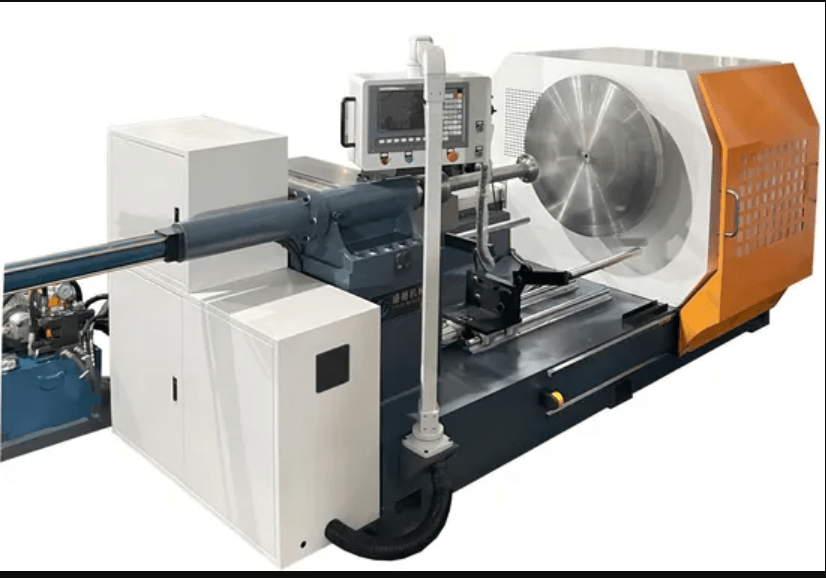

CNC Metal Spinning and Flow Forming Machine: A metal spinning machine is a highly specialized piece of equipment designed for forming sheet metal into symmetrical, often cylindrical or conical shapes through a process known as metal spinning. Unlike conventional stamping or pressing, metal spinning relies on the controlled rotation of a metal blank against a forming tool or mandrel, gradually shaping the material into the desired geometry. This technique is widely used in industries such as aerospace, defense, automotive, lighting, household appliances, and energy production, where both precision and efficiency are essential.

Modern metal spinning machines can be classified into manual, semi-automatic, and fully CNC-controlled systems. Manual spinning machines are used for custom, small-batch production where craftsmanship and flexibility are prioritized. Semi-automatic machines combine operator skill with mechanized support for increased consistency and reduced labor intensity. The most advanced CNC spinning machines employ computerized controls, servo motors, and hydraulic systems to deliver repeatable, high-precision results suitable for mass production. These systems can handle a variety of metals, including aluminum, stainless steel, titanium, copper, and special alloys, allowing for applications ranging from lightweight components to high-strength, pressure-resistant parts.

The advantages of using a metal spinning machine include material efficiency, as the process typically involves little to no material waste compared to stamping or deep drawing, as well as structural strength, since spinning often enhances the grain structure of the metal. Additionally, tooling costs are significantly lower than those of large-scale pressing dies, making spinning particularly cost-effective for medium-volume production runs or prototyping. With CNC integration, spinning machines are capable of handling complex geometries, multi-pass forming, hot spinning (using induction or gas heating for difficult materials), and flow forming, which further refines wall thickness with high accuracy.

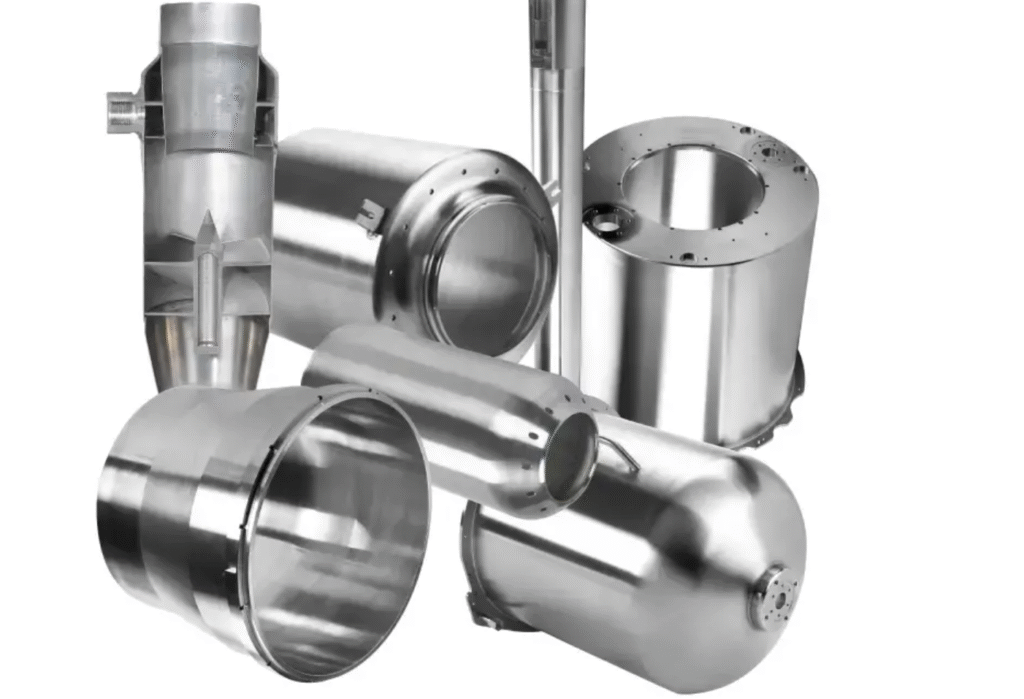

In recent years, the technology has advanced to include hybrid machines capable of performing spinning, flow forming, trimming, beading, and even necking operations within a single setup. This multi-functionality reduces production time and improves process reliability. Industries such as defense, for example, rely heavily on CNC spinning and flow forming machines for producing artillery shells, rocket motor casings, and other critical cylindrical components. Similarly, aerospace applications involve the production of turbine engine parts, nose cones, and jet housings where dimensional accuracy and material integrity are paramount.

The choice of a metal spinning machine depends on several factors: the material to be processed, the thickness of the blank, the size of the part, production volume, and the level of precision required. Safety features, automation options, and energy efficiency also play a growing role in machine selection as manufacturers seek sustainable and operator-friendly production solutions. As the demand for lightweight, high-performance, and custom-shaped components increases, the role of metal spinning machines continues to expand, making them an indispensable technology in modern metal forming.

A metal spinning machine represents one of the most versatile technologies in modern metal forming, providing the ability to transform flat circular blanks or pre-formed workpieces into seamless, axisymmetric parts with high structural integrity. The principle of operation is based on rotating the metal blank at high speed against a mandrel while applying controlled pressure through forming rollers or tools, gradually shaping the material without cutting or welding. This cold-forming or hot-forming process enables manufacturers to produce components with superior mechanical properties, as the continuous deformation refines the grain structure and enhances strength while maintaining excellent dimensional precision. Metal spinning machines have evolved from traditional manually operated lathes, which relied on the skill and experience of the operator, to advanced CNC-controlled systems capable of handling complex geometries, large-scale industrial production, and specialized applications in aerospace, defense, automotive, renewable energy, household equipment, and lighting industries.

The advantages of using a metal spinning machine are numerous, making it one of the most efficient methods for producing hollow, rotationally symmetric parts such as pressure vessels, lamp reflectors, cookware, nozzles, artillery shells, and turbine components. Compared to conventional forming processes like stamping or deep drawing, spinning requires significantly lower tooling costs, since the mandrels are relatively simple and inexpensive compared to large-scale dies. Additionally, the process generates minimal scrap because the metal is formed through plastic deformation rather than cutting, allowing near-net-shape production with efficient material utilization. This efficiency is particularly important when working with expensive materials such as titanium or nickel alloys, which are common in aerospace and high-performance engineering. Another significant advantage is the flexibility of the process, as a single machine can be adapted to produce a wide variety of part sizes and shapes without the need for extensive retooling. This adaptability makes metal spinning machines ideal not only for large production runs but also for small-batch manufacturing and prototyping, where cost control and design changes are frequent.

