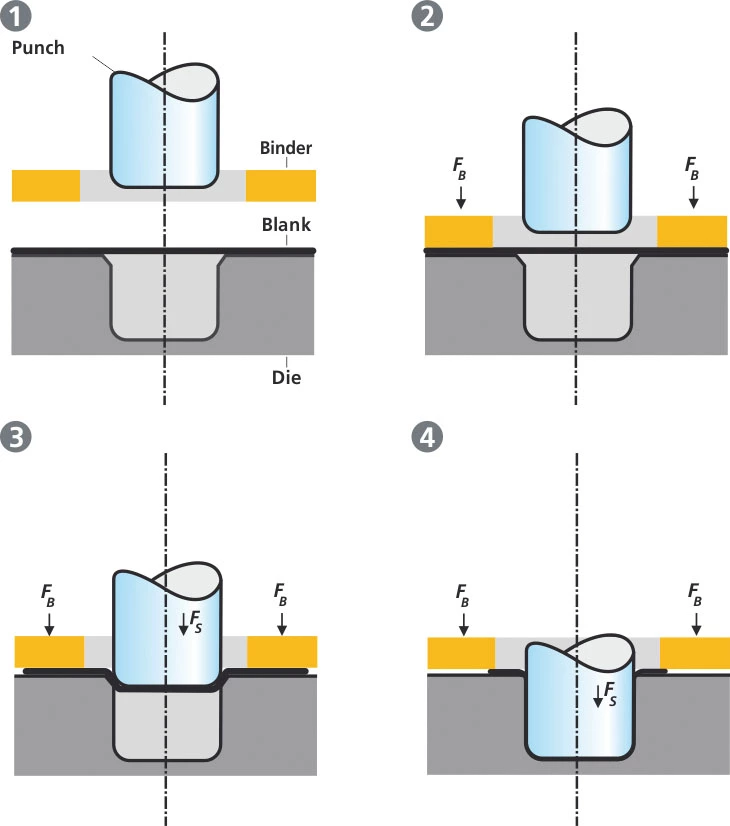

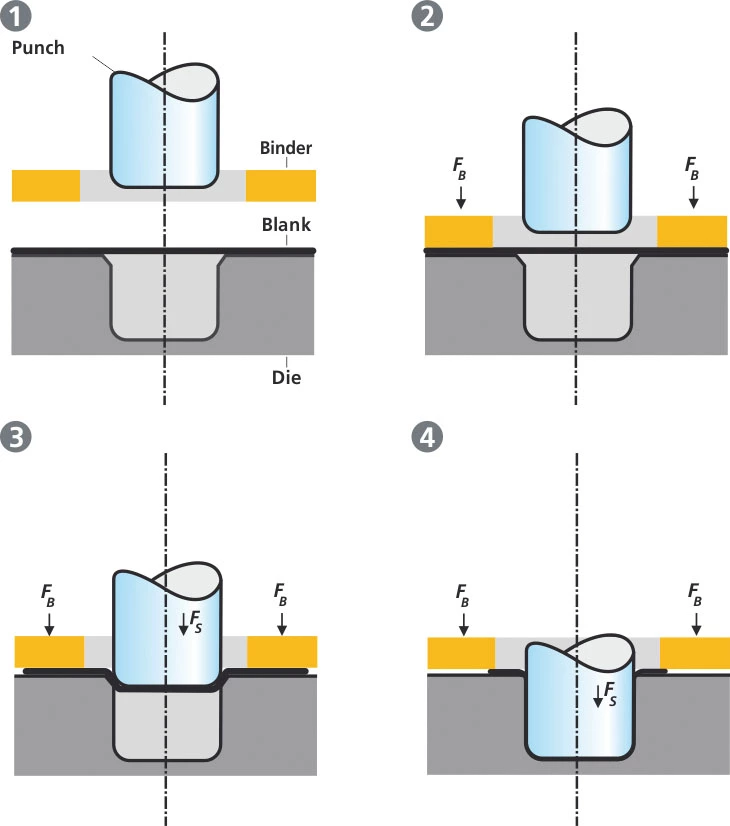

The process begins when a blank holder secures the metal sheet in place, ensuring it does not wrinkle during the operation. As the press ram moves downwards, the punch forces the metal into the die cavity. The hydraulic system allows for precise control over the force, ensuring that the metal flows smoothly into the die without tearing or cracking.

Hydraulic deep drawing presses are distinguished by their ability to provide constant pressure throughout the forming process. Unlike mechanical presses, which generate force based on momentum and reach peak force at the bottom of the stroke, hydraulic presses apply continuous force throughout the entire stroke length. This makes them ideal for drawing deep, intricate shapes with even material distribution and minimal defects.

Hydraulic System Functionality: Fluid Power Principles

The hydraulic system consists of several critical components that work together to generate and control the force needed for deep drawing. Key elements include:

- Hydraulic Pump: This component converts mechanical energy into hydraulic energy by pressurizing the hydraulic fluid. Pumps can vary in design, with gear pumps, vane pumps, and piston pumps being common in hydraulic press systems. The type of pump used affects the flow rate, pressure capacity, and efficiency of the system.

- Hydraulic Fluid: The pressurized medium that transmits force from the pump to the hydraulic cylinders. Maintaining the correct fluid levels and quality is crucial for smooth operation and consistent force output. The fluid also acts as a lubricant for internal parts, reducing wear and tear.

- Hydraulic Cylinder: The component that converts hydraulic energy into linear mechanical force, allowing the press to perform the deep drawing action. Hydraulic cylinders consist of a piston inside a barrel, which moves in response to the pressurized fluid.

- Pressure Control Valves: These regulate the pressure within the system, ensuring that the desired force is applied during the deep drawing process. Overpressure can damage the press or the part being formed, so these valves maintain operational safety and precision.

- Reservoir: Stores the hydraulic fluid when not in use and helps in temperature control by allowing the fluid to cool between cycles. Proper reservoir management ensures long-term system efficiency and prevents overheating.

The Deep Drawing Process

Deep drawing is a metal forming technique that involves the transformation of a flat metal sheet (or blank) into a hollow object with depth greater than its diameter. This process is typically carried out in several stages to prevent material failure, such as tearing or wrinkling, especially for deep or complex shapes. The main stages include:

- Clamping: The metal blank is securely clamped between a blank holder and the die.

- Punching: The hydraulic ram, equipped with a punch, presses the metal into the die cavity, forcing it to take the die’s shape.

- Material Flow: As the punch pushes the blank into the die, the metal flows radially inward. The hydraulic press’s control over force and speed ensures that this flow happens smoothly, without stretching the material too thin or causing defects.

- Release and Ejection: Once the part has been formed, the punch retracts, and the newly formed part is ejected from the die.

This process can be repeated multiple times for particularly deep parts, where intermediate stages (known as redrawing) might be necessary. These stages allow the metal to progressively form deeper shapes without inducing stress or weakening the material.

Factors Affecting Precision and Performance

Several factors impact the precision and performance of hydraulic deep drawing presses, including:

- Pressure Control: The ability to finely adjust pressure during the drawing process is one of the key advantages of hydraulic presses. This ensures a smooth flow of material and reduces the likelihood of defects.

- Speed Regulation: Unlike mechanical presses that operate at fixed speeds, hydraulic presses allow for variable speed control, offering flexibility in working with different materials and drawing depths.

- Force Distribution: Hydraulic presses maintain a consistent force distribution, which is crucial for creating uniform parts. This is especially important when working with thin metals or when deep drawing shapes with intricate details.

- Temperature and Lubrication: Heat can accumulate in the press and affect both the hydraulic fluid and the metal being formed. Effective lubrication and fluid management are critical to prevent overheating and ensure consistent operation.