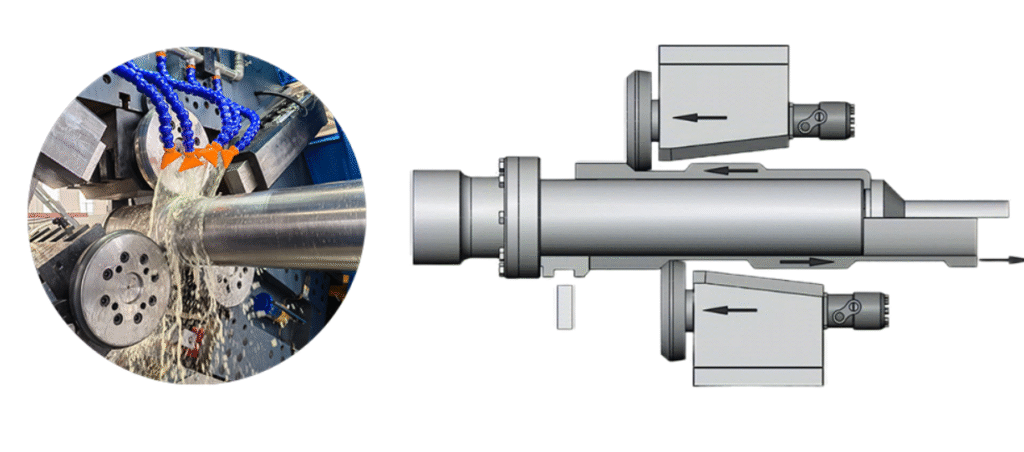

Modern CNC metal spinning machines have further revolutionized the field by introducing computer-controlled precision, automation, and repeatability. CNC technology allows for multi-pass forming, where the machine can gradually reduce thicknesses, create flanges, beads, or necks, and even perform flow forming operations that enable the controlled elongation of tubular components with tight tolerances. CNC integration also supports hot spinning, where localized induction or gas heating is applied to materials that are otherwise difficult to form at room temperature, such as high-strength steels, titanium, or certain composites. These advanced systems are equipped with servo-driven axes, hydraulic or electric clamping systems, and intelligent software that ensures consistent production quality while reducing operator intervention. In industries such as defense, CNC spinning and flow forming machines are critical for the production of seamless artillery cartridges, missile bodies, and rocket casings, where structural reliability under extreme pressure and temperature conditions is non-negotiable. Similarly, in the aerospace industry, the production of jet engine components, nose cones, and structural housings benefits from the precision and grain refinement offered by metal spinning.

The global demand for metal spinning machines continues to grow, driven by trends toward lightweight construction, high-performance materials, and cost-effective production. In automotive manufacturing, for example, spinning machines are increasingly used to produce lightweight wheel rims, gas cylinders, and structural reinforcements, contributing to energy efficiency and sustainability. In renewable energy, components for wind turbines, solar concentrators, and hydrogen storage vessels are produced using spinning techniques due to their ability to withstand high loads and pressures. The food and household equipment industries rely on spinning machines to produce cookware, kitchen utensils, and stainless steel containers with smooth finishes and durable structures. Each application highlights the adaptability of the process and reinforces why metal spinning remains indispensable despite the rise of additive manufacturing and other modern forming technologies.

Choosing the right metal spinning machine requires careful consideration of material type, blank thickness, finished part dimensions, and production volume. Manual and semi-automatic machines remain relevant for artisanal work, specialty items, and flexible small-batch production, while fully automated CNC systems dominate large-scale industrial applications where precision and efficiency are paramount. Key decision factors also include safety features, operator ergonomics, energy consumption, and the availability of integrated processes such as trimming, beading, flanging, or necking, which can reduce production time by consolidating multiple forming stages into a single operation. As manufacturers increasingly prioritize sustainability, modern spinning machines are being designed with energy-efficient drives, optimized hydraulic systems, and automation features that reduce waste and improve workplace safety. The result is a forming technology that combines centuries-old principles with cutting-edge engineering, ensuring that metal spinning machines remain a cornerstone of advanced manufacturing across industries worldwide.

A metal spinning machine is at the heart of one of the most efficient and resourceful metal forming processes, delivering results that combine traditional craftsmanship with modern technological innovation. By rotating a circular blank at high speed while applying pressure through specially designed rollers against a mandrel, the machine reshapes the metal into seamless cylindrical, conical, or parabolic geometries without material removal. This forming method creates parts that are stronger due to work hardening and grain refinement, while also reducing waste compared to machining or stamping methods. The versatility of the metal spinning machine lies in its ability to handle a broad spectrum of metals, including aluminum, stainless steel, copper, brass, titanium, and nickel alloys, enabling industries such as aerospace, automotive, defense, lighting, household goods, renewable energy, and chemical processing to produce highly functional and precise components. From cookware and reflectors to artillery shells and turbine housings, the range of applications is virtually limitless, and the efficiency of the process makes it one of the most sustainable and cost-effective options in the field of metal forming.

The transition from manual spinning lathes to advanced CNC metal spinning machines has fundamentally transformed the industry, expanding capabilities and unlocking new applications. While manual machines require skilled operators to shape the workpiece with handheld tools against the mandrel, CNC-controlled systems employ servo-driven rollers guided by pre-programmed paths that ensure accuracy, repeatability, and consistency across large production runs. This advancement not only improves productivity but also allows for the manufacture of complex geometries that were once nearly impossible with manual methods. CNC spinning machines are capable of performing flow forming, a variant of spinning that reduces wall thickness while elongating the workpiece with high precision, making it invaluable for producing rocket motor casings, gas cylinders, and other critical hollow components where structural integrity and dimensional accuracy are paramount. Hot spinning techniques, where localized induction heating softens the material during forming, further expand the possibilities by enabling the shaping of hard-to-form metals like titanium and high-strength steels used in aerospace and defense applications.

One of the greatest advantages of using a metal spinning machine is the significant reduction in tooling costs compared to processes like stamping or deep drawing. Instead of investing in massive, expensive dies, manufacturers only need relatively simple mandrels and forming tools, making the process highly adaptable to design changes, prototyping, and small- to medium-volume production. At the same time, the method achieves near-net-shape forming, which minimizes scrap and optimizes the use of expensive raw materials. This efficiency is particularly critical in industries where material costs are high, such as the production of nickel-based alloys for jet engines or titanium alloys for aerospace structures. The resulting parts are not only strong and precise but also free of weld seams or joints, offering superior durability under pressure, vibration, and thermal stress. This explains why defense contractors rely heavily on CNC spinning and flow forming machines to produce munitions, rocket shells, and missile casings, while energy companies use them to create pressure vessels, storage tanks, and turbine components designed to withstand extreme operational conditions.

Modern metal spinning machines are increasingly being designed as multifunctional systems that integrate additional operations such as trimming, flanging, beading, and necking within a single setup. This integration reduces handling, shortens production cycles, and enhances overall efficiency, making the equipment even more attractive for large-scale manufacturing environments. Automation has also advanced to include robotic handling, real-time quality monitoring, and intelligent software that optimizes forming paths and minimizes tool wear. These developments make the latest generation of spinning machines not just forming tools but complete production solutions that can adapt to the demands of Industry 4.0. In sectors like renewable energy, this capability is particularly relevant for producing hydrogen storage vessels, wind turbine hubs, and solar concentrator components where high strength, precise geometry, and cost control are equally critical. In consumer industries, spinning machines continue to dominate the production of durable cookware, lighting reflectors, and stainless steel appliances, delivering a balance of strength, aesthetics, and affordability.

The future of metal spinning machines is tied to the increasing demand for lightweight structures, energy-efficient processes, and high-performance materials. As manufacturers aim to reduce carbon footprints and improve sustainability, the low-waste nature of spinning makes it an indispensable process, especially when combined with recyclable metals like aluminum and stainless steel. With continuous improvements in CNC control, automation, and heating technologies, the metal spinning machine is no longer limited to simple rotational components but is increasingly capable of creating complex, multifunctional parts that serve critical roles across industries. Whether for the mass production of defense and aerospace components, the efficient manufacture of automotive parts, or the crafting of high-quality consumer goods, the metal spinning machine continues to stand as a symbol of adaptability, precision, and cost-effectiveness in modern manufacturing. It bridges centuries of forming tradition with the demands of today’s high-technology industries, securing its position as one of the most valuable assets in the field of advanced metalworking.

A metal spinning machine is one of the most important tools in modern metal forming because it makes it possible to create seamless, symmetrical parts from flat circular blanks or pre-formed pieces. The process works by rotating the blank at high speed against a mandrel while applying pressure with rollers or forming tools, gradually reshaping the metal without cutting or welding. This technique is highly efficient and strengthens the material by refining its grain structure. It is used across many industries, including aerospace, defense, automotive, energy, household appliances, and lighting, because it can handle metals such as aluminum, stainless steel, copper, titanium, and nickel alloys. Products made with metal spinning machines include cookware, reflectors, turbine housings, gas cylinders, artillery shells, and pressure vessels, all of which benefit from the precision and strength that the process provides.

The evolution from manual machines to CNC metal spinning machines has transformed the technology. Manual spinning requires the operator’s skill to shape the workpiece with handheld tools, while CNC-controlled machines use servo-driven rollers guided by programmed paths to achieve accuracy and repeatability for large production runs. CNC systems also make it possible to perform flow forming, where the wall thickness of the workpiece is reduced while its length increases, producing rocket casings, artillery cartridges, and gas cylinders with high dimensional precision and strength. Hot spinning, where induction heating is applied during forming, expands the capability to harder metals such as titanium and advanced steels. These innovations have made spinning machines essential for demanding sectors like aerospace and defense, where part reliability under extreme pressure and temperature is vital.