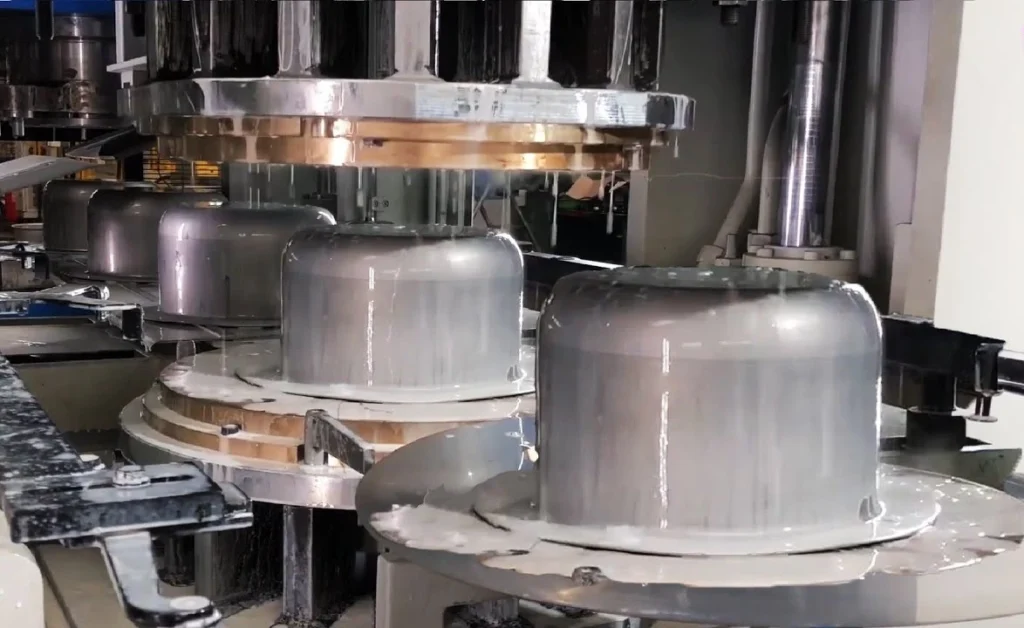

Hydraulic deep drawing presses are an essential piece of equipment in the manufacturing industry, utilized for forming sheet metal into desired shapes through a process called “deep drawing.” These presses use hydraulic fluid to exert force on a punch, which then presses a metal blank into a die, creating complex geometries with high precision.

The deep drawing process allows for the creation of cylindrical, box-shaped, and irregularly shaped components with a high degree of consistency. Hydraulic presses are favored for their ability to exert constant force over long distances, making them ideal for deep drawing processes that involve high-strength materials.

Historically, deep drawing presses were mechanical, relying on mechanical linkages to drive the punch. The evolution to hydraulic systems brought greater control over the force and speed of the press, leading to improvements in precision, safety, and operational efficiency. This shift has cemented hydraulic deep drawing presses as the technology of choice for industries requiring high-quality, complex metal forming.

Hydraulic deep drawing presses are widely used in automotive, aerospace, consumer electronics, medical devices, and more. Their ability to handle high-strength materials and produce intricate, precise shapes makes them invaluable in industries requiring both durability and complex designs.

Basic Principles of Deep Drawing Process

Deep drawing is a metal-forming process in which a flat sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. The result is a part with a depth that exceeds its diameter, such as a cup or can.

The deep drawing process can be divided into several key stages:

- Blanking: The flat metal sheet is cut into a blank, typically a circular shape.

- Drawing: The blank is placed over a die cavity, and the punch pushes the blank into the die, forming the desired shape.

- Redrawing: If the depth of the part is greater than what can be achieved in a single stroke, the part may be redrawn through a series of dies to gradually achieve the final shape.

- Trimming and Finishing: After the deep drawing process, excess material is trimmed, and the part may undergo finishing processes to smooth out any rough edges.

The main characteristic of deep drawing is that the material undergoes plastic deformation, which is necessary for forming complex, deep geometries. The process requires careful control of various parameters, including the force applied, the speed of the punch, and the quality of the material to avoid common defects like tearing, wrinkling, or excessive thinning.

Hydraulic deep drawing presses play a critical role in this process. The hydraulic system provides consistent pressure, which is essential for achieving uniform part dimensions. Unlike mechanical presses, where the force can fluctuate, hydraulic presses offer precise control over the pressure applied during the drawing process, allowing for more accurate results. This is particularly important in high-volume production environments where consistency and quality are paramount.

Components of a Hydraulic Deep Drawing Press

The hydraulic deep drawing press is composed of several critical components, each playing a crucial role in the successful operation of the machine. Understanding these components is essential for optimizing the performance of the press and ensuring that the deep drawing process is both efficient and accurate.

- Hydraulic Cylinder: The hydraulic cylinder is the heart of the press, responsible for generating the force necessary for deep drawing. Hydraulic fluid is pumped into the cylinder, which moves the piston and creates the downward force needed to push the punch into the die.

- Punch and Die: The punch and die are the tools used to shape the metal blank. The punch is attached to the hydraulic cylinder and presses the blank into the die, which has the shape of the final part. The design and precision of the punch and die are critical for producing high-quality parts.

- Pressure System: The hydraulic pressure system controls the flow and pressure of the hydraulic fluid. It includes components such as pumps, valves, and reservoirs, which work together to ensure the correct amount of pressure is applied throughout the deep drawing process.

- Control System: Modern hydraulic deep drawing presses are equipped with computerized control systems that allow operators to precisely control the speed, force, and timing of the press. These systems also provide real-time feedback on press performance, allowing for adjustments to be made on the fly.

- Safety Mechanisms: Hydraulic presses are equipped with safety features to protect operators and equipment. These include emergency stop buttons, pressure relief valves, and guarding systems that prevent accidental contact with moving parts.

Each of these components plays a crucial role in ensuring that the hydraulic deep drawing press operates smoothly and efficiently. The integration of advanced control systems and safety mechanisms has made modern hydraulic presses more reliable and user-friendly than ever before.

Hydraulic System and Working Mechanism

At the core of any hydraulic deep drawing press is the hydraulic system, which powers the press and controls the force applied during the deep drawing process. Understanding how this system works is essential for comprehending the advantages that hydraulic deep drawing presses offer in terms of precision, control, and adaptability.

How Hydraulic Systems Work

Hydraulic systems operate based on Pascal’s Law, which states that when a fluid is placed under pressure in a confined space, the pressure is transmitted equally in all directions. This principle allows hydraulic systems to generate large amounts of force with minimal input. In a hydraulic deep drawing press, a hydraulic pump is used to pressurize hydraulic fluid, which then moves through a series of valves and pipes to reach the hydraulic cylinder. The pressurized fluid exerts force on a piston within the cylinder, which in turn pushes the punch against the metal blank.

A key advantage of hydraulic systems is their ability to apply constant pressure over the full stroke of the piston. This ensures uniform force throughout the deep drawing process, allowing for more consistent and accurate parts compared to mechanical presses, where the force may vary at different points of the stroke.

Key Components of the Hydraulic System

The hydraulic system of a deep drawing press includes several important components that work together to ensure smooth and reliable operation:

- Hydraulic Fluid: The hydraulic fluid is the medium through which force is transmitted in the system. Typically, specialized hydraulic oils are used because they possess the right combination of viscosity, temperature stability, and lubricating properties. The quality and maintenance of hydraulic fluids are critical since contaminants or degraded fluids can lead to inefficiencies and even damage the system.

- Hydraulic Pump: The pump is responsible for generating pressure in the system by forcing the hydraulic fluid through the pipes and into the cylinder. There are different types of pumps used in hydraulic presses, including gear pumps, vane pumps, and piston pumps. The choice of pump depends on the specific requirements of the press, such as the pressure needed and the speed of operation.

- Valves and Regulators: Valves are used to control the flow of hydraulic fluid within the system, allowing the operator to precisely regulate the amount of pressure applied to the cylinder. Regulators are also used to ensure that the pressure does not exceed safe limits, preventing damage to the press and maintaining a safe working environment.

- Hydraulic Cylinder: The hydraulic cylinder is the component that converts the fluid pressure into mechanical force. The cylinder contains a piston that moves when the fluid is pressurized, creating the motion needed to drive the punch into the metal blank. Cylinders are typically made from high-strength materials to withstand the enormous forces generated during the deep drawing process.

- Pressure Accumulators: In some hydraulic systems, accumulators are used to store hydraulic fluid under pressure, which can then be released when needed. This allows for more efficient operation and provides a buffer to handle fluctuations in demand for pressure.

Working Mechanism of a Hydraulic Deep Drawing Press

The operation of a hydraulic deep drawing press can be broken down into several key stages:

- Initial Setup: Before the press is operated, the blank (a flat sheet of metal) is prepared and placed over the die. The die is mounted onto the lower bed of the press, while the punch is attached to the piston of the hydraulic cylinder.

- Pressure Build-up: Once the machine is set up, hydraulic fluid is pumped into the system, building pressure in the hydraulic cylinder. This pressure is carefully controlled to ensure that the correct amount of force is applied during the drawing process.

- Drawing Process: The press is activated, causing the hydraulic cylinder to drive the punch downward. As the punch moves into the die, it forces the blank into the desired shape. The constant pressure provided by the hydraulic system ensures that the blank deforms evenly, reducing the likelihood of defects such as wrinkling or tearing.

- Reversing the Cycle: After the drawing process is complete, the hydraulic system reverses the flow of fluid, retracting the piston and lifting the punch out of the die. The completed part is then removed, and the press is ready for the next cycle.

Advantages of Hydraulic Systems in Deep Drawing Presses

- Precise Control of Force: Hydraulic systems provide highly precise control over the force applied during the drawing process. Operators can adjust the pressure based on the specific requirements of each job, ensuring that the right amount of force is applied for different materials and part geometries.

- Constant Pressure Throughout Stroke: One of the key benefits of hydraulic presses is that they can maintain constant pressure throughout the entire stroke of the piston. This results in more uniform part quality and reduces the risk of defects compared to mechanical presses.

- Adaptability and Flexibility: Hydraulic presses are highly adaptable and can be adjusted to perform a wide range of tasks. For example, operators can modify the stroke length, pressure, and speed to accommodate different materials, part shapes, and production volumes.

- Reduced Wear and Tear: The smooth operation of hydraulic systems results in less wear and tear on the machine components compared to mechanical presses, where the high impact forces can cause damage over time. This reduces maintenance costs and extends the lifespan of the press.

A hydraulic press is a mechanical device that uses a hydraulic cylinder to generate a compressive force. It operates based on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows hydraulic presses to exert significant force with minimal input, making them essential tools in industries requiring high-pressure applications.

A single-acting hydraulic press uses hydraulic pressure to move the piston in one direction, typically the downward or compressive stroke. After the press completes this action, the piston returns to its original position using an external force such as a spring or the weight of the cylinder. This differs from a double-acting hydraulic press, where hydraulic pressure is applied in both the forward and return strokes.

The simplicity and cost-effectiveness of single-acting hydraulic presses make them ideal for a variety of applications, including small to medium-scale production, metal fabrication, and mechanical testing. These presses are widely used in industries such as automotive, aerospace, manufacturing, and even laboratories for precision tasks.

The core advantage of a single-acting hydraulic press lies in its simplicity. Fewer moving parts and a straightforward design reduce both the initial cost and ongoing maintenance requirements. However, the trade-off is that the press lacks the stroke control and power range of more complex systems, limiting its effectiveness in higher-end or more precise applications.

How Single-Acting Hydraulic Presses Work

The fundamental operation of a single-acting hydraulic press relies on Pascal’s Law, which underpins all hydraulic systems. According to this principle, when a force is applied to a fluid inside a closed system, the pressure is transmitted evenly throughout the fluid. In a hydraulic press, this means that the force generated by a pump acting on a small volume of hydraulic fluid can be magnified to create a much larger output force.

Key Components of a Single-Acting Hydraulic Press:

- Cylinder and Piston: The hydraulic cylinder contains a piston that moves up and down. In a single-acting press, hydraulic fluid forces the piston downwards, creating the press action.

- Hydraulic Pump: The pump generates pressure within the hydraulic system, pushing the fluid into the cylinder to drive the piston.

- Reservoir: This stores hydraulic fluid, which is pumped into the cylinder during operation.

- Valves: Control the flow of hydraulic fluid, directing it into the cylinder for the pressing stroke.

- Return Mechanism: In single-acting systems, this is usually a spring or gravitational force that returns the piston to its original position after the pressing action.

Pressing and Return Process:

- Pressing: When the press operator activates the system, hydraulic fluid is pumped into the cylinder. The increase in pressure forces the piston downward, applying force to the material placed under the press head. The force can range from several tons to hundreds of tons, depending on the press’s specifications.

- Return Stroke: Once the pressing action is complete, the external force—usually a spring or gravity—returns the piston to its starting position. Unlike double-acting presses, where hydraulic pressure can control both strokes, single-acting presses rely on this mechanical or natural return.

Advantages and Limitations:

- Advantages: Single-acting presses are simple, affordable, and easy to maintain. They are ideal for tasks that do not require precise control over the return stroke or where the pressing force is the primary concern.

- Limitations: The primary limitation is the lack of control over the piston’s return stroke, which can make single-acting presses less suited to precision applications. Additionally, since only one stroke is powered, these presses are less efficient in tasks requiring continuous motion or high-speed operation.

Types of Single-Acting Hydraulic Presses

Single-acting hydraulic presses come in several varieties, each suited to different applications and operational needs.

1. Manually Operated Hydraulic Presses:

These presses are powered by a hand-operated pump, which provides the hydraulic pressure needed to move the piston. They are ideal for small-scale applications or environments where electricity is not available. These presses are portable and commonly used in repair shops, garages, or remote field locations. Their affordability and ease of use make them popular for light-duty tasks like pressing bearings or removing shafts.

2. Electric-Powered Hydraulic Presses:

Electric-powered hydraulic presses use an electric motor to drive the hydraulic pump, offering greater efficiency and consistency compared to manual models. These presses are suitable for more intensive industrial applications where higher force or faster operation is required. They are commonly found in manufacturing plants, where they can be integrated into production lines for repetitive tasks such as stamping, forging, or cutting.

3. Air-Driven Hydraulic Presses:

In these systems, compressed air is used to generate hydraulic pressure. They are commonly used in industrial environments where compressed air is readily available. Air-driven hydraulic presses are often employed in applications where speed and convenience are critical, and they offer a middle ground between manually operated and electric-powered presses in terms of power and cost.

Applications of Each Type:

- Manually Operated: Ideal for low-volume tasks, repair work, or environments lacking electrical infrastructure.

- Electric-Powered: Suitable for continuous, heavy-duty applications in factories and production environments.

- Air-Driven: Often used in automotive workshops and for lighter industrial tasks where compressed air is available.

Applications of Single-Acting Hydraulic Presses

Single-acting hydraulic presses are versatile tools used across a wide range of industries for different applications.