One of the key advantages of a metal spinning machine is the reduced tooling cost compared to stamping or deep drawing. Mandrels are simpler and less expensive than full-scale dies, which makes the process well suited to prototyping, medium-volume runs, and designs that need frequent changes. At the same time, the forming method uses very little material waste, which is especially valuable when working with costly alloys. Parts produced

A metal spinning machine is one of the most important tools in modern metal forming because it makes it possible to create seamless, symmetrical parts from flat circular blanks or pre-formed pieces. The process works by rotating the blank at high speed against a mandrel while applying pressure with rollers or forming tools, gradually reshaping the metal without cutting or welding. This technique is highly efficient and strengthens the material by refining its grain structure. It is used across many industries, including aerospace, defense, automotive, energy, household appliances, and lighting, because it can handle metals such as aluminum, stainless steel, copper, titanium, and nickel alloys. Products made with metal spinning machines include cookware, reflectors, turbine housings, gas cylinders, artillery shells, and pressure vessels, all of which benefit from the precision and strength that the process provides.

The evolution from manual machines to CNC metal spinning machines has transformed the technology. Manual spinning requires the operator’s skill to shape the workpiece with handheld tools, while CNC-controlled machines use servo-driven rollers guided by programmed paths to achieve accuracy and repeatability for large production runs. CNC systems also make it possible to perform flow forming, where the wall thickness of the workpiece is reduced while its length increases, producing rocket casings, artillery cartridges, and gas cylinders with high dimensional precision and strength. Hot spinning, where induction heating is applied during forming, expands the capability to harder metals such as titanium and advanced steels. These innovations have made spinning machines essential for demanding sectors like aerospace and defense, where part reliability under extreme pressure and temperature is vital.

One of the key advantages of a metal spinning machine is the reduced tooling cost compared to stamping or deep drawing. Mandrels are simpler and less expensive than full-scale dies, which makes the process well suited to prototyping, medium-volume runs, and designs that need frequent changes. At the same time, the forming method uses very little material waste, which is especially valuable when working with costly alloys. Parts produced are seamless, durable, and resistant to stresses, which explains their extensive use in industries that require both strength and efficiency.

A metal spinning machine continues to stand out in the manufacturing world because it brings together efficiency, flexibility, and strength in a way few other forming processes can achieve. Its ability to take a flat circular blank or a pre-formed disc and, through controlled high-speed rotation combined with steady pressure applied by rollers, create seamless and precise components has made it indispensable in countless industries. What makes this process particularly valuable is the structural integrity it provides; as the metal is shaped, the grain structure becomes more refined, which leads to parts that can withstand pressure, vibration, and high temperatures without failure. This is why aerospace engineers rely on metal spinning machines for jet housings, nose cones, and turbine engine parts, while the defense sector depends on them for artillery shells, missile casings, and rocket motor bodies. Even in more everyday applications such as cookware, lamps, or reflectors, the process ensures durability, accuracy, and smooth finishes that meet both functional and aesthetic demands.

Modern CNC metal spinning machines have redefined the limits of what can be produced, transforming the process from an operator’s art into a highly repeatable, programmable, and automated production method. With servo-driven rollers, hydraulic clamping systems, and intelligent CNC controls, these machines can execute complex forming paths with precision, ensuring that every piece produced matches strict tolerances. They can also integrate advanced processes such as flow forming, where the wall thickness is carefully reduced to create elongated, pressure-resistant structures, and hot spinning, where localized heating allows the forming of high-strength steels, nickel alloys, and titanium that would otherwise be nearly impossible to shape cold. These capabilities have broadened the role of metal spinning machines in industries pushing the boundaries of engineering, from renewable energy where they form hydrogen storage tanks and wind turbine hubs, to automotive manufacturing where they produce lightweight yet strong wheel rims and structural reinforcements.

What continues to drive interest in metal spinning machines is their remarkable cost-effectiveness combined with adaptability. Unlike stamping or deep drawing, which demand expensive and rigid dies, spinning requires only relatively simple mandrels and forming tools, making it far more affordable for small-batch runs, prototypes, or projects where frequent design modifications are needed. At the same time, scrap generation is minimal, a factor that is increasingly important as companies look to reduce waste and improve sustainability in their manufacturing processes. This efficient material usage becomes even more critical when dealing with costly alloys like titanium or nickel, where every gram counts. The latest generations of machines are designed as multifunctional units that can perform trimming, beading, necking, and flanging in a single setup, drastically reducing production time and improving efficiency. Combined with automation, robotic integration, and quality-monitoring systems, metal spinning machines today are not only tools for shaping metal but complete production solutions that align with the principles of Industry 4.0.

As demand continues to grow for lightweight, high-performance, and cost-efficient components, metal spinning machines will remain central to the evolution of manufacturing. They represent a process that balances tradition and modernity, rooted in centuries-old manual spinning practices yet now operating with advanced computer controls, precision engineering, and automated systems. Whether in the defense industry for producing seamless casings, in aerospace for components that must perform under extreme conditions, in the automotive sector for stronger and lighter parts, or in consumer products for durable and stylish everyday items, the metal spinning machine embodies the flexibility, precision, and efficiency that modern production demands. It is this unique blend of adaptability and performance that ensures the technology’s continued importance in shaping the future of metal forming.

A metal spinning machine remains one of the most versatile and efficient tools in the metalworking industry, able to take a simple circular blank and transform it into a seamless, symmetrical, and structurally strong component with applications that span from everyday household items to critical aerospace and defense equipment. The process of spinning involves clamping the blank against a mandrel and rotating it at high speeds while applying steady pressure through rollers that gradually force the material into the desired shape without cutting or welding. This forming method not only improves the mechanical properties of the part by refining the grain structure through plastic deformation but also minimizes material waste, making it both cost-effective and sustainable. The adaptability of the technique allows manufacturers to use a wide variety of metals including aluminum, stainless steel, titanium, copper, and nickel alloys, ensuring that the same fundamental process can be applied to industries as diverse as lighting, cookware, renewable energy, automotive manufacturing, and high-tech aerospace components. From simple bowls and reflectors to artillery shells, rocket motor cases, turbine housings, and gas cylinders, the versatility of the metal spinning machine secures its role as a cornerstone of modern forming technology.

The evolution from traditional manual spinning lathes to advanced CNC-controlled spinning machines has pushed the boundaries of what is possible with this technology. Manual spinning, once a highly skilled craft relying on the dexterity and precision of operators, has now largely given way to computer-controlled systems capable of delivering repeatability, precision, and productivity at an industrial scale. CNC spinning machines, with servo-driven axes and programmable forming paths, are able to produce complex geometries with remarkable consistency while also offering the flexibility to quickly adapt to new designs or part specifications. They have made possible advanced techniques such as flow forming, where the machine elongates and thins the walls of tubular components while maintaining precise tolerances, and hot spinning, where induction heating enables the shaping of high-strength steels and titanium alloys that would be difficult or impossible to form at room temperature. These capabilities make the machines indispensable in the production of aerospace parts like jet engine housings, nose cones, and pressure-resistant tanks, as well as in defense applications where seamless strength is required for munitions, missiles, and rocket casings.

What makes metal spinning machines even more attractive to manufacturers is the balance they strike between cost savings and production efficiency. Unlike stamping or deep drawing, which require expensive dies and long lead times, spinning machines rely on relatively simple mandrels and forming rollers, which reduces tooling costs and makes the process especially suitable for prototyping, small- to medium-volume production, and applications where frequent design changes are required. The process generates very little scrap, making it ideal when working with high-value alloys, and it produces parts that are seamless, which enhances strength and reliability under demanding conditions. Modern machines are often designed as multifunctional systems that integrate trimming, beading, flanging, and necking, all within a single setup, which streamlines production and reduces cycle times. Automation, robotic handling, and intelligent control systems have further expanded their potential, making them not just machines for shaping metal but full-scale production solutions that can be integrated into Industry 4.0 environments.

As industries worldwide pursue lightweight construction, improved energy efficiency, and cost-effective manufacturing solutions, the role of the metal spinning machine continues to grow in importance. In automotive manufacturing, the technology contributes to lighter and stronger parts that support fuel efficiency and performance, while in renewable energy it enables the production of durable and pressure-resistant vessels, wind turbine components, and solar concentrator elements. Consumer goods industries benefit from the durability and aesthetics of spun parts in cookware, stainless steel containers, and decorative lighting. Across all these applications, the advantages of flexibility, efficiency, strength, and precision ensure that the metal spinning machine remains vital in a rapidly evolving industrial landscape. Its ability to combine centuries-old forming techniques with the power of modern CNC and automation makes it one of the most valuable and adaptable tools in metalworking, a technology that continues to meet the challenges of both traditional applications and the most advanced engineering demands.

A metal spinning machine continues to define itself as a fundamental technology in the evolution of modern manufacturing, offering a unique combination of adaptability, efficiency, and strength that few other metal forming methods can rival. The process of spinning, based on the principle of rotating a blank at high speed against a mandrel while applying controlled pressure through rollers or tools, enables the creation of seamless, geometrically precise components that carry superior mechanical properties due to the refinement of the material’s grain structure during forming. Unlike subtractive methods such as machining, spinning involves plastic deformation rather than cutting, which minimizes waste and maximizes the use of raw materials. This is particularly important when working with expensive alloys like titanium, nickel, or advanced stainless steels, making the technology especially attractive to industries where both cost control and material performance are critical. The ability of metal spinning machines to handle metals ranging from soft aluminum and copper to hard alloys designed for aerospace and defense adds to their versatility, making them indispensable for sectors as varied as lighting, cookware, renewable energy, chemical processing, automotive, and high-performance aerospace engineering.