1. Metal Forming and Fabrication:

In the metalworking industry, hydraulic presses are used to shape, bend, punch, and cut metal sheets and components. Single-acting presses are especially useful in tasks where the return stroke is less critical, such as metal stamping or bending. These presses are commonly used in fabrication shops, tool and die manufacturing, and custom metalwork projects.

2. Press Fitting and Assembly Tasks:

Single-acting presses are commonly employed in press fitting, where parts are mechanically forced together using high pressure. This includes tasks such as pressing bushings, bearings, gears, and other components into place. These presses are widely used in the automotive industry for assembly operations, as well as in machinery and equipment manufacturing.

3. Material Testing and Laboratory Uses:

In laboratories, single-acting hydraulic presses are often used for testing materials under compressive force. For example, engineers and scientists may use hydraulic presses to measure the compressive strength of materials like concrete, metals, or plastics. The simplicity of single-acting presses makes them ideal for controlled experiments where large forces are required without complex control systems.

4. Automotive and Aerospace Industries:

In the automotive sector, single-acting hydraulic presses play a crucial role in various assembly and maintenance tasks, such as pressing in bushings, removing bearings, and straightening parts. Their use extends to aerospace industries for tasks such as forming lightweight components, shaping metal parts, or assembling intricate systems that require precise force application.

Examples of Practical Applications:

- Metal Stamping: Single-acting presses are used to punch or stamp metal parts for various industries, including automotive and electronics.

- Bearing Installation: Presses ensure that bearings are seated correctly without causing damage to delicate components.

- Cutting and Trimming: Hydraulic presses can be used to cut metal, plastic, or composite materials, making them essential in production environments.

Advantages of Single-Acting Hydraulic Presses

Single-acting hydraulic presses have several advantages, making them a popular choice in a variety of applications.

1. Simplicity and Cost-Effectiveness:

Due to their basic design, single-acting hydraulic presses are more affordable than their double-acting counterparts. They have fewer moving parts and require less complex control systems, reducing both the upfront cost and the likelihood of mechanical failure. This makes them ideal for smaller operations or businesses looking for cost-effective solutions.

2. Efficiency in Force Delivery:

Despite their simplicity, single-acting hydraulic presses can deliver tremendous force, making them suitable for heavy-duty tasks like metal forming or assembly. They can generate forces ranging from a few tons to several hundred tons, depending on the size and type of the press, enabling them to handle a wide range of materials and tasks.

3. Reduced Maintenance:

With fewer components, single-acting presses are easier and less costly to maintain. Routine maintenance is generally limited to inspecting seals, checking hydraulic fluid levels, and ensuring that the return mechanism (spring or gravity) is functioning properly.

4. Portability and Space Efficiency:

Single-acting presses are typically more compact than double-acting presses, making them easier to move and install in smaller workspaces. This portability is especially valuable in environments where space is limited, such as small workshops or laboratories.

Challenges and Limitations of Single-Acting Hydraulic Presses

While single-acting hydraulic presses offer many benefits, they also have certain limitations that can affect their performance in specific applications.

1. Limited Stroke Control and Precision:

Because the return stroke is not powered by hydraulics, single-acting presses lack the precise control over the piston’s movement during the return phase. This makes them less suitable for applications requiring fine control of both the forward and return strokes.

2. External Force Required for Return Stroke:

The reliance on springs or gravity for the return stroke introduces limitations. Springs can wear out over time, reducing the efficiency of the press, and gravitational return may be too slow for certain high-speed applications.

3. Power Limitations:

Single-acting presses typically have less power and speed compared to double-acting systems. For tasks requiring high force or rapid cycling, a double-acting press may be more appropriate.

4. Environmental Considerations:

Hydraulic systems, including single-acting presses, can pose environmental risks if not properly maintained. Leaking hydraulic fluid, for instance, can cause environmental contamination, making proper maintenance and disposal of used fluids critical.

Maintenance and Safety Considerations

Proper maintenance and adherence to safety protocols are essential to ensure the safe and efficient operation of single-acting hydraulic presses.

Maintenance Procedures:

- Hydraulic Fluid Levels: Regularly check and maintain the hydraulic fluid to ensure smooth operation. Low fluid levels can reduce press efficiency and lead to mechanical wear.

- Seals and Hoses: Inspect seals and hoses for wear and tear, as leaks can cause pressure loss and reduce the effectiveness of the press.

- Return Mechanism: Check the spring or gravity-based return system for signs of fatigue or failure. Over time, springs may lose tension, reducing the effectiveness of the return stroke.

Safety Protocols:

- Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including safety goggles, gloves, and hearing protection.

- Proper Training: Ensure that all operators are trained in the correct use of the press and are aware of potential hazards.

- Emergency Stops: Hydraulic presses should be equipped with emergency stop buttons to allow operators to quickly halt the machine in case of malfunction or danger.

Future of Single-Acting Hydraulic Presses

Advancements in technology are opening new possibilities for single-acting hydraulic presses. As industries evolve, the demand for more efficient and eco-friendly machinery is growing.

1. Advancements in Hydraulic Technology:

Innovations in hydraulic systems are leading to more efficient and powerful single-acting presses. For instance, new hydraulic fluids with better thermal stability and lower environmental impact are being developed, reducing the ecological footprint of hydraulic systems.

2. Energy Efficiency Improvements:

Modern hydraulic presses are being designed with energy efficiency in mind. Enhanced pump designs, variable speed motors, and more efficient control systems are reducing energy consumption and operational costs.

3. Integration with Automation:

The future of hydraulic presses lies in their integration with automated and smart systems. Automated single-acting presses equipped with sensors and computer control systems can adjust force, speed, and stroke in real time, enhancing precision and adaptability.

4. Future Applications and Innovations:

As industries continue to demand more from hydraulic systems, single-acting presses are likely to be used in new applications such as additive manufacturing (3D printing) and precision engineering. The increasing focus on sustainability may also drive the development of greener, more energy-efficient presses.

Introduction to Double-Acting Hydraulic Presses

Hydraulic presses are mechanical devices that use fluid pressure to generate significant force, commonly employed in industries where large-scale pressing, forming, or molding is required. They operate on Pascal’s Law, which states that pressure applied to a fluid in a confined space is transmitted equally in all directions. This principle allows hydraulic presses to amplify force, making them crucial in metalworking, manufacturing, automotive industries, and beyond.

A double-acting hydraulic press differs from its single-acting counterpart in that it applies hydraulic pressure in both directions—both for the pressing stroke and the return stroke. In contrast, a single-acting press relies on external forces, like springs or gravity, for the return motion, which limits control and precision.

The use of double-acting hydraulic presses has revolutionized several industrial processes due to the enhanced control and precision they offer. With powered movement in both directions, these presses are capable of handling more complex and demanding tasks, such as deep drawing, forging, or any process where high precision and consistent force are essential. These presses are widely used in automotive production, aerospace manufacturing, and large-scale industrial operations.

How Double-Acting Hydraulic Presses Work

Double-acting hydraulic presses function based on hydraulic principles, which utilize fluid power to amplify force. The critical difference from single-acting presses is that double-acting presses can apply hydraulic pressure in both the pressing and return strokes. This provides enhanced control and versatility.

Core Components of a Double-Acting Hydraulic Press:

- Cylinder and Piston: A double-acting press has a hydraulic cylinder with a piston that moves in two directions. Hydraulic fluid is directed into the cylinder on either side of the piston to control both the downward and upward strokes.

- Hydraulic Pump: The hydraulic pump provides pressure by moving hydraulic fluid into the cylinder. In double-acting presses, the pump must be capable of routing the fluid to either side of the piston, depending on whether it is the pressing or return stroke.

- Valves and Control Systems: Double-acting presses require more sophisticated valve systems to control the flow of hydraulic fluid. These valves direct fluid pressure to either side of the piston, enabling the precise control of both strokes.

- Power Source: These presses can be powered by manual pumps, electric motors, or pneumatic systems, depending on the scale and application of the press.

The Pressing and Return Strokes:

- Pressing Stroke: The hydraulic pump directs fluid into the top of the cylinder, pushing the piston downward. This downward force can range from a few tons to hundreds of tons, depending on the press’s size and design. The press head applies this force to the material being processed, whether it’s for stamping, molding, or cutting.

- Return Stroke: After the pressing operation, hydraulic pressure is redirected to the bottom of the piston. This lifts the piston back to its starting position, ensuring precise and controlled movement. The ability to hydraulically control both strokes eliminates the reliance on gravity or springs, allowing for faster cycle times and more complex tasks.

Precision and Control:

The ability to control both strokes of the piston provides greater accuracy in industrial processes. Unlike single-acting presses, where the return stroke can vary in speed and efficiency, double-acting presses offer consistent performance across all movements. This precision makes them ideal for complex forming processes, deep drawing, and precision cutting operations, where both the force and the return timing must be tightly controlled.

Types of Double-Acting Hydraulic Presses

Double-acting hydraulic presses come in various forms, each tailored for specific industrial applications. Here are some of the main types:

1. Manual Double-Acting Hydraulic Presses:

Manual versions of double-acting presses are powered by hand-operated hydraulic pumps. These are typically used in small workshops or repair facilities where tasks like pressing, bending, or assembling components do not require extensive automation. These presses are portable, cost-effective, and often used in low-production environments.

2. Electric-Powered Double-Acting Hydraulic Presses:

Electric-powered double-acting presses are more common in industrial settings where high force and consistent operation are required. The hydraulic pump is driven by an electric motor, allowing for automated control of both strokes. These presses are essential for high-volume operations, such as metal stamping, die forming, and precision cutting. The electric-powered system allows for greater precision, repeatability, and faster cycle times.

3. Pneumatic Double-Acting Hydraulic Presses:

Pneumatic-powered double-acting presses use compressed air to drive the hydraulic fluid in both strokes. These presses are favored in industries where pneumatic systems are already integrated into the production environment, such as in automotive assembly lines. Pneumatic systems provide rapid action, and the integration with hydraulics ensures the generation of high forces, making them suitable for mid-sized industrial applications.

4. Specialized Double-Acting Presses:

Some double-acting hydraulic presses are designed for specific applications, such as hydraulic press brakes used in bending and shaping metal sheets. These presses provide precise control over the angle and force applied, making them ideal for custom metal fabrication. Another example includes forging presses, where high tonnage and precise control are required to shape metal components.

Applications of Double-Acting Hydraulic Presses

Double-acting hydraulic presses are widely employed across a variety of industries due to their versatility and ability to handle complex tasks with precision. Here are some of the key applications:

1. Metal Forming and Deep Drawing:

One of the primary uses of double-acting hydraulic presses is in metal forming, particularly deep drawing. Deep drawing is a manufacturing process where a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Double-acting presses provide the precise control necessary to form complex shapes in metals like aluminum, steel, and copper without cracking or deforming the material.

2. Punching, Forging, and Die Forming:

In punching and forging operations, double-acting presses apply controlled force to deform or cut metal parts. This is commonly used in the automotive and aerospace industries, where high-strength materials are forged into critical components like gears, axles, and structural parts. The ability to control both the pressing and return strokes ensures consistent quality and reduces the risk of material damage.

3. Composite Material Molding:

As industries increasingly adopt composite materials, double-acting hydraulic presses have become essential for forming and molding these materials. Composites, such as carbon fiber or fiberglass, require careful handling during the molding process to maintain their strength and durability. Double-acting presses allow for precise pressure application during both the pressing and release phases, making them indispensable in industries like aerospace and automotive, where lightweight, high-strength components are essential.

4. Automotive and Aerospace Industries:

The automotive industry relies heavily on double-acting hydraulic presses for the production of body panels, frames, and engine components. The precision and repeatability of these presses ensure that every part is manufactured to exact specifications. In the aerospace industry, where weight, strength, and safety are critical, double-acting presses are used to form lightweight components like aircraft skin panels, structural parts, and engine elements.

5. Examples of Industrial Applications:

- Automotive: Deep drawing for body panels, stamping parts like hoods, doors, and roofs.

- Aerospace: Forming of lightweight metal and composite parts for aircraft and spacecraft.

- Heavy Machinery: Forging of large components for construction equipment and industrial machinery.

- Consumer Electronics: Precision forming of metal casings and components.

Advantages of Double-Acting Hydraulic Presses

Double-acting hydraulic presses offer several significant advantages that make them indispensable in many industries.

1. Precise Control Over Both Strokes:

The ability to apply hydraulic force in both the pressing and return strokes gives double-acting presses greater control over the entire operation. This precision is particularly valuable in tasks that require consistent force and motion, such as deep drawing, forging, and punching. Both strokes can be finely adjusted to meet the exact requirements of the material and application, leading to superior product quality.

2. Higher Efficiency in Repetitive Operations:

In manufacturing environments where tasks must be repeated at high speed, double-acting presses outperform single-acting models. Since both the press and return strokes are powered, cycle times are faster, and operators have more control over the movement of the piston, which boosts productivity in high-volume production lines.

3. Versatility in Complex Tasks:

Double-acting presses are incredibly versatile, able to handle a wide variety of materials and tasks. They can be used for pressing, forming, bending, cutting, and molding, which makes them highly adaptable to different industries and processes. Whether the task requires the shaping of metals, molding of composites, or assembly of mechanical components, these presses can be fine-tuned to meet the needs of the job.

4. Suitability for Heavy-Duty and Continuous Use:

Double-acting hydraulic presses are built for heavy-duty applications and continuous use in industrial settings. The ability to power both strokes ensures that even the toughest materials, such as steel and titanium, can be shaped and formed without compromising on speed or accuracy. Their robust design and advanced control systems make them ideal for industries where durability and long-term performance are critical.

Challenges and Limitations of Double-Acting Hydraulic Presses

Despite their advantages, double-acting hydraulic presses also come with challenges and limitations that must be considered before implementation.

1. Higher Cost and Complexity:

Double-acting hydraulic presses are generally more expensive than single-acting presses due to their more complex design and the additional control systems required to power both strokes. This can make them less appealing for small-scale operations or businesses with tight budgets.

2. Increased Maintenance Requirements:

With more moving parts and components to manage, double-acting presses require more frequent and thorough maintenance than their single-acting counterparts. Components like seals, valves, and hydraulic lines must be regularly inspected and serviced to prevent leaks and ensure optimal performance. This adds to the operational costs over the lifespan of the machine.

3. Space and Energy Requirements:

Double-acting hydraulic presses tend to be larger and consume more energy than simpler presses. This means they require more space and have higher energy costs, which can be a limiting factor in smaller workshops or facilities with limited energy resources.

4. Specialized Training and Safety Considerations:

Operators of double-acting hydraulic presses must be thoroughly trained to handle the complex control systems and high pressures involved. The increased force and speed of these presses mean that strict safety protocols must be followed to prevent accidents and equipment damage.

Maintenance and Safety Considerations

Proper maintenance and safety protocols are crucial for ensuring the long-term operation and safety of double-acting hydraulic presses.

Maintenance Procedures:

- Hydraulic Fluid Levels: Maintaining appropriate hydraulic fluid levels is essential for the proper operation of both strokes. Low fluid levels can result in uneven pressure distribution and lead to damage.

- Seal and Hose Inspections: Double-acting presses have more seals and hoses than single-acting models, which makes regular inspections critical. Leaks in these components can cause a loss of pressure, reduced efficiency, and safety hazards.