The modern CNC metal spinning machine has transformed what was once a manual art into a sophisticated, automated, and programmable process capable of achieving levels of precision and repeatability that were previously unimaginable. In the past, manual spinning demanded years of experience, as operators had to skillfully manipulate handheld tools against the spinning blank to achieve the desired shape. Today, CNC-controlled machines employ servo-driven rollers, hydraulic clamping, and advanced software to perform the same operations with far greater accuracy and consistency, making it possible to produce thousands of identical parts to tight tolerances. This evolution has also enabled advanced techniques such as flow forming, where the material is progressively elongated and thinned to create long, seamless, pressure-resistant cylinders that are vital in defense and aerospace applications, including artillery shells, missile casings, and rocket motor housings. Hot spinning, another innovation integrated into CNC machines, uses induction or gas heating to soften the material during forming, allowing for the production of components from high-strength steels, titanium, and superalloys that are otherwise extremely difficult to shape. These capabilities not only expand the scope of possible applications but also ensure that metal spinning machines remain relevant in industries that demand cutting-edge performance.

What makes the technology so appealing to manufacturers is the balance between flexibility and cost-effectiveness. Tooling for metal spinning is far less expensive than the massive dies required for stamping or deep drawing, meaning that design changes can be accommodated quickly and economically, which is especially beneficial for prototyping and low- to medium-volume production runs. At the same time, the process generates minimal scrap, improving sustainability and lowering overall production costs, while the seamless construction of spun parts ensures superior strength and reliability compared to welded or assembled alternatives. Many modern spinning machines are designed as multifunctional systems that can perform several operations such as trimming, beading, flanging, and necking in one setup, further reducing production times and increasing efficiency. Automation has also advanced significantly, with robotic part handling, integrated quality control, and intelligent CNC programs that optimize forming paths to reduce tool wear and energy consumption, aligning the technology with Industry 4.0 standards.

The growing emphasis on lightweight design, high-performance materials, and sustainable production methods across industries reinforces the importance of metal spinning machines in the future of manufacturing. In automotive engineering, they are used to produce lightweight yet strong structural components, wheel rims, and gas cylinders that support fuel efficiency and safety. In renewable energy, spinning is essential for hydrogen storage tanks, wind turbine hubs, and components for solar power systems, where durability and precision under high loads are non-negotiable. In consumer markets, the same machines produce cookware, stainless steel containers, and lighting fixtures that combine aesthetics with strength. Across all these applications, the consistent thread is the unmatched ability of metal spinning machines to adapt to different materials, shapes, and volumes while maintaining cost efficiency and product reliability. The technology embodies the perfect blend of tradition and innovation, carrying forward centuries-old forming principles into an era of automation, digital control, and advanced engineering, ensuring that the metal spinning machine remains not only relevant but central to global industrial progress.