- System Pressure Checks: Monitoring and adjusting the system’s pressure levels ensures that the press operates within its designed parameters, preventing over-pressurization and component failure.

Safety Protocols:

- Operator Training: Given the complexity of double-acting presses, operators must be trained in their safe use. They should understand the machine’s control systems, emergency stop features, and troubleshooting procedures.

- Regular Inspections: Presses should be inspected regularly for signs of wear or malfunction. Safety devices like pressure relief valves and emergency stops should be tested to ensure they are functioning properly.

- Personal Protective Equipment (PPE): Operators should always wear appropriate PPE, including gloves, goggles, and ear protection, especially in high-noise environments.

Future Trends in Double-Acting Hydraulic Press Technology

As technology evolves, double-acting hydraulic presses are expected to undergo several advancements that will enhance their performance and broaden their applications.

1. Technological Advancements:

Innovations in hydraulic control systems, such as the integration of proportional valves and servo-driven pumps, are improving the precision and efficiency of double-acting presses. These systems allow for finer control of pressure and movement, resulting in higher-quality output and reduced material waste.

2. Energy Efficiency:

One of the key areas of development is the push for more energy-efficient hydraulic systems. With the increasing focus on sustainability, new technologies are emerging that reduce energy consumption, such as variable-speed pumps that adjust output based on demand. These advancements not only lower operational costs but also reduce the environmental impact of hydraulic presses.

3. Automation and Industry 4.0:

The integration of double-acting hydraulic presses with automation and smart manufacturing systems is another significant trend. By connecting presses to factory networks, manufacturers can monitor machine performance in real-time, predict maintenance needs, and optimize press cycles. This leads to increased productivity and minimizes downtime due to unexpected equipment failure.

4. Future Innovations:

Looking ahead, double-acting presses may see further improvements in force capacity, miniaturization for precise applications, and modular designs that allow presses to be easily reconfigured for different tasks. Additionally, advancements in green hydraulic fluids will reduce the environmental risks associated with hydraulic systems.

Triple Action Deep Drawing Press

Deep drawing is a popular metal forming process used to shape flat sheet metal into cylindrical or box-like shapes. The process involves placing a metal blank over a die and pressing it into the die cavity with a punch. This transforms the flat blank into a three-dimensional shape, making it essential for producing components like automotive body panels, kitchen sinks, and various enclosures. The process can be repeated to achieve more complex shapes with greater depth, but the challenges increase as the material undergoes severe deformation.

A Triple Action Deep Drawing Press is a specialized machine designed to address the complexity of the deep drawing process. Unlike conventional single-acting or double-acting presses, a triple action press incorporates three independent force mechanisms:

- Blank Holder Action: Keeps the metal blank firmly in place, controlling material flow and preventing wrinkling.

- Punch Action: The primary force that shapes the blank by pushing it into the die.

- Ejector Action: Removes the finished part from the die after the drawing process is complete.

This triple-action mechanism provides greater control over the deep drawing process, allowing for the production of more complex shapes, with fewer defects, and better efficiency. The ability to control all three forces independently is particularly important in producing deep-drawn components for industries like automotive, aerospace, and consumer goods, where precision and quality are critical.

How Triple Action Deep Drawing Presses Work (500 words)

To understand how triple action deep drawing presses function, it’s essential to break down the mechanics of the deep drawing process and how each action contributes to shaping the material.

The Deep Drawing Process:

The deep drawing process transforms a flat metal blank into a three-dimensional component. The key stages include:

- Blank Placement: A flat metal blank is placed over the die cavity.

- Blank Holder Engagement: The blank holder clamps the blank around its edges, preventing movement or wrinkling during drawing.

- Punch Stroke: The punch moves downward, pressing the blank into the die cavity, forming the desired shape. This action stretches and deforms the material, thinning it in certain areas.

- Ejection: Once the part is formed, the ejector mechanism releases the part from the die, ready for the next cycle.

Components of a Triple Action Deep Drawing Press:

- Blank Holder: The blank holder is crucial in controlling material flow. Its force must be precisely regulated to avoid wrinkling, which can occur if the material is allowed to move too freely. At the same time, too much force from the blank holder can result in tearing.

- Punch: The punch is the main shaping tool. In triple-action presses, the punch force is adjustable, allowing for greater flexibility in handling different materials or thicknesses. As the punch presses the blank into the die, it forms the desired shape.

- Ejector: The ejector action ensures the formed part is smoothly removed from the die without causing damage to the component or slowing down the production process. The ejector often uses hydraulic or mechanical systems to push the part upward, releasing it from the die.

Key Advantages of the Triple Action System:

- Independent Control of Forces: One of the main benefits of triple action presses is that each force (blank holder, punch, ejector) can be independently controlled. This ensures optimal pressure at each stage, reducing the risk of defects such as wrinkling, tearing, or excessive thinning.

- Complex Shapes: By using all three actions in a coordinated manner, triple action presses can produce complex, deep-drawn components that would be difficult or impossible with a standard press.

- Minimized Defects: The precise control over material flow, punch pressure, and ejection force allows manufacturers to achieve higher-quality products with fewer defects, making triple-action presses ideal for high-precision industries.

Types of Triple Action Deep Drawing Presses

Triple action deep drawing presses come in various types, each suited to different applications and production environments. The main types include mechanical, hydraulic, and servo-electric presses.

1. Mechanical Triple Action Presses:

Mechanical triple action presses use mechanical linkages, cams, and gears to generate and control the forces required for the blank holder, punch, and ejector. These presses are known for their high speed and are commonly used in high-volume production environments, such as automotive manufacturing. However, they tend to offer less precision than hydraulic presses, making them less suitable for complex or precision deep drawing applications.

2. Hydraulic Triple Action Presses:

Hydraulic presses are the most common type of triple action deep drawing presses. These machines use hydraulic cylinders to apply force independently to the blank holder, punch, and ejector. Hydraulic presses are favored for their precision and the ability to control force and speed at every stage of the process. This makes them ideal for deep drawing applications that require complex shapes, deep draws, or challenging materials. Additionally, hydraulic systems can apply constant force throughout the entire stroke, providing a smooth and consistent draw.

3. Servo-Electric Triple Action Presses:

Servo-electric presses use electric motors to control the movement of the blank holder, punch, and ejector. These presses offer the highest level of precision and flexibility, allowing manufacturers to program specific force and speed profiles for different stages of the drawing process. Servo-electric presses are energy-efficient and offer precise control, making them ideal for applications requiring high precision, such as aerospace components and medical devices.

Comparison of Press Types:

- Mechanical: Best for high-speed, large-volume production; less precise.

- Hydraulic: Ideal for precision deep drawing, complex shapes, and variable materials; slower but more controlled.

- Servo-Electric: Offers the highest precision and flexibility, with energy efficiency; often used in highly specialized applications.

Applications of Triple Action Deep Drawing Presses

The versatility and precision of triple action deep drawing presses make them indispensable across a wide range of industries. Their ability to form complex, deep-drawn parts with minimal defects and high repeatability is a key reason for their widespread use.

1. Automotive Industry:

In the automotive sector, deep drawing presses are essential for producing a wide array of components, including body panels, fuel tanks, and engine components. Triple action presses are particularly well-suited for forming large, complex parts such as car doors, hoods, and trunk lids, which require high precision to ensure they meet the industry’s stringent safety and performance standards.

For example, the ability to control the blank holder force ensures that body panels are formed without wrinkling, a common defect in deep drawing. Additionally, the precision of triple-action presses allows for tight tolerances in the production of complex components like fuel tanks, which must be leak-proof and structurally sound.

2. Aerospace Industry:

In the aerospace industry, the demand for lightweight yet strong components is paramount. Triple action deep drawing presses are used to form aircraft skin panels, engine housings, and other structural components. The ability to control every aspect of the drawing process, including the exact force applied by the blank holder and punch, ensures that aerospace parts meet the high standards required for safety and performance.

Additionally, the triple action mechanism is crucial for working with materials like titanium, aluminum, and composites, which are commonly used in the aerospace industry but can be difficult to form due to their strength and tendency to crack under stress.

3. Consumer Goods:

Triple action deep drawing presses are widely used to manufacture various consumer goods, particularly in the production of kitchenware (e.g., stainless steel sinks, pots, and pans) and household appliances (e.g., washing machine drums, microwave enclosures). The ability to form deep, complex shapes in materials like stainless steel or aluminum with smooth surfaces and minimal defects is essential for consumer products where aesthetics and durability are key selling points.

4. Industrial Containers and Enclosures:

Industries requiring industrial containers, cylindrical tanks, or enclosures for sensitive equipment often rely on triple action deep drawing presses. These presses allow for the formation of durable, uniform containers with precise dimensions, ensuring that they meet stringent industry standards for storage and protection.

Case Studies and Real-World Examples:

- Automotive: A major automotive manufacturer uses triple action presses to produce seamless body panels for luxury vehicles, ensuring high quality and eliminating the need for secondary finishing processes.

- Aerospace: Leading aerospace companies utilize triple action deep drawing presses for the production of lightweight, high-strength structural components, ensuring aircraft performance while reducing weight.

- Consumer Goods: A well-known kitchenware brand uses triple action presses to manufacture stainless steel cookware with flawless surfaces and uniform thickness, enhancing both performance and aesthetics.

Advantages of Triple Action Deep Drawing Presses

Triple action deep drawing presses offer numerous advantages that make them essential in industries requiring precision metal forming.

1. Enhanced Control Over the Deep Drawing Process:

One of the most significant advantages of a triple action press is the ability to independently control the blank holder, punch, and ejector forces. This precision control allows for adjustments throughout the deep drawing process, ensuring consistent material flow and reducing the risk of defects such as wrinkling, tearing, or excessive thinning.

2. Ability to Form Complex, Precise Shapes:

The precise control offered by triple action presses enables the formation of intricate shapes and deep-drawn components. The ability to fine-tune the force applied at each stage ensures that even challenging materials can be drawn without damage. This is especially important in industries like aerospace and automotive, where components must meet exacting standards for performance and safety.

3. Minimization of Defects:

Triple action presses significantly reduce common defects in the deep drawing process, such as wrinkling, cracking, and material thinning. The blank holder’s independent force ensures that the material is held securely, while the punch and ejector forces can be adjusted to optimize material flow. This results in higher-quality parts and reduced scrap, making triple action presses more efficient and cost-effective in large-scale production.

4. High Efficiency for Large-Scale Production:

Triple action presses are ideal for high-volume production, offering fast cycle times and repeatable precision. The automation of these presses allows for continuous operation, reducing downtime and increasing throughput. This efficiency is critical in industries where large quantities of parts must be produced quickly and to tight tolerances, such as automotive manufacturing.

Challenges and Limitations of Triple Action Deep Drawing Presses

Despite their numerous advantages, triple action deep drawing presses also present certain challenges and limitations.

1. High Initial Investment and Complexity:

Triple action deep drawing presses are more expensive than single or double-action presses due to their complexity and advanced control systems. The cost of purchasing and setting up a triple action press can be prohibitive for smaller operations or manufacturers with limited budgets. Additionally, these presses require more sophisticated control systems and software, which can increase the initial investment.

2. Greater Maintenance Requirements:

The complexity of triple action presses means that they require more frequent and thorough maintenance compared to simpler presses. The hydraulic systems, punch, blank holder, and ejector mechanisms all need regular inspection and servicing to prevent breakdowns and ensure the press operates at peak efficiency. Maintenance costs and downtime can be a challenge, especially in high-production environments.

3. Limitations in Smaller-Scale Operations:

For smaller-scale manufacturers or those producing limited quantities of deep-drawn parts, the high cost and complexity of triple action presses may not be justified. These presses are best suited to large-scale operations where the benefits of increased precision, efficiency, and reduced scrap outweigh the higher costs.

4. Energy and Space Requirements:

Triple action presses require significant amounts of energy to operate, especially hydraulic models, which need continuous power to maintain pressure. They are also large machines that require a substantial amount of floor space, limiting their use in smaller production facilities or workshops.

Maintenance and Safety Considerations

Proper maintenance and safety protocols are essential to ensure the longevity and safe operation of triple action deep drawing presses.

Maintenance Procedures:

- Hydraulic System Maintenance: Hydraulic presses rely on clean, properly pressurized fluid systems to function efficiently. Regular checks of hydraulic fluid levels, cleanliness, and pressure are necessary. Dirty or low fluid can cause increased wear on components or lead to system failure.

- Lubrication: Proper lubrication of moving parts, including the punch, blank holder, and ejector, is critical to reduce friction and wear. Over time, insufficient lubrication can lead to damage and expensive repairs.

- Seal and Hose Inspections: Hydraulic seals and hoses should be regularly inspected for wear and leaks. Any signs of leakage must be addressed immediately to prevent pressure loss, damage to components, or safety hazards.

- Alignment Checks: Regular alignment checks for the punch, die, and blank holder ensure that parts are being formed accurately and uniformly. Misalignment can lead to defective parts and increased machine wear.

Safety Protocols:

- Operator Training: Operators should be thoroughly trained in the use of triple action presses, including how to safely load blanks, adjust controls, and handle finished parts. Understanding how to safely manage the hydraulic systems and high forces involved is critical for preventing accidents.

- Emergency Stops and Safety Guards: Triple action presses should be equipped with emergency stop systems and safety guards to protect operators. These features ensure that the machine can be immediately stopped in the event of a malfunction or danger.

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including gloves, goggles, and protective clothing, to reduce the risk of injury from moving parts, flying debris, or hydraulic fluid leaks.

Future Trends in Triple Action Deep Drawing Press Technology

The future of triple action deep drawing presses is being shaped by advancements in technology, materials, and manufacturing processes.

1. Innovations in Press Control Systems:

As manufacturing becomes more automated and digital, the control systems used in triple action presses are becoming more sophisticated. Proportional hydraulic control valves and servo-driven systems are allowing for even more precise control over the forces applied during the deep drawing process. This enhanced control not only improves part quality but also reduces waste and increases efficiency.

2. Material Advancements:

As industries increasingly demand stronger, lighter, and more durable materials, triple action presses are evolving to handle these new challenges. Advances in high-strength steel, aluminum alloys, and composites are pushing the limits of what deep drawing presses can do. Modern presses are being designed with enhanced force capabilities and precision to work with these advanced materials, enabling the production of lightweight, high-strength components for the automotive, aerospace, and electronics industries.

3. Integration with Industry 4.0:

The integration of Industry 4.0 technologies, such as sensors, real-time data monitoring, and predictive maintenance systems, is helping manufacturers optimize the performance of their triple action presses. Smart systems can monitor machine performance in real-time, automatically adjust press settings, and even predict when maintenance is needed, reducing downtime and improving overall productivity.

4. Environmental Sustainability and Energy Efficiency:

Energy efficiency is becoming a priority for manufacturers using triple action presses. New designs are focusing on reducing energy consumption through variable-speed hydraulic pumps, energy recovery systems, and servo-electric technologies. These advancements not only reduce operational costs but also help companies meet their environmental sustainability goals by reducing the energy footprint of their manufacturing processes.