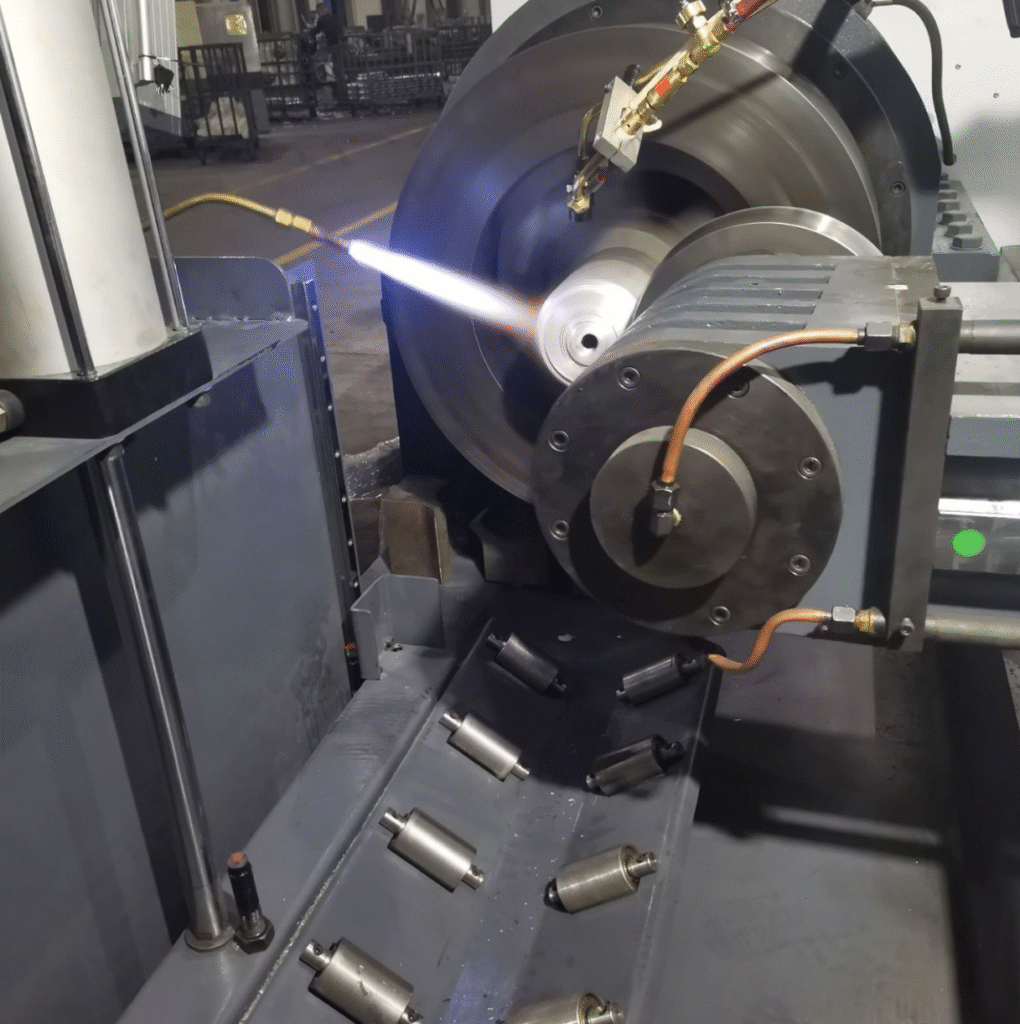

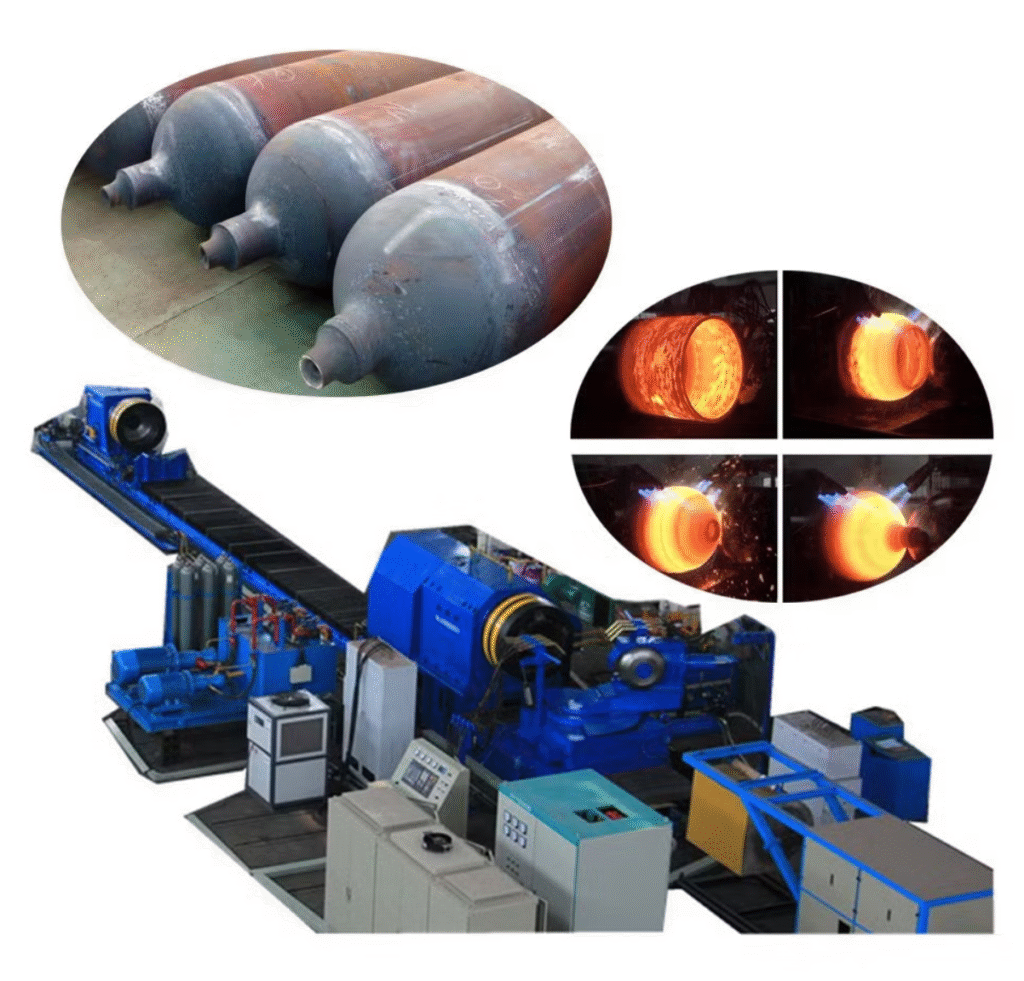

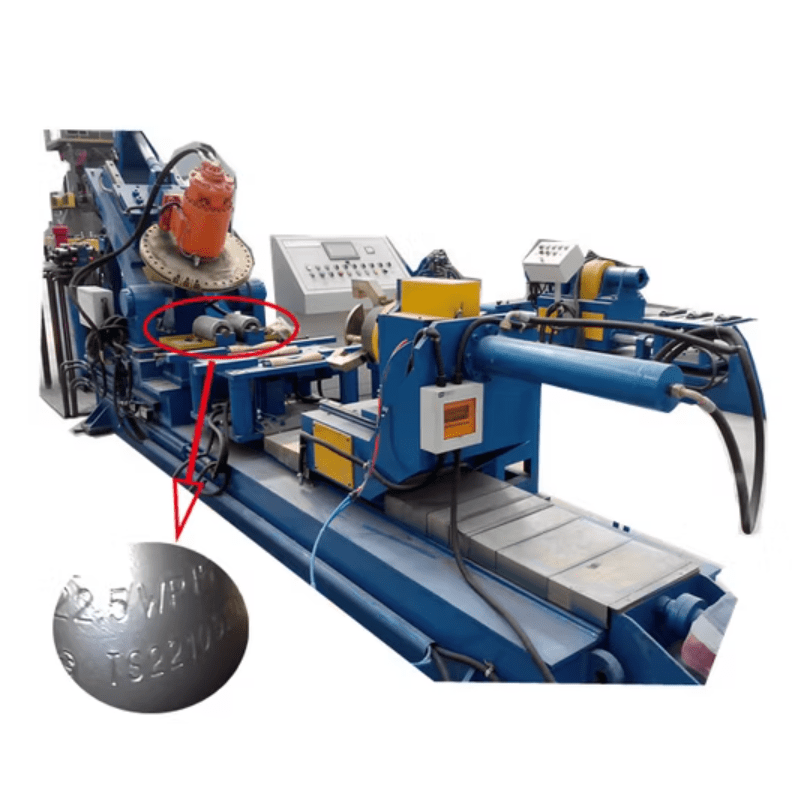

Hot Metal Spinning Forming Machine

A hot metal spinning lathe is a highly specialized machine used in advanced metal forming, designed to shape and elongate materials that are too strong or too brittle to be worked efficiently at room temperature. The principle of hot metal spinning is similar to conventional spinning, where a flat circular blank or preformed disc is clamped against a mandrel and rotated at high speed while rollers apply controlled pressure to force the material into the required geometry. However, in hot spinning, the workpiece is heated—often by induction heating systems or gas burners—so that the material becomes more ductile during forming. This makes it possible to process high-strength steels, nickel-based alloys, titanium, and other difficult-to-form metals that would otherwise risk cracking or excessive tool wear under cold forming conditions. The hot metal spinning lathe therefore bridges the gap between traditional spinning and high-performance engineering, allowing industries to produce large, seamless, pressure-resistant components that meet stringent structural demands.

The applications of a hot metal spinning lathe are most prominent in aerospace, defense, energy, and heavy industry, where performance and reliability are paramount. Aerospace manufacturers rely on these machines for producing jet engine housings, rocket motor casings, nose cones, and turbine components, all of which must withstand extreme stress and high operating temperatures. In defense applications, the hot spinning process is used to manufacture artillery shells, missile bodies, and other seamless cylindrical structures where strength and precision are critical. The energy sector benefits from the ability to create hydrogen storage vessels, high-pressure gas cylinders, and components for nuclear and thermal power systems, where metals must endure both internal pressures and thermal cycles without failure. Hot metal spinning lathes are also valuable for producing large industrial components such as chemical reactors, pressure tanks, and heavy-duty piping elements that require exceptional durability.

The introduction of CNC technology has greatly advanced the capabilities of hot metal spinning lathes, combining the flexibility of thermal-assisted forming with the precision and repeatability of computer control. CNC hot spinning systems allow exact control over forming paths, roller pressure, heating zones, and rotation speeds, which ensures consistent part quality even in mass production. The integration of induction heating directly into the lathe enables localized and controlled heating of the workpiece, reducing energy consumption and improving efficiency compared to traditional open flame heating. This synergy between heating and automated forming not only improves productivity but also extends the life of forming tools by reducing stress on rollers and mandrels. In addition, multifunctional hot metal spinning lathes can perform additional operations such as trimming, beading, or flow forming within a single setup, further streamlining the production process.

The demand for hot metal spinning lathes continues to grow as industries push for stronger, lighter, and more reliable components that can endure extreme working conditions. The technology plays a key role in supporting global trends toward advanced aerospace engineering, modern defense systems, renewable energy solutions, and efficient industrial production. Its ability to reduce material waste, lower tooling costs, and deliver seamless high-strength parts makes it one of the most valuable investments for manufacturers working with advanced alloys. By combining centuries-old spinning principles with modern heating systems and CNC automation, the hot metal spinning lathe has secured its place as an indispensable tool in the future of high-performance metal forming.

A hot metal spinning lathe is one of the most advanced and powerful machines in the field of metal forming, created to handle materials that are otherwise too strong, too thick, or too brittle to be shaped through conventional cold spinning methods. The working principle is rooted in the traditional spinning process, where a flat disc or preformed blank is clamped onto a mandrel and rotated at high speed while forming rollers gradually force the material into a seamless, symmetrical geometry. The difference lies in the fact that a hot metal spinning lathe introduces heat, often through induction coils or gas torches, to make the workpiece ductile enough for controlled shaping without cracking or producing excessive tool wear. This combination of rotational forming and thermal assistance opens the door to working with high-strength steels, titanium alloys, nickel-based superalloys, and other metals that are vital to aerospace, defense, and energy industries but are notoriously difficult to form at room temperature. By allowing these advanced materials to be processed efficiently, the hot spinning lathe ensures that seamless, high-strength, and pressure-resistant parts can be produced to meet the highest engineering standards.

The use of a hot metal spinning lathe is especially important in aerospace applications, where components such as turbine housings, jet engine casings, rocket motor shells, and nose cones must not only achieve precise geometries but also maintain structural integrity under extreme thermal and mechanical loads. Defense industries also depend heavily on hot spinning technology, as it is one of the most reliable ways to produce seamless artillery shells, missile bodies, and rocket cases that can withstand explosive pressures without failure. In the energy sector, hot spinning lathes are applied to the production of hydrogen storage vessels, natural gas cylinders, nuclear power containment parts, and high-pressure tanks that require maximum durability and resistance to fatigue. Heavy industrial manufacturing also benefits from this process, as chemical reactors, boilers, and large pressure vessels are often shaped using hot spinning to ensure smooth, defect-free walls that can handle continuous operation in aggressive environments. The fact that the process produces parts with improved grain flow and strength due to the combined effects of forming and heating makes it a natural choice for critical industries where reliability and performance are non-negotiable.

The integration of CNC technology into hot metal spinning lathes has elevated the process to a level where precision, repeatability, and efficiency are guaranteed even for complex and demanding designs. CNC-controlled lathes not only automate the forming path of rollers but also synchronize heating, pressure application, and rotational speeds with incredible accuracy. Induction heating systems built directly into these machines allow localized and controlled thermal input, ensuring the metal is softened exactly where needed without overheating or wasting energy. This level of control reduces the overall forming forces required, extends tool life, and produces consistent quality across high-volume production. Moreover, modern CNC hot spinning lathes can perform multifunctional operations such as trimming excess material, beading edges, flanging rims, and even applying flow forming techniques, all within the same cycle. This consolidation of processes reduces production times, lowers labor requirements, and makes the machines ideal for industries moving toward fully automated and digitized manufacturing systems.

As the demand for stronger, lighter, and more durable components continues to increase across aerospace, defense, automotive, and renewable energy sectors, the role of hot metal spinning lathes becomes more important than ever. Manufacturers are under constant pressure to deliver high-performance parts at lower costs while meeting strict sustainability targets, and this technology supports those goals by minimizing waste, reducing tooling expenses, and maximizing material efficiency. The seamless construction of spun components ensures reliability in high-stress environments, while the adaptability of the machines allows rapid switching between prototypes, small production runs, and mass manufacturing. The hot metal spinning lathe thus embodies the union of ancient forming principles with cutting-edge heating and CNC control, creating a production technology that is both timeless and future-ready. Its presence in modern industry ensures that the most challenging metals and the most demanding applications can be met with confidence, precision, and efficiency.