Double-Acting Hydraulic Presses

Double-acting hydraulic presses provide more control and flexibility during the deep drawing process, particularly for applications that require more complex or deeper shapes. In a double-acting press, two separate hydraulic systems work in tandem—one controls the downward motion of the punch, while the other operates the blank holder, applying force independently to hold the material in place.

- Structure: The press has two rams or cylinders—one for the punch and another for the blank holder. This setup allows for precise control of both the drawing force and the holding force, preventing material slippage or wrinkling during the drawing process.

- Applications: Double-acting presses are commonly used in automotive, aerospace, and household appliance manufacturing, where complex shapes and deeper draws are required. For instance, components like fuel tanks, car body panels, and aircraft parts are often made using double-acting hydraulic presses.

- Advantages: The independent control over the punch and blank holder forces allows for more precise and uniform drawing, reducing the risk of defects such as tearing or wrinkling. These presses are suitable for larger and more intricate parts and offer greater flexibility in handling a variety of materials and shapes.

Triple-Action Hydraulic Presses

For the most demanding and complex deep drawing applications, triple-action hydraulic presses provide unparalleled performance. These presses add a third hydraulic system to control additional movements or processes during the drawing operation.

- Structure: In addition to the punch and blank holder, triple-action presses feature a third force, often applied from the bottom of the press. This additional motion allows for processes like reverse drawing or extrusion, enabling the machine to handle extremely deep or complex shapes that require multiple stages of forming.

- Applications: Triple-action presses are typically used in highly specialized industries such as aerospace and defense, where precision and complexity are paramount. Components like deep drawn fuel cells, engine components, and structural parts for aircraft or heavy machinery are ideal for these machines.

- Advantages: These presses provide maximum control and precision, allowing manufacturers to produce parts with extreme depth or complexity without compromising on quality. They also offer higher productivity by enabling multiple forming operations in a single press cycle.

Automated vs. Manual Hydraulic Presses

Automation is an important factor in modern manufacturing, and hydraulic deep drawing presses are no exception. Buyers can choose between manual presses, which require human intervention for loading, unloading, and controlling the operation, or automated presses, which integrate robotic systems and computerized controls to manage the entire process.

- Manual Hydraulic Presses: These presses are operated by technicians who manually load the blank, initiate the drawing process, and remove the formed part. While manual presses are typically less expensive and easier to maintain, they are best suited for low-volume production runs or applications where flexibility is required.

- Automated Hydraulic Presses: Automated presses use Programmable Logic Controllers (PLCs) or Computer Numerical Control (CNC) systems to control the drawing process. Automation allows for higher precision, increased production speed, and greater consistency in the final product. Automated presses are ideal for high-volume production environments where efficiency and accuracy are critical.

Specialized Hydraulic Presses for Tailor-Made Applications

In addition to the standard configurations, there are specialized hydraulic presses designed for specific industries or applications. These machines are often custom-built to meet unique production requirements, such as forming particular shapes, materials, or sizes. For example:

- Automotive Industry: Hydraulic presses tailored for producing large, complex automotive parts, such as chassis components, doors, and structural parts.

- Aerospace Industry: Presses designed for handling high-strength alloys and lightweight materials, where the precision and complexity of the shapes are critical.

- Consumer Goods: Smaller, more compact hydraulic presses used to produce kitchenware, metal containers, and packaging components.

Types of Hydraulic Deep Drawing Presses

Hydraulic deep drawing presses come in various configurations, each designed to meet specific manufacturing requirements. The main types of hydraulic presses used in deep drawing applications include single-action, double-action, and triple-action presses. Understanding the differences between these types is crucial for selecting the right press for a particular application.

1. Single-Action Hydraulic Press

A single-action hydraulic press is the simplest type of press, using a single hydraulic cylinder to apply force. In this configuration, the blank is placed over the die, and the punch is driven into the die by the hydraulic cylinder. The force is applied in a single direction, hence the name “single-action.”

- Applications: Single-action presses are ideal for simpler deep drawing tasks, where the shape of the part is not too complex, and only moderate drawing depths are required. They are often used for producing parts such as cups, bowls, and shallow containers.

- Advantages: These presses are generally more affordable and easier to maintain compared to multi-action presses. They are also more compact, making them suitable for smaller manufacturing facilities.

- Limitations: Single-action presses are not as versatile as their double- and triple-action counterparts, as they lack the ability to handle more complex shapes or deeper draws.

2. Double-Action Hydraulic Press

Double-action hydraulic presses have two separate cylinders: one for the punch and another for the blank holder. This allows for more precise control over the drawing process, as the blank holder can be independently controlled to hold the metal blank in place while the punch draws it into the die.

- Applications: Double-action presses are commonly used for more complex parts that require greater precision and deeper draws. They are widely used in the automotive industry for forming large body panels, such as doors and hoods, where maintaining uniform material flow is critical.

- Advantages: The ability to control both the punch and the blank holder independently results in better control over the material flow, reducing the risk of defects like wrinkling or tearing. Double-action presses are also more versatile, as they can handle a wider range of part shapes and sizes.

- Limitations: These presses are more expensive and larger than single-action presses, making them more suitable for high-volume production environments.

3. Triple-Action Hydraulic Press

Triple-action hydraulic presses feature three separate cylinders: one for the punch, one for the blank holder, and a third for the ejector. The ejector is used to remove the finished part from the die after the drawing process is complete, allowing for continuous production with minimal downtime.

- Applications: Triple-action presses are used for highly complex deep drawing applications that require precise control over every aspect of the process. They are commonly used in industries such as aerospace, where parts often have intricate geometries and tight tolerances.

- Advantages: Triple-action presses offer the highest level of control and versatility, making them suitable for the most demanding deep drawing tasks. The use of an ejector system also improves production efficiency, as it reduces the time required to remove finished parts from the die.

- Limitations: These presses are the most expensive and require the largest amount of floor space. They also require more maintenance due to the increased complexity of the hydraulic system.

Key Considerations for Selecting a Hydraulic Deep Drawing Press

When selecting a hydraulic deep drawing press, several factors must be considered to ensure that the press meets the specific requirements of the production environment:

- Part Complexity: More complex parts with deeper draws and intricate geometries may require double- or triple-action presses for precise control.

- Production Volume: High-volume production environments may benefit from the continuous operation and efficiency offered by triple-action presses.

- Material Type: The type of material being formed will also influence the choice of press, as some materials require higher forces or more precise control over the drawing process.

Process Parameters Affecting Deep Drawing

The deep drawing process is highly sensitive to a range of parameters that can directly impact the quality, consistency, and overall success of the formed parts. Proper management of these parameters ensures defect-free production, reduces material waste, and improves production efficiency. The key parameters that influence deep drawing include blank holder force, drawing speed, lubrication, blank material properties, and the geometry of the die and punch.

1. Blank Holder Force

The blank holder force is the pressure applied to hold the metal blank in place during the drawing process. Its primary role is to control the material flow as the punch moves the blank into the die. If the blank holder force is too low, the material may wrinkle due to excessive material flow. On the other hand, if the force is too high, it can lead to tearing or cracking because the material cannot move freely enough into the die.

Achieving the correct balance in blank holder force is essential. Modern hydraulic deep drawing presses often feature adjustable blank holder systems, allowing operators to fine-tune the force to suit the specific material and part geometry. The use of dynamic control systems can further improve the process by automatically adjusting the force in real time as the press operates.

2. Drawing Speed

Drawing speed refers to the rate at which the punch moves into the die during the deep drawing process. It directly affects the material’s flow, the heat generated during forming, and the risk of defects like tearing or thinning. If the drawing speed is too fast, the material may not have enough time to flow into the die, leading to defects such as cracking or excessive thinning in certain areas.