A hot metal spinning lathe is a cornerstone of advanced metal forming technology, providing manufacturers with the ability to produce seamless, high-strength components from metals that are difficult or impossible to shape cold. The process combines the mechanical principles of traditional spinning with thermal assistance, using heat from induction coils, gas torches, or other localized sources to make the metal more ductile while it is rotated at high speed against a mandrel. This allows rollers or forming tools to gradually shape the workpiece into cylindrical, conical, or complex axisymmetric forms without cracking, tearing, or excessive tool wear. Materials such as titanium, high-strength steels, nickel-based superalloys, and other specialty metals can be formed into precision components that meet the stringent requirements of aerospace, defense, energy, and industrial applications. The heating process not only facilitates forming but also enhances the mechanical properties of the finished part by producing a refined grain structure, improving strength, durability, and resistance to fatigue, which is critical in high-performance or safety-critical applications.

In aerospace, the hot metal spinning lathe is used to manufacture turbine casings, jet engine housings, nose cones, and other aerodynamic components where precision, structural integrity, and weight reduction are crucial. The defense industry relies on this technology for the production of artillery shells, missile casings, and rocket motor housings that require seamless construction and exceptional pressure resistance. In the energy sector, the lathe enables the creation of hydrogen storage vessels, high-pressure gas cylinders, nuclear containment components, and industrial reactors that must withstand extreme operational conditions while maintaining exact tolerances. Even in heavy industry and large-scale manufacturing, hot spinning allows the production of pressure tanks, chemical reactors, and industrial piping components where both strength and dimensional accuracy are critical. The ability to produce parts with smooth, defect-free walls and enhanced material properties sets hot metal spinning apart from other forming processes.

The adoption of CNC technology has revolutionized hot metal spinning lathes, bringing automation, precision, and repeatability to the forefront. CNC-controlled lathes can manage complex roller paths, regulate mandrel rotation, and synchronize localized heating zones with remarkable accuracy, ensuring consistent part quality across high-volume production runs. Induction heating systems integrated into the lathe provide controlled, energy-efficient heating, allowing only the necessary areas of the workpiece to reach the required temperature, minimizing thermal stress and conserving energy. Modern CNC hot spinning machines are capable of performing additional operations such as trimming, beading, flanging, and flow forming within the same setup, drastically reducing production times and operator intervention while increasing efficiency and flexibility. These capabilities allow manufacturers to switch rapidly between prototypes, small-batch production, and large-scale industrial runs without significant retooling, making the technology ideal for industries where precision, speed, and adaptability are vital.

The importance of hot metal spinning lathes continues to grow as industries demand stronger, lighter, and more durable components while striving to reduce costs and improve sustainability. The process minimizes material waste, lowers tooling expenses compared to stamping or deep drawing, and produces seamless components capable of withstanding high stress, vibration, and thermal cycling. Automotive manufacturers benefit from lightweight structural components and gas cylinders, while renewable energy sectors use the technology for turbine hubs, solar concentrator elements, and hydrogen storage solutions. Consumer industries also rely on hot spinning to create high-quality cookware, stainless steel containers, and industrial-grade appliances that combine strength with aesthetic appeal. By merging centuries-old spinning principles with modern CNC automation, precision control, and thermal forming capabilities, the hot metal spinning lathe remains a vital technology that supports advanced manufacturing across aerospace, defense, energy, automotive, and consumer product sectors, ensuring that high-performance metal components can be produced efficiently, reliably, and with exceptional quality.

A hot metal spinning lathe is an essential tool in modern metalworking, combining traditional spinning principles with thermal assistance to form metals that are otherwise too strong, hard, or brittle to shape cold. The process involves clamping a blank onto a mandrel, rotating it at high speeds, and applying controlled pressure with rollers to gradually form cylindrical, conical, or other axisymmetric shapes. What sets hot spinning apart from conventional spinning is the addition of heat, typically provided by induction coils, gas torches, or electric heaters, which softens the metal locally and makes it more ductile, allowing complex shapes to be formed without cracking or tool wear. This method is particularly effective for high-strength steels, titanium, nickel-based superalloys, and specialty metals used in aerospace, defense, energy, and heavy industry. The heat-assisted process not only facilitates forming but also enhances the mechanical properties of the finished component by refining its grain structure, resulting in parts that are stronger, more durable, and capable of withstanding high pressures, thermal cycles, and mechanical stresses.

Hot metal spinning lathes are widely used in aerospace for producing turbine casings, jet engine housings, nose cones, and other precision components where structural integrity and weight reduction are critical. Defense industries depend on them for artillery shells, missile casings, and rocket motor housings that require seamless construction and precise dimensions to withstand explosive pressures and high-speed impact. In the energy sector, these machines are used to manufacture hydrogen storage vessels, high-pressure gas cylinders, nuclear containment parts, and industrial reactors, all of which demand flawless walls and exact tolerances. Heavy industrial applications also benefit from hot spinning, as it allows the creation of pressure tanks, chemical reactors, and large piping elements with superior strength and dimensional accuracy. The ability to produce seamless, high-performance components with minimal waste and optimized material properties makes hot metal spinning a preferred method for critical applications.

The introduction of CNC technology has greatly expanded the capabilities of hot metal spinning lathes. CNC control allows precise programming of roller paths, mandrel rotation, heating zones, and applied pressures, ensuring consistent quality across high-volume production. Induction heating systems integrated into these machines provide localized, energy-efficient thermal input that reduces stress on the workpiece while minimizing energy consumption. Advanced CNC hot spinning lathes can also perform multiple operations within a single setup, such as trimming, flanging, beading, and flow forming, reducing production times and eliminating the need for multiple machines or setups. This multifunctional capability, combined with automation and robotic handling, enables manufacturers to switch seamlessly between prototypes, small batches, and large-scale production, enhancing flexibility and reducing lead times.

As industries increasingly demand lightweight, high-strength, and reliable components, hot metal spinning lathes remain indispensable. Automotive manufacturers use them to create lightweight structural parts and durable gas cylinders, while renewable energy sectors rely on them for turbine hubs, solar concentrator elements, and hydrogen storage systems. Consumer and industrial goods industries also benefit from hot spinning for high-quality cookware, stainless steel containers, and appliances that combine durability with aesthetic appeal. The process minimizes material waste, lowers tooling costs compared to stamping or deep drawing, and produces seamless, structurally superior parts. By merging the principles of traditional spinning with modern CNC automation and thermal forming, the hot metal spinning lathe continues to be a critical technology for producing high-performance metal components across aerospace, defense, energy, automotive, and consumer product sectors, ensuring efficiency, precision, and reliability in demanding applications.

Large-Diameter Metal Spinning Machine

A large-diameter metal spinning machine is a specialized type of metal forming equipment designed to handle exceptionally wide or oversized blanks, producing seamless, rotationally symmetric components with diameters that often exceed several meters. The machine operates on the same fundamental principle as conventional metal spinning: a flat or pre-formed metal blank is clamped against a mandrel and rotated at high speeds while rollers or forming tools apply controlled pressure to gradually shape the material into cylindrical, conical, parabolic, or other axisymmetric forms. What distinguishes a large-diameter spinning machine is its ability to handle very wide blanks, thicker sheets, and extended radii, which requires enhanced structural rigidity, high-torque drive systems, and robust roller assemblies to maintain precision over the full span of the part. These machines are capable of processing a wide range of metals, from lightweight aluminum and copper to high-strength steels, titanium, and nickel-based alloys, making them suitable for applications where both scale and structural integrity are critical.

Industries such as aerospace, defense, renewable energy, heavy industrial manufacturing, and shipbuilding are among the primary users of large-diameter metal spinning machines. In aerospace, these machines can produce turbine casings, large engine housings, nacelles, and structural airframe components that require tight tolerances, smooth surfaces, and enhanced strength due to work-hardening during spinning. The defense industry relies on them for oversized projectile casings, rocket components, and other critical cylindrical structures that must maintain uniform wall thickness and seamless construction. In renewable energy, large-diameter spinning is used to manufacture wind turbine hubs, solar concentrators, and large pressure vessels, where precision and durability are essential for operational efficiency. Heavy industrial applications such as chemical reactors, storage tanks, and industrial piping systems also benefit from the ability to produce large, seamless parts that can withstand high pressures, thermal cycling, and mechanical stress without failure.

Modern large-diameter metal spinning machines often integrate CNC control, which allows precise automation of roller paths, mandrel rotation, and forming speeds across the extended surface area of the workpiece. CNC systems ensure consistent thickness, accurate profiles, and minimal defects even for extremely large components, while reducing the labor intensity traditionally associated with manual spinning. Some advanced models also incorporate induction or localized heating for hot spinning, enabling the forming of high-strength or heat-sensitive metals that would otherwise be difficult to shape at room temperature. In addition, multifunctional capabilities such as flanging, trimming, beading, and flow forming can be integrated into the same setup, streamlining production and reducing the need for secondary processing.

The advantages of large-diameter metal spinning machines include their ability to produce oversized, seamless parts with superior strength, minimal material waste, and lower tooling costs compared to stamping or deep-drawing large components. Their structural rigidity and precision make them essential in applications where dimensional accuracy, high performance, and safety are critical. As industries continue to demand larger, more complex, and higher-performing components, the role of large-diameter metal spinning machines remains indispensable. They combine traditional spinning techniques with modern CNC control, heating systems, and multifunctional operations, providing manufacturers with the capability to create large-scale, high-strength, and precision-engineered parts efficiently, reliably, and sustainably.

A large-diameter metal spinning machine is an advanced and specialized piece of equipment designed to handle oversized blanks and produce large, seamless, axisymmetric components with diameters that often reach several meters. The machine operates on the fundamental principles of metal spinning, where a blank is secured to a mandrel and rotated at high speeds while forming rollers gradually shape the material under controlled pressure. What sets a large-diameter machine apart is its ability to maintain precision, uniform wall thickness, and structural integrity over an extended surface area, which requires enhanced rigidity, high-torque drive systems, and robust roller assemblies. These machines can work with a wide variety of metals, including aluminum, stainless steel, titanium, copper, and nickel-based alloys, allowing the production of lightweight, high-strength, and durable parts. Large-diameter spinning provides significant advantages over conventional stamping or deep-drawing for oversized components because it reduces tooling costs, minimizes material waste, and produces seamless parts capable of withstanding extreme mechanical and thermal stresses.

The applications for large-diameter metal spinning machines are particularly prominent in aerospace, defense, renewable energy, heavy industrial, and shipbuilding sectors. In aerospace, the machines are used to produce turbine casings, engine housings, nacelles, and structural airframe components that demand precise geometry, smooth surfaces, and superior strength due to work-hardening during the spinning process. Defense industries rely on these machines to manufacture large projectile casings, rocket motor shells, and missile bodies where seamless construction and uniform wall thickness are critical for safety and performance. Renewable energy applications, such as wind turbine hubs, solar concentrators, and hydrogen storage vessels, require the ability to produce durable and precise large-scale components capable of withstanding operational loads, environmental stress, and thermal cycling. Heavy industrial and shipbuilding applications benefit from the production of large storage tanks, pressure vessels, chemical reactors, and industrial piping systems that demand exceptional durability and dimensional accuracy. The ability of a single machine to handle these wide-ranging applications makes large-diameter metal spinning an indispensable technology in modern manufacturing.

Modern large-diameter metal spinning machines increasingly employ CNC control to achieve automation, precision, and repeatability across the extended diameter of the workpiece. CNC systems allow exact control of roller paths, mandrel rotation, forming pressure, and speed, ensuring consistent thickness and dimensional accuracy even for extremely large components. Some machines also integrate induction or localized heating systems for hot spinning, enabling the forming of high-strength metals like titanium and nickel alloys that are difficult to shape at ambient temperature. Advanced machines can perform multiple operations in one setup, including trimming, flanging, beading, and flow forming, which reduces production time, minimizes handling, and increases efficiency. Automation, along with real-time monitoring and control, ensures not only superior quality but also safer and more efficient operation, especially when dealing with very large and heavy workpieces.

The value of large-diameter metal spinning machines lies in their ability to produce oversized, seamless components with high structural integrity, minimal material waste, and reduced tooling costs. They are critical in industries where precision, durability, and performance cannot be compromised. As demands continue to rise for larger, more complex, and high-performing components across aerospace, defense, energy, automotive, and industrial sectors, large-diameter spinning machines provide a reliable, flexible, and efficient solution. By combining traditional spinning techniques with CNC automation, heating systems, and multifunctional capabilities, these machines ensure that manufacturers can meet the challenges of producing large-scale, high-strength, and precision-engineered components with consistency, speed, and cost-effectiveness.

A large-diameter metal spinning machine is one of the most versatile and essential tools in modern metal forming, capable of producing seamless, high-strength components that are both oversized and precise. Unlike smaller spinning machines, a large-diameter system is designed to handle extremely wide blanks, thick sheets, and extended radii, requiring enhanced structural rigidity, high-torque drive systems, and heavy-duty roller assemblies to maintain accuracy across the full surface of the part. The process itself relies on the same principles as conventional metal spinning: a blank is clamped onto a mandrel, rotated at high speed, and gradually shaped by forming rollers that apply precise pressure to achieve the desired geometry. However, the scale of the workpiece introduces unique challenges, including uniform thickness control, consistent material flow, and maintaining surface finish across large diameters, all of which the machine must overcome to ensure the final product meets stringent engineering requirements. Large-diameter spinning machines are capable of working with a broad range of metals, from lightweight aluminum and copper to high-strength steels, titanium, and nickel-based alloys, making them suitable for industries that demand both size and structural integrity.

Industries such as aerospace, defense, renewable energy, shipbuilding, and heavy industrial manufacturing rely heavily on large-diameter metal spinning machines for applications that require durability, precision, and seamless construction. In aerospace, these machines are used to produce large turbine casings, jet engine housings, nacelles, and structural components of airframes, where smooth surfaces, precise dimensions, and reinforced material properties are essential. The defense industry utilizes them for oversized artillery shells, missile casings, and rocket motor housings, components where uniform wall thickness and seamless integrity are critical for safety and performance. Renewable energy applications, including wind turbine hubs, solar concentrator mirrors, and hydrogen storage vessels, demand large-scale, precise components capable of withstanding high mechanical loads and environmental stress. Heavy industrial applications, such as chemical reactors, pressure tanks, and large-scale piping, benefit from the ability of these machines to create seamless, structurally sound parts that meet the highest standards of durability and dimensional accuracy.

The integration of CNC technology into large-diameter metal spinning machines has transformed the capabilities and efficiency of the process. CNC control allows precise programming of roller paths, mandrel rotation, forming speed, and applied pressure, ensuring consistent thickness and geometry even for extremely large components. Many machines also incorporate localized or induction heating systems, which enable hot spinning of high-strength alloys like titanium and nickel that would otherwise be difficult to form cold. Advanced machines can perform multiple operations within a single setup, including flanging, trimming, beading, and flow forming, which minimizes handling, reduces cycle time, and increases overall efficiency. Automation, real-time monitoring, and intelligent software ensure not only product consistency and quality but also safer operation when handling massive workpieces, which would be challenging or hazardous in manual setups.

Large-diameter metal spinning machines offer a combination of flexibility, efficiency, and structural performance that is unmatched in the production of oversized components. They allow manufacturers to produce large, seamless parts with minimal material waste and lower tooling costs compared to traditional stamping or deep drawing methods, while maintaining high precision and mechanical strength. As industries worldwide continue to demand larger, more complex, and higher-performing components, these machines remain central to manufacturing operations in aerospace, defense, energy, shipbuilding, and heavy industrial sectors. By combining traditional metal spinning principles with modern CNC automation, thermal forming capabilities, and multifunctional processing, large-diameter metal spinning machines enable the efficient production of high-quality, durable, and precise parts on a scale that meets the most demanding engineering and industrial requirements.

A large-diameter metal spinning machine is a critical asset in modern manufacturing, designed to handle oversized blanks and create seamless, rotationally symmetric components with diameters that often exceed several meters. The machine operates by clamping a flat or preformed metal blank onto a mandrel and rotating it at high speeds while rollers or forming tools gradually apply pressure to shape the metal into precise cylindrical, conical, or complex geometries. The large scale of these machines requires exceptional structural rigidity, high-torque drives, and reinforced roller assemblies to maintain uniform wall thickness and dimensional accuracy across the entire workpiece. Capable of handling a wide range of materials—from lightweight aluminum and copper to high-strength steels, titanium, and nickel-based alloys—these machines are essential for industries where both size and structural integrity are paramount. The process minimizes material waste, reduces tooling costs compared to stamping or deep drawing, and produces seamless components that offer superior mechanical properties, including enhanced strength and resistance to fatigue and thermal stress.

Large-diameter metal spinning machines are indispensable in aerospace, defense, renewable energy, shipbuilding, and heavy industrial applications where precision, durability, and seamless construction are critical. In aerospace, they produce turbine casings, engine housings, nacelles, and large airframe components that demand exact dimensions, smooth surfaces, and reinforced structural properties achieved through work hardening during spinning. In the defense sector, these machines are used for oversized artillery shells, missile bodies, and rocket motor casings that require uniform wall thickness and reliable, defect-free construction to withstand explosive forces and high-speed impact. Renewable energy industries use them to fabricate wind turbine hubs, large solar concentrators, and hydrogen storage vessels, all of which must endure significant mechanical loads and environmental conditions. Heavy industrial applications such as chemical reactors, high-pressure storage tanks, and large piping systems benefit from the ability of these machines to create oversized, seamless components that meet stringent operational standards and durability requirements.

Modern large-diameter metal spinning machines are increasingly integrated with CNC technology, allowing for precise automation of roller paths, mandrel rotation, forming pressure, and rotational speed to achieve consistent results even on extremely large components. Some models incorporate localized or induction heating, enabling hot spinning of high-strength metals like titanium and nickel alloys that are difficult or impossible to form at ambient temperatures. CNC-controlled systems can also integrate multifunctional operations, including trimming, beading, flanging, and flow forming, in a single setup, which reduces production time, improves efficiency, and minimizes handling of massive workpieces. Automation and real-time monitoring ensure consistent quality, reduce human error, and allow for high-volume production without compromising precision or structural integrity.

The combination of flexibility, efficiency, and mechanical performance makes large-diameter metal spinning machines an irreplaceable tool in modern manufacturing. They allow the creation of oversized, seamless components with superior strength, minimal waste, and lower tooling costs, making them particularly valuable in industries where high performance and reliability are essential. As demand for larger, more complex, and high-performing components continues to grow in aerospace, defense, renewable energy, shipbuilding, and heavy industry, large-diameter metal spinning machines provide a reliable and efficient solution. By combining traditional metal spinning techniques with CNC automation, thermal forming capabilities, and multifunctional processing, these machines enable manufacturers to produce high-quality, precision-engineered components that meet the most demanding engineering, industrial, and safety requirements while maintaining efficiency and cost-effectiveness.

Industrial Metal Bowl Spinning Machine

An industrial metal bowl spinning machine is a specialized type of metal forming equipment designed to produce seamless, rotationally symmetric bowls, domes, hemispherical shells, and similar components with high precision and repeatability. The machine operates by securing a flat or preformed metal blank to a mandrel and rotating it at high speed while a roller or forming tool gradually presses the material into the desired bowl shape. This process, often called metal spinning or spin forming, works without cutting or welding, allowing for the creation of strong, durable parts with uniform thickness and smooth surfaces. Industrial metal bowl spinning machines can handle a wide range of metals, from lightweight aluminum and copper to stainless steel, titanium, and other high-strength alloys, making them suitable for industries that require both structural integrity and aesthetic quality. The process strengthens the metal through work hardening, producing components that are not only precise in geometry but also resistant to mechanical stress, fatigue, and thermal cycling, which is essential for both functional and decorative applications.

These machines are widely used in manufacturing sectors that produce kitchenware, lighting reflectors, industrial containers, and pressure-resistant vessels, as well as in aerospace and defense applications where hemispherical or domed components are required. In consumer industries, industrial metal bowl spinning machines allow the production of stainless steel bowls, cooking pots, and lampshades that combine durability with smooth, polished surfaces. In industrial and engineering sectors, they are used to manufacture chemical processing bowls, protective domes, and components for reactors and pressure vessels, all of which demand exact dimensional control, uniform wall thickness, and seamless construction. Defense and aerospace applications also rely on these machines to create hemispherical or conical components for missile housings, satellite parts, and turbine components, where precision, reliability, and material performance are critical.

Modern industrial metal bowl spinning machines are often equipped with CNC control systems, which provide highly precise automation of roller paths, mandrel rotation, forming speeds, and applied pressure. CNC control ensures consistent wall thickness, accurate contours, and repeatability across multiple components, which is essential for large-scale production. Some machines also integrate hot spinning capabilities using induction or localized heating, allowing harder metals like stainless steel, titanium, or nickel alloys to be formed efficiently without cracking or excessive tool wear. Advanced systems can incorporate multifunctional capabilities such as flanging, trimming, beading, or flow forming within a single setup, reducing production times, minimizing material handling, and increasing overall operational efficiency. Automation and real-time monitoring improve product consistency, reduce errors, and make it feasible to produce large batches of identical high-quality components with minimal operator intervention.

The advantages of industrial metal bowl spinning machines include the ability to produce seamless, structurally strong, and precise components with minimal material waste and lower tooling costs compared to stamping or deep drawing processes. They are flexible enough to accommodate different sizes, thicknesses, and metals, which makes them suitable for prototyping, small-batch production, and large-scale industrial runs. The combination of speed, precision, and material efficiency ensures that industrial metal bowl spinning machines remain indispensable in a wide variety of sectors, including consumer goods, aerospace, defense, chemical processing, and energy. By merging the traditional craftsmanship of spinning with modern CNC automation, heating systems, and multifunctional processing, these machines provide manufacturers with the ability to create high-quality, durable, and aesthetically refined components that meet the demanding standards of contemporary industry.

An industrial metal bowl spinning machine is an essential tool in modern manufacturing, designed to produce seamless, rotationally symmetric bowls, domes, hemispherical shells, and other concave or curved components with high precision and consistent quality. The machine functions by clamping a flat or preformed metal blank onto a mandrel and rotating it at high speed while a roller or forming tool gradually presses the material into the desired shape. Unlike stamping or welding, the spinning process does not remove material or require seams, which ensures the final part maintains uniform thickness, superior strength, and smooth surfaces. Industrial metal bowl spinning machines can handle a wide variety of metals, including aluminum, stainless steel, copper, titanium, and nickel-based alloys, allowing them to meet the requirements of both consumer and industrial applications. As the material is spun and formed, it work-hardens, improving its mechanical properties and providing enhanced resistance to stress, fatigue, and deformation, which is particularly important for high-performance or pressure-bearing components.

These machines find applications across multiple sectors where precision, durability, and aesthetic quality are essential. In consumer products, industrial metal bowl spinning machines are used to create cookware, stainless steel bowls, lampshades, and decorative containers that require smooth surfaces, uniform thickness, and attractive finishes. In industrial and engineering applications, they produce chemical processing bowls, protective domes, pressure vessels, and reactor components where structural integrity and tight dimensional tolerances are critical. Aerospace and defense sectors also rely on metal bowl spinning machines to manufacture hemispherical or conical components for missile casings, satellite housings, turbine end caps, and other parts that must endure high stress, extreme temperatures, and vibration without failure. The versatility of these machines enables the production of both small and large components with consistent quality, meeting the demands of industries where performance and reliability cannot be compromised.

Modern industrial metal bowl spinning machines are often equipped with CNC control, which allows precise automation of mandrel rotation, roller paths, forming speed, and applied pressure. CNC integration ensures uniform wall thickness, accurate contours, and high repeatability across multiple parts, making it ideal for both small-batch production and high-volume manufacturing. Some machines also incorporate hot spinning capabilities, using induction or localized heating to soften the metal during forming. This is particularly useful when working with high-strength or heat-sensitive materials such as stainless steel, titanium, or nickel alloys, which would otherwise be difficult to shape at room temperature. Advanced systems may combine spinning with additional operations such as flanging, trimming, beading, and flow forming in a single setup, streamlining production, reducing material handling, and improving efficiency. Automation and real-time monitoring not only increase consistency and quality but also reduce labor intensity and potential for human error, allowing manufacturers to produce high-quality components more reliably and cost-effectively.

The advantages of industrial metal bowl spinning machines lie in their ability to produce seamless, structurally strong, and precise components with minimal waste and lower tooling costs compared to stamping, deep drawing, or welding processes. They provide flexibility in handling different metals, sizes, and thicknesses, making them suitable for prototyping, medium-volume production, and large-scale industrial operations. Their ability to create parts that combine mechanical strength, aesthetic appeal, and functional reliability makes them indispensable in consumer goods, aerospace, defense, chemical processing, and energy sectors. By integrating the traditional craftsmanship of metal spinning with modern CNC automation, thermal forming, and multifunctional capabilities, industrial metal bowl spinning machines enable manufacturers to produce high-quality, durable, and precise components that meet the stringent demands of contemporary industry, balancing efficiency, performance, and versatility in a single manufacturing solution.

An industrial metal bowl spinning machine is a key piece of equipment in metal forming, specifically engineered to produce seamless, rotationally symmetric bowls, domes, and hemispherical components with high precision and consistent quality. The fundamental operation involves clamping a flat or pre-formed metal blank onto a mandrel and rotating it at high speeds while rollers or forming tools gradually press the material into the desired shape. Unlike other forming methods such as stamping or welding, spinning does not remove material or require seams, resulting in components with uniform wall thickness, superior mechanical strength, and smooth, defect-free surfaces. Industrial metal bowl spinning machines are capable of handling a wide variety of metals, including aluminum, stainless steel, copper, titanium, and nickel-based alloys, which allows manufacturers to meet the rigorous demands of both functional and aesthetic applications. As the metal is spun and shaped, work-hardening occurs, improving the material’s durability, resistance to fatigue, and ability to withstand thermal or mechanical stress, which is essential for components that will endure heavy use or extreme conditions.

These machines serve a wide range of industries due to their versatility and precision. In consumer goods, they are used to manufacture cookware, stainless steel bowls, lampshades, decorative containers, and other household items that require both aesthetic appeal and durability. Industrial applications include chemical processing bowls, reactor domes, protective covers, and pressure vessels where uniform thickness and exact tolerances are critical for operational safety and efficiency. In aerospace and defense, industrial metal bowl spinning machines are essential for producing hemispherical or conical parts such as missile casings, satellite housings, turbine end caps, and protective shells that must maintain structural integrity under extreme stress, high pressure, and vibration. The ability to create large or small components with precision and consistency makes these machines indispensable in sectors where performance, reliability, and longevity are non-negotiable